Page 1

®

an

INSTRUCTION

TACKERS

&

BUTTON

BOOK

er

&

PARIS

SEWERS

BOOK

CLASSES:

552, 554, 555, 558,

600, 660, 710

cJ..ancller

CHAN

•

oyer,

543, 546, 548,

DL

ERM~HINE

mass.Ol432 u.

s.a

,

tel.

(617)

560,

~

CO

772-3393

Page 2

FLAT

HOOK

BUTTON

AND

SEWERS

EYE ............................. Model 710-1HE ..........................

............... Model 710-1 ...............................

Model 710-5 ...............................

Model 710-10 ............................. 24 stitch, side vih

Model 710-35 .............................

710-55 .............................

Model

710-85 .............................

Model

710-120 ........................... 24

Model

Modei710-5HE

..........................

16

stitch. side vih

12

stitch. side vih.,

16

stitch. hack & forth.

16

stitch, cross (X) stitch.

12

stitch, back & forth,

sti~ch,

l6

stitch. side vib

l2

stitch, side vib.,

square

..

..

pattern.

.•

CURRENT PRODUCTION MODELS OF

CHANDLER CLASS 600 & 710 MACHINES

auto

clamp lilt.

auto

clamp

lilt.

auto

ch1mp hft.

auto

clump lift.

auto

clamp lift.

auto

clump lift.

auto

clamp

clamp

lil1.

lift.

auto

WHIPPING

NECKING ......................................... Model 710-IN ............................

SHANK

TACKERS

BONE

JOKERS

BAR

HIG~

TWIN

....................................... Model 710-12 ............................. 24 stitch. for whipping suit buttons.

BU

ffON

SEWERS

......................................... Model 600-15 ............................. 6 stitch. back & forth

RING

.....................................

............................................

TACK

....................................... Model 710-70BT ........................ 24 stitch zig-zag pattern.

LIFT

.......................................

NEEDLE f ACKER

............ Model 710-IS .............................

............... Model 660- ................................. 8 stitch. back & forth,

71

Model

Model710-50

Model 710-65 .............................

Model

Model

Model 600-60 ............................. 6 stitch, side vih.

Model 600-75 .............................

Model

Model

Model 600-75KD .......................

Model

Model600-BR

Model

Model

Model

0-5S .............................

.............................

600-25 ............................. 8 stitch, back & forth

600-25S ........................... 8 stitch, side

600-750

600-75K ..........................

600-95 ............................. 6 stitch,

600-BR.500 .....................

600- ................................. Special machines for

658

..........................

............................

or

758 ....................... Full ~ inch bigger

16

stitch. side vib.

16

stitch. side vib

12

stitch. side

12

stitch. hack & forth, front loading.

16

stitch.

12

stitch,

12

stitch.

12

stitch.

(both

of

combination

12

stitch, back & forth vib.

12

stitch, back & forth vih.

Yt

stroke

removable objects. Normally modified square patterns.

Bulky tacking problems. etc. Specify

Change prefix from

NOTE: Any

built

in

knife mechanism. Add suffix

Please specify needle gauges from

increments. Non adjustable.

..

side loading.

vi b ..

side loading.

h<~ck

& forth, front loading. shank master.

vih_-

combination

combination

combination

above)

for

extra

vib.,

dmpery.

vib ..

dmpery

vib., drapery knife thread

Vlb.

large bone rings.

attaching

stroke.

Designed

"600"

to

"651<".

of

the

above

machines may be

labels

I~ -2~

extra

and

for

"K"

hea

other

extra

above

'Y

needle

cutter

large

shank

machine desired.

equipped

in

~,.

buttons.

with a

STAND

CLAMPS

This

.............................................. Model 2Tc-600-l ........................ Board only

...........................................

edltion

printed

10.1972

Stand,

complete .........................

Stand

..........................................

Stand

..........................................

Flat

button

Shank

button-

..

:-.;;

Shank

button

Snap

........................................... Adjustable,

Snap

........................................... Non-adjustable, square.

Hook

and

Whipping

Necking

Tacking

Tacking ......................................

Bone ring ...................................

Flat

button

....................... Side loaaang ·

.............................

eye

.................................

Complete

Complete

Complete

Front

Compensating

Compensating

Front

"H"

"K"

"K"

loading

part

(shank

round

only

~----~------------~CHANDLER~--------------------

NOTE:

FOR

BUTTONROBOTS, HOPPERS,

CHANDLER

SALES & SERVICE CO.,

AUTOMATIC

246

7th

AVE

FEEDING DEVICES CONTACT

.•

N.Y., N.Y.

legs. I

IOV.

legs. IIOV.

legs. 220V.

master)

or

square

10001

TEL.

212-226-7300

Page 3

:..

.....

MECHANICS

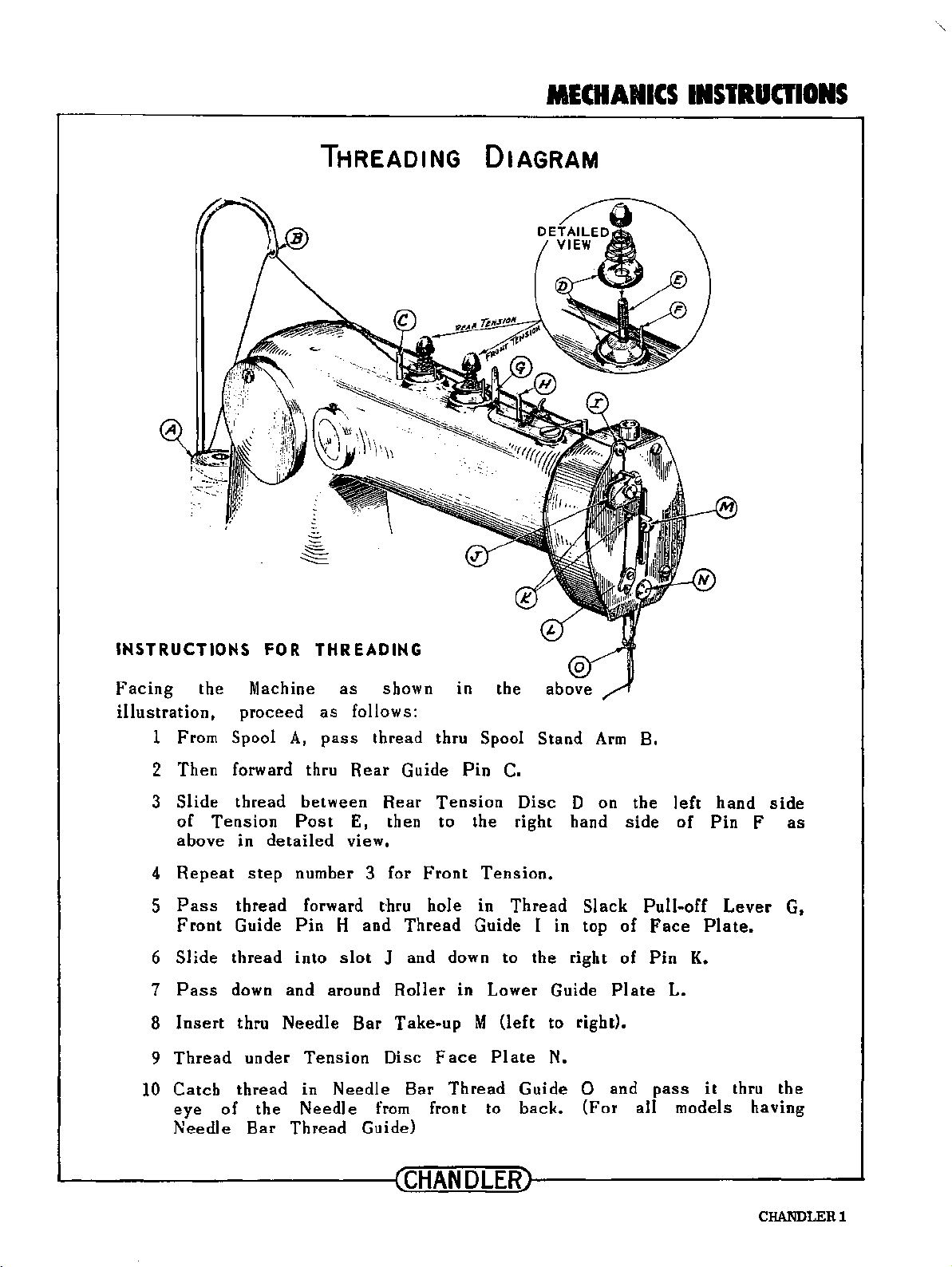

THREADING DIAGRAM

INSTRUCTIONS

INSTRUCTIONS

Facing

illustration,

10

the

1 From Spool

2

3

4

5

6

7

8

Thread

9

Catch

eye

Needle

Then

Slide

of

above

Repeat

Pass

Front

Slide

Pass

Insert

forward thru

thread

Tension

thread

Guide

thread

down and around

of

FOR

Machine

proceed

A,

in

detailed

step

thru

Needle

under

thread

the

Bar

Thread

THREADING

as

shown in

as

follows:

pass

between

Post

number 3 for

forward

Pin

into

Tension

in

Needle

thread

Rear

E,

view.

t·hru

H

and

slot

Bar

Needle

from

Guide)

Rear

then to

J and down to

Roller

Take-up

Disc

thru Spool

Guide

Tension

Front

hole

Thread

Face

Bar

Thread

front to

the

Stand

Pin

·C.

Disc

the

right hand

Tension.

in

Thread

Guide I

in Lower Guide

M

(left

Plate

Guide

back.

D on

in

the

right

to right).

N.

0 and

Slack

top

(For

Arm

B.

the

side

Pull-of£

of

of

Plate

all models

left

of

Face

Pin

L.

pass

Pin

Plate.

K.

it

hand

Lever

thru

side

F

as

G,

the

having

~--------------~CHANDLER~--------------~

CHANDLERl

Page 4

-CHANICS

IISTRUOIOIIS

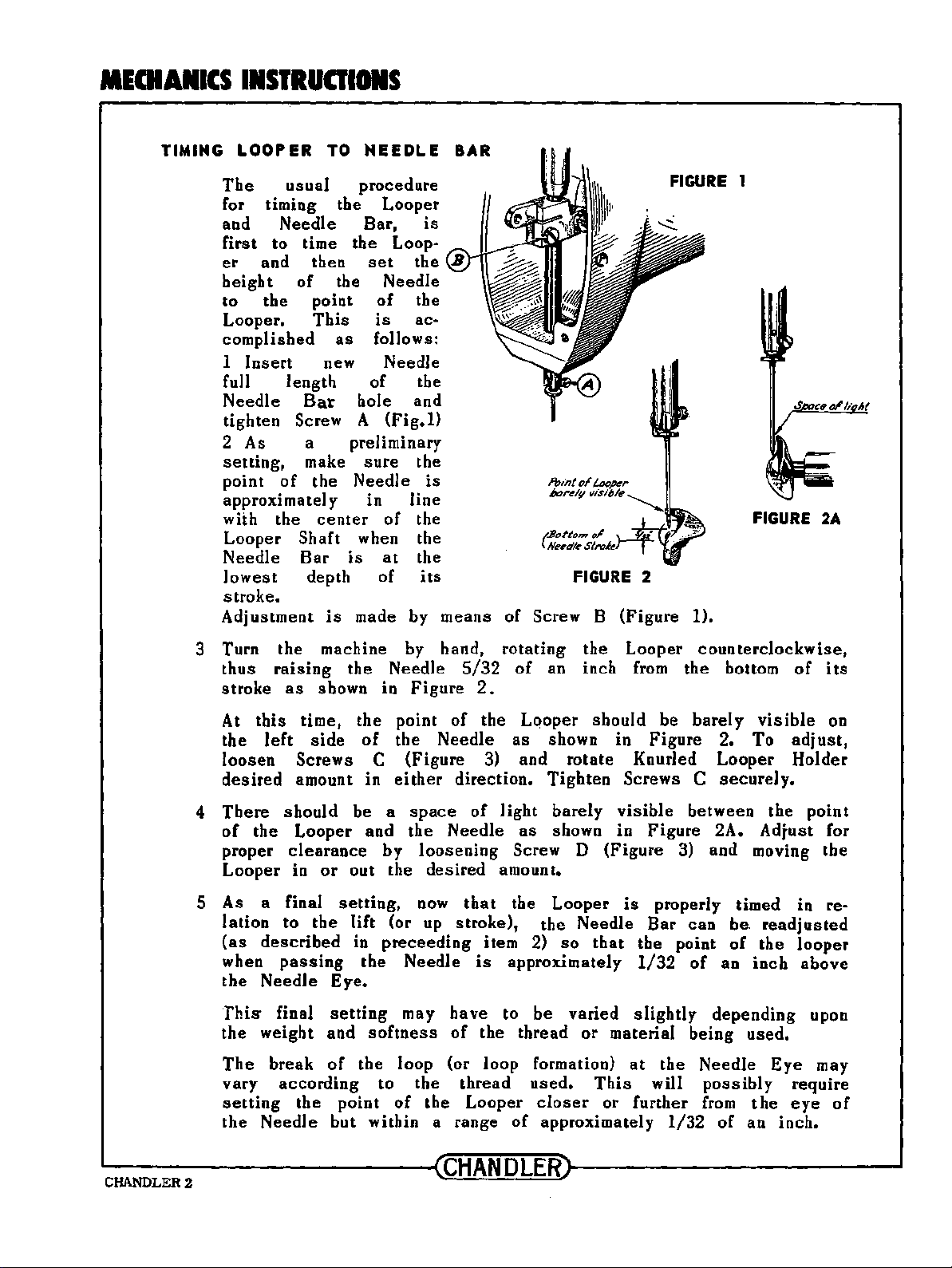

TIMING

LOOPER

The

usual

TO

NEEDLE

procedure

for timing the Looper

and

first

er

height

to

Looper.

Needle

to time the Loop-

and then

of

the point

This

complished

Insert

1

fuJl length

Needle

Bar hole and

tighten Screw A

Bar,

set

is

the

the Needle

of

the

is

ac-

as

follows:

new Needle

of

the

(Fig.1)

2 As a preliminary

setting,

point

approximately in

with the

of

make

the

center

sure

Needle

of

the

is

line

the

Looper Shaft when the

Needle

1 owes t depth of

Bar

is

at

the

its

stroke.

Adjustment

is

made by means

BAR

t.Boftom

( Neeel/e

of

Screw B (Figure 1).

ol

Sirek

FIGURE

2

FIGURE

1

FIGURE

2A

3 Turn

thus

stroke

At

the

loosen

desired

4

There

of

proper

Looper

the

raising

as

this

time,

left

side

Screws C (Figure 3) and

amount in

should

the

Looper

clearance

in

5 As a final

lation

(as

when

the

to

described

passing

Needle

This- final

the

weight and

The

break

vary

setting

the

according

the

Needle but within a range

machine by hand,

the Needle

shown in

the

be a

or

out the

setting,

the

lift

in

the

Figure

point

of

the

either

space

and the

by

loosening

now

(or up

preceeding

Needle

of

Needle

direction.

Needle

desired

stroke),

Eye.

setting

of

point

may

softness

the

loop (or loop formation)

to

of

have

of

the

the

rotating

5/32

of

2.

the

as

of

light

as

Screw D

amount.

that

the Looper

item 2)

is

approximately

to

the thread

thread

Looper

of

the

an inch

Lqoper

should

shown in

rotate

Tighten

barely

shown in

(Figure

the Needle

so

that

be

varied

or

used.

closer

This

or

approximately

Looper

from

Figure

Knurled

Screws C

visible

Figure

counterclockwise,

the bottom

be

barely

2.

Looper

securely.

between the

2A.

3) and moving

is

properly timed in re-

Bar

can

be.

the point

1/32

slightly

material

at

the

will

further

1/32

of

of

an

depending upon

being

Needle

possibly

from

of

of

visible

To

adjust,

Holder

point

Adjust

readjusted

the

looper

inch

above

used.

Eye

require

the

eye

an inch.

its

on

for

the

may

of

----------------~CHANDLER~----------------

CHANDLER2

Page 5

MECHANICS

IISTRUOIOIIS

\

~

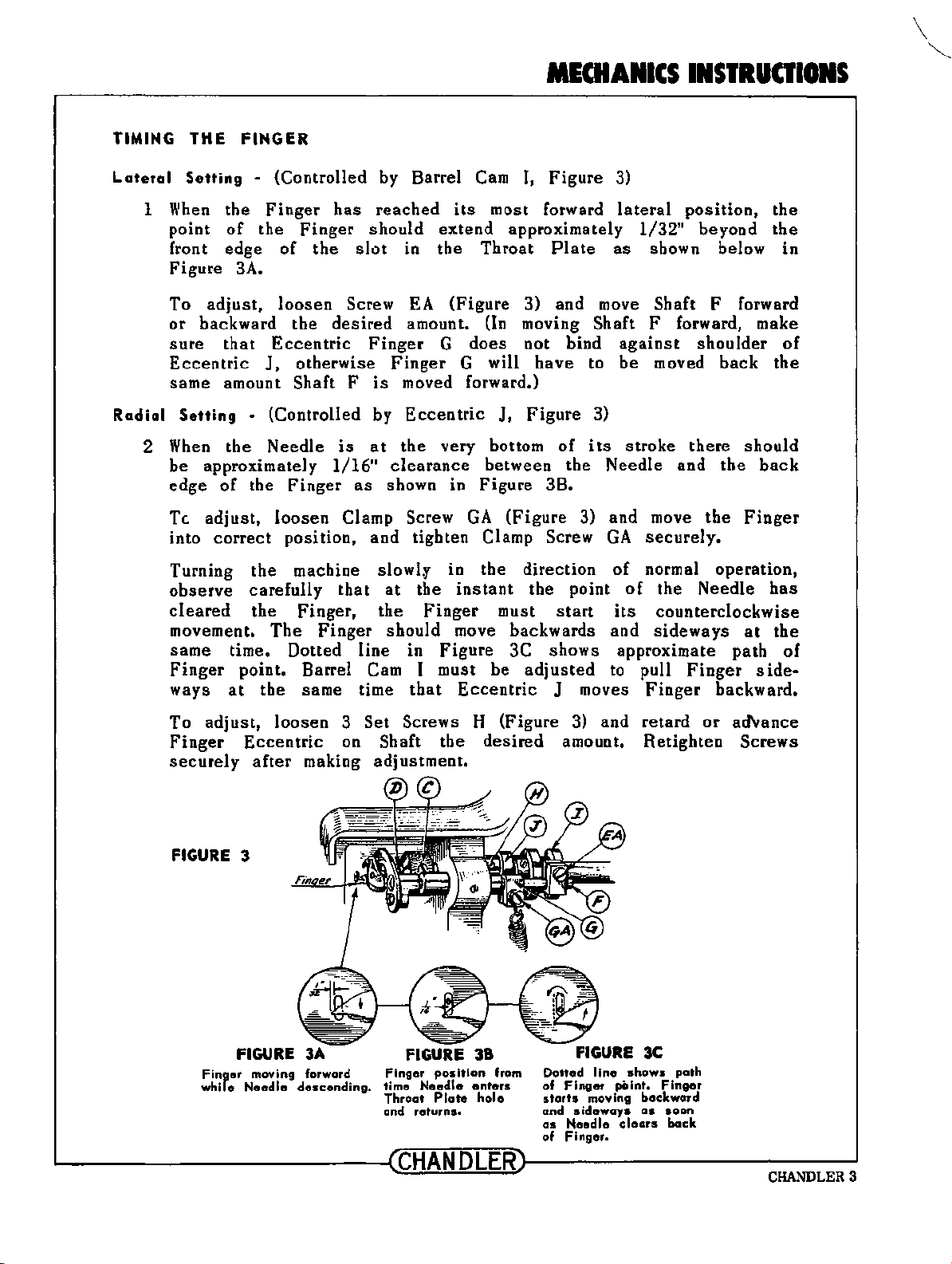

TIMING

Lateral

1

Radial

2

THE

Setting

When

point

front edge

Figure

To

or

sure

Eccentric

FINGER

- (Controlled by Barrel

the

Finger

of

the

3A.

adjust,

backward

that

J,

has

Finger

of

the

loosen

the

desired

Eccentric

otherwise

Screw

same amount Shaft F

Setting

When

be

edge

Tc.

into

Turning

observe

cleared

movement.

same

Finger

ways

- (Controlled by

the

Needle

approximately

of

the

Finger

adjust,

correct

loosen

position,

the

carefully

the

The

is

1/16"

Clamp Screw

machine

that

Finger,

Finger

time. Dotted

point. Barrel Cam I must be

at

the same time

reached

should

slot

in

extend

the

EA

amount.

Finger

G

Finger

is

moved forward.)

Eccentric

at

the very bottom

clearance

as

shown in

and

tighten Clamp Screw

slowlf

at

the

the

Finger

should

line

in

Figure

that

Cam

its

I,

Figure

most forward

3)

approximately

Throat

(Figure

{In

does

G will

J,

between the

Figure

GA

Plate

as

3) and move Shaft F forward

moving Shaft F forward, make

not bind

have

Figure

of

to

3)

its

Needle

3B.

(Figure

3) and move

GA

in

the

instant

must

direction

the point

start

of

its

move backwards and

3C

shows

adjusted

Eccentric

J moves

to pull

lateral

1/32"

position,

beyond

shown below in

against

be

stroke

moved

there

and

shoulder

back

the

the

securely.

normal operation,

of

the Needle

counterclockwise

sideways

approximate

path

Finger

Finger

backward.

the

the

of

the

should

back

Finger

has

at

the

of

side-

To

adjust,

Finger

securely

FIGURE

Finger

while

~--------------~CHANDLER~--------------~

loosen

Eccentric

after

3

FIGURE

moving forward

Needle

making

3A

descending.

3

Set

Screws H (Figure 3) and

on Shaft the

adjustment.

FIGURE

Finger

time

Throat

and

position

Needle

Plate

returns.

desired

38

from

enters

hole

amount.

Dotted

of

Finger

starts

and

sideways

as

Needle

of

Finger.

II

ne

point.

moving

clears

retard

Retighten

shows

path

Finger

backward

as

soon

back

or

ad'vance

Screws

CHANDLERS

Page 6

MECHANICS

INSTRUCTIONS

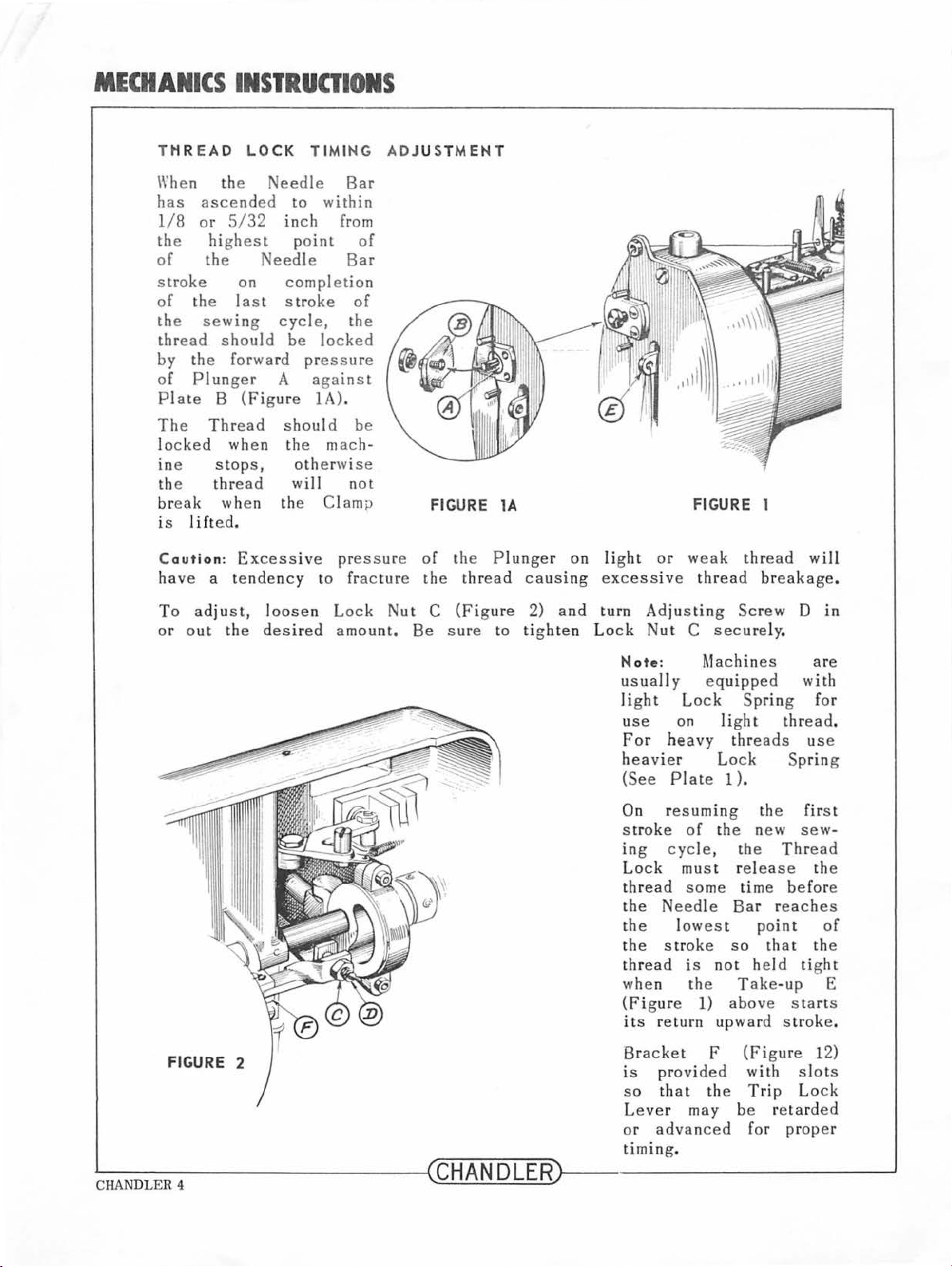

THREAD LO

\\'he n the

has

ascended

1/8

or 5/

the

of

hi

the

ghest

stroke

of

th e

the

sewi

thr

ead

shou

32

on

last

ng

CK

TIMING

Needle

to

inch

po

Needle

completion

stroke

cycle,

ld

be locked

Bar

within

from

int

Bar

of

the

by the forwa rd pressure

of

Plunger

PI

ate B

The

l

in e

the

ocked

Thr

wh

stops,

thread

break when

is 1 ift

Caut

have

To a

or

ion

out

a t

dju

ed.

:

st,

the

A

against

(Figu

re

1A).

ead

shoul d

e n the mach-

otherwise

will

the

Clamp

Excessive

endency

loose

to

n Lock

desired

be

not

pressure

fra c

amount.

ADJUST

of

ture the

Nu

MENT

FIGURE l A

of the P l

thr

ead

t C (Figu

Be sure

re

to

unge

causi

2)

tigh

r on li

ng

excessive thread breakage.

and

turn Ad j

ten L

ght

ock

FIGURE 1

or weak

usting

Nut

C

thre

Screw

secure

ad

ly.

will

D in

FIGURE 2

~------

CHANDLER

4

----

N ote: Machi

usually

li

ght

use

Lo

on ligh t

For heavy thr

heavier

(See

On r

stroke

ing

L

ock

thr

the

Plate

esuming

of

cycle,

must release

ead

some

Ne

edle

the lowest

the

s t

roke

t

hread

when

(Figur

i

ts return upward

Br

1s

is

the

e 1)

acket

provided

so that

Leve

r may

or

advance

ming

ti

.

nes

e

quipped

ck

Spring

with

thread

Lo

eads

ck

us

Spring

1 ).

the

first

the new

th e

time

Bar

sew

Thre

befo

reache

point

so

that

not held tigh t

Take

-up E

above starts

s t

roke

F (Fig

the

with

Tr

ip

ure

slots

Lock

be retarded

d fo r proper

--------~CHANDLERr----------------

are

for

.

e

-

ad

the

re

s

of

the

12)

--

.

--~

Page 7

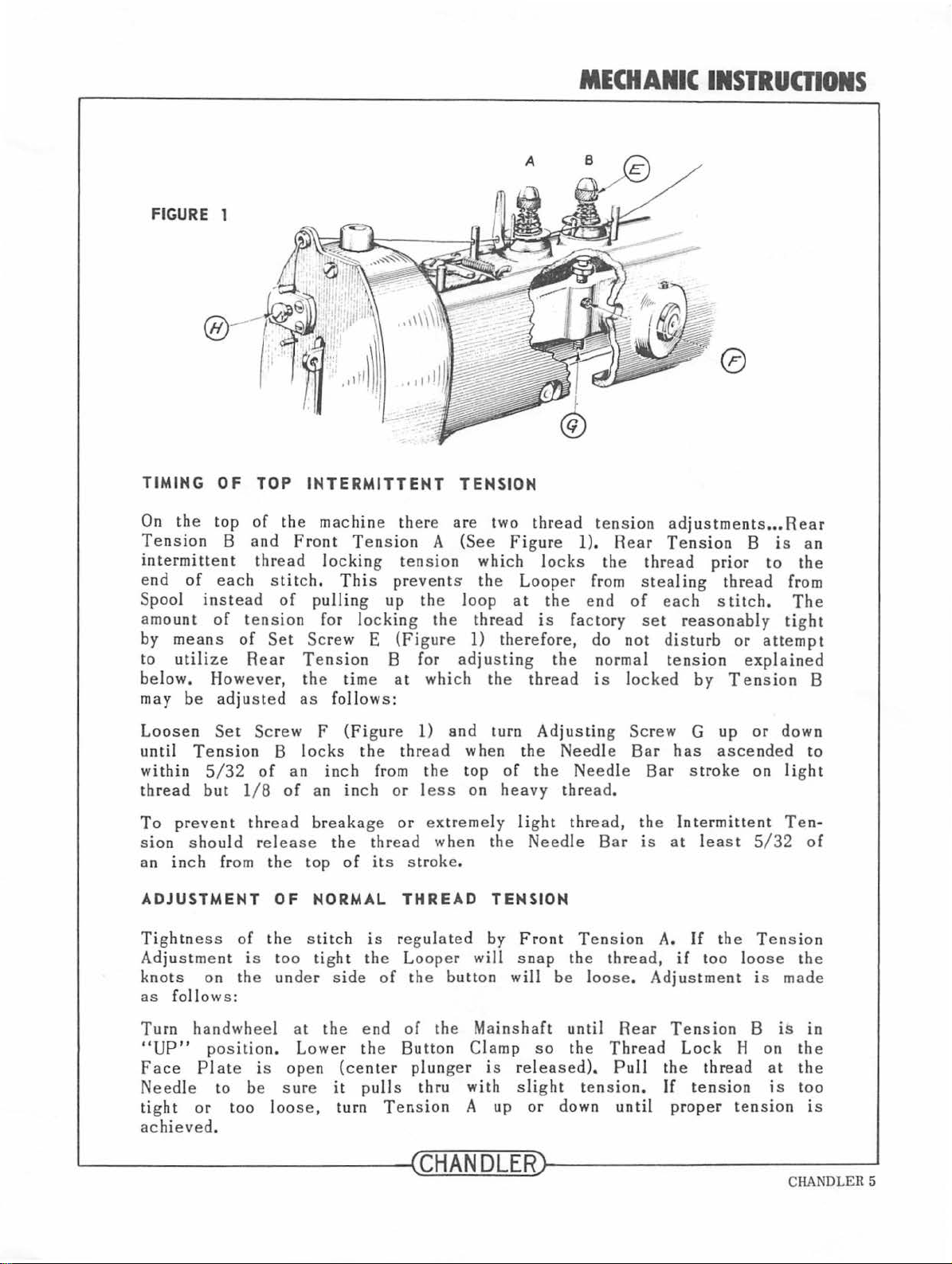

FIGURE 1

MECHANIC

INSTRUCTIONS

0

TIMING

On the

Te

nsion

intermittent

e

nd

Spool instead

amo

by means

to

b

elow.

may

Loosen

until

within

thread

To

sion

an inch from th e

ADJUSTMENT

Tightness

Ad ju s tme

knots

as

top

of

each

unt

of

utili

ze

However,

be

adjusted

Set Screw

Tension

5/32

but

prevent

s ho

nt

on the

follows

OF

TOP

of

the

B

and

thr

ead lockin g t

stitch.

of

tension

of

Set

Rear

B

of

l/ 8

thread

uld release

OF

of

the stit

is too tig

under

:

INTERMITTENT

machin

Front

Tension

th e time a t

as

locks

an

of

Tens

This pr

pulling

for l

ock

Screw

F

a n

breakage

top

NORMAL

E

follows :

(Fi

gu re

the

inch

inch

th e

thr

of

its

ch i s regul ated

ht

th e

side

TENSION

e th

ere

are two

ion

A (See Figure 1).

ens

ion

which locks

eve

nt s the

up

the l

oop

ing

the

thr

(Figure

B for

l)

thr

ead

from the top

or l

or extr

ead

stroke

THREAD

Looper

of

the butt

adjusting

which

and

ess

eme

when

.

l)

wh

on

will

on

thread tens

Loop

at

the

ead

is

therefore,

the

thread

turn

Adjusting

en

th e

of

the

heavy

ly light

the

Needle

TENSION

by

Front

s n

ap

will

ion adjustments •••

Rear

the

er from s tealing

end of

factory

do

the normal tension

is

Needle

Needle

thread.

thread,

Bar

Ten

sio

th e thread,

be loose.

Tension

thr

ead

prior

each

set

reasonably

not

dist

urb or

locked

Screw

Bar

Bar stroke on lig

the

is

n A.

by

G

has

Intermittent

at leas

If

if too loose

Adjus tm

B

is

to

thr

ead

stitc

h.

atte

expl

ained

Tension

up

or

down

ascended

t 5/

32

the

Tension

ent

is

made

Rear

an

the

from

The

tight

mpt

B

to

ht

Ten-

of

the

Turn

"UP"

Face

Need

tight

achieved

~------

handwheel

position.

Plate

le to be

or

to o l

.

is

at

Lower

open

sure

oose,

----------

the

end

of

the

th e

Button

(center

it pulls thru

turn

plunger

Tension

Clamp

with

A up

--~CHANDLER~

Mainshaft

so

is

rele

slight

or

until

the

ased

down

--

Rear Tension

Thread

).

Pull

tension.

until

the

If

prop

Lock

thread

ten

H on

s ion is

er

tension

B

at

is

in

the

the

too

is

----------------~

CHANDLER 5

Page 8

MECHANICS

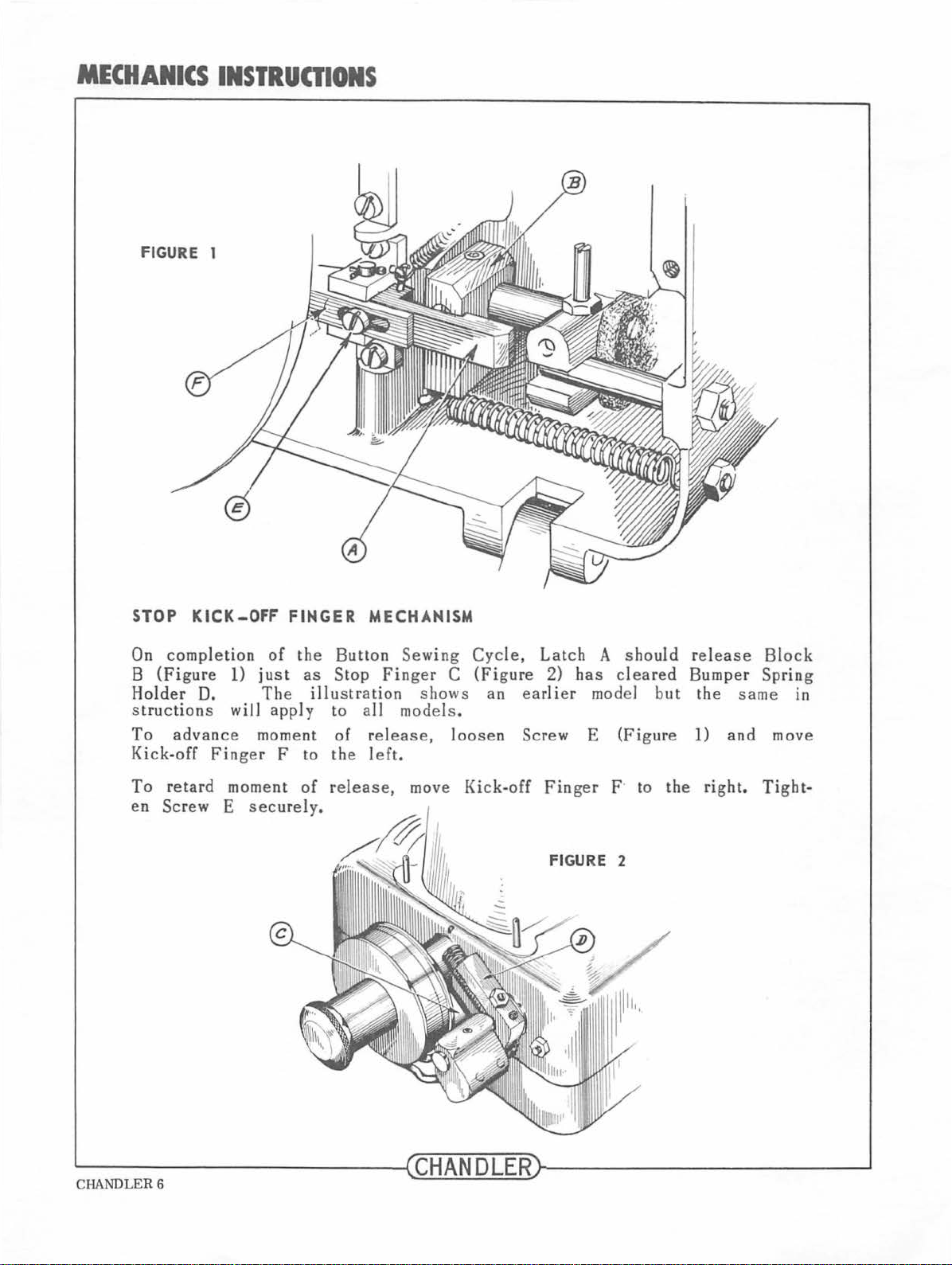

FIGURE 1

INSTRUOIONS

STOP

On

completion

B

(Figure

Holder

st

ruction

To

advance

Kick-off

To

retard

en

Screw E

KICK-OFF

of

1)

just

D. The

s will

Finger

apply

moment

moment

securely.

FINGER

the

as

illu

F

to

of

MECHANISM

Button

Stop

stration

to all models .

of

the left,

release,

Finger

rel

ease,

Sewing

C

shows

loosen

move

Cycle,

(Figure

an

earlier

Screw

Kick-off

Latch

2)

has

model

E

Finger

FIGURE 2

A

shou

cleared

(Figure

F· to

ld

but

the

release

Bumper

the

same

1)

and

right.

Block

Spring

in

move

Tight-

~----------------~CHANDLER~----------------

CHANDLER 6

~

Page 9

MECHANICS

INSTRUCTIONS

AUTOMATIC

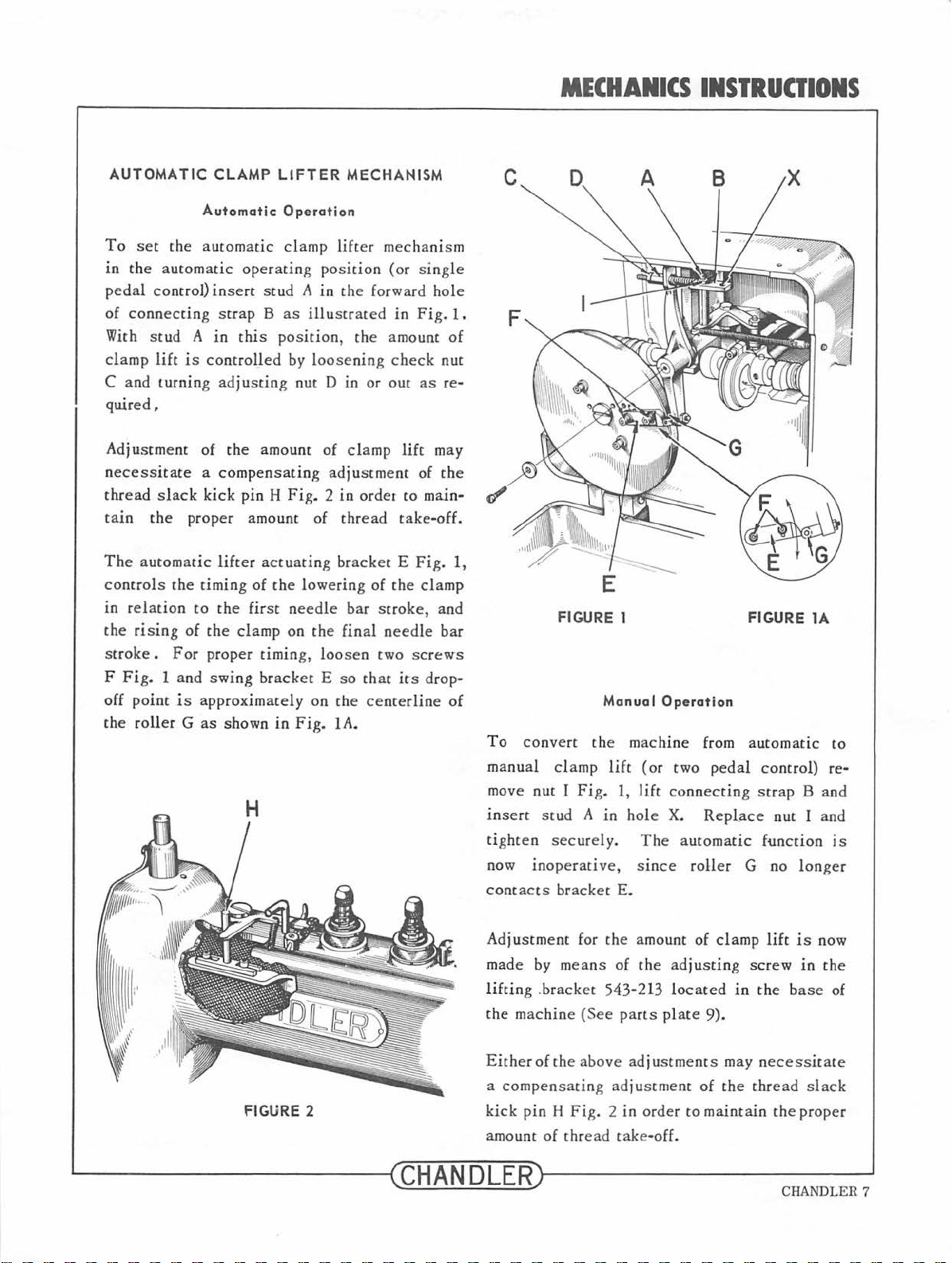

To set

in the automatic

pedal

contro

connecting

of

With stud A

clamp

C a

quired,

Adjustment of

n

thread slack

tain

The

controls

in

the

s

F

off

the

lift

nd

turning adj

ecessi

troke.

tate a compensating

the

automat

rel

ation

rising

Fig.

1 and

point

roller G as

CLAMP

Automatic

the

automatic

l)

insert

strap B as

in

is

controlled

kick

proper amount of thread

ic

lifter

the timing of

to th

of

the

For

proper tim ing, loosen two screw

swing

is approxim

LIFTER

Operation

clamp

operating position

stud A in the forward hole

this

pos

by l

ustin

g nut D

the

amount

pin H

Fig. 2 in

actuatin

the lowering of

e first

clamp on

shown

needle

bracket E so that its drop-

ately

in

Fig.

MECHANISM

lift

illustrat

ition

, the amount

oose

ning ch

in

of clamp

adjustment

g br

acke

bar

the

final need

on the

1A

.

er

ed

or out

ordet

scroke, and

centerli

mechanism

(or sin

t E

the

gle

in

Fig.

eck

nut

as

lift

may

of

the

to main-

take-off.

Fig.

clamp

le

bar

ne

1.

of

re-

1,

s

of

FIGURE 1 FIGURE

Manual

To

convert the machin e from

manual cla

mov

e nut 1

insert stud A in

tighten

now inoperative, stnce

contacts

mp

Fig.

sec

urely.

bracket

lift

Operation

(or two

1,

lift

hol e

The automatic

E.

automatic

pedal contro

connecting strap B

X.

RepLace nut I and

function

roller

G no

longer

lA

to

l) re-

and

is

FIGURE 2

~--------------~C

Adjustment

made by

liftin

g .bracket 543-213 located

the machine (See

Ei

ther

a compen

kick

pin H Fig.

amo

unt of thr

HANDLER~----------

for the amount of clamp

me

of

the

sating adjustment of

ans of

above

ead

the adju

parts

plate 9).

adjustments

2 in order to maintain

take

-off.

lift

sting s

crew

in

the b

may ne

the

thread slack

the

cess

------~

is now

in

the

ase

of

itat

e

proper

CHANDLER 7

Page 10

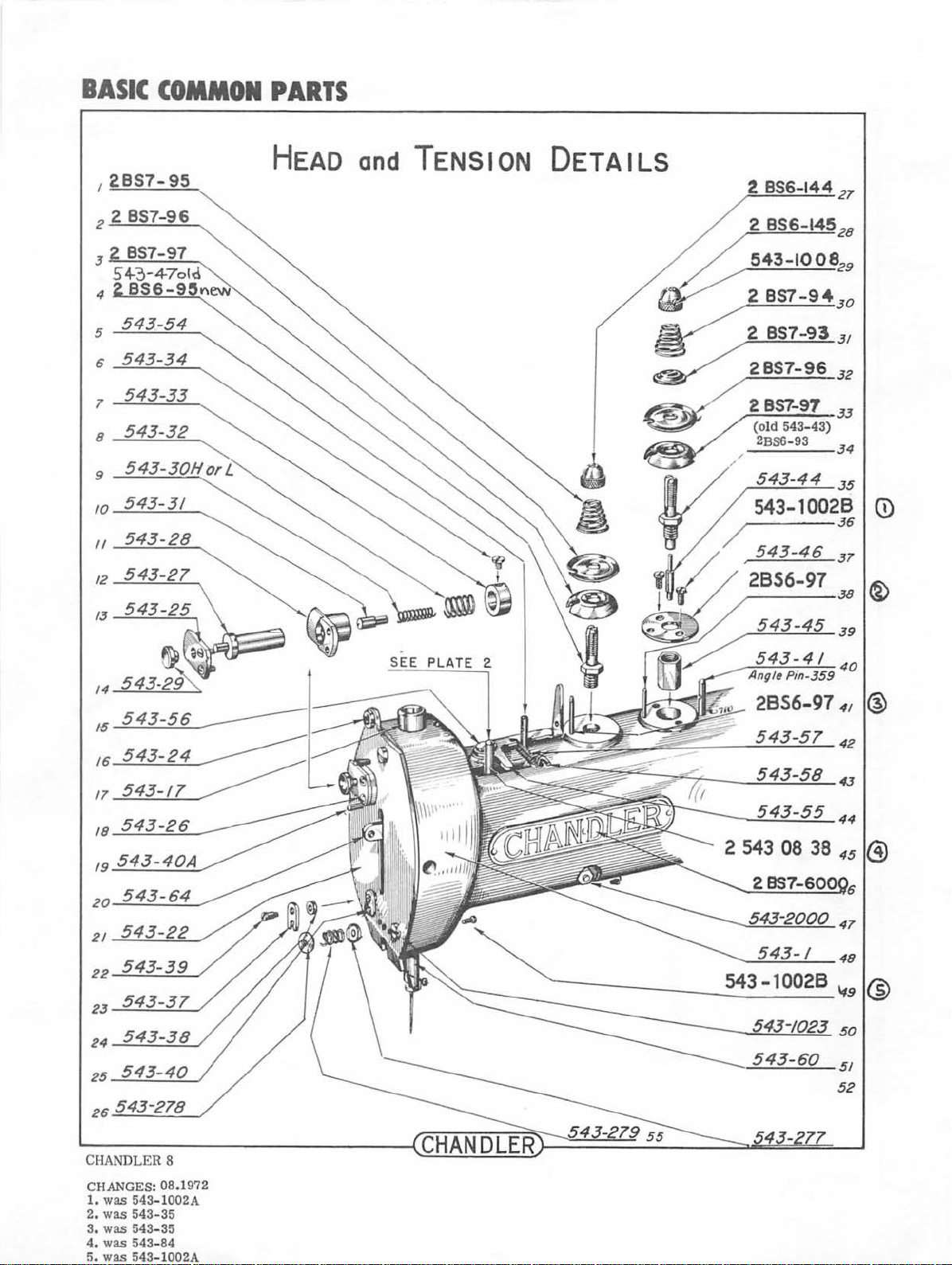

BASIC

COMMON

PARTS

I

2857-95

1

543-33

8

543-32

10

543-31

11

543-28

12

543-27

HEAD

and

TENSION

DETAILS

~32

2

856-144

2

857-93

2

857-97

(old

543-

2BS6-

93

21

31

33

43)

34

/8

19

20

21

22

23

24

25

26

543-37

54

543-

S

.

EE

PLATE

2.

CHANDLER 8

CHANGES: 08.1972

1.

was

543-1002A

2.

was

543-35

3.

was

543-35

4.

was

5.

543-84

was

543-1002A

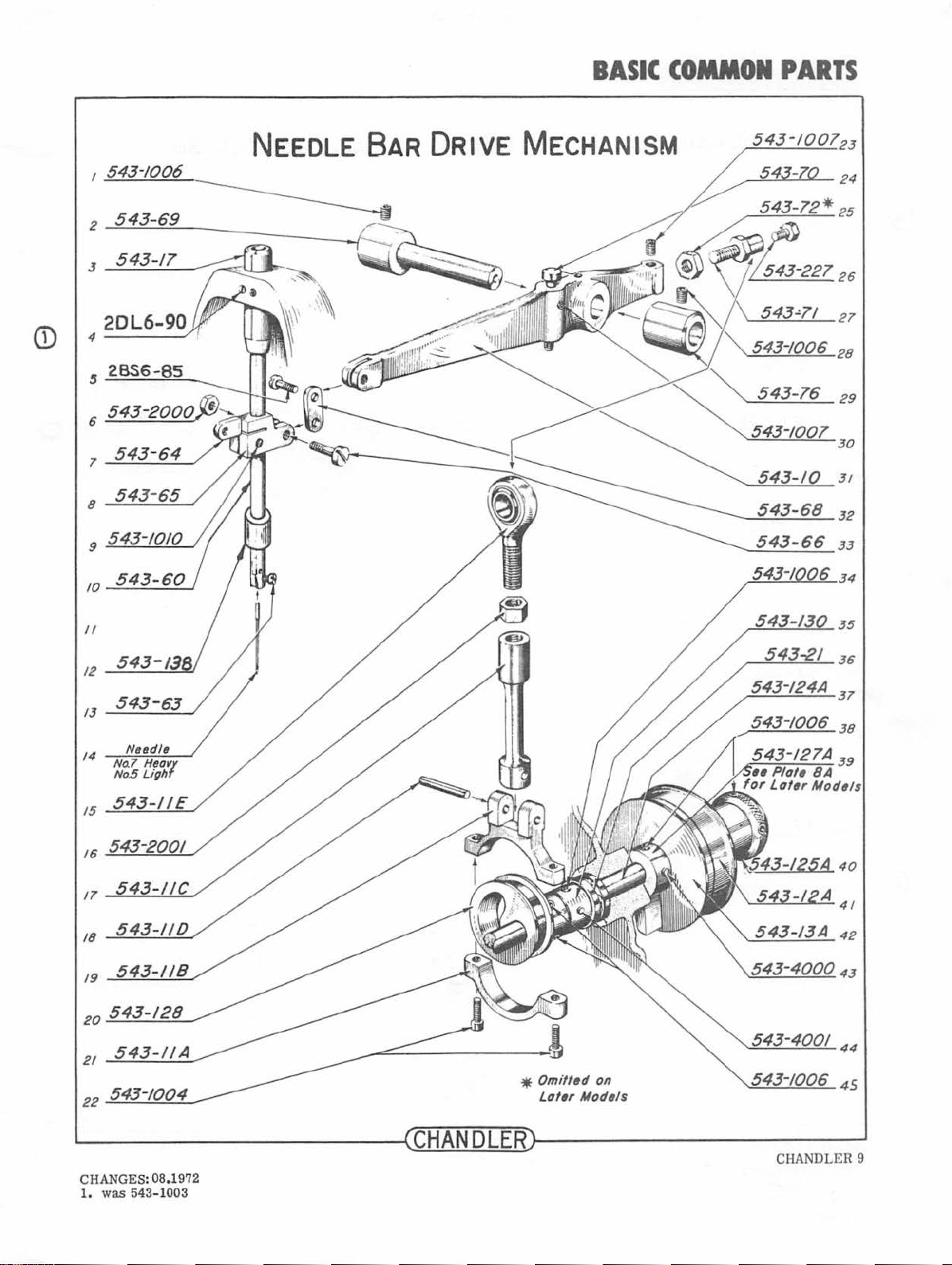

Page 11

BASIC

COMMON

PARTS

I

543-/006

2

543-69

7

543-64

8

543-65

9 543-1010

NEEDLE BAR

DRIVE

MECHANISM

543-10

543-68

543-66

3 /

32

33

34

II

12

13

14

No.7

No.5

15

543-200/

16

17

18

/9

20

21

22

Nudls

Hsa1

Ligh

*

Omitted

Later

35

36

37

38

on

Models

~----------------~CHANDLERr-----------------~

CHANGES: 08.1972

1.

was 543-1003

CHANDLER 9

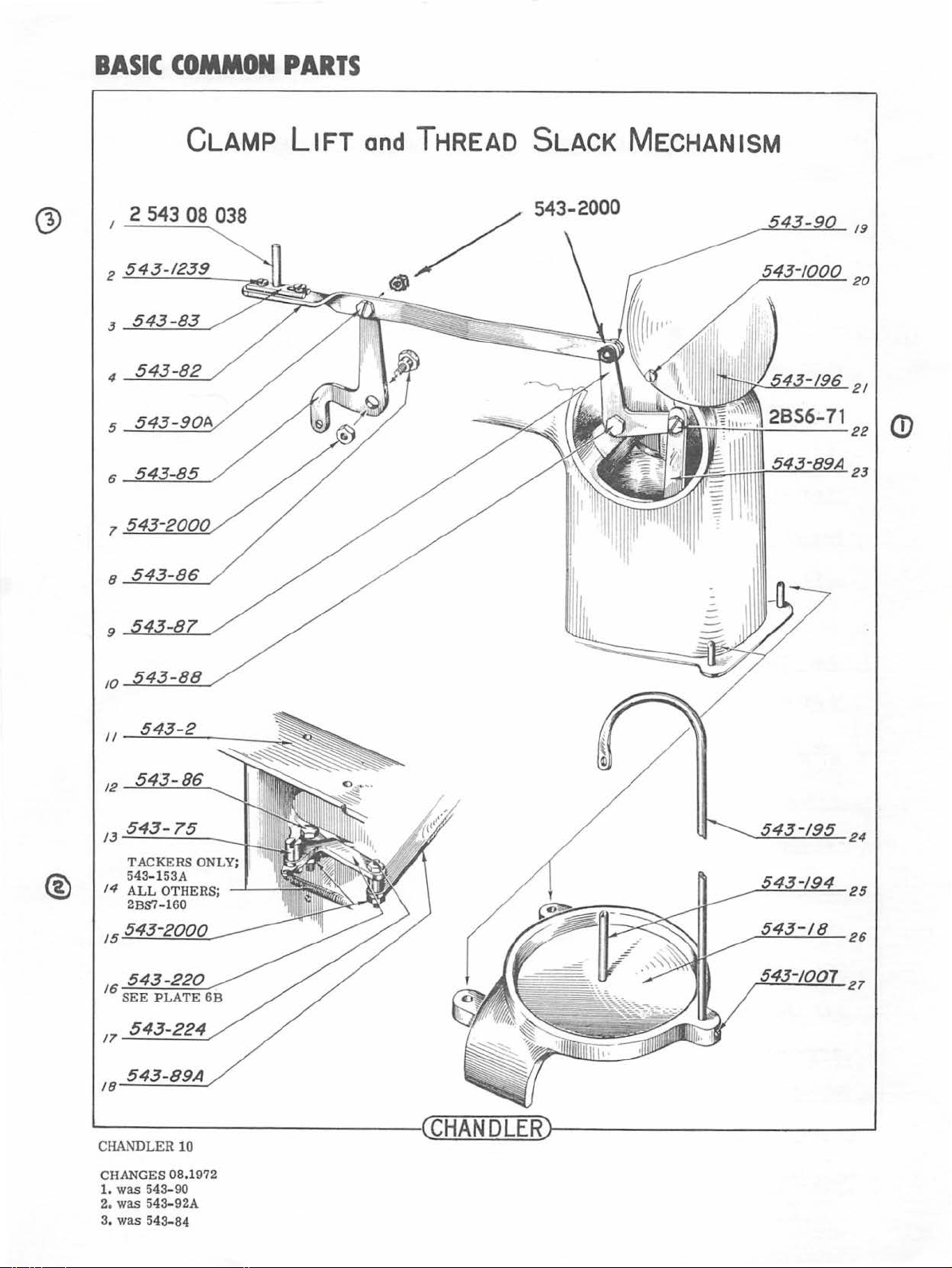

Page 12

BASIC

COMMON

PARTS

CLAMP

2 543 08 038

8

LIFT

and

THREAD SLACK MECHANISM

' I

®

9

10

II

12

15

.....:::5;__;4...:::..3.......:-8::....::9...:...:A._,

18-

24

25

26

27

CHANDLER

CHANGES

1.

was

2. was 543

3.

was

10

08.1972

543-90

-92A

543-84

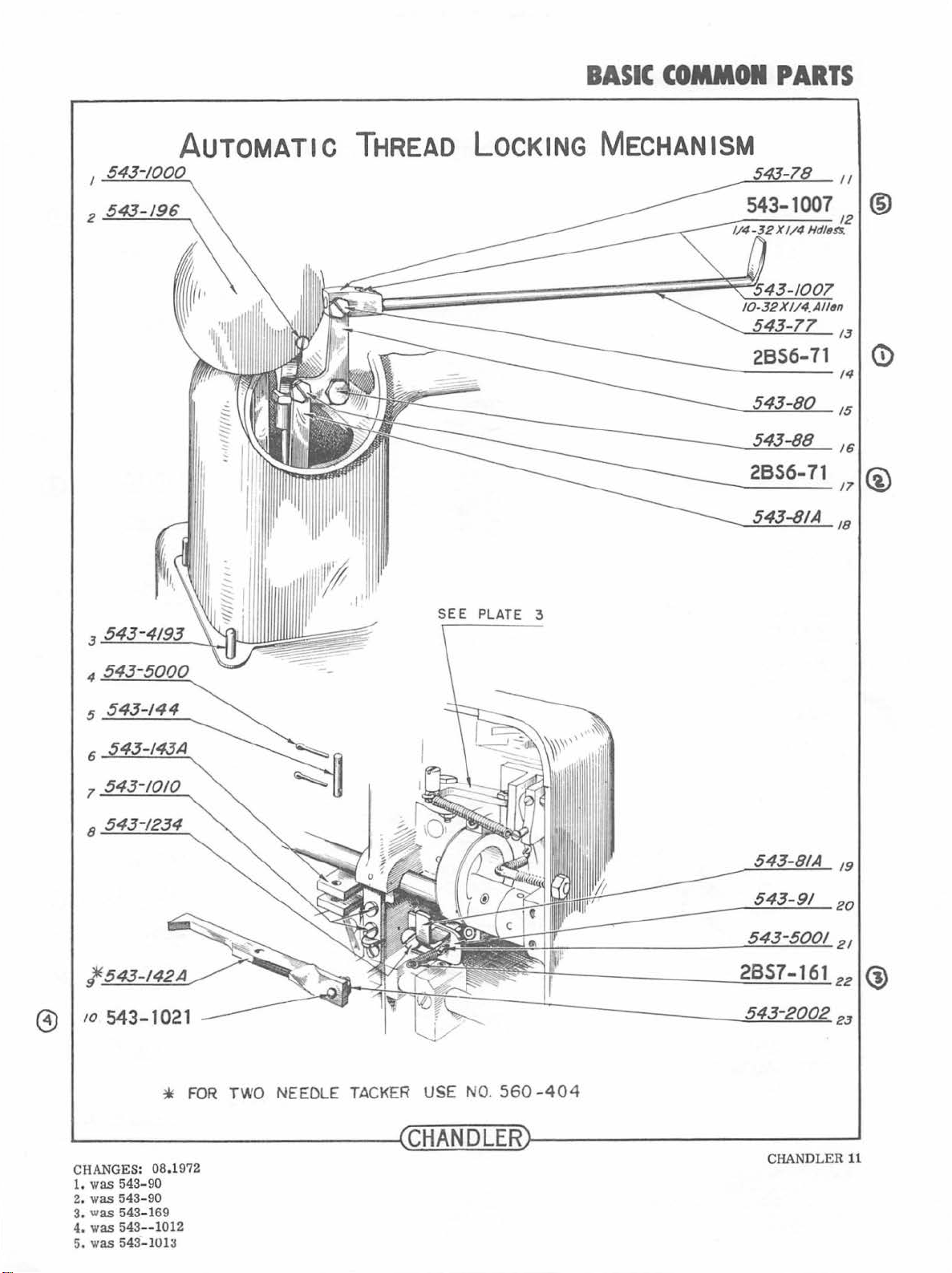

Page 13

BASIC

COMMON

PARTS

2

543-/96

AUTOMATIC

THREAD LOCKING MECHANISM

SEE

PLATE 3

2856-71

13

14

15

16

/1

/8

0

@

5

543-144

6

1

8

l.

/0

@

543-1021

CHANGES:

1.

was

543-90

2.

was

5

was

43-90

54

543--

543 -101

3.

4. was

5. was

08.1

3-169

1012

*

~

FOR

972

TWO NEEDLE TACK

ER USE

NO. 560

CHANDLER

-40

4

2857-161

CHAN

DLER

/9

20

21

22

23

®

11

Page 14

B

ASIC

CO

MMON

PARTS

2

543-1002

6

543-137

7

543-2

8

LOOPER

and

FINGER MECHANISM

552-320

543-/32

2857-

161

20

21

24

25

26

<D

®

®

G>

10

II

543-!24A

17

2856-400

18 543-141

CHAND

LE R

12

CHANGES:

1.

was

In

2.

was

3. was 543-1016

08.

543-121 & 122

1968

needle plate was

543- 205

4

1972

changed

543-4273

to

one pi

ece

--C-HA_N

__

D~L-=E=--R

4. was 543-1018

was

543-15

5.

was

543- 135

6.

7.

was

543-1003

29

20L6-90

552-315

552-320

1

JT

38

J9

(J)

Page 15

BASIC

COMMON

PARTS

CD

®

1

552-336

7

552-325

8

543-187

9

543-209

543-10028

II

543-330

/J--!:::....:..:::_-.=2 ____

FoR

CLAss 552

----.,

AND

LATER MoDELS

543-326

552-328

552-337

543-1002825

543-

22

2J

24

28

JO

J/

Q)

No

~----------

CHANGES: 08.1972

1.

was

552-329

2.

was

543-1002A

3.

was

543-184

Shouldu

--

----~~C~H~AN~D~L~E~R~

(N~w

Sho

ulder

Sly!~)

Stud

543-140;-:A

543-140

--------

-~---

~~

§.j_~'Qg?._~,B

--------~

CHANDLER

13

Page 16

CD

BASIC

COMMON

PARTS

STOPPING MECHANISM

NOTE: BELOW SPRING

IN 1948.

MODIFICATIONS.

SEE

FOLLOWING PAGES

STOP

DISCONTINUED

FOR

LATER

<D

@

12

------..

552-313

13 543-1010

543-/9A

16

2BS7-161

17

-------,.

NEEDLE TACKER

*

USE

NO.

560-402

T

USE

N0.560-403

L------------------4CHANDLER~--

CHANDLER

CHANGES: 08.1972

1.

was

2.

was 543- 20

3.

was

4.

was

14

543-169

543-1018

543-235

(a!ter

1970,

"C"

clips

used)

------

--------~

Page 17

BASIC

COMMON

PARTS

STOPPING

2 543 08 036

MECHANISM

INTRODUCED 1952

543-391

4

52-4000

5

552-1006

7~~-~4~0~0~0--------~~

-

FoR

CLASS

552

MACH.

552-33514

552-3002'15

552-309

16

8~~~0~0~6

*_5::....;5::....:;2:..._-.=....3:....::1

II

12

552-1010

FOR

TWO NEEDLE

*

USE

t

USE

·

------~~------~

8"-/

TACKER

NO.

560-429

NO.

560-

403

-

~------------------~CHANDLERr-----------------~

CHA

NGES : 08.1972

1. was 543-311,

also

see

assy

dwgs

CHANDLER 15

Page 18

BASIC

CO-ON

PARTS

STOPPING

MECHANISM

INTRODUCED 1971

~~---------552-3002

~~---------600-309

FOR

~-----------600-335

CLASS

600

MACHINE

600-332A

WASHER

FOR

CUSHIONSPRING

MUST

discontinued.

CLASS

WILL

WHICH

PURCHASED

SEE PAGE 34

COMPLETE

~----------------~CHANDLER~--------------~~

CHANDLER16

CHANGES: 08ol972

1. was 552-311. also see assy dwgs

THOSE

BE

552

BE

REPLACED

IS

FOR

UNIT.

WISHING

TO

HOLDERS,

PURCHASED.

)

REBOUND

BY

HEAVIER.

(600-

ASSEMBLY NUMBER

NEW

335).

CONVERT

PART

(spring

FINGER

A

NEW

SCREWS

FOR

NO.

no.

552

STOP

THEIR

600-323

-332

GUIDE

ONE

(

600

MUST

CLASS

ADAPTER

will

be

(552-309)

-

309)

ALSO

552

,

BE

Page 19

BASIC

COMMON

PARTS

<D

543-94

2

543-213

3

543-2002

4

543

5

543-10/9

6

7

-10

/9

TREADLES

and

TRIP

LEVERS

2855-177

543-2002

543

-1018

543-2002

543-1021

543

-200

/6

17

18

19

20

21

2 2

g)

®

8

9

II

/2

13

14

15

543-226

1010

24

25

26

27

28

29

30

~--

CHANGES: 08.1972

1.

2.

3.

4.

--

was 543

was

was B

was 543- 1019

54

3-7

S-7

-9

3

9

7

------

----

--~~

CHruA~N~D~L&E~Rr---

--

----

------

CHANDLER

--~

17

Page 20

OPTIONAL -NOT

FOUND

ON

ALL

MACHINES

GROOVE

4

555-380

PIN

AUTOMATIC

CLAMP

LIFTER

555-387

.

555-381

543-2000

13

14

15

®

5

6

7

555-377

8

543-3001

543-1023

9

II

555-382

~

--

CHANDLER 18

--------------~CHANDLER~------------------~

543-220A

543-2005

552-367

555-378

555-379

543-200018

555-383

543-241

/6

17

19

2 0

CHANGES: 08.1972

was 543

1.

was 543

2.

-101

-101

6

8

Page 21

n

I

0

...

rrl

543-1002

541-59K

552-320

KNIFE

MEOtANISM

OPTIONAL-see machines model

cover. Non-knife machines cannot

to

knife

machines,

"K"

different

SUFFIX

base casting.

MACHINES.

Hst

inside

be

conve··ted

front

543-10028

IOOWire

fil

hd

/4

1oowire

....

•

,..

•

;;;

....

....

(")

~

E3

~

t::l

::d

.....

CD

541-281

~EA-U8

HJ-Zil

-

-

PI:

-

-

PI:

•

...

-

Ill

I

,..

•

-

Ill

•

....

Page 22

TWO

NEEDLE

TACKER

TWO

2BS6-1442REQD

2 8S7 -95 2

2BS6-51

560-4201.

543-57 2 REQD

560-420R

560-445

560-421

543-34

543-33

543-32

543-31

543•

543-28

543-27

543-25

543-26

543-29

543-40 2 REQD

543-38

543-37

543-39

560-

543-1007

NEEDLE

REQD

30Horl

2 EA

414A-G

see

box

TACKER

2BS6-145

543-1008 I EA

2

BS7-9S 2 REQD

2 857-96 4

2

f1!R-97

et;0-441 2

~60-

I0-32X3/810C flathd

510-446 2 REQO

543-35

560-4 4Z5 2 REQO

560-407

560-415

543-17

543-24

543-1023

543-

560-408

543-1002A2

560-419

6-40x

560543-63 2 REQD

134-35-110 2 REQD

2 R£00

2REQD

REQ

4

REQD

REQD

442 2 REQD

4R£QO

2fEQD

2

REQD

40A 4

REQD

REQD

5/1611hd21'eqd

413A-H

see

bca

D

~----------------~CHANDLER~----------------~

CHANDLER20

Page 23

TWO

NEEDLE

TACKER

543-154A

NUT OTHER SIDE

TWO

NEEDLE

TACKER

2BS6-160

~

2856-4005

-

'part

no.

for MACHINE

_,..

looper

bro block

bot

r»Y«

loooer oft.

man

sft

nose

frame

moin

veer

loooer

aoor

needle pl

brg

block

bot.

OOYtr

looper

sfl

main

aft

nose

tom<

mcin gear

ooar

''0-4011

SI0-4008

St0·4MA

...,_...,.

K0·4ZIA

oto-401A

510-•UIII

510-4311

:IC0·40tE

$60-60$[

H0-433C

010-4108

010·421

D80-401C

!t60-438( 510-431

OI0-4"Y

*"'

I

1/4

I

1/2

__

...,..,

seo-•

oec

000-4>31

M0-4t0.

I<G-<ZU

~o.o--·

11

0·4liC

510-43a

MACHINE

SIZE

2"

2

1/4

~...,.,

$eO-~'

S80-433

C

80-4a01

510-4UI

8

SI0-401C

E

5S0-4M'

chort

for

c::orrect

SI~E

;;;-

I

3/4

M0-

4De

500-4000

SI0-4UI

,.,.4f0

* ·

4l:ll

Ia«>-

oto-4MD

c

Oto-

4Je

cent.

2 172

SI0-40tG

S&0-40~

O«l·

433C

810-W

t0-42ft

"0·40tC

,

M0-4310

..........

port

no.

no.

reQII

_

I

I

I

•

•

I

I

I

D

•

I

I

I

I

•

I

I

I

•

CHANGES: 08,1972

1.

was

543-92A

2.

was 543-169

3.

was 543-151

was 543- 1016

4.

CHAN

DLER

21

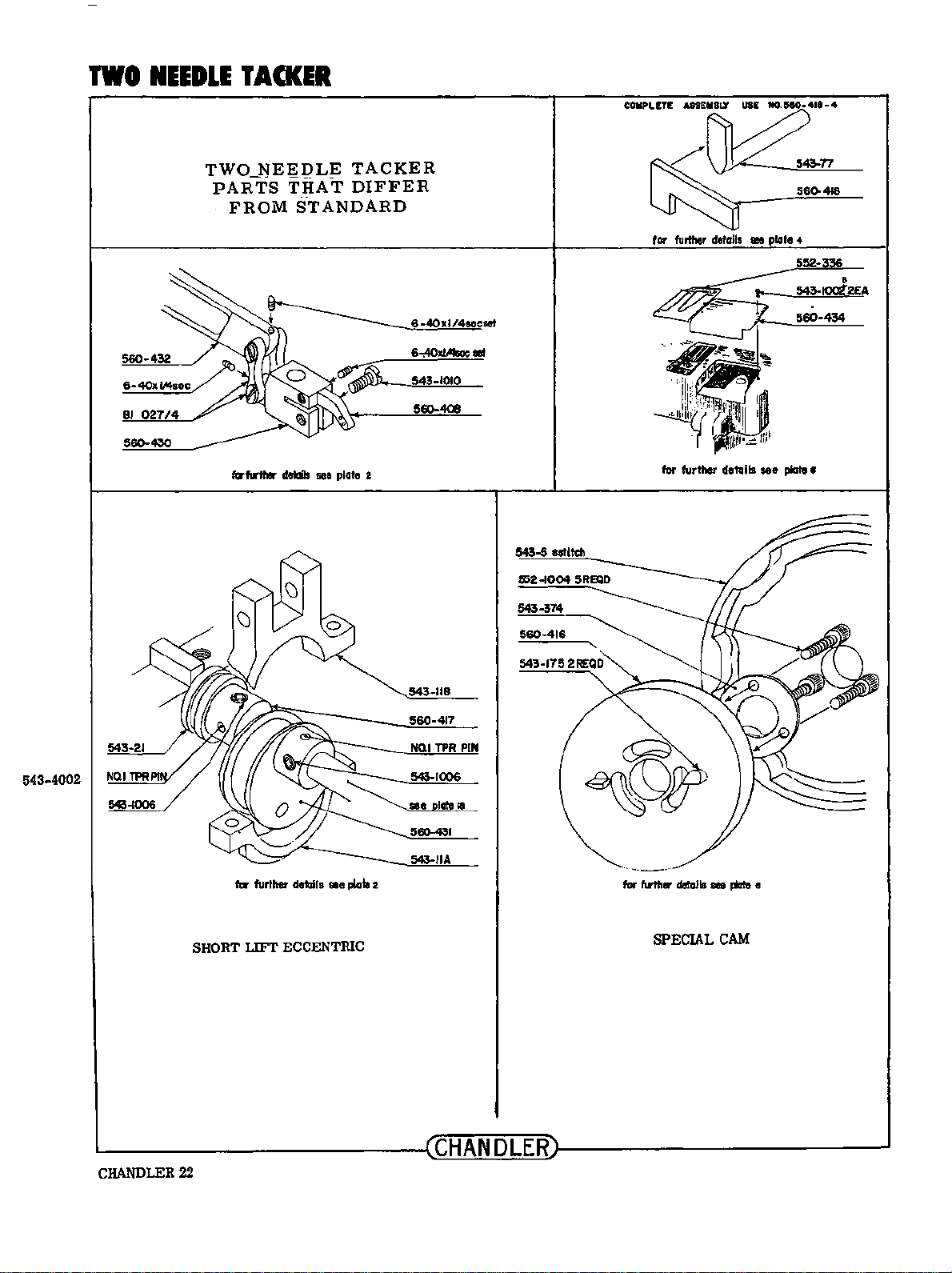

Page 24

TWO

NEEDLE

TACKER

TWO

PARTS

FROM

fcrfwtlw dellils

NEEDLE

THAT

STANDARD

see

TACKER

DIFFER

plato 2

6-40xl/4socset

560-408

543-5 eatitch

560-416

for

further details

for further details

1110

plato 4

see

560-434

plate •

543-4002

543-118

560-417

NO.I

TPR

PIN

560-431

543-IIA

SHORT

for further details

LIFT

ae

plata

ECCENTRIC

2

for

further

derails

SPECIAL

see

CAM

plata •

~------------------~CHANDLER~------------------~

CHANDLER22

Page 25

TWO

543-301

543-299

560-422

543-299A

NEEDLE

TWO

TACKER

NEEDLE

TACKER

CLAMPS

-543-1002

S43-300A

543-1237 6

543-3003

REQD

6REQD

(!)

543-2003

543-300

543-!00t 2 REQD

2REQD

560-372

543-118

543-119

543-265X

*552-376

543-96

543-95

543-97

2REQD

552-375*

560-435 2 REQD

543-302X

543-1002

560-423

I Dart

MACH.

SIZE

too

aeo-..ooa

11/4

S80-400C

II/I

aeo-40ao

I

Sf4

11110-400!

2'

SS0-400f

21/4

1100-4000

1112

no.

for clamli

2

REQO

I bottom

ooo-40111

1100·401C

1100·401D

1100·401!

IIIS0-401F

oeo-401 G

~----------------~CHANDLER~----------------~

CHANGES: 08.72

1.

was

543-372

CHANDLER23

Page 26

CLAMPS

I

543-85

2

543-123

Q)

3 2856-158

BUTTON CLAMP ASSEMBLY

543-120

543-2004

543-119

18

19

20

543-/05

543-3000

543

543-114

Pin

543-1/0

552-369

543-97

-118

21

22

26

28

29

30

13

543-108

®

17

543-390

543-1015

~----------------~~C~HA~N~D~L~E~R~~--------------~

CHANDLER

CHANGES:

1.

was

2.

was

3.

was

4. was 543

24

08.

543- 116

543-1015

543-98

-11

5

1972

& 543-

99

Page 27

BUTTON CLAMP ASSEMBLY

All

In

One

Style

r 8

'

-32

CLAMPS

X 1

/4

SlOtted

hdless

See

Item

Plole

29

543-272

5

4

- 543-390

NOTE

Ports

Not

Bear

ing

Mimbers

Are

Identified

~-------------------------------------------~CHANDLER~-------------------~

On

Plate 5

CHANDLER 25

Page 28

CLAMPS

543-244

543-244A

2

543-243

3

543-246

4

543-260

5

54

7

8

9

543-237

10

3-238

SHANK

C/ol/1

BUTTON

Support

For

ATTACHMENT

54

3-2

45

543-250

543-249

543-105

543 -

257

543-3000

543-242

/9

20

21

22

24

26

27

28

29

18

543-2

55-C

WHEN

ORDERING,

BUTTON

BE

PROPER CUP

AND

SPECIFIED

LINE

SIZE

OF

SHANK BUTTON MUST

IN

ORDER

SIZE

AND

TO

SUPPLY

HEIGHT.

STAY

543-247 30

5

43-

2003

31

543

-241

543-240

33

~------------------~CHANDLER~--

CHANDLER 26

--

--------------

~

Page 29

CLAMPS

543-1000

SHANK

BUTTON

All

In

One

ATTACHMENT

Style

8-32x1/4 slotted hdls

4

543-390

Cloth

Supporl

Fo,

NOT£

Parts

Not Bearing Numbers

Are

Identified

WHEN

ORDERING,

8UTTON AND

BE SPECIFIED

PROPER

On

Plate

LINE

SHANK

IN

CUP

10

ORDER

SIZE AND HEIGHT.

SIZE

OF

TO

STAY

SUPPLY

BUTTON MUST

543-275

543-276

5

8

9

~----------------~CHANDLER~----------------~

CHANDLER27

Page 30

CLAMPS

I

543-299

2

43-299A

.3

543-2003

4

543-300

5

543-372

6

543•//9

7 543-118

8

543-303

543-303A

ATTACHMENTS

(CONT.)

543-30113

543-123714

543-300/.

543-300A

543-1002

543-302X

54!-1237

54!-3001

54~304

-265-4

15

Q)

9

543-5000

12

543-305A

Slay Bullon Plate

07

543-261A

double

Whippilll Allochment

bend

543-261 25

543-120

"

543-119

---...;....;;;;....~-28

543-262

543-263

543-1015

543-264

543

543-305

543-305C

26

27

29

30

31

32

.JS

CHANDLER28

CHANGES: 08.1972

1.

was

543-302

Page 31

CLAMPS

CD

543-271

I

2

3

4

543-267

5

43-118

ATTACHMENTS

Snap Aflachm6nf

For

Squar•

Snaps

(Cont.)

543-/237

543-300/

II

12

7

543-268

Under Side

NOTE•

Sam~

Snap Attachment

For

Round Snops

ASSEMBLY NUMBER

UNIT

All

OthtJr

Ports

As

Plot~

5

AS

SHOWN:

-4

COMPLETE

2-543-08-033

------------------~CHANDLER~------------------~

CHANGES: 08.1972

1.

was 543-1236

CHANDLER

29

Page 32

CLAMPS

543-2000

543-1002

543-299A

552-348

543-1237

552-342R

552-365

552-342L

552-364

552-344~

552-350

552-353

543-1014

~

552-343

552-346

___

552-347

CD

543-2003

A

''\.

_

oo

/

~

~

SHANK-

-&,

<

l

l

I

I

,,.

•

.

.

__:=:::r:e

:;:::

1

==:a

________;

___,

o

MASTER ATTACHMENT

l

~

I

I

_.

•

•

~

•,

• " •

/

J

.

'

~

1

....--

9 I--

I

0 0

543

543-1002

543-1237

543-300

543·3001

543·/20A

552-340

543·/18

5

543-272

I

•

8- 32-1/ 4

11

.

543-301

•

543-300A

543-299

-271

43-265

slotted

hd

less

@ 543-1017 .

552-366

543-1002

543-1002

552-345

543·1002~

~--------

CHANDLER30

CHANGES:

1.

was 552- 353

2.

was

3.

was

•

08,

552-352

552-351

/

l..-~

~

----------~

1972

1

CHANDLER~--

----

------------~

ASSEMBLY NUMBER

ABOVE

2-543-

ec_p

00

!

ENTIRE

08-

034

543-1002

543-266

543-302

552-341

-:43-3001

~

43·1237

FOR

UNIT:

Page 33

ACCESSORIES

Left

Hand Button

BUTTON

Spacer

ACCESSORIES

Left

Hand and

Button Spacer

~------------------~CHANDLER~------------------~

Right

Hand!

I NUT 543-2000

552-322

CHANDLER

3

31

Page 34

ASSEMBLY

GROUPS

NEEDLE

2 -543-08-001 standard machines

2-558-08-001 high

2-560-08-001 two needle tacker

BAR ROCKER

arm

ARM

ASSEMBLY

machines

FACE

PLATE

2-543-08-003 standard machines

2-560-08-003 two needle tackers

ECCENTRIC CONNECTING

2-543-08-002 standard maeblnes

2-558-08-002 high

2-560-08-002 two needle tacker

ASSEMBLY

arm

ROD

machines

.ASSEMBLY

THREAD

2-543-08-004 standard machines

2-543-08-004 two needle tackers

560

CLAMP

2-560-08-004-twa

CLAMP

2-543-08-006 standard machlnes

2-555-08-006 Automatic clamp

2-558-08-006 high

PUSH ROD ASSEMBLY

VERTICAL CONNECTING STRAP ASSEMBLY

arm

Uft

CLAMP

STRAP

2-543-08-005

UPPER

ASSEMBLY

CONNECTING

~------------------~CHANDLER~------------------~

CHANDLER

32

Page 35

MAIN

2- 5432- 560-

SHAFT

08-007

08-007

ASSEMBLY

standard

two

needle

machines

tackers

ASSEMBLY

GROUPS

FINGER

2-543-08

2-

560-08-008

STOP

ASSEMBLY

2-543-08

SHAFT ASS

-008

standard

two

SHAFT

-010

EMBLY

needle

BLOCK

machines

tackers

STOP

SHAFT

BLOCK

2

-543-08-011

~UID

ASSEMBLY

E

THREAD

ASSEMBLY

2- 543 - 08-009

2- 543 - 08-009A

2- 560 -

LOCK

08-009

CLAMP

2- 543-08- 012

FINGER

standal'd

specials

two

needle

IJFTER

machines

tackers

LEVER

ASSEMBLY

FOOT

STARTER

LEVER

2- 543-08- 013

ASSEMBLY

BELT

2-543

SHIFTER

-08- 014

ASSEMBLY

CHANDLER

33

Page 36

ASSEMBLY

GROUPS

STOP MOTION KICKOFF

TRIPPER

2-543-08-015

ASSEMBLY

FRONT ADJUSTING STITCH

LEVER

2-543-08-016

ASSEMBLY

STOPPING MECHANISM ASSEMBLY

2-543-08-017

FRONT & REAR STITCH ADJUSTING ASSEMBLY

2-543-08-018

~------------------~CHANDLER~------------------~

CHANDLER 34

AUTOMATIC

ASSEMBLY

2-555-08-019

LIFT

LEVER

Page 37

REAR

THREAD

TENSION

ASSEMBLY

2-

543-08-020

FRONT

TENSION

ASSEMBLY

2-

THREAD

543-08-021

ASSEMBLY

THREAD

ASSEMBLY

TWO

TACKER

2-56

TENSION

FOR

NEEDLE

0-08-022

GROUPS

THREAD

2-543-08-023

2-560-08-023

STAND ASSEMBLY

standard

two

needle

machines

tackers

FRONT

ARM ASSEMBLY

2-543-08-0

CAM

24

REAR

CAM

ARM ASSEMBLY

2-543-08-0

25

L-----------------------~C~H~A~N~D~L~E~R~-----------------c-~-N-DL_E_R~3s-

Page 38

ASSEMBLY

FLAT

BUTTON

ASSEMBLY

2-543

-08-026

GROUPS

CLAMP

FLAT

BUTTON JAW

HOLDING

2-543-08

PLATE

-026A

ASSEMBLY

BUTTON

More

2-543-08- 26C

2-543-08-260

CLAMP BASE

stablllity but

for

for

(short type)l

less

reach.

Flat

BUttons

Shank

Buttons(castlng

ears longer)

BUTTON CLAMP BASE (long type)2

Less stabllity,

2-543-08

2-543-08-026F

-026E

more

for

for

reach.

flat

buttons

Shank B

uttons

(casting

ears

longer)

~------------------~CHANDLER~----------~------~

CHANDLER 36

Page 39

ASSEMBLY

GROUPS

BUTTON

CLAMP

2-543-08-027

TOP

HINGE ASSEMBLY

SHANK BUTT

SIDE LOADING.

Left

hand and

(left

hand loading

pop

ular

2- 543 -08-0

95%

27

ON

right

of

the

A

CLAMP

is

ASSEMBLY

hand loading

shown

and

time)

available.

is

most

STAY

BUT

TON

SUPPORT

08-027C

2-.543-

CLAMP

ASSEMBLY

CLOTH

SHANK BUTTON

SUPPORT

2- 543-

WHEN ORDERING,

BUTTON ANO SHANK BUTTON

BE

SPECIFIEO

PROPER CUP

IN

SIZE

LINE

ORDER

SIZE

OF

TO

ANO HEIGHT.

SUPPLY

STAY

MUST

--------------------~CHANDLER~--------------------

ASSEMBLY

08

-027 B

CLAMP

CLOTH

CHANDLER 37

Page 40

ASSEMBLY

GROUPS

BACK & FORTH TACKING

2-543-08-029

CLAMP

2.:.543-08-028

CLAMP

HINGE ASSEMBLY

ASSEMBLY

/)

SIDE MOTION TACKING

2-543-08-030

COMBINATION TACKING

2-543-08-031

~------------------~CHANDLER~------------------~

CHANDLER38

CLAMP

ASSEMBLY

CLAMP

ASSEMBULY.

~

I

·

..

,,

Page 41

ASS

EMILY

GROUPS

SQUARE SNAP

2- 543-08-032

ATTACHMENT

ASSEMBLY

ROUND

ASSEMBLY

2-543-08-033

L----------------1

SNAP

ATTACHMENT

CHANDLER

~---------C-HAN_D_L-ER-3

........

9

Page 42

ASSEMBLY

GROUPS

CLAMP

LEVER

ASSEMBLY

2-543-08-035

THREAD

ASSEMBLY

2- 543-08 -038

SLACK KICKPIN

SHIF

STUD

TER

REBOUND

ASSEMBLY

2- 543-08-0

FINGER

36

AUTOMATIC

ASSEMB

2

-543-

LY

08-039

REAR

STITCH

INDICATOR ASSEMBLY

2-

543-08-037

LIF'l

COMPLETE

BOTTOM BASE

2-

543

-08-040

ASSEMBLy

GEAR

& WORM ASSEMBLY

Specif

y s

2- 543-08-041

titch

count

~------------------~CHANDLERr-------------------~

CHANDLER 40

Page 43

ADDITIONAL NOTES:

NEEDLE BARS:

There are three types

I.

543-60

2.

543-60A

3.

543-60D

RECOMMENDED NEEDLES:

Use

only genuine Chandler needles for best results.

REGULAR:

PBS3-14

PBS3-16

PBS3-18

PBS3-20

LONG SHANK: (shank buttons)

PBS7-16 medium

PBS7-20 heavy

DRAPERY TACKER

PB DT-22

332

lgCF No.

160

of

needle bars available for the Chandler tackers and button sewers.

Regular needle bar

Special long needle bar for high

arm

machines, classes 558,

Special large needle hole for extra heavy needle.

tackers

555-75K, 600-75, & 600-75K

Needle code: 332lgCF-No.

very light work

light work

medmm, heavy work

heavy work

Drapery needle for regular needle

543-60

bar

Extra heavy drapery needle for

bar

needle

543-60D

Used on many

classes

555.-75,

658

160

RECOMMENDED SPEEDS:

Machine classes

and later models can be operated

LUBRICATION:

Use

a light No.

Gears and cam races are lubricated with a special non drying grease which

"Oilzum" grease.

543,

546, &

10

sewing machine oil on all moving parts.

548

are not to be operated in excess

at

speeds up to

1500

rpm.

We

can supply this in quart

of

1000

RPM. Models

we

can also supply.

or

gallou cans.

Ask

552

for

~--------------------~~CHANDLER~~----------------------~

Loading...

Loading...