Charmglow Plasma F500070 Installation Instructions Manual

1

FOR USE ONLY WITH DECORATIVE TYPE

UNVENTED ROOM HEATERS.

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

• DO NOT light any appliance.

• DO NOT touch any electrical switches.

• DO NOT use any phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone.

Follow your gas suppliers instructions.

• If your gas supplier cannot be reached, call the fire

department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

WARNING: IF THE INFORMATION IN THIS MANUAL

IS NOT FOLLOWED EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY

DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

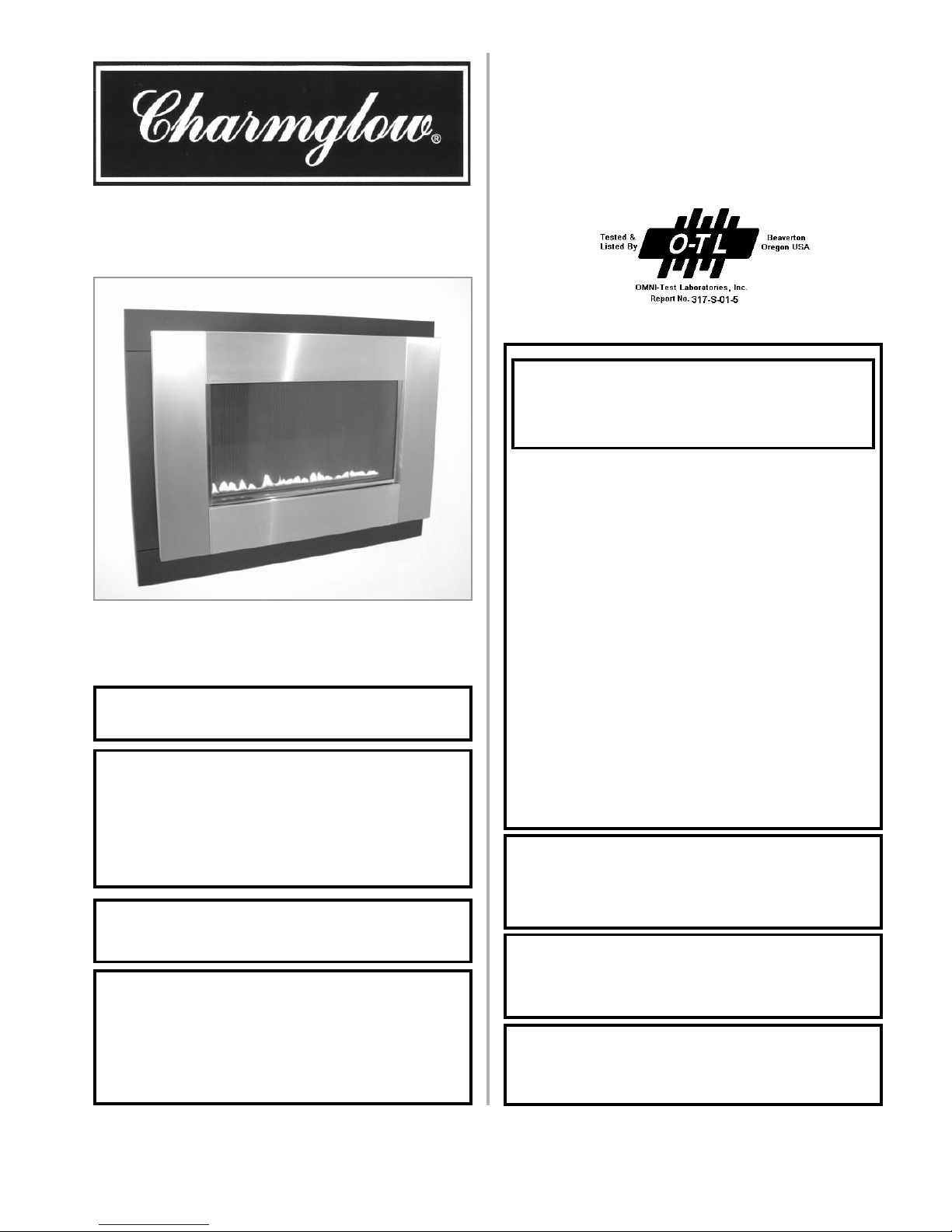

PLASMA

MODEL : F500070

UNVENTED WALL MOUNTED ROOM HEATER

INSTALLATION INSTRUCTIONS

(Para Instrucciones en español, ver la página 12)

Installer And Consumer Are

To Retain The Appliance

Manual With The Installed

Appliance

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

INJURY OR PROPERTY DAMAGE. REFER TO THIS

MANUAL. FOR ASSISTANCE OR ADDITIONAL

INFORMATION CONSULT A QUALIFIED INSTALLER,

SERVICE AGENCY OR THE GAS SUPPLIER.

WARNING: DO NOT BUILD A WOOD FIRE. DO NOT

BURN WOOD OR OTHER MATERIAL IN THESE

APPLIANCES.

This is an unvented gas-fired heater. It uses air

(oxygen) from the room in which it is installed.

Provisions for adequate combustion and ventilation air

must be provided. Refer to Combustion and Ventilation

Air Section, Page 3.

This appliance may be installed in an aftermarket,

permanently located, manufactured (mobile) home,

where not prohibited by local codes.

The appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases.

Issue E-15/06

INSTALLER:

LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER:

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Due to high temperatures, the appliance should be

located out of traffic and away from furniture or

draperies. Do not place clothing or other materials on or

near this appliance.

This appliance is a high efficiency, unvented, flame effect gas heater. It

provides radiant and convected warmth both efficiently and safely

utilizing the latest type catalytic convertor burner technology. The

appliance does not require a flue system of any type as the catalytic

converter cleans the flue products to provide a complete combustion

system, which is intrinsically safe.

These heaters are fitted with a specially designed pilot utilizing an

oxygen depletion sensor (ODS) which responds to the amount of

oxygen available in the room and shuts the heater off before the oxygen

level drops below 18%. The pilot can be relit only when fresh air is

available. Refer to the Combustion and Ventilation Air section.

The appliance is designed to fit various types of situations as listed in

the Installation Requirements.

This appliance is factory set for operation on the gas type, and at the

pressure stated on the appliance rating plate.

On initial light up of a new appliance, the ‘newness’ will burn off within

the first few hours of operation. During this period some smoke may be

emitted from outlet grille, this should be no cause for concern.

Accordingly, the room should be well ventilated with all windows and

doors open during this period.

Read all these instructions before commencing installation.

All instructions must be handed to the user for safekeeping.

QUANTITY DESCRIPTION

1 Firebox and burner assembly

1 Installation and operating instructions

1 Decorative frame assembly

1 Screw and wall plug pack

1 Wall mounting plate

1 Rubber grommet

1 Fitting template

STATE OF MASSACHUSETTS: THE INSTALLATION MUST BE MADE

BY A LICENSED PLUMBER OR GAS FITTER IN THE

COMMONWEALTH OF MASSACHUSETTS.

Carbon Monoxide Poisoning: Early signs of carbon monoxide

poisoning are similar to the flu with headaches, dizziness and/or

nausea. If you have these signs, obtain fresh air immediately. Turn off

the gas supply to the appliance and have it serviced by a qualified

professional, as it may not be operating correctly.

2

Section Contents Page No.

1.0 General Information 2

2.0 Inventory 2

3.0 Appliance Data 2

4.0 Important Safety Information 2

5.0 Codes 3

6.0 Combustion and Ventilation Air 3

7.0 Site Requirements 4

8.0 Preparing the Appliance 5

9.0 Mounting the Appliance 5

10.0 Checking the Burner 6

11.0 Final Fitting of the Frame Assembly 6

12.0 Connecting a Gas Line 6

13.0 Checking the Gas Connections 6

14.0 Gas Pressure Check 6

15.0 Spark Gap 7

16.0 Briefing the customer 7

17.0 Servicing 7

18.0 Servicing the Burner 7

19.0 Pilot Assembly 8

20.0 Catalysts 8

21.0 Testing for Firebox Leakage 8

22.0 Cleaning 8

23.0 Lighting Instructions 9

24.0 To Turn off gas to Appliance 9

25.0 Troubleshooting Guide 10

26.0 Shortlist of Spare Parts 10

27.0 Positioning of field assembled parts 11

WARNING: FAILURE TO COMPLY WITH THE INSTALLATION

AND OPERATING INSTRUCTIONS PROVIDED IN THIS

DOCUMENT WILL RESULT IN AN IMPROPERLY INSTALLED

AND OPERATING APPLIANCE, VOIDING ITS WARRANTY.

ANY CHANGE TO THIS APPLIANCE AND/OR ITS

OPERATING CONTROLS IS DANGEROUS. IMPROPER

INSTALLATION OR USE OF THIS APPLIANCE CAN CAUSE

SERIOUS INJURY OR DEATH FROM FIRE, BURNS,

EXPLOSION OR CARBON MONOXIDE POISONING.

1.0 GENERAL INFORMATION

2.0 INVENTORY

4.0 IMPORTANT SAFETY INFORMATION

TABLE OF CONTENTS

3.0 APPLIANCE DATA

Gas Type Natural Gas

Gas inlet pressure Maximum 10.5” w.c.

Minimum 6” w.c.

Regulator Pressure Setting 5” w.c.

Max Energy Input 8,870 BTU/hour

Min Energy Input 5,110 BTU/hour

Pilot Energy Input 560 BTU/hour

Burner (Manifold) Pressure High 3.6” w.c. (+/-0.3” w.c.) Hot

3.5” w.c. (+/-0.3” w.c.) Cold

Low 1.2” w.c. (+/-0.3” w.c.) Hot

1.1” w.c. (+/-0.3” w.c.) Cold

Main burner flow restrictor Stereo 1.45mm (1/4” BSP)

Oxypilot SIT/Bray 9082

Gas Inlet Connection 3/8” NPT at regulator

Ignition Piezo spark

Spark Gap 1/8” - 3/16”

Please see Data Plate affixed to appliance for current data.

This appliance is for use only with the gas type, and at the pressure

stated on the appliance Data Plate.

IMPORTANT: READ AND UNDERSTAND THESE

INSTRUCTIONS COMPLETELY BEFORE INSTALLING OR

OPERATING YOUR UNVENTED ROOM HEATER.

WARNING: FAILURE TO KEEP THE PRIMARY AIR

OPENING(S) OF THE BURNER(S) CLEAN MAY RESULT IN

SOOTING AND PROPERTY DAMAGE.

• Children and adults should be alerted to the hazard of high surface

temperature and should stay away to avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the

same room with the heater.

• Do not place clothing or other flammable material on or near the

heater.

• Any safety screen or guard removed for servicing the heater must be

replaced prior to operating the heater.

• Installation and repair should be done by a qualified service person.

The heater should be inspected before use and at least annually by a

professional service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. It is

important that control compartments, burners and circulating air

passageways of the heater be kept clean.

• Allow the heater to cool before servicing. Always shut off the gas to

the heater while performing service work.

• The installation must conform with local codes or, in the absence of

local codes with the National Fuel Gas Code, ANSI Z223.1.

• The heater and its individual shut-off valve must be disconnected

from the gas supply piping system while performing any tests of the

gas supply piping system at pressures in excess of 1/2 psig.

• The heater must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig.

• Keep heater area clear and free from combustible materials, gasoline

and other flammable vapors and liquids.

• Do not use this heater if any part has been under water. Immediately

call a qualified service technician to inspect the room heater and to

replace any part of the control system and any gas control which has

been under water.

• Input ratings are shown in BTU per hour and are for elevations up to

4,800 feet. Do not install this heater at an elevation above 4,800 feet if

the gas supply has not been derated for that elevation. Consult your

local gas supplier. (For operation at elevations above 4,800 feet,

equipment ratings shall be reduced at the rate of 4 percent for each

1,000 feet above sea level before selecting appropriately sized

equipment.)

• Ensure that the heater is clean when operating. Excessive dust

accumulation on the burner will increase the amount of carbon

monoxide formation and could lead to carbon monoxide poisoning

and/or death.

• This appliance is intended for supplemental heating

Adhere to all local codes or in their absence the latest edition of The

National Fuel Gas Code ANSI Z223.1 or NFPA54 which can be obtained

from The American National Standards Institute, Inc. (1430 Broadway, New

York, NY, 10018) or National Fire Protection Association, Inc.

(Batterymarch Park, Quincy, MA, 02269).

Seller of unvented propane or natural gas fired supplemental room heaters

shall provide to each purchaser a copy of 527 CMR 30 upon sale of the

unit.

This Focal Point Unvented Gas Room Heater is certified by OMNI-Test

Laboratories, Inc to ANSI Z21.11.2-2004b standard.

This heater shall not be installed in a confined space or unusually tight

construction unless provisions are provided for adequate combustion and

ventilation air.

The National Fuel Gas Code, ANSI Z223.1/NFPA 54 defines a confined

space as a space whose volume is less than 50 ft

3

per 1,000 BTU/Hr (4.8

m3per kW) of the aggregate input rating of all appliances installed in that

space and an unconfined space as a space whose volume is not less than

50 ft 3per 1,000 BTU/Hr (4.8 m3per kW) of the aggregate input rating of all

appliances installed in that space.

Rooms communicating directly with the space in which the appliances are

installed, through openings not furnished with doors, are considered a part

of the unconfined space.

Unusually tight construction is defined as construction where:

a. wall and ceilings exposed to the outside atmosphere have a continuous

water vapor retarder with a rating of one perm or less with openings

gasketed or sealed, and

b. weather stripping has been added on operable windows and doors, and

c. caulking or sealants are applied to areas such as joints around window

and door frames, between sole plates and floors, between wallceiling joints,

between wall panels, at penetrations for plumbing, electrical, and gas lines,

and at other openings.

Use the following equations to determine if you have a confined or

unconfined space.

3

5.0 CODES

6.0 COMBUSTION AND VENTILATION AIR4.0 IMPORTANT SAFETY INFORMATION (continued)

Determine the volume of space — ft 3.

Length x Width x Height = _____ ft

3

(Include adjoining rooms with doorless passageways or ventilation

grills between rooms.)

Example: 24' (L) x 16' (W) x 8' (H) = 3072 ft

3

Divide the volume of space by 50 ft 3to determine the maximum

BTU/Hr the space can support.

______ (volume of space – ft 3)/ 50 ft 3=

(Maximum BTU/Hr the space can support)

Example: 3072 ft 3 / 50 ft 3 = 61.44

or 61,440 BTU/Hr the space can support.

Add the BTU/Hr of all the fuel burning appliances in the space.

Vent-Free heater _______ BTU/Hr

Gas appliance #1* _______ BTU/Hr

Gas appliance #2 + _______ BTU/Hr

Gas appliance #3 + _______ BTU/Hr

Total = _______ BTU/Hr

Example:

Vent-free heater #1 9,000 BTU/Hr

Vent-free heater #2 23,000 BTU/Hr

Gas appliance #1 35,000 BTU/Hr

(water heater)

Total = 67,000 BTU/Hr

* Do not include direct-vent gas appliances. Direct-vent is sealed

combustion and draws combustion air from the outdoors.

1.

2.

3.

The space in the previous example is a confined space because the actual

BTU/Hr used is more than the maximum BTU/Hr the space can support.

You must provide additional fresh air.

Your options are:

a. Rework equations adding the space of adjoining room(s). If the extra

volume provides an unconfined space, then remove door or add ventilation

grills between rooms. Refer to National Fuel Gas Code, ANSI Z223.1,

Section 5.3.

b.

Vent room directly to the outdoors. Refer to National Fuel Gas Code,

ANSI Z223.1, Section 5.3.

c. Install a lower BTU/Hr heater to make the area an unconfined space.

If the actual BTU/Hr used is less than the maximum BTU/Hr the space can

support, then the space is an unconfined space. You will need no additional

fresh air ventilation for an unconfined space.

This appliance is designed to be wall-hung. Do not recess any part

of the appliance into the wall.

This Appliance may be installed in any room in a home except Bathrooms

- or areas where large amounts of steam are likely to be generated.

Installation in living rooms is common, however other rooms such as

kitchens, dining rooms and hallways are permitted, providing a suitable

natural gas supply is available, and rooms sizing and ventilation

requirements are strictly adhered to (see section 6.0).

The appliance is designed to be versatile, and as such will operate correctly

when exposed to normal gentle draughts experienced within the home. It is

not recommended, however that the appliance be installed in areas where

it is likely to be exposed to persistent strong draughts, that may be

generated by outside doors or windows, air vents etc. It is recommended

that the appliance should not be installed within 20” of any air vent.

Clearances to non-combustibles

Non-combustible surfaces are defined as brick, metal, marble, concrete

etc. and also a number of man-made materials impervious to flame. If in

doubt refer to the material manufacturer for further information before

proceeding with installation.

Clearances to the sides of the appliance are 4”. Clearance to the front of

the appliance is 20”.

The back of the appliance may be installed directly onto a non-combustible

wall, providing the area behind the appliance is flat and does not interfere

with the various vent holes in the back panel of the appliance.

The appliance may be installed with or without a non-combustible hearth. If

a hearth is fitted, the size and design may be as desired.

A non-combustible shelf of any depth may be positioned above the

appliance provided it is no closer than 16” from the top of the appliance

glass panel and the wall above the appliance is non combustible.

Clearances to combustible materials

Combustible materials are defined as wood, fabrics, or other materials

likely to combust if exposed to flame. Generally, any material, which is likely

to discolour, melt or misshape when exposed to moderate heat, should be

considered as a combustible material or surface.

Clearance to the sides of the appliance are 4” but curtains, drapes and

other fabrics are not permitted within a distance of 20” of the appliance

sides. No such materials are permitted directly above the appliance

regardless of distance.

The minimum clearance to the ceiling above the appliance is 32” measured

from the top of the appliance glass panel.

Combustible materials should not be positioned directly in front of the

appliance within a distance of 40”.

Under no circumstances should any electrical equipment e.g. plasma

screen TV sets etc. be positioned on the wall above the appliance. The

appliance is designed to be wall mounted alone and not in conjunction with

any type of combustible fire surround. No combustible shelves should be

positioned on the wall above the appliance. It should be established that

any mirrors or picture frames etc. to be positioned on the wall above the

appliance are able to withstand prolonged exposure to moderate heat and

moisture before proceeding with their installation.

The back of the appliance may be installed directly onto a combustible wall,

providing it is relatively flat and does not interfere with the various vent

holes in the back panel of the appliance. The wall must be structurally

sound and constructed from a material capable of withstanding moderate

heat. Finished plaster, conventional wall paper and dry-lined plasterboard

are examples of suitable materials. Materials such as flock, blown vinyl and

embossed paper which are sensitive to even small amounts of heat should

be avoided as scorching and or discoloration may occur over time.

If the appliance is to be mounted on a dry-lined wall or a timber framed

construction wall then the integrity and ability of the wall to carry the weight

of the appliance must be confirmed. It is important in these circumstances

that any vapor control barrier is not damaged, and that any structural

members of the house frame are not damaged.

The appliance may be positioned as close to a solid floor (i.e. stone,

wooden laminate etc.) as the particular design of fire frame permits,

however it is not permitted to install the appliance within 4” of carpet, rugs

or fabric materials of any kind. This dimension is measured vertically to the

bottom of the appliance frame.

4

6.0 COMBUSTION AND VENTILATION AIR - continued

WARNING: IF THE AREA IN WHICH THE HEATER MAY BE

OPERATED IS SMALLER THAN THAT DEFINED AS AN

UNCONFINED SPACE OR IF THE BUILDING IS OF

UNUSUALLY TIGHT CONSTRUCTION, PROVIDE ADEQUATE

COMBUSTION AND VENTILATION AIR BY ONE OF THE

METHODS DESCRIBED IN THE NATIONAL FUEL GAS CODE,

ANSI Z223.1/NFPA54, SECTION 5.3 OR APPLICABLE LOCAL

CODES.

7.0 SITE REQUIREMENTS

4.

Compare the maximum BTU/Hr the space can support with the

actual amount of BTU/Hr used.

_______ BTU/Hr (max. the space can support)

_______ BTU/Hr (actual amount of BTU/Hr used)

Example:

61,440 BTU/Hr (max. the space can support)

67,000 BTU/Hr (actual amount of BTU/Hr used)

WARNING: DO NOT USE A BLOWER INSERT, HEAT

EXCHANGER INSERT OR OTHER ACCESSORY NOT

APPROVED FOR USE WITH THIS HEATER.

Loading...

Loading...