Charnwood BD610 Owner's Manual

BELT & DISC SANDER

OWNERS MANUAL

MODEL: BD610

Charnwood Machinery Ltd, Cedar Court, Walker Road,

Bardon Hill, Leicestershire, LE67 1TU

Tel. 01530 516 926 Fax. 01530 516 929

email: sales@charnwood.net website: www.charnwood.net

GENERAL SAFETY RULES

WARNING: Do not attempt to operate the machine until you have read thoroughly and

understood completely all instructions, rules, etc. contained in this manual. Failure to comply

may result in accidents involving fire, electric shock, or serious personal injury. Keep this

owner's manual and review frequently for continuous safe operation.

1. Know your machine. For your own safety, read the owner's manual carefully. Learn its application and

limitations, as well as specific potential hazards pertinent to this machine.

2. Make sure all tools are properly earthed.

3. Keep guards in place and in working order. If a guard must be removed for maintenance or cleaning,

make sure it is properly replaced before using the machine again.

4. Remove adjusting keys and spanners. Form a habit of checking to see that the keys and adjusting

spanners are removed from the machine before switched it on.

5. Keep your work area clean. Cluttered areas and workbenches increase the chance of an accident.

6. Do not use in dangerous environments. Do not use power tools in damp or wet locations, or expose

them to rain. Keep work areas well illuminated.

7. Keep children away. All visitors should be kept a safe distance

8. from the work area.

9. Make workshop childproof. Use padlocks, master switches and remove starter keys.

10. Do not force the machine. It will do the job better and be safer at the rate for which it is designed.

11. Use the right tools. Do not force the machine or attachments to do a job for which they are not

designed. Contact the manufacturer or distributor if there is any question about the machine's suitability for

a particular task.

12. Wear proper apparel. Avoid loose clothing, gloves, ties, rings, bracelets, and jewellery which could get

caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain long

hair.

13. Always use safety glasses. Normal spectacles only have impact resistant lenses. They are not safety

glasses.

14. Do not over-reach. Keep proper footing and balance at all times.

15. Maintain the machine in good condition. Keep the machine clean for best and safest performance.

Follow instructions for lubrication and changing accessories.

16. Disconnect the machine from power source before servicing and when changing the blade.

17. Never leave the machine running unattended. Turn the power off. Do not leave the machine until it

comes to a complete stop.

18. Do not use any power tools while under the effects of drugs, alcohol or medication.

19. Always wear a face or dust mask if operation creates a lot of dust and/or chips. Always operate the tool

in a well ventilated area and provide for proper dust removal. Use a suitable dust extractor.

Risk of Injury. Wear Eye Wear Ear

Never reach into Protection Protection

a moving part

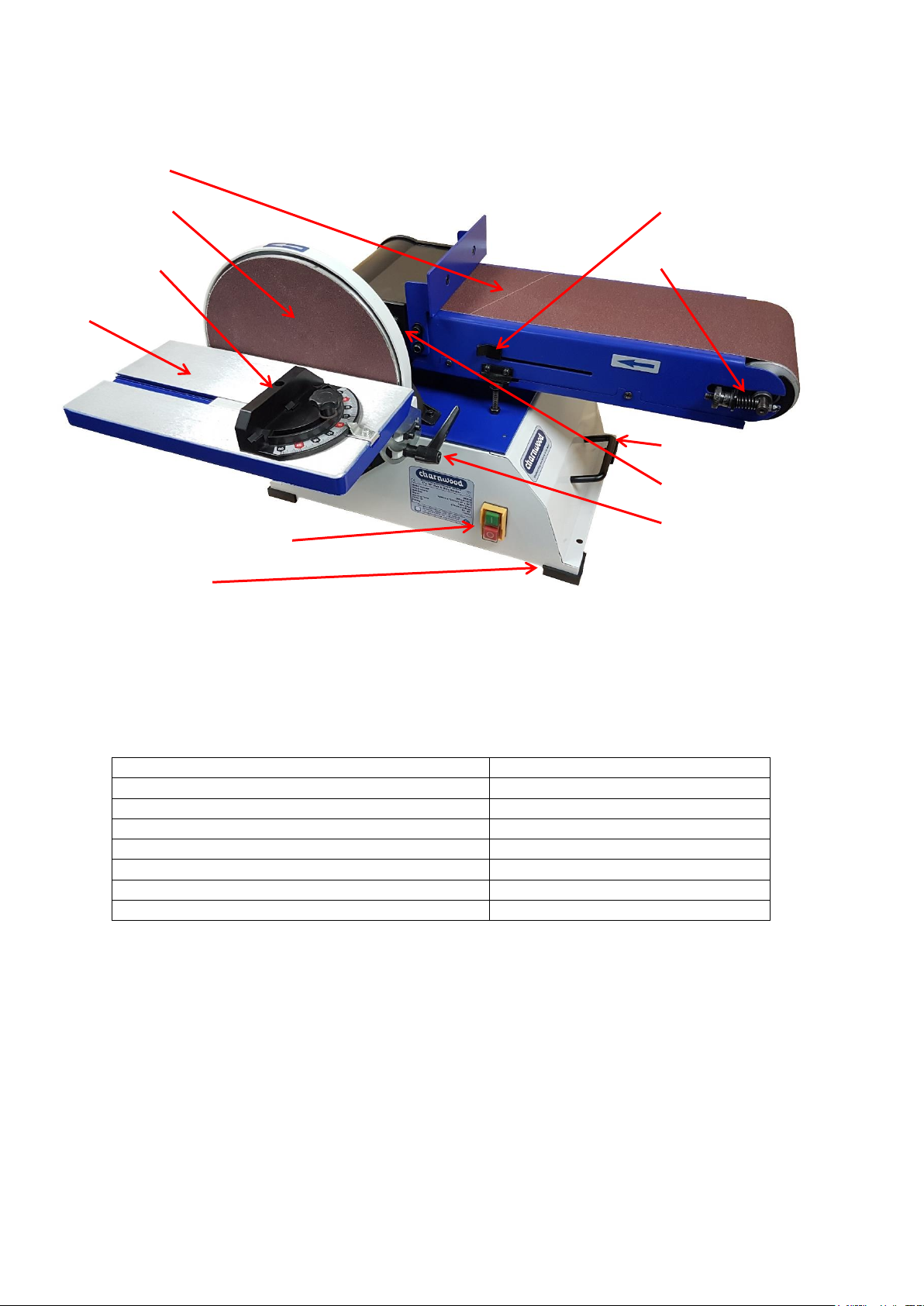

Overview of BD610 Belt & Disc Sander

Sanding Belt

Sanding Disc Sanding Belt

Tension Lever

Mitre Fence Tracking Adjuster

Sanding Table

Carry Handle

Belt Angle Lock

Table Angle Lock

On/Off Switch

Feet

Specification

Disc Diameter

250mm (10”)

Disc Speed

2850rpm

Belt Size

150mm x 1220mm (6” x 48”)

Belt Speed

550m/min

Motor (Induction) 240v 50hz

750w (1hp)

Weight

31kg

Manufacturer’s Warranty

1 year

Rating

Hobby

Rating Description

Hobby: Suitable for Weekend DIY'ers and woodworking enthusiasts.

Generally lighter weight machines with lower power ratings and smaller tooling capacities. Typicaly only

ever used by one person for short periods of time or longer periods of time infrequently. Machinery should

be well maintained in a clean, dry environment such as a home workshop, garage or timber shed.

Expected maximum use of 100 hours annually.

Please Note: Using a product in excess of its rating will void the manufacturer’s free warranty.

Unpacking

All items are contained in one carton.

Carefully unpack and check that all the

items are included as in the photograph.

Assembly

Place the sander on a level surface and

adjust the two bed supporting bolts so

that the belt is also level.

Tighten the locknuts using a 13mm

spanner.

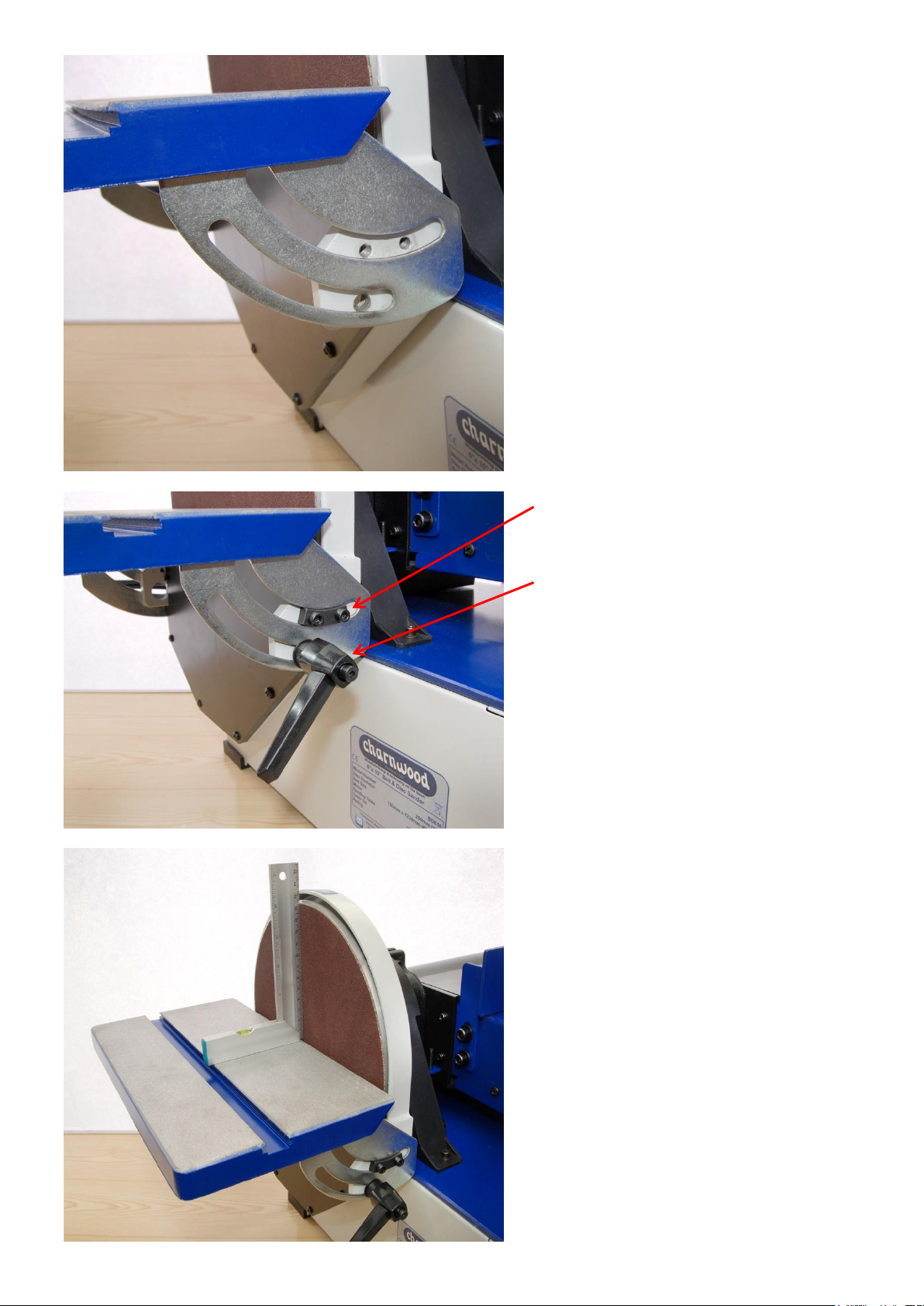

Attaching the Work Table

First, offer up the table so that the curved

slots in the brackets align with the holes

in the base, as shown.

Insert one of the guide blocks into the

upper slot and secure with two M5 x

16mm screws using a 4mm hex key.

Insert the M8 Locking Handle through the

lower slot.

Repeat with the other bracket at the

opposite end of the table.

Adjust the table using a set square so

that it is at right angles to the disc.

Tighten both locking handles.

Loading...

Loading...