Page 1

Model

CM101

INSTRUCTION

MANUAL &

PARTS

LIST

Page 2

1.

Unpacking

the

Machine

INSTRUCTION

INDEX

..........................................................

MANUAL

1

2. Setting-up

3.

Hand

4.

Oiling

5.

Replacing Needle

Threading

6.

7.

Inserting

8.

Adjustment

9. Stitch

10. Needle

11. Skip Stitch Device

12. Removal

Cloth

13.

14. Stitch Stabilizing

wheel

Length

Machine

Rotation

and

Maintenance

......•...........................................................

Machine

the

Work

of

Needle

Regulation

Recommendation

of

the

Work

Retainer

Spring

.................................................................

and

Speed

..........................................................

...............................................................

and

Starting

Penetration

.........................................................

........................................................

................................................................

from

Adjustment

Guide

..........................

................................................

to sew

the

Machine

.............................................

.......................................

....................................

...........................................

.,

..............................

1

1

1

2

3

4

4

5

5

6

6

7

7

Page 3

1.

Unpacking the Machine

Open

parts

Small accessory

materials

Clean

mechanism

packing

which

from machine all grease,

box

project

parts

without

and

looper.

by

carefully removing its cover so as

from

the

are

packed

prior

scrutiny

2. Setting-up the Machine

Assemble knee lifter lever to machine

from

the

front

edge

of

the table. Line

3.

Hand

groove

sewing table

The

motor

for a brand

weeks

increased

of

drive mechanism

and

place felt

wheel Rotation

hand

wheel should

drive is set

new machine is 1,800 to 2,000 stitches

and

after

the

up

to 2,500 stitches

up

to

operator

rotate

operate

and

top, such as

separately

as to contents.

dirt

(motor

pad

under

Speed

away

in

the

has

become skilled in

per

minute.

the

tension

in

individual packages. Do

or

dust.

Pay

particular

and

place on sewing table so

up

belt groove in belt pulley

or

clutch).

machine

from

same

Mark

bed

the

operator

clockwise rotation.

three

before machine is tightened down.

per

the

not

to damage the machine

parts.

not

discard

attention to

screw holes

in a clockwise direction. Be

The

minute.

operation

After

of

area

around

that

the

lever is 13mm

of

the

hand

wheel

for

fastening machine to

recommended

a breaking-in

the machine,

or

those

any

packing

the

with

sure

the

operating

period

the

speed

of

looper

distant

belt

speed

of

several

can

its

be

4. Oiling

It

is

every oiling

done

the

machine carefully to avoid soiling

Never

depressed. This will

and

Maintenance

important

sparingly several times a day.

operate

not

point

the

to

operate

along

the

machine

prevent

the

top

of

without

damage

machine before high quality oil

the

machine.

Thereafter,

the

material

to

the

When

one oiling daily will

material.

under

needle

breaking-in a new machine oiling should

the

and

presser

the feed dog as well as

foot unless

has

been applied to each

be

sufficient.

the

knee lever is

the

and

After

feed platens.

oiling, wipe

be

1

Page 4

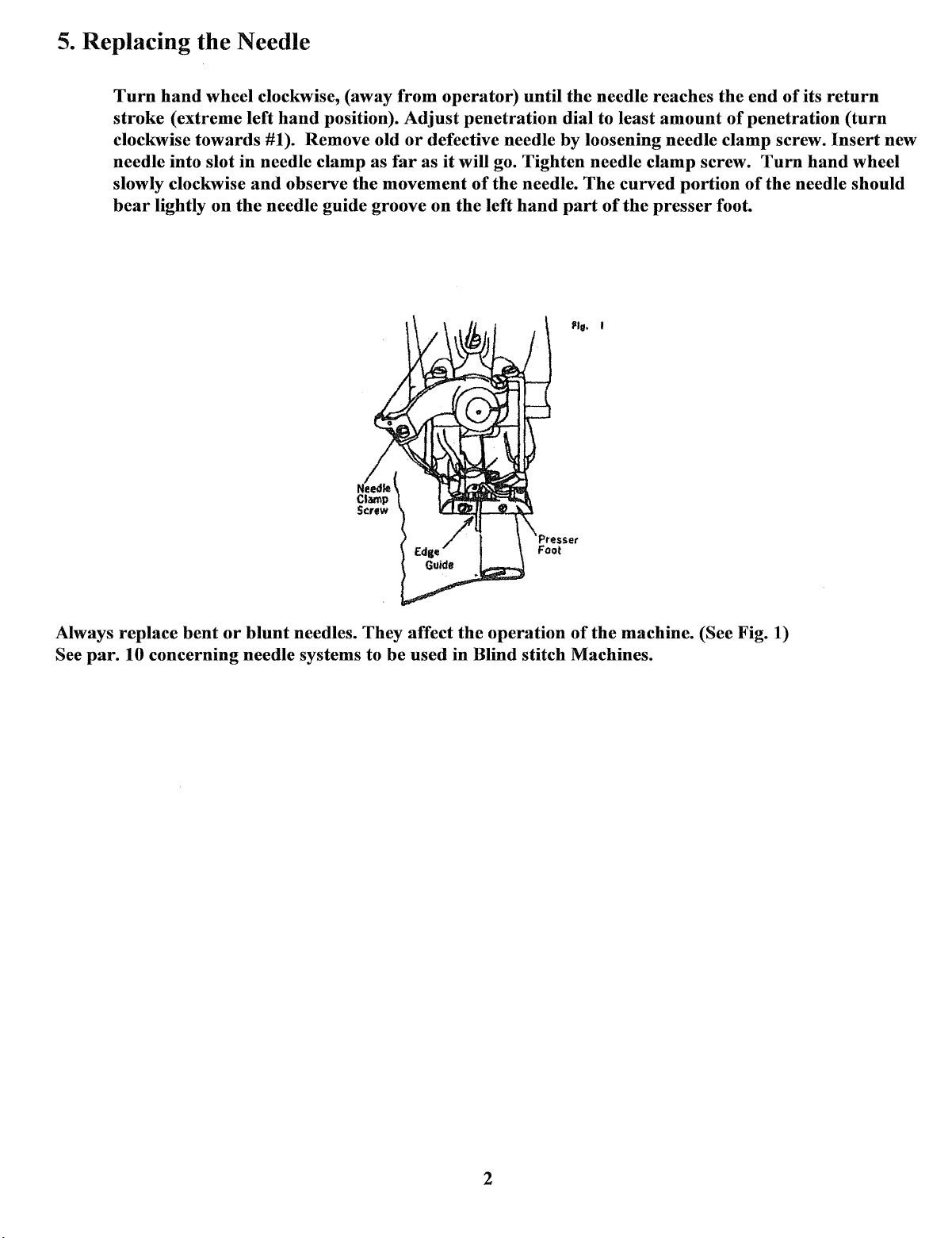

5.

Replacing the Needle

Turn

hand

wheel clockwise, (away

stroke

clockwise

needle into slot

slowly clockwise

bear

(extreme left

towards

lightly

on

in

and

the

from

hand

position).

#1). Remove old

needle clamp as

observe

needle guide groove

the

Adjust

or

far

movement

operator)

penetration

defective needle by loosening needle clamp screw.

as

it

will go. Tighten needle clamp screw.

of

on

the

the

left

until

needle.

hand

the

needle reaches

dial to least

The

curved

part

of

the

amount

portion

presser

the

end

of

penetration

Turn

of

the

foot.

of

its

needle should

return

Insert

hand

(turn

new

wheel

Always replace

See

par.

10 concerning needle systems to

bent

or

blunt

needles. They affect

be

used

the

operation

in

Blind stitch Machines.

of

the

machine. (See Fig. 1)

2

Page 5

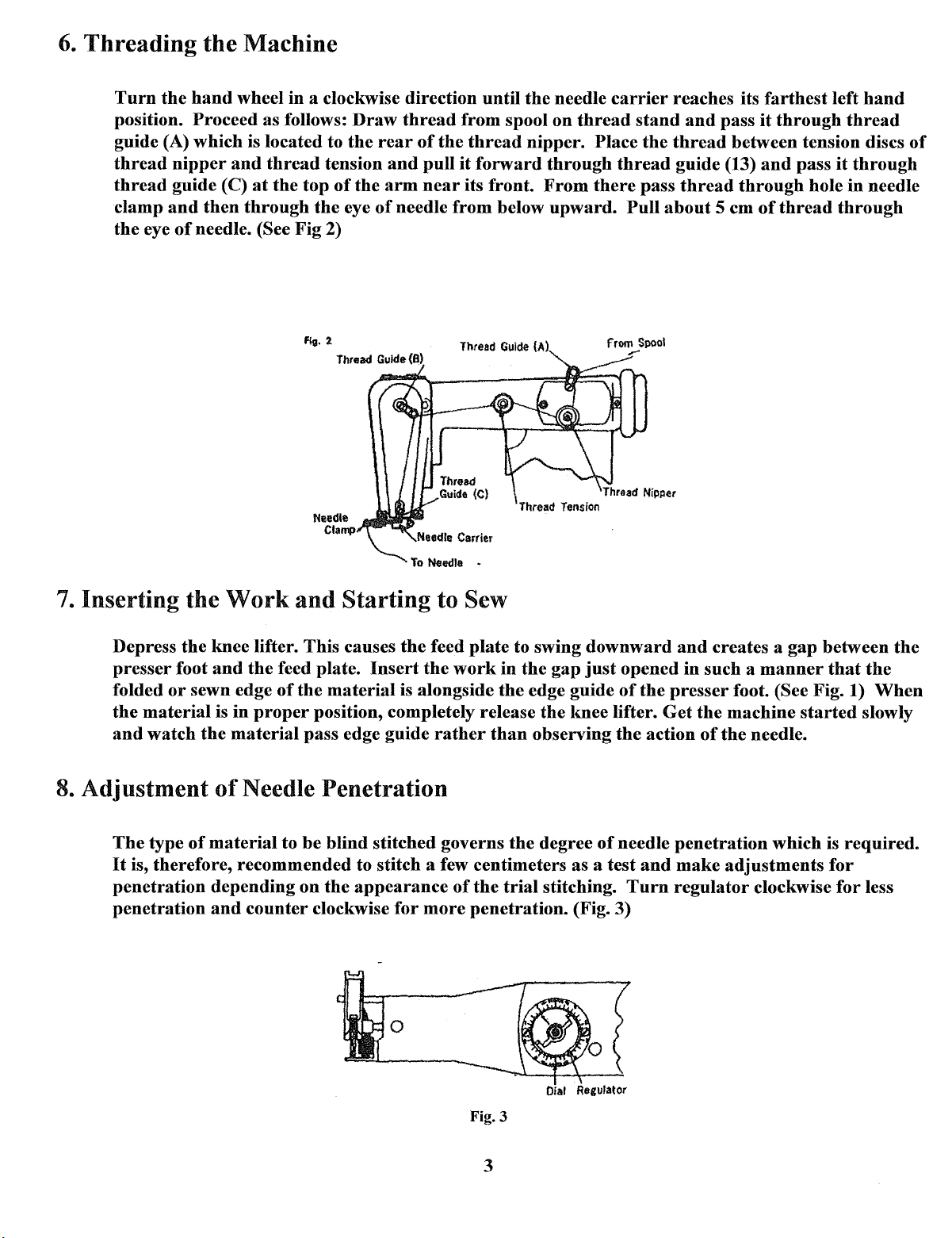

6.

Threading

Turn

position. Proceed as follows:

guide (A) which is located to

thread

thread

clamp

the

the

nipper

guide (C)

and

eye

of

the

Machine

hand

wheel in a clockwise direction until the needle

and

thread

at

the top

then

through

needle. (See

the

Fig

Draw

the

tension

of

eye

2)

the

rear

and

arm

of

needle

thread

of

the

pull

near

from spool on

thread

it

forward

its front.

from

below

Thread Guide (A)

carrier

thread

nipper. Place

through

From

upward.

thread

there

Pull

from

,...

reaches its

stand

the

thread

guide (13)

pass

about

Spool

and

pass

thread

5 em

farthest

it

through

between tension discs

and

through

of

thread

left

hand

thread

pass

it

through

hole in needle

through

of

7.

Inserting the

Depress

presser

folded

the

material

and

watch

8.

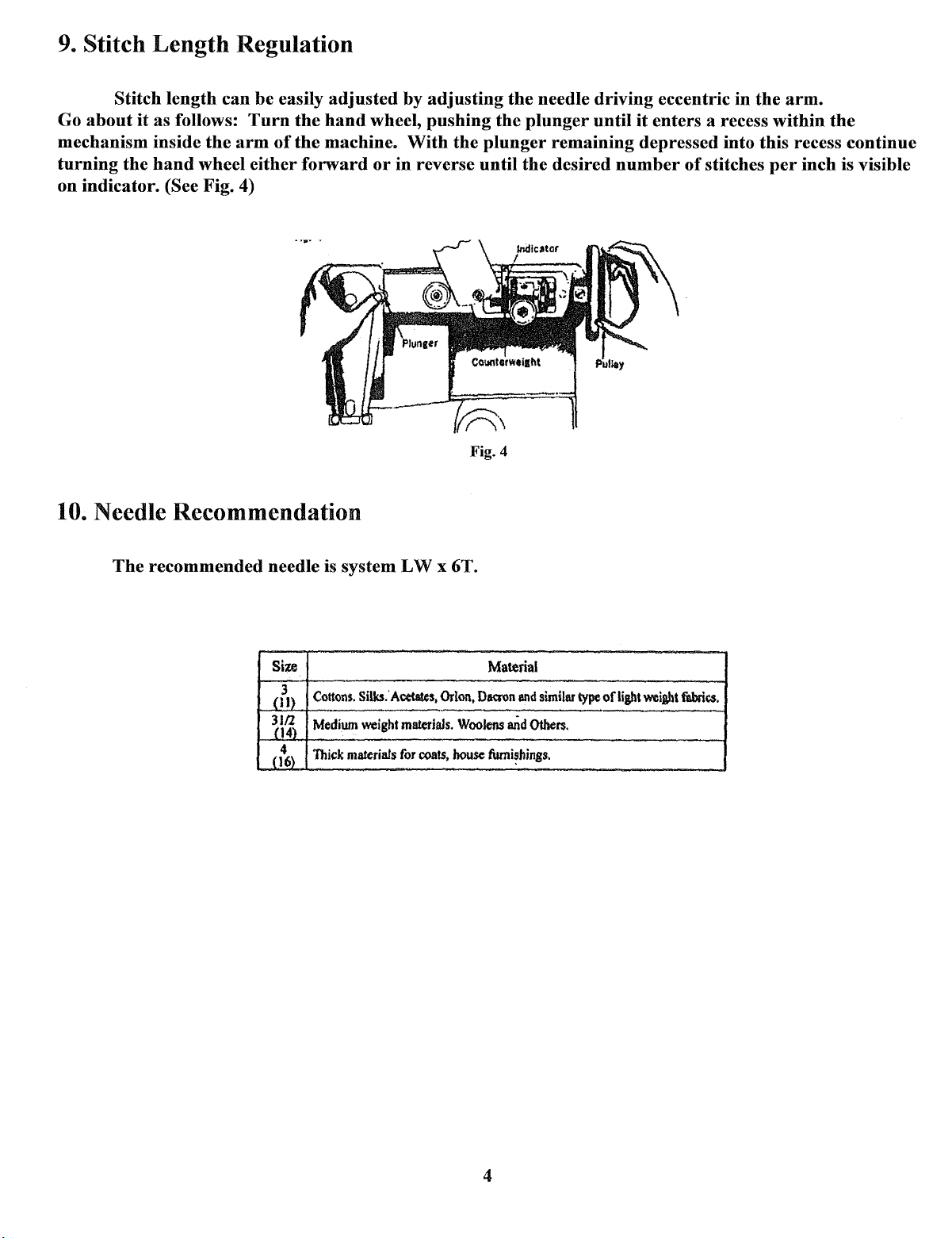

Adjustment

The

type

It

is, therefore, recommended to stitch a few centimeters as a test

penetration

penetration

Work

the

knee lifter. This causes

foot

and

or

sewn edge

is

in

the

material

of

Needle Penetration

of

material

depending on

and

counter

the

feed plate.

of

proper

to

and

the

Starting

Insert

material

position, completely release

pass edge guide

be

blind stitched governs

the

appearance

clockwise

to Sew

the

feed

the

work

is alongside

rather

of

for

more

0

plate

in

the

than

the

trial

penetration. (Fig. 3)

to swing

the

gap

edge guide

the

observing

the

degree

stitching.

downward

just

opened in such a

of

the

knee lifter.

the

action

of

needle

and

Turn

and

creates a

presser

Get

penetration

make

regulator

foot. (See Fig. 1)

the

machine

of

the

adjustments

gap

manner

started

needle.

which is

clockwise

between

that

the

When

slowly

required.

for

for

less

the

Oial

Fig.3

3

Regulator

Page 6

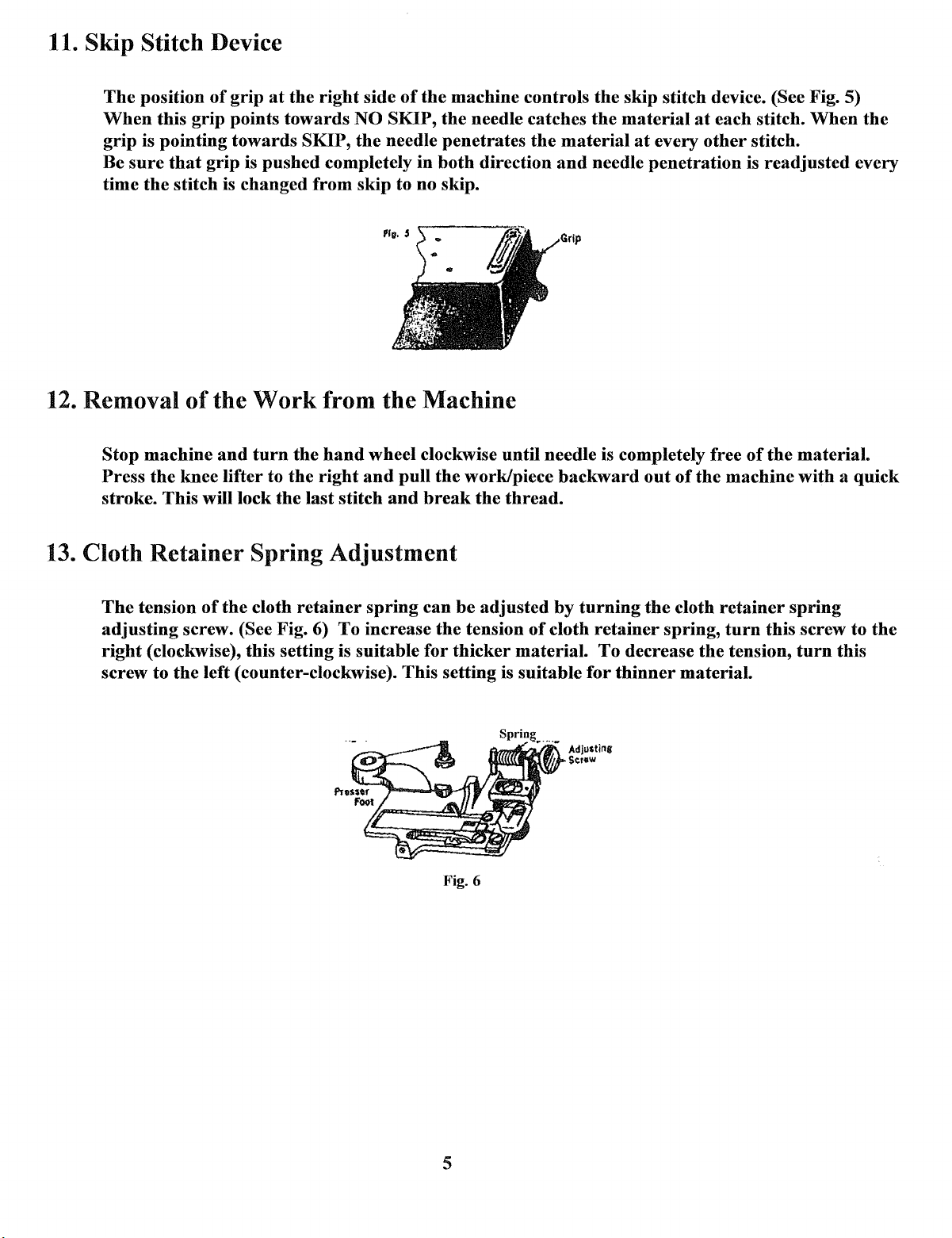

9.

Stitch Length Regulation

Stitch length

Go

about

it

as follows:

mechanism inside

turning

on indicator.

the

hand

(See Fig. 4)

can

be

easily

Turn

the

arm

of

wheel either

adjusted

the

hand

the

machine.

forward

10. Needle Recommendation

by

wheel,

With

or

in

adjusting

pushing

the

reverse

Fig. 4

the

the

plunger

plunger

until

the desired

needle driving eccentric in the

until

it

enters a recess within

arm.

the

remaining depressed into this recess continue

number

of

stitches

per

inch is visible

The

recommended needle is system

Size

3

Cottons.

_(11}

Medium

~\~

4

Thick

(16)

Silks.'

weight

materials

LW

Acetates,

materials.

for

coats,

x 6T.

Orion,

Woolens

house

Material

Da®n

end

similar

type

and

Others.

fumi~hings.

ofligbt

weigbt

fabrics.

4

Page 7

11. Skip Stitch Device

The

position

When

grip

is pointing

sure

Be

time

the

this grip points

of

grip

at

towards

that

grip

is

pushed

stitch is changed

the

right

towards

SKIP,

completely in

from

side

of

the

machine controls the skip stitch device. (See Fig. 5)

NO SKIP,

the

needle penetrates

skip to no skip.

the

both

needle catches

the

material

direction

and

the

material

needle

at

at

every

penetration

other

each stitch.

stitch.

is

readjusted

When

the

every

12. Removal

Stop

machine

Press

stroke. This will lock the last stitch

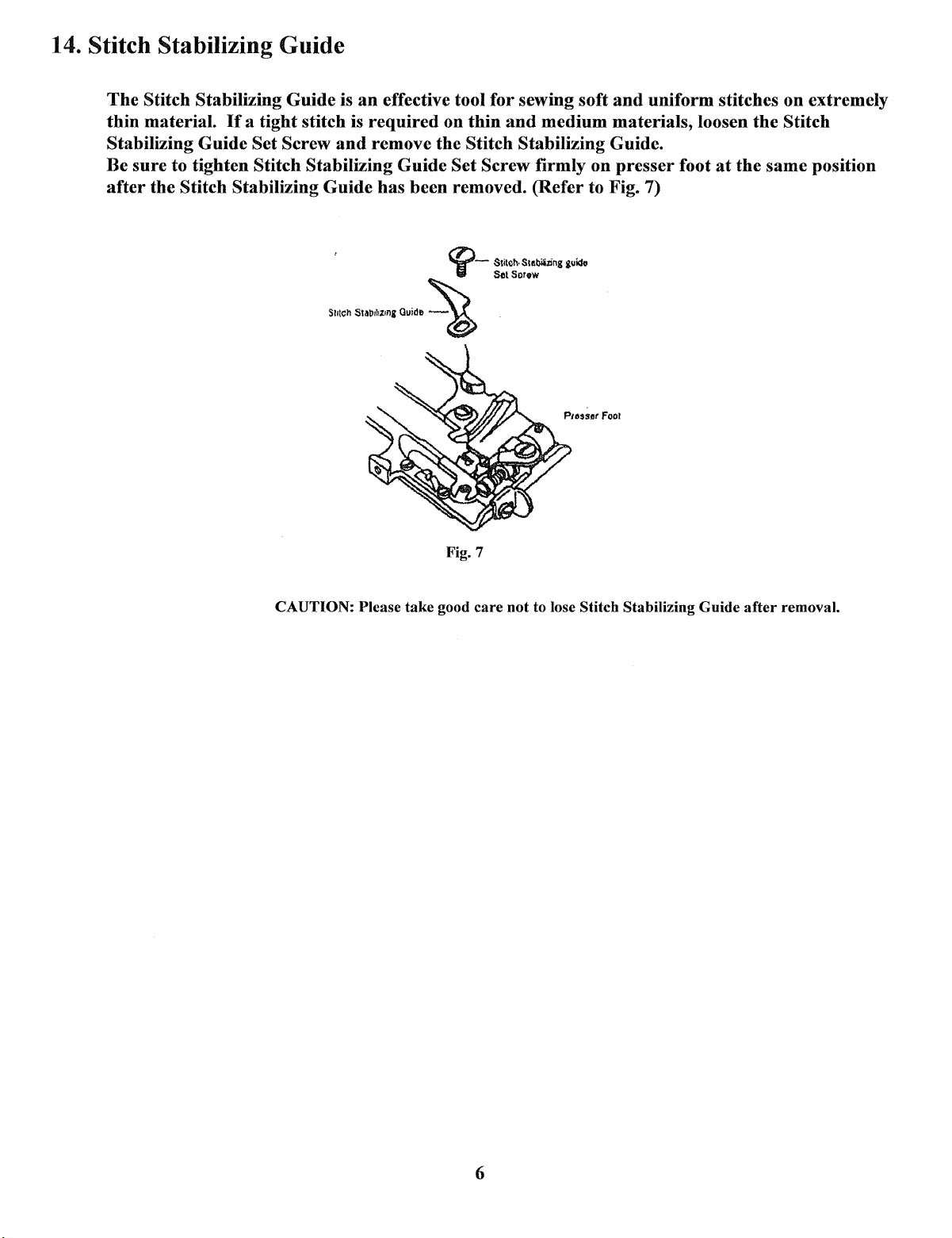

13. Cloth

The

adjusting

right

screw to

the knee lifter to

Retainer

tension

(clockwise), this setting is suitable

of

the

Work

and

turn

Spring

of

the

cloth

screw. (See Fig. 6)

the

left (counter-clockwise). This setting is suitable

from

the

hand

wheel clockwise until needle is completely free

the

right

and

Adjustment

retainer

spring

To

increase the tension

the

Machine

pull the work/piece

and

break

can

for

the

be

adjusted

thicker

Wi\IUII'!ir.IIY/J'

thread.

material.

backward

by

of

cloth

AdJU$tins

...

Sc:r•w

turning

retainer

To

decrease

for

thinner

out

of

the

cloth

spring,

the

machine

retainer

turn

the

tension,

material.

of

the

material.

with a quick

spring

this screw to

turn

the

this

Fig. 6

5

Page 8

14. Stitch Stabilizing Guide

The

Stitch Stabilizing Guide is

thin

material.

Stabilizing Guide

Be

sure

to tighten Stitch Stabilizing Guide Set Screw firmly on

after

the Stitch Stabilizing Guide

If

a tight stitch is

Set Screw

and

an

effective tool

required

on

for

thin

sewing soft

and

medium

and

materials, loosen

remove the Stitch Stabilizing Guide.

presser

has

been removed. (Refer to Fig. 7)

uniform stitches on extremely

the

Stitch

foot

at

the

same position

CAUTION: Please

take

Fig. 7

good

care

not

to lose Stitch Stabilizing Guide

after

removal.

6

Page 9

PARTS

LIST

CONTENTS

Machine Frame & Covers Components

Main

Shaft Mechanism Components

Needle

Looper

Ridge

Disc

Forming

Oscillating

Carrier & Feed

Drive

Mechanism & Presser

Disc &

Mechanism & Knee

Dog

Mechanism

Feed

Plate

.........................................................

Foot

Mechanism

Press

Components

Thread

Work

Standard Accessories

Tension &

Plate,

Knee

Nipper

Press & Belt

............................................................................

Parts

Components

Cover

Parts

......................................................

Components

Parts

Components

Components

Shaft

....................................

.....................•....

..............................

Parts

....................................

...............................................

Components

.........................•......

1

2, 3

3,

.4, 5

6

7

8

9

1 0

4

Additional

Additional Parts for Model

Parts

for

Model

CM

101 (Non-Skip Stitch)

CM

101

..........................

....•.............................

o

••••••••••••••••••••••••••••••

11

12

Page 10

Machine

Ref. No.

Frame & Cover

Pam

No.

4139

1

2 4144

4137

3

5227

4

4138-B

s

4141

6

1

4140-A

4143.

8

4048-A

9

10 AMIOO-Il

tl

11091 End

12

lllS3

4214

13

14

AC-15

AC-17

15

AC-16

16

Arm

Side

Arm

Side

Arm

Side

Arm

Side

Arm

Top

Arm

Top

Arm

Top

Belt Guard

Belt

Guard

Machine

Cover

End

Cover

Machine

Machine

Machine

Machine

Components

DeJcription

Cover

Cover

Set

Screw

Cover

Plate

Cover

Plate

Screw

Cover

Plate

Cover

Plate

Screw

Cover

Plate

Washer

Set

Screw

Frame

Set Sctew

Base

Felt

Pad

BaS8

Clamp

Screw

Base

Washer

Base

Nut

1

Page 11

Main Shaft Mechanism Components

18

R~f.l\lo.

1

llOOs

2

3

4217

4

4128--.1\

5

413J

6

132

7

8

4134

9

l(i

11

12

13

14

114

llOQ6

4003-.1\

6048

96

4162

Parr, No.

Oek,it:~tion

Main

13J

98

Shaft Bushing

Alain

Shaft

Felt

1Ju$hing

Oiling

Oil

Cap

Counterw!!\sht (WfStitch Length NuJnbers)

Couttterweight Set Screw (Shott)

~ounterweight

Stitch Length Indicator

Slitch Length Indicator Set Screw

Main Shaft Bushing (Rear}

Main

Shaft

Thread

Tension

~eteasing

Thread

Tension

Skip Stitch Gear <Small)

Releasing Eccentric Set Screw

Wrono

Set

Screw

Set Screw (Long)

£ccentric

2

Page 12

Main Shaft Mechanism Components (continued)

15

16

17

18 105 &;centric Rod Set Screw

19

20

21

22

23

24

25

26

27

28

29

JO

31

% Skip Stitch Gear Set Screw

525-A

4065 Eccentric Rod

114-B

4077-A

132

4163

4164 Eccentric Rod Connection

4166-A

131

4168

Eccentric Rod Assembly (w/Ref. Nos. 17, 18)

Eccentric Bushing Screw

98

Stud

Eccentric Rod

Skip Stitch Gear Shaft Collar (Small)

Skip Stitch Gear Shaft Collar Set Screw

Skip Stitch Gear (Large} Assembly

Skip Stitch Gear Shaft

Skip Stitch Gear Shaft Set Screw

Skip Stitch Gear Shaft Collar

Stud

Set

132 Skip Stitch Gear Shaft Collar Set Screw

4142-B

131

4207-A

Hand Wheel (Pulley)

Hand Wheel

Hand Wheel Rubber Cap

Set

Screw

Screw

(large)

3

Page 13

Needle

Carrier

& Feed Dog Mechanism Components

Ref. No.

1

2

3

4

s

6

7

8

9

10

11

12

13

14

15

16

17

18

19

10

11

22

23

24

2S

26

21

28

2.9

30

31

32

33

34

35

36

37

38

39

40

Parts No.

4128-A

4217

4623-A

Oil C.p

O.lling

Needle Carrier

Description

Felt

4024 Needle Carrier Set Screw

4019 Needle

Canier

Shaft

4022 Noedle Carrier Shaft Collar

129-8

4020-A

129-

4021-A

129-A

4017-A

4018-A

114-

Needle Caniei

Shaft

Needlo Carrier Shaft

A Needle Carrier

. Needle

Needle

NeedleCaulor

Canier

Carrier

Shaft

Shaft

Shaft

SbaftCrank

Needle Carrier Shaft Crank

A Needle Carrier

Shaft

Collar Set Screw

BUJhln.g

Bushing Set Screw

BuJhin&

BuJhin&

Set

Crank Clamp Screw "

11139 NeedlcCfamp

121

4181

1151 Needle Drivins Eccentric Assembly

4211

4173

4009-B

4012-A

4010

4011-A

4014

4()]5

1 1 902 Feed

11124-J

11121

10129 Feed

2528 Feed

4048-A

1152

4173

4642-A

4044 Feed Link

4043

129-

520-A

129--A

Needle

Clamp Set Screw

Ntedle{Sy,tem

Reaulator A Serews (Ref. Nos.

-C

Balt Connecting

Ball

Connecting

Needle Driving Eccentric

Stitch

Regulator Sc:rew

Stitch

Regulator

Stitch

Regulator Spring

BallConnectlJ1i

Ball Connecting

Rod

Rod

Lever

Oiling Felt

OiJCap

Do,g

Dog

Washer

Screw

&.

Stud

Link Clamp Sctew

-A

Feed

Feed Dos Set

Feed Link

FMd Link Stud Set Screw

Feed

A Feed

Stitch

Stitch

Ec011ntric

Link

Ecoontdc

Link

Ecoonuic Stud Bushing

Length Regulating Plunger Assembly

Length Regulating Plunger

LW

Rod

Rod

Ban

x 6T)

Set

Screw (Short)

Set Screw

Set

Cap

Cap

Set

Stud

Stud

Bushing

Screw

Screw

(Front)

(Rear)

Set Screw

Screw

wjRod,

19-

22)

(Lon,g)

Set

Screw

Set

Screw

4

Page 14

2

24

.-

15

Looper Drive Mechanism &

Looper Drive Crank Assembly w /Looper Y

A

Screws

Looper

Looper Drive Clank

Looper Drive Crank Stud Collar Set Screw

Looper

Looper Yoke Set

Looper Yoke

Looper Yoke

Looper Carrier Assembly

Looper Carrier

Looper Carrier

Looper Carrier

Looper Carrier

Looper Carrier

Looper

Looper

Eccentric

Eccentric

PteJSer

Presser

Presser

Presser

Presser

Presser

P.resscr

Plain

Needle

Stitdl Slllbili:dJis Guide

(Ref. Nos.

Drive

Yoke

Clamp Screw

Sleeve

Sleeve

Foot Set Screw

Foot Bracket

Foot

Foot

Foot

Foot

Foot

Presser

Guide

2-8)

Clank Set

Stud

Screw

Pin

Pin

Set Screw

Nut

BaU

Joint Set Screw

Ball

Joint Clamp

Ball

Spot Screw

A Pin

Clamp Screw

Bracket Adjusting Screw

Bracket Holding

Braclcet

Washer

HoldUtg

Screw

Auembly (Ref.

Foot

2

3

4

s

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27-1

538-A

4191

5039-A

129-B

4030-A

4031

4032-A

8142

539-A

4035-A

4116

4216

4213

4179-D

4040

4039

sos

4038

4050

4061-A

4062

121-B

11158

4186-A

PFlOO

4049-B

11563

11563-A

Presser

Screw

Nut

w/BaU

Joint &

Screw

Screw

Nos.

26-40)

Foot

olce

Screws

(Ref.

Parts

Nos.

1 O-J S

Components

5

Page 15

Looper

28

29

30 4185 · O!alnfna Finger Set Screw

31

32 4185

33 4056

34 4054

35

36 4053

37

38

39

40 4059 Edge Guide

41 4185

Drive Mechanism &

4052-B

4058-A

4055CAS

4183

130-.B Ooth Retainer Eccentric Stud

4051-C

4182 Ooth Retainer Stopper Set Screw

Needle Guide Set Screw

O!aining Finger

Oath

Retainer

Oath

Retainer Screw

Ooth

Retainer Spring

Ootlt

Retainer Eccentric Stud

Ooth

Retainer

Ooth

Ret.uner Eccentric Stud

Ooth

Retainer Stopper

Edge

Guide Set Screw

~ccentric

Presser

Stud Set Screw

Bushing

Bushing

Foot

Set Screw

Parts

Components (continued)

Ridge

Forming

Disc & Feed Plate Mechanism Components

7

6 I

5~

6

Page 16

Ridge

Forming

Disc & Feed Plate Mechanism Components

Rof. No.

l

l

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

2l

24

25

26

1.1

28

29

30

31

32

n

34

35

36

37

38

39

40

41

42

Parts No. Description

11220-T

4208

52Z2-B

f:llSO

4109-A

4111 Rid,ie Formin& Dlsc Shaft Collar

129-B

4112

lll-B

SIS-A

108

4176

4102 Dille Adjusting Holder

4 HIS Disc

98

4107

98-A

4104

4105

4106

4103-A

5208

U075-A

4(143

98

4090

129

SHi-B

4101 Feed Plate Taper Bearing Screw

4070

4096 Feed Plate Shoulder Bearing Screw

4093-BA

4094 Feed Plate Sprifl!l Screw

Ridge

Forming Disc

Ridge

Forml11g

Ridge Formin& Disc Washer

Ridge Forming

Ridge

Forming Disc ,Shaft·

Ridge Forming Disc Shaft Collar

Ridge Formhlg Disc Shaft Crank

Ridge Forming Disc Shaft Crank Set Screw

BaU

Joint&. Stud Assembly with Screws (w/Ref.

Ball Joint Set Screw

B!!U

Stud Nut

AdjU$ting

Disc

Adjusting

Disc

Adjusting

Disc Adjusting Holder Pivot Bearing Pin Set Screw

Disc Adjusting Holder Spring

Disc Adju$tlng Holder Spring Screw

Disc Adjusting Holder Spring Nut

Disc Adjusting Holder Spring Stud

Disc

Adjusting Holder Spring Stud Nut

Fet~d

Plate Shaft

Feed Plate Shaft Bushing

Feed Plate Shaft Bushing Set Screw

Feed Plate Shaft Collar

-8

Feed Plate Shaft Collar Set Screw

Feed Plate Assembly w/Screws& Nuts (Ref. Nos. 29, 30)

Feed Plate

Feed Plate Spring

Disc Nut

Disc

Positioning Pin

Holder Pivot Bearing Screw

.Holder

.Pivot Bearing Screw Set Screw

.Holder

Pivot Bearing

Nut

~~

4095 Feed Plate Spring Adjusting Nut

4091-A

113-B

4122

4129 Disc Adjusting Dial Set Serew

519-AA

4010

4011 Disc Adjusting Regulator Spring

115 Disc Adjusting Regulator Base Set Scxew

Feed Pltlte Bracket

Feed Plate Bracket Set Screw

Disc Adjusting Dial

Due AdjuS!ing Regulator Assembly

Disc

Adjusting Regulator Ball ·

Screw

Pin

N;,.

10

7

Page 17

Disc Oscillating Mechanism & Knee Press Shaft

Parts

Components

8

Page 18

Disc Oscillating Mechanism & Knee Press Shaft

Rot.

No.

17

18

19

2()

21

22

23

24

z.s

26

'27

28

2~

3()

31

32

:n

34

JS

36

37

38

39

40

41

42

43

44

4.5

46

47

48

49·

so

.51

.sz

10

11

12

1:)

14

J5

16

1

2

J

..

.5

6

7

8

9

p,...n No.

4013-A

4074

407.5

416?

406.5

H4-B

s-.406688

119-B

4115

129-A

4065

4031-A

4069-A

4010

4076

4017-A

132

131

4098-A

lOS

4178--A

5;!()7

4()85

-406"1-A

4068-A

4083

4084

4087

4088-A

52(17

4085

4081-A

4206

420S

4177

H063-A

11!139

4221

4084

4222-A

4U6

11050

4061.1-A

4171

4010

40ll

4174

4170

4172

4173

4l1:S-A

4070-A

Dl•c

Ooclllatln.a;

Dbc:

Osclllatlna

Dltc

O.tcll!Atlng

Conn.,clina

Connactlna

Conn.,ctl.ng

Dbc

Oscilla(mg

Disc

OacUiatms

Dllc

Owclllatlnlf

DMc

O•clliAtmg

Dllc

OtclU..tln.a

Disc

Oocillatlna

Disc

O&c111atms

Disc

Osdllatlnt~

Disc

O•cillatlns

Disc

OsclllatlJ1jC

Disc

0scllla1lne

Dhc

O•cillatln,g

FeC!d

Plato

Fcod

Plate

Ctank

Ctank

Connecting

Connecll.t1g l..inl<

Conncctlna

Kne"

Pren

Knoe

l'l'eu

ConneC:tlJl,l!

Connec:ttns

Connecting

Crank&.

Knee

Prell.

Kne4>

Prou

KneCI Pc:en

Knee

Proto

K11oe

Prefl

Knee

f'r•••

KnC!a

Pro••

knee

Pr.;u

knee

l'r"u

Knee

Prou

Knoe

Prttn

Knee

Prest

Slclp-Stltch

Skip-Stitch

Skip-Stitch

Sldp-Stltch

Skip-Stitch

Skip-Stitch

Skip-Stitch

Skip-Stitch

Skip-Stitch

Oe6t:ript:ton

R<>d

Rod

Rod

Rod

Rod

Ro4

Ro<l

Rod

Rod

Rod

Rod

Rod

D"prouing

Doprcasins

&.

J..lnk Sh(!Uld<Cit

<'It

Ltnk

Shouldu

Link

Ll.t1k

Sh...Ct

Shaft

Unk

Link

l.Jnk

Unk

Shoulder

Shaft

Shaft

Shaft

Sh11ft

Sloove

Shaft

Shaft

Wa•her

Stop

Lev"r

Stop

Lever

Stop

LovC!r

Stop

Lovot

Stop

Love•

Stop

Lever

Selectl.t1g

Selecting

SeiC!ctlng Sprl.t1g

Selecting

Selvc:tlfl#

Selcctl.t1J;

Scloctlnc:

Selecting

Selecting

Rod

l:lrac;Jc;.,t

Rod

Bracket

Rod

Braclcel

Stud

Stu<l

Set

Rod

AuembiY

Rod

Shaft

Rod

Pin

Pin

Stud

Stud

Bracket

Bucl<et

ttracl<61

Bracket

)hack.,!

Bradc.,t

Ct.o.nk

Cranl<

Screw

ScH•w

{La•ge)

Guide

Scrow

Guld<~:

Screw

Crank

Crank

Sot,Screw

(Small}

Set

S<:rew

Set

Screw

Screw

Buthin.g

Bu•hing

Waoher

Bushing

Clamp

Spdng

Spdng

Limit

Limit

Cr!p

Ball

Spring

Ctlp

Cam

Cam

Cam

Stud

Cam

Stud

Spdns

Sprlfl#

Spflng

Scr<>w

Set

S..t

Screw

Set

Sc:rcw

Spdnt~

Sprlnj!

Shaft

Shaft

Sha(t

Shaft

S"l

Nut

Nut

Nut

Nut

ScJ<>w

Pl.t1

$or(Ow

Screw

Holder

Bushing

Sot

Screw

Nut

(wfRe(.

Setcw

Collar

Set

Screw

Nut

Screw

Nut

Stud

Stud

Collar

No.

Nut

Set

Sctcw

8}

Screw

Parts

Components

9

Page 19

Thread

Tension & Nipper

Parts

Components

23

ll

24~

10

Page 20

Thread

Tension &

Nipper

Parts

Components

Allf. No. Partsl\19.

11136

1

113-A

2

3

4 79-B

s 77

5190-A

6

7 4204 Tluead Tension

4209

8

4068-A

9

4201

10

4202

11

12

4203-A

13 4193

14

4199

15

4198

16

17

18 5067

19

20

21

22

23

24

25

26

71

5190-A

4197

11162

6053 Thread Nipper Releasing

130-B

4195-C

8158

4194-A

8158

'l'htead Guide with

Thread Guide Set

81

Tfuead Tension Nut

Thread Tension Sprina

TJuead Temion

Tluead

'Thread

'Thread

Th.rcad

Thread Tendon

'J.'hread

Thread Guide Set

Th.read

Thtead Nipper Spring

Thread Nipper

Thread Nipper Disc

Thr~d

Thread Nipper Disc Prop

Thread Nipper

Thread Nipper

Thread Nipper

Thread Nipper

Thtead Nipper

Th.read

Dm:rlpti~n

Ceramic

Screw

Washer

Te!Uion

DW.:

DisC

Pin

Tendon Staff

T,nlion Staff Nut

Tension Staff Bracket

Releasing

Guide

Pin

Screw

Nipper Nut

Washer

Nipper Staff

Nipper

Releasing

Relc<asing

Releasing

Releasing

Releasing

Releasing

Pin

Pin

Pin

Pin

Pin

Pin

Pin

CoUar

Collar Set Screw

Support

Support Set

Lever

Lever Set Screw

Screw

11

Page 21

Work

Plate, Knee Press & Belt Cover

Parts

Components

18

1

20

12

Page 22

Work

Plate, Knee Press & Belt Cover

Parts

Components

Ref. No.

Parta No.

4153

2

4156

3

5230

4

4157-A

5

4159

4160

6

7

4161

8

4048-A

4158

9

10 4154-A

11

12 4155

13 132

14

4180

15

4146-A

16 4147-B

17

4148-A

18

4212

19 4149

20

4147-B

'"21

*22

4219-A

11554

"23 5233

"24

11551 Belt Cover

Work

Wotk Plate Latch

Work

Plate Latch Set Screw

Wodc

Plate Bracket

Work

Plate Bracket Spring

Work

Plate Bracket Leaf

Work Plate Bracket Leaf

Work

Plate Bracket

Work

Plate llracket Set

Work

Plate Shaft

Work

99-A

Plate Shaft Sctewed

Work

Plate

Work

Plate Shaft Collar Set

Work

Plate Shaft Set Screw

Knee

Press Rod

Knee

l'reu

KneePreuRod

Kneel'reuPad

Knee

Press Plate

Knee

Press Plate Set Screw

Belt Cover

Belt

Cover

Belt

Cover

Oo$ctlption

Plate

Shaft

Collar

Sleeve

Rod

Sleeve

Bracket

Bracket Set Screw

Wood

Screw

Leaf

Set

Pin

Sprlng

Sprlng

Sprlng

Screw

Cap

Screw

Screw

(Long)

(Short)

Set Screw

•

*Extra

Accessories

13

Page 23

Standard

Accessories

1

14

Page 24

Additional

Parts

for Model CM101 (Non-Skip Stitch)

~·

3

17 18

?I

16

~

15

,~~

13~

~

8

@

~

~

11

12

/

15

Page 25

Additional

Ref,

No.

Parts No.

1 4145

2

4110-AA

3

4 105

5

6

7

B

9

10

11

12

13

14

15

16

17

18

.S07-A

98

4218

4065

S4066AB'

129-8

4031-A

4115

129-A

4069-A

4070

4078

4070

4067-A

4068-B

Parts

Disc OsciUating

Disc Oscillating

Disc Oscillating

Disc Oscillating

Connecting

Connecting Link Guide Screw

for

Model CM101 (Non-Skip Stitch)

Description

Screwed

Ecoentric

Eccentric Rod Set Screw

Eccentric Bushing Screw

Oiling Felt

Disc Oscillating

Disc Oscillating

Disc Oscillating Rod Shaft Set Screw

Disc Oscillating Rod

Due

DiscOseiUating Rod Pin Set Screw

Ridg~

Forming Disc

Oscillating

Cap

(for

hole

of

Rod

Assembly (w/Ref. Nos.

Rod

Stud

R9d

Assembly (w/Ref. No.

Stud

Rod

Pin

Rod

Brack~t

Rod

Bracket Spring Stud

R~d

Bracket Adjtuting Screw

Rod

Bracket Adjusting Screw Nut

Unk

Guide Screw

Grip

Set Screw

4171)

Spring

Nut

4-6)

9)

Stud

Nut

16

Page 26

Additional

Parts

Ref. No.

1

2

3 11563

4

s

6

1

8

9

10

11

12

13

14

·IS

16

17

18

19

Parts No. OM<:ription

PFlOOH

4301-C

4052-B

4304

4182-A

4302-S

4308

10037

10038

121

4312-A

10040

10039

5233-A

4311-A

15128

4058-A

418S Otaining Finger Set Screw

Universal Presser Foot ASJembly (Ref. Nos.

l'tain Univetsal Presser

Needle Guide.

Needle Guide Set Screw

Edge

Guide

Edge Guide Set Screw

Ootb

Retainer

.

Ootb

Retainer Set Screw

Ootb

Retainer Holder

Ootb

Retainer Bracket

Ooth

Retainer Bracket Set Screw

Ootb

Retainer Spring

Ooth

Retainer Spring Adjusting Screw

Ootb

Retainer Spring Adjusting Screw Prop

Ooth

Retainer Spring Adjusting Screw Prop Set Screw

Ootb

Retainer Spring Bushing

Ootb

Retainer Spring Pin

Chaining Finger

2-19)

Foot

17

Loading...

Loading...