Page 1

OPERATING

INSTRUCTIONS

for

the

CHANDLER

All

ckax:dler

Models

DARNER

Mi-..-.

CO.

Ayer,

Page 2

KNOW

YOUR

DARNER!

Read

thoroughly

these

instructions

before

operating

carefully

machine.

and

Page 3

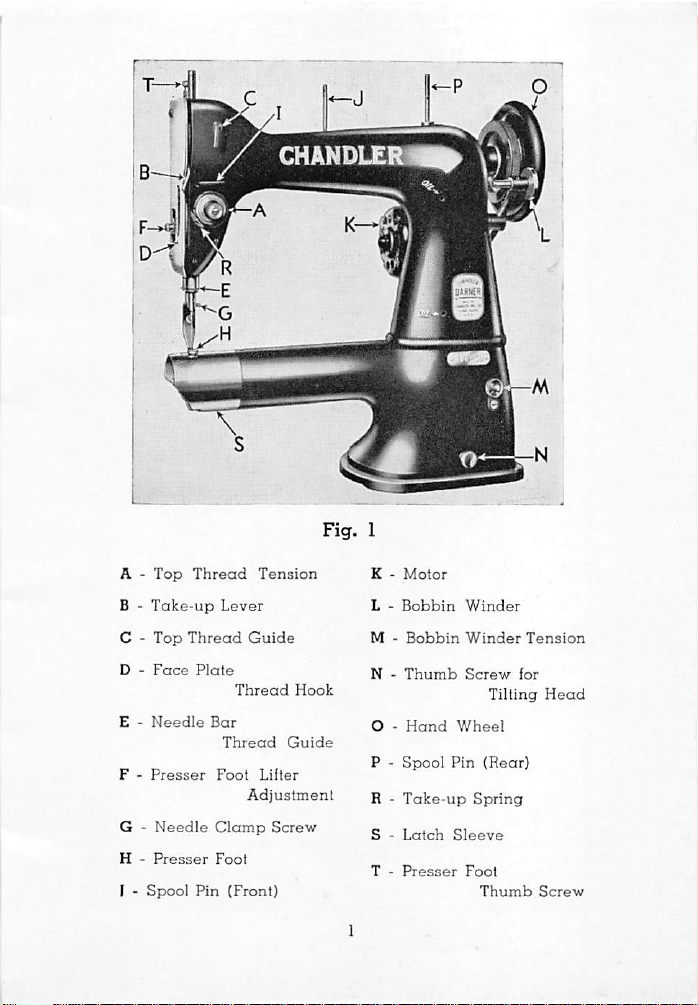

A -

B -

C -

D -

E -

F -

G -

H -

1 -

Top

Take-up

Top

Face

Needle

Presser

Needle

Presser

Spool

Thread

Thread

Plate

Bar

Foot

Clamp

Foot

Pin

Lever

Guide

Thread

Thread

Adjustment

(Front)

CHANDLE

Tension

Hook

Guide

Lifter

Screw

K -

L -

M -

N -

O -

P -

R -

S -

T -

Motor

Bobbin

Bobbin

Thumb

Hand

Spool

Take-up

Latch

Presser

Winder

Winder

Screw

Wheel

Pin

Sleeve

Foot

Tilting

(Rear)

Spring

Thumb

Tension

for

Head

Screw

Page 4

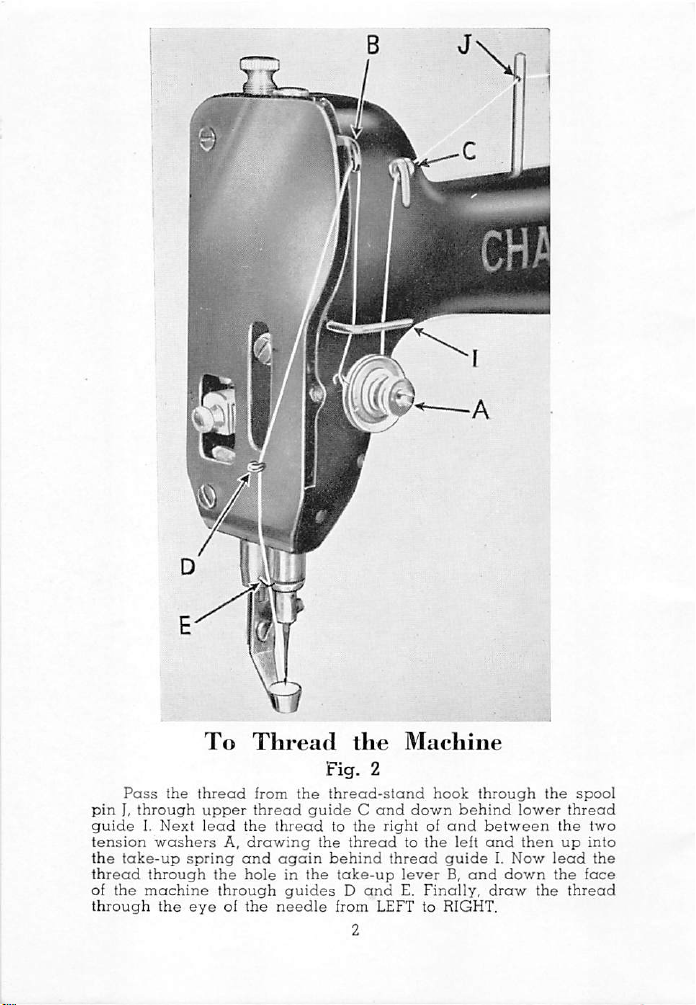

To

Pass

pinI,through

guideI.Next

tension

the

thread

of

through

the

washersA,drawing

take-up

through

the

machine

the

thread

upper

lead

the

spring

and

the

holeinthe

through

eyeofthe

Thread

from

thread

threadtothe

again

guidesDandE.Finally,

needle

the

Fig.

2

the

thread-stand

guideCand

the

rightofand

threadtothe

behind

thread

take-up

from LEFT to RIGHT.

leverB,and

Machine

hook

down

behind

left

guideI.Now

through

between

and

down

draw

the

spool

lower

thread

the

the

lead

the

two

the

face

thread

thenupinto

Page 5

Turn

the

barisin

(Fig.4)located

ing

on

arm.

its

its

This

hinge

Liftuphinging

and

shake

To

bobbin

guide

of

and

bin.

Wind

hand,

hand

position.

Then

by

placing

your

ter

turn

hand

chine.

be

retightened.

If

save

the

following

1.

2.

Always

necessary

out

wind

winder

pinIdown

between

the

and

then

wheel

release

your

right

toward

wheel

After

the

machineisalready

rethreading

Release

lifter

Then,

the

thread

the

tension

winder

wear

To

Remove

hand

wheel

uppermost

under

allows

the

releasing

clamp

the

bobbin.

To

Wind

the

bobbin,

L (Fig. 1).

the

the

tension

thread

raise

belt.

The

the

hand

left

hand

loosening

youoruntil

to

turn

without

the

bobbin

the

machine

alternate

thread

W (Fig. 8).

remove

the

from

discsMand

arm.

lower

the

against

the

toward

position.

the

nickeled

bobbin

the

bobbin

F (Fig. 3)

the

placeiton

Now

front of

discsM,and

around

the

the

bobbin-winder

tension

wheel

on

the

hand

it is free.

running

has

been

threaded,

method:

tension

thread

the

last

bobbin

the

belt.

Bobbin

you

Then

sleeveSon

case

holder

case.

with

Bobbin

the

lead

the

the

machine,

bobbinafew

spring

the

for

hand

will

winding

wheel

This

the

wound,

by

winding

by

raising

from

the

thread

guide

uptothe

winder

imtil

the

lift

up

on

the

to fall

the

fingernail

spindleofthe

thread

to

uptothe

unit

against

holditin

the

wheel

knob,

will

allow

restofthe

the

knob

the

operator

the

bobbin

the

needle

and

E (Fig. 2) to

bobbin

unit

to

needle

latch

mend

from

the

times

bobbin,

and

a

quar

on

save

A

back

the

left

bob

by

the

this

with

the

ma

must

may

by

hand

draw

the

un

Page 6

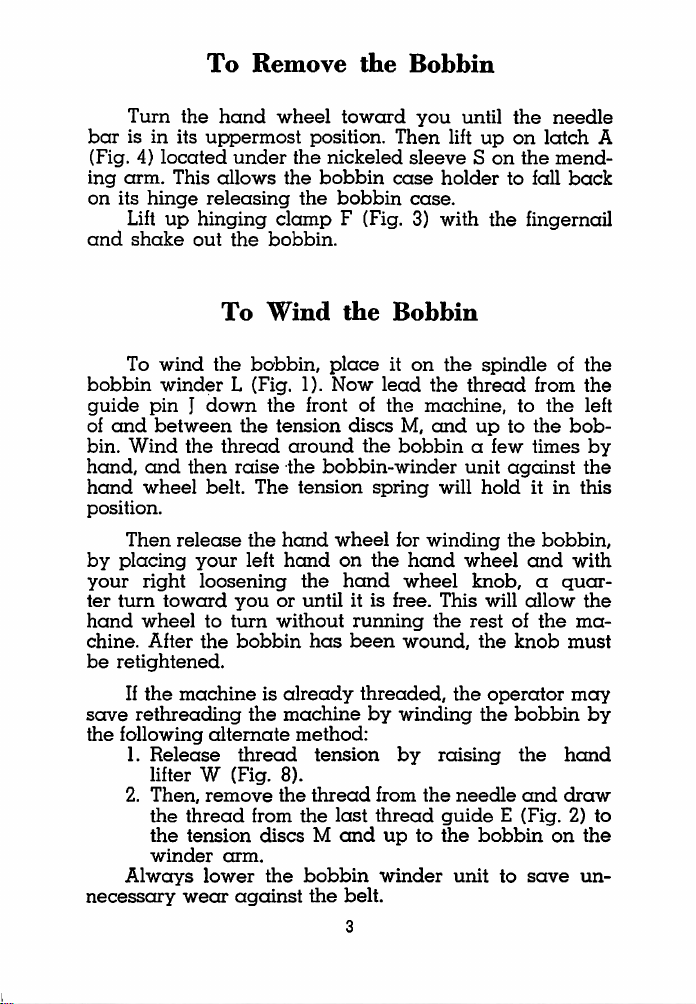

Fig.

3

To

Hold

and

toward

with

Now

thread

Care

the

spring.

From

the

bobbin

bobbin

the

machine.

the

forefinger

the

right.

the

hinge

insert

through

should

the

caseisnow

Thread

bobbininthe

with

With

"F"

the

slotDand

be

taken

spring,

case

and

the

the

opened.

bobbin

lead

draw

threaded

the

right

thread

left

on

to

see

the

Bobbin

drawing

hand

the

under

that

thread

it

through

and

hand

center

between

hold

the

the

to

ready

tension

Case

the

offatthe

the

bobbin

stemE,draw

spring

thread

the

the

to

is

projection

hole

be

placed

thumb

bottom

case

the

under

on

B.

The

C.

in

Page 7

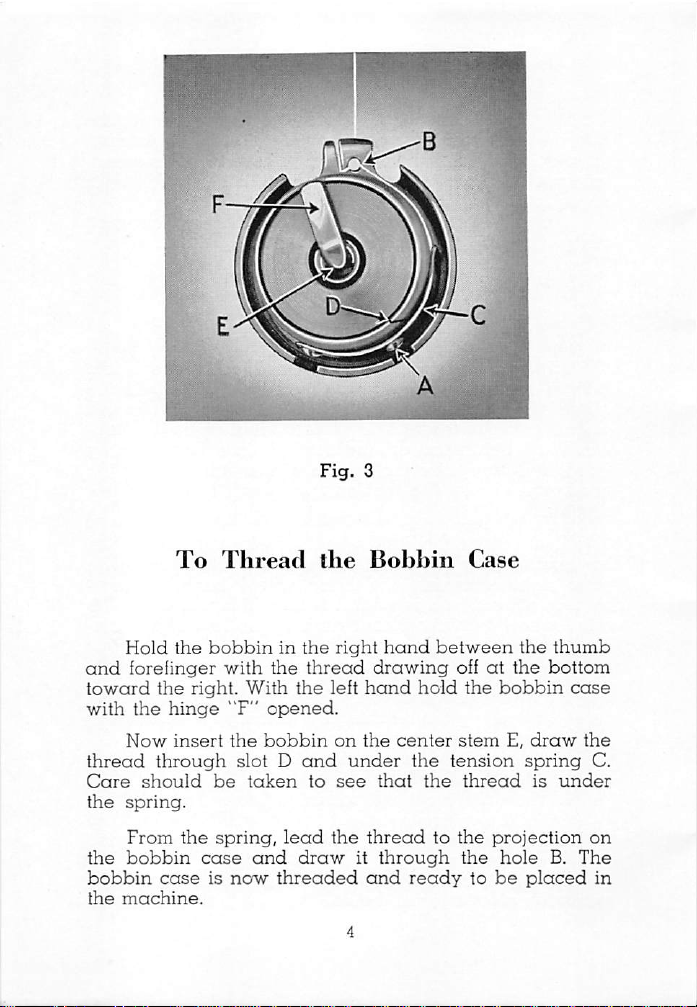

To Replace

And

Complete

the

Bobbin

Case

Threading

Fig.

4

After

the

placeitonto

case

should

Retaining

lyinginthe

To

close,

Before

hook,

break

Hold

merely

latch

closing

andbesure

the

top

bobbin

under

retaining

the

needleisdown,

will

drawing

threads

bobbin

the

lieinthe

proper

thread

caseisthreaded,

bobbin

your

holdonthe

position

snap

will

lock

latch,

the

latch

needle.

and

thread

presser

case

cut-out

up

it in

make

the

needle

will

turn

up

foot to

holder.

of

while

the

not

machine

through

the

the

thread

closing

bobbin

place.

sure

is in its

close

rear.

take

The

holder.

no

needle

will

case

accumulated

uppermost

and any

by

it in

your

left

projectionofthe

keep

the

the

bobbin

hand

holeinsleeve.

bobbin

case

holder

so

threadisin

position.Ifthe

attemptstoforce

one

full

hand

and

bobbin

case

holder.

that

the

revolution,

Lay

both

it

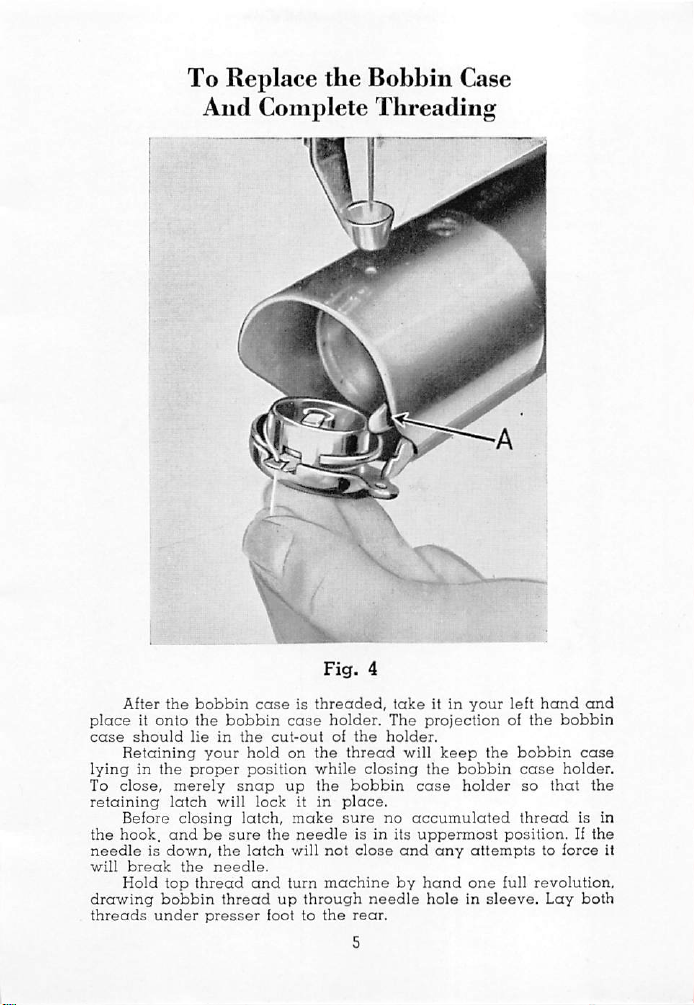

Page 8

With

the

begin

become

Liftupthe

and

insert

Then

release

position.Aslight

the

machine.

machine

mending.Afew

accustomed

presser

the

the

To

Begin

properly

piecesofscrap

to

the

footbymeansofthe

material

hand

to

liftertolower

pressuretothe

threaded,

feelofthe

be

darned

Mending

you

material

machine.

hand

beneath

the

presser

knee

or foot

are

now

shouldbeused

lifter

the

footinoperating

rheostat

ready

"W"

presser

will

(Fig. 8)

to

to

foot.

start

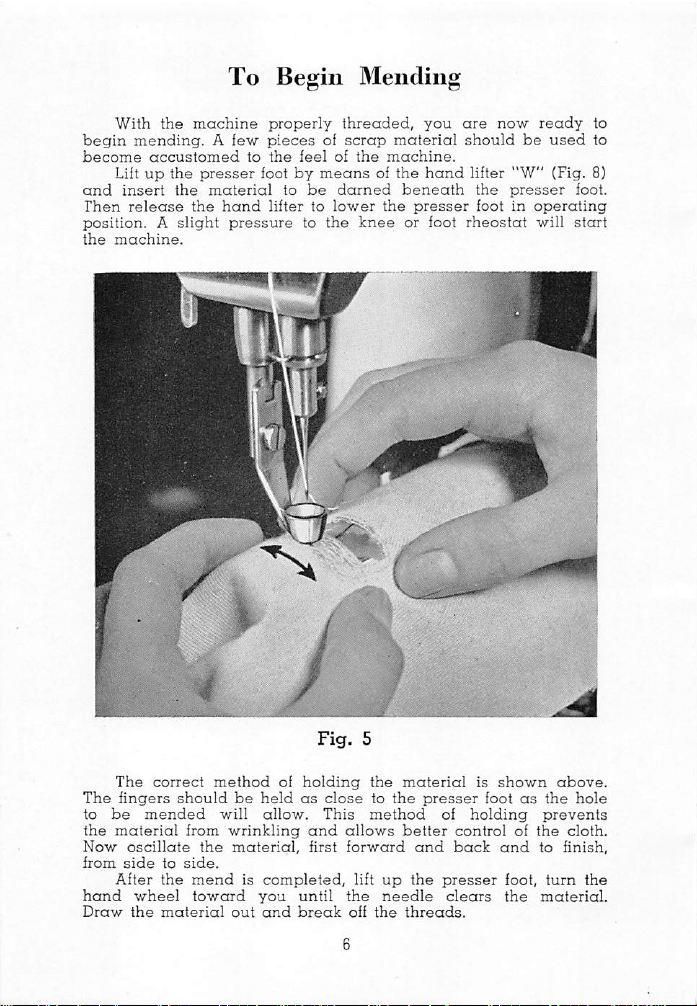

Fig.

5

The

The

to

the

Now

from

hand

Draw

be

correct

fingers

mended

material

oscillate

sidetoside.

After

wheel

the

methodofholding

should

be

heldasclosetothe

will

from

the

the

mendiscompleted,

toward

material

allow.

wrinkling

material,

you

out

and

and

first

until

break

This

allows

forward

liftupthe

the

off

the

materialisshown

presser

method

better

and

of

controlofthe

back

presser

needle

the

threads.

clears

footasthe

holding

andtofinish,

foot,

the

above.

hole

prevents

cloth.

turn

material.

the

Page 9

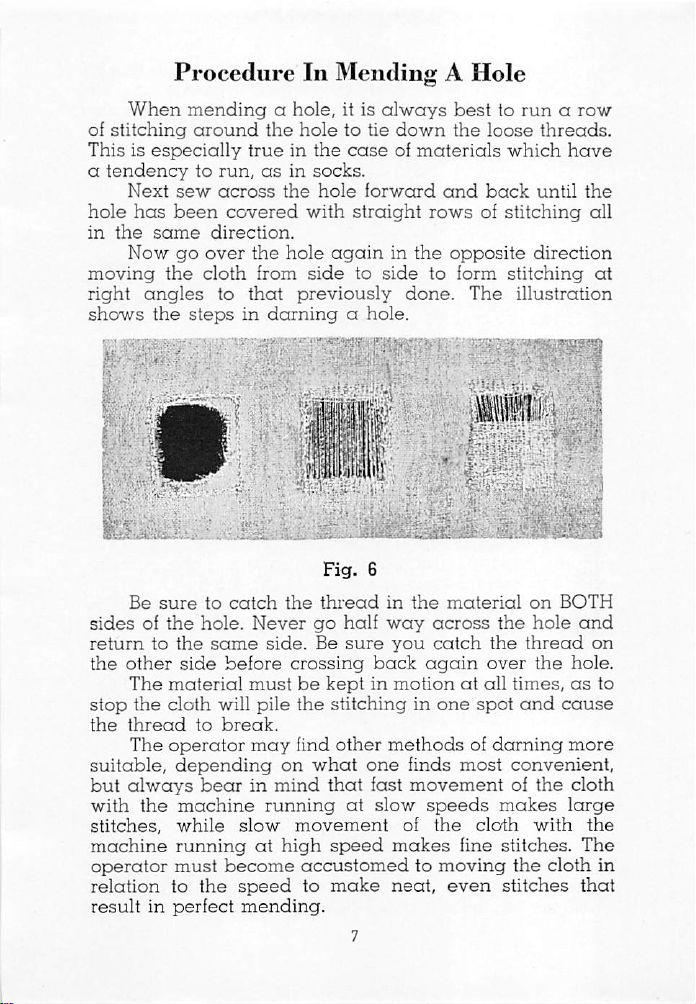

Procedure

When

mendingahole,

of

stitching

Thisisespecially

a

tendency

Next

hole

in

the

Nowgoover

moving

right

shows

around

to

run,asin

sew

across

has

been

same

direction.

the

cloth

angles

the

to

stepsindarningahole.

the

trueinthe

covered

the

from

that

In

MendingAHole

it is

always

holetotie

socks.

the

hole

with

hole

againinthe

side

down

caseofmaterials

forward

straight

to

side

previously

besttorunarow

the

loose

which

and

back

rowsofstitching

opposite

to

form

stitching

done.

The

threads.

hove

until

the

all

direction

at

illustration

f'y

^ y 'jr

1 • - ' » £ yj

Fig.

6

Be

sure

to

catch

the

sidesofthe

returntothe

the

other

The

stop

the

the

thread

The

suitable,

but

always

with

stitches,

machine

operator

relation

resultinperfect

material

cloth

operator

depending

the

machine

while

running

must

to

side

hole.

same

to

bearinmind

the

thread

Never

before

mustbekeptinmotionatall

will

break.

may

slow

become

speed

mending.

go

side.Besure

crossing

pile

the

find

on

what

running

movement

at

high

accustomedtomoving

to

in

the

material

half

way

across

you

catch

back

again

stitchinginone

other

methodsofdarning

one

finds

that

fast

movement

at

slow

speeds

of

the

speed

make

makes

neat,

even

the

over

spot

most

cloth

fine

on

BOTH

the

hole

thread

the

times,asto

and

cause

convenient,

of

the

makes

with

stitches.

the

cloth

stitches

I

Jil

and

on

hole.

more

cloth

large

the

The

in

that

Page 10

Some

holes

alone.Inthis

patch

edges

patch

after

to

on

the

the

Use

When

you

(Page

foot. Be

the

plate

there

will

find

19). To install this

sure

ontothe

maybetoo

case

mend

trimming

underside.

undersideofthe

of

the

is a

great

the

Chandler

the

needleisat

sleeve

by

stray

Then

Flat

dealofflat

plate

large

patching,

threads

trim off

material.

Work

Flat

Work

simply

its

of

this

for

darning

darning

or

the

worktobe

Plateofreal

lift

highest

machine.

folding

cornersofthe

Plate

up

point

will fit in the cut-out in the plate. Then tighten

screwatthe

sewing.

a

larger

of the machine. Some operators

with

patches,

venient

mended.

The

(Fig. I6c2) is for

tighten

andtoloosen

The tension on

the

small

centerofthe

Take

cessories

bin

thread

The

minedbyhanging

tensionistoo

thread.

bobbintobe

not

be

The

first

and

stitchonthe

loops

are

bottomofthe

This

plate

willbefoundtobeagreat

surfaceisneeded

as

the

handling

To

small

of

Regulate

thumb

regulating

the

top

thread

the

tension

the

spring

and

correct

bobbin

the

small

turn

tension

tension

case

screw

this

andtothe

tension

the

The

loose,

correct

shaken

the

tensionisone

yoke,

and

than

provided

use

the plate in mending

extra

surface

the

patch

the

nutinfrontofthe

tension,

turn

bobbin

screw

thread

driver

screw

to

allows

under

Tensions

the

top

turn

counter

threadisregulated

A (Fig. 3)

tension

furnished

the

lefttoloosen

righttoincrease

on

the

bobbin

bobbin

bobbin

down

case

case

the

thread.Ifthe

by

which

the

plateisset

by

free

the

tension

thread

this

nut

clockwise.

locatedinthe

spring

thread

the

will

slide

will

shaken down the thread, the tension is too tight.

usual

then

procedure

the

under

top

sideofthe

thread

is to

set

the

bobbin

tensionisadjusted

material

is perfect

formedasdecribed in the following

with

thread

around

the

The

the

back

mended,

value.

presser

and

slide

sleeve

clamp-

the

the

for

help

where

the

sleeve

and

con

article

to

discs

be

tension. To

clockwise

by

C (Fig. 3),

with

the

ac

the

the

bob

tension.

is

deter

thread.Ifthe

down

the

allow

bobbin

tension

until

and

the

can

the

no

paragraphs.

A

Page 11

Tensions

Perfect stitching depends to a great extent on the

proper adjustment of the

as

it comes to you,

but you

on

properly

will

need to readjustthem

typeofmaterial

If

the

stitching is

adjusted,

the

thread

has

the tensions properly adjusted,

tensions. The machine,

frequently,

sewed

and

correctly

threads

thicknessofthread

done

and

the

should

meetinthe

of the material,asshownbyA (Fig.7).

3000L

B

depending

used.

tensions

center

are

Fig.

7

If

the

top

too loose,

the

materialasillustratedinC (Fig.7).

When

thread

under

is too tight, the

sideofthe

form loops.

these

loops to

bunchy

and

threadistoo

the

bottom

the

When

appear,

will

top

thread

materialasshowninB (Fig.7),orit will

the top

not

give

thread

bobbin

the

tightorthe

will

is

too

thread

thread

darning

the

appearance

bobbin

be

pulledtothe

loose

or

will lie

is too loose,

will

tension

the

along

appear

of a

top

bobbin

causing

to

neat

is

of

the

be

job.

Page 12

Presser

The

knob

enable

by

making

comestoyou,isadjusted

heavy

encountered,

and

take

and

turnahalf

into

its

On

to

its

original

F (Fig. 8) isanadjustment

it to

workonthe

only

the

simplestoiadjustments.

work

as

nets,

raise

turn

position.

position.

the

adjusting

toward

holdofthe

new

returningtolight

V LF

Foot

heaviest

ior

coats,

presser

work,

Adjustiiieiit

built into the

as

wellasthe

light

and

the

this

medium

over-alls,

adjustment

adjustment

blankets,

lootbymeansofthe

knobF(Fig.

you;

machine

lightest

The

machine,asit

work.

When

and

8),

hand

Pull

this

knob

will

mustbereturned

materials

aprons

lifter

knob

then

such

out

slip

to

is

W

Fig.

8

Page 13

In

ordertoget

the

motor,

it is

adjusted.Ifthe

wear

of

the

slow

down

the

will

slip

and

The

tensionofthe

of

the

motor

the

motortothe

good

policytoalso

as

this

will

give

pulled

outofadjustment.

The

size

*16

and

needles

requirements.

mending,

such

as

and

nets,

Motor

Belt

the

essential

beltistoo

bearings,

machine.Ifthe

fail to

lock

bring

screw.

position

tighten

additional

furnished

asarule

Size

will

#14 is

sizes #18

coarse

cloth

Adjustment

maximum

that

tight,

belt,

the

belt

Loosen

desired

resistancetothe

Needles

be

and

and

speed

the

it will

and

beltistoo

machine

may

be

the

motor

with

the

found

obtainable

# 20 for

coveralls.

motor

and

beltiscorrectly

cause

motor

shaft

uptospeed.

adjusted

this

screw

and

retighten.

hinge

machine

to

meet

very

power

unnecessary

and

loose,

the

by

and

pin

motor

are

all

the

for

very

heavy

from

also

belt

means

bring

It is a

screw,

being

of

the

usual

fine

work,

nets,

SizeofThread

40

and

heavier

80to40

60to80

Fine

ClassofWork

work,

overalls,

trousers,

All

general

work,

shirts,

etc.

work

linens,

11

coats,

etc.

Size

20

16

and

14

Heavy

18

Page 14

To

Set

the

Needle

Turn

the

hand

wheel

bar

is in

its

uppermost

into

the

holeinthe

shank

the

Now

needle

toward

needleispushedupinto the holeasfarasit will go.

clamp

the

clamp

needle

the

needle

needleinthis

screw.

toward

position.

bar

clamp

you

Then

with

the

screw.

position

until

insert

FLAT

Make

by

the

the

SIDEofthe

means

Thread

A

good

machine. If the

with difficulty

cessful

useofthe

Left twist

thread

the

purposes.

any

used

materials.

linens, etc.,

paragraph

same

hard

for

for

both

size. A 60

It

qualities.

mending

A 40 (0)

as

under

grade

should

of

thread

threadisrough

through

thread

the

this

the

machine

should

needle

(GO)

be

soft,

A 40 (0)

coats,

thread

work

"needles."

is

and

thread

threadisheavier

aprons,

should

requires

should

be

or uneven, or, if it

eye

of

the

needle,

interfered

always

the

can

mercerized

nets

not

the

with.

be

bobbin

be

and

be

finer

used

and

used

used,

should

for

not

and

other

used

thread.

needle

needle

sure

that

of

the

with

the

passes

the

suc

and

the

be

general

contain

can

be

heavier

for socks,

See

of

are

at

To

in

least

Oiling

insure

movable

onceaday.

and

Lubrication

the

life of the machine, all

contact

with

A fine,

each

light

12

oil

parts

other

should

shouldbeused

be

which

oiled

which

Page 15

you

can

obtain

All oil

holes

the

motor

bearingsateach

ings

should

pending

not

over-oil

A

raceway

also

helps

Onceortwiceamonth

tion of a light

gearsinthe

moving

to

the

screwN(Fig.l)

Do

heavy

it to

run

grade

To

At

thread

bobbin

arm.

We

working

Remove

and

slide

the

unitofall

be

sure

the

sleeve

on

drop

of

the

side;

not

motor

slow

sewing

Oean

regular

and

unit

recommend

week.

off

haveafew

the

the

motor.

of oil

the

prevent

greaseorgear

machine.

nickeled

the

bottom

and

useacheap

oils,asthis

and

machine

lint

inside

the

the

thread

that

before

from

the

factoryorany

are

plcdnly

endofthe

drops

amountofuse

should

hook.

upper

This

The

be

thread

top

plateatthe

gears

tilting

the

oil,

gums

overstrain

oil.

the

Hook

intervals

which

retaining

sleeve

the

will

the

that

and

needle

it is

nickeled

this

screw

from

lint.

tightening

authorized

marked

with

the

motor.

of oil

occasionally

that

the

machine

applied

prevents

every

undue

breakage.

we

recommend

lubricanttothe

gears

may

be

top

rearofthe

by

removing

machine

and

the

motor.

and

the

back.

also

keep

machine

Always

Bobbin

the

necessarytoclean

accumulate

sleeve

be

done

the

When

lines

the

retaining

on

the

end

replacing

up

in

on

at

the

sleeveS(Fig.l)

of

the

with

exception

These

has.

day

friction

the

applica

two

reached

machine

base

away

and

useahigh

Unit

the

hook

the

mending

endofeach

arm.

the

the

hole

screw.

agent.

bear

all

de

to

and

sets

thumb

from

causes

out

and

Clean

sleeve

of

Do

the

of

by

the

in

To

base.

table

to

wipe

Excess

To

and

prevent

soiling

out

oil

the

screwN(Fig.l)

Qean

will

run

this

goodstobe

base

weekly. Todothis,

and

tilt

from

excess

machine

Base

inside

Plate

the

oil from flooding

mended,

it is a

remove

back.

13

machine

good

the

onto

thumb

to

the

the

policy

Page 16

Thread

Breakage

Occasionally

this

case

1.

Top

2.

Remove

tension

3.

Wrong

needle

4.

Follow

been

5.

Be

sure

ing

undue

6.

Check

bar.

same

7.

Run

small

replace

8. Do

not

machine

material.

9. In

darning

on

either

turntothe

willbecarried

snap

some

check

thread

bobbin

and

thread.

being

top

double

no

against

and

the

following

tension

correct

Either

used.

thread

twisted

cord,

or

uneven

thread

too

and

back

box

is

contacting

thread

needletosee

Flat

partofneedle

sideasthe

finger

nail

burr

or

with

needle

along

bent

new

point.Ifburr

needle.

continuetosewinone

run

any

length

acrossahole,besuretocatch

side.

Do

not

same

side.

downtothe

your

thread.

10. Too violent motion of

the

material

needle.

11. Remove

hooktoseeifneedle

its

point.

point.

Do

nor

loosened

will

the

nickel-plated

Use

a fine

not

use

unless

snap

stonetoremove

a file.

breakage

for

the

trouble:

tight.

checktosee

threading,

wrong

around

nor

from

anyofthe

other

twist

needle

obstruction

thread

if it is

must

needle

release

properly

clamp

from

betothe

screw.

point

is felt,

spot;

of timeonthe

darn

half

way

The

loose

loopofthe

hook

by

the

cloth or

the

thread

has

struckitto

Hook

sleeve

and

should

pointisactually

might

thatithas

or

too

to

see

thread

cone

the

occur.

proper

heavy

if it

guides.

is

causing

cone.

placedinneedle

right,onthe

and

check

for

remove

do

not

let

same

spot

the

thread

across

and

thread

the

needle

sudden

in

the

jerks

eyeofthe

check point of

causeaburr

any

burronhook

not

be

removed

broken

off,

In

for

has

lean

any

and

the

of

re

and

of

on

14

Page 17

INSTRUCTIONS

for

TIMING,

THE

All

strictly

with.

The

who

must

who

have

their

machines

on

the

machines

Important

the

ADJUSTING,

MECHANICAL

mechanical

alone,

and

following

replace

experienced

mechanical

are

properly

replaceable

end

should

pages

essential

and

of

these

AND

settings

SETTINGS.

should

not

be

are

only

CHECKING

tampered

partsorfor

troubleinoperating

wish

to

double

settings

to

see

adjusted.

Parts

illustrated

instructions

for

be

those

those

check

if

left

the

at

15

Page 18

Top

Thread

Tension

Details

DM-67

DM-67

of

Assembly

Assembly

Assembly

PositionofJ)M-67

Check

Sprinff@ is opposite CenterLine of Set

as

il/ustrated

obore...Toobtain

Screu! @ and rotate

Then

tiyhten

Stud^)

Set

until

When ossemb/iny

rotate

-NOTE-

Assembit/ is correct tuben top

this

DM-67

Assemb/y

position,

the desired

Screm @ securely.

details

—Before tiyhteniny

Spriny

(^positions itself ayainst

Loosen

Set

of

Screuit^

Set

amount.

Screut

lotuer

shoulder ujith a very sliyht tension. Otherujise Spriny(^

ujill have no tension

ing of the

Tension

andusill

Barrel

'float' in the

@ .

16

s/otted

open

Page 19

-y

/

"sr£P

'Remoye

take

Z"^3TEP

Sarasfaraspossib/e,

timing

direct/gintineuiith Pin(^as

Sereuis(2)@

o/y

Face

P/ate

Making

sure

the

mark ©

j

^^

\f

\

' L r\ //

I Nig.ZHandatthe

\ 1

Fig.

iTi\

W

j of the

gA as shouin beloin in

J

(y

Fig.2

NEEDLE

and

Latch

Need/eisup

turn

2 onCrankHead©

Ht this time the point

Hook©Fig.

the

lierticai

Needle

shouin

To

ments,

lined

Machine

TO HOOK

S/eeve.

into

shouin

2 shou/d beat

Center

and

the

Needle

until

inFig.2.

'f/eofan

Needle

machine

aboye

in enlarged

scarf

in the

make these

proceedasaut--

be/oui in

d'l

Fig.

P 4

step

2A

Timing

/is-

^

of

Line

of.

£ye

yiem

center

Needle

Fig.

2B.

adjust-

.

ISeAEr

lin

NecBiE

Fig.

^

.lArcM

2B

ii4arAiiiiiici!s

TCliahaucs

•3k

0 _

Sceiye

Loosen

Yokc

Fig.

PssenOLy

3

to L

d Screuist^Fig^ and turn

eft

or Right on

Noui

check

tuteen

scarf

as

shouininFig.

To

adjust

loosenSet Screui@ Fig.3

Yoke

Assembly in or out on

certain

(^omst the

that

Tighten3 Screuis ©

securely

bind

atO).

Hook

making

Shaft@the

for

Yesofan

in Needle

2B.

lateral

position of

hubofHook

Yokeatpoint @

and

certain

Shaft

and

mch

clearancebe—

and

pointofNook

and

Shaft

shoulders

Set

thai

bu

too

more entire

Figs.kB

ScreuiQ)

desired

Hook

and

@ making

firmly

and

youdonot

much

pressure

Hook(^

amount.

Yokej

3•

Fig.3

Page 20

I^^STCP

The

clearance

Holder!^

and

F'iffs.Iand

ly

'/az

ofan

To

adjust

(^(nearest

three

Set

Screius on undersideofYoke

Castiny) F7y.l

Bobbin

betiueen

£obbin

JA) should be approximate

inch.

c/earance,

one

toujords operator of

and

Sobb/n

@ at (^(See

Joosen

turn

Eccentric

Set

Screiu

Clearance

Screu!@ rightor /eft until the desired

c/earonceisobtained.

Set

Screui@ securely.

Si

j/cr

The

amountofclearance

ed

endsofAdjusting

(SeeF/gs.J

the

Lock

on Bobbin Case -

in

position

Excessive

will

Ciass-/36-I3S-I40

and

threadtopass

liutsand turn

with screwdriver

clearanceat(xi^

Cause

rattling of

For

Chanbler

Then

tighten

between

Sereuis(^and £obbin^)at(x^

JA) should beJust sufficient to

then

-NOTE-

between

Adj.

loosen

them.7badjust, loosen

Screw

(^untHit

aboutWofaturn.-hold

and

tighten

Tig.

Darner

AND

JA

Case(^.

144-

BoMin

the

inside

tightens

Lock

For

Chanbler

crown

alloia

Huts.

Darner

Class-/46

Fiq.1

Fig.

JA

/

STEP

The

Fig.

2

STEP

point

Adjust

for

clearance

F'igIAby

means

of Adjusting Screuis(^Fig 2

using

same

linedinthe

procedure

above

as

out

B^^STSP.

Holderf^and Bobbin

F'gs2and

Ig '/asofan inch. 7b

L

ock

ed

at

desired

Threaded

Lock

clearance

Nut @

washer

clearanceisobtained.

Washer

Hut

between

IA)shauldbe

Fig.2and

@ in or out

@ in

secure/g.

@at

adjust,

turn

until

position^

Bobbin

@(See

app/vximafe'

loosen

Threadthe

Holding

tighten

Page 21

Parts

Replacement

List

Important—^When ordering parts please give

CLASS

and

SERIAL

number

19

of

machine.

Page 22

DM-

DM-

DM-

DM-

DM-

DM-

67

72

17

18

19

18

Tension

Tension

Thread

Thumb

Tension

Thread

Parts

Washer

Release

Tension

Tension

Stud

Guide

List

Disk

Spring

Nut

DM-105

DM-

DM-

DM-

DM-

DM-101

DM-177

DM-

DM-

DM-

30

8G-B

67-AS

33

20

40-AS

39

Thread

Needle

Take-Up

Thread

Presser

Presser

Tension

Thread

Presser

Presser

Guide

Bar

Thread

Guide

Spring

Tension

Lifter

Lifter

Spring

Tension

Assembly

Cam

Cam

Barrel

Release

Roller

Bar Lifting Block,

Bar

Guide

20

Pin

Assembled

Page 23

I

Page 24

DM-

DM-

DM-

78-AS

79A-AS

79-AS

Bobbin

Bobbin

Bobbin

Parts

Case,

Case,

Case,

List

Assembled

Holder

Holder

Assembled

Assembled

DM-130

DM-132

DM-

89

DM-190

DM-

45

DM-127-AS

DM-

87

DM-189A

DM-

77

DM-

38

DM-189

Bobbin

Bobbin

Bobbin

Bobbin

Latch

Bobbin

Latch

Latch

Hook

Latch

Latch

Case,

Case,

Case,

Case,

Adjusting

Case,

Guard

Sleeve

Tension

Tension

Adjustment

Adj.

Screw

Washer

Bobbin

Clamp

Screw

Spring

Spring

Screw

Lock

Retaining

Adj.

Nut

Screw

Latch

22

Page 25

DM-169

FOR CLASS 136, 138

AND

140

MODELS

DM-38

Page 26

DM-

5-AS

Bobbin

Parts

Winder

List

Assembled

DM-178

DM-

22

DM-110

DM-136

DM-183-AS

DM-

24

DM-104

DM-113

DM-

55

DM-

32

DM-

9

DM-

34

DM-

lOA

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Presser

Presser

Take-Up

Take-Up

Take-Up

Needle

Needle

Take-Up

Winder

Winder

Winder

Winder

Foot

Foot

Lever

Fulcrum

Yoke

Bar

Conn.

Bar

Conn.

Fulcrum

Spindle

Wheel

Tension

Tension

Hand

Rod

Lifter

Hub

Link

Stud

Hub

Spring

Strap,

Stud

Assembled

DM-

DM-

8

81

Take-Up

Needle

Yoke

Clamp

Screw

24

Page 27

DM-5-AS

DM-II3

DM-34

DM-lOA

Page 28

CHANDLER

Chandler

An

indispensable

cylindrical

By

even

mended.

binding

is

provided

bobbins.

Will fit

arm.

numberofmachine

A

should

armofthe

the

use

laundry

Slips on or off

screw

for

any

When

Monuiacturers

ordering,besuretospecify

real

practical

not

be

CHANDLER

located

without

"Flat

accessory

Darning

of this

nets

plate,

can

merelybythe

under

convenience

model

for

having

which

accessory

one.

AVER,

ol

the

famous

Work"

easily

Machine.

sheets,

be

easily

the

plate.

in

placing

a 2"

plateisrequired.

for

MFG.

COMPANY

MASS.

CHANDLER

Plate

attached

towels,

and

smgle

An

or

diameter

model

your

DARNER

to

napkins

conveniently

and

twistofthe

opening

slide

removing

cylindrical

and

serial

Darner; you

the

the

Page 29

A

for

the

Darning

itself to

spots.

fast

colors.

Chandler

large

supplyofSpecial

convenience

Thread

machine

Availableinblack,

of

is of a soft

darning

Darning

Darning

our

many

mercerized

without

white

Thread

Threadisstocked

customers.

nature

making

and32vat

Chandler

which

hard,

dyed—boiled

lends

lumpy

These

into

the

wound

white

Ready

paper

Chandler

bobbins

only.

bobbins

Darner,

packed

Wound

are

all

Saves

in half gross

Bobbins

wound,

winding

boxes—black

readytoinsert

time.

Ready

and

Page 30

A

complete

tableatany

A flexible socket

DOUBLE

held

clamp

FEATURE

to the

which

Chandler

unit

location

light adjustment. The complete unit is

edge

of the

can

be

which

the

operator

attached

table

expanded

Sewing

Light

clampsonany

finds

to a flexible

by

meansofan

to fit a

sewing

most

table

machine

convenient.

arm

gives

adjustable

withamaxi

mum thickness of 2". The Chandler Light although de

signed

typesofsewing

for

the

Chandler

Darner

can

also

be

used

on

equipment,

You will find this light indispensable on rainy

other

days

or in the winter when the light is weak. If your sewing

equipment

Chandler Light today] It

is

SAVE

Manufacturers

EYESTRAIN

CHANDLER

not

well

Comes

ot

lighted,

complete

AVER.

the

pays

—

MFG.

famous

big

DO

with

COMPANY

MASS.

CHANDLER

by

all

dividends.

NEATER

cord

means

WORK

DARNER

order

a

Page 31

CHANDLER

^ DARNING AND MENDING MACHINES.

4 FLUTING MACHINES, HAND OR POWER

4 HAND OR POWER

^

SEWING

4

REBUILT

4 PLEATING MACHINES.

^ RUFFLE mONERS.

4

CUFFTACKERS.

^ LABEL

THREADS.

TAILORING MACHINES.

TAGGERS.

BUTTON

SEWERS.

Loading...

Loading...