Page 1

Operating & Installation Instructions

charnwood

FB100, FB200 & FB300

®

Page 2

Page 3

CONTENTS

OPERATING INSTRUCTIONS

Charnwood Flue Boilers

Safety Warning

Stove and Boiler Operation

Maintenance

Health & Safety Precautions

System

Chimney, Hearth & Fire Surround

Connection to Flues

Installation

Commissioning/ Dimensions

Parts Lists

Guarantee

4

5

5

5

6

6

8

8

8

9

10

11

INSTALLATION INSTRUCTIONS

Page 4

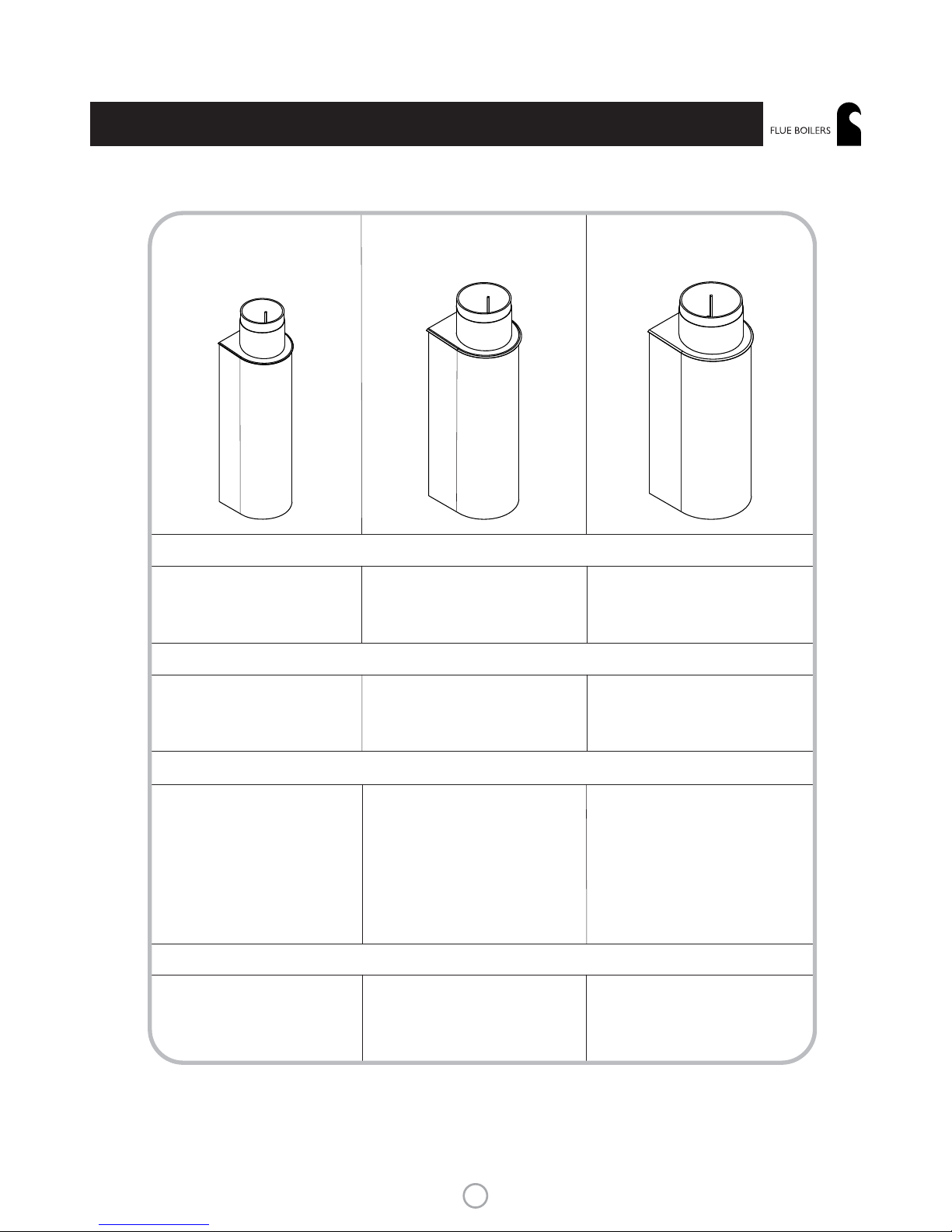

130mm (5in) FB100 150mm (6in) FB200 180mm (7in) FB300

Cove 1

Country 4

Cove 2

Island 1

Island 2

Country 6

Country 8

Country 12

Cove 3

Island 3

Average Water Heating Output:

1.8 kW 2.4 kW 3.4 kW

For use with the following stoves:

Nominal Size

Internal Diameter

130mm 155mm 183.7mm

FB100

FB200

FB300

®

charnwood

CHARNWOOD FLUE BOILERS

4

Page 5

The Charnwood Flue Boiler provides a means of heating water by

utilising some of the flue heat to provide domestic hot water and

some radiator heating. This is achieved by circulating water through a

jacket around the flue, whilst slowing the flue gases to transfer the

heat.

The boiler is bolted directly to the top of the stove and has two 1in

BSP connections for flow and return water pipes. The flue contains

boiler chains which cause turbulence in the flue gases and improve

the transfer of heat to the water.

Fumes from blocked flues can kill. Remove the access door and brush

off the chain hangers at least monthly. See ‘Maintenance’ section.

Do not light the stove without water in the system.

SAFETY WARNING

Do not light the stove if any part of the system is frozen.

There are some differences in operating the stove once a boiler has

been fitted. Before lighting ensure that all installation work has been

carried out according to these instructions, and that the chains and

the access door are securely fitted. Do not light the stove without

water in the system. It is important to allow time for the fire cement

to dry out before lighting - at least one day.

On initial lighting considerable condensation will be produced and this

will normally drip from the drip ring at the base of the boiler tube

onto the throatplate of the stove where it will evaporate. Some initial

sweating may occur at the joint between the boiler base and the flat

top of the stove, but this should cease after approx 2 hrs of

operating. If the sweating persists, this indicates an inadequate seal,

and the joint must be re-sealed. Start with a small fire and allow the

stove to heat up gradually so that the internal paint and fire cement

may cure evenly. When the stove and the boiler return pipe are both

hot, then all condensation should cease. When hot water is being

continuously used, then the stove should be well loaded and run at

such a rate that the return temperature does not fall below 40°C.

Once per month the access door must be unclipped and any soot

build up on the chain hangers brushed off with a small brush. Check

for any flue obstruction.

The chimney must be swept at least once per heating season, and the

boiler’s internal flue is cleaned at the same time. In order for this to

STOVE AND BOILER OPERATION

MAINTENANCE

Side Chain Hanger

Centre Chain

Hanger

Chains

Fig 1. Chain Access (access door removed)

happen, the boiler chains must first be removed. Ensure that the fire

is out and the stove is cold. Undo the clip on the back of the access

door, spring apart the two ends of the door and remove it from the

boiler. Unhook each of the chains from the hangers and allow them

to drop down onto the throatplate of the stove. Lift out the three

Chain Hangers. Remove the chains from above the throatplate, clean

them using a small brush The access door may now be replaced and

the chimney swept in the normal way through the stove. Remove the

access door again and and re-hang the chains on the hanger hooks.

When the hanger has had all its chains replaced, thread the lower

ends of the chains through the access opening, allow the ends to drop

down and manouevre the chain hanger back into its slots. It is easier

to replace the side hangers first, then the centre hanger. Replace the

access door and the stove is ready for re-lighting.

®

OPERATING INSTRUCTIONS

5

charnwood

Page 6

HEALTH AND SAFETY PRECAUTIONS

SYSTEM

Please take care when installing the boiler that the requirements of

the Health and Safety at Work Act 1974 are met.

Some types of fire cement are caustic and should not be allowed to

come into contact with the skin. In case of contact wash with plenty

of water.

If there is a possibility of disturbing any asbestos in the course of

installation then please use appropriate protective equipment.

In addition to these instructions the requirements of BS.8303 and

BS.6461 Pt 1&2; 1984 must be fulfilled. Local Authority Bylaws and

Building Regulations, including those referring to National and

European Standards regarding the installation of Solid Fuel burning

appliances, flues and chimneys must also be observed.

The Charnwood Flue Boiler is designed to be used with a Charnwood

stove. It can be used as a ‘stand alone’ heating system for domestic

hot water and/or radiators, or as part of a larger heating system.

There are a variety of ways in which it is possible to link up this boiler

with a larger system, and some of these are shown in Figs 2 to 4.

When a small stove such as the Cove 1 and a Flue Boiler FB100 are

used, a simple system as shown in Fig 2 may be used. A larger size of

hot water cylinder (i.e. above 115 Litres) is usually required to reduce

the possibility of boiling, since on this system no heat leak radiator is

shown. If the stove is to be run near its full capacity, then a heat leak

radiator should be considered.

If a larger stove such as the Island 3 and Flue Boiler FB300 are used,

then extra radiators may be added to the system as shown in Fig 3.

These are controlled by a high limit pipe thermostat mounted on the

This is particularly

necessary if the room is double glazed. It must be positioned such

that it is not liable to blockage.

Careful consideration must be given to the siting of the stove and

boiler, since the Boiler Access door MUST be accessible in order to

sweep the chimney. This means that there must be at least 750mm

free space above the top of the stove. The flow pipe connected to the

top of the boiler must rise continuously up to the vent. It must not

drop down and nominally horizontal runs should have some upward

slope.

!

There must be an adequate air supply into the room in which the

appliance is installed to provide combustion air. The combustion air

supply must be via a permanently open vent.

Domestic Hot

Water Draw Off

Drain Cock at Lowest Point

Drain Cock

Gravity Return 28mm

Gravity Flow 28mm

Indirect Hot Water Cylinder

Cold Water Tank

Overflow

Overflow

Feed and Expansion Tank

22mm Open Vents

Flue Boiler

Fig 2. Basic System Where Heat Leak Radiator

Is Not Required

Fig 3. Larger System With Heat Leak Radiator

Controlled By High Limit Pipe Thermostat

Radiator Return

Domestic Hot

Water Draw Off

Drain Cock at Lowest Point

Drain Cock

Gravity Return 28mm

Gravity Flow 28mm

Indirect Hot Water Cylinder

Cold Water Tank

Overflow

Overflow

Feed and Expansion Tank

22mm Open Vents

Radiator(s)

Circulating Pump

Injector Tee

Minimum Return

Thermostat

High Limit Pipe

Thermostat

Flue Boiler

®

INSTALLATION INSTRUCTIONS

6

charnwood

Page 7

gravity flow pipe, which gives priority to the domestic hot water, but

brings the pump on to heat the radiators when the flow pipe

temperature exceeds the set temperature. A minimum return pipe

thermostat will prevent cold water being pumped around the circuit

The stove and flue boiler may be installed as part of a larger system,

to provide back up or additional heat whilst the main boiler is not

operating. There are many ways in which this “Link Up” may be

achieved, and a basic link up system is shown in Fig 4. This uses a

“Dual Coil”cylinder. In this way the Flue Boiler is able to input heat

into the system without affecting the circulation in the other primary

coil(s). Similarly, if the other heat source is operating and the stove is

not lit, then there will be very little effect on the circulation through

the flue boiler. Additional controls such as an electronic timer may be

added in the “Link up” case if required and in some instances the

controls of the main boiler may be extended to control a pump in the

flue boiler circuit.

Fig 4. Basic Link Up system. Flue Boiler provides

input to existing system via Dual Coil Tank

Gravity Return (28mm Pipe)

Central Heating

Return

Common

Return to Boiler

(28mm Pipe)

Fig 5. Injector Tee as used in Fig 3 .

Domestic Hot

Water Draw Off

Drain Cock at Lowest Point

Drain Cock

Gravity Return 28mm

Gravity Flow 28mm

Dual Coil Hot

Water Cylinder

Cold Water Tank

Overflow

Overflow

Feed and Expansion Tank

22mm Open Vents

Heat Leak

Gravity Radiator

Flue Boiler

Additional Heat

source, e.g. oil or

gas boiler, solar

heating panel etc.

Fig 6. Free standing Installation

Double Insulated

Flue Pipe

Flue Connector

Flue Boiler

Stove

Hearth

Water

Flow

Water

Return

Access Door

Support Bracket

Fig 7. Horizontal Register Plate Into Conventional Chimney

Flue Boiler

Stove

Hearth

Water

Flow

Water

Return

Access Door

Register Plate

Soot Door

With Soot Door

Alternative

Positions

®

INSTALLATION INSTRUCTIONS

7

charnwood

Page 8

Sleeved Pipe

Soot Door

In Side or Rear

Of Chimney

Fig 8. Vertical Register Plate With Bricked Up Fireplace

Flue Boiler

Stove

Hearth

Access Door

Water

Flow

Water

Return

CHIMNEY, HEARTH & FIRE SURROUND

CONNECTIONS TO FLUES

Ensure that all the Instructions and Regulations contained in the

Charnwood Stove Installation Instructions are carried out and

adhered to. The Flue Boiler will limit the number of Flue Connection

options available, and three typical options are shown in Figs. 6 - 8.

There are several different ways of connecting the Flue, but in each

case the top flue outlet of the stove is used. The Flue Boiler is not

designed to use the rear flue outlet.

The adaptor is available from the Fluepipe

manufacturer. The double insulated flue must be supported by

brackets, and not rely on the boiler for its support, since this would

make removal of the boiler very difficult. The adaptor may require a

short piece of single wall stainless steel fluepipe to slide into the top

of the boiler.

A freestanding installation is shown in Fig 6 using double insulated

stainless steel fluepipe connected to the top of the boiler using a

short adaptor.

Fig 7 shows the flue connections into a standard chimney using a high

Sealing Face

Boiler Outer must be

pulled down onto stove

top using two M6 x 25mm

bolts and nuts.

Fig 9. Fitting& Sealing the Boiler to the Stove

level horizontal register plate. The minimum distance above the top

of the stove in this case is 800mm.

Fig 8 Utilises a 135° Bend to connect into the flue.

In each of these instances the chimney may be swept through the

stove.

spread

attach

INSTALLATION

First remove the top blanking plate of the stove and fire

cement evenly on the sealing face. Lower the boiler into position as

shown in Fig 9. Align the boiler fixing tags with the flue ring tags on

the stove, and insert the two M6 x 25mm bolts, their nuts and

tighten until the outer lower edge of the boiler is drawn firmly into

contact with the top of the stove. Remove excess fire cement which

has squeezed out of the joint . It is essential that this joint is well made

to prevent condensation escaping from the boiler / stove interface.

Slide the adaptor up until its inner diameter is aligned with the flue

boiler and lower it down into the top of the Flue Boiler and seal the

joint with fire cement.

When the Stove, Boiler and Fluepipe have all been fixed in position,

remove the access door and check the position and location of the

chains and hangers since these are held in by gravity and may have

come out during installation. Replace the Access door and clip firmly

together.

Connect the 28mm diameter flow and return water pipes to the

1inch BSP fittings on the back of the boiler using brass compression

fittings and ensure that the flow pipe (top) rises continuously to the

vent. Fill the system with water + antifreeze + corrosion inhibitor as

required and check for leaks.

®

INSTALLATION INSTRUCTIONS

8

charnwood

Page 9

FB100

450

132.5

109

621

124

140

190

8

BACK VIEW

194

606

SIDE VIEW

130

98.5

8

TOP VIEW

Internal Dia

FB200

621

211

450

130

124

132.5

8

165

131

155

9

TOP VIEW

237

606

BACK VIEW

SIDE VIEW

Internal Diameter

FB300

450

621

160

250

132.5

8

193.7

124

146

183.7

12

TOP VIEW

606

BACK VIEW

271

SIDE VIEW

Internal Diameter

COMMISSIONING

On completion of the installation and after allowing a suitable period

of time for the fire cement and mortar to dry out, light the stove and

check to ensure that smoke and fumes are taken from the appliance

up the chimney and emitted safely. Also check all joints and seals for

soundness.

Adjust the central heating pump (if fitted) to give the correct water

flow against the circuit resistance and balance the system correctly.

On completion of the installation and commissioning please leave the

operating instructions with the customer and advise on the use of the

appliance and any controls on the system.

®

INSTALLATION INSTRUCTIONS

9

charnwood

Page 10

Issue B

6

5

1

3

4

3

2

FB100

FB200

1

5

6

3

4

2

3

FB300

Item Part No. Description

1 010/FB100/## Flue Boiler 130mm

2 006/FB112 Boiler Chain Length

3 010/FB107 2 Hook Hanger

4 010/FB207 3 Hook Hanger

5 004/FB113 Top Cover Plate

6 004/FB108 Access Door

Item Part No. Description

1 010/FB200 Flue Boiler 150mm

2 006/FB112 Boiler Chain Length

3 010/FB207 3 Hook Hanger

4 010/FB306 4 Hook Hanger

5 004/FB213 Top Cover Plate

6 004/FB208 Access Door

Item Part No. Description

1 010/FB300/## Flue Boiler 180mm

2 006/FB112 Boiler Chain Length

3 010/FB306 4 Hook Hanger

4 010/FB307 5 Hook Hanger

5 004/FB313 Top Cover Plate

6 004/FB308 Access Door

To obtain spare parts please contact your local stockist giving Model,

Part No. and Description. In case of difficulty contact the

manufacturer at the address shown.

4

1

6

5

3

2

3

®

FLUE BOILERS PARTS LIST

®

charnwood BI SHO P S WAY, NEW PORT, IS LE OF WI GHT P O30 5WS, UN ITE D KING DOM

T:+44 (0)1983 537799 • F:+44 (0)1983 537788 • SPARES@CHARNWOOD.COM • WWW.CHARNWOOD.COM

charnwood

10

charnwood

Page 11

CHARNWOOD FLUE BOILER GUARANTEE

Your Charnwood Flue Boiler is guaranteed against material and

manufacturing defect for a period of 1 year from date of purchase.

The following conditions apply:

?

?

?

?

?

?

?

?

If any part fails due to manufacturing or material defect within the

guarantee period Charnwood will, free of charge, either repair or

replace the part at their discretion. The decision of Charnwood is

final.

This guarantee is for parts and labour only.

Consumable items such as rope seal and associated parts are not

included.

Charnwood will not be liable for any consequential loss or

incidental loss, damage or injury however caused.

This guarantee will become void if the appliance: is not installed in

accordance with the installation instructions; is not regularly

serviced, in accordance with the installation instructions; is subject

to misuse or neglect, including the use of non-recommended fuel

or operation without water in the boiler; is used on stoves other

than those manufactured by Charnwood; or if repairs or

modifications have been carried out by anyone other than

Charnwood or their official representatives.

All claims on this guarantee must be made through the supplier of

the appliance and must be accompanied by proof of purchase.

Nothing in this guarantee shall affect your statutory rights.

This guarantee is applicable in the UK, Ireland and France.

®

GUARANTEE

11

charnwood

Page 12

A D i v i s i o n o f A . J . W e l l s & S o n s L i m i t e d R e g i s t e r e d i n E n g l a n d N o . 0 3 8 0 9 3 7 1

charnwood BI SHO P S WAY, NEW PORT, IS LE OF WI GHT P O30 5WS, UN ITE D KING DOM

T:+44 (0)1983 537777 • F:+44 (0)1983 537788 • CONTACT US AT WWW.CHARNWOOD.COM

charnwood

y ou r p re m ie r de a l e r

REV. FB 11.08

®

Loading...

Loading...