Page 1

PRODUCT GUIDE

MODEL 463226513

Grilling's Juicy Little Secret TM

b®

Classic C-69G3

IMPORTANT:Fill out the product record information below.

Serial Number

Seeratinglabelongrillfor serial number.

Date Purchased

Forsupportandto registeryour

grill,pleasevisitusat

www.charbroil.com

Ifyouhavequestionsor need

assistanceduringassembly,

pleasecall1-800-241-7548.

© 2013 Char-Broil,LLC Columbus,GA 31902 PrintedinChina Assemblyinstructions© 2013 08/01/12. G651-001-210801

Page 2

ill,,

ForYourSafety.................................... 2-3

GrillingGuide...................................... 4-7

UseandCare .................................... 8-14

LimitedWarranty.................................... 15

PartsList.......................................... 16

PartsDiagram...................................... 17

Assembly....................................... 18-27

Troubleshooting.................................. 28-30

RegistrationCard................................... 31

Safety Symbols

The symbols and boxesshown below explain what each heading

means. Read and follow all of the messages found throughout

the manual.

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or your fire department.

1. Do not store or use gasoline or other

flammable liquids orvapors in the vicinity of

this or any other appliance.

2. An LP cylinder not connected for use shall not

be stored in the vicinity of this or any other

appliance.

WARNING: Indicatesa potentially hazardous situation

which, if notavoided, could result indeath or serious injury.

CAUTION

CAUTION: Indicatesa potentiallyhazardoussituationor

unsafe practicewhich, if notavoided, may result inminor

or moderate injury.

DANGER: Indicatesan imminentlyhazardous situation

which, if notavoided,will result indeath orserious injury.

INSTALLER/ASSEMBLER:

Leavethis manual with consumer.

CONSUMER=

Keepthis manualfor future reference.

Failureto follow all manufacturer's instructionscould

result in seriouspersonal injury and/or propertydamage.

CAUTION

Forresidential use only. Do not usefor commercial

cooking.

CAUTION

Readand follow all safety statements,assembly

instructions,and use and care directions before

attemptingto assembleand cook.

CAUTIO.

Some parts may contain sharp edges.

Wearprotective gloves if necessary.

Page 3

CAUTION

CALIFORNIAPROPOSITION65

1.Combustibleby-productsproducedwhenusing

thisproductcontainschemicalsknowntotheState

ofCaliforniatocausecancer,birthdefects,or

otherreproductiveharm.

2.This product containschemicals, includinglead

and lead compounds, known to the State of

California to cause cancer, birth defects or

other reproductive harm.

Washyour hands after handling this product.

Installation Safety Precautions

• Use grill, as purchased, only with LP (propane) gas and the

regulator/valve assembly supplied. If your grill is Dual Fuel ready,

a conversion kit mustbe purchased for usewith natural gas.

• Grill installation must conform with local codes, or in their

absence of local codes, with either the National Fuel Gas

Code,ANSI Z223.1/NFPA 54, Natural Gas and Propane

Installation Code, CSAB149.1, or Propane Storage and

Handling Code, B149.2.

• All electrical accessories (such as rotisserie) must be

electrically grounded in accordance with local codes, or

National Electrical Code,ANSI / NFPA70 or Canadian

Electrical Code, CSA C22.1. Keep any electrical cords and/or

fuel supply hoses away from any hotsurfaces.

• This grill is safety certified for use in the United States and/or

Canada only. Do not modify for use inany other location.

Modification will result in a safety hazard.

Do not attempt to repair or alter the

hose/valve/regulator for any "assumed" defect. Any

modification to this assembly will void your warranty

and create the risk of a gas leak and fire. Use only

authorized replacement parts supplied by

manufacturer.

Using pots larger than 6 quarts in capacity could

exceed weight limit of the

or side shelf,

resulting in failure

CAUTION

GreaseFires

• Putting out grease fires by closing the lid is not

possible. Grills are well ventilated for safety reasons.

• Do not use water on a grease fire. Personal injury may

result. If a grease fire develops, turn knobs and LP tank

off.

• if grill has not been regularly cleaned, a grease fire can

occur that may damage the product. Pay close attention

while preheating or burning offfood residue to insure

that a grease fire does not develop. Follow instructions

on General Grill Cleaning and Cleaning The Burner

Assembly to prevent grease fires.

• The best way to prevent grease fires is regular cleaning

ofthe grill.

NOTE: DONOT over tightenscrews andwashers that

come intocontact with porcelain coated surfaces. Over

tightening may cause the porcelain coatingto crack and

break, resultingin exposed metal that will be proneto rust.

Page 4

First Time Use

Read yourAssembly Manual and ensure the grill is puttogether

properly. Remove all Point-of-Purchase advertising material from

all grill surfaces before first use. We recommend operating your

grill on its highest setting for 15-20 minutes prior to your first use.

This aids in removing the oils used during manufacturing.

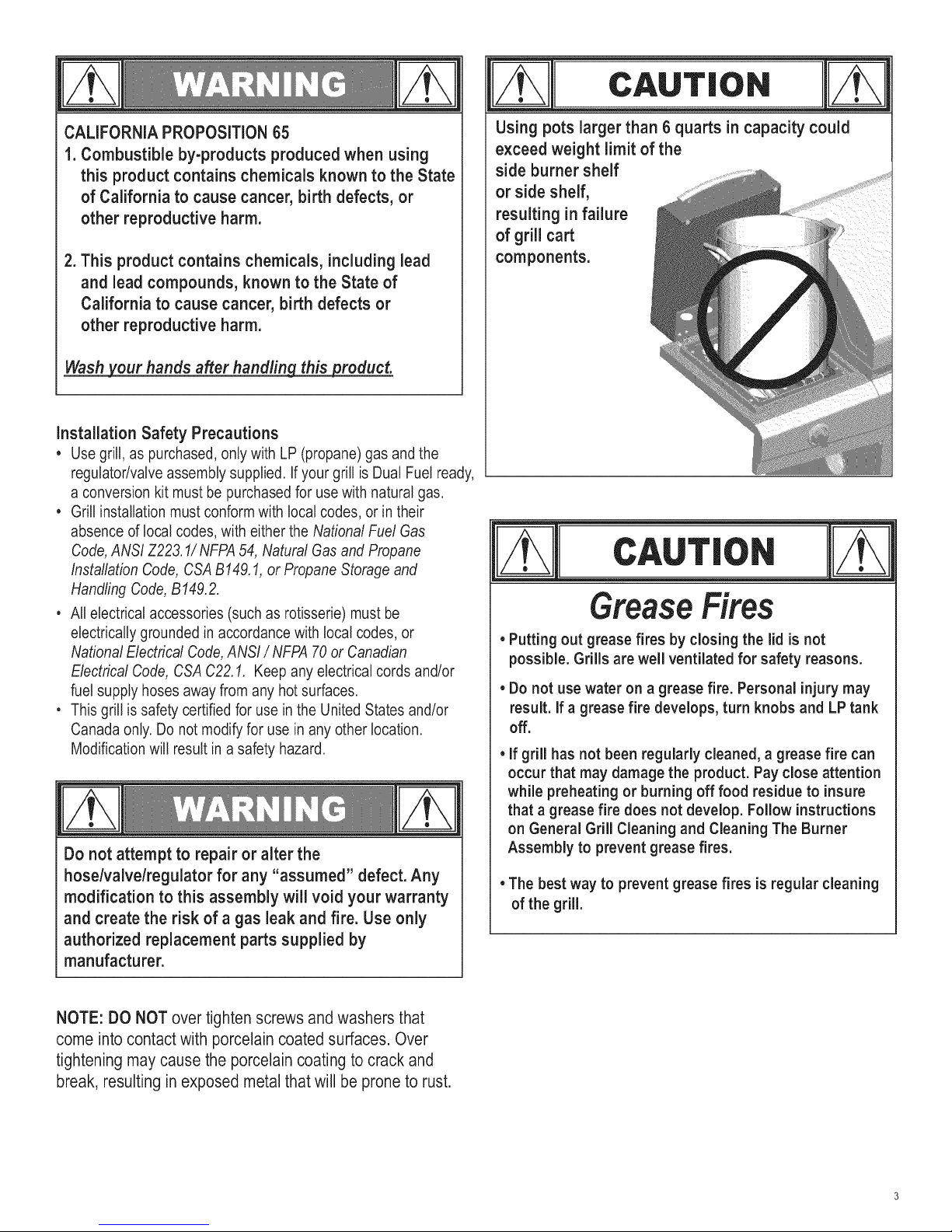

Lava Rock / Briquettes

This gas grill has been designed, engineered, and tested to be

used with flame tamers or heat distribution platesto provide

more even heating, improve the cleaning process, and reduce

flare-ups. The addition of after market lava rocks, charcoal, or

briquettes of any type will cause poor combustionand increase

the likelihood of a grease fire, and is not recommended. Using

briquettes, lava rock, or charcoal in this grillwill void your

warranty. For extra smoke flavor,we recommend using a

smoker box with wood chips.

Temperature - Convective Grills ONLY.

The temperature gauge in the hood of your new grill measures

air temperature. The air temperature inside your grill will never

be as hot as the temperature at the cooking surface.

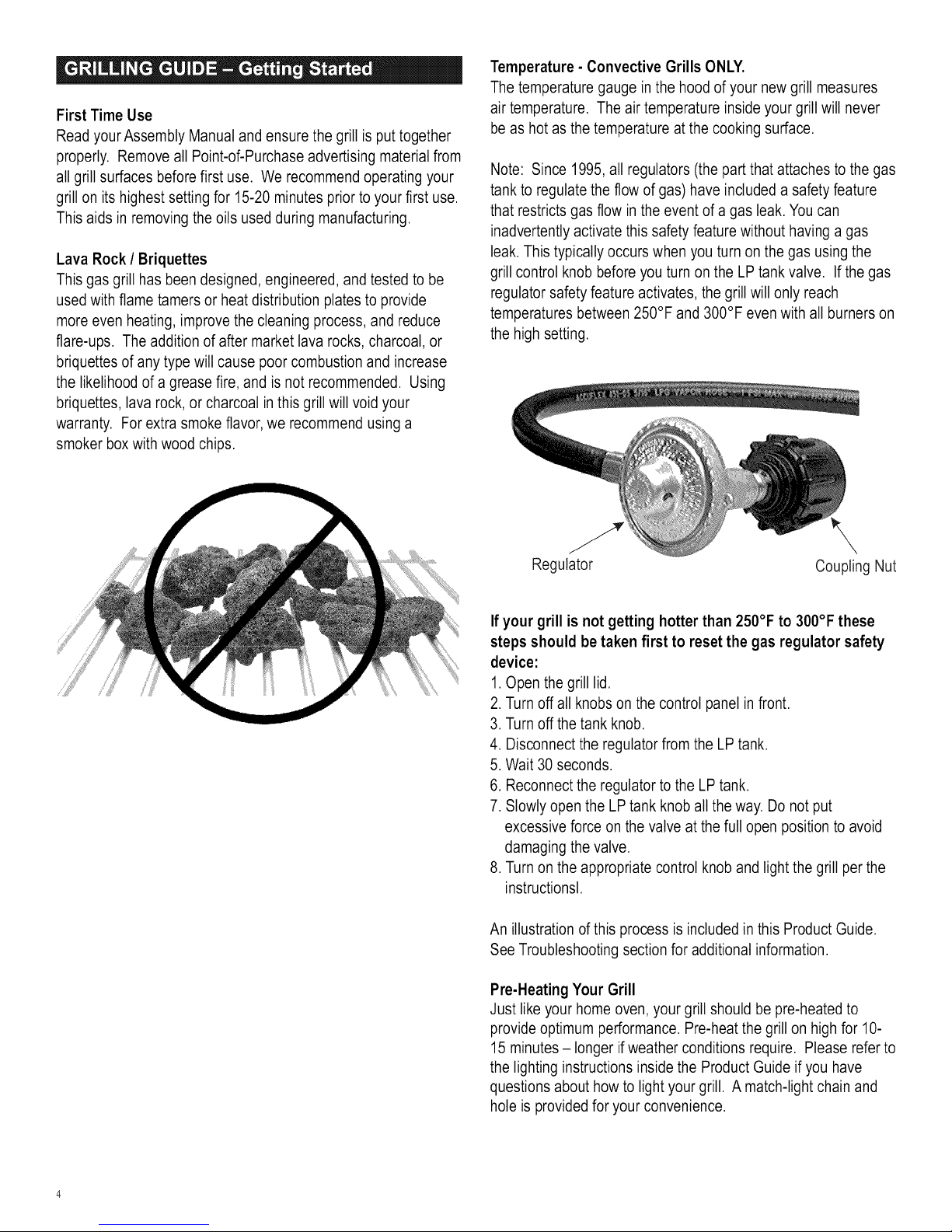

Note: Since 1995,all regulators (the part that attaches to the gas

tank to regulate the flow of gas) have included a safetyfeature

that restricts gas flow in the event of a gas leak. You can

inadvertently activate this safety feature without having a gas

leak. This typically occurs when you turn on the gas using the

grill control knob before you turn on the LP tank valve. If the gas

regulator safety feature activates, the grill will only reach

temperatures between 250°F and 300°F evenwith all burners on

the high setting.

Regulator

Coupling Nut

If your grill is not getting hotterthan 250°F to 300°F these

steps should be taken first to reset the gas regulator safety

device:

1.Open the grill lid.

2. Turnoff all knobs on the control panel in front.

3. Turnoff the tank knob.

4. Disconnect the regulator from the LP tank.

5. Wait 30 seconds.

6. Reconnect the regulator to the LP tank.

7. Slowly open the LP tank knob all the way. Do not put

excessive force on the valve at the full open position to avoid

damaging the valve.

8. Turnon the appropriate control knob and lightthe grill per the

instructionsl.

An illustration of this process is includedin this Product Guide.

See Troubleshooting section for additional information.

Pre-HeatingYour Grill

Just like your home oven, your grill should be pre-heated to

provide optimum performance. Pre-heat the grill on highfor 10-

15 minutes- longer ifweather conditions require. Please refer to

the lighting instructions inside the Product Guide if you have

questions about how to light your grill. A match-lightchain and

hole is provided for your convenience.

Page 5

Outdoorgrillingisreallyquitesimple.You'llsucceedwith

burgers,dogs,orsteaksusuallyonyourveryfirsttry.With

experience,youwilllearnhowtoworkwithyourgrill,creating

moreimaginativemealsallthetime.Thisknowledgemakesup

theartofgrilling.Beforeyoustartgrilling,organizeyourfood

accordingtocookingtechniqueandrequiredcookingtime,and

optimizetheuseofyourgrillingarea.

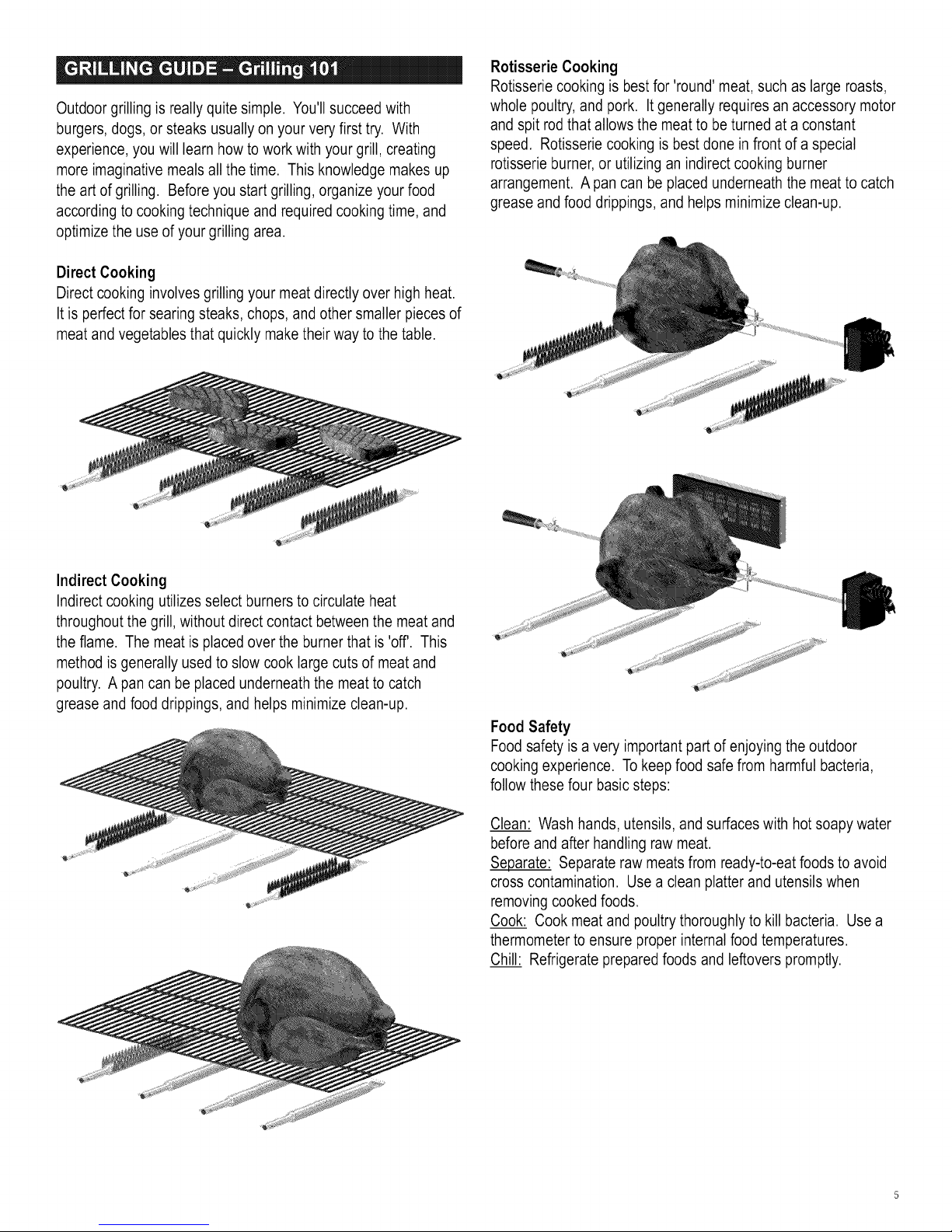

DirectCooking

Directcookinginvolvesgrillingyourmeatdirectlyoverhighheat.

Itisperfectforsearingsteaks,chops,andothersmallerpiecesof

meatandvegetablesthatquicklymaketheirwaytothetable.

RotisserieCooking

Rotisseriecookingisbestfor'round'meat,suchaslargeroasts,

wholepoultry,andpork.Itgenerallyrequiresanaccessorymotor

andspitrodthatallowsthemeattobeturnedataconstant

speed.Rotisseriecookingisbestdoneinfrontofaspecial

rotisserieburner,orutilizinganindirectcookingburner

arrangement.Apancanbeplacedunderneaththemeattocatch

greaseandfooddrippings,andhelpsminimizeclean-up.

IndirectCooking

Indirectcookingutilizesselectburnerstocirculateheat

throughoutthegrill,withoutdirectcontactbetweenthemeatand

theflame.Themeatisplacedovertheburnerthatis'off'.This

methodisgenerallyusedtoslowcooklargecutsofmeatand

poultry.Apancanbeplacedunderneaththemeattocatch

greaseandfooddrippings,andhelpsminimizeclean-up.

FoodSafety

Foodsafetyisaveryimportantpartofenjoyingtheoutdoor

cookingexperience.Tokeepfoodsafefromharmfulbacteria,

followthesefourbasicsteps:

Clean: Wash hands, utensils, and surfaces with hot soapy water

before and after handling raw meat.

Separate: Separate raw meats from ready-to-eat foods to avoid

cross contamination. Usea clean platterand utensils when

removing cooked foods.

Cook: Cookmeat andpoultry thoroughlyto kill bacteria. Use a

thermometer to ensure proper internalfood temperatures.

Chill: Refrigerate prepared foods and leftovers promptly.

Page 6

Cookingonyournewgrillisahands-onexperience,anditis

recommendedtoremainoutsidewithyourgrillwhilecooking.

Grillingcanbeaffectedbymanyexternalconditions.Incold

weather,youwillneedmoreheattoreachanidealcooking

temperature,andgrillingmaytakelonger.Themeat'sinternal

temperatureandthicknesscanalsoaffectcookingtimes.Cold

andthickermeatswilltakelongertocook.

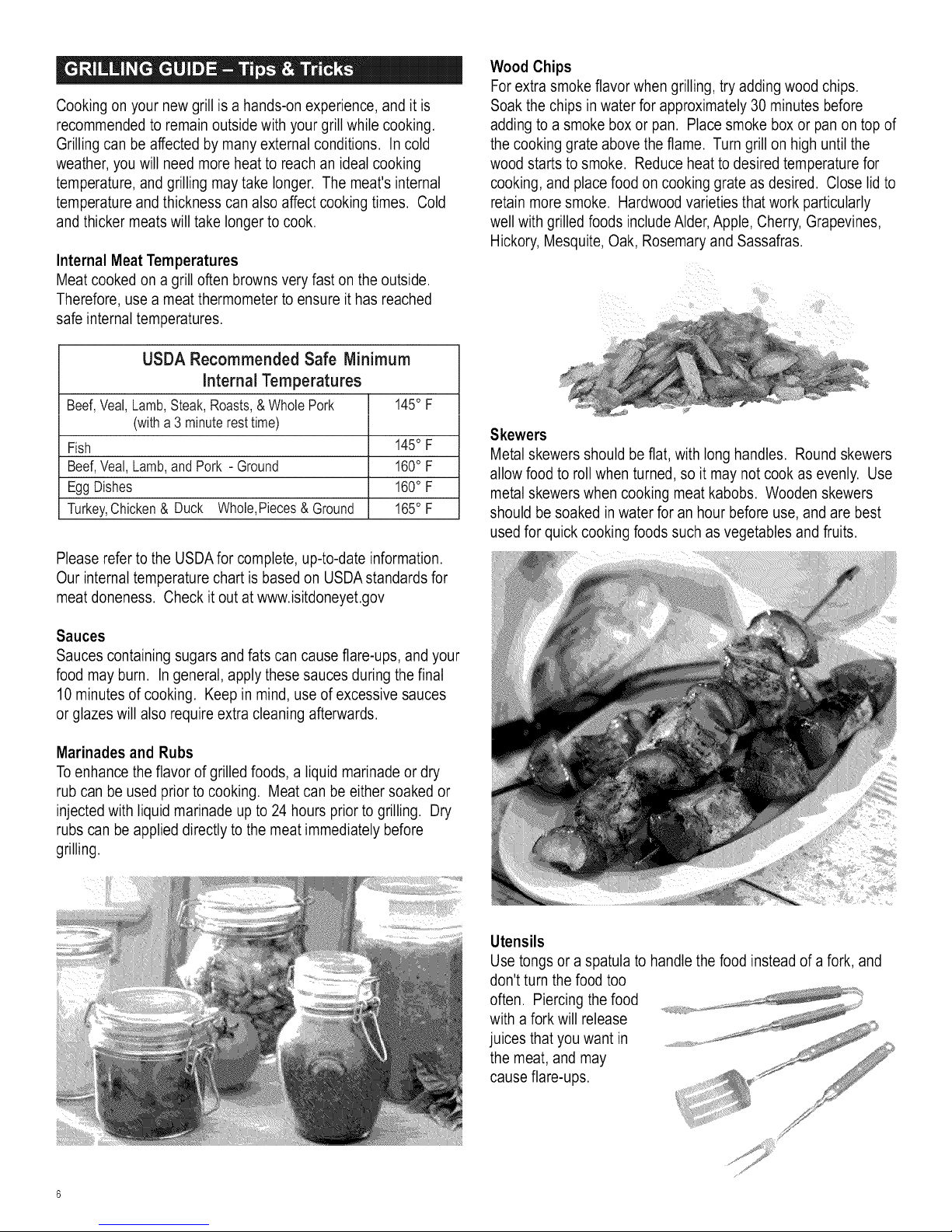

InternalMeatTemperatures

Meatcookedonagrilloftenbrownsveryfastontheoutside.

Therefore,useameatthermometertoensureithasreached

safeinternaltemperatures.

USDA Recommended Safe Minimum

internal Temperatures

Beef,Veal,Lamb,Steak,Roasts,&WholePork 145° F

(witha 3 minuteresttime)

Fish 145° F

Beef,Veal,Lamb,andPork - Ground 160° F

EggDishes 160° F

Turkey,Chicken& Duck Whole,Pieces& Ground 165° F

Please refer to the USDAfor complete, up-to-date information.

Our internal temperature chart is based on USDAstandards for

meat doneness. Check it out at www.isitdoneyet.gov

Wood Chips

For extra smoke flavor when grilling, try addingwood chips.

Soak the chips in water for approximately 30 minutes before

adding to a smoke box or pan. Placesmoke boxor panon top of

the cooking grate above the flame. Turn grill on high untilthe

wood starts to smoke. Reduce heat to desired temperature for

cooking, and place food on cooking grate as desired. Close lidto

retain more smoke. Hardwood varieties that work particularly

well with grilled foods include Alder, Apple, Cherry, Grapevines,

Hickory, Mesquite, Oak, Rosemary and Sassafras.

Skewers

Metal skewers should be flat, with long handles. Round skewers

allow food to roll when turned, so it may not cookas evenly. Use

metal skewers when cooking meat kabobs. Wooden skewers

should be soaked in water for an hour before use, and are best

usedfor quickcooking foods such as vegetables and fruits.

Sauces

Sauces containing sugars and fats can cause flare-ups, andyour

food may burn. Ingeneral, apply these sauces duringthe final

10 minutes of cooking. Keep inmind, use of excessive sauces

or glazes will also require extra cleaning afterwards.

Marinades and Rubs

Toenhance the flavor of grilled foods, a liquid marinadeor dry

rub can be used prior to cooking. Meat can be either soaked or

injected with liquid marinade up to 24 hours prior to grilling. Dry

rubs can be applied directly to the meat immediately before

grilling.

Utensils

Use tongs or a spatula to handle the food instead of a fork, and

don'tturn the food too

often. Piercing thefood

with a fork will release

juices that you want in

the meat, and may

cause flare-ups.

Page 7

WhyClean?

We'veallheardthesaying'Anounceofpreventioniswortha

poundofcure'.Thisisgreatadvicewhenitcomestokeeping

yourgrillclean.

Cooking surfaces: If a bristle brush is used to cleanany of the

grill cooking surfaces, ensure no loose bristles remain on cooking

surfaces prior to grilling. It is not recommended to clean cooking

surfaces while grill is hot.

RoutineCare

Periodiccleaningofthisgrillisnecessary,

asgrillfirescanoccurwhengreaseand

fooddebriscollectinthebottomofthegrill.

Aftereachuse,removeanyremaining

foodparticlesfromthecookinggrateand

insideofthegrillusingagrillbrush.Do

thisafterthegrillhascooleddown,yetis

stillwarm.Itismucheasiertocleanfood

particleswhilewarmthisstillpresent,than

afterthefoodparticleshavecompletely

cooledandhardened.Thisgrillisnot

designedtobe'burnedoff'byclosingthe

lidandturningtheburnersonHighforan

extendedtime.Theexcessiveheat

generatedcancauseleftovergreaseto

catchfire,andcancausepermanent

damagetoyourgrill.

GeneralCleaning

Plastic parts: Wash with warm soapy water and wipe dry. Do not

use abrasive cleaners, degreasers or a concentrated grill cleaner

on plastic parts. Damage to and failure of parts can result.

Storing Your Grill

• Clean cooking grates.

• Store grill in dry location.

• When LP cylinder is connected to grill, store outdoors in a well

ventilated space and out of reachof children.

• Cover grill if stored outdoors. Choosefrom avariety of grill

covers offered by manufacturer.

• Store grill indoors ONLYif LPcylinder is turned off,

disconnected, and removed from grill. Never store LP cylinder

indoors.

• When removing grill from storage, follow the 'Cleaning the

BurnerAssembly' instructions in the Use and Care section of

the Product Guide.

Critters

Spiders like to make their homes in the venturi tubes of grills.

These must be inspected and cleaned regularly to ensure there

are no blockages. Refer to the Use and Care portion of this

Product Guide for complete information.

Porcelain surfaces: Because of glass-like composition, most

residue can be wiped away with baking soda/watersolution or

glass cleaner. Use non-abrasive scouring powderfor stubborn

stains.

Painted surfaces: Wash with mild detergent or non-abrasive

cleaner and warm water. Wipe drywith a soft non-abrasive cloth.

Stainless steel surfaces: Stainless steel can rust under certain

conditions. This can be caused byenvironmental conditions

such as chlorine or salt water, or improper

cleaning tools such as wire or steel

wool. It can also discolor dueto heat,

chemicals, or grease build-up. To

maintain your grill's high quality

appearance, wash with mild detergent

and warm water,or use a stainless

steel grill cleaner. Baked-on grease

deposits may require the use of an

abrasive plastic cleaning pad. Use only

in direction of brushed finish to avoid

damage. Do not use abrasive pad on

areaswith graphics.

The Char-Broil®grill is equippedwith GearTraxTM, which

allow forthe easy mounting of our unique line of GearTrax

accessories. Pleasevisit charbroil.comfor a complete list

of Gear Trax accessories, *Availableon most models,

%

ViSiT CHARBRO|L,COM FOR

ALL YOUR GRiLLiNG NEEDS!

Page 8

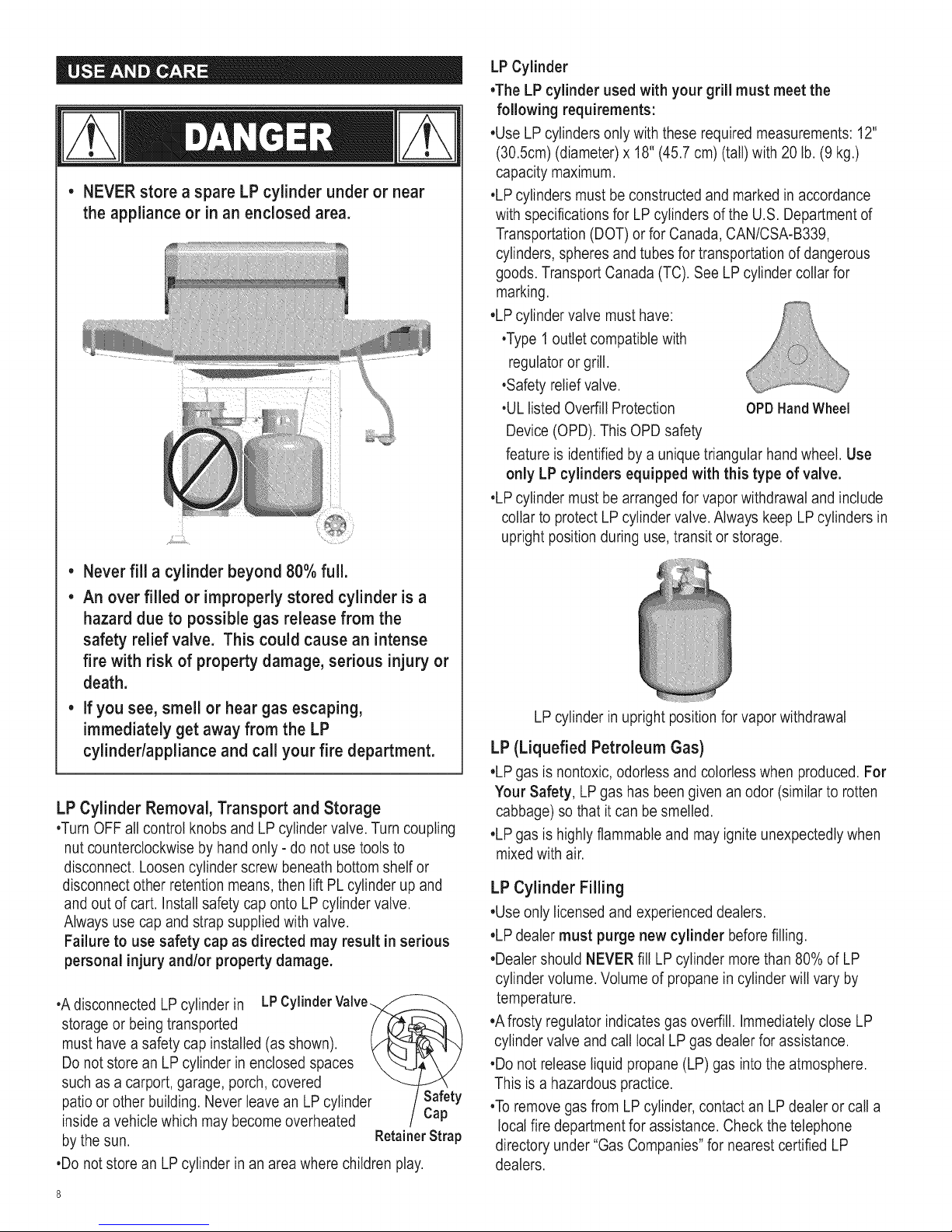

• NEVERstore a spare LP cylinder under or near

the appliance or inan enclosed area.

LP Cylinder

•The LP cylinder used with your grill must meet the

following requirements:

•Use LP cylinders only with these required measurements: 12"

(30.5cm) (diameter) x 18" (45.7 cm) (tall) with 20 lb. (9 kg.)

capacity maximum.

•LPcylinders must be constructed and marked in accordance

with specifications for LP cylinders of the U.S. Departmentof

Transportation (DOT) or for Canada, CAN/CSA-B339,

cylinders, spheres and tubes for transportation of dangerous

goods. Transport Canada (TC). See LP cylinder collar for

marking.

•LPcylinder valve must have:

•Type 1 outlet compatible with

regulatoror grill.

•Safety reliefvalve.

•ULlisted Overfill Protection OPDHandWheel

Device (OPD). This OPD safety

feature is identified by a uniquetriangular hand wheel. Use

only LP cylinders equipped with this type of valve.

•LPcylinder must be arranged for vapor withdrawal and include

collar to protect LP cylinder valve.Always keep LP cylinders in

upright position during use, transit or storage.

• Never fill a cylinderbeyond 80%full.

• An over filled or improperlystored cylinder is a

hazard due to possible gas release from the

safety relief valve. This could cause an intense

fire with risk of property damage, serious injury or

death.

If you see, smell or hear gas escaping,

immediatelyget away from the LP

cylinder/appliance and call your fire department.

LP Cylinder Removal, Transport and Storage

•Turn OFFall controlknobs and LP cylinder valve. Turn coupling

nut counterclockwise by hand only -do not use toolsto

disconnect. Loosencylinder screw beneath bottom shelf or

disconnect other retention means, then lift PL cylinder upand

and out of cart. Install safety cap onto LP cylindervalve.

Always use cap and strap supplied with valve.

Failure to use safety cap as directed may result in serious

personal injury and/or property damage.

•Adisconnected LP cylinder in LPCylinder

storage or being transported

must have a safety cap installed (as shown).

Do notstore an LP cylinder in enclosed spaces

such as a carport, garage, porch, covered

patioor other building. Never leave an LP cylinder Safety

inside a vehicle which may become overheated Cap

bythe sun. RetainerStrap

•Do notstore an LP cylinder in an area where children play.

LP cylinder in upright position for vapor withdrawal

LP (Liquefied Petroleum Gas)

•LPgas is nontoxic, odorless and colorless when produced. For

Your Safety, LPgas has been given an odor (similar to rotten

cabbage) so that it can be smelled.

•LPgas is highly flammable and mayignite unexpectedly when

mixed with air.

LP Cylinder Filling

•Useonly licensed and experienced dealers.

•LPdealer must purge new cylinder before filling.

•Dealer should NEVERfill LP cylinder more than 80% of LP

cylinder volume. Volume of propane in cylinder will vary by

temperature.

•Afrosty regulator indicates gas overfill. Immediatelyclose LP

cylinder valve and call local LP gas dealer for assistance.

•Do not releaseliquid propane (LP) gas into the atmosphere.

This is a hazardous practice.

•Toremove gas from LP cylinder,contact an LP dealeror call a

local fire department for assistance. Check the telephone

directory under "Gas Companies" for nearest certified LP

dealers.

Page 9

LP Cylinder Exchange Connecting Regulator to the LP Cylinder

•Many retailers that sell grills offer you the option of replacing

your empty LP cylinder through an exchange service. Use only

those reputable exchange companies that inspect, precision fill,

test and certify their cylinders. Exchange your cylinder only

for an OPD safety feature-equipped cylinder as described

in the "LP Cylinder" section of this manual.

•Always keep newand exchanged LP cylinders in upright

position during use, transit or storage.

•Leak test new and exchanged LP cylinders BEFORE

connecting to grill.

•Place dust cap on cylinder valve outlet whenever the cylinder is

notin use. Only installthe type ofdust cap on the cylinder valve

outlet that is providedwith the cylinder valve. Other types of caps

or plugs may result in leakage of propane.

LP Cylinder Leak Test

For your safety

•Leak test must be repeated each time LP cylinder isexchanged

or refilled.

•Do notsmoke during leak test.

•Do notuse an open flame to check for gas leaks.

•Grill must be leak tested outdoors in a well-ventilated area,

away from ignitionsources such as gas fired or electrical

appliances. During leak test, keep grill away from open flames

or sparks.

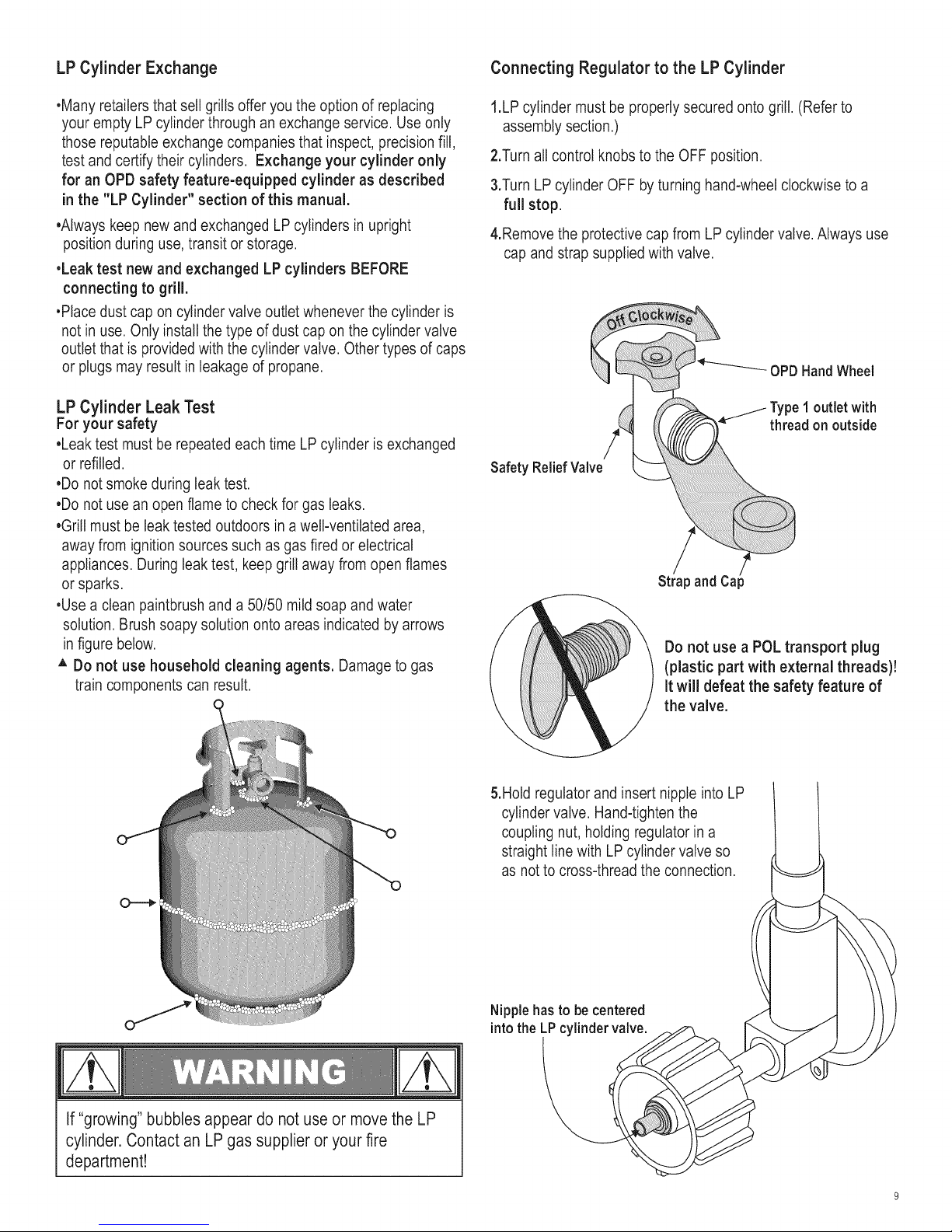

•Usea clean paintbrushand a 50/50 mild soap and water

solution. Brushsoapy solution onto areas indicated byarrows

in figure below.

A Do not use household cleaning agents. Damage to gas

train components can result.

I.LP cylinder mustbe properly secured onto grill. (Referto

assembly section.)

2.Turn all control knobs to the OFF position.

3.Turn LP cylinder OFF by turning hand-wheel clockwise to a

full stop.

4.Remove the protective cap from LP cylinder valve.Always use

cap and strap suppliedwith valve.

OPDHandWheel

/ Type1outlet with

threadon outside

SafetyReliefValve

•

Strapand Cal_

Do not use a POLtransport plug

(plastic part with external threads)!

It will defeat the safety feature of

the valve.

If"growing" bubblesappear do not useor move the LP

cylinder.Contact an LPgas supplier oryour fire

department!

5.Hold regulator and insert nipple into LP

cylinder valve. Hand-tighten the

coupling nut, holding regulator in a

straight line with LP cylinder valve so

as notto cross-thread the connection.

Nipplehas to be centered

intothe LP cylinder valve.

Page 10

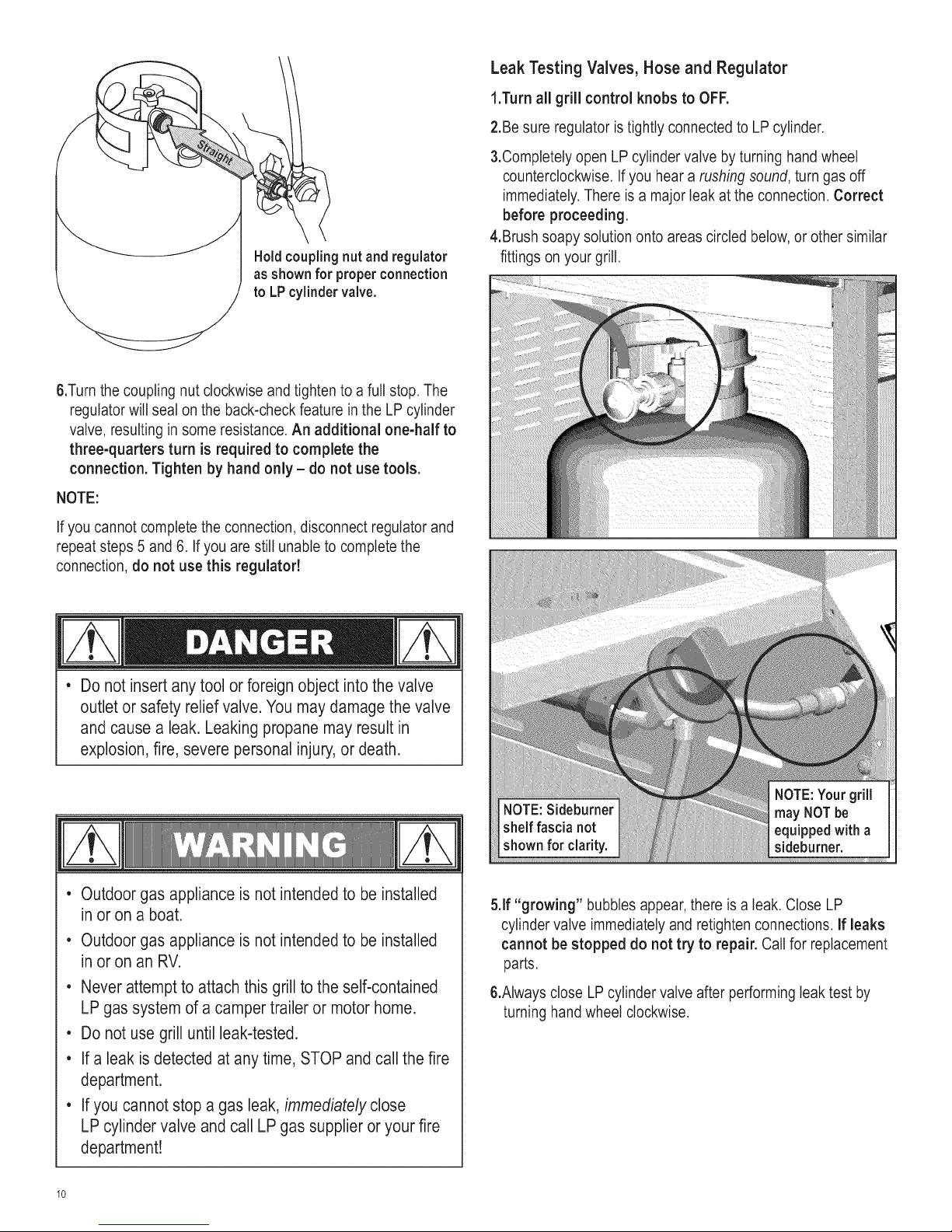

Holdcoupling nutand regulator

asshown for properconnection

to LP cylinder valve.

6.Turn the coupling nut clockwise and tighten to a full stop. The

regulatorwill seal onthe back-check feature inthe LP cylinder

valve, resulting in some resistance. An additional one-half to

three-quarters turn isrequired to complete the

connection. Tighten by hand only- do not use tools.

NOTE:

Leak Testing Valves, Hose and Regulator

1.Turn all grill control knobs to OFF.

2.Be sure regulator istightly connected to LP cylinder.

3.Completelyopen LPcylinder valve by turning hand wheel

counterclockwise. If you hear a rushing sound, turn gas off

immediately.There is a major leak at the connection. Correct

before proceeding.

4.Brush soapy solution onto areas circled below, or other similar

fittings on your grill.

If you cannot complete the connection, disconnect regulatorand

repeat steps 5 and 6. If you arestill unableto completethe

connection, do not use this regulator!

Do not insertany tool or foreignobject into thevalve

outlet or safetyrelief valve. Youmay damagethe valve

and cause a leak. Leaking propane may result in

explosion,fire, severe _ersonal injury,or death.

Outdoorgas applianceis notintendedto beinstalled

in oron a boat.

Outdoorgas applianceis notintendedto beinstalled

in oron an RV.

• Never attemptto attach this grill to theself-contained

LPgas systemof acamper trailer or motorhome.

• Do not use grill until leak-tested.

• If a leak is detected at any time, STOPand call the fire

department.

• If you cannot stopa gas leak,immediately close

LPcylinder valve and call LPgas supplier or your fire

department!

5.If "growing" bubbles appear, there is a leak. Close LP

cylinder valve immediately and retighten connections. If leaks

cannot be stopped do not try to repair. Callfor replacement

parts.

6.Always close LPcylinder valveafter performing leak test by

turning hand wheel clockwise.

Page 11

For Safe Use of YourGrill and to Avoid Serious

Injury:

• Do not letchildren operateor play near grill.

• Keepgrill area clearand free from materials that burn.

• Do not blockholes in sidesor backof grill.

• Check burnerflames regularly.

• Use grill only inwell-ventilated space. NEVER usein

enclosedspace such as carport,garage, porch,

covered patio,or underan overhead structureof any

kind.

• Do not use charcoalor ceramic briquetsin a gasgrill.

(Unlessbriquets are supplied with your grill.)

• Donot cover grates with aluminumfoil or anyother

material. This will blockburner ventilation andcreate

a potentiallydangerous condition resultingin

propertydamage and/or personalinjury.

• Use grill at least 3 ft. from any wall or surface.

Maintain 10ft. clearanceto objectsthat can catchfire

or sources of ignition such aspilot lightson water

heaters,live electrical appliances,etc.

Safety Tips

A Beforeopening LP cylinder valve, check the coupling nutfor

tightness.

A When grill is not in use, turn off all control knobs and LP

cylinder valve.

A Never move grill while in operation or still hot.

A Use long-handled barbecue utensils and oven mitts to avoid

burnsand splatters.

A Maximum load for sideburner and side shelf is 10 Ibs.

A The grease trayor cup must be installed during use and

emptied after each use. Do not remove grease tray orcup

until grill has completely cooled.

A Clean grill often, preferably after each cookout. Ifa bristle

brush is used to clean any of the grill cookingsurfaces,

ensure no loose bristles remain oncooking surfaces prior to

grilling. Itis not recommendedto clean cooking surfaces

while grill is hot.

A If you notice grease or other hot material dripping from grill

onto valve, hoseor regulator, turn off gas supply at once.

Determinethe cause, correct it, then clean and inspect valve,

hoseand regulator before continuing. Perform aleak test.

A Keep ventilation openings in cylinder enclosure (grill cart) free

and clear of debris.

A Donot store objects or materials inside the grillcart

enclosure that would block the flow of combustion air to the

undersideof either the control panel orthe firebox bowl.

A The regulator maymake a humming or whistling noise during

operation. This will notaffect safety or use of grill.

A If you have a grill problem see the "Troubleshooting Section".

A If the regulator frosts, turn off grill and LP cylindervalve

immediately.This indicates a problemwith the cylinder and it

should notbe used on any product. Returnto supplier!

• Apartment Dwellers:

Checkwith managementto learnthe requirements

and firecodes for using an LPgas grill in your

apartmentcomplex. If allowed, useoutside on the

ground floorwith a three (3)foot clearance from walls

or rails. Do not use onor under balconies.

• NEVERattempt to light burner with lid closed. A

buildup of non-ignited gas inside a closed grill is

hazardous.

• Never operate grill with LP cylinder out of correct

position specified in assembly instructions.

• Always close LP cylinder valve and remove

coupling nut before moving LP cylinder from

specified operation position.

Page 12

ignitor Lighting

A Do not lean over grill while lighting.

1. Turn O OFF gas burner control valves.

2. Turn ON gas at LP cylinder.

3. Open lid during lighting.

4. To ignite, push and turn IGNITION BURNER knobto _.

5. Pushand hold ELECTRONIC IGNITION buttonuntil the burner

lights.

6. If ignition does NOT occur in 5 seconds, turn the burner

controlsO OFF, wait 5minutes and repeat the lighting

procedure.

7.To ignite remaining burners, turn knob to the _ position

starting with the burners closest to IGNITION BURNERfirst.

If ignitor does not work, follow match lighting instructions.

8. For grills equipped with ELECTRONIC iGNiTiON at

each burner:

Repeat steps 4 through 6 to light each burner.

9. Onceeach burner has ignited, turn knobs to desired setting.

Turncontrolsand gas source or tank OFFwhen not

in use.

SEAR Burner ignitor Lighting

A Do not lean over grill while lighting.

1. TurnO OFF gas burner control valves.

2. Turn ON gas at LP cylinder.

3. Open lid during lighting.

4. Toignite, push and turn SEAR burner knob to _.

5. Pushand hold ELECTRONIC IGNITION button until the

burner lights.

6. If ignition does NOToccur in 5 seconds, turn the burner

controls O OFF, wait 5 minutes and repeat the lighting

procedure.

SEAR Burner Match-Lighting

A Do not lean over grill while lighting.

1. Open lid. Turn ON gas at LP cylinder.

2. Place match into match holder (hangingfrom right side

panel of grill). Light match; then light burner by placing

match through the match light hole on right side of grill.

3. Push in and turn SEAR burner knobto the _ position.

Be sure burner lights and stays lit.

/L cAuTioN/L

if ignition does NOToccur in5 seconds, turn the

burner controls O OFF,wait 5 minutes and repeat the

lighting procedure. If the burner does not ignite with

the valve open, gas will continue to flow out of the

burner and could accidently ignite with risk of injury.

Match-Lighting

A Do not lean over grill while lighting.

1. Open lid. Turn ON gas at LP cylinder.

2. Place match into match holder (hangingfrom leftside panel of

grill). Light match; then light burnerby placing match through

the match light hole on left side of grill.

3. Push in and turnfar left burner knob to the _ position.

Be sure burner lights and stays lit.

4. Lightadjacent burners in sequenceby pushing knobs inand

turning to the _ position.

A Do not lean over grill while lighting.

1. Open sideburner lid. Turn ON gas at LPcylinder.

2. Turn sideburner knob to the _ position, push and hold

ELECTRONIC IGNITOR button.

3. Ifsideburner does NOT light within 5 seconds, turn knob to

O OFF, wait5 minutes,then

repeat lighting procedure.

Sideburner Match Lighting

1. Open sideburner lid. Turn ON

gas at LP cylinder.

2. Placelit match near burner.

3. Turn sideburner knob to the

position.

Be sure burner lights and

stays lit.

12

Page 13

Burner Flame Check

• Remove cooking grates and flame tamers. Light burners, rotate

knobs from HIGH to LOW. You should see a smaller flame in

LOW position than seen on HIGH. Perform burner flamecheck

on sideburner, also.Always check flame priorto each use. If

only low flame is seen refer to "Sudden drop or low flame" in

the TroubleshootingSection.

General Grill Cleaning

• Do not mistake brown or black accumulation of grease and

smoke for paint. Interiors of gas grills are not painted at the

factory (and should never be painted). Apply a strong solution

of detergent and water or use a grill cleaner with scrub brush

on insides of grill lid and bottom. Rinse andallow to completely

air dry. Do not apply a caustic grill/oven cleaner to painted

surfaces.

Plastic parts: Wash with warm soapy water and wipe dry.

s Do not use citrisol, abrasivecleaners, degreasers ora

concentrated grill cleaner on plastic parts. Damage to and

failure of parts can result.

Turning Grill Off

• Turnall knobsto the 0 OFF position.Turn LP cylinder

OFF by turning hand-wheel clockwise to a full stop.

ignitor Check

• Turn gas off at LP cylinder. Press and hold electronic ignitor

button. "Click"should be heardand sparkseen each time

between each collector box or burner and electrode. See

"Troubleshooting" if no click or spark.

Valve Check

• important: Make sure gas is off at LP cylinder before

checking valves. Knobs lock in OFF position.To check

valves, first push in knobs and release, knobs should spring

back. If knobs do not spring back, replace valve assembly

before using grill. Turn knobs to LOW positionthen turn back to

OFF position. Valves should turn smoothly.

Hose Check

• Before each use, check to see if hoses are cut or worn or kinked.

Replace damaged hoses before usinggrill. Use only

valve/hose/regulator specified by manufacturer.

Porcelain surfaces: Because of glass-like composition, most

residue can be wiped away with baking soda/watersolution or

specially formulated cleaner. Use nonabrasive scouring powder

for stubborn stains.

Painted surfaces: Wash with mild detergent or nonabrasive

cleaner and warm soapy water. Wipe dry with a soft

nonabrasive cloth.

Stainless steel surfaces: To maintain your grill's high quality

appearance, wash with mild detergent and warm soapy water

and wipe dry with a soft cloth after each use. Baked-ongrease

deposits may require the use of an abrasiveplastic cleaning

pad. Use only in direction of brushed finishto avoid damage.

Do not use abrasive pad on areaswith graphics.

Cooking surfaces: If a bristle brush is used to cleanany of

the grill cooking surfaces, ensure no loose bristles remain on

cooking surfaces prior to grilling. It is not recommendedto

clean cooking surfaces while grill is hot.

Page 14

II l cAuTioN

r

SPIDER ALERT!

SPIDERAND WEBS

iNSiDE BURNER

If your barbeque is getting hard to light or

the flame is weak, check and clean the

venturis and burners.

Spiders or small insects are known to create

"flashback" problems by building nests and

laying eggs in the barbeque's venturi or

burner obstructing the flow of gas. The

backed-up gas can ignite behind the control

panel. This flashback can damage your

barbeque and cause injury. To prevent

flashbacks and ensure good performance,

the burner and ventud tube assembly should

be removed and cleaned whenever the

barbeque has been idle for an extended

period of time.

3. Remove carryover tubes and burners.

4. Detach electrode from burner.

NOTE: Removal/Detachment method will depend on the

burner configuration. See different configurations in

illustrations below.

5. Carefully lift each burner up and away from valve openings.

We suggest three ways to clean the burner tubes. Usethe one

easiest for you.

(A) Bend a stiff wire (alight weight coat hanger works welt)

into a small hook. Run the hook through each burner

tube several times.

(B) Use a narrow bottle brushwith a flexible handle (do not

use a brass wire brush), runthe brush through each

burner tube several times.

(C) Wear eye protection: Usean airhose to force airinto

the burner tube and out the burner ports. Check each

port to make sure air comes out each hole.

6. Wire brush entire outer surface of burner to remove food

residue and dirt.

7. Clean any blocked ports with a stiff wire such as an open

paper clip.

8. Check burner for damage, due to normal wear and corrosion

some holes may become enlarged. Ifany large cracksor

holes are found replace burner.

VERY iMPORTANT'.Burner tubes must reengage valve

openings. See illustrations at right,

9. Attach electrode to burner. Correct

10. Carefully replace burners, engagement

11. Attach burners to brackets on firebox.

12. Reposition carryover tubes and attach

to burners. Replace flame tamers and

cooking grates.

burner-to-valve

Storing Your Grill

, Cleancooking grates.

* Store in dry location.

* When LP cylinder is connected to grill, store outdoors in a well-

ventilated space and out of reachof children.

* Cover grill ifstored outdoors. Choose from a variety of grill

covers offered by manufacturers.

* Store grill indoors ONLY if LPcylinder isturned off and

disconnected, removed from grill and stored outdoors.

* When removing grill from storage, follow "Cleaning the Burner

Assembly' instructions before starting grill.

Cleaning the Burner Assembly

Follow these instructionsto clean and/or replace partsof burner

assembly or if you have trouble ignitinggrill.

1. Turn gas OFF at control knobs and LP cylinder.

2. Remove cooking grates and flame tamers.

Firebox

burner

bracket

Electrode

;off

electrode with

a flat blade

screwdriver

Page 15

This warranty only applies to units purchased from an authorized retailer. Manufacturer warrants to the m_jnal consumer-purchaser only that this

product shall be fiee from defects in workmanship and materials after correct assembly and under normal and reasonable home use for the periods

indicated below beginning on the date of purchase*. The manufacturer reserves the right to require that defective parts be returned, postage and or

freight pre-paid by the consumer for review and examination.

SCOPE OF COVERAGE PERIOD OF COVERAGE TYPE OF FAILURE COVERAGE

Stainless Burner

Firebox and Lid

All Other Parts

*Note: A dated sales receipt WILL be required for warranty service.

The original consumer-pro'chaser will be responsible for all shipping charges for parts replaced under the terms of this limited warranD_.

This limited warranty is applicable in the United States and Canada only, is only available to the original owner of the product and is not transferable.

Manufacturer requires proof of your date of pro'chase. Therefore, you should retain yore" sales slip or invoice. Registering your product is not a

substitute for proof of purchase and the manufacturer is not responsible for or required to retain proof of purchase records.

5 years from date of purchase*

2 years from date of purchase*

1 year from date of purchase*

PERFORATION, MANUFACTURING,

AND MATERIAL DEFECTS ONLY

This limited warranty applies to the functionality of the product ONLY and does not cover cosmetic issues such as scratches, dents, corrosions or

discoloring by heat, abrasive and chemical cleaners or any tools used in the assembly or installation of the appliance, surface rust, or the

discoloration of stainless steel surfaces. RUST is not considered a manufactm'ing m" materials defect.

This limited warranty will not reimbm'se you for the cost of any inconvenience, food, personal injm'y m" properD_ damage.

ITEMS MANUFACTURER WILL NOT PAY FOR:

1. Shipping cost, standard or expedited, for warranty and replacement parts

2. Service calls to your home.

3. Repairs when your product is used for other than normal, single-family household or residential use.

4. Damage, failures, or operating difficulties resulting from accident, alteration, careless handling, misuse, abuse, fire, flood,

acts of God, improper installation or maintenance, installation not in accordance with electrical or plumbing codes, or use

of products not approved by the manufacturer.

5. Any food loss due to product failures or operating difficulties.

6. Replacement parts or repair labor costs for units operated outside the United States or Canada.

7. Pickup and delivery of your product.

8. Repairs to parts or systems resulting from unauthorized modifications made to the product.

9. The removal and/or reinstallation of your product.

DISCLAIMER OF IMPLIED WARRANTIES and LIMITATION OF REMEDIES

Repair or replacement of detective parts is your exclusive remedy under the terms of this limited warranty. In the event of parts availability issues,

the manufacturer resmwes the right to substitute like or similar parts that are equally functional.

Manufacturer will not be responsible for any consequential or incidental damages arising from the breach of either this limited warranty or any

applicable implied warranty, or for failure or damage resulting from acts of God, improper care and maintenance, grease fire, accident, alteration,

replacement of parts by anyone other than Manufacturer, misuse, transportation, commercial use, abuse, hostile environments (inclement weather,

acts of nature, animal tampering), improper installation or installation not in accordance with local codes or printed manufacturer instructions.

THIS LIMITED WARRANTY IS THE SOLE EXPRESS WARRANTY GIVEN BY THE MANUFACTURER. NO PRODUCT PEREORMANCE

SPECIFICATION OR DESCRIPTION WHEREVER APPEARING IS WARRANTED BY MANUFACTURER EXCEPT TO THE EXTENT SET

FORTH IN THIS LIMITED WARRANT"L ANY IMPLIED WARRANTY PROTECTION ARISING UNDER THE LAWS OF ANY STATE,

INCLUDING IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE, IS HEREBY

LIMITED IN DURATION TO THE DURATION OF THIS LIMITED WARRANTY.

Neither dealers am" the retail establishment selling this product has any authori_ to make any additional warranties m"to promise remedies

in addition to or inconsistent with those stated above. Manufacturer's maximum liabilRx, in any event, shall not exceed the purchase price of the

product paid by the original consumer.

NOTE: Some states do not allow an exclusion or limitation of incidental or consequential damages, so some of the above limitations or exclusions

may not apply to you. This limited warranty gives you specific legal rights as set foth herein. You may also have other rights which vary from state

to state. In the state of California only, if refinishing or replacement of the product is not commercially practicable, the retailer selling this product or

the Manufacturer will refund the purchase price paid for the product, less the amount directly attributable to use by the original consumer-purchaser

prior to discovery of the nonconformity. In addition, in the state of California only, you may take the product to the retail establishment selling this

product in order to obtain performance under this limited warranty.

If you wish to obtain performance of any obligation under this limited warran_, you should

write to:

Consumer Relations

P. O. Box 1240

Columbus, GA 31902-1240

Consumer returns will not be accepted unless a valid Return Authorization is first acquired. Authorized returns are clearly marked on the outside of

the package with an RAnumber and the package is shipped freight/postage pre-paid. Consumer returns that do not meet these standards will be

refused.

15

Page 16

A 1 FIREBOX

B 5 MAIN BURNER-TUBE BURNER

C 1 MAIN BURNER-BAR BURNER

D 1 ELECTRODE, F/TUBE BURNER

E 1 ELECTRODE, F/BAR BURNER

F 4 CARRY OVER TUBE

G 1 CONTROL PANEL, MAIN

H 1 ELECTRONIC IGNITION MODULE

I 1 BUTTON, F/IGNITION MODULE

J 1 SHIELD,F/ELECTRONIC IGNITION MODULE

K 1 HOSE VALVE REGULATOR ASSEMBLY

L 7 BEZEL F/CONTROL KNOB

M 7 CONTROL KNOB

N I TOP LID

O 1 LOGO PLATE F/LID

P 1 TEMPERATURE GAUGE

Q 1 BEZEL, F/TEMPERATURE GAUGE

R 2 LID BUMPER, RECTANGLE

S 2 LID BUMPER, ROUND

T 1 TOP LID HARDWARE

U 1 HANDLE, F/LID

V 5 HEATTENT

W 4 COOKING GRATE

X 1 WARMING RACK

Y 1 LEFT SIDE SHELF F/SB

Z 1 DRIP PAN, F/SB

AA 1 SIDEBURNER GRATE

BB 1 ELECTRODE, F/SB

CC 1 ELECTRODE WIRE, F/SlDEBURNER

DD 1 SIDEBURNER LID

EE 1 SIDEBURNER

FF 1 SIDEBURNER VALVE CLIP

GG 1 CONTROL PANEL, F/SB

HH 1 RIGHT SIDE SHELF

II 1 FASCIA, F/RIGHT SHELF

JJ 1 RIGHT SIDE CART PANEL

KK 1 LEFT SIDE CART PANEL

LL 1 BOTTOM SHELF

MM 1 FRONT DOOR BRACE

NN 1 LEFT DOOR

OO 1 RIGHT DOOR

PP 2 HANDLE, F/DOOR

QQ 1 BACK BRACE

RR 2 TANK EXCLUSION WIRE

SS 1 GREASE TRAY

TT 1 GREASE PAN

UU 4 CASTER SOCKET

W 2 CASTER, LOCKING

WW 2 CASTER, FIXED

XX 2 MATCH HOLDER

YY 1 TANK RETAINER SCREW

ZZ 2 MAGNET ASSEMBLY

AAA 1 SHIELD, F/TANK

BBB 2 DOOR PIN, FIXED

CCC 1 WEIGHT BLOCK

DDD 2 DOOR PIN, SPRING

EEE 1 HEAT TENT, F/BAR BURNER

NOT Pictured

... 1 CASTER PIN

... 1 PRODUCT MANUAL, ENGLISH

... 1 PRODUCT MANUAL, SPANISH

... 1 HARDWARE PACK

r

16

Page 17

X

)! _i,

....jw / w !w ,_w

N

EEE

!JBB

E__i_ ,zFF

,B /C i.@ 710

.... .... '_ ' ...... ' :_ S U

ZF /F iF /F \D _ /

\L XL \L \L \L \L

k_..../ /,

R

ST

/I

, iJ

_G

\M \M \M \M \M \M

\L \M

/

YY

/PP

iPP

\

DDD

ZZ D_DD

/LL

ZZ

Page 18

fortheLPcylindershouldbeon theleftside.

" Attachbottomshelftoleftandrightlegassemblieswith 1/4-20×2-3/8"machine screws and1/4-20flange nuts. Thecut outhole

ForFrontDoor

Y

RightSidePanel

/

LeftSidePanel

/

1/4-20×2-3/8"

MachineScrew

Qty:6

1/4-20

FlangeNut

BottomShelf

Qty: 6

" Placebackbracebetweensidepanelsasshown.Attachto leftandrightsidepanelswith1/4-20x2-3/8"machinescrews.

1/4-20x2-3/8"

MachineScrew

Qty:4

LeftSidePanel

1/4-20

FlangeNut

Qty:4

MagnetAssembly

Page 19

D " Hangtankexclusionwireontothe holesonbackbrace,attachotherendsto bottomshelfwith#8x3/8"sheet metalscrews.

BackBrace

#8x3/8"

SheetMetalScrews

Qty.2

flange nuts.

" Placefrontdoorbraceasshown.Attachto leftandrightlegassemblieswith 1/4-20×2-3/8"machinescrews and1/4-20

1/4-20×2-3/8"

MachineScrew

Qty:4

1/4-20

FlangeNut

\

FrontDoorBrace

Qty: 4

Page 20

Caster Pin

Caster

" Turnassemblyupsidedown.

" InsertCasterPinintothecastermountingplatetolockitinplace,shownA.Spinthecasterclockwiseintothethreadsonthebottom

shelfuntilsecure.RemovetheCasterPinandrepeatforremainingcasters.Makesurethetwolockingcastersaresecuredatthe

rearandthenon-lockingcastersaresecuredatthefront(B).Afterall4castersaresecureremovetheCasterPinandsavefor

futuremaintenance.

" Standcartupright.

" Attachweightblocktobottomshelfwith(2)1/4-20x2"machinescrewsand1/4-20flangenuts(C).

FixedCaster

FixedCaster LockingCaster

/ LockingCaster X

Q

1/4-20×2"

MachineScrew

Qty:2

1/4-20

FlangeNut

Qty: 2

2O

Page 21

D " Thisstep requirestwo peopleto liftand positiongrillheadontocart.

__ screws.

" Cardullylowerthegrill headontothecart.Makesure the regulatorhoseis hangingoutsidethecart.Attachwith 1/4=20x1/2"

GrillHead

1/4-20×1/2"Screw

Qty: 4

21

Page 22

" Hooktherightsideshelfto fireboxbythe pre-assembledscrews(A).

" Insidefirebox,insert7ramfiber washer and1/4-20x1/2"screw as shown(B).

" Attachshelfwith 1/4-20x1/2"screwand 1/4-20flangenuts, and fastenthe two pre-assembledscrews (C).

Right Side Shelf

/

1/4-20x1/2" 1/4-20

Screw FlangeNut

Qty.2 Qty: 1

7ram

FiberWasher

Qty.1

From

FiberWasher

" Attachfasciatofireboxwith#8x3/8" sheet metalscrews.

Fascia,

RightSideShelf

#8×3/8"

SheetMetalScrews

Qty.2

22

Page 23

• Hooktheleftsideshelftofireboxbythepre-assembledscrews(A).

" Insidefirebox,insert7ramfiber washer and1/4-20x1/2"screw as shown(B).

" Attachshelfwith 1/4-20x1/2"screwand 1/4-20flangenuts, and fastenthe two pre-assembledscrews (C).

LeftSideShelf

\

1/4-20×1/2"

MachineScrew

Qty.2

From

FiberWasher

1/4-20

FlangeNut

Qty: 1

7ram

FiberWasher

Qty.1

" Attachfasciatofireboxwith#8x3/8" sheet metalscrews.

sheetmetal screws

LeftSideShelf

T _ascia,

#8x3/8"

Qty.2

23

Page 24

" Attachsideburnerbezelandvalvewith#8x3/8"SSscrews. (A).

" Placesideburnerintoshelf. Makesure valveis insidesideburnertube.AttachsideburnerwithNo.8wing nut (B).

clip tosideburnertubeandaroundmanifold.Attachside burnerignitorwireto ignitorasshown(C).

" Presssideburnercontrolknobontovalvestem(D).

" Placegrateontoside burnershelf(E).

Sideburner_Bezel

Hookventuri

SideBurner

/

J Side BurnerTube

0

Sideburner Control Knob

Clip

0

\

#8X3/8 SSScrew

Qty.2

No.8WingNut

Qty.1

24

Sideburner Grate

Page 25

• Attachhandletodoorwith#10-24x1/2"machine screws,5ram fiat washersand5ramlock washers (A).

" Inserthingepinon bottomshelfinto holein door.Pressupperhingepininfrontdoorbrace,alignhingeholeon topofdoor,and

releasehingepininto door.

Him!ePin hole A HingePin hole

5ramLock Washer

MachineScrew

#10-24×1/2"

............. Qty:4

Left

Y

LeftDoor

\

5ramFlatWasher

Right Handle

5ramFlatWasher

Qty: 4

Right Door

5ramLock Washer

Qty: 4

25

Page 26

• Placeheattentsovertube burners andtheheattentforsearburneroversearburner byinsertingtabsintoslotsinfrontof firebox.

Oppositeendsof heattentsrestonpinsinbackoffirebox.

HeatTent,

F/SearBurner

StainlessSteel)

" Placecookinggratesonto graterests.

" InsertendsofWarmingRackpivotwireintoholesinsidesof gril lid.insertendsof WarmingRacklegwireintoholesinsidesof

firebox.

NOTE:Pivotandlegwires,runningside-to-side,shouldbeunderwiresrunningfront-to-back,tfpivotandlegwiresareontop,

WarmingRackisinstalledupside-down.

" UnscrewignitorcapandplaceAAbatteryintoignitorslotwith positiveend(+)facingoutward.Screwignitorcapontoignitor,

Warming Rack

LegWire

Cooking Grate

26

Page 27

" Attachtheheatshieldtogreasetraywith #8x3/8"sheet metal screws (A).

" Placegreasepanintogreasetray,thenplacethetray intothe cart(B).

S

GreaseTray

Greas(_Pan

#8x3/8"

SheetMetalScrews

Qty.4

O

HeatShield

GreaseTray

,/

I1 1T,O.

Failure to install grease tray and

grease pan will cause hot grease to

drip from bottom of grill with risk of

fire or property damage.

LPtankissoldseparately.Useonlywithan OPD(over-fillprotectiondevice)equippedLPtank.Fillandleak-checkbeforeattaching

togrillandregulator.SeeUseand Caresection to correctly LeakTestand performthe Burner FlameCheck.

PlaceLPtankinto holein bottomshelfwithtankcollaropeningfacingto the frontas shown.Fingertightentankthumbscrewto hold

LPtanksecurelyinplace.

Tlo./fl

Always keepLPcylinders in

upright positionduring use,

transport, and storage.

Failure to install tank correctly may

allow gas hoseto be damaged in

operation, resulting in the risk of fire.

LPTank

27

Page 28

DANGER; if a gas leak cannot be stopped, or a fire occurs due to gas leakage, call the fire department,

Gasleakingfrom

cracked/cut/burned

hose.

GasleakingfromLP

cylinder.

GasleakingfromLP

cylindervalve.

Gasleakingbetween

LPcylinderand

regulatorconnection.

Firecomingthrough

controlpanel.

Greasefireor

continuousexcessive

flamesabovecooking

surface.

Troubleshooting

Burner(s)willnot light

usingignitor.

(SeeElectronicIgnition

Troubleshootingalso)

Continuedonnext

page.

•Damagedhose.

•Mechanicalfailureduetorustingor

mishandling.

•Failureofcylindervalvefrom

mishandlingormechanicalfailure.

•Improperinstallation,connectionnot

tight,failureof rubberseal.

•Firein burnertubesectionofburnerdue

toblockage.

•Toomuchgreasebuildupin burnerarea.

GASISSUES:

•Tryingtolightwrongburner.

•Burnernotengagedwithcontrolvalve.

•Obstructioninburner.

•Nogasflow.

•TurnoffgasatLPcylinderoratsourceon naturalgassystems.If

anythingbutburned,replacevalve/hose/regulator.If burned,

discontinueuseofproductuntila plumberhasinvestigatedcause

andcorrectionsare made.

•ReplaceLPcylinder.

•Turnoff LPcylindervalve.ReturnLPcylindertogassupplier.

•Turnoff LPcylindervalve.Removeregulatorfromcylinderand

visuallyinspectrubbersealfor damage.SeeLPCylinderLeakTest

andConnectingRegulatortotheLP Cylinder.

•TurnoffcontrolknobsandLPcylindervalve.Leavelidopento

allowflamestodiedown.Afterfireisoutandgrill is cold,remove

burnerandinspectforspidernestsorrust.SeeNaturalHazard

andCleaningthe BurnerAssemblypages.

•TurnoffcontrolknobsandLPcylindervalve.Leavelidopento

allowflamestodiedown.Aftercooling,cleanfoodparticlesand

excessgreasefrominsidefireboxarea,greasetray,andother

surfaces.

•Seeinstructionsoncontrolpanelandin UseandCaresection.

•Makesurevalvesarepositionedinsideofburnertubes.

•Ensureburnertubesarenotobstructedwithspiderwebsor other

matter.Seecleaningsectionof UseandCare.

•MakesureLPcylinderisnotempty.If LPcylinderisnotempty,

referto "Suddendropin gasflow."

• Fora grillequippedwith theAUTO-CLEANTM feature,makesure

theAUTO-CLEANTM valveissetto"Grill"

•Vaporlockatcouplingnutto LPcylinder.

•CouplingnutandLPcylindervalvenot

fullyconnected.

ELECTRICALISSUES:

•Electrodecrackedorbroken;"sparksat

crack."

•Electrodetip notinproperposition.

•Wireand/orelectrodecoveredwith

cookingresidue.

•Wiresarelooseordisconnected.

•Wiresareshorting(sparking)between

ignitorandelectrode.

•Deadbattery.

28

•Turnoff knobsanddisconnectcouplingnutfromLPcylinder.

Reconnectandretry.

•Turnthe couplingnutapproximatelyone-halftothree-quarters

additionalturnuntilsolidstop.Tightenbyhandonly- do not use

tools.

•Replaceelectrode(s).

MainBurners:

•Tipofelectrodeshouldbepointingtowardgasportopeningon

burner.Thedistanceshouldbe 1/8"to 1/4".Adjustif necessary.

Sideburner:

•Tipofelectrodeshouldbepointingtowardgasportopeningon

burner,thedistanceshouldbe 1/8"to 3/16".Adjustif necessary.

•Cleanwireand/orelectrodewithrubbingalcoholandcleanswab.

•Reconnectwiresor replaceelectrode/wireassembly.

•Replaceignitorwire/electrodeassembly.

•Replacewitha newalkalinebattery.

Page 29

Troubleshooting(continued)

Burner(s)willnot light

usingignitor.

(SeeElectronicIgnition

Troubleshootingalso)

Burner(s)willnot

matchlight.

Suddendropin gas

floworlowflame.

Flamesblowout.

Flare-up.

ELECTRONICIGNITION:

•Nospark,noignitionnoise.

•Nospark,someignitionnoise.

•Sparks,butnotatelectrodeorat full

strength.

•See"GAS ISSUES:"onpreviouspage.

•Matchwillnot reach.

•Impropermethodof match-lighting.

•Outofgas.

•Excessflowvalvetripped.

•Vaporlockatcouplingnut/LPcylinder

connection.

•Highorgustingwinds.

•LowonLPgas.

•Excessflowvalvetripped.

•Greasebuildup.

•SeeSectionI ofElectronicIgnitionSystem.

•SeeSectionII ofElectronicIgnitionSystem.

•SeeSectionIIIof ElectronicIgnitionSystem.

•Uselong-stemmatch(fireplacematch).

•See"Match-Lighting"sectionof UseandCare.

•Checkforgasin LPcylinder.

•Turnoff knobs,wait30secondsandlightgrill.Ifflamesarestilllow,

turnoff knobsandLPcylindervalve.Disconnectregulator.

Reconnectregulatorandleak-test.Turnon LPcylindervalve,wait

30secondsandthenlightgrill.

•Turnoff knobsandLPcylindervalve.Disconnectcouplingnutfrom

cylinder.Reconnectandretry.

•Turnfrontofgrilltofacewindor increaseflameheight.

•RefillLPcylinder.

•Referto"Suddendropin gasflow"above.

•Cleanburnersandinsideofgrill/firebox.

Persistentgreasefire.

•Excessivefat in meat.

•Excessivecookingtemperature.

•Greasetrappedby foodbuilduparound

burnersystem.

•Trimfatfrommeatbeforegrilling.

•Adjust(lower)temperatureaccordingly.

•Turnknobsto OFF.Turngasoffat LPcylinder.Leavelidin position

andletfireburnout.Aftergrillcools,removeandcleanall parts.

Flashback... •Burnerand/orburnertubesareblocked. •Turnknobsto OFF.Cleanburnerand/orburnertubes.Seeburner

(firein burnertube(s)), cleaningsectionofUseandCare.

Unabletofill LP

cylinder.

Oneburnerdoesnot

lightfromother

•Somedealershaveolderfillnozzles •The wornnozzlesdon'thaveenough"bite"toengagethe valve.Try

withwornthreads, a secondLPdealer.

•Greasebuildupor foodparticlesin

•Cleancarry-overtube(s)withwirebrush.

end(s)ofcarryovertube(s).

burner(s).

Timerdoesnot work

(Greenlightdoesnot

flash)

, DeadBattery

, Batteriesinstalledincorrectly.

, KnobPositiondid notstarttheClean

Cycle

, Replacebatteries

, Installbatteriescorrectly.

, PushKnobin to startthecleancycle.(GreenLEDshouldbeginto

flash)

NoLED'swill illuminate , DeadBattery , Replacebatteries

, LowBatteryStrengthRedLED nextto battery

symbolis illuminated

, Preparetoreplacebatteries(NOTE:Cleancyclewilloperatewith

a weakbattery.

29

Page 30

Troubleshooting - Electronic ignition

pmm !

SECTIONI

Nosparksappearat

anyelectrodeswhen

ElectronicIgnitionButton

ispressed;nonoise can

be heardfromspark

module.

• Battery not installed

properly.

•Deadbattery.

•Checkbatteryorientation. • Installbattery(makesurethat "+"and"-"

connectorsareorientedcorrectly,with"+"endup

and"-" enddown.)

•Hasbatterybeenused

previously?

•Replacebatterywith newalkalinebattery.

SECTIONII

Nosparksappearat

anyelectrodeswhen

ElectronicIgnitionButton

ispressed;noisecan

beheardfromspark

module.

SECTIONIII

Sparksare present

butnot at all

electrodesand/ornot

atfullstrength

•Buttonassemblynot

installedproperly.

•Faultysparkmodule.

•Outputlead

connectionsnot

connected.

•Outputlead

connectionsnot

connected.

•Arcingto grillaway

fromburner(s).

Checkto insurethreadsare

properlyengaged.Button

shouldtravelupanddown

withoutbinding.

If nosparksaregenerated

withnewbatteryandgood

wireconnections,moduleis

faulty.

•Are outputconnectionson

andtight?

•Are outputconnectionson

andtight?

If possible,observegrillin

darklocation.Operate

ignitionsystemandlookfor

arcingbetweenoutputwires

andgrillframe.

•Unscrewbuttoncap assemblyandreinstall,making

surethreadsarealignedandengagedfully.

•Replacesparkmoduleassembly.

•Removeandreconnectall outputconnectionsat

moduleandelectrodes.

•Removeandreconnectall outputconnectionsat

moduleandelectrodes.

•If sparksareobservedotherthanfromburner(s),

wireinsulationmaybedamaged.Replacewires.

•Weakbattery.

•Electrodesarewet.

•Electrodescrackedor

broken"sparksat

crack".

3O

All sparkspresentbutweak

or at slowrate.

Hasmoistureaccumulated

on electrodeand/orin burner

ports?

Inspectelectrodesfor

cracks.

•Replacebatterywitha newalkalinebattery.

•Usepapertoweltoremovemoisture.

•Replacecrackedor brokenelectrodes.

Page 31

Please register your product online at:

Registre su producto en linea en"

Veuillez enregistrer votre produit a radresse:

_®

Grilling's Juicy Little Secret"

(ifyouregisteronline,youdo notneedtosendinthis registrationcard.)

(Siregistra en linea,noes necesafioenviaresta tarjetade registro.)

(Sivousenregistrezvotreproduiten ligne,il n'estpasn6cessaired'envoyer lacarte

d'enregistrement.)

PLEASEFILLOUTTHISCARDANDATTACHA COPYOF YOURSALESRECEIPT. RETURNITWlTHINIO DAYS OF PURCHASE.FOR WARRANTYSERVICEPROOFOF PURCHASE

WlLLBE REQUIRED.THISWARRANTYIS NON-TRANSFERABLE.

LLENE ESTA TARJETAY DEVUELVALADENTRODE LOS 10 DIASDE LA COMPRA.PARA ELSERVlCIODE GARANTIAES NECESARIOQUE PRESENTESU COMPROBANTEDE

COMPRA.CONSERVELA FACTURA.ESTAGARANTIAES INTRANSFERIBLE.

VEUILLEZCOM PLETE RCETTECARTE ETLA RETOU RN ERDANS LES 10 JOU RSSUIVANTL'ACHAT. POU RO BTENI RLESE RVlCESO USGARANTIE,UN EPREUVED'ACHAT DOlT

ETRE PRESENTEE.VEUILLEZCONSERVERVOTRE FACTURE.LA PRESENTEGARANTIEN'ESTPAS TRANSFERABLE.

*Required I Necesario I Exig_ ~ PLEASEPRINT~ IMPRIMAPOR FAVOR ~S'IL VOUSPLA'[TIMPRIMEI_

*O First Name I Nombre I Pr_nom

Address (number & street) I Direcci6n (n0mero y cane) I Adresse (num_ro et rue) Apt Number I N-°de aPart I N-°d'app t.

* O E-mail Address I Direccibn de correo electrbnico I Adresse _lectronique * O Phone Number I Nt_mero telef6nico I Num_ro de t_l_phone

Initial llnicialllnitiale Last Name I Apellido I Nom de Famillie

Zip Code I C6digo Zip I Code PostalCity I Cludad I Ville State I Estado I Province

ilc_;_ ¸ _ _'_ : I

Serial Number I N_mero de seriel Num_ro de s_rie

0

Date of Purchase I Fecha de compra I Date de I'achat

O Store Name I Nombre de la tienda I Nom du magasin

STICI(IION PRODUCT

$

0

Purchase Price I Precio de compra I Prix d'achat

@

Which product are you registering?

_.Qu_ producto est_i registrando?

Quel produit enregistrez-vous?

1. []Gas Grill I Parrilla a gas I Gril au gaz

2. [] Electric Grill I Parrilla el_ctrica I Gril _lectrique

3. []Smoker I Ahumador ] Fumoir

4. []Charcoal Grill I Parrilla a carb6n I Barbecue au charbon

S. [] Cooker/Fryer I Cocina/freidora I Cuiseur/Friteuse

6. []Otherl Otro I Autre

We respect your privacy. I Respetamos su privacidad. I Nous respectons votre vie priv_e.

• If you prefer not to receive special offers and promotions from Char-Broil, please check here: [ /

• Marque aquf si no desea recibir ofertas y promociones especiales de Char-Broil:

• Si vous pr_f_rez ne pas recevoir d'informations concernant des offres sp_ciales et des

promotions de Charbroil, veuiNez cocher ici:

O Your Gender I Sexo I Sexe:

[] Male I Masculino I Masculin

[]Femalel Femenino I F_minin

Mai! to: / Enviar a: / Envoyer _ :

Char-Broil Warranty Registration

P.O. Box 1240

Columbus, GA 31902-1240

I

* l_Attach copy ofyour

sales receipt here.

Adjunte aqui la copia

de su recibo de

compra

Veuillez attacher une

copie de votre regu

icL

:! 71

Thank you for completing this questionnaire. I Gracias por completer este cuestionario. I Merci d'avoir bien voulu remplir ce questionnaire.

31

Page 32

FO YOU

URCHASE

C

F

T

Grilling's Juicy Little Secret _°

C

G

• Valuable product information

• Inspiring grilling accessories

• Reliable customer support

• Delicious recipes and tips from chefs

• Exciting events and promotions

• And much more!

C

T

OU

OU

TT

F

ESE

TU

ITE

Loading...

Loading...