Page 1

Professional 3 Burner

467790317, 467791317

IMPORTANT: Fill out the product record information below.

See rating label on unit for serial number.

Date Purchased

Note: Sales docket must be kept as proof of

purchase date.

For support with your new barbecue, please call us at:

Amalgamated Hardware Merchants

Ph: 07 3208 1233

Email: enquiries@ahmaustralia.com.au

Gas Grill

.

AGA 8544 G

© 2017 Char-Broil, LLC Columbus, GA 31902

For use with propane gas only ● For Outdoor Use Only

DO NOT USE INDOORS.

Printed in China

Assembly instructions © 2017

06/07/17 • G466-016-150801

Page 2

TABLE OF CONTENTS

DANGER

For Your Safety..........................................................................2-3

Use and Care .........................................................................4-10

Limited Warranty.........................................................................11

Parts List.....................................................................................12

Parts Diagram.............................................................................13

Assembly................................................................................14-33

Troubleshooting......................................................................36-37

FOR YOUR SAFETY

Safety Symbols

The symbols and boxes shown below explain what each heading

means. Read and follow all of the messages found throughout

the manual.

WARNING

If you smell gas:

1. Shut off gas to the appliance, if possible.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or your fire department.

WARNING

1. Do not store or use petrol or other

flammable liquids or vapors in the vicinity of

this or any other appliance.

2. A gas cylinder not connected for use shall not

be stored in the vicinity of this or any other

appliance.

WARNING: Indicates an potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION: Indicates a potentially hazardous situation or

unsafe practice which, if not avoided, may result in minor

or moderate injury.

DANGER

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

DO NOT MODIFY THIS APPLIANCE.

IF THIS APPLIANCE REQUIRES SERVICING,

THE SERVICE MUST BE CARRIED OUT BY

AUTHORIZED PERSONNEL ONLY.

CAUTION

For residential use only. Do not use for commercial

cooking.

THIS BARBECUE IS FOR OUTDOOR USE ONLY.

CAUTION:

Read and follow all safety statements, assembly

instructions, and use and care directions before attempting

to assemble and cook.

INSTALLER/ASSEMBLER:

Leave this manual with consumer.

CONSUMER:

Keep this manual for future reference.

WARNING:

Failure to follow all manufacturer’s instructions could result

in serious personal injury and/or property damage.

NEVER OPERATE THIS BARBECUE FOR

MORE THAN 15 MINUTES WITH THE LID

CLOSED.

CAUTION:

Some parts may contain sharp edges – especially as noted

in the manual! Wear protective gloves if necessary.

2

2

Page 3

Gas Installation Codes

The appliance is certified

To AS 5263.0 and 5263.1.7 by AGA

Barbecue must be used in accordance with the

installation requirements of your local gas supply

authority, and the appropriate installation standard

AS 5601.

Specification

Gas consumption @ 2.75 kPA

3 main burners at 8.43 MJ/h each

1 side burner at 13.7 MJ/h

Total 39.0 MJ/h

Injector size

Injector size

Main burners - 0.82 mm

Side burner - 1.07 mm

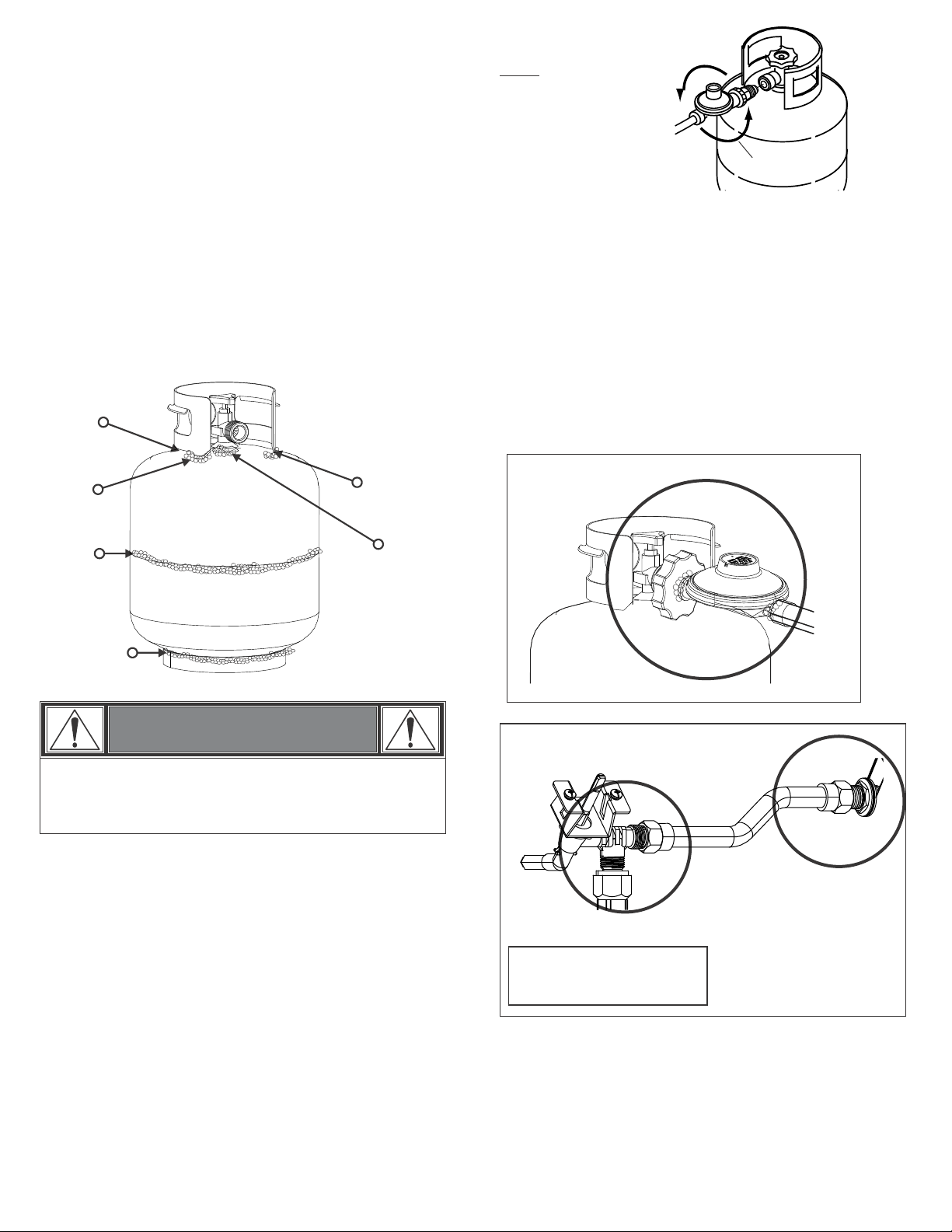

WARNING

Leak check the regulator cylinder connection at

each use as shown on page 5.

Check that "o" ring seal between the appliance

and the gas container are in place and in good

condition before connecting the gas container

Do not use this appliance if it has damaged or

worn "o" ring seal.

Each time prior to connecting regulator to

cylinder verify “o” - ring is in position as shown

below.

If damaged or missing replace prior to use.

Gas Connection Requirements.

The regulator supplied with the barbecue must be used.

The regulator is supplied with a POL cylinder connection

for connection to a 9 kg gas cylinder.

The regulator supplied has a outlet pressure of 2.75 kPa

This pressure is preset and cannot be adjusted.

USE OF BARBECUE UNDER OVERHEAD

While acceptable locations to use the barbecue are shown

on page 6. Char-Broil recommends not to use the barbecue

under any overhead. The smoke from cooking, especialy

with IR cooking, contains grease particles which will deposit

on the overhead.

WARNING

The barbecue has been evaluated for safety only with one

griddle plate. Use of more may create an unsafe condition.

Seal

O-Ring

Recommended Maintenance

Each Use

Clean and oil cooking grate assemblies

Clean/Inspect firebox

Clean grease tray

Check gas supply hose for cracks/leaks

Check gas regulator for leaks

Check that all gas fittings are tight

Every 6 months

Clean/Inspect burners and venturis

Check burners for corrosion

Others

Leak checks as specified in guide

3

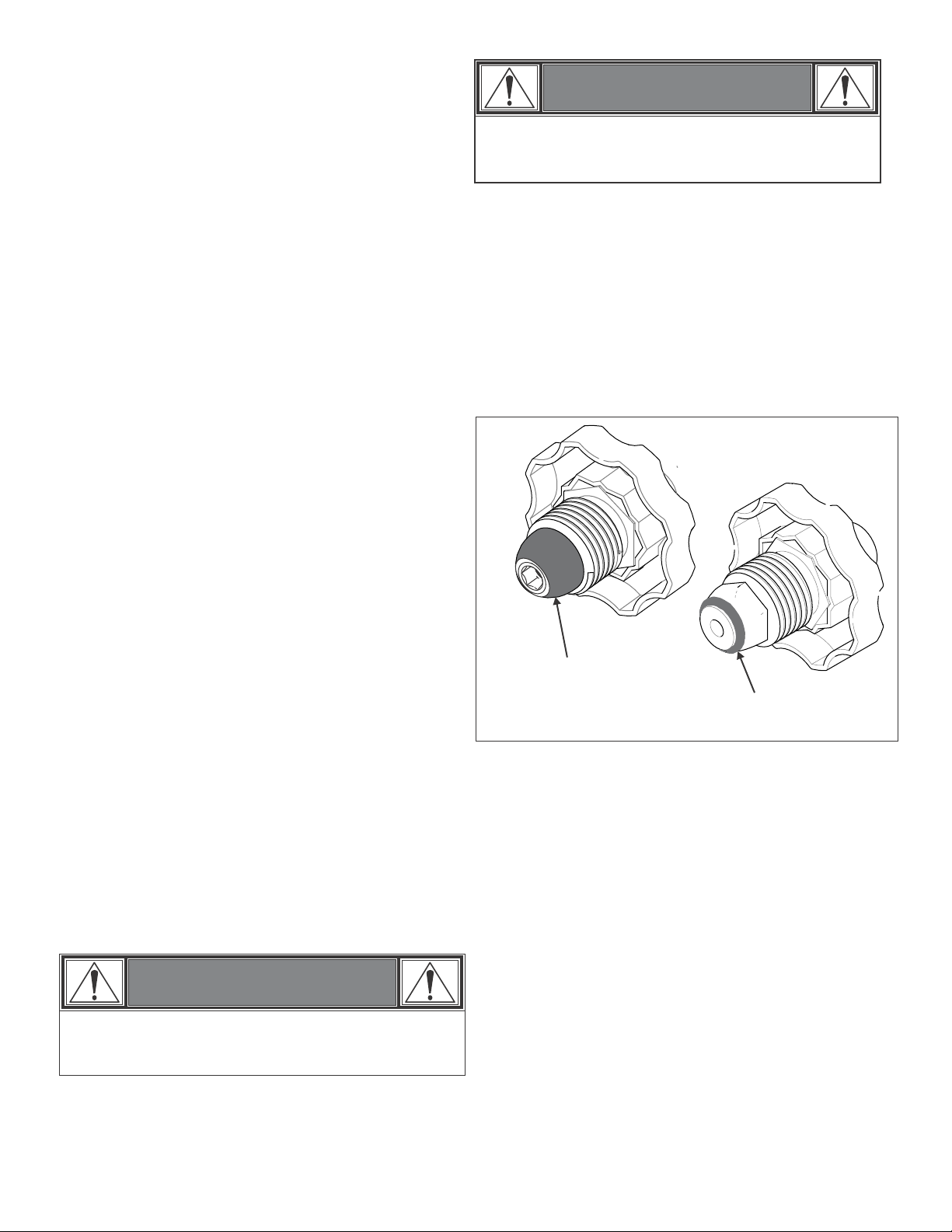

Page 4

USE AND CARE

WARNING

Do not store spare gas cylinder/s in this compartment

•

or near this appliance; use only the cylinder storage

facility provided.

•

If this warning is not followed, a fire causing

injury or damage may occur.

Gas Cylinder

• The gas cylinder used with your barbecue must meet the

following requirements:

• Use gas cylinders only with these required measurements:

30.5 cm diameter x 45.7 cm tall with 9 kg. capacity maximum.

This is the minimum cylinder that can be used.

•

Gas cylinder must be arranged for vapor withdrawal and include

collar to protect gas cylinder valve. Always keep gas cylinders in

upright position during use, transit or storage.

Gas cylinder in upright position for vapor withdrawal

Ensure gas cylinder conforms to Australian Standard

•

AS2469 and is less than 10 years old, or re-certified

if older than 10 years.

LPG (Liquefied Petroleum Gas including Propane)

• LPG is nontoxic, odorless and colorless when produced. For

Your Safety, LPG has been given an odor (similar to rotten

cabbage) so that it can be smelled.

• LPG is highly flammable and may ignite unexpectedly when

mixed with air.

• If you see, smell or hear gas escaping,

immediately get away from the gas

cylinder/appliance and call your fire department.

Gas Cylinder Removal, Transport and Storage

•Turn OFF all control knobs and gas cylinder valve. Turn coupling

nut clockwise to disconnect. Lift gas cylinder up and out of trolley.

Do not store a gas cylinder in enclosed spaces

•

such as a carport, garage, porch, covered

patio or other building. Never leave a gas cylinder

inside a vehicle which may become overheated

by the sun.

• Do not store a gas cylinder in an area where children play.

• Always disconnect regulator from cylinder, never disconnect

hose from barbecue. Gas hoses are factory fitted and

leak tested.

Do not subject gas cylinder to excessive heat.

•

Cylinder Valve

Gas Cylinder Filling or Exchange

• Use only licensed and experienced gas dealers or exchange

at a reputable cylinder exchange outlet.

• A frosty regulator indicates gas overfill. Immediately close gas

cylinder valve and call local gas dealer for assistance.

• Do not release liquid propane gas into the atmosphere.

This is a hazardous practice.

• To remove gas from cylinder, contact a gas dealer or call a

local fire department for assistance.

WARNING

• Outdoor gas appliance is not intended to be installed

in or on a boat.

• Outdoor gas appliance is not intended to be installed

in or on a caravan.

• Never attempt to attach this barbecue to the selfcontained gas system of a caravan.

• Do not use barbecue until leak-tested.

• If a leak is detected at any time, STOP.

•

If you cannot stop a gas leak, immediately close

gas cylinder valve and call gas supplier or your fire

department!

4

Page 5

Gas Cylinder Leak Test

For your safety

• Leak test must be repeated each time gas cylinder is exchanged

or refilled.

• Do not smoke during leak test.

• Do not use an open flame to check for gas leaks.

• Barbecue must be leak tested outdoors in a well-ventilated area,

away from ignition sources such as gas fired or electrical

appliances. During leak test, keep barbecue away from open flames

or sparks.

• Use a clean paintbrush and a 50/50 mild soap and water

solution.

in figure below.

•

Do not use household cleaning agents. Damage to gas

train components can result.

Brush soapy solution onto areas indicated by arrows

NOTE: The connection to

the gas cylinde r is an

‘ANTI-CLOCKWISE connection.’

Ensure the connection

is tightened firmly. Normally

1

only 1-1

assembly connection should

remain visible.

threads of the hose

2

/

Direction for

tightening

Leak Testing Valves, Hose and Regulator

1.Turn all barbecue control knobs to OFF.

2.Be sure regulator is tightly connected to gas cylinder.

3.Completely open gas cylinder valve by turning hand wheel

counterclockwise. If you hear a rushing sound, turn gas off

immediately. There is a major leak at the connection. Correct

before proceeding.

4.Brush soapy solution onto areas circled below, or other similar

fittings on your barbecue.

WARNING

If “growing” bubbles appear do not use or move the gas

cylinder. Contact a gas supplier or your fire

department!

Connecting Regulator to the Gas Cylinder

1.Gas cylinder must be properly secured onto barbecue. (Refer to

assembly section.)

2.Turn all control knobs to the OFF position.

3.Turn gas cylinder OFF by turning hand wheel clockwise to a

full stop.

4. Prior to connecting check o ring on regulator nipple

for damage. Replace if damaged.

5. Hold regulator and insert nipple into

coupling nut, holding regulator in a

valve so as not to cross-thread the connection.

cylinder valve. Tighten the

straight line with gas cylinder

NOTE: Sideburner shelf

fascia and other parts not

shown for clarity.

5.If “growing” bubbles appear, there is a leak. Close gas

cylinder valve immediately and retighten connections. If leaks

cannot be stopped do not try to repair. Call for replacement

parts.

6.Always close gas cylinder valve after performing leak test by

turning hand wheel clockwise.

5

Page 6

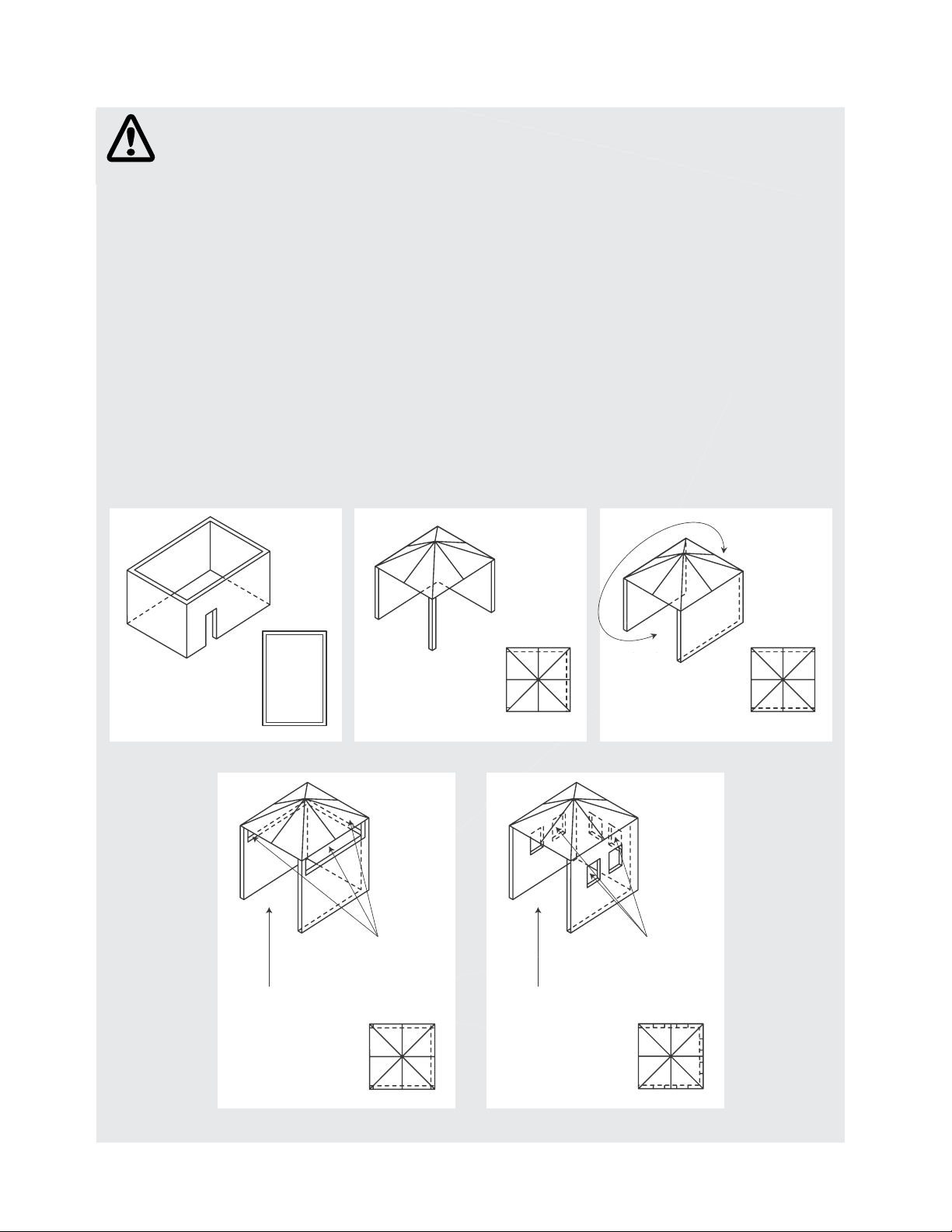

THIS APPLIANCE SHALL ONLY BE USED IN AN ABOVE GROUND OPEN AIR SITUATION WITH NATURAL

VENTILATION, WITHOUT STAGNANT AREAS, WHERE GAS LEAKAGE AND PRODUCTS OF COMBUSTION

ARE RAPIDLY DISPERSED BY WIND AND NATURAL CONVECTION.

ANY ENCLOSURE IN WHICH THE APPLIANCE IS USED SHALL COMPLY WITH ONE OF THE FOLLOWING:

• AN ENCLOSURE WITH WALLS

ON ALL SIDES, BUT AT LEAST

ONE PERMANENT OPENING AT

GROUND LEVEL AND NO

OVERHEAD COVER

• WITHIN A PARTIAL

ENCLOSURE THAT INCLUDES

AN OVERHEAD COVER AND NO

MORE THAN TWO WALLS

• WITHIN A PARTIAL

ENCLOSURE THAT INCLUDES

AN OVERHEAD COVER AND

MORE THAN TWO WALLS, THE

FOLLOWING SHALL APPLY:

(i) AT LEAST 25% OF THE TOTAL

WALL AREA IS COMPLETELY

OPEN: AND

(ii) AT LEAST 30% OF THE

REMAINING WALL AREA IS

OPEN AND UNRESTRICTED

• IN THE CASE OF BALCONIES,

AT LEAST 20% OF THE TOTAL

OF THE SIDE, BACK AND FRONT

WALL AREAS SHALL BE AND

REMAIN OPEN AND

UNRESTRICTED

• DO NOT USE YOUR BARBECUE

IN GARAGES, PORCHES,

BREEZEWAYS, SHEDS OR

OTHER ENCLOSED AREAS.

YOUR BARBECUE IS TO BE

USED OUTDOORS ONLY.

Refer below.

• THE BARBECUE IS NOT

INTENDED TO BE INSTALLED IN

OR USED ON RECREATIONAL

VEHICLES AND/OR BOATS AND

SHOULD NOT BE PLACED

ADJACENT TO OR UNDER ANY

SURFACE THAT WILL BURN.

• DO NOT OBSTRUCT THE FLOW

OF COMBUSTION AND

VENTILATION AIR AROUND

THE BARBECUE HOUSING

WHILST IN USE.

The following diagrams are examples of outdoor areas.

These same principles apply to canopy or shaded cloth areas.

Open side at

least 25% of total

wall area

30% or more in total of

the remaining wall area

is open and unrestricted

Both ends

open

30% or more in total of

the remaining wall area

is open and unrestricted

Open side at

least 25% of total

wall area

6

Page 7

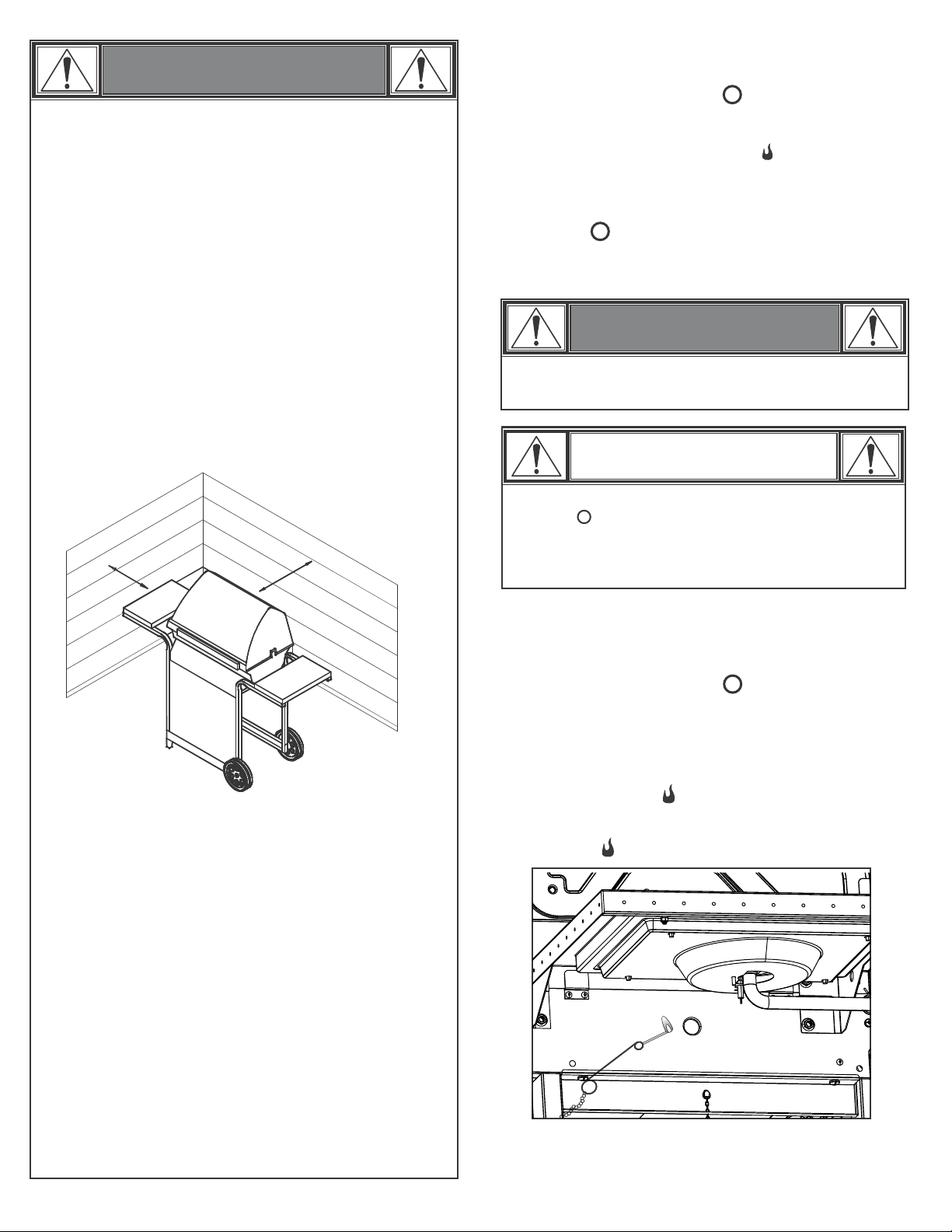

WARNING

For Safe Use of Your Grill and to Avoid Serious Injury:

• Do not let children operate or play near barbecue.

• Keep barbecue area clear and free from materials that burn.

• Do not block holes in sides or back of barbecue.

• Check burner flames regularly.

• Use barbecue only in well-ventilated space. NEVER use in

enclosed space such as carport, garage, porch, covered

patio, or under an overhead structure of any kind.

• Do not use lump charcoal or ceramic briquettes in

a gas barbecue.

• Do not cover grates with aluminum foil or any other

material. This will block burner ventilation and create a

potentially dangerous condition resulting in property

damage and/or personal injury.

• Use barbecue at least 3 ft. from any wall or surface. Maintain

10 ft. clearance to objects that can catch fire or sources of

ignition such as pilot lights on water heaters, live electrical

appliances, etc.

3 ft.

3 ft.

Ignitor Lighting

• Do not lean over grill while lighting.

1. Turn gas burner control valves to (off).

2. Open lid during lighting or re-lighting.

3. Turn ON gas at LP cylinder.

4. To ignite, push and turn burner knob to HIGH. Immediately,

push and hold ELECTRONIC IGNITOR button until the burner

lights.

5. If ignition does NOT occur in 5 seconds, turn the burner

controls off , wait 5 minutes and repeat the lighting

procedure.

6. Repeat steps 4 and 5 to light other main burners.

WARNING

Turn controls and gas source or tank OFF when not

in use.

CAUTION

If ignition does NOT occur in 5 seconds, turn the burner

controls off, wait 5 minutes and repeat the lighting

procedure. If the burner does not ignite with the valve

open, gas will continue to flow out of the burner and

could accidently ignite with risk of injury.

• NEVER attempt to light or re-light burner with lid

closed. A buildup of non-ignited gas inside a closed

barbecue is hazardous.

• Never operate barbecue with LP cylinder out of correct

position specified in assembly instructions.

• Always close LP cylinder valve and remove coupling nut

Before moving LP cylinder from specified operation

position.

Ÿ DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS

APPLIANCE WHILE IT IS IN OPERATION.

Ÿ DO NOT USE OR STORE FLAMMABLE MATERIALS IN OR

NEAR THIS APPLIANCE.

Ÿ DO NOT PLACE ARTICLES ON OR AGAINST THIS

APPLIANCE. DO NOT MODIFY THIS APPLIANCE.

• Apartment Dwellers:

Check with management to learn the requirements and fire

codes for using an LP gas barbecue in your apartment complex.

If allowed, use outside on the ground floor with a three (3)

foot clearance from walls or rails. Do not use on or under

balconies.

Match-Lighting

• Do not lean over grill while lighting.

1. Turn gas burner control valves to (off).

2. Open lid during lighting or re-lighting.

3. Turn ON gas at LP cylinder.

4. Place match into match holder (hanging from side panel of

grill). Light match; then light burner by placing match through

the match light hole on side of grill. Immediately push in and

turn burner knob to the HIGH position. Be sure burner lights

and stays lit.

5. Light adjacent burners in sequence by pushing knobs in and

turning to the HIGH position.

7

Page 8

Sideburner Ignitor Lighting

• Do not lean over grill while lighting.

1. Turn gas burner control valves to (off).

2. Open lid during lighting or re-lighting.

3. Turn ON gas at LP cylinder.

4. Turn sideburner knob to the HIGH position, push and hold

ELECTRONIC IGNITOR button.

5. If sideburner does NOT light within 5 seconds, turn knob

to off, wait 5 minutes, then repeat lighting procedure.

Sideburner Match Lighting

• Do not lean over grill while lighting.

1. Turn gas burner control valves to (off).

2. Open lid during lighting or re-lighting.

3. Turn ON gas at LP cylinder.

4. Place lit match near burner. Immediately turn sideburner

knob to the HIGH position. Be sure burner lights and stays

lit.

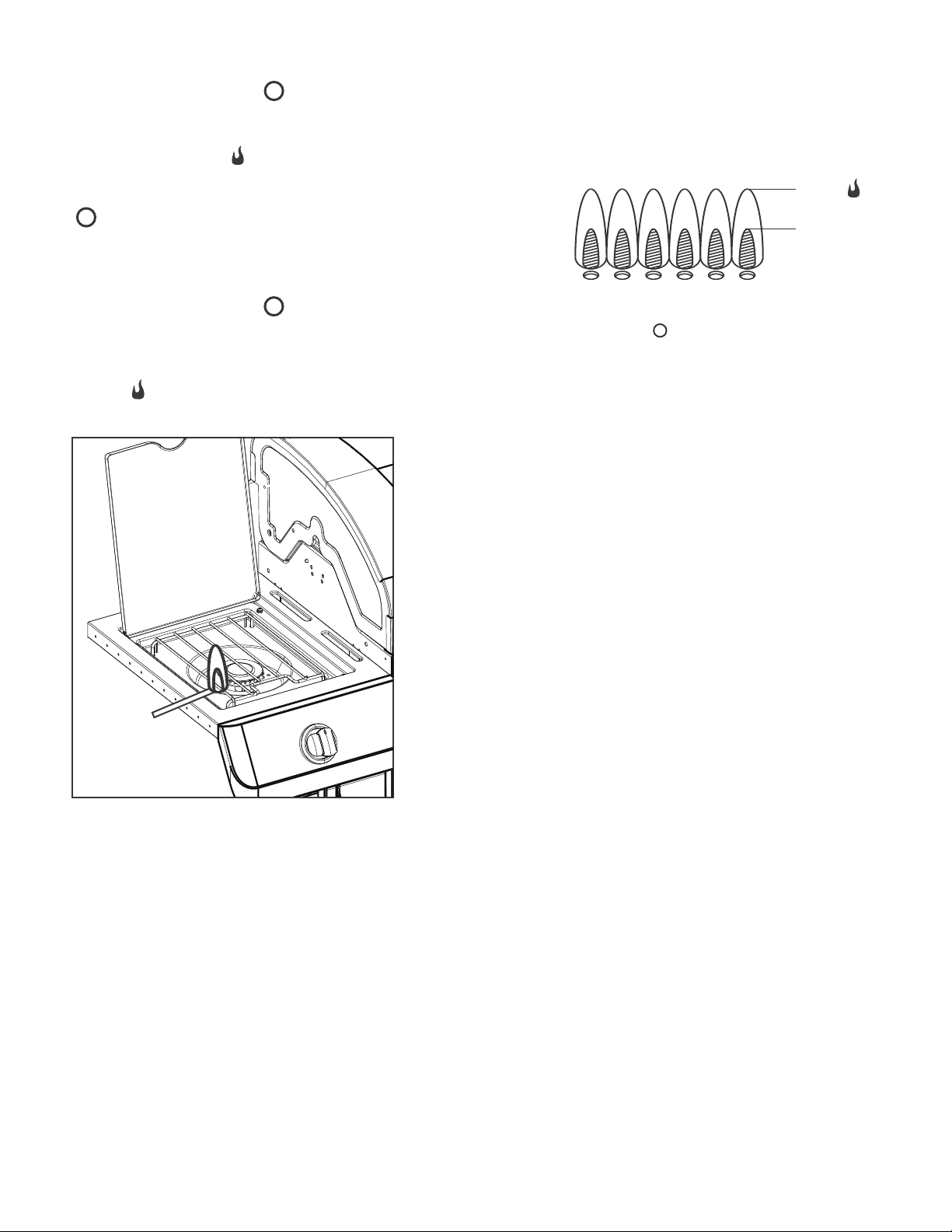

Burner Flame Check

• Remove cooking grates and heat tents. Light burners, rotate

knobs from HIGH to LOW. You should see a smaller flame in

LOW position than seen on HIGH. Perform burner flame check

on side burner, also. Always check flame prior to each use. If

only low flame is seen refer to "Sudden drop or low flame" in

the Troubleshooting Section.

HIGH

LOW

Turning Grill Off

• Turn all knobs to the off position. Turn LP cylinder off by

turning hand-wheel clockwise to a full stop.

Ignitor Check

• Turn gas off at LP cylinder. Press and hold electronic ignitor

button. "Click" should be heard and spark seen each time in

each collector box or between burner and electrode. See

"Troubleshooting" if no click or spark.

Valve Check

• Important: Make sure gas is off at LP cylinder before

checking valves. Knobs lock in off position. To check valves,

first push in knobs and release, knobs should spring back. If

knobs do not spring back, replace valve assembly before using

Barbecue. Turn knobs to LOW position then turn back to off position.

Valves should turn smoothly.

Hose Check

• Before each use, check to see if hoses are cut or worn or

Kinked. Replace damaged hoses before using barbecue. Use only

valve/hose/regulator specified by manufacturer.

Storing Your Grill

• Clean cooking grates.

• Store in dry location.

• When LP cylinder is connected to barbecue, store outdoors in a

well-ventilated space and out of reach of children.

• Cover barbecue if stored outdoors. Choose from a variety of barbecue

covers offered by Char-Broil at charbroil.com.

• Store barbecue indoors ONLY if LP cylinder is turned off and

Disconnected, removed from barbecue and stored outdoors.

• When removing barbecue from storage, follow “Cleaning the

Burner Assembly” instructions before starting barbecue.

8

Page 9

MAINTENANCE

It is your responsibility to properly maintain your barbecue.

The frequency of the maintenance will depend on the level

you use the barbecue. Cooking grates and hot plates should

be cleaned after or just prior to each use. At least once a year

you need to clean the cooking chamber and inspect the burners

for corrosion. More frequent cleaning will be needed with

heavy use.

It is recommended that an annual inspection be made by a

qualified technician.

Following are recommend items to check at each use and

general cleaning instructions.

Ignitor Check

•Turn gas off at gas cylinder. Press and hold electronic ignitor

button. "Click" should be heard and spark seen each time

between each collector box or burner and electrode. See

"Troubleshooting" if no click or spark.

Valve Check

•Important: Make sure gas is off at gas cylinder before

checking valves. Knobs lock in position. To check

valves, first push in knobs and release, knobs should spring

back. If knobs do not spring back, replace valve assembly

before using barbecue. Turn knobs to LOW position then turn back to

OFF

position. Valves should turn smoothly.

OFF

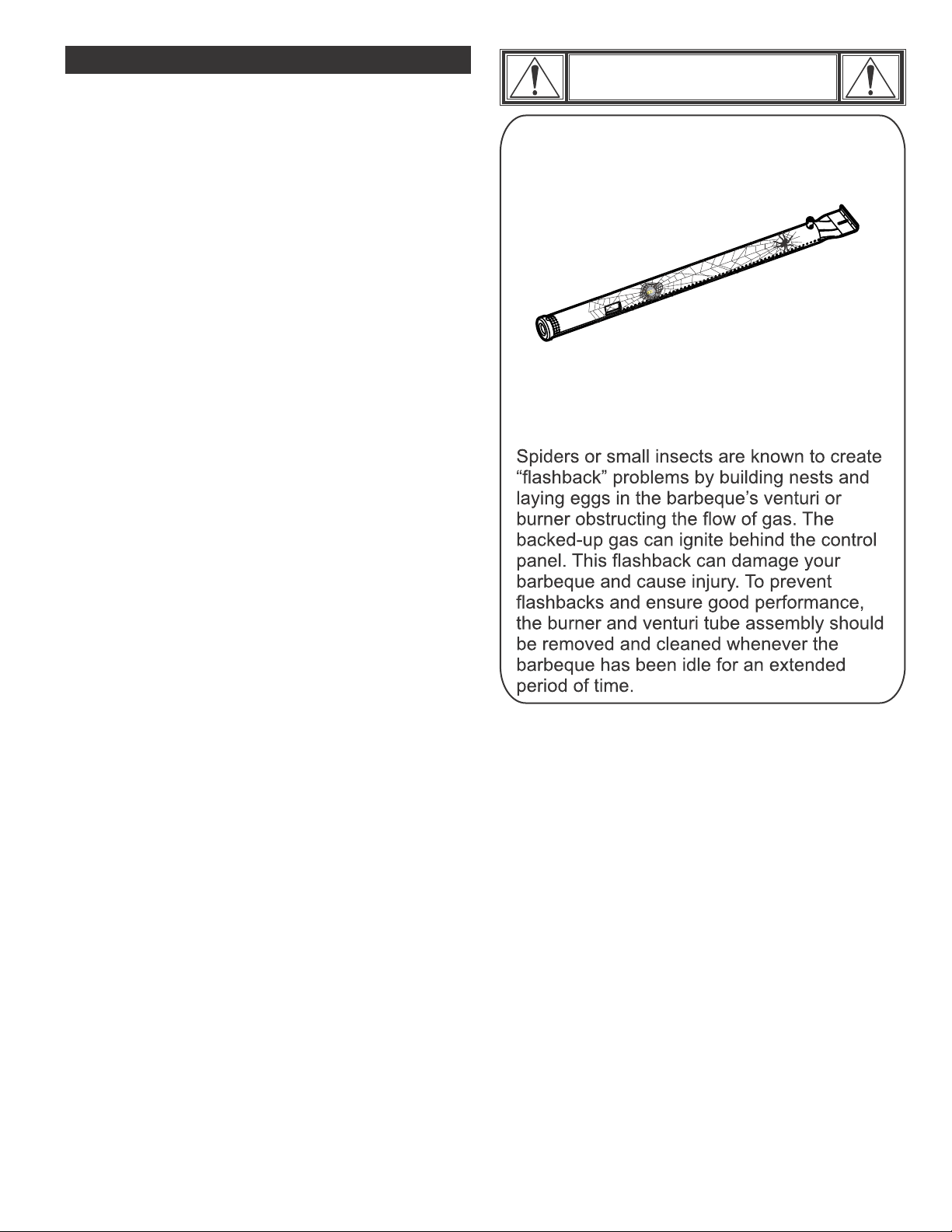

CAUTION

SPIDER ALERT!

SPIDER AND WEBS

INSIDE BURNER

If your barbecue is getting hard to light or

the flame is weak, check and clean the

venturis and burners.

Hose Check

•Before each use, check to see if hoses are cut or worn.

Replace damaged hoses before using barbecue. Use only

valve/hose/regulator specified by manufacturer.

General barbecue Cleaning

•Do not mistake brown or black accumulation of grease and

smoke for paint. Interiors of gas barbecues are not painted at the

factory (and should never be painted). Apply a strong solution

of detergent and water or use a barbecue cleaner with scrub brush

on insides of barbecue lid and bottom. Rinse and allow to completely

air dry. Do not apply a caustic barbecue/oven cleaner to painted

surfaces.

• Plastic parts: Wash with warm soapy water and wipe dry.

Do not use citrisol, abrasive cleaners, degreasers or a

concentrated barbecue cleaner on plastic parts. Damage to and

failure of parts can result.

•Porcelain surfaces: Because of glass-like composition, most

residue can be wiped away with baking soda/water solution or

specially formulated cleaner. Use nonabrasive scouring powder

for stubborn stains.

•Painted surfaces: Wash with mild detergent or nonabrasive

cleaner and warm soapy water. Wipe dry with a soft

nonabrasive cloth.

•Stainless steel surfaces: To maintain your barbecue’s high quality

appearance, wash with mild detergent and warm soapy water

and wipe dry with a soft cloth after each use. Baked-on grease

deposits may require the use of an abrasive plastic cleaning

pad. Use only in direction of brushed finish to avoid damage.

Do not use abrasive pad on areas with graphics.

• Cooking surfaces: If a bristle brush is used to clean any of

the barbecue cooking surfaces, ensure no loose bristles remain on

cooking surfaces prior to barbecueing. It is not recommended to

clean cooking surfaces while barbecue is hot.

Storing Your barbecue

•Clean cooking grates.

•Store in dry location.

•When gas cylinder is connected to barbecue, store outdoors in a wellventilated space and out of reach of children.

•Cover barbecue if stored outdoors. Choose from a variety of barbecue

covers offered by manufacturer.

•Store barbecue indoors ONLY if gas cylinder is turned off and

Disconnected, removed from barbecue and stored outdoors.

•When removing barbecue from storage, follow “Cleaning the Burner

Assembly” instructions before starting barbecue.

Special Operating Instructions

Never operate this barbecue for more than 8 minutes on

high with hood closed.

9

Page 10

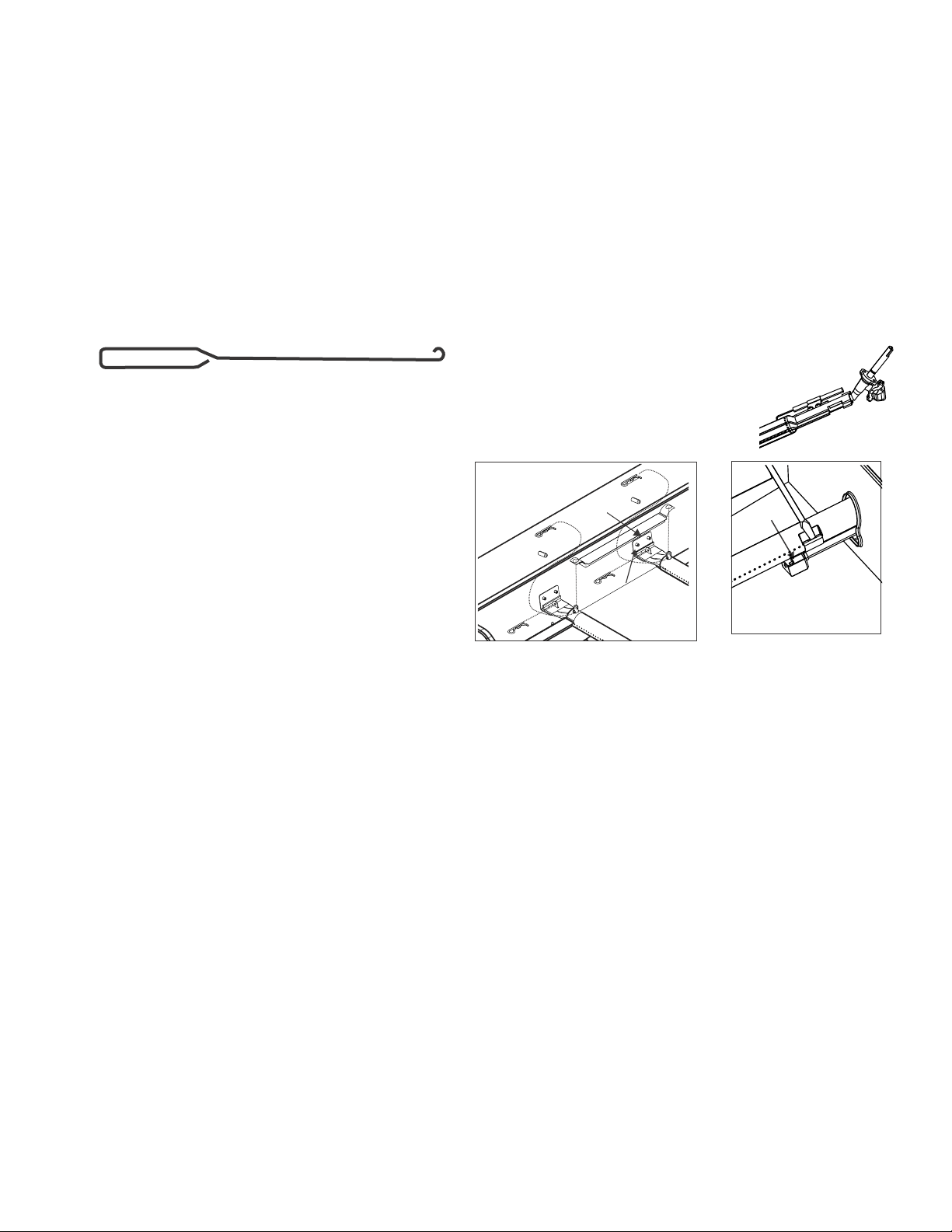

Cleaning the Burner Assembly

Follow these instructions to clean and/or replace parts of burner

assembly or if you have trouble igniting barbecue.

1. Turn gas off at control knobs and gas cylinder.

2.

Remove cooking grates and flame tamers.

3. Remove carryover tubes and burners.

4.

Detach electrode from burner.

5. Carefully lift each burner up and away from valve openings.

We suggest three ways to clean the burner tubes. Use the one

easiest for you.

(A) Bend a stiff wire (a light weight coat hanger works well)

into a small hook. Run the hook through each burner

tube several times.

(B) Use a narrow bottle brush with a flexible handle (do not

use a brass wire brush), run the brush through each

burner tube several times.

(C) Wear eye protection: Use an air hose to force air into

the burner tube and out the burner ports. Check each

port to make sure air comes out each hole.

6. Wire brush entire outer surface of burner to remove food

residue and dirt.

7. Clean any blocked ports with a stiff wire such as an open

paper clip.

8. Check burner for damage, due to normal wear and corrosion

some holes may become enlarged. If any large cracks or

holes are found replace burner.

VERY IMPORTANT: Burner tubes must reengage valve

openings. See illustrations at right.

9. Attach electrode to burner.

10. Carefully replace burners.

Correct

burner-to-valve

engagement

11. Attach burners to brackets on firebox.

12. Reposition carryover tubes and attach

to burners. Replace flame tamers and

cooking grates.

Firebox

Carryover tube

Electrode

Firebox burner

bracket

Pry off

electrode with

a flat blade

screwdriver

10

Page 11

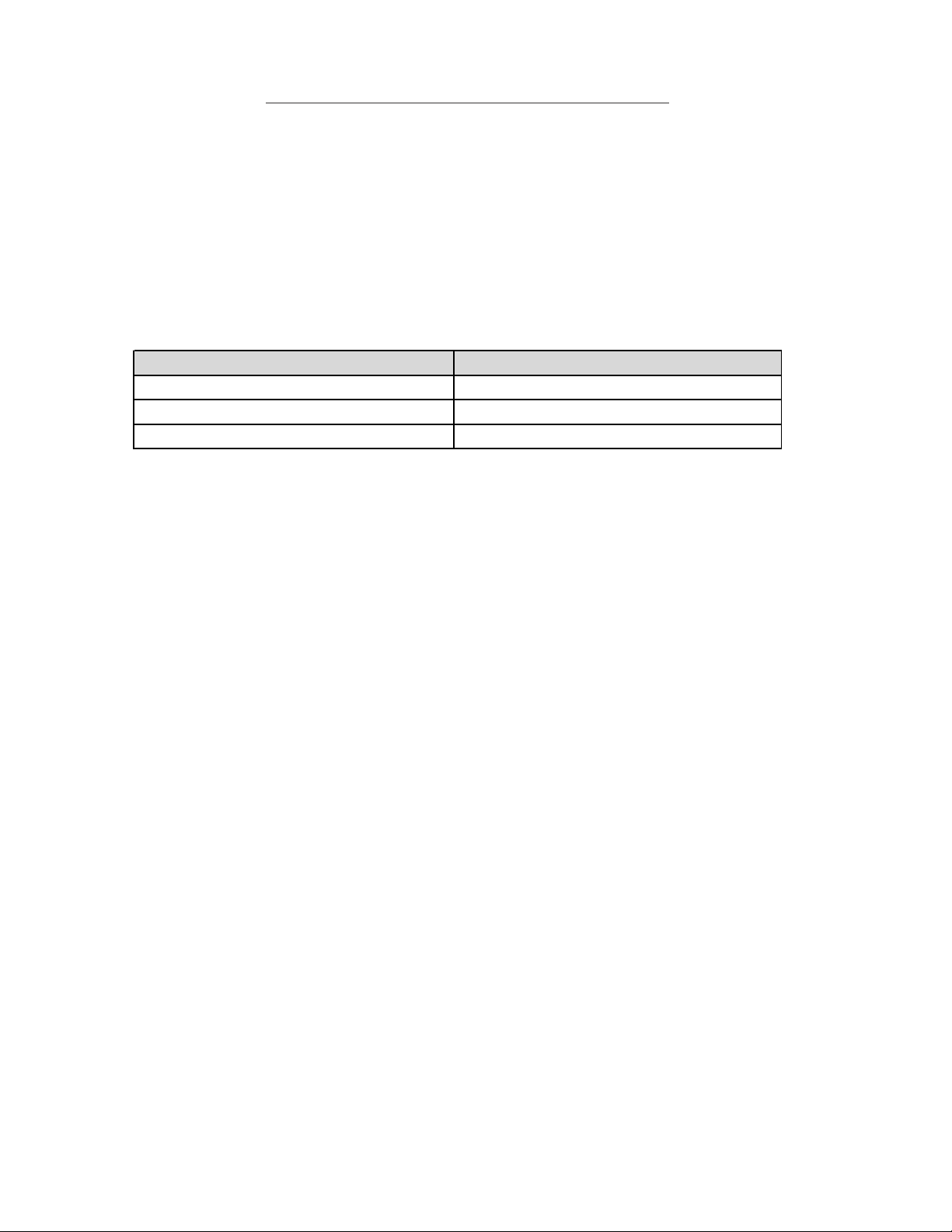

MANUFACTURER’S WARRANTY STATEMENT

PRODUCT PART DESCRIPTION PERIOD OF COVERAGE

Stainless Burner 2 years fron date of purchase

Firebox and Lid 2 years fron date of purchase

All other Parts 1 years fron date of purchase

The benefits under this manufacturer's warranty are in addition to other rights and remedies

under law in relation to goods. Our goods come with guarantees that cannot be excluded

under the Australian Consumer Law. You are entitled to a replacement or refund for a

major failure and for compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of

acceptable quality and the failure does not amount to a major failure.

The Manufacturer warrants that this product shall be free from defects in workmanship and

materials at the time of purchase. The manufacturer reserves the right to require that any

product, or portion of a product, that is claimed as defective to be returned for inspection.

The Manufacturer’s Warranty applies to the parts of your product as per the below table:

To claim under this Manufacturer’s Warranty, you will be required to produce proof of

purchase of your product that clearly states the date of purchase.

The Manufacturer’s Warranty does not include:

1. Transport costs for replacement parts, or for the purpose of returning parts for

inspection.

2. The cost of in-home service calls or works undertaken on your behalf without

the Manufacturer’s authorisation.

3. Loss of food, fuel or other consumables as a result of a fault of the product.

4. Any other form of loss or damage as a result of a fault of the product.

This Manufacturer’s Warranty shall not cover faults or defects that are in the

Manufacturer’s assessment caused by:

1. Improper or incorrect installation or assembly of the product.

2. Alteration or retrofitting of the product in form or function.

3. Usage in a commercial context or uses other than domestic use.

4. Neglect, mistreatment or other acts inconsistent with a reasonable standard

of care for the product.

5. Fair wear and tear, including naturally occurring processes such as

oxidisation causing rust.

The maximum liability assumed under this Manufacturer’s Warranty is limited to the

provision of replacement product or replacement parts for your product.

How to claim under the Manufacturer’s Warranty:

There are two methods of obtaining service under this warranty:

1. Contact your place of purchase.

2. Contact the Australian Distributor:

Amalgamated Hardware Merchants

By mail: Unit 4 – Compton Plaza 126-130 Compton Road WOODRIDGE,

QLD 4114 By phone: (07) 3208 1233

By email: enquiries@ahmaustralia.com.au

11

Page 12

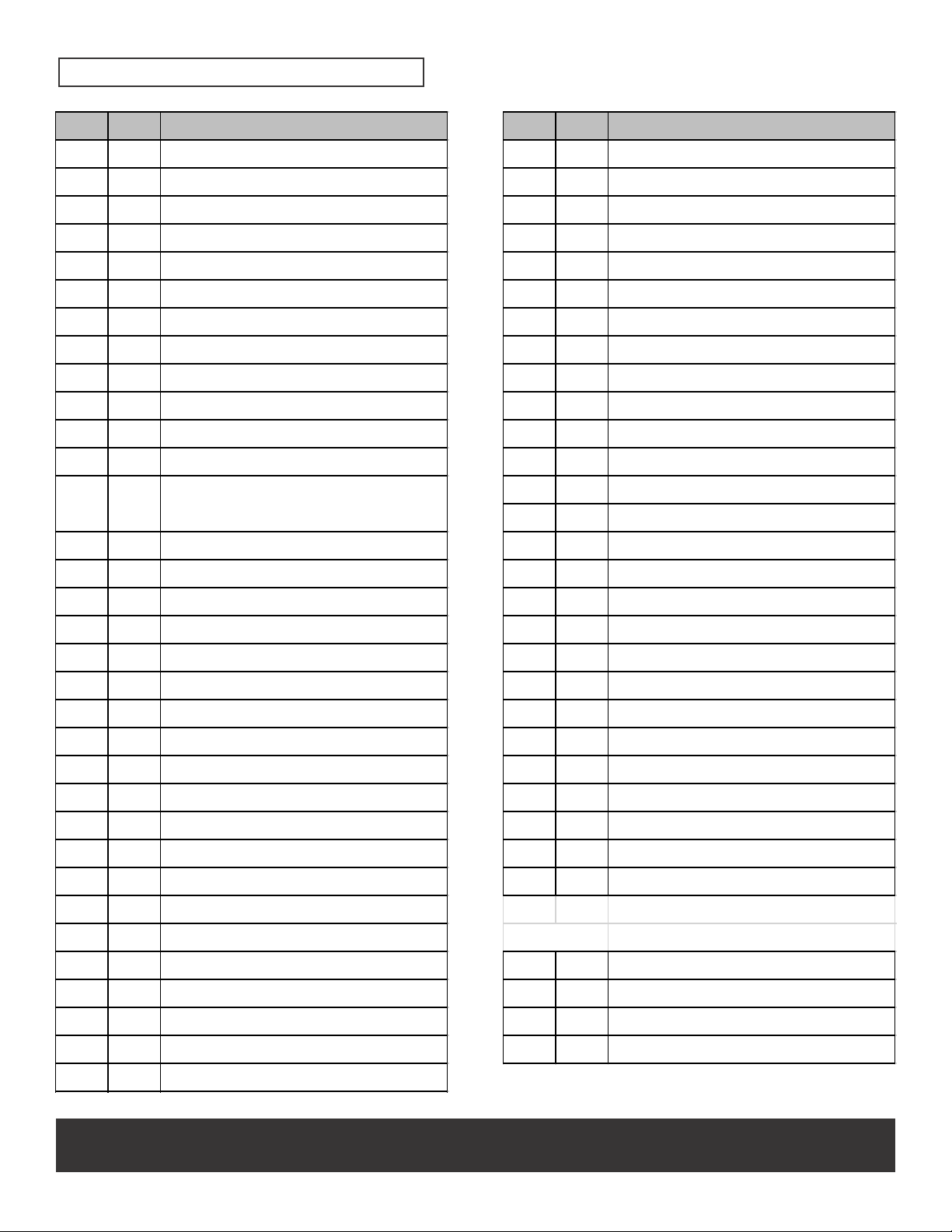

PARTS LIST

Key Qty Description

1 1 TOP LID

2 1 TEMPERATURE GAUGE

3 1 BEZEL, F/ TEMP GAUGE

4 1 LOGO PLATE

5 1 HANDLE F/ TOP LID

6 2 BEZEL, F/ HANDLE

7 2 RUBBER BUMPER, W/ HOLE, F/ TOP LID

8 2 RUBBER BUMPER, ROUND

9 1 TOP LID HARDWARE

10 1 FIREBOX

11 3 BURNER BRACE

12 3 MAIN BURNER TUBE, NO ELECTRODE

13 3

Key Qty Description

34 1 REAR TROLLEY PANEL B

35 1 UPPER REAR TROLLEY PANEL

36 1 FRONT DOOR BRACE

37 4 SIDE SHELF CONNECTION BRACE

38 2 RAIL, F/ GREASE TRAY

39 1 GREASE TRAY

40 1 LEFT DOOR, NO HANDLE

41 1 RIGHT DOOR, NO HANDLE

42 2 HANDLE, F/ DOOR

43 4 DOOR BUSHING, F/ HANDLE

44 1 LEFT SIDE SHELF

45 1 HOT PLATE SHELF

46 1 DRIP PAN, F/ HOT PLATE

47 2 SILICONE RUBBER BUMPER, F/ HOT PLATE

48 1 HOT PLATE LID

49 1 CONTROL PANEL, F/ HOT PLATE SHELF

50 1 HOT PLATE

51 1 ELECTRODE, F/ HOT PLATE

52 1 WIRE, F/ HOT PLATE ELECTRODE

53 1 HEAT SHIELD, FIREBOX

54 1 HEAT SHIELD, F/ TANK

55 1 GRATE, F/ HOT PLATE

56 1 ELECTRONIC IGNITION MODULE

57 1 CAP, F/ EI MODULE

58 1 HEAT SHIELD, F/ IGNITION MODULE

59 1 HOT PLATE

60 1 FIREBOX SEPARATOR

NOT Pictured

… 2 MAGNET

… 1 PRODUCT GUIDE, AUSTRALIA

… 1 HARDWARE PACK

… 1 IR CLEANING TOOL

ELECTRODE SET, F/ MAIN BURNER

14 2 FLAME CARRY OVER TUBE

15 1 MAIN CONTROL PANEL, TOP

16 1 MAIN CONTROL PANEL, BOTTOM

17 1 HOSE VALVE REGULATOR

18 4 CONTROL KNOB

19 4 BEZEL, KNOB

20 1 IGNITER SWITCH MODULE

21 3 HEAT TENT

22 1 WARMING RACK

23 3 COOKING GRATE

24 3 COOKING GRATE, INFRARED EMITTER

25 1 BOTTOM SHELF

26 2 TANK SUPPORT

27 2 CASTER, LOCKING

28 2 CASTER, FIXED

29 1 LEFT TROLLEY ASSEMBLY

30 1 MATCH HOLDER

31 1 RIGHT TROLLEY ASSEMBLY

32 1 GROMMET

33 1 REAR TROLLEY PANEL A

NOTE: Some grill parts shown in the assembly steps may differ slightly in appearance from

those on your particular grill model. However, the method of assembly remains the same.

12

Page 13

PARTS DIAGRAM

#9

#22

#8

#7

#4

#3

#1

#2

#23

#24

#15

#16

#35

#36

#21

#50

#47

#59

#37

#55

#51

#12

#13

#49

#11

#46

#18

#58

#17

#48

#56

#52

#57

#14

#44

#6

#5

#20

#10

#19

#45

#60

#43

#54

#40

#32

#42

#29

#25

#28

#39#38

#53

13

#27

#34

#30

#33

#26

#42

#31

#41

Page 14

HARDWARE LIST

Hardware is shown actual size. You may have spare hardware after assembly is complete.

Key Description Picture Qty

A

B

C

D

E

F

G

H

Cleaning Tool

Knob

Bezel, Knob

#8x3/8" self-tapping Screw

AA Battery

#8x3/8" self-tapping Screw(Black)

1/4-20x1/2” Screw

1/4-20x1/2” Screw(Black)

J

1/4-20x2-3/8” Screw

-

+

1

1

1

9

1

14

20

8

6

K

L

M

N

P

R

S

T

#10-24x3/8” Screw(Black)

#10-24x3/4” Screw 4

#8-32x3/8” Screw

M4 Wing Nut

1/4" Nut

#10-24x3/8” Screw

#10-24 Nut

1/4-20x1 ½” Screw

4

2

1

4

3

1

4

14

Page 15

ASSEMBLY

1

G

x2

G

#31

#29

#25

2

G

x8

G

#34

#33

15

Page 16

33

R

x1

#26

S

x1

G

S

1ST

x4

#26

R

2ND

#26

#25

#25

G

16

Page 17

4

#28

J

x4

#28

#28

#27

#27

P

x4

P

J

5

H

x4

#37

#37

H

17

Page 18

6

#49

R

x2

#44

R

R

1ST

#45

2ND

#45

7

G

J

x2

x6

#15

G

G

#16

#15

#16

G

J

#17

18

Page 19

8

#38

D

x6

D

D

#54

D

19

Page 20

9

#53

D

x3

#54

10

2ND

#53

D

T

x4

1ST

#54

#53

#35

T

20

Page 21

11

K

x4

#10

#45

K

#10

#44

K

K

#10

K

#45

21

Page 22

12

WARNING

Burner must properly engage valve as

shown. Failure to engage valve as shown

may result in personal injury and/or

property damage.

#12

#13

1ST

2ND

Before

After

#14

3RD

22

Page 23

13

#21

14

#24

23

Page 24

15

#23

OR

#23

#59

24

Page 25

16

#22

#22

#10

25

Page 26

17

1ST

Remove screws and washers

Enlevez les vis et rondelles

Retire los tornillos y arandelas

B

x1

C

x1

M

x2

2ND

3RD

#17

C

M

M

B

26

Page 27

18

#50

#51

#50

N

x1

#51

N

19

#55

27

Page 28

20

20

H

x4

H

2ND

1ST

H

#36

#20

-

E

x1

+

3RD

#56

#58

4TH

AA Battery

#57

28

Page 29

21

F

x2

F

#60

F

22

F

F

F

x6

F

2ND

#60

3RD

F

F

F

1ST

29

Page 30

23

F

x2

24

F

F

x4

F

#60

30

F

F

F

F

Page 31

25

L

x4

#42

L

L

#40

#41

L

L

#42

#40

2ND

1ST

#41

31

Page 32

26

A

x1

A

27

#39

32

Page 33

332834

Page 34

NATURAL GAS CONVERSION

TO BE INSTALLED ONLY ON OR IN A NON-

WARNING

COMBUSTIBLE ENCLOSURE

NATURAL GAS CONVERSION ONLY TO BE DONE

BY AN AUTHORISED PERSON OR LICENSED

PLUMBER.

Improper installation, adjustment, alteration, service

or maintenance can cause injury or property damage.

Read the instructions thoroughly before installing or

servicing this equipment.

This appliance must not be installed or used indoors.

An AGA approved natural gas pressure regulator

must be installed in the pipeline and be set at 1 kPa.

The authorised person will provide a certificate of

compliance.

Warning: Improper installation, adjustment, alteration,

service or maintenance can cause injury or property

damage. Read the instructions thoroughly before

installing or servicing this equipment.

Servicing Instructions

Appliances should be serviced at least annually and

servicing must only be carried out by a Licensed Plumber

or Authorised Person.

Clean the Burner Ports and top with a Soft Brush.

Inspect and clean all combustion air inlets, then replace

the Burner ensuring it is firmly secured.

Specification Natural Gas

Note: Recommended clearances must be maintained,

see page 4.

Gas Piping

1.

(a) A minimum pipe diameter of 15mm is required

for inlet piping. A lever operated shut-off valve

should be installed within 1 metre of the

appliance for servicing the unit.

(b) Where it is not practical to install solid tube

AGA certified stainless steel braided hose can

be installed. This hose assembly must comply

with AS5601 Gas Installations, pipe sizing

tables and shall not exceed 3 metres in length.

The internal diameter of the hose must not be

less than the 10mm.

(c) Chain or wire of adequate strength must be

fixed to the appliance. Only one end to the

appliance, the other end to be securely

anchored to wall or floor. The length of the

chain or wire is not to exceed 80% of the length

of the gas assembly.

(d) Tools are required to assemble the

Conversion Kit.

2 adjustable spanners

7 mm scoket

2. Check with local and state plumbing and heating

codes regarding sizing of the gas lines.

3. All gas pipe connections must be sealed with a

gas pipe compound resistant to Natural Gas.

Gas consumption @ 1.0kPA

3 main burners at 8.43 MJ/h each

1 side burner at 13.7 MJ/h

Total 39.0 MJ/h

Injector sizeInjector size

Main burners - 1.43 mm

Side burner - 1.90 mm

4. Installation of a drip leg if required in the supply line

must conform to AS5601.

5. When checking for gas leaks, do not use an open

flame. Use a soap and water solution and check for

bubbles indicating gas leakage.

6. Installation of 1/8” NPT plugged tapping, accessible

for test gauge connections, is required upstream of

the gas supply connection.

Page 35

Appliance conversion - Main Burners

1.Remove cooking grate, hot plate, and heat tents.

2.Remove clips retaining flame carryover tubes and burners.

3.Remove flame carryover tubes and burners.

4.Using a 7 mm nut drive remove LP orifices and save in case barbecue needs to be converted

back to LP.

5.Remove control knobs and screws and washers (Shown below). Only do one

control knob at a time.

6.Install NG bezel plates supplied in hardware pack using screws and washer removed In step 5

and replace control knobs (shown below).

7.Replace burners, flame carryover tubes, retaining clips, heat tents, cooking grate and hot plate.

Appliance conversion - Side Burner

1.Remove side burner.

2.Using a 7 mm nut drive remove LP orifices and save in case barbecue needs to be converted

back to LP.

3.Remove control knobs and screws and washers (Shown below).

4.Install NG bezel plates supplied in hardware pack using screws and washer removed in step 3

and replace control knobs (shown below).

5.Replace side burner.

TEST OPERATION OF APPLIANCE BEFORE LEAVING

Remove knob and screws/washers

Install NG Bezel, screws/washers and knob

NG Bezel

35

Page 36

EMERGENCIES: If a gas leak cannot be stopped, or a fire occurs due to gas leakage, call the fire department.

Emergencies

Gas leaking from

cracked/cut/burned hose.

Gas leaking from LP cylinder.

Gas leaking from LP

cylinder valve.

Gas leaking between LP

cylinder and regulator

connection.

Fire coming through control

panel.

Grease fire or continuous

excessive flames above

cooking surface.

Troubleshooting

Problem

Burner(s) will not light

using ignitor.

(See Electronic Ignition

Troubleshooting also)

Continued on next page.

Possible Cause

• Damaged hose.

• Mechanical failure due to rusting or mishandling.

• Failure of cylinder valve from mishandling or

mechanical failure.

• Improper installation, connection not tight, and/or

failure of rubber seal in clyinder valve.

• Fire in burner tube section of burner due to blockage.

• Too much grease buildup in burner area.

Possible Cause

GAS ISSUES:

• Trying to light wrong burner.

• Burner not engaged with control valve.

• Obstruction in burner.

• No gas flow.

Prevention/Solution

•Turn off gas at LP cylinder or at source on natural gas systems. Discontinue use of

product and replace hose/regulator. Once hose/regulator is replaced conduct

complete leak check per manual.

• Replace LP cylinder.

• Turn off LP cylinder valve. Return LP cylinder to gas supplier.

•Turn off LP cylinder valve. Remove regulator from cylinder and visually inspect rubber

seal in cylinder valve for damage. If damage or cannot correct leak replace cylinder.

See LP Cylinder Leak Test and Connecting Regulator to the LP Cylinder.

• Turn off control knobs and LP cylinder valve. Leave lid open to allow flames to die

down. After fire is out and grill is cold, remove burner and inspect for spider nests or

rust. See Natural Hazard and Cleaning the Burner Assembly pages.

• Turn off control knobs and LP cylinder valve. Leave lid open to allow flames to die

down. After cooling, clean food particles and excess grease from inside firebox area,

grease tray, and other surfaces.

Prevention/Solution

• See instructions on control panel and in Use and Care section.

• Make sure valves are positioned inside of burner tubes.

• Ensure burner tubes are not obstructed with spider webs or other matter. See

cleaning section of Use and Care.

• Make sure LP cylinder is not empty. If LP cylinder is not empty, refer to

“Sudden drop in gas flow.”

Burner(s) will not match light.

• Coupling nut and LP cylinder valve not fully

connected.

ELECTRICAL ISSUES:

• Electrode cracked or broken; “sparks at crack.”

• Electrode tip not in proper position.

(Does not apply to SUREFIRE.)

• Wire and/or electrode covered with cooking residue.

• Wires are loose or disconnected.

• Wires are shorting (sparking) between ignitor and

electrode.

• Dead battery.

ELECTRONIC IGNITION:

• No spark, no ignition noise.

• No spark, some ignition noise.

• Sparks, but not at electrode or at full strength.

• See “GAS ISSUES:” .

• Match will not reach.

• Improper method of match-lighting.

• Turn the coupling nut approximately one-half to three-quarters additional turn until

solid stop. Tighten by hand only - do not use tools.

• Replace electrode(s).

Main Burners:

• Tip of electrode should be pointing toward gas port opening on burner. The

distance should be 1/8” to 1/4”. Adjust if necessary.

Sideburner:

• Tip of electrode should be pointing toward gas port opening on burner. the

distance should be 1/8” to 3/16”. Adjust if necessary.

• Clean wire and/or electrode with rubbing alcohol and clean swab.

• Reconnect wires or replace electrode/wire assembly.

• Replace ignitor wire/electrode assembly.

• Replace with a new alkaline battery.

• See Section I of Electronic Ignition System.

• See Section II of Electronic Ignition System.

• See Section III of Electronic Ignition System.

• Use long-stem match (fireplace match).

• See “Match-Lighting” section of Use and Care.

36

Page 37

Troubleshooting (continued)

Problem

Sudden drop in gas flow or

low flame.

Flames blow out.

Flare-up.

Persistent grease fire.

Flashback (fire in

burner tube(s)).

One burner does not light

from other burner(s).

Possible Cause

• Out of gas.

• Excess flow valve tripped.

• Vapor lock at coupling nut/LP cylinder connection.

• High or gusting winds.

• Low on LP gas.

• Excess flow valve tripped.

• Grease buildup.

• Excessive fat in meat.

• Excessive cooking temperature.

• Grease trapped by food buildup around

burner system.

• Burner and/or burner tubes are blocked.

• Grease buildup or food particles in end(s) of

carryover tube(s).

Prevention/Solution

• Check for gas in LP cylinder.

• Turn off knobs, wait 30 seconds and light grill. If flames are still low, turn off knobs

and LP cylinder valve. Disconnect regulator. Reconnect regulator and leak-test. Turn

on LP cylinder valve, wait 30 seconds and then light grill.

• Turn off knobs and LP cylinder valve. Disconnect coupling nut from cylinder.

Reconnect and retry.

•Turn front of grill to face wind or increase flame height by turning gas valve to a

higher postion.

• Refill LP cylinder.

• Refer to “Sudden drop in gas flow” above.

• Clean burners and inside of grill/firebox.

• Trim fat from meat before grilling.

• Adjust (lower) temperature accordingly.

• Turn knobs to OFF. Turn gas off at LP cylinder. Leave lid in position and let fire

burn out. After grill cools, remove and clean all parts.

• Turn knobs to OFF. Clean burner and/or burner tubes. See burner cleaning

section of Use and Care.

• Clean carry-over tube(s) with wire brush.

Troubleshooting - Electronic Ignition

Problem (Ignition)

SECTION I

No sparks appear at any

electrodes when Electronic

Ignition Button is pressed;

no noise can be heard from

spark module.

SECTION II

No sparks appear at any

electrodes when Electronic

Ignition Button is pressed;

noise can be heard from spark

module.

SECTION III

Sparks are present but not at

all electrodes and/or not at

full strength

Possible Cause

• Battery not installed properly.

• Dead battery.

• Button assembly not

installed properly.

• Faulty spark module.

• Output lead connections not

connected.

• Output lead connections not

connected.

• Arcing to grill away from

burner(s).

• Weak battery.

• Electrodes are wet.

• Electrodes cracked or broken

“sparks at crack”.

Check Procedure

• Check battery orientation.

• Has battery been used previously?

• Check to insure threads are properly

engaged. Button should travel up and

down without binding.

• If no sparks are generated with new

battery and good wire connections,

module is faulty.

• Are output connections on and tight?

• Are output connections on and tight?

• If possible, observe grill in dark

location. Operate ignition system and

look for arcing between output wires

and grill frame.

• All sparks present but weak or at

slow rate.

• Has moisture accumulated on electrode

and/or in burner ports?

• Inspect electrodes for cracks.

Prevention/Solution

• Install battery (make sure that “+” and “–” connectors are

oriented correctly, with “+” on cap end.)

• Replace battery with new alkaline battery.

• Unscrew button cap assembly and reinstall, making sure

threads are aligned and engaged fully.

• Replace spark module assembly.

• Remove and reconnect all output connections at module and

electrodes.

• Remove and reconnect all output connections at module and

electrodes.

• If sparks are observed other than from burner(s), wire insulation

may be damaged. Replace wires.

• Replace battery with a new alkaline battery.

• Use paper towel to remove moisture.

• Replace cracked or broken electrodes.

37

Page 38

383940

Page 39

Page 40

.

AGA 8544 G

For support with your new barbecue, please call us at:

Amalgamated Hardware Merchants

Ph: 07 3208 1233

Email: enquiries@ahmaustralia.com.au

For use with propane gas only ● For Outdoor Use Only

DO NOT USE INDOORS.

Loading...

Loading...