Charles Industries 31929E User Manual

Section 319–29E–202

Equipment Issue 2

Third Printing, June 1999Charles Industries, Ltd.

STS 3192–9E Powering T1 Network Interface Unit (NIU)

CLEI Code: T1STETT1AA

Recognized under Underwriters Laboratories Standard 1459, Second Edition*

CONTENTS PAGE

Part 1. GENERAL 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 2. APPLICATION ENGINEERING 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 3. CIRCUIT DESCRIPTION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 4. INSPECTION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 5. MOUNTING 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 6. OPTIONS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 7. TESTING 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 8. TECHNICAL ASSISTANCE 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 9. WARRANTY & CUSTOMER SERVICE 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 10. SPECIFICATIONS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PWRG

T1

NIU

3192–9E

FA

NET

LOS

CI

LOS

LB

ESF

R

P

T

M

O

N

0.6V

R

P

T

M

O

N

MLB

WESCOM

91–31929E

ISS. 2

R

C

V

X

M

T

Figure 1. 3192–9E Powering T1 NIU

1999 Charles Industries Ltd.

CLEI is a trademark of Bell Communications Research, Inc.

All rights reserved. Printed in United States of America.

The availability of features and technical specifications herein subject to change without notice.

Page 1 of 14

Section 319–29E–202

1. GENERAL

1.1 Document Purpose

This document provides general, circuit, and testing information for the Charles Industries Span Termination System (STS) 3192–9E Powering T1 Network Interface Unit (NIU), shown in Figure 1. The 3192–9E is a member of

the Charles Industries STS–3192 family of high density span termination equipment. For additional information on

the STS–3192 System, see sections 319–211–100 and 319–211–200.

1.2 Document Status

This practice is reprinted to correct Figure 4 and related text. The Issue 2 equipment provides one additional loop

up code and one additional loop down code over the Issue 1 equipment; form remains unchanged.

1.3 Equipment Function

The 3192–9E combines the functions of a Powering T1 Office Repeater plus a T1 Network Interface Unit conforming to Bellcore TR–TSY–000312 in a single high density plug-in module. When equipped in the 3192–11 23

inch mounting shelf, up to 28 3192–9E units can be provided in 5.25 inches of vertical equipment space. The

3192–9E can be intermixed with other plug in units of the STS-3192 Family in the shelf assembly.

CAUTION

Field repairs/modifications may void compliance with Underwriters Laboratories Standard 1459 – 2nd

Edition. Compliance is restricted to inside plant wiring.

1.4 Equipment Mounting/Location

The 3192–9E is fully qualified for operation over a –40 to 65C temperature range, and can be deployed in outside plant electronics cabinets or indoor building Remote Terminals, typically in Span Termination System

(STS–3192) Mounting Shelves.

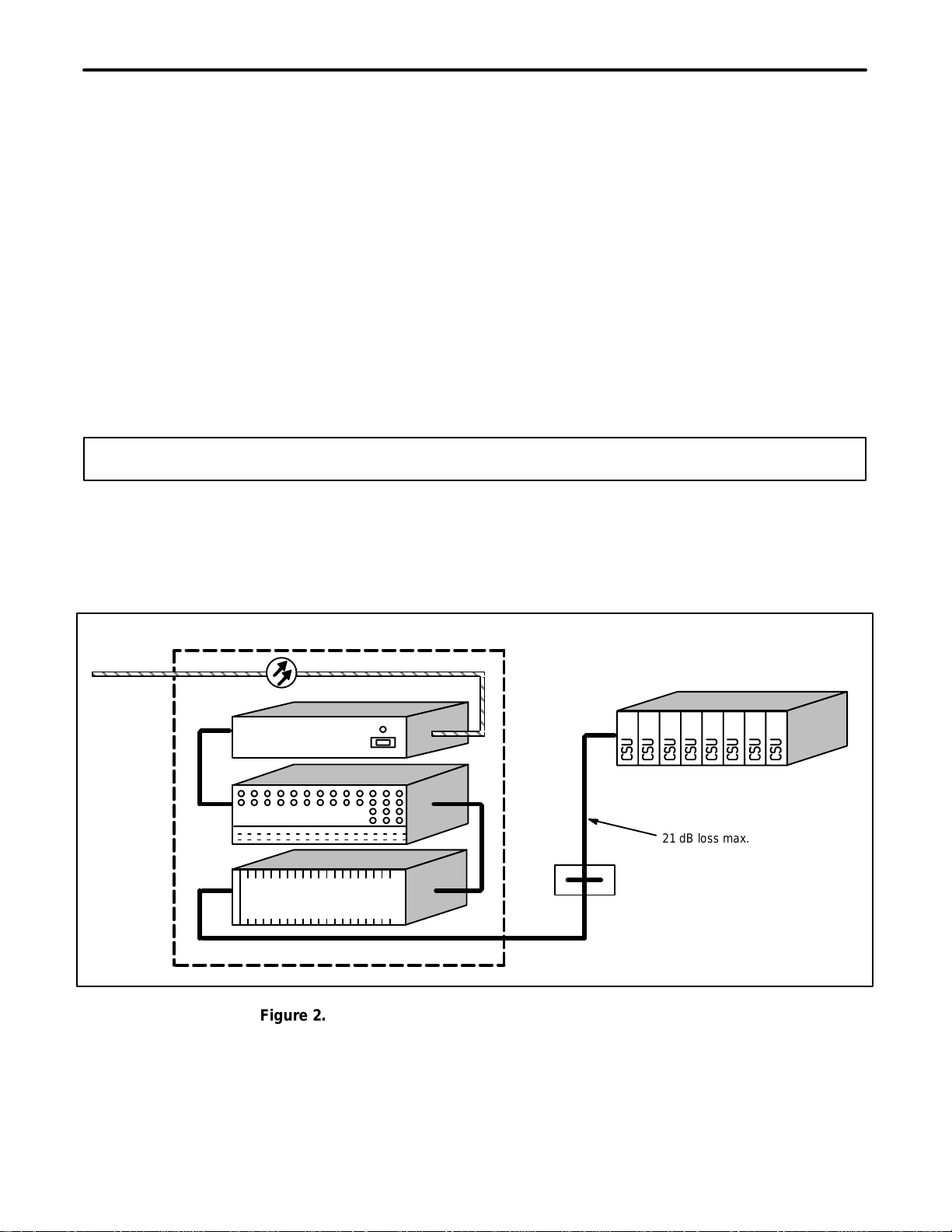

Building Remote Terminal

Fiber

Facility

To LEC

Network

Lightwave

Multiplexer

Customer CPE

DSX-1 Crossconnect

3192–11 STS

Equipment Shelf

e/w 28 ea. 3192–9E

Network

Equipment

21 dB loss max.

Interface

Figure 2. 3192–9E T1 Powering NIU Typical Configuration

2

Section 319-29E-202

2. APPLICATION ENGINEERING

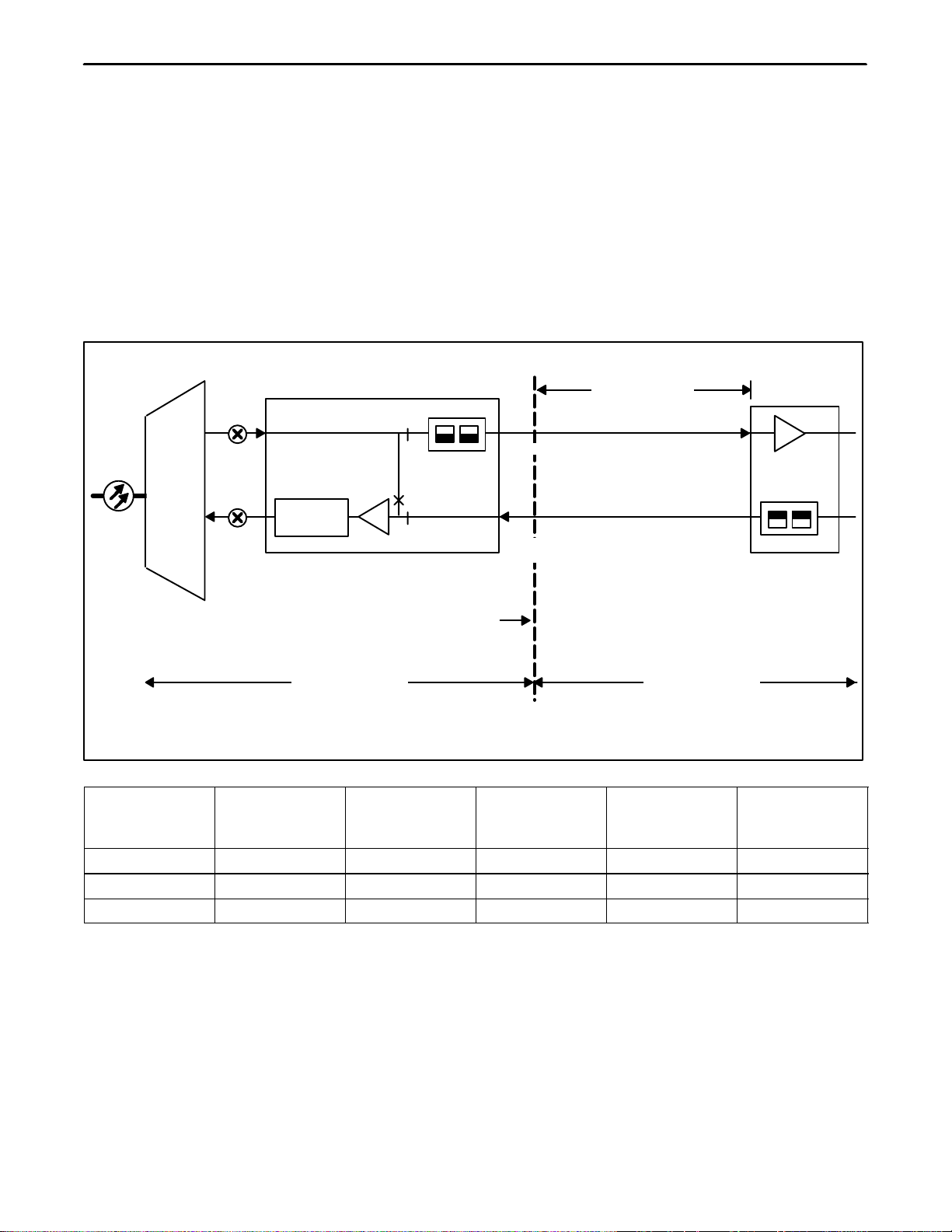

The 3192–9E is ideally suited for use in provisioning T1 High Capacity Digital Service (HCDS) from lightwave-fed

building Remote Terminals located at customer premise locations. See Figure 2 for a typical application. The

3192–9E, used as adjunct equipment to the Lightwave Multiplexer, provides transmission loopback for maintenance activities. In addition, the 3192–9E can be optioned to provide a 60mA constant current power source towards the network interface, which can be used to power the customers’ Channel Service Unit (CSU). This service arrangement is typical in MPOP (Minimum Point Of Presence) applications.

The 3192–9E is intended to be co-located with the lightwave transport equipment and serves to extend the normal DSX range of that equipment. The 3192–9E provides a fixed DSX pre-equalizer for 0 to 110 feet of cable. In

the transmit direction the unit provides variable pads for level coordination toward the CPE. The 3192–9E can

accommodate up to 21dB of cable loss between the customer’s CSU and the 3192–9E.

Figure 3 shows a typical 3192–9E application with associated transmission levels.

Customer

Wiring

Maximum

Loss 21.0dB

(See NOTE)

Lightwave

Multiplexer

DSX–1

0.0

Pre

Equalizer

3192–9E Powering T1 NIU

Customer

Network

Interface

LEC Equipment CPE Equipment

–1.5dB

-1.5 To

-22.5dB

Note:

Signal Levels Referenced

To 3V Base-To-Peak

–1.5 To

–22.5dB

LBO

–1.5dB

0.0

T1 CSU

Note: Range is limited to maximum cable loss of 21.0db. See table below for maximum cable length at

various cable gauges.

CABLE @ 130 F

AERIAL - PIC

MAXIMUM

LENGTH -KF

TOTAL DCR

@ MAXIMUM

REFERENCE

LOSS - dB/KF

REFERENCE

LOSS - OHMS/

KF

REFERENCE

MAXIMUM

LOSS

22 GA-CU 4.29 KF 78 OHMS 4.9 dB/KF 18.3 OHMS 21.0dB

24 GA-CU 3.44 KF 100 OHMS 6.1 dB/KF 29.2 OHMS 21.0dB

26 GA-CU 2.56 KF 119 OHMS 8.2 dB/KF 46.7 OHMS 21.0dB

Figure 3. 3192–9E T1 Powering NIU Typical Configuration

2.1 Customer Interface Powering Options

The 3192–9E provides three, switch-selectable, CI (Customer Interface) side power modes: line powering, sealing current, and looped simplex. See Part 6 for more information.

2.2 System Power Engineering

The 3192–9E generates all necessary voltages for its operation from a –48V (nominal) battery input source. The

3192–9E contains an internal high efficiency DC–DC converter to minimize input current, and consequently, maximize battery reserve time in the remote terminal assembly.

3

Section 319–29E–202

Simple

The 3192–9E input current is highly dependent on application. Those applications that require the 3192–9E to

power a customer’s CSU will require a greater input current.

Table 1 shows input current and heat release versus the equivalent series simplex resistance (at 60mA) present

on the CI side of the unit.

Table 1. 3192–9E Power Consumption and Heat Release

Typical Application Option S1

Position

Non-CPE Powering S1 = LP N/A 0.07 2.86 0.06 2.87 0.06 3.00

Sealing Current Only S1 = SC 0 Ohms 0.08 3.35 0.07 3.53 0.07 3.77

S1 = PWR 200 Ohms 0.10 2.91 0.08 3.02 0.07 3.12

S1 = PWR 400 Ohms 0.11 3.04 0.10 3.12 0.08 3.18

Powering Co-located 24V CSU S1 = PWR 600 Ohms 0.13 3.09 0.11 3.12 0.10 3.13

S1 = PWR 800 Ohms 0.14 3.18 0.13 3.13 0.11 3.14

S1 = PWR 1000 Ohms 0.16 3.22 0.14 3.18 0.13 3.15

Powering Co-located 68V CSU S1 = PWR 1200 Ohms 0.18 3.32 0.16 3.22 0.14 3.22

S1 = PWR 1400 Ohms 0.20 3.45 0.18 3.23 0.16 3.28

S1 = PWR 1600 Ohms 0.22 3.55 0.20 3.38 0.18 3.39

Equivalent

External

x

Resistance

–42.5 Volt

Battery

I W I W I W

48.0 Volt Battery

56.0 Volt Battery

Note: W = Heat release in watts

I = Input current in amps

2.3 Maintenance Loopback

The 3192–9E provides a signal path Loopback feature, which can be used to differentiate circuit problems on either side of the network interface.

The 3192–9E will respond to Loopback control codes in either SF or ESF protocols. SF control codes are received as 5 or 6 bit inband repeating patterns, while ESF codes are via 16 bit messages in the ESF framing data

link. The operation of this feature is automatic, that is, when the unit is passing unframed or SF framed traffic it

will recognized the 5 or 6 bit inband SF Loop codes, when the unit is passing ESF traffic it will only recognize the

ESF data link Loopback control codes.

When the 3192–9E is in the maintenance loopback state, it will send an AIS (all ones) signal toward the Customer Interface.

3. CIRCUIT DESCRIPTION

Refer to Figure 4, the 3192–9E Block Diagram, Figure 5, the 3192–9E State Table, and Figure 6, Front Panel

Features and Options Location, when reading the following circuit description.

4

Section 319-29E-202

LIGHTWAVE

MULTIPLEXER

DSX

FA

-BATT

GND

FRA

MEGND

A

1

Network

Side

B

2

10

8

5

J

MON RPT

MON RPT

FA

XMT

RCV

POWER

SUPPLY

NETWORK

SIGNAL

DETECTOR

LOOPBACK

CODE

DETECTOR

CONTROL

LOGIC

LB

MLB

PREEQ

STEADY = LOS

FLASH = AIS

S2

DSX

NET LOS

ESF

LB

LOOPDOWN

CONTROL

SIGNAL

REGEN

LB

AIS

GENERATOR

CI LOS

GENERATOR

LB

BUFFER

AMP

-48V

LB

DISABLE

ENABLE

DISABLE

AIS

FLASH = SENDING AIS

STEADY = CI LOS

AIS

+

ASPR

0-96V

-

7.5 7.5

XMT LBO

S4

S3-2

PWR

LP

4K

100

LB

CUSTOMER

INTERFACE

DETECTOR

SC

SIGNAL

CPE

EQUIPMENT

NETWORK

INTERFACE

SURGE

PROTEC

TION

CSU

F

6

-

XMT

+

S1

+

RCV

-

SURGE

PROTEC

TION

CI

Side

K

9

DISABLE

LOS

S3-1

LOS ALM

H

ALM

RECEIVE

LOOPUP SIGNAL FROM

NETWORK

OR MLB

Figure 4. 3192–9E T1 Powering NIU Block Diagram

IDLE

STATE 1

20 MIN.

TIMEOUT

LOOPBACK

STATE 2

DETECT LOS FROM

CUSTOMER INTERFACE

DETECT SIGNAL PRESENT

CUSTOMER INTERFACE

RECEIVE LOOPUP SIGNAL

RECEIVE

FROM NETWORK

LOOPDOWN

SIGNAL FROM

NETWORK

OR MLB

DETECT SIGNAL PRESENT

CUSTOMER INTERFACE

RECEIVE LOOPUP SIGNAL

FROM NETWORK

Figure 5. 3192–9E Operational State Table

CI LOS

NOTIFICATION

STATE 3

RECEIVE

LOOPDOWN

SIGNAL FROM

NETWORK

CI LOS

CUT-THRU

STATE 4

5

Loading...

Loading...