Page 1

FILE NO. SM-CTV-O-123

SERVICE MANUAL

CHASSIS NO. CH-20

:

Please read this manual carefully before service.

Page 2

TABLE OF CONTENTS

SAFETY INSTRUCTIONS......................................................................................1

ADJUSTMENTS..................................................................................................... 4

STRUCTURE AND CHASSIS FUNCTION DESCRIPTION................................... 17

SERVICE DATA ................................................................................................... 17

REPLACEMENT OF PARTS.................................................................................. 55

APPENDIX CIRCUIT DIAGRAMS

Page 3

SERVICE MANUAL

INSTRUCTIONS FOR SERVICE SAFETY AND MAINTENANCE

ADJUSTMENTS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY

RADIATION PRECAUTION”, “SAFETY PRECAUTION”AND “PRODUCT

SAFETY NOTICE”INSTRUCTION BELOW.

X-RAY RADIATION PRECAUTION

The EHT must be checked every time the TV is serviced to ensure that the CRT does not emit

1.

X-ray radiation as result of excessive EHT voltage. The maximum EHT voltage permissible in

any operating circumstances must not exceed the rated value. When checking the EHT, use

the High Voltage Check procedure in this manual using an accurate EHT voltmeter.

2. The only source of X-RAY radiation in this TV is the CRT. The TV minimizes X-RAY radiation,

which ensures safety during normal operation. To prevent X-ray radiation, the replacement

CRT must be

3. Some components used in this TV have safety related characteristics preventing the CRT from

emitting X-ray radiation. For continued safety, replacement component should be made after

referring the PRODUCT SAFETY NOTICE below.

4. Service and adjustment of the TV may result in changes in the nominal EHT voltage of the

CRT anode. So ensure that the maximum EHT voltage does not exceed the rated value after

service and adjustment.

identical to the original fitted as specified in the parts list.

SAFETY PRECAUTION

WARNING: REFER SERVICING TO QUALIFIED SERVICE PERSONNEL ONLY.

1. The TV has a nominal working EHT voltage. Extreme caution should be exercised when

working on the TV with the back removed.

1.1 Do not attempt to service this TV if you are not conversant with the preca utions and procedures

for working on high voltage equipment.

1.2 When handling or working on the CRT, always discharge the anode to the TV chassis before

removing the anode cap in case of electric shock.

1.3 The CRT, if broken, will violently expel glass fragments. Use shatterproof goggles and take

extreme care while handling.

1.4 Do not hold the CRT by the neck as this is a very dangerous practice.

2. It is essential that to maintain the safety of the customer all power cord forms be replaced

exactly as supplied from factory.

3. Voltage exists between the hot and cold ground when the TV is in operation. Install a suitable

isolating transformer of beyond rated overall power when servicing or connecting any test

equipment for the sake of safety.

4. When replacing ICs, use specific tools or a static-proof electric iron with small power (below

35W).

5. Do not use a magnetized screwdriver when tightening or loosing the deflection yoke assembly

to avoid electronic gun magnetized and decrement in convergence of the CRT.

1

Page 4

SERVICE MANUAL

6. When remounting the TV chassis, ensure that all guard devices, such as nonmetal control

buttons, switch, insulating sleeve, shielding cover, isolating resistors and capacitors, are

installed on the original place.

7. Replace blown fuses within the TV with the fuse specified in the parts list.

8. When replacing wires or components to terminals or tags, wind the leads around the terminal

before soldering. When replacing safety components identified by the international hazard

symbols on the circuit diagram and parts list, it must be the company-approved type and must

be mounted as the original.

9. Keep wires away from high temperature components.

PRODUCT SAFETY NOTICE

CAUTION: FOR YOUR PROTECTION, THE FOLLOWING PRODUCT SAFETY NOTICE

SHOULD BE READ CAREFULLY BEFORE OPERATING AND SERVICING THIS TV SET.

1. Many electrical and mechanical components in this chassis have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual inspection and

the X-ray radiation protection afforded by them cannot necessarily be obtained by using

replacements rated at higher voltages or wattage, etc. Components which have these special

safety characteristics in this manual and its supplements are identified by the international

hazard symbols on the circuit diagram and parts list. Before replacing any of th ese componen ts

read the parts list in this manual carefully. Substitute replacement components which do not

have the same safety characteristics as specified in the parts list may create X-ray radiation.

2. Do not slap or beat the cabinet or CRT, since this may result in fire or explosion.

3. Never allow the TV sharing a plug or socket with other large-power equipment. Doing so may

result in too large load, causing fire.

4. Do not allow anything to rest on or roll over the power cord. Protect the power cord from being

walked on, modified, cut or pinched, particularly at plugs.

5. Do not place any objects, especially heavy objects and lightings, on top of the TV set. Do not

install the TV near any heat sources such as radiators, heat registers, stove, or other

apparatus that produce heat.

6. Service personnel should observe the SAFETY INSTRUCTIONS in this manual during use and

servicing of this TV set. Otherwise, the resulted damage is not protected by the manufacturer.

SAFETY SYMBOL DESCRIPTION

The lightning symbol in the triangle tells you that the voltage inside this product

may be strong enough to cause an electric shock. Extreme caution should be

exercised when working on the TV with the back removed.

This is an international hazard symbol, telling you that the components identified

by the symbol have special safety-related characteristics.

FDA This symbol tells you that the critical components identified by the FDA marking

have special safety-related characteristics.

UL

This symbol tells you that the critical components identified by the UL marking

2

Page 5

SERVICE MANUAL

have special safety-related characteristics.

C UL

VDE

This symbol tells you that the critical components identified by the C-UL marking

have been evaluated to the UL and C-UL standards and have special

safety-related characteristics.

This symbol tells you that the critical components identified by the VDE marking

have special safety-related characteristics.

MAINTENANCE

1. Place the TV set on a sta ble stand or base that is of adequate size and strength to prevent it

from being accidentally tipped over, pushed off, or pulled off. Do not place the set near or

over a radiator or heat register, or where it is exposed to direct sunlight.

2. Do not install the TV set in a place exposed to rain, water, excessive dust, mechanical

vibrations or impacts.

3. Allow enough space (at least 10cm) between the TV and wall or enclosures for proper

ventilation.

4. Slots and openings in the cabinet should never be blocked by clothes or other objects.

5. Please power off the TV set and disconnect it from the wall immediately if any abnormal

condition are met, such as bad smell, belching smoke, sparkling, abnormal sound, no

picture/sound/raster. Hold the plug firmly when disconnecting the power cord.

6. Unplug the TV set from the wall outlet before cleaning or polishing it. Use a dry soft cloth for

cleaning the exterior of the TV set or CRT screen. Do not use liquid cleaners or aerosol

cleaners.

3

Page 6

SERVICE MANUAL

ADJUSTMENTS

SET-UP ADJUSTMENTS

The following adjustments should be made when a complete realignment is required or a new

picture tube is installed.

Perform the adjustments in the following order:

1. Color purity

2. Convergence

3. White balance

Notes:

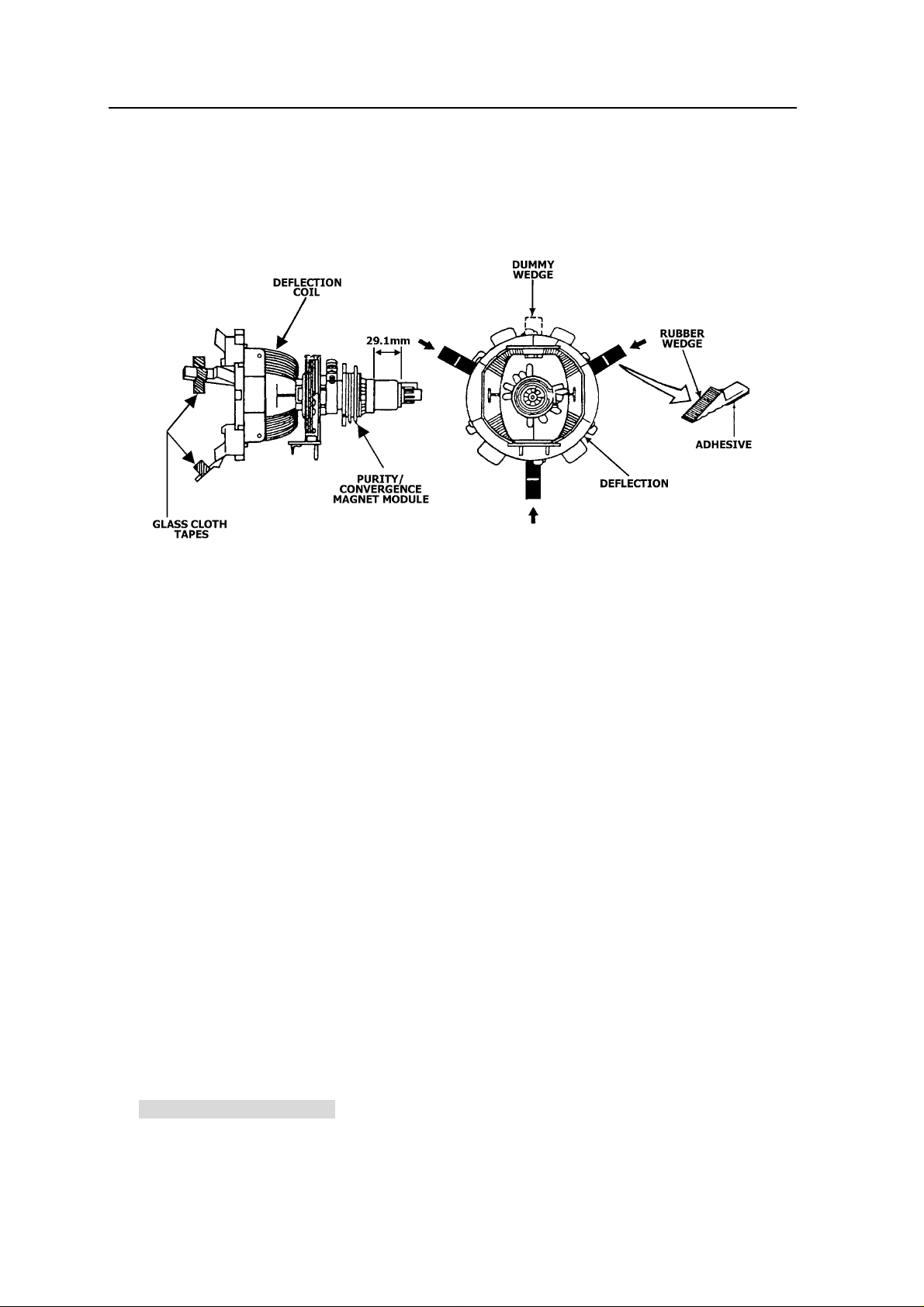

① The purity/convergence magnet assembly and rubber wedges need mechanical

positioning. Refer to Fig1, 2.

② For some picture tubes, purity/ convergence adjustments are not required.

1. Color Purity Adjustment

Preparation:

Before starting this adjustment, adjust the vertical sync, horizontal sync, vertical amplitude and

focus.

1.1 Face the TV set north or south.

1.2 Connect the power plug into the wall outlet and turn on the main power switch of the TV set.

1.3 Operate the TV for at least 15 minutes.

1.4 Degauss the TV set using a specific degaussing coil.

1.5 Set the brightness and contrast to maximum.

1.6 Counter clockwise rotate the R /B low brightness potentiometers to the end and rotate the

green low brightness potentiometer to center.

1.7 Receive green raster pattern signals.

1.8 Loosen the clamp screw holding the deflection yoke assembly and slide it forward or backward

to display a vertical green zone on the screen. Rotate and spread the tabs of the purity magnet

around the neck of the CRT until the green zone is located vertically at t he center of the screen.

1.9 Slowly move the deflection yoke assembly forward or backward until a uniform green screen is

obtained.

1.10 Tighten the clamp screw of the assembly temporarily. Check purity of the red raster and blue

raster until purities of the three rasters meet the requirement.

2. Convergence Adjustment

Preparation:

Before attempting any convergence adjustment, the TV should be operated for at least 15

minutes.

2.1 Center convergence adjustment

2.1.1 Receive dot pattern.

2.1.2 Adjust the brightness/contrast controls to obtain a sharp picture.

4

Page 7

SERVICE MANUAL

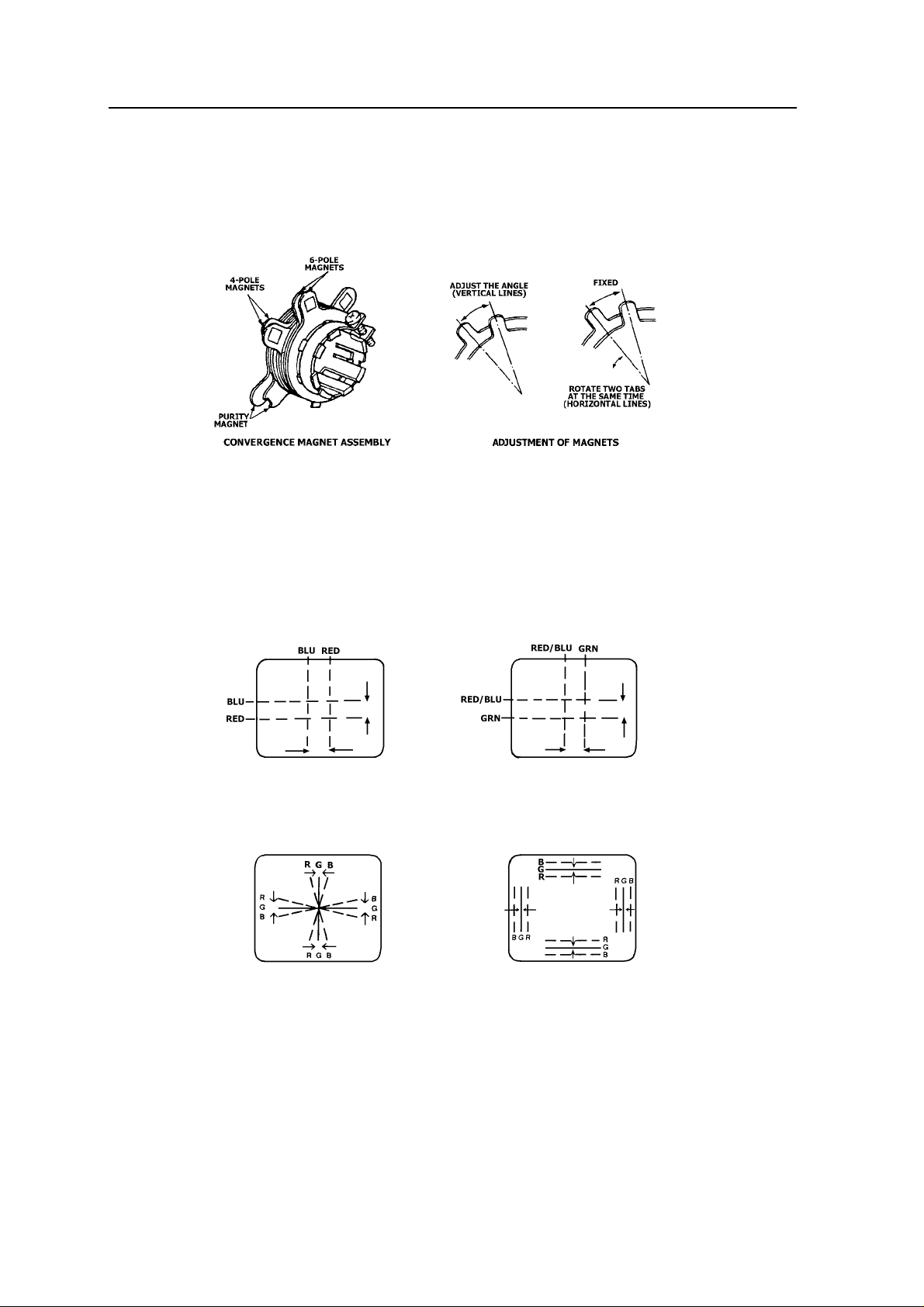

2.1.3 Adjust two tabs of the 4-pole magnet to change the angle between them and red and blue

vertical lines are superimposed each other on the center of the screen.

Fig. 1

Yok

2.1.4 Turn both tabs at the same time keeping the angle constant to superimpose red and blue

horizontal on the center of the screen.

2.1.5 Adjust two tabs of the 6-pole magnet to superimpose red/blue line and green line.

2.1.6 Remember red and blue movement. Repeat steps 2.1.3~2.1.5 until optimal convergence is

obtained.

2.2 Circumference convergence adjustment

2.2.1 Loosen the clamp screw holding the deflection yoke assembly and allow it tilting.

2.2.2 Temporarily put the first wedge between the picture tube and deflection yoke assembly.

Move front of the deflection yoke up or down to obtain better convergence in circumference.

Push the mounted wedge in to fix the yoke temporarily.

2.2.3 Put the second wedge into bottom.

2.2.4 Move front of the deflection yoke to the left or right to obtain better convergence in

circumference.

2.2.5 Fix the deflection yoke position and put the third wedge in either upper space. Fasten the

deflection yoke assembly on the picture tube.

2.2.6 Detach the temporarily mounted wedge and put it in either upper space. Fasten the

deflection yoke assembly on the picture tube.

2.2.7 After fastening the three wedges, recheck overall convergence and ensure to get optimal

convergence. Tighten the lamp screw holding the deflection yoke assembly.

3. White Balance Adjustment

Generally, white balance adjustment is made with professional equipment. It’s not practical to

get good white balance only through manual adjustment. For TVs with I

2

C bus control, change

5

Page 8

the bus data to adjust white balance.

SERVICE MANUAL

Fig. 2

4-pole Magnet Movement 6-pole Magnet Movement

Center Convergence by Convergence Magnets

Incline the Yoke Up (or Down) Incline the Yoke Right (or Left)

Circumference Convergence by DEF Yoke

Fig.3

6

Page 9

SERVICE MANUAL

CIRCUIT ADJUSTMENTS

Preparation:

Circuit adjustments should be made only after completion of set-up adjustments.

Circuit adjustments can be performed using the adjustable components inside the TV set. For TVs

2

C bus control, first change the bus data.

with I

1. Degaussing

A degaussing coil is built inside the TV set. Each time the TV is powered on, the degaussing

coil will automatically degauss the TV. If the TV is magnetized by external strong magnetic field,

causing color spot on the screen, use a specific degausser to demagnetize the TV in the

following ways. Otherwise, color distortion will be shown on the screen.

1.1 Power on the TV set and operate it for at least 15 minutes.

1.2 Receive red full-field pattern.

1.3 Power on the specific degausser and face it to the TV screen.

1.4 Turn on the degausser. Slowly move it around the screen and slowly take it away from the TV.

1.5 Repeat the above steps until the TV is degaussed completely.

2. Confirmation and Adjustment for Voltage

Caution: +B voltage has close relation to high voltage. To prevent X-ray radiation, set +B

voltage to the rated value.

2.1 Power on the TV and receive Philips test pattern.

2.2 Check the resistors and coils for being burned. (If the fuse is burned out, do not power on the

TV again until the cause is found out.)

2.3 Measure voltages of test points with the digital voltmeter. Measure the CRT high voltage with

the high-voltage testing equipment and heater voltage with the high-frequency effective

voltmeter. The rated values are shown as table 1

Table 1

Test Point Voltage (V)

One Pin of L807

Positive of C834

Positive of C837

Positive of C832

One Pin of L806

Positive of C839

Positive of VD822

Positive of C429

Positive of C436A

145V±1.5V

12V±1V

12V±1V

16V±1V

16V±1.5V

3.3±0.3V

3.9±0.3V

195V±5V

48V±3V

(Continued)

7

Page 10

SERVICE MANUAL

Positive of C434

Positive of C840

One Pin of 326

Positive of C424

Heater 6.3V±0.3Vrms

CRT anode voltages

3. High Voltage Inspection

Caution: No high voltage adjustment components inside the chassis. Please perform

high voltage inspection in the following ways.

3.1 Connect a precise static high voltmeter to the second anode (inside the high voltage cap) of the

CRT.

3.2 Plug in the supply socket (220V ~, 50Hz) and turn on the TV. Set the brightness and contrast to

minimum (0μA).

3.3 The high voltage reading should be less than the limited EHT voltage.

3.4 Change the brightness from minimum to maximum, and ensure high voltage not beyond the

limitation in any case.

Nominal EHT voltage Limited EHT voltage Remarks

29KV±1.5KV 33KV for 29" CRT

31.0KV±1.5KV 35KV for 34" CRT

Note: The data sheet may differ dependent on different CRTs.

4. Focus Adjustment

Caution: Dangerously high voltages are present inside the TV. Extreme caution should

be exercised when working on the TV with the back removed.

4.1 After removing the back cover, look for the FBT on the main PCB. There should be a FCB on

the FBT.

4.2 Power on the TV and preheat it for 15 min.

4.3 Receive a normal TV signal. Rotate knob of the FCB until you get a sharp picture.

13.5V±1V

8V±0.5V

12V±1V

5V±0.5V

29KV±1.5KV (For 29” CRT)

31.0KV±1.5KV (For 34” CRT)

Before Adjusting After Adjusting

Fig. 4

8

Page 11

SERVICE MANUAL

5. SERVICE mode

5.1 To enter the SERVICE mode

Set the volume to 0 by the remote control. Then press and hold the MUTE button on the

remote control and MENU button on the TV at the same time for over 2 seconds. In the S mode,

press the POWER button to quit the S mode.

Use the ↓/↑buttons on the remote control to highlight an adjustment and the ←/→ buttons

to adjust it.

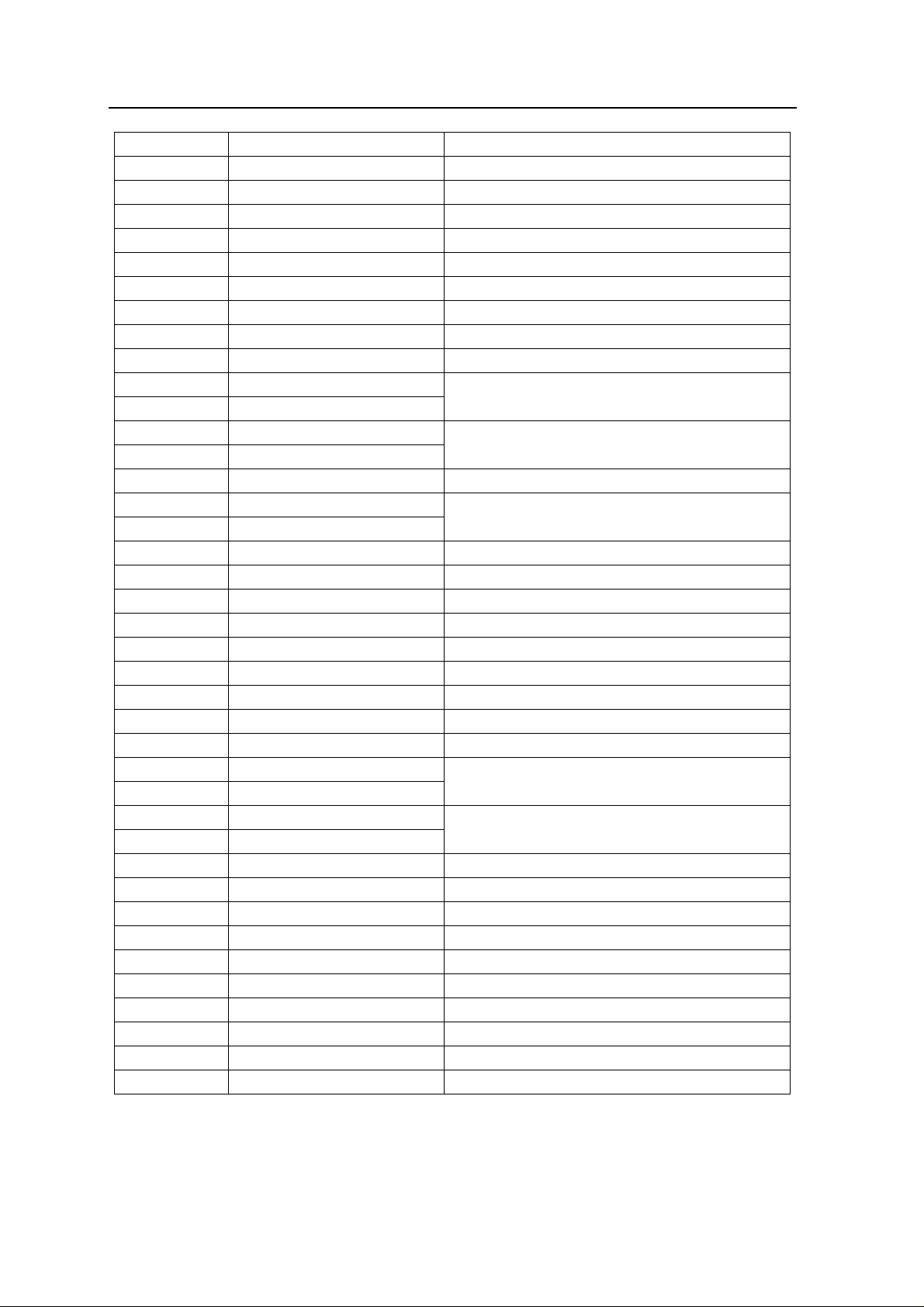

Bus data

5.2

Item Adjustment Description

S

(“S”is red and other items are yellow.)

Table 2 Bus data

VX00 19 4:3

VX50 01 16:9

VX99 38 ZOOM

5VS/6VS Set to the optimal mode Half vertical center for 50/60Hz

5VA/6VA Set to the optimal mode Vertical amplitude for 50/60Hz

5SC/6SC Set to the optimal mode Vertical S correction for 50/60Hz

5VSH/6VSH Set to the optimal mode Vertical center for 50/60Hz

5VOF/6VOF Set to the optimal mode Character position for 50/60Hz

5HP/6HP Set to the optimal mode Parallelogram correction for 50/60Hz

5HB/6HB Set to the optimal mode Curve correction for 50/60Hz

5HSH/6HSH Set to the optimal mode Horizontal center for 50/60Hz

5HA/6HA Set to the optimal mode Horizontal amplitude for 50/60Hz

5EW/6EW Set to the optimal mode Pincushion and barrel correction for 50/60Hz

5UCR/6UCR Set to the optimal mode Upper corner correction for 50/60Hz

5LCR/6LCR Set to the optimal mode Lower corner correction for 50/60Hz

5TC/6TC Set to the optimal mode Trapezoidal correction for 50/60Hz

RCUT White balance adjustment Red gun cutoff voltage

GCUT White balance adjustment Green gun cutoff voltage

RDRV Dark balance adjustment Red gun drive voltage

GDRV Dark balance adjustment Green gun drive voltage

BDRV 20 Blue gun drive voltage

YDFP 8 PAL brightness delay time

YDFN 2 NTSC brightness delay time

YDFS 2 SECAM brightness delay time

(Continued)

9

Page 12

SERVICE MANUAL

RAGC Set to the optimal mode AGC adjustment(19—1E recommended)

VOL 29 AV output volume control for TDA7442

WBF 30

WBR 30

SOC 1 PWL clip level(5%)

PWL 8 White peak limit

IFO 32 IF phase lock

PEAK 2

BLS 0 Blue extension

BKS 1 Black stretch

CON100 23

CON50 0D

BRI100 32

BRI50 20

COL100 3F Sub color

SHP100 3B

SHP50 1C

VMDL 03 VM delay

VMAM 03 VM amplitude

COR 3

WS 0 White stretch setting

HDOL 0B Cathode drive level

AGCS 1 AGC speed

VG2B 24 Brightness setting when adjusting G2

VENH 03 Vertical enhance

CBNR 03 Comb noise reduce

TRE1 64

TRE2 32

BAS1 64

BAS2 32

VOLA 40/53 MSP3410G/TDA7442

VOLB 46/58 MSP3410G/TDA7442

VOLC 4B/60 MSP3410G/TDA7442

VOLD 51/63 MSP3410G/TDA7442

LOUD 20 Loudness (not for TDA7442)

SC1 74 SCART1 PRESCAL (not for TDA7442)

SC2 74 SCART2 PRESCAL (not for TDA7442)

SCIN 1E SCART IN PRESCAL (not for TDA7442)

FMIN 13 FM frequency bias setting (not for TDA7442)

NNIN 5A NICAM setting (not for TDA7442)

Sub contrast

Sub brightness

Sub sharpness

Treble linearity

Bass linearity

(Continued)

10

Page 13

SERVICE MANUAL

WOCF 1E ( not for TDA7442)

MEFF 44

MAMP FF

MHAR 64

MLOP 19

MHIP 05

OP1

OP2 20 Option set byte 2

OP3 0C Option set byte 3

OP4 11 Option set byte 4

OP5 88 Option set byte 5

OP6 0F Option set byte 6

OP7 08 Option set byte 7

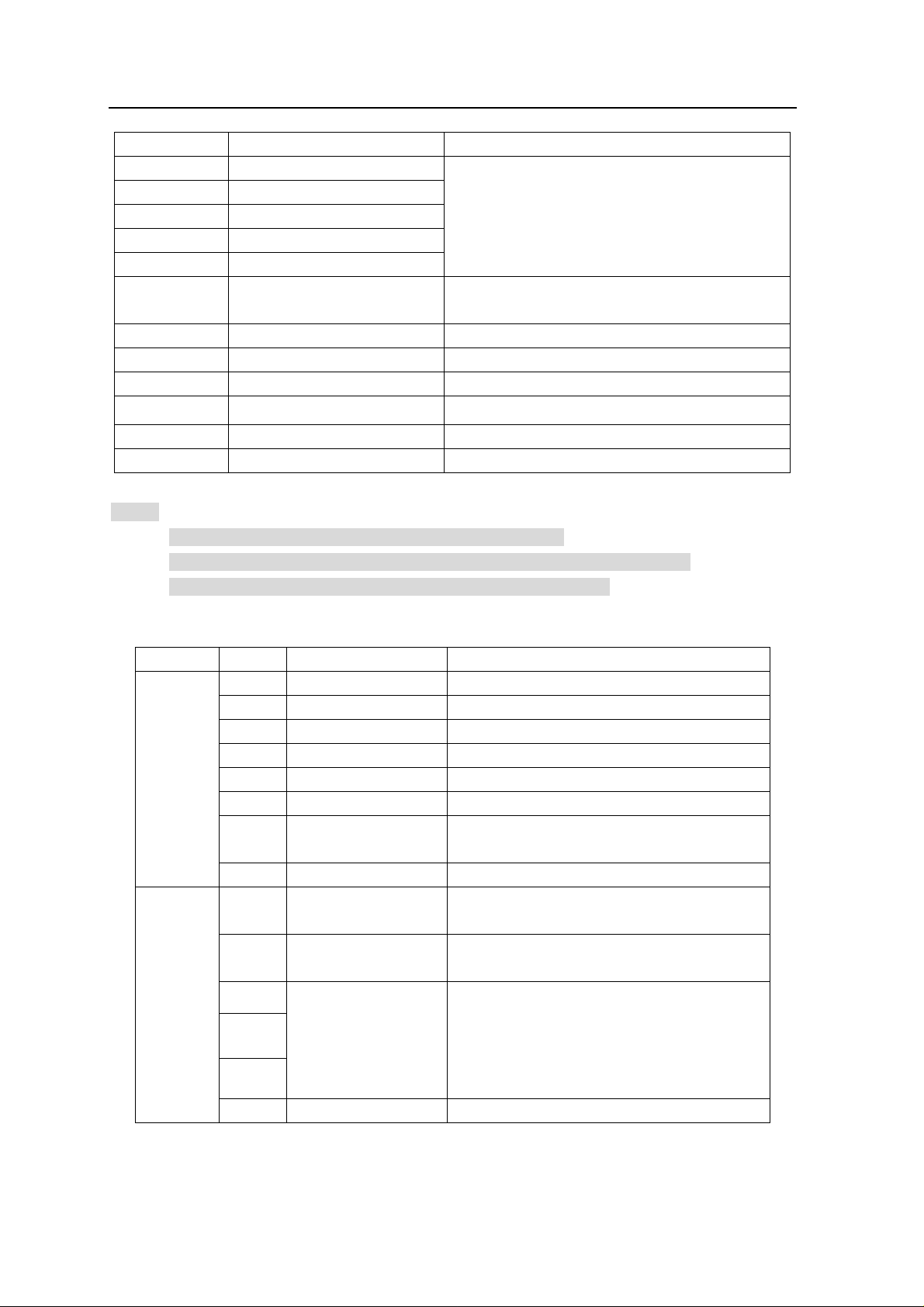

Notes:

① The data sheet may differ dependent on different models.

② The data sheet may differ dependent on different CRTs for the same model.

③ Designs and specifications are subject to change without notice.

Bit Item Description

OP1

OP2

F8 (For PF29T18/34t18 only)

D8 (For CPF29T99 only)

Table 3 Option bit setting

0 OP_NICAM 1: MSP3410;0: TDA7442

1 OP_COMB 1: Yes; 0: No

2 OP_SVM 1: Yes; 0: No

3 OP_AV2 1: Yes; 0: No

4 OP_FAV 1: Yes; 0: No

5 OP_FAVS 1: Yes; 0: No

6 OP_STORE

7 OP_OSO 1

0 OP_AVC

1 OP_MDB

2

3

4

5 OP_ PARENT 1 (Child lock)

Text setting

MDB setting (not for TDA7442)

Option set byte 1

0: West Europe

1: East Europe

1: MSP3410;

0: TDA7442

1: MSP3410;

0: TDA7442

000: West Europe text

001: East Europe text

010: Ukrainian text

100: Russian text

110: Greek text

(Continued)

11

Page 14

SERVICE MANUAL

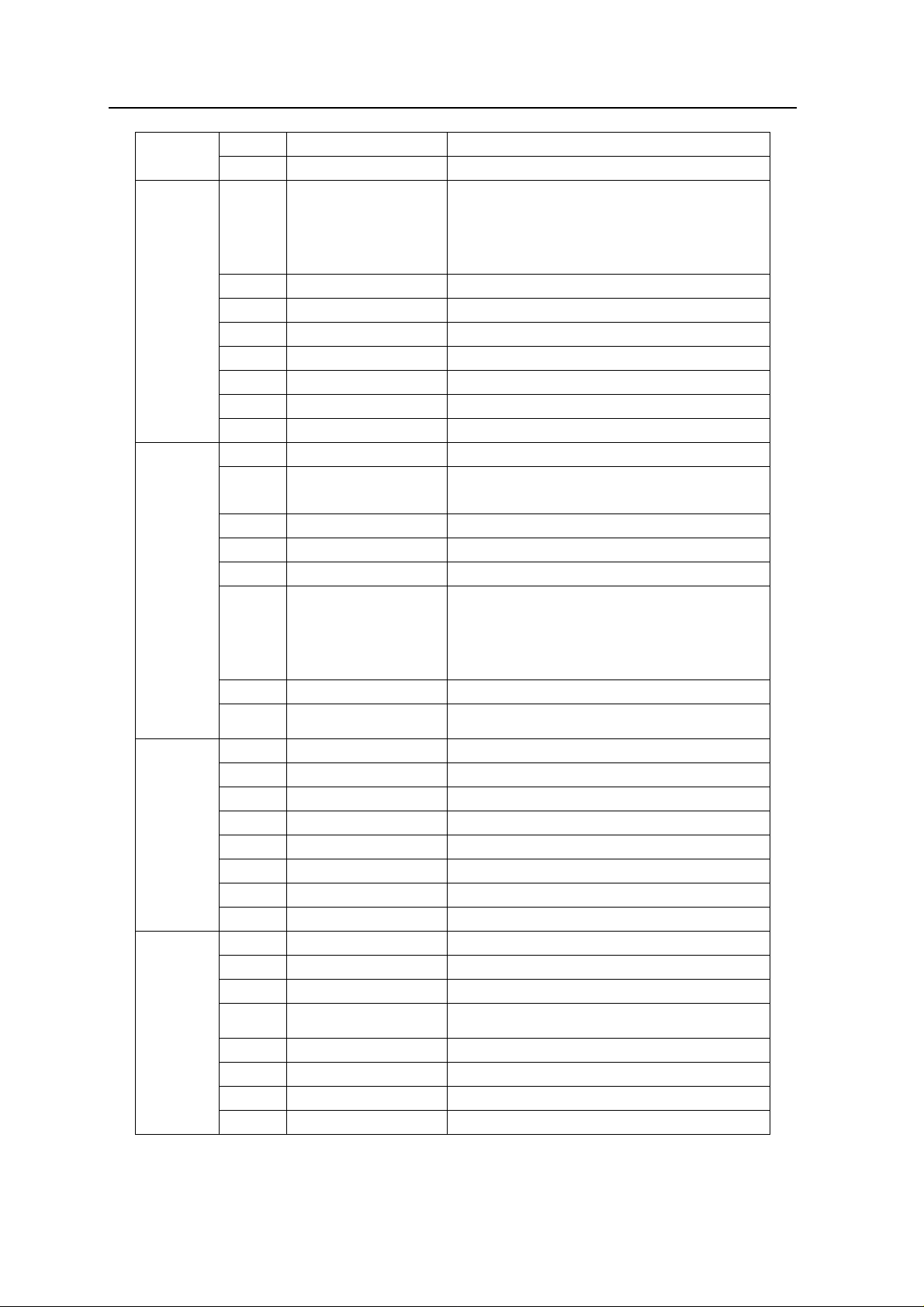

OP3

OP4

6 OP_TILT Tilt correction

7 OP_FSL 0

1: Black screen available when changing

0 OP_BSCREEN

1 OP_5060 0

2 OP_DK 1: D/K option

3 OP_BG 1: B/G option

4 OP_I 1: I option

5 OP_L 1: L option

6 OP_AUTO_SOUND 1: MSP3410;0: TDA7442

7 OP_EQUAL 1: MSP3410;0: TDA7442

0 OP_FMWS 1

1 OP_POWER

2 OP_COUNTRY 1: COUNTRY display option

3 OP_LOGO 0: LOGO display not available

4 OP_DFL 1

5 OP_BLUE_BACK

6 OP_ACI 1: Yes; 0: No

channels;

0: Black screen not available when changing

channels

1: Memory on

0: Soft on

0: Blue back not available under no signal

condition;

1: Blue back available under no signal

condition

OP5

OP6

7 OP_ATS 1: Yes; 0: No

0 OP_LANG0 0

1 OP_LANG1 0

2 OP_LANG2 0

3 OP_LANG3 0

4 OP_SOUND0 0

5 OP_SOUND1 0

6 OP_SOUND2 1

7 OP_STRIKE 1

0 OP_MUTE 1

1 OP_TUNER 1: West Europe 0: BG

2 OP_AFT 1

3 OP_ENGLISH 1

4 OP_FRANCE 1

5 OP_GERMAN 1

6 OP_SPAIN 1

7 OP_DANMARK 1

(Continued)

12

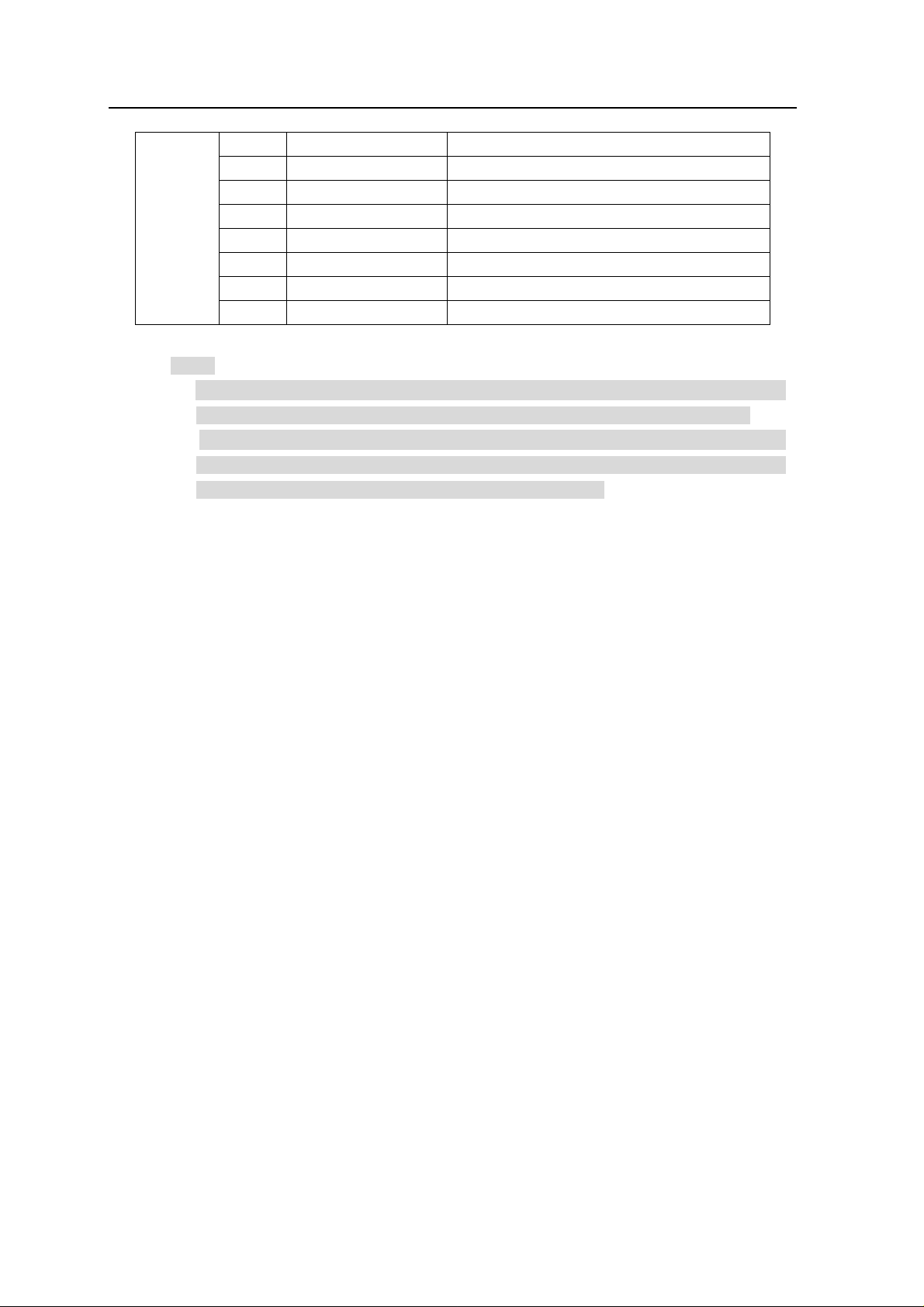

Page 15

SERVICE MANUAL

0 OP_HOLAND 1

1 OP_SUOMI 1

2 OP_GREECE 1

OP7

3 OP_ITALY 1

4 OP_NORWAY 1

5 OP_PORTUAL 1

6 OP_SWEDEN 1

7 OP_TURKY 1

Note :

① Bit6, Bit5, Bit4 in OP5 are outgoing audio option settings as follows: 000: East Europe

(D/K); 001: West Europe (B/G); 010: UK (I); 110: France (L); 100: Europe (Auto).

② Bit3, Bit2, Bit1 and Bit0 in OP5 are outgoing language option settings as follows:

English, French, German, Spanish, Danish, Dutch, Finnish, Greek, Italian, Norwegian,

Portuguese, Swedish and Turkish successively begun with.

13

Page 16

SERVICE MANUAL

STRUCTURE AND CHASSIS FUNCTION DESCRIPTION

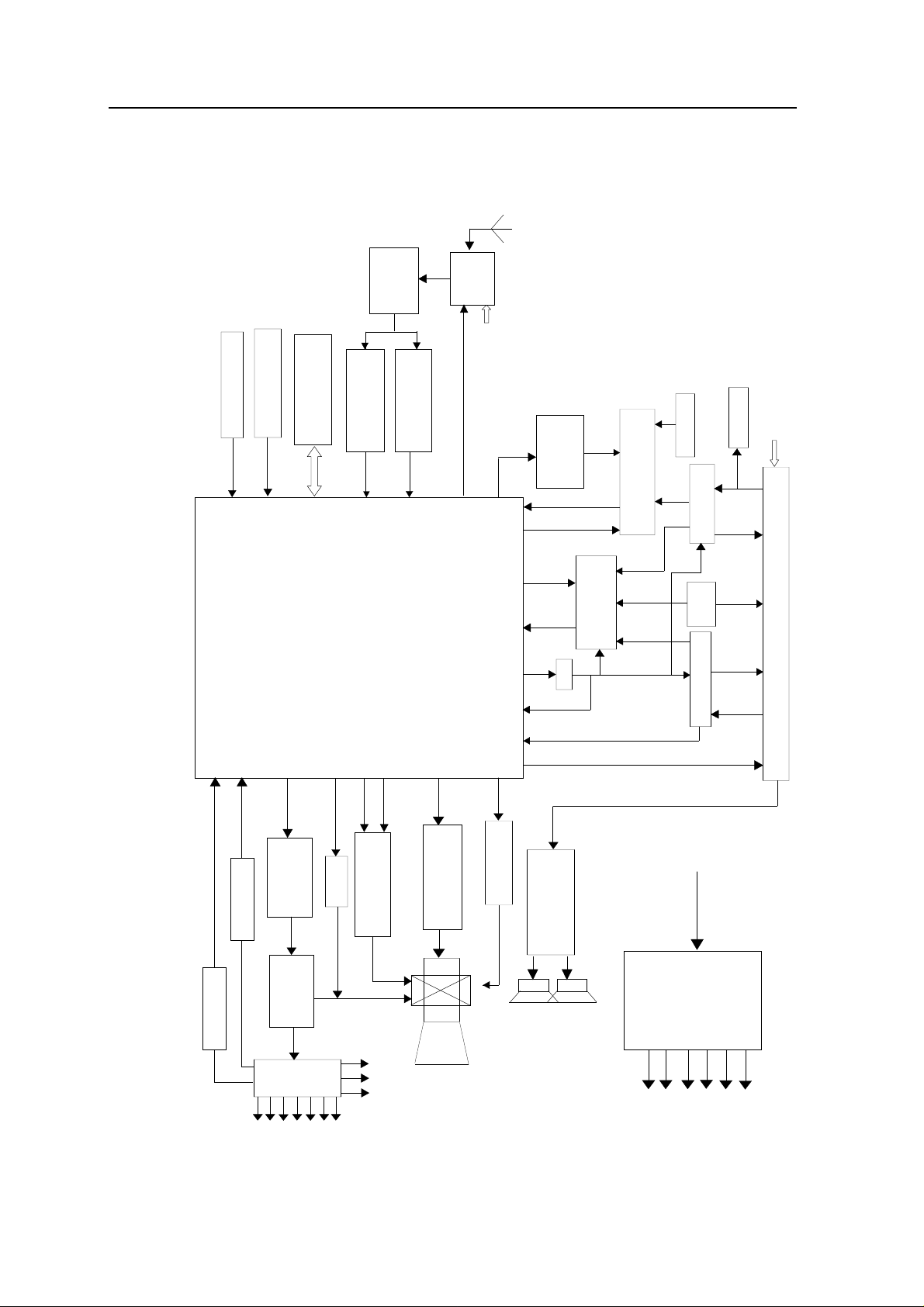

1. Structure Block Diagram

V002

amplifier

IF Pre-

Circuit for Buttons

Remote Sensor

Fig.5 Structure Block Diagram for CH-20 Chassis

AT24C16 (N102)

EEPROM

IIC

K9656M (Z002)

SAW Filter

SIF

K3953M (Z003)

(UOC)

TDA9594 (N101)

Microcontroller

Small Signal Processor &

H-out

V-out-

V-out+

TDA8359 (N401)

EHT Circuit

V402,T401

Including

Line Drive

Vertical Output

E-W

Output V404

ABL Circuit

Horizontal

FBT

+200V

+14V

Voltage

HV

FV

SV

Filament

T402

+8V

+12V-2

+5V

+45V

SAW Filter

VIF

TDA6108JF

A001

Tuner

AGC

R/G/B

Video Amplifier

To VM Coil

CRT

IIC

47

SVM Circuit

73,78

67,68

CTRL SIG

42

38

40

48

SVM

(N501)

TC90A49

CTRL SIG

AV-CVBS

IFO

TV-CVBS

TDA8944J (N603)

Amplifier

Sound Power

Speakers

Comb Filter

Y/C

Trap

R/L

(N301)

Main

Y/C

HEF4052

Video Switch

R/G/B Input

HEF4052 (N302)

Video Switch

CVBS 2

AV-CVBS

CVBS 1 In

Audio Out

+3.3V

Y/C

+3.9V

S- Video In

SCART Jack 2

V1 Out

AV In

Side

SCART Jack 1

V2 Out

50/60Hz

220-240V AC

(N801)

STR-W6856

Power Circuit

+15V-2

+12V

Audio Out

R/L2 Out

R/L2 In

R/L3 In

R/L1 In

R/L1 Out

+145V

+15V-1

IIC

Audio Processor TDA7442 (N602)

14

Page 17

SERVICE MANUAL

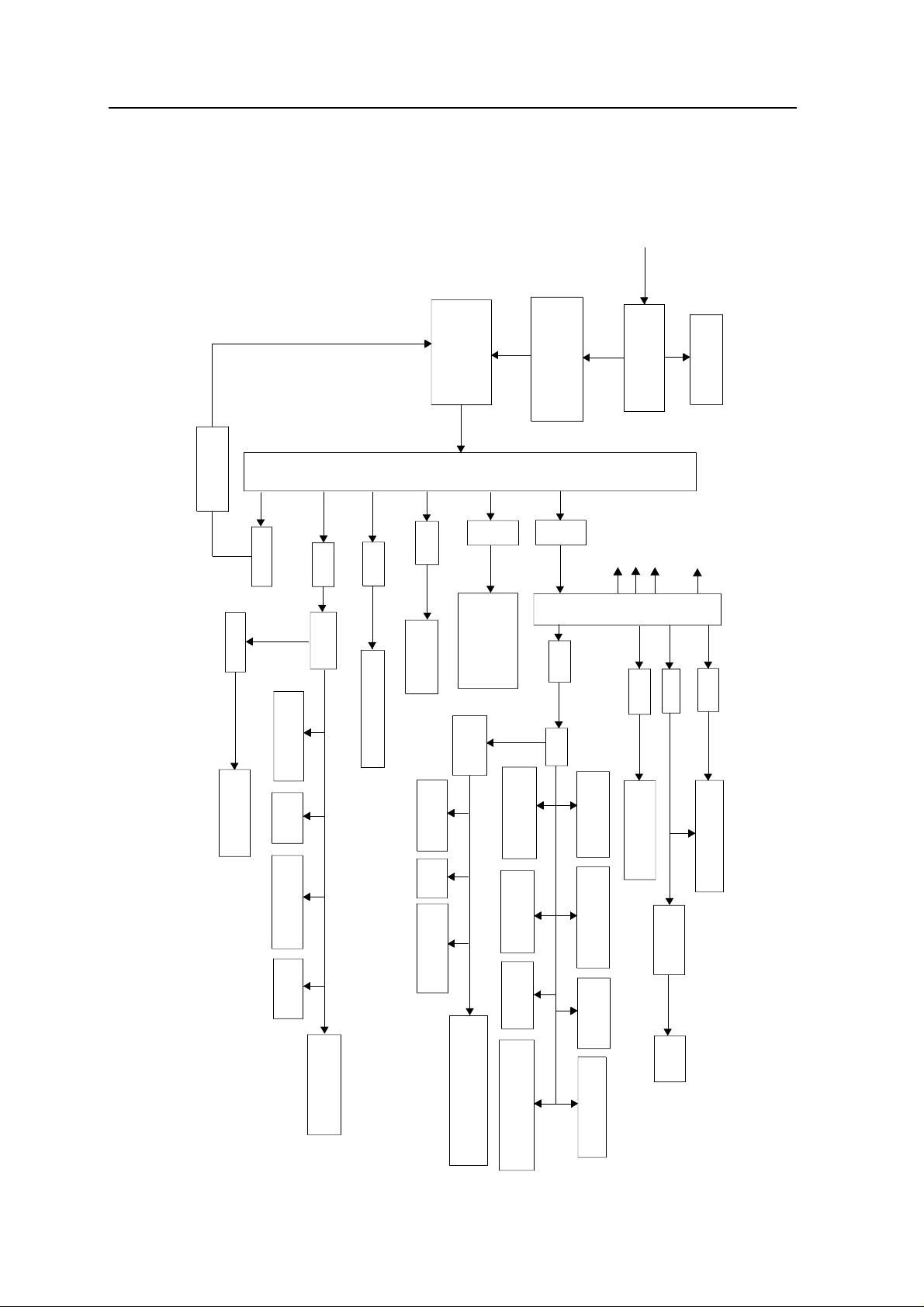

2. Block Diagram for Supply Voltage System

Fig.6 Block Diagram for Supply Voltage System for CH-20 Chassis

Circuit N801

Feedback

VD816

+3.9V

VD816

TDA9594 (N101)

TDA9594 (N101)

UOC

UOC

Bus Data

Driver Circuit

LED

Circuit

Hs0038

Remote Sensor

Buttons

Circuit for

VD820

V806

Regulator

+3.3V

AT24C16 (N102)

EEPROM

VD817

+12V-1

Fl501 HFD2-CL2-M

(N801)

STR-W6856

and Control

Power Regulation

Switch Transformer BCK-24339L

VD818

VD815

+15V-1

(N603)

TDA8944J

Amplifier

Circuit

Line Drive

V405

Regulator

TC90A49

Comb Filter

+5V

A001

Tuner

HEF4052

Video Switch

Circuit Including KAV, etc.

Control Signal Driver

+15V-2

Sound Power

lifier V301,V302

V505-V510

Circuit

V303,V304,V310,V311

Video Out Amp-

Y/C Amplifier

ABL & EHT

Audio Out Amplifier

C804,C807,C808

VD801-VD804,C803,

Bridge Rectifier

VD819

+145V

HV

FBT T402

VD410

+12V-2

V808

+8V

TDA9594 (N101)

UOC

TDA7442 (N602)

Audio Processor

V002

IF Amplifier

CRT RGB Board

AC

50/60Hz

220-240V

Circuit

Interference-proof

Filament

SV

FV

Voltage

VD414

VD412

+45V

+200V

TDA6108JF

Video Amplifier

VD003

Regulator

+33V

A001

Tuner

Circuit

Degaussing

VD411

+14V

TDA8359 (N401)

Vertical Output

15

Page 18

SERVICE MANUAL

3. Chassis Description

General Description

CH-20 chassis is applied in CPF29T99/PF29T18/34T18, which mainly uses Philips’ advanced

2

UOC-ultimate one chip TDA959X and I

microcontroller and small signal processor, the TDA959X features high-integrity,

high-performance-to-price ratio and high-reliability and advanced functions with fewer external

components, which provide much more convenience for manufacturing and technical service.

In addition, TDA959X is good in geometric distortion, more suitable for pure flat TV sets.

The following features are available in the chassis:

RF color systems: PAL/SECAM

Video systems: PAL/SECAM/NTSC

Sound systems: D/K B/G I H L L1

100 programs preset

2

C bus control

I

Audio output: Main channel: 7W+7W (distortionless) (THD 7%)

Selectable sound modes: Music, Theatre, Speech, Personal

Selectable picture modes: Personal, Rich, Natural, Soft

AV stereo + audio processing (MSP34XX or TDA7442)

PAL/NTSC 3-line comb filter

Earphone output

Selectable aspect ratio: 4:3, 16:9, Zoom

Auto identification and changeover of vertical frequency 50/60Hz

Auto identification of SCART picture input format (4:3,16:9)

Auto identification of SCART1 signal source input (RGB/CVBS)

The chassis mainly uses the following ICs and assemblies.

Table 4 Key ICs and Assemblies

C-bus controlled IC. With combination of

Serial No. Position Type Function Description

1 N101 TDA9594H Microcontroller and small signal processor (UOC)

2 N102 AT24C16 EEPROM

3 N602 TDA7442 Audio processor

4 N603 TDA8944J Sound power amplifier

5 NY01 TDA6107JF /TDA6108JF Video amplifier

6 N501 TC90A49P COMB Filter

7 N301/N302 HEF4052BP Electronic switch circuit

8 N401 TDA8359J Vertical scan output stage circuit

9 N801 STR-W6856 Power module

10 A001 TDQ-6B3-P/ TAF5-EPB2 Tuner

16

Page 19

SERVICE MANUAL

SERVICE DATA

1. Technical Data of Key ICs

1.1 Microcontroller and Small Signal Processor TDA959X

(1) General Description

The various versions of the TDA959X H/PS-N1 series combine the functions of a video

processor together with a m-Controller and US Closed Caption decoder. Most versions have

a Teletext decoder on board. The Teletext decoder has an internal RAM memory for 1 or 10

page text. Some versions can generate a ‘Mixed-down’ I-signal for the demodulation of DVB

signals. The ICs are intended to be used in economy television receivers with 110 picture

tubes.

The ICs have supply voltages of 8 V and 3.3 V and they are mounted in an SDIP-64 or QFP

80 envelope.

The features are given in the following feature list. The differences between the various ICs

are given in the table.

(2) Features

TV-signal processor

Available in all versions

● Multi-standard vision IF circuit with alignment-free PLL demodulator

● Internal (switchable) time-constant for the IF-AGC circuit

● Integrated chrominance trap circuit Integrated luminance delay line with adjustable delay

time

● Picture improvement features with peaking (with switchable centre frequency, depeaking,

variable positive/negative overshoot ratio and video dependent coring), dynamic skin tone

control and blue- and black stretching

● Scan Velocity Modulation output

● Integrated chroma band-pass filter with switchable centre frequency

● Only one reference (12 MHz) crystal required for the m-Controller, Teletext- and the colour

decoder

● Multi-standard colour decoder with automatic search system

● Internal base-band delay line

● Indication of the Signal-to-Noise ratio of the incoming CVBS signal

● A linear RGB/YUV/YPBPR input with fast blanking for external RGB/YUV sources. The

synchronization circuit can be connected to the incoming Y signal. The Text/OSD signal s are

internally supplied from the m-Controller/Teletext decoder.

● RGB Cathode Calibration’, white point and black level off-set adjustment so that the colour

temperature of the dark and the light parts of the screen can be chosen independently.

● Contrast reduction possibility during mixed-mode of OSD and Text signals

● Adjustable ‘wide blanking’ of the RGB outputs

● Horizontal synchronization with two control loops and alignment-free horizontal oscillator

17

Page 20

SERVICE MANUAL

● Vertical count-down circuit

● Vertical driver optimized for DC-coupled vertical output stages

● Horizontal and vertical geometry processing

● Horizontal and vertical zoom function for 16 : 9 applications

● Horizontal parallelogram and bow correction for large screen picture tubes

● Low-power start-up of the horizontal drive circuit

Available in S-DIP 64 versions

● Sou r c e s e l e ct i o n between t h e ‘ i n t e r n a l ’ C VBS and an external CVBS or Y/C signal

Available in QFP-80 versions

● The mono in tercarrier soun d circuit has a selective F M-PLL demo dulator wh ich can be switched to

the different FM sound freq uencies (4.5/5.5/6 .0/6.5 MHz). The quality of this system is such that the

external band-pass filters can be omitted.

● The FM-PLL demodulator can be set to centre frequencies of 4.74/5.74 MHz so that a second sound

channel can be demodulated. In such an application it is necessary that an external bandpass filter is

inserted.

The vision IF and mono intercarrier sound circuit can be used for the demodulation of FM radio signals

● The QSS and mono FM functionality are both available so that an FM/AM TV receiver can be built

without the use of additional ICs

● Video switch with 2 external CVBS inputs and a CVBS output. One of the CVBS inputs can be used

as Y/C input.

● 2 external audio inputs. The selection of the various inputs is coupled to the selection of the CVBS

signals

● Switchable group delay correction in the CVBS path

● White stretching and a switchable DC transfer ratio for the luminance signal

m-Controller

● 80C51 m-controller core standard instruction set and timing

● 1 ms machine cycle

● 32 - 128Kx8-bit late programmed ROM

● 3 - 12Kx8-bit Auxiliary RAM (shared with Display)

● Interrupt controller for individual enable/disable with two level priority

● Two 16-bit Timer/Counter registers

● One 16-bit Timer with 8-bit Pre-scaler

● WatchDog timer

● Auxiliary RAM page pointer

● 16-bit Data pointer

● Stand-by, Idle and Power Down modes

● 14 bits PWM for Voltage Synthesis Tuning

● 8-bit A/D converter with 4 multiplexed inputs

● 5 PWM (6-bits) outputs for control of TV analogue signals

18

Page 21

SERVICE MANUAL

Data Capture

● Text memory for 1 or 10 pages

● In the 10 page versions inventory of transmitted Teletext pages stored in the Transmitted Page Table

(TPT) and Subtitle Page Table (SPT)

● Data Capture for US Closed Caption

● Data Capture for 525/625 line WST, VPS (PDC system A) and Wide Screen Signalling (WSS) bit

decoding

● Automatic selection between 525 WST/625 WST

● Real-time capture and decoding for WST Teletext in Hardware, to enable optimized m-processor

● Automatic selection between 625 WST/VPS on line 16 of VBI

● throughput

● Automatic detection of FASTEXT transmission

● Real-time packet 26 engine in Hardware for processing accented, G2 and G3 characters

● Signal qua li t y detector for video and WST/VPS data types

● Comprehensive teletext language coverage

● Full Field and Vertical Blanking Interval (VBI) data

● capture of WST data

Display

● Teletext and Enhanced OSD modes

● Features of level 1.5 WST and US Close Caption

● Serial and Parallel Display Attributes

● Single/Double/Quadruple Width and Height for characters

● Scrolling of display region

● Variable flash rate controlled by software

● Enhanced display features including overlining, underlining and italics

● Soft colours using CLUT with 4096 colour palette

● Globally selectable scan lines per row (9/10/13/16) and character matrix [12x10, 12x13, 12x16

(VxH)]

● Fringing (Shadow) selectable from N-S-E-W direction

● Fringe colour selectable

● Meshing of defined area

● Contrast reduction of defined area

● Cursor

● Special Graphics Characters with two planes, allowing four colours per character

● 32 software redefinable On-Screen display characters

● 4 WST Character sets (G0/G2) in single device (e.g. Latin, Cyrillic, Greek, Arabic)

● G1 Mosaic graphics, Limited G3 Line drawing characters

● WST Character sets and Closed Caption Character set in single device

19

Page 22

SERVICE MANUAL

e

(3) Functional Difference between the Various IC Versions

Table 5

IC Version (TDA)

9590PS 9591PS 9592PS

9593PS 9594PS

9590H 9591H 9592H 9593H 9594H

TV range 110 110 110 110 110 110 110 110 110 110

Mono intercarrier multi-standard

sound demodulator (4.5 - 6.5 MHz)

√ √ √ √ √

with switchable centre frequency

Audio switch √ √ √ √ √

Automatic Volume Leveling or

subcarrier output (for comb filter

√ √ √ √ √

applications)

QSS sound IF amplifier with separate

input and AGC circuit

AM sound demodulator without extra

reference circuit

Generation of a ‘Mixed-down’ I-signal

for the demodulation of DVB signals

√ √ √ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √ √ √

√ √ √ √

FM radio option (via QSS amplifier) √ √ √ √ √

FM radio option (with FM tuner) √ √ √ √ √

PAL decoder √ √ √ √ √ √ √ √ √ √

SECAM decoder √ √ √ √ √ √ √ √ √ √

NTSC decoder √ √ √ √ √ √ √ √ √ √

Horizontal geometry (E-W) √ √ √ √ √ √ √ √ √ √

Horizontal and vertical zoom √ √ √ √ √ √ √ √ √ √

ROM size 64 k 64-28k 64 k 32-64k 64-128k 64 k 64-28k 64 k 32-64k 64-128k

User RAM size 2 k 2 k 2 k 2 k 2 k 2 k 2 k 2 k 2 k 2 k

Teletext 10 pag

1 page 10 page 10 page 1 page 10 page

Closed captioning √ √ √ √ √ √ √ √ √ √

20

Page 23

SERVICE MANUAL

A

r

(4) Pinning (QFP-80 ENVELOPE)

26

27

32

33

Pin

Description

port 0.6 (8 mA current sinking capability for direct drive of LEDs) or

Composite video input. A positive-going 1V(peak-to-peak) input is

required

narrow band PLL filter

utomatic Volume Levelling / subcarrier reference output / sound IF

32

input /

external reference signal input for I signal mixer for DVB operation

decoupling sound demodulator

-

QSS intercarrier output / AM output in stereo applications o

35

deemphasis

(front-end audio out) / AM output in mono applications

Symbol

QFP-80 SDIP-64

P3.1/ADC1 1 6 port 3.1 or ADC1 input

P3.2/ADC2 2 7 port 3.2 or ADC2 input

P3.3/ADC3 3 8 port 3.3 or ADC3 input

VSSC/P 4 9 digital ground for m-Controller core and periphery

P0.5 5 10 port 0.5 (8 mA current sinking capability for direct drive of LEDs)

P0.6/CVBSTD 6 11

VSSA 7 12 digital ground of TV-processor

SECPLL 8 13 SECAM PLL decoupling

VP2 9 14 2nd supply voltage TV-processor (+8V)

DECDIG 10 15 supply voltage decoupling of digital circuit of TV-processor

PH2LF 11 16 phase-2 filter

PH1LF 12 17 phase-1 filter

GND3 13 18 ground 3 for TV-processor

DECBG 14 19 bandgap decoupling

EWD 15 20 East-West drive output

VDRB 16 21 vertical drive B output

VDRA 17 22 vertical drive A output

IFIN1 18 23 IF input 1

IFIN2 19 24 IF input 2

IREF 20 25 reference current input

VSC 21 26 vertical sawtooth capacitor

AGCOUT 22 27 tuner AGC output

SIFIN1/DVBIN1 (1) 23 28 SIF input 1 / DVB input 1

SIFIN2/DVBIN2 (1) 24 29 SIF input 2 / DVB input 2

GND2 25 30 ground 2 for TV processor

SNDPLL

AVL/REF0/SNDIF/

REFIN (1)

AUDIO2 28 - audio 2 input

AUDIO3 29 - audio 3 input

HOUT 30 33 horizontal output

FBISO 31 34 flyback input/sandcastle output

DECSDEM

QSSO/AMOUT/

AUDEEM (1)

EHTO 34 36 EHT/over voltage protection input

PLLIF 35 37 IF-PLL loop filter

SIFAGC/DVBAGC (1) 36 31 AGC sound IF / internal-external AGC for DVB applications

INTCO/DVBO (1) 37 - intercarrier output (from QSS or vision IF amplifier) / DVB output

IFVO/SVO/DVBO (1) 38 38 IF video output / selected CVBS output / DVB output

VP1 39 39 main supply voltage TV processor

CVBS1 40 40 internal CVBS input

GND 41 41 ground for TV processor

21

Page 24

SERVICE MANUAL

f

Pin

Symbol

Description

QFP-80 SDIP-64

CVBS2 42 - external CVBS2 input

GND 43 - ground for TV-processor

CVBS3/Y 44 42 CVBS3/Y input

C 45 43 chroma input

WHSTR 46 - white stretch capacitor

CVBSO 47 - CVBS output

AUDOUT /AMOUT 48 - audio output /AM audio output (volume controlled)

SVM 49 44 scan velocity modulation output

INSSW2 50 45 2nd RGB / YUV insertion input

R2/VIN 51 46 2nd R input / V (R-Y) input / PR input

G2/YIN 52 47 2nd G input / Y input

B2/UIN 53 48 2nd B input / U (B-Y) input / PB input

BCLIN 54 49 beam current limiter input

BLKIN 55 50 black current input / V-guard input

RO 56 51 Red output

GO 57 52 Green output

BO 58 53 Blue output

VDDA 59 54

analog supply of Teletext decoder and digital supply o

TV-processor (3.3 V)

VPE 60 55 OTP Programming Voltage

VDDC 61 56 digital supply to core (3.3 V)

OSCGND 62 57 oscillator ground supply

XTALIN 63 58 crystal oscillator input

XTALOUT 64 59 crystal oscillator output

RESET 65 60 reset

VDDP 66 61 digital supply to periphery (+3.3 V)

P1.0/INT1 67 62 port 1.0 or external interrupt 1 input

P1.1/T0 68 63 port 1.1 or Counter/Timer 0 input

P1.2/INT0 69 64 port 1.2 or external interrupt 0 input

P1.3/T1 70 1 port 1.3 or Counter/Timer 1 input

P1.6/SCL 71 2 port 1.6 or I2C-bus clock line

P1.7/SDA 72 3 port 1.7 or I2C-bus data line

P2.0/TPWM 73 4 port 2.0 or Tuning PWM output

P2.1/PWM0 74 - port 2.1

P2.2/PWM1 75 - port 2.2

P2.3/PWM2 76 - port 2.3

P2.4/PWM3 77 - port 2.4

P2.5/PWM4 78 - port 2.5

SYNC_FILTER 79 -

CVBS (i.e. P0.6/CVBS) Sync filter input: This pin should be

connected to VSSA via a 100 nF capacitor.

P3.0/ADC0 80 5 port 3.0 or ADC0 input

Note:

1. The functional content of these pins is dependent on the envelope (SDIP-64 or QFP-80), the mode of

operation and on some I

2

C-bus control bits.

22

Page 25

(5) Black Diagram

)

)

)

(4X)

(

)

SERVICE MANUAL

ROGOBO

BLKIN

BCLIN

+ 3.3 V

PWMS

I/O PORTS (4x

ADC IN (4x

VST OUT

SDA

SCL

LED OUT (2x

1/10 PAGE

MEMORY

TELETEXT/OSD

H

C-BUS

2

I

I/O PORTS

TRANSCEIVER

VST PWM-DAC

TELETEXT

CVBS

BL

B

GB

DISPLAY

RG

V

COR

SYNC

ACQUISITION

CCC

R

WHITE-P. ADJ.

BLUE STRETCH

CONTR/BRIGHTN

OSD/TEXT INSERT

SATURATION

WHITE STRETCH

BLACK STRETCH

RGB/YUV INSERT

Y

U

V

EW GEOMETRY

G/Y B/U BL

R/V

EWD

EHTO

VPE

RESET

AUDOUT

AUDIO3

AUDIO2

ENHANCED

80C51 CPU

ROM/RAM

DELAY LINE

BASE-BAND

V- DRIVE +

GEOMETRY

V

VMOUT

HOUT V-DRIVE

Block diagram

7

Fig .

PEAKING

AVL

AVL

SOUND PLL

DEEMPHASIS

AUDIO SWITCH

VOLUME CO NTROL

VMOUT

LUMA DELAY

DECODER

PAL/SECAM/NTSC

SNDIF

AUDEEM

QSSO/AMOUT

REF

REF

AGC

QSS MIXER

QSS SOUND IF

AM DEMO DU LTOR

SIFIN

TUNERAGC

AGC/AFC

VISION IF

VIDEO AMP.

PLL DEMOD.

DVB MIXER

IFVO/DVBO

VIFIN

TRAP

SOUND

VIDEO IDEN T.

VIDEO SWITCH

GROUP DELAY

CORRECTION

VIDEO FILTERS

CVBS2

CVBSO

CVBS3/Y

C

LOOP

nd

H-SHIFT

H-DRIVE

2

7

H

8

H-OSC. + PLL

H/V SYNC SEP.

+8V

23

Page 26

(6) Pining

SERVICE MANUAL

P3.1/ADC1

P3.2/ADC2

P3.3/ADC3

VSSC/P

P0.6/CVBSTD

SECPLL

DECDIG

PH2LF

PH1LF

DECBG

AGCOUT

DVBIN1/SIFIN1

DVBIN2/SIFIN2

P0.5

VSSA

VP2

GND3

EWD

VDRB

VDRA

IFIN1

IFIN2

IREF

VSC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

P2.5/PWM4

P3.0/ADC0

80

SYNC_FILTER

79

P2.3/PWM2

P2.2/PWM1

P2.1/PWM0

P2.4/PWM3

77

75

76

78

TDA959X series

QFP-80

25

GND2

26

27

282930

AUDIO2

SNDPLL

31

HOUT

FBISO

AUDIO3

P1.6/SCL

P1.2/INTO

P1.1/T0

P2.0/PMW

P1.7/SDA

P1.3/T1

71

73

74

72

706968

32

333435

PLLIF

EHTO

DECSDEM

P1.O/INT1

VDDP

RESET

67

65

66

XTALOUT

64

XTALIN

63

OSCGND

62

VDDC

61

VPE

60

VDDA

59

58

BO

57

GO

56

RO

55

BLKIN

54

BCLIN

53

B2/UIN

52

G2/YIN

51

R2/VIN

50

INSSW2

49

SVM

48

AUDOUT /AMOUT

47

CVBSO

46

WHSTR

45

C

44

CVBS3/Y

43

GND

42

CVBS2

41

37

38

36

39

DVBO

SIFAGC/DVBAGC

SVO/IFOUT/DVBO

GND

40

VP1

CVBS1

AVL/REFOUT S N DIF/REFIN

AMOUT/QSSO/AUDEEM

Fig. 8 Pin configuration (QFP-80)

24

Page 27

SERVICE MANUAL

X

P1.3/T1

P1.6/SCL

P1.7/SDA

P2.0/TPMW

P3.0/ADC0

P3.1/ADC1

P3.2/ADC2

P3.3/ADC3

VSSC/P

P0.5

P0.6

VSSA

SECPLL

VP2

DECDIG

PH2LF

PH1LF

GND3

DECBG

EWD

VDRB

VDRA

IFIN1

IFIN2

IREF

VSC

AGCOUT

SIFIN1/DVBIN1

SIFIN2/DVBIN2

GND2

SIFAGC/DVBAGC

REFO/AMOUT/

REFIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

XX

TDA959X series SDIP-64

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

SVM

C

43

42

41

40

39

IFVO/SVO/DVBO

38

37

36

QSSO/

35

AMOUT

34

FBISO

33

Fig. 9 Pin configuration (SDIP 64)

(7) Refer to Table 12 about Functions and Data of the IC’s Pins.

P1.2/INT0

P1.1/T0

P1.0/INT1

VDDP

RESET

XTALOUT

XTALIN

OSCGND

VDDC

VPE

VDDA

BO

GO

RO

BLKIN

BCLIN

B2/UIN

G2/YIN

R2/VIN

INSSW2

CVBS/Y

GND

CVBS1

VP1

PLLIF

EHTO

HOUT

25

Page 28

SERVICE MANUAL

/

1.2 EEPROM AT24C16 (N101)

(1) Features

·Low Voltage and Standard Voltage Operation

5.0 (V

2.7 (V

2.5 (V

1.8 (V

= 4.5V to 5.5V)

CC

= 2.7V to 5.5V)

CC

= 2.5V to 5.5V)

CC

= 1.8V to 5.5V)

CC

·Internally Organized 128 x 8 (1K), 256 x 8 (2K),

512 x 8 (4K),1024 x 8 (8K) or 2048 x 8 (16K)

·2-Wire Serial Interface

·Bidirectional Data Transfer Protocol

·100 kHz (1.8V, 2.5V, 2.7V) and 400 kHz (5V)

Compatibility

·Write Protect Pin for Hardware Data Protection

·8-Byte Page (1K, 2K), 16-Byte Page (4K, 8K,

16K) Write Modes

·Partial Page Writes Are Allowed

·Self-Timed Write Cycle (10 ms max)

·High Reliability

Endurance: 1 Million Cycles

Data Retention: 100 Years

·Automotive Grade and Extended Temperature

Devices Available

(3) Pin Configurations

·8-Pin and 14-Pin JEDEC SOIC and 8-Pin

PDIP Packages

(2) Description

The AT24C01A/02/04/08/16 provides

1024/2048/4096/8192/16384 bits of serial

electrically erasable and programmable read

only memory (EEPROM) organized as

128/256/512

The device is optimized for use in many

industrial and commercial applications where

low power and low voltage operation are

essential. The AT24C01A/02/04/08/16 is

available in space saving 8-pin PDIP, 8-pin

and 14-pin SOIC packages and is accessed

via a 2-wire serial interface. In addition, the

entire family is available in 5.0V (4.5V to

5.5V), 2.7V (2.7V to 5.5V), 2.5V (2.5V to

5.5V) and 1.8V (1.8V to 5.5V) versions.

1024/2048 words of 8 bits each.

Fig. 10

26

Page 29

(4) Block Diagram

SERVICE MANUAL

Fig. 11

(5) Refer to Table 13 about Functions and Data of the IC’s Pins.

27

Page 30

SERVICE MANUAL

1.3 Tone Control and Surround Digitally Controlled Audio Processor TDA7442/TDA7442D

(1) Features

4 Stereo Inputs

Input Attenuation Control In 0.5db Step

Treble And Bass Control

Two Surround Mode Available With 4 Selectabler Responses:

- Music

- Simulated Stereo

Two Speaker Attenuators:

- 2 Independent Speaker Controls

In 1db Steps For Balance Facility

- Independent Mute Function

All Functions Programmable Via Serial Bus

2 Monitor Output (Only For Tda7442)

(2) Description

The TDA7442/42D is volume tone (bass and treble) balance (Left/Right) processors for quality audio

applications in TV and Hi-Fi systems. It reproduces surround sound by using a programmable

phase shifter. Control of all the functions is accomplished by serial bus.

The AC signal setting is obtained by resistor networks and switches combined with operational

amplifiers.

Thanks to the BIPOLAR/CMOS Technology used, Low Distortion, Low Noise and DC stepping are

obtained.

(3) Pin Connections

Fig. 11

28

Page 31

(4) Block Diagram (TDA7442)

SERVICE MANUAL

0.47mF

0.47mF

0.47mF

0.47mF

0.47mF

0.47mF

0.47mF

0.47mF

L-IN1

L-IN2

L-IN3

L-IN4

R-IN1

R-IN2

R-IN3

R-IN4

5.6nF

TREBLE-L

OFF

SURR

AMP

AMP

TREBLE BASS

TREBLE BASS

SURR

OFF

Vref

5.6nF

SYMULATED

-

+

100nF

PS1

RPS1

PS1

90Hz

SYMULATED

MUSIC

L-R

OFF

LPF

EFFECT

9KHz

CONTROL

V

LP TREBLE-R

S

1.2nF

MUSIC/

SUPPLY

AGND

MIXING

MIXING

CREF

22mF

2.2mF

MONITOR(L)

MUXOUT(L)

5

50K

6

50K

7

50K

8

50K

2

50K

1

50K

32

50K

31

50K

MONITOR(R)

31.5dB

control

31.5dB

control

4 11 13 182 7 282 6 22 14 13

MUXOUT(R)

IN(L)

30K

-

+

L+R

+

30K

IN(R)

2.2mF

5.6K

100nF

100nF

BOUT(L)

BIN(L)

171620193 109

RB

FIX

I2C BUS DECODER +LATCHES

VAR

RB

BIN(R) BOUT(R)

100nF 100nF

5.6K

79dBCONTROL

MUTE

MUTE

79dBCONTROL

D98AU947B

SPKR

ATT

30

LOUT

24

SCL

25

SDA

23

DIG GND

SPKR

ATT

29

ROUT

-

VAR

+

FIX

FIX

+

-

(5) Block Diagram (TDA7442D)

2.2mF

0.47mF

0.47mF

0.47mF

0.47mF

0.47mF

0.47mF

0.47mF

0.47mF

L-IN1

L-IN2

L-IN3

L-IN4

R-IN1

R-IN2

R-IN3

R-IN4

MUXOUT(L)

4

50K

5

50K

6

50K

7

50K

3

50K

2

50K

1

50K

28

50K

31.5dB

control

31.5dB

control

MUXOUT(R)

IN(L)

30K

-

+

2.2mF

L+R

30K

SYMULATED

IN(R)

+

10 11 16 24 25 23 19 12 13

100nF

PS1

RPS1

PS1

90Hz

MUSIC/

SYMULATED

SUPPLY

AGND

MIXING

MIXING

CREF

22mF

MUSIC

L-R

-

+

OFF

LPF

EFFECT

9KHz

CONTROL

LP TREBLE-R

V

S

1.2nF

5.6nF

TREBLE-L

OFF

SURR

AMP

AMP

TREBLE BASS

TREBLE BASS

SURR

OFF

Vref

5.6nF

5.6K

100nF

100nF

BOUT(L)

BIN(L)

1514181798

RB

FIX

I2C BUS DECODER +LATCHES

VAR

RB

BIN(R) BOUT(R)

100nF 100nF

5.6K

79dBCONTROL

MUTE

MUTE

79dBCONTROL

D01AU1248

SPKR

ATT

SPKR

ATT

27

LOUT

21

SCL

22

SDA

20

DIG GND

26

ROUT

-

VAR

+

FIX

FIX

+

-

29

Page 32

SERVICE MANUAL

a

1.4 Sound Power Amplifier TDA8944J (N603)

(1) General Description

The TDA8944J is a dual-channel audio power amplifier with an output power of

2 × 7 W at an 8Ω load and a 12V supply. The circuit contains two Bridge Tied Load

(BTL) amplifiers with an all-NPN output stage and standby/mute logic. The TDA8944J

comes in a 17-pin DIL-bent-SIL (DBS) power package. The TDA8944J is

printed-circuit board (PCB) compatible with all other types in the TDA894x family.

One PCB footprint accommodates both the mono and the stereo products.

(2) Features

·Few external components

·Fixed gain

·Standby and mute mode

·No on/off switching plops

·Low standby current

·High supply voltage ripple rejection

·Outputs short-circuit protected to ground, supply and across the load

·Thermally protected

·Printed-circuit board compatible.

(3) Block Diagram Pinning

Fig. 10 Block Diagr

m

Fig. 11 Pin Configuration.

(4) Refer to Table 14 about functions and Service Data of the IC’s Pin’s

30

Page 33

SERVICE MANUAL

1.5 Triple Video Output Amplifier TDA6108JF/6107Q

(1) Features

Typical bandwidth of 9.0MHz (for

TDA6108JF) or 5.5MHz (for TDA6107Q)

for an output signal of 60 V (peak-to-peak

value)

·

High slew rate of 1850V/μs (for

TDA6108JF) or 900V/μs (for

TDA6107Q)

·No external components required

·Very simple application

·Single supply voltage of 200 V

·Internal reference voltage of 2.5 V

·Fixed gain of 51 (for TDA6108JF) or 50 (for

TDA6107Q)

·Black-Current Stabilization (BCS) circuit

·Thermal protection.

(2) General Description

The TDA6107Q/6108JF includes three video

output amplifiers in one plastic DIL-bent-SIL

9-pin medium power (DBS9MPF) package (SOT

111-1), using high-voltage DMOS technology,

and is intended to drive the three cathodes of a

colour CRT directly. To obtain maximum

performance, the amplifier should be used with

black-current control.

(3) Ordering Information

Table 6

Type

Number

Name Description Version

Package

Plastic

DIL-bent-SIL

TDA6108JF/

DBS9MPF

medium power

TDA6107Q

package with fin;

SOT111-1

(4) Block Diagram

9 leads

Fig. 12

31

Page 34

Table 7 Pinning

g

SERVICE MANUAL

Symbol Pin Description

V

1 Inverting input 1

i(1)

V

2 Inverting input 2

i(2)

V

3 Inverting input 3

i(3)

GND 4 ground (fin)

Black-current

Iom 5

measurement output

VDD 6 Supply voltage

V

7 Cathode output 3

oc(3)

V

8 Cathode output 2

oc(2)

V

9 Cathode output 1

oc(1)

(5) Refer to Table 15 about Functions and Data of the IC’s Pins.

Fig. 13 Pin Confi

uration.

32

Page 35

SERVICE MANUAL

1.6 COMB Filter TC90A49P (N1)

(1) Features

·TV format : NTSC (3.58), PAL, M-PAL, and N-PAL

·Dynamic comb filter

·Vertical edge enhancement circuit

·PLL 8 × multiplier circuit

·Internal 8-bit 4 fsc AD converter

·Internal 8-bit precision 8 fsc DA converter (2 ch)

·Sync tip clamp circuit

·Internal 4H-line memory

2

·I

C bus interface

·Package : DIP 20-pin and SOP 24-pin

·5V single power supply

(2) Block Diagram

(3) Pin Assignment

Fig. 14

Fig. 15

Fig. 16

(4) Refer to Table 16 about Functions and Service Data of the IC’s Pins.

33

Page 36

SERVICE MANUAL

1.7 Dual 4-channel Analog Multiplexer/Demultiplexer HEF4052

(1) Description

The HEF4052 is a dual 4-channel analog multiplexer/demultiplexer with common channel select

logic. Each multiplexer/demultiplexer has four independent inputs/output s (Y

input/output (Z). The common channel select logic includes two address inputs (A

to Y3) and a common

0

and A1) and an

0

active LOW enable input (E).

Both multiplexers/demultiplexers contain four bidirectional analog switches, each with one side

connected to an independent input/output (Y

to Y3) and the other side connected to a common

0

input/output(Z).

With E LOW, one of the four switches is selected (low impedance ON-state) by A

HIGH, all switches are in the high impedance OFF-state, independent of A

are the supply voltage connections for the digital control inputs (A

is 3 to 15 V. The analog inputs/outputs (Y

and V

V

as a negative limit.

EE

may not exceed 15 V.

DD VEE

to Y3, and Z) can swing between V

0

, A1 and E). The VDD to Vss range

0

0

and A1. With E

0

and A1. VDD and Vss

as a positive limit

DD

For operation as a digital

multiplexer/demultiplexer, V

V

(typically ground)

SS

is connected to

EE

YOA to Y3A Independent inputs/outputs

YOB to Y3B Independent inputs/outputs

Table 8 Pinning

(2) Block Diagrams

AO A1 Address inputs

E Enable input (active LOW)

ZA ZB Common inputs/outputs

Family data, lDD LIMITS category MSI

See Family Specifications

Fig. 17

HEF4052P (N): 16-lead DIL; plastic

(SOT38-1)

HEF4052D (F): 16-lead DIL;

(cerdip) (SOT74)

HEF4052T (D): 16-lead SO;

(SOT109-1)

( ): Package Designator North America

Fig. 18Pinning Diagram

ceramic

plastic

34

Page 37

(3) Function Table

SERVICE MANUAL

Fig. 19 Schematic Diagram (One Switch)

Table 9

Inputs Channel

E A1 A

L L L YOA-ZA; YOB-ZB

L L H Y1A-ZA; Y1B-ZB

L H L Y2A-ZA; Y2B-ZB

L H H Y3A-ZA; Y3B-ZB

H X X none

On

0

Notes

H=HIGH state (the more positive voltage)

L=LOW state (the less positive voltage)

X=state is immaterial

Ratings

Limiting values in accordance with the Absolute Maximum System (IEC 134)

Supply voltage (with reference to V

Note

To avoid drawing V

voltage drop across the bidirectional switch must not exceed 0,4V. If the switch current flows into

terminal Z, no V

across the switch, but the voltages at Y and Z may not exceed V

(4) Refer to Table 17 about Functions and Data of the IC’s Pins.

current out of terminal Z, when switch current flows into terminals Y, the

DD

current will flow out of terminals Y, in this case is no limit for the voltage drop

DD

) VEE -18 to +0,5 V

DD

or V

DD

EE

35

Page 38

SERVICE MANUAL

1.8 Vertical deflection output TDA8359J

(1) Introduction

The TDA8359J is an integrated power circuit for use in 90° and 110° colour deflection systems. It

contains a vertical deflection bridge output, operating as a high efficiency class G system and can

handle field frequencies from 25 to 200 Hz. The vertical coil of a 4 : 3 as well a 16 : 9 picture tube

can be connected to this vertical deflection device. Due to the bridge configuration a DC deflection

output application can be designed with a positive main supply of typical 12 Volts and a positive

flyback supply of typical 45 Volt. (Depending on the coil data).

This integrated circuit is designed in a Low Voltage DMOS (LVDMOS) process that combines

bipolar, CMOS and DMOS components. DMOS output transistors (MOSFETs) are used because of

the absence of secondary breakdown, which gives a better SOAR performance . The internal circuits

are designed in such way that only a few external components are needed to get a correct working

application.

The TDA8359J is functional the same as the TDA8357J vertical deflection output stage. The

TDA8359J differs in only one aspect from the TDA8357J, it is able to deliver a higher output current

which is more suitable for large picture tubes.

A detailed investigation procedure to determine an optimum application is given at the end of this

report.

(2) Features

· Few external components required

· High efficiency fully DC coupled vertical bridge output circuit

· Short rise and fall time of the vertical flyback switch

· Picture tube burn in protection signal (guard circuit)

· Temperature (thermal) protection circuit

· Differential mode inputs

· Blanking pulse generator (guard)

· Improved EMC performance due to differential inputs

(3) Pinning

Table 10

Symbol Pin Description

INA 1 Input A

INB 2 Input B

VP 3 Supply voltage

OUTB 4 Output B

GND 5 Ground

VFB 6 Flyback supply voltage

OUTA 7 Output A

INA

INB

V

OUTB

GND

V

FB

OUTA

GUARD

FEEDB

2

3

P

4

5

TDA835 9J

6

7

8

9

GUARD 8 Guard output

FEEDB 9 Feedback input

Fig. 20

36

Page 39

(3) Block Diagram

V

V

i(bias)

i(p-p)

0

V

i(p-p)

V

i(bias)

0

INA

INB

SERVICE MANUAL

GUARD

863

GUARD

CIRCUIT

1

INPUT

AND

FEED

BACK

CIRCUIT

2

VV

P

M2

D1

M4

M1

M3

FB

M5

D3

D2

OUTA

7

9

FEEDB

4

OUTB

5

TDA8359J

GND

Fig. 21

37

Page 40

SERVICE MANUAL

1.9 Switch-mode Power Supply STR- W68XX

(1) General Description

The STR-W6800 Series are thick-film ICs for Quasi-Resonant flyback SMPS with MOSFET and

control built-in, featuring fewer external components, simplified circuit design, small-size and

standard power supply.

“STR-W6800 Series ICs” offers three operation modes: Quasi-Resonant, Multi-Bottom Skip and

Time Fix Control, thus guaranteeing high efficiency in all loading areas by means of the automatic

change-over of the operation modes.

QR---- Quasi-Resonant operation at the time of heavy load

MBS---- Multi-Bottom Skip operation at the time of medium load for preventing oscillating f requency

rising up and fixing operating frequency

TFC---- Time Fix Control at the time of light load such as stand-by load

By adopting chip-on-chip construction, even small package can deal with big power.

(2) Features

Seven-pin small SIP style package FM207 (generally called TO220), affording dielectric

isolation

Guarantees space of 1.8mm between high voltage pin and other pins, thus high voltage

MOSFET built-in allowed

Offers low startup current by employing BCD-Process

Automatic change-over of QR and MBS operations

With MOSFET turn-on at the bottom of VDS, "STR-W 6800 Series ICs" offers high efficiency

and low noise at the wide areas from the heavy load to stand-by load and fixed operating

frequency, and enables SMPS to become smaller.

TFC operation delivers low-power standby mode for fixing turn-on time, enabling external

components to adjust turn-on time.

Avalanche breakdown energy-guaranteed and high damage-resistance power MOSFET

By guaranteeing avalanche breakdown energy of built-in power MOSFET, "STR-W 6800

Series ICs" simplifies design of absorption circuit of surge voltage without VDSS residual

considered during design.

MOSFET fixed voltage drive circuit built in

Various protection functions

Pulse-by-pulse over-current protection

Over-voltage protection →lockout

Over-load protection →lockout

Thermal protection →lockout (not for STR-W6854/6)

38

Page 41

SERVICE MANUAL

(3) Black Diagram

Vcc

4 Pin

+

RTFC

7 Pin

-

OVP

TSD

REG

+

-

OLP

Current

Mirror

FB/OLP

6 Pin

LATCH

R

S

Current

Mirror

OSC

Q

TFC

BEC

Fig. 22

Drive REG

REG

+

-

BD

BIC

D

1 Pin

DRV

S/GND

3 Pin

OCP/BD

5 Pin

+

OCP

-

(4) Pinning

Table 11

Pin No. Symbol

1 D

2 NC

3 S/GND

4 Vcc

5 OCP/BD

Name

Source for MOSFET

Source/GND for MOSFET

Supply voltage

Over-current protection

Function Description

Source/ GND for Control

detection/Bottom detection

6 FB/OLP

Feedback/Over-load protection

detection

7 RTFC

Time Fix Control regulation

(5) Refer to Table 18 about Functions and Data of the IC’s Pins.

39

Page 42

SERVICE MANUAL

2. WAVEFORMS OF KEY POINTS

Waveform during C802 Startup

Waveform during +B Voltage Startup

40

Page 43

SERVICE MANUAL

41

Page 44

SERVICE MANUAL

42

Page 45

SERVICE MANUAL

43

Page 46

SERVICE MANUAL

44

Page 47

SERVICE MANUAL

Waveform during V404’s Base

T=64us

45

Page 48

SERVICE MANUAL

Waveform during V404’s C Electrode

46

Page 49

SERVICE MANUAL

47

Page 50

3. SERVICE DATA OF KEY ICS

Table 12 Functions and Service Data of TDA9594H (N101)’s Pins

SERVICE MANUAL

Pin No. Function Description

1 P3.1/ADC1 6.8

2 P3.2/ADC2 6.8

3 P3.3/ADC3 1.3 0.196

4 VSSC/P 0 0

5 P0.5 10.4 0

6 P0.6/CVBSTD 10.4 0

7 VSSA 0 0

8 SECPLL 5,420

9 VP2 1.1 7.68

10 DECDIG 30.6

11 PH2LF 5,410

12 PH1LF 5,450

13 GND3 0 0

Resistance to Ground

(KΩ)

Reference Voltage

(V)

14 DECBG 38

15 EWD 1,760

16 VDRB 3.03

17 VDRA 3.03

18 IFIN1 36.4 1.89

19 IFIN2 36.4 1.9

20 IREF 38.9

21 VSC 5,440

22 AGCOUT 1.7 2.0

23 SIFIN1/DVBIN1 (1) 36.5 1.89

24 SIFIN2/DVBIN2 (1) 36.6 1.89

25 GND2 0 0

26 SNDPLL - -

(Continued)

48

Page 51

SERVICE MANUAL

27 AVL/REF0/SNDIF/REFIN (1) 3,680 2.4

28 AUDIO2 - 29 AUDIO3 - 30 HOUT 7,660 3.2

31 FBISO 1,360 0.9

32 DECSDEM 5,290

QSSO/AMOUT/

33

AUDEEM (1)

34 EHTO 7.4 2.54

35 PLLIF 5,440

36 SIFAGC/DVBAGC (1) 5,000

37 INTCO/DVBO (1) - 38 IFVO/SVO/DVBO (1) 3,660 2.05

3,690 0.6

39 VP1 1.1 7.6

40 CVBS1 5,230

41 GND 0 0

42 CVBS2 5,380

43 GND 0 0

44 CVBS3/Y 5,340 3.74

45 C 82.3 1.47

46 WHSTR 5,190

47 CVBSO 5,500

48 AUDOUT /AMOUT 5,500

49 SVM 5,500 4.5

50 INSSW2 0.075

51 R2/VIN 5,500 2.5

52 G2/YIN 5,500 2.5

53 B2/UIN 5,500 2.5

54 BCLIN 0.069 3.7

55 BLKIN 23 3.2

56 RO 5.8 2.7

(Continued)

49

Page 52

SERVICE MANUAL

57 GO 5.8 2.6

58 BO 5.8 2.7

59 VDDA 0.28 3.2

60 VPE 0 0

61 VDDC 0.28 3.3

62 OSCGND 0.014

63 XTALIN 2,500 1.5

64 XTALOUT 5 1.5

65 RESET 0 0

66 VDDP 0.28 3.3

67 P1.0/INT1 10 0.06

68 P1.1/T0 10 0.06

69 P1.2/INT0 12,200 3.3

70 P1.3/T1 0.19 0.7

71 P1.6/SCL 8.7 3.7

72 P1.7/SDA 9 3.8

73 P2.0/TPWM 10.5 0.06

74 P2.1/PWM0 2.5 0.1

75 P2.2/PWM1 3.7 0.06

76 P2.3/PWM2 6.2 0.05

77 P2.4/PWM3 - 78 P2.5/PWM4 10.6 0.1

79 SYNC_FILTER 3,700

80 P3.0/ADC0 - -

50

Page 53

SERVICE MANUAL

Table 13 Functions and Service Data of AT24C16 (N102)’s Pins

Digital Multimeter

Pin

Functions Description

No.

1 Address input 0 0 0

2 Address input 0 0 0

3 Address input 0 0 0

4 Common ground 0 0 0

5 Serial data 4 6.37 6.4

6 Serial clock input 4.2 6.37 6.44

7 Write protect 0 0 0

8 Supply voltage 4.9 3.03 3.02

Reference Voltage

(V)

Positive Resistance

(20KΩ)

Negative Resistance

(20KΩ)

Table 14 Functions and Service Data of TDA8944J (N603)’s Pins

Digital Multimeter

Pin

Functions Description

No.

1 Negative loudspeaker terminal 1 7.98

2 Ground channel 1 0 0 0

3 Supply voltage channel 1 14.9 5.8 7.7

4 Positive loudspeaker terminal 1 7.3

5 Not connected 0

6 Positive input 1 7.3

7 Not connected 0

8 Negative input 1 7.4

9 Negative input 2 7.3

Mode selection input (standby,

10

mute, operating)

Reference Voltage

(V)

0 7.8 8.9

Positive Resistance

(20KΩ)

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

Negative Resistance

(20KΩ)

Half supply voltage decoupling

11

(ripple rejection)

12 Positive input 2 7.3

7.6

∞ ∞

∞ ∞

(Continued)

51

Page 54

SERVICE MANUAL

13 Not connected 0

14 Negative loudspeaker terminal 2 7.3

15 Ground channel 2 0 0 0

16 Supply voltage channel 2 14.8 3.5 3.5

17 Positive loudspeaker terminal 2 7.3

∞ ∞

∞ ∞

∞ ∞

Table 15 Functions and Service Data of TDA6107Q/TDA6108JF (NY01)’s Pins

Digital Multimeter

Pin No.

1

2

3

Function Description

G inverting input 3.33 5.32 4.72

R inverting input 3.26 5.32 4.72

B inverting input 3.28 5.32 4.72

Reference Voltage

(V)

Positive Resistance

(20KΩ)

Negative Resistance

(20KΩ)

Ground 0.00 0.00 0.00

4

Black level current input 6.03 18.65 5.65

5

Supply voltage 199

6

B output 69.9

7

R output 69.18

8

G output 65.9

9

Table 16 Functions and Service Data of TC90A49P (N501)’s Pins

Pin

Functions Description

No.

ADC and DAC analog power

1

supply.

ADC bias voltage. Stabilize by

2

attaching a 0.01µF capacitor.

∞

∞

∞

∞

Digital Multimeter

Reference Voltage

(V)

4.98 0.55 0.54

1.41

Positive

Resistance (20KΩ)

∞ ∞

4.48

5.45

5.45

5.45

Negative

Resistance (20KΩ)

(Continued)

52

Page 55

SERVICE MANUAL

ADC input range D upper limit

3

voltage. Stabilize by attaching a

0.01µF capacitor.

ADC input. Inputs 1.0 Vp-p video

4

signal. Sync tip clamp is performed.

ADC input range D lower limit

5

voltage. Stabilize by attaching a

0.01µF capacitor.

6 ADC and DAC logic power supply. 4.98 0.55 0.55

Logic and internal DRAM GND

7

(digital).

8 Internal DRAM power supply 4.98 0.55 0.55

9 I2C BUS SDA 4.12 6.39 6.44

3.15 0.64 0.63

2.14

1.84 0.497 0.49

0 0 0

∞ ∞

10 I2C BUS SCL 4.25 6.4 6.45

2

Shipment test mode switch or I

11

bus setting reset pin.

Y signal comb function ON / OFF

12

switch.

13 Clock input pin. 2.54

Connect the APC filter in the 8 fsc

14

PLL circuit

15 PLL power supply 4.98 0.55 0.55

16 ADC, DAC, and PLL GND (analog). 0 0 0

17 Outputs chrominance signal. 2.25

DAC output range D upper limit

18

voltage.

DAC output range D lower limit

19

voltage

C

0 0 0

0 0 0

∞ ∞

0

3.14 0.57 0.57

1.84 0.42 .043

∞ ∞

∞ ∞

20 Outputs luminance signal. 2.16

∞ ∞

53

Page 56

SERVICE MANUAL

Table 17 Functions and Service Data of HEF4052 (N301/N302)’s Pins

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Function Description

Signal input 0 12.52 6.46

Signal input 0 12.5 6.46

Signal input 0 12.52 6.46

Signal output 0 12.43 6.25

Signal input 0 12.5 6.46

Ground 0 0 0

Ground 0 0 0

Ground 0 0 0

Control signal input 4.98 7.8 5.6

Control signal input 4.98 7.8 5.6

Control signal input 0 0 0

Signal input 0 0 0

Signal output 0 0 0

Reference Voltage (V)

Digital Multimeter Pin

Positive Resistance (KΩ)

Negative Resistance (KΩ)

14

Signal input 0 0 0

15

Audio output 0 12.48 6.46

16

Supply voltage 5.09 6.89 4.44

Table 18 Functions and Service Data of STR-W6856 (N801)’s Pins

Pin No. Symbol

1

2

3

D

NC

S/GND

Reference Voltage

(V)

303 ∞

0 1.3

16.7 ∞

Resistance to Ground

(MΩ)

4 Vcc 3.1 8.5

5 OCP/BD 1.5 1.3

6 FB/OLP 7.2 1.6

7

RTFC

54

Page 57

SERVICE MANUAL

REPLACEMENT OF PARTS

1. Description

Many electrical and mechanical components in this chassis have special safety-related

characteristics. Components which have these special safety characteristics in this manual

and its supplements are identified by the international hazard symbols or UL, FCC, FDA or

VDE marking on the circuit diagram and parts list. When replacing any of these components,

substitute the one which has the same safety characteristics as specified in the manual.

Description of the special markings:

A: The components identified by the A marking have special safety-related characteristics.

AE: The components identified by the AE marking are listed by EMC and have special

safety-related characteristics.

CB: The components identified by the CB marking have been evaluated to the CB standard.

E: The components identified by the E marking are listed by EMC

G: The components identified by the G marking have critical characteristics.

Z: The components identified by the Z marking have important characteristics.

Note:

Models and specifications of components in this table may be somewhat different with your unit.

In this case, please rely on the actual unit.

55

Page 58

Circuit Diagram for PF29T18 (2)

This circuit diagram is only for reference, specifications are subject to change without reference.

1. Any components identified by have special safety-related characteristics. Use replacement

Which have the same characteristics as original parts.

2. Cold ground Hot ground

Page 59

Circuit Diagram for PF29T18 (1)

This circuit diagram is only for reference, specifications are subject to change without reference.

1. Any components identified by have special safety-related characteristics. Use replacement

Which have the same characteristics as original parts.

2. Cold ground Hot ground

Loading...

Loading...