Page 1

an

ARNING

MACHINE

er

MODEL:

• •

Shirts • Socks • Coats

Aprons • Overalls • Ath

letic

SE

!rS •

•

Pillow

•

Laundry Nets

671

for

DARNING

an

d MENDING

Equipment

Towels • Sheets

Cases

HEAVY

• T

rou

• Lin

ens

DUTY

-

-

Fc•r deta ils phone:

DESIGNED

Used

LAUNDRIES

HOTELS

SUPPLIERS

COAT

INSTITUTIONS OF

&

MFG.

BY

: c

h<>n

dler

mach

by:

- HOSPITALS - TOWEL

-

and

.

en

.

::~vPr. m

DRY

ORPHANAGES

LINEN

CLEANERS

SUPPLIERS

ALL

::~

c:«

KINDS

014

::1?

Po

rtio lly

Completed work

II

Work

Comple

ted

Page 2

SHEET 2

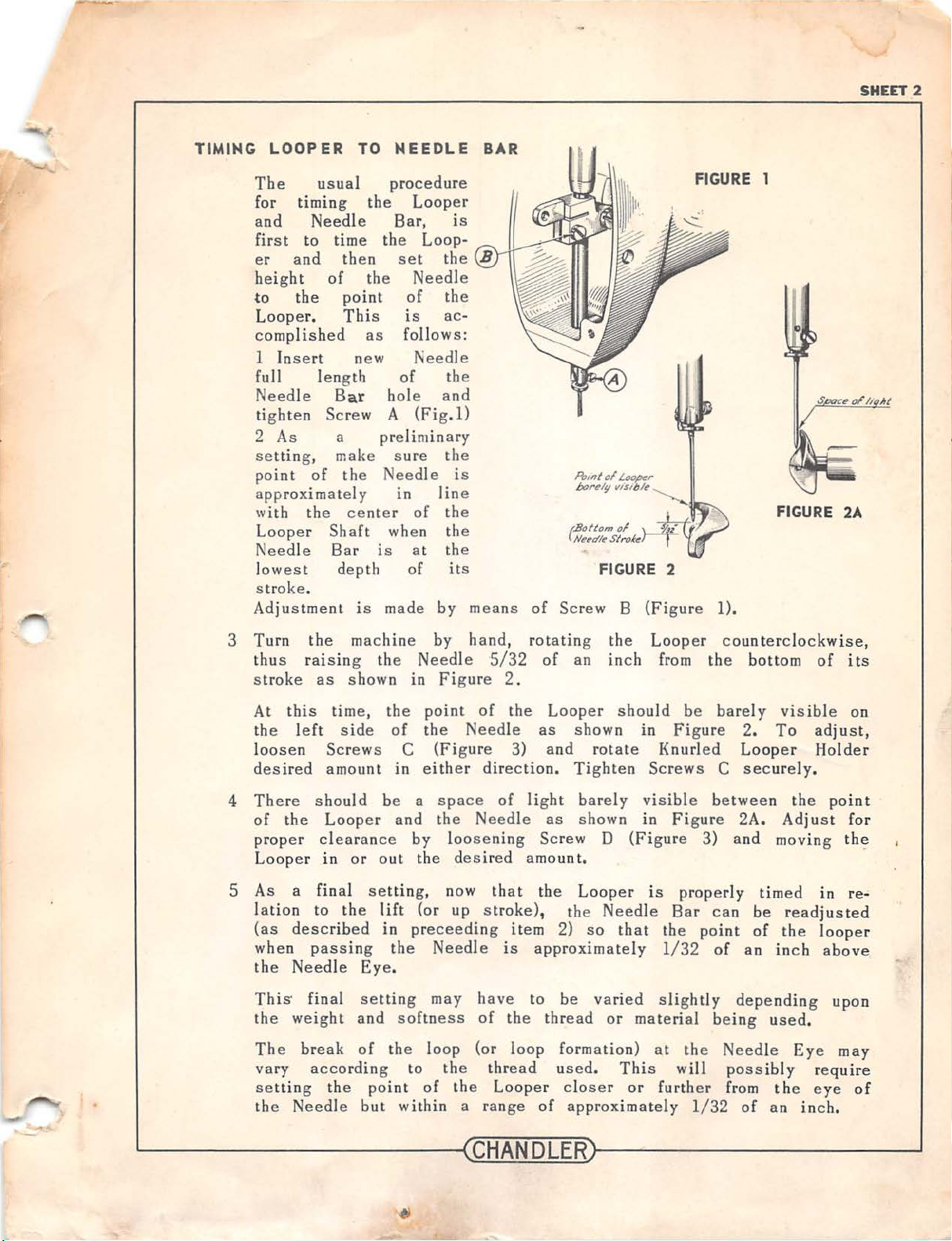

TIMING

LOOPER

The

for

and

first

er

height

to

Looper.

usual

timing

Needle

to

and

of

the

time

then

point

This

complished

1

Insert

full

Need

ti gh

le

ten

new

len

gth

Bar

Screw A

2 As a

setting,

point

of

make

the

approximately

with

Looper

Needle

lowest

the

center

Shaft

Bar

depth

stroke.

Adjustment

TO

NEEDLE

procedure

the

Looper

Bar,

the

set

the

Needle

of

is

as

follows:

of

bole

preliminary

sure

Need

in

when

is

at

of

is

made

is

Loop-

the

the

ac-

Needle

the

and

(Fig.1)

the

le

is

line

of

the

the

the

its

by

BAR

means

of

Potn!

.bor

e/9

FIGURE 2

Screw

of

Loopt!r

vtstble

B

(Figure

FIGURE

1).

FIGURE

2A

3

4

5

Turn

thus

st

roke

At

this

the

left

loosen

desired

There

of

the

proper

Looper

As

a

lation

(as

described

when

the

Needle

This

· final

the

weight

The

break

vary

setting

the

Needle

the

machine

raising the

as

shown

time,

side

the

of

Screws

amount m

should

be

Looper

clearance

in

or

out

final setting,

to

the

lift

in

passing

the

Eye.

setting

and

of

the

according

the

point

but

by

Needle

in

Figure

point

the

C

(Figure

either

a

space

and

the

by

loosening

the

now

(or up

preceeding

Needle

may

softness

loop

to

the

of

within

hand,

5/32

of

Needle

direction.

of

Needle

desired

that

stroke),

have

of

(or

thread

the

Looper

a

range

rotating

of

2.

the

Looper

as

3)

and

light

as

Screw D

amount.

the

the

item

is

the

loop

2)

approximately

to

be

thread

formation)

used.

closer

of

approximately

the

an

inch

should

shown

rotate

Tighten

barely

shown

Looper

Needle

so

that

varied

or

This

Looper

from

in

Figure

Knurled

Screws

visible

in

Figure

(Figure

is

Bar

the

1/32

slightly

material

at

or

further

counterclockwise,

the

bottom

be

barely

2.

Looper

C

securely.

between

2A.

3)

and

properly

can

be

point

of

of

an

depending

being

the

Needle

will

possibly

from

1/32

of

visible

To

the

Adjust

moving

timed

readjusted

the

inch

used.

Eye

the

an

inch.

of

its

on

adjust,

Holder

point

for

th~

in

re"'

looper

above

upon

may

require

eye

of

~----------

------~CHANDLERr---------------

--

~

Page 3

SHEET 3

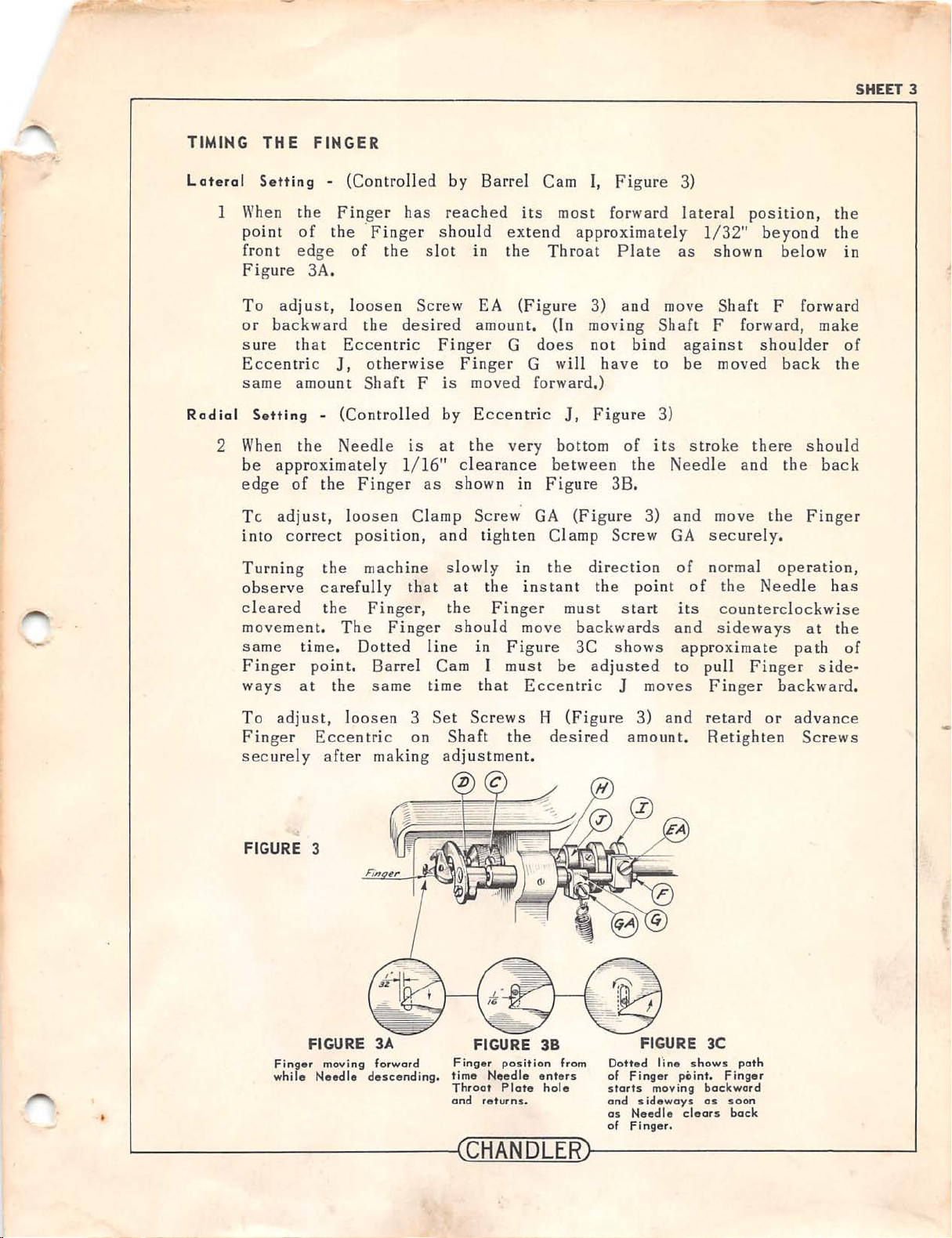

TIMING

Lateral

1

Radial

2 When

THE

Setting

When the

point

front

Figur

To

or

sure that

Eccentric

same

Setting

be

edge

Tc adju

into

Turning

observe

cleared

movement.

same

Finger

ways

FINGER

-

Finger has

of

th e ·

edge

e 3A.

adjust, loosen Sc

backward

Eccentric

J,

amo

unt

-

(Controll

the

Need

approximately

of

th e

s t, loosen

correct posit

the

carefully that

the

The Finger

time.

po

int.

at

the

(Controll

ed

by

reached

Finger should

of

the slot

rew EA

the

desired

Finger

ot

herwi

se

Shaft

le

F is

ed

is

by Ecce

at

1/16" cleara

Finger

as

Cla

mp

ion,

and tighten

s hown in

machine slowllf

at

Finger,

the

shoul d move

Dotted

Bar

same

line in

rel Cam I

time

Barrel

its

extend

In

the

(Fi

amount. (In

G

Fin

ger

G w

moved

forward.)

ntric

the

very

nce

Screw. GA

in

the ins ta

F i

nger must

Figure

must

that

Eccentric

Cam

most

approximate

Throat

gure

does

ill

J,

bot

between

Figure

(Figure

Cla

the

nt

3C

be adju

I,

Figure

forward

Plate

3)

and move

moving

not

bind

have

Figure

tom

of

the

3B.

3)

mp

Screw

direction

the

point

start

backwards

s hows

sted

J

moves

3)

lateral

ly 1

as

Shaft

against

to

be

3)

its str

Needle

and

GA

of

of

its

and

approxima

to

position,

/32"

beyond

shown below

Shaft F

forward

F forward,

shoulder

moved

oke

move

there

and

back

the

th e

sho

Finger

securely.

normal

the

operation,

Need

le h

counterclockwise

sideways

pull

Finger

Finger

at

te

path

backward.

the

the

In

make

of

the

uld

back

as

the

of

side-

To adjust, loosen

Finger

sec

urely after mak

FIGURE 3

Finger moving

while

~--------

3

Ecce

ntric on

ing adju

FIGURE

Need

--------

3A

forward

le

descending.

--~CHA

Set

Shaft

Screws

stm e

FIGURE

Fing

time

Throat

and

H

the

(Figure

desired

3)

and

amount.

retard

or

Retighten

advance

Screws

nt.

er position

Needle

Plate hoi

returns

.

38

fro

enters

m

e

FIGURE

Dotted

of

starts

and s idoways

a s

of

fine shows path

F ing

er

moving

Noodle

Fing

er.

3C

point. Fin

backward

as

soo

clears

back

ger

n

NDLERr-----------------

--~

Page 4

SHEET 4

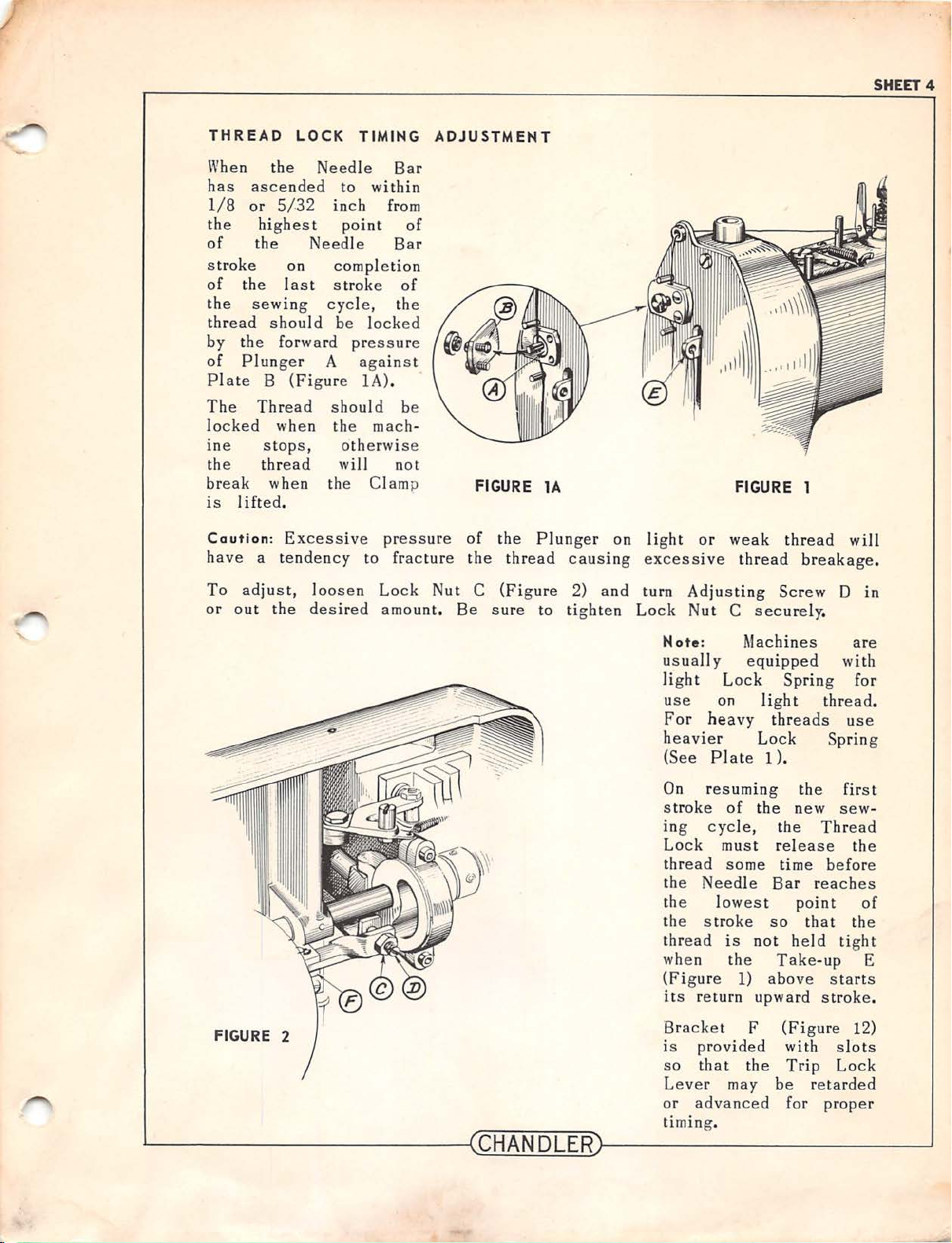

THREAD

When

has

ascended

l

/8

or

the

of

s

of

the

highest

the

troke

the last

sewing

thread

by

the

of

Plunger

Plate

The

l

Thread

ocked

me

the

thr

break

is

lifted.

Caution:

ave

h

To

or

a t

adjus

out

LOCK

the

5/32

Need

to

inch

TIMING

le

within

point

Need

le

on

completion

stroke

cycle,

should

be

locked

forward pressure

A

against

B

(Figure

lA

should

when the mach-

stops,

ead

when

Ex

endency

t,

the

o

therwi

will

the Clamp

cess

ive

to

loos

en

desired

Bar

from

of

Bar

of

the

).

be

se

not

pressure

fracture

Lock

amount.

ADJUSTMENT

FIGURE

of

the

the

thread

Nut

C

(Figure

Be

sure

lA

Plunger

causing

2)

to

tighten

on light

excessive

and

turn Adj

Lock Nut

or

weak

usti

C

FIGURE 1

thread

thread

ng

breakage.

Screw

securely

wil l

0

in

.

FIGURE 2

L-------------

------~

Note:

usua

li

ght

use

For

heavier

(See

On

r

oke

st

ing

Lock

thread

the

the lowes

the stroke

thread

when

(Figure

its return

Bracket

is

so

L

ever

or

advanced

timin

Machines

ll y

eq

uipped

Lock

on

light

heavy

threads

Lock

Plate

res

uming

of

the

1 ).

cycle,

must release

some

Need

le

Bar

t

so

is

not

the

1)

Take-up

above

upward

F

provided

that

the

may

be retarded

g.

with

Spring

thread.

use

Spring

the

fir

new

sew-

the

Thr

ead

time

before

rea

ches

point

that

held tight

sta

stroke.

(Figure

with

slots

Trip Lock

for

proper

are

for

st

the

of

the

E

rts

12)

CHANDLER~------------------~

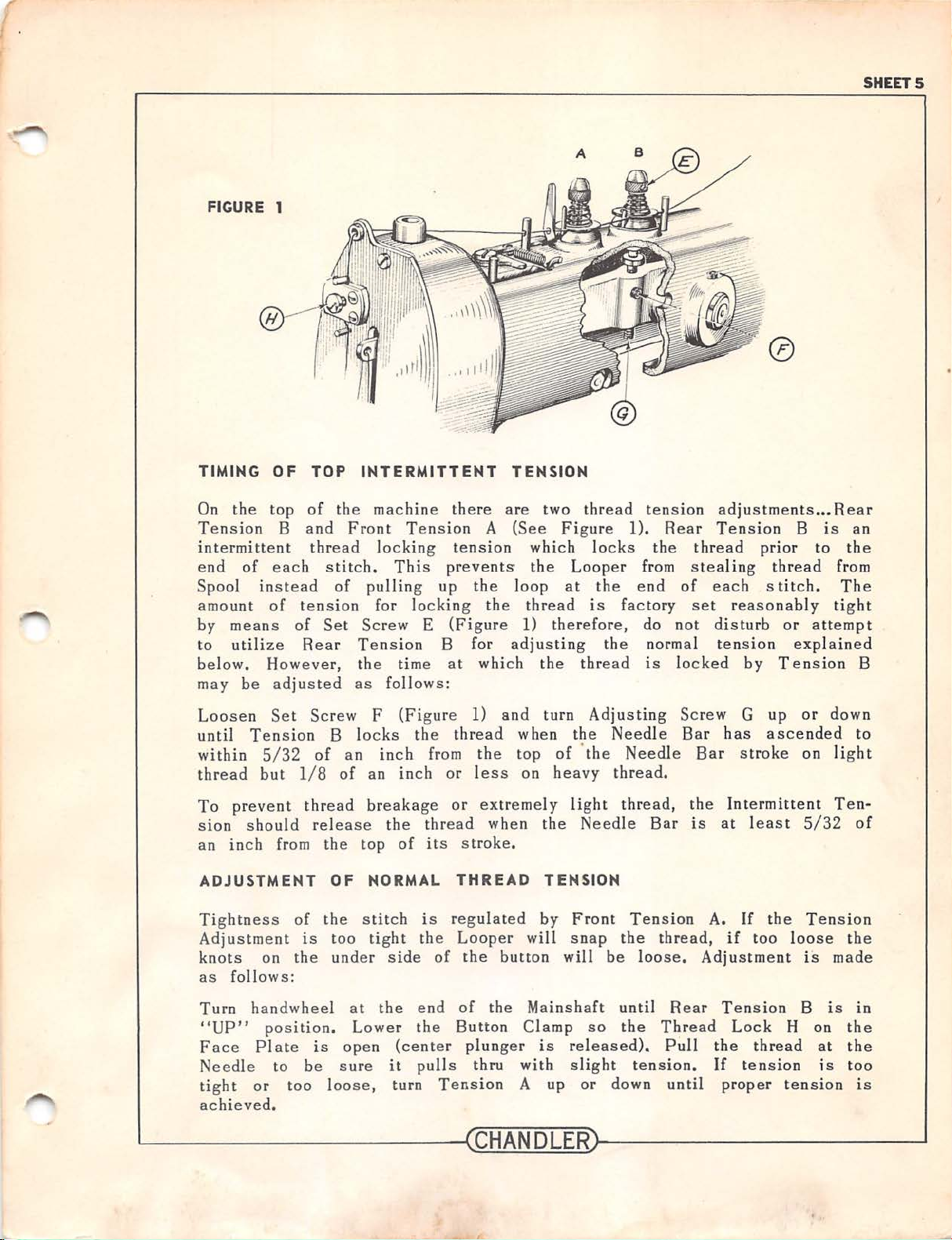

Page 5

FIGURE 1

SHEET 5

A

0

TIMING

On

Tension

intermittent

end

Spool

amount

by

to

below.

may

Loosen

until

with in 5/ 32

thread

To

sion

an

ADJUSTMENT

Tightness

Adjustment

knots

as

OF

the

top

B

of

each

instead

of

means

utilize Rear

be

prevent

should

inch

follows:

of

However,

adjusted

Set

Tension

but

from

of

on

the

TOP

of

and

thread lock

tension

Screw

of

1/ 8

thr

release

is

INTERMITTENT

the

machine

Front

stitch.

of

pulling

for

Set

Screw

Tension

the

as

F

B locks

an

of

an

ead

breakage

the

top

OF

NORMAL

the

stitch

too

tight

under

Tension

ing

This

locking

E

time

follows:

(Figure

the

inch

inch

the

of

side

from

thread

its

is

the

there

tension

prevents

up

(Figure

B for

at

thread

or

or

THREAD

regulated

of

are

A

the loop

the

which

1)

and

the

less on

extremely light

when

stroke.

Looper

the

button

TENSION

two

(See

adjusting

which

the

thread

1)

therefore,

the

turn

when

top

the

TENSION

by

will

Figure

Looper

at

the

of 'the

heavy

Front

snap

will

thread

1).

locks

the

end

is

factory

the

thread

Adjusting

Needle

Needle

thread.

thread,

Needle

Tension

the

be

loose.

tension

Rear

the

thread

from

do

stea

of

each

set reasonably

not

normal

is locked

Screw

Bar

Bar

the

Bar

is

A.

thread,

Adjustment

adjustments

Tension

prior

ling

st

disturb

tension

by

G up

has

ascended

stroke

Intermittent

at least 5/32

If

the

if

too

•••

B

to

thread

itch.

or

attempt

explained

Tension

or

on

Ten

loose

is

Rear

is

the

from

The

tight

down

light

Ten-

s i

the

made

an

B

to

of

on

Turn

"UP"

Face

Needle

tight

achieved.

handwheel

position.

Plate

or

to

is

be

too

at

Lower

open

sure

loose,

the

(center

it

turn

end

the

pulls

Tension

of

the

Button

plunger

thru

Mainshaft

Clamp

is

with

A up

~------------------~CHANDLER~------------------~

until

so

the

released).

slight

or

tension.

down

Rear

Thread

Pull

until

Tension

Lock

the

thread

If

tension

proper

B

is

H on

at

is

tension

in

the

the

too

is

Page 6

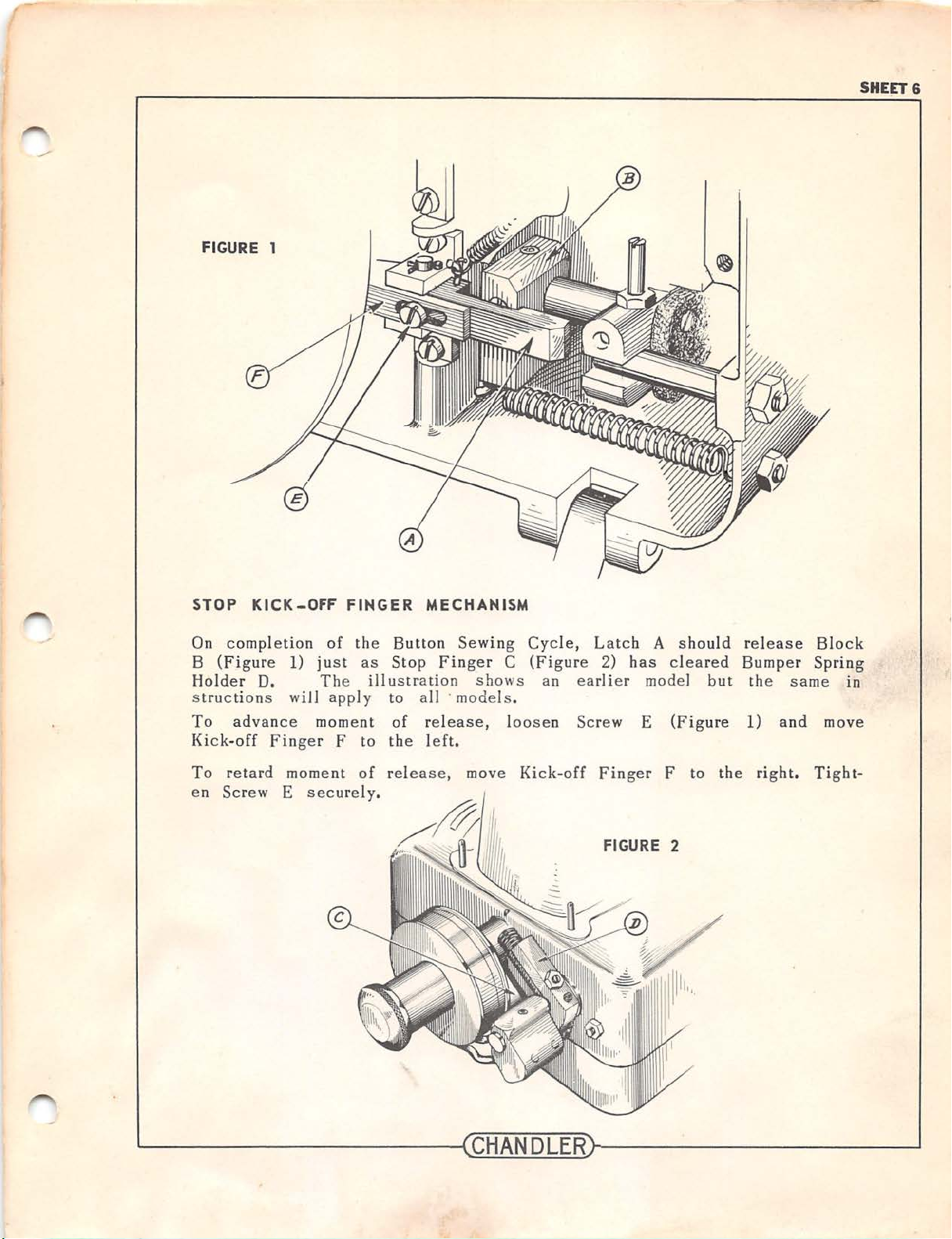

FIGURE 1

SHE~&

STOP

On

B

Holder

KICK-OFF

completion

(Figure

D.

structions

To

advance

Kick-off

To

retard

en

Screw

1)

will

Finger

moment

E

securely.

of

just

The

apply

mom

F to

FINGER

the

Button Sewing

as

Stop

illustration

to

ent

of

the

of rele

MECHANISM

Finger

C

shows

all ·models

.

release, loose

left.

ase

, move

Kick-off

Cycle,

(Figu

an

Latch

re 2)

earlier

n Screw E

A

has

model

Finger

FIGURE 2

should

cleared

(Figure

F to

but

the

release

Bumper

the

same

1)

and

ri ght.

Block

Spring

in

move

Tight-

~------------------

~CHANDLER~

----------------

--

~

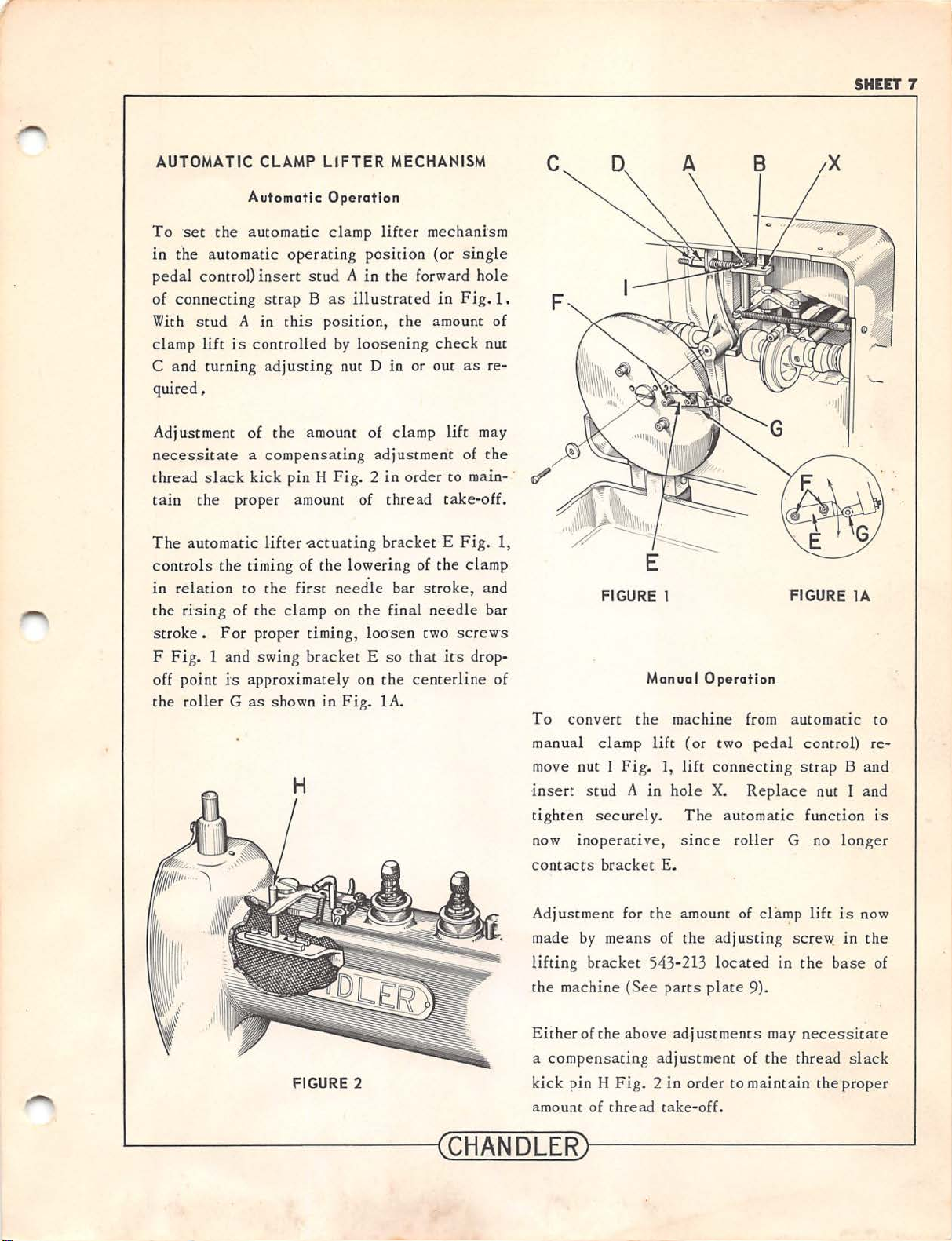

Page 7

SHEET 7

AUTOMATIC

To

set

in

the

automatic

pedal

control)

of

connecting

With

stud

clamp life

C and turning

the

A in

is

CLAMP

Automatic

automatic

operating

insert

stud A in

strap B as

this

controlled

adjusting

LIFTER

Operation

clamp

illustrated

position,

by

nut D

quired,

Adjustment of

the

amount of

nece·ssitate a compensating

thread

tain

The

controls

in

the

stroke .

F

off point

the

slack

the

automatic

the timing

relation

ri-sing of

For

Fig.

1 and swing

is

roller G as

kick pin H

Fig. 2 in

proper amount of

lifter

-actuating

of

the

lowering of

to

the

first

needle

the

clamp on

proper timing, loo·

bracket E so

approximately on

shown in

Fig.

MECHANISM

lifter

mechanism

position

the

forward hole

the

loosening

in

or out

clamp

adjustment

order

thread

bracket E Fig.

bar

stroke,

the

final

needle

sen

two

that

the

centerline

1A.

(or

single

in

Fig.

amount

check

as

lift

of

co

main- ·

take-off.

the

clamp

screws

its

drop·

1.

of

nut

re-

may

the

and

bar

of

1,

To

manual

move nut I

insert

tighten

now

contacts

FIGURE 1 FIGURE

convert

the

clamp

Fig.

stud

A in

secure!

inoperative,

bracket

Manual

life

y.

machine

(or

1,

lift

hole

The

swce

E.

Operation

from

two

pedal

connecting

X.

Replace

automatic

roller

automatic

control) re-

strap

B and

nut I and

function i·s

G no

longer

lA

to

Adjustment for the amount of

made

lifting bracket

the

machine

Either

a

compensating

riGURE 2

kick

amount of thre ad cake-off.

~

--

----

--

----

--~CHANDLER~----------------~

by

of

the

pin H

means

543-213

(See

above

Fig. 2 in

of

the

adjusting

located

parts

plate

adjustments

adjustment

order to

cliu~p

sere"'!

in

9).

may

of

the

maintain

lift

is

now

in

the

base

necessitate

thread

the

slack

proper

the

of

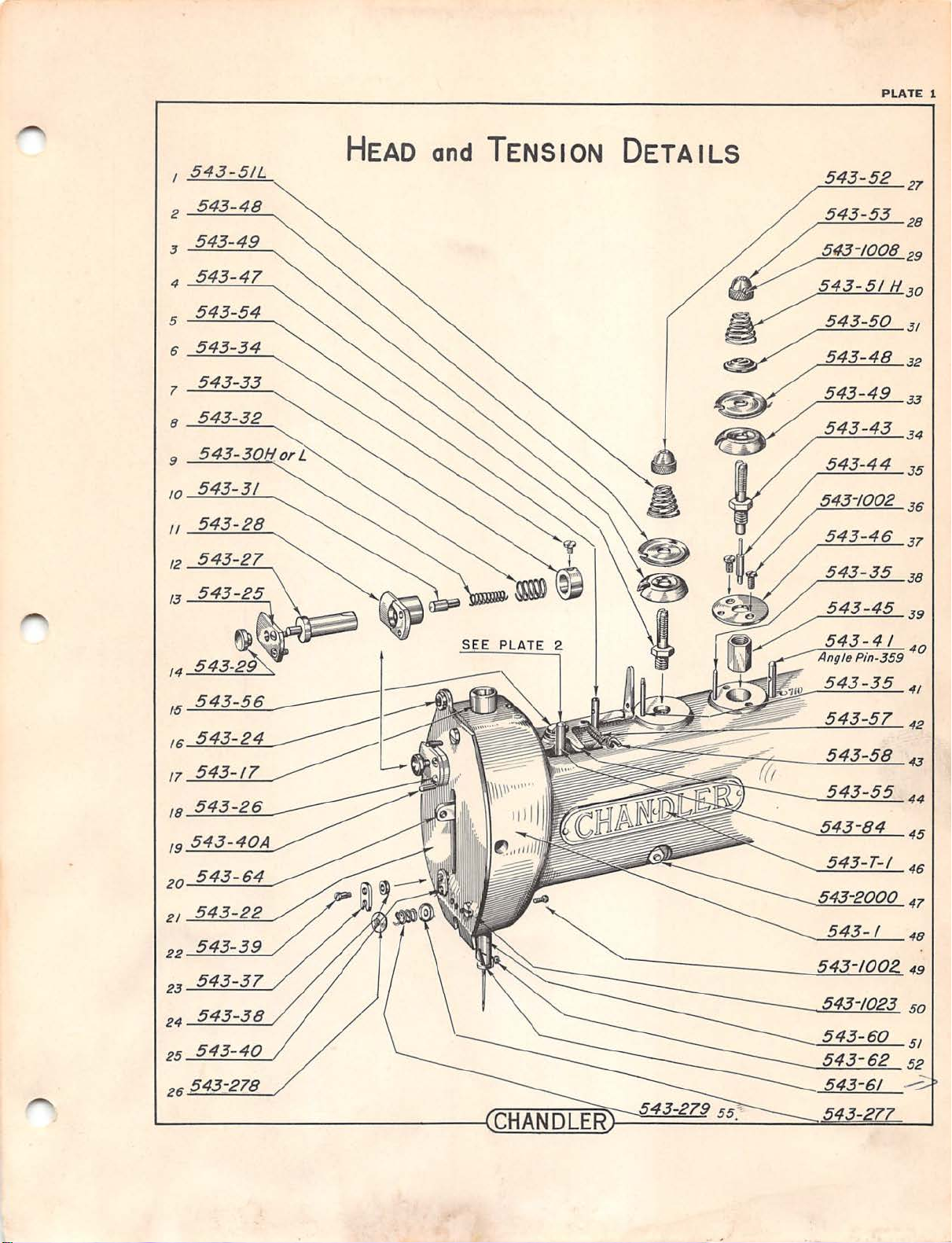

Page 8

PLATE

1

543-5/L

543-48

2

543-49

3

543-47

4

543-54

5

543

6

543-33

1

543-32

8

9

543-31

10

543-28

II

12

13

-34

HEAD

and

TENSION

DETAILS

543-52

543-53

5

43-

1008

543-51H

543-43

543-

44

27'

28

29

3

33

34

35

36

37

38

39

o

20

21

22

23

24

25

26

543-37

543-40

S E

PLATE

2.

543-1

543-1002.

-.~....:::...._.=.:::.._

---

.._..:_..:..:::.....-=-

_

48

49

5/

52

·

---

-.

Page 9

1

543-/005

2

543-69

3

543

6

543-64

1

543-65

8

-17

NEEDLE BAR DRIVE MECHANISM

PLATE 2

543-10

543-6

8

30

3 1

32

9 543-1010

10

543-62

II

543

12

13

14

15

16

11

19

-61

Need

le

No.7 Hear

NoS

Ligh

543-200

543-1/B

54

3-66

33

/

20

543-128

~----

----

--------~CHANDLERr-

*

Omifled

Lofer

Models

--

on

----

------

----

~

Page 10

PLATE

3

CLAMP

LIFT

and

THREAD SLACK MECHANISM

543-89A

18

Page 11

2 54

PLATE 4

AUTOMATIC THREAD LOCKING MECHANISM

3-/96

5

6

7

8

9

10

543-1

44

SEE PLATE 3

< •

543-9/

543-5001

543-/69

543

-

/9

20

21

22

23

CHANDLER

Page 12

PLATE 5

543-85

2

543-123

J

543-//6

543-1/T

4

8 5

BUTTON CLAMP

ASSEMBLY

543-120

543-2004

543-119

543-/05

543-3000

-/02A

18

19

20

21

22

24

12

543

17 543-101

5

+

~

------------

--------

~5~4~3~-1~27

543-114

Pin

543-//0

543-118

552-369

543-97

543-95

-96

543-99

26

28

29

30

31

32

35

L-------------------~CHANDLER~------------------~

Page 13

BUTTON CLAMP ASSEMBLY

.

All

In

One

Style

PLATE SA

See

Item

Plate

29

543-272

5

4

6

NOTE

Ports Not Beorinq Nvmbers

Are

Identified

~----------------~CHANDLER~----------------~

On

I

Plate 5

Page 14

PLATE 6

LOOPER

I

543-122

3....:::.....:~=::....--..__

4

....::.......~.:....:::....::--....

5 __;;..

...;_;;,_-=---...

and

6

543-1

7

543-2

8

FINGER MECHANISM

_........=.__:....=:.____:....=:.-==..

----

...:::......:...:::...._:...=..:.._

~

_.;....

__;,__;__

9~:o....!...!:~:...!...:::...-22

~...:.....;::_..:...;;;....;...;o.__23

05

19

20

2/

24

26

21

10

II

15

.::......:....

/6

---=-....:..=..-=

/8

543-141

.:::::::-==::::::-

...-

-/

~~

~

~------

~L-

--~~~

---=;.....:.-=:.......:...:::...:..-=-_

--...=._..:...=;._

--.......=:......:....::___:_:::....:....._

--~~~~36

\-"

.:..=..:....::;..__

-----=:c...:....::--:....::::=- 3 5

=~=-,t-38

29

~

31

32

33

3 4

CHANDLER

~----------~

~~~39

Page 15

PLATE 7

FoR

2

543-327

3

552-326

5

552-331

Q

552-329

1

552-325

8

543-187

9

-=-:.=....;~:::...-~

10

543

-1014

II

543-330

/J---!::......:....::

14

:..._

--=2~

543-/90

---

CLAss 552 AND LATER MoDELS

---..

543-326

552-328

552-337

543-1002

-

~--!..::!..

543-187

22

23

24

~~29

30

No

Shoulde

r St

Shoulder

Stud

yle)

543-140

CHANDLER

544-140A

Page 16

STOPPING MECHANISM

PLATE

8

See

Plate

SA

For

Other Models

18

543-20

543-172A

21

~

/

22~

L-----

--------

----~~CH~A~N~D~L~EGR~

------------

----~

Page 17

7 '

STOPPING MECHANISM

3~~~~------

4

552-4000

5

552-1006

~

FoR

CLASS

552

MACH

552-33514

552-300215

552-309

---------'--

552-312

PLATE

..

-!55

SA

/6

17

19

20

552-318

II

___;;_;c..=.....:........;;.___,

~--------

--

--------~CHANDLERl

--

--------------

552-208A

--

--~

J/

Page 18

PLATE 9

TREADLES

2

3

543-2002

4 19

5

543-10/9

6

1

8

and

TRIP

LEVERS

543-74

543

-2002

543-1018

543-1019

543-2002

543-1021

/6

17

18

20

21

3

9

10

II

12

13

14

15

24

25

26

27

29

CHANDLER

Page 19

PLATE

10

543-244

543-244A

2

543-243

3

543-246

4

54

5

7

543-238

3-260

SHANK

Cloth

BUTTON

Support

For

ATTACHMENT

543-245

543-250

543-249

543-252

543-256

543-105

/9

20

21

2

3

25

26

16

543-255

WHEN

BUTTON

BE

SPECIFIED IN

543-255-C

18

PROPER CUP

~------------------~CHANDLER~------------------~

ORDERING,

LINE

AND SHANK BUTTON

ORDER

SIZE

AND

SIZE

TO

HEIGHT.

OF

STAY

MUST

SUPPLY

~

--....:;:._5_;_43::....--=2..:....7.

543-276

.::....

'5

_

39

40

Page 20

PLATE

lOA

SHANK

BUTTON

All

In

One

®

'

I

ATTACHMENT

Style

Cloth

Support

I 543-1015

~------------------~CHANDLER~------------------~

For

NO

Ports

Not Bearing Numbers

Are

Identified

WHEN

BUTTON

BE

SPECIFIED

PROPER CUP

TE

On

Plate 10

ORDERING

, LINE

ANO

SHANK BUTTON MUST

IN

ORDER

SIZE

SIZE

OF STAY

TO

AND HEIGHT.

SUPPLY

543-274A

543-27458

543-275

543-276

5

6

1

8

9

Page 21

PLATE

11

I

543-299

2"'---'--'o<.......!:-==

.3

543-2003

4--=:...;~~=-o

5

543-

543-119

6

7 543-118

.:....:......_

_ _

ATTACHMENTS {CONT.)

543-1238

\

24

Stay

Button

Plate

Necking Attachment

Whipping

Attachment

543-261

543-119

25

27

Page 22

PLATE

12

4

543-118

5

543-267

ATTACHMENTS

Snap Attachment

For

Square Snaps

(Cont.)

543-/237

543-300/

543-265

543-266

II

12

13

15

7

543-268

Under Side

NOTE'

Same

All

Other Parts

As

Plate 5

Snap

Attachme

For Rou

nd

nt

Snaps

~----------------~CHANDLER~------------------~

Page 23

PLATE

14

2

555-384

3

543-/003

4

555-380

AUTOMATIC

CLAMP

LIFTER

Straight

555-387

555-381

543-2000

------

Pin

00/13

/4

15

;6

6

555-386

1

555-377

8

543-3001

555-378

555-379

IT

18

543-200019

II

555-382

555-383

543

-24/

20

I

~------------------~CHANDLER~------------------~

Page 24

PLATE

15

Left

Hand

BUTTON

Button

Spacer

ACCESSORIES

Right

Hand

Button

Spacer

Left

I

552-32/

Hand

and

Button

Right

Spacer

Hand

552-322

~----------------~CHANDLER~----------------~

2

3

Page 25

RECOMMENDED

NEEDLES

CLASS

175 X 3

175

175

175

175

175

NUMBER

X 3

X

3

X

3

LONG

X 7

X 7

SHANK

SIZE

#4

f:/

5

#7

#8

(Fo

#5

f:/

7

r

Shonk

APPLICATION

Very

Light

Medium

Heavy

Buttons)

Medium

Heavy

Light

Work

Heavy

Work

...

~------

~l

a c

hine

e

xcess

ope

rat

Use

Gea

rs

spec

white

--

classes

of 1000

ed

at

a l

ight textile

and

ial non-drying gr

grease

--------~CHANDLER~----------------~

RECOMMENDED

543,

ll .P.M. Model

speeds

up to 1

oil for all moving parts.

cam races

ease, whic

that

you

546

and

500

LUBRICATION

are lu

h we

see

on all new machines.

SPEEDS

548

are not

552

and late

R.P.M

bricated

can

.

with

supp

to

be

operated

r mode ls

"Lubriplate

ly.

This

1n

can be

" a

is

the

Loading...

Loading...