Page 1

OPERATING

INSTRUCTIONS

For

the

CHANDLER

BUTTON

Models

401

461

471

472P

475P

SEWER

CHANDLER

Ayer,

MACHINE

Mass.

CO.

Page 2

KNOW

YOUR

MACHINE

Read

to fully

these

understand

instructions

your

carefully

machine.

and

thoroughly

Page 3

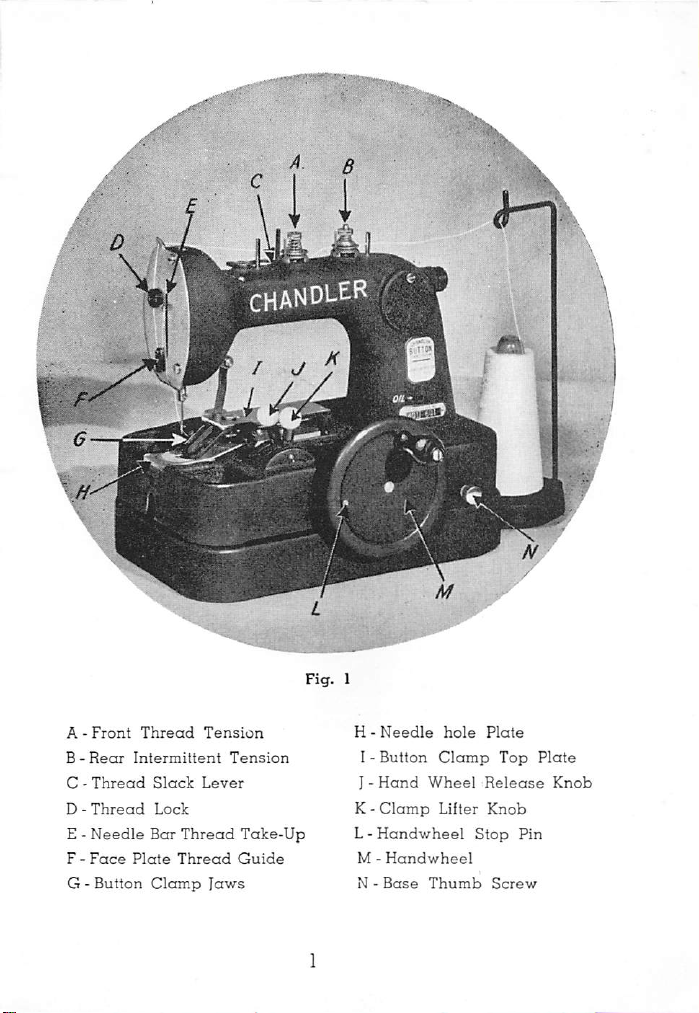

A -

B -

C -

D -

E -

F -

G -

Front

Rear

Thread

Thread

Needle

Face

Button

Thread

Intermittent

Slack

Lock

Bar

Thread

Plate

Thread

Clamp

chandler

Tension

Tension

Lever

Take-Up

Guide

laws

H -

Needle

I -

Button

J -

Hand

K -

Clamp

L -

Handwheel

M -

Handwheel

N -

Base

hole

Clamp

Wheel

Lifter

Thumb

Plate

Release

Knob

Stop

Screw

Top

Plate

Knob

Pin

Page 4

f-

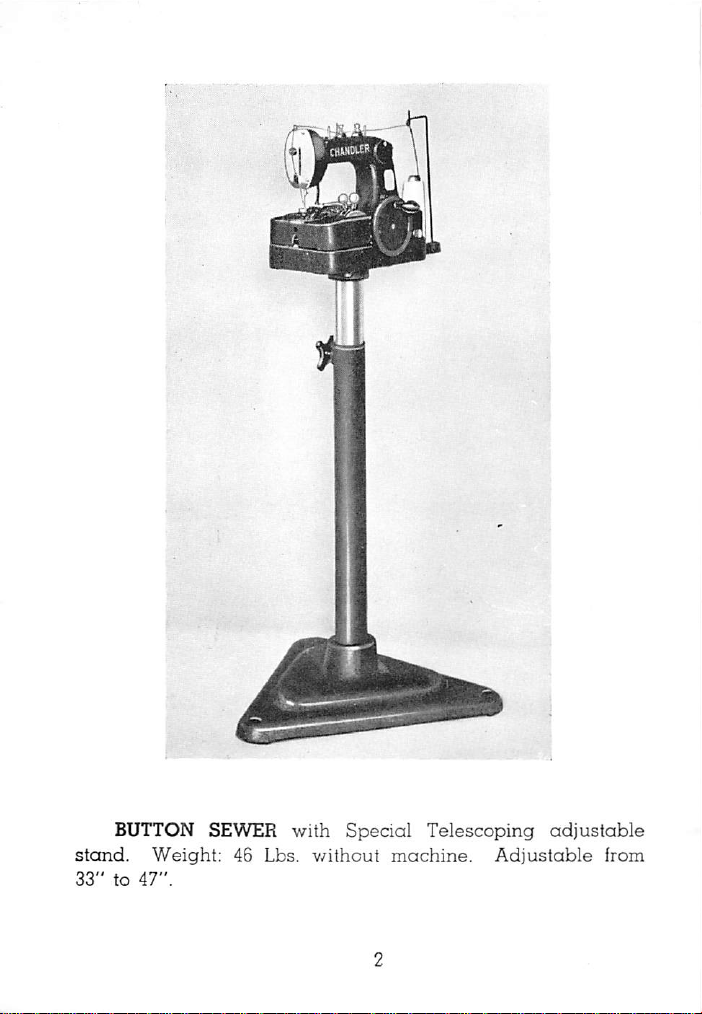

BUTTON SEWER

stand.

33"

to

Weight:

47".

46

Lbs.

with

v^ithout

Special

machine.

Telescoping

Adjustable

adjustable

from

Page 5

The

Chandler

erated

industries

machine.

hospitals,

It

will

from

the

pajamas,

The

Sewing

blocked

button

the

the

thread

The

cross

at

clamp

sewing

stitch,atthe

as

laundries,

hotels,

handle

smallest

coats,

the

to

on

the

over

{on a 4

very

Button

It is

purposely

coat

dry

cleaners,

either2hole

shirt

aprons,

cycle

is fully

completion

release

underside

cycle

consists

hole

endofthe

Sewer

button

etc.

of

the

button)

is a

designed

and

apron

etc.

or4hole

to

automatic,

the

material

of

the

of 12

cycle.

single

supplies,

that

used

sewing

automatically

button.

stitches,

and

thread,

for

buttons

the

cycle.

the

tieing, or

hand

use

institutions,

in

on

underwear,

flywheel

Raising

which

op

in

such

any

size

being

breaks

includes

locking

the

Double

button

lowering

releases

cycle.

Thread

upto12,000

clamp.

of

the

release

the

hand

The

button

controls

right

wheel

clamp

for

standinrearofmachine

yard

size.

are

located

hand

button

whereas

the

continuationofthe

to

controls

the

head

the

right

the

left

hand

provides

lifting

next

button

sewing

for

of

and

cones

the

Page 6

w

m

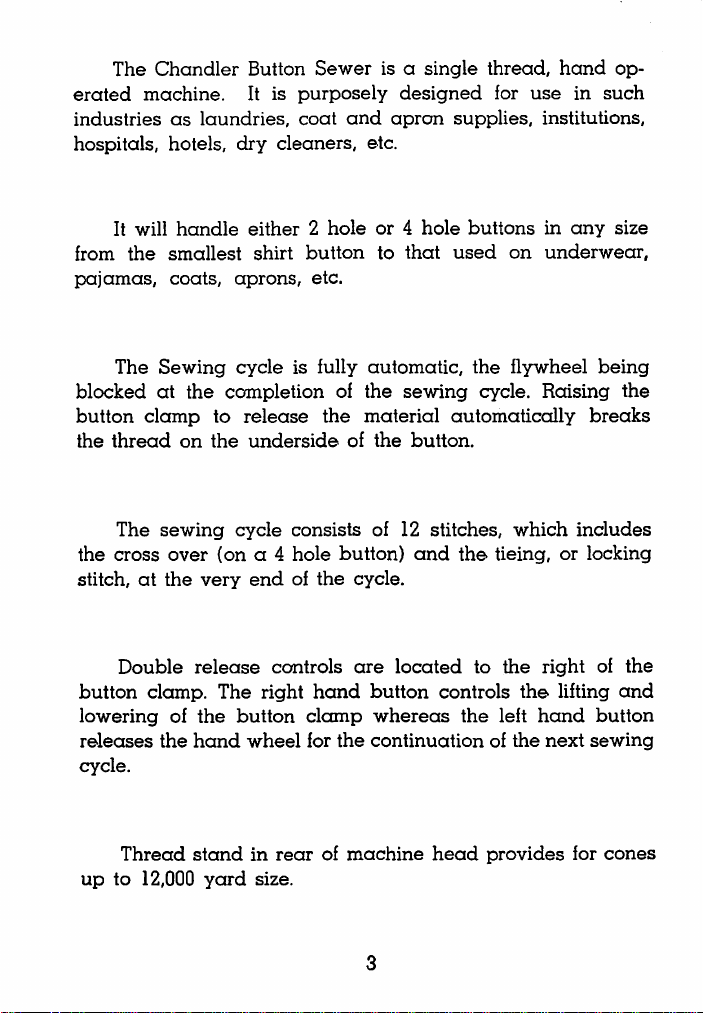

THREADING

Threadingisthe

the

Chandler

consider after carefully unpacking the machine

it UD

for

use.

first

phase

Button Sewer,

in the successful

and

usually the first step to

operation

and

setting

of

Page 7

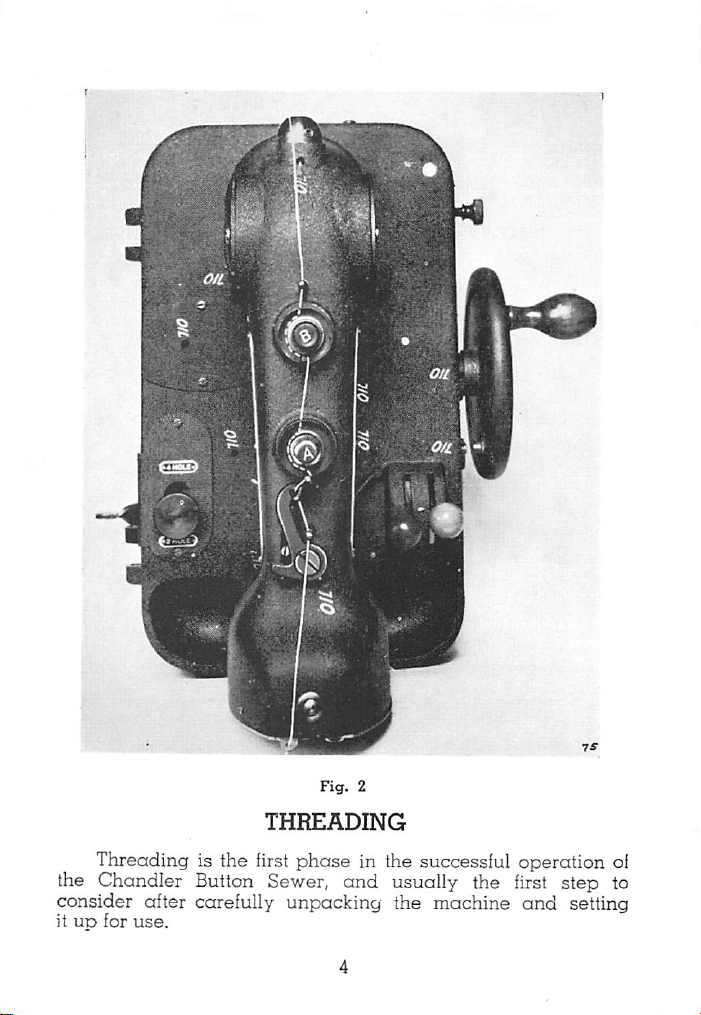

Careful attention to the proper threading procedure is

most

importantinordertobe

by

the

machine.

Two views

threading

steps:

andtohelp

1. From

2.

3.

4.

5.

6.

the

pin

whichislocated

Passitbetween

the

tension

pin

locatedinthe

Carry

the

of

Pass

off

Then

over

the

LEFT of

the

little

thread

lever.

through

to the hole in

spool

are

herewith

makeitclear,

pin

post

thread

the

pininthe

through

front

the

assuredofperfect

shown

pass

the

thread

on

the

rear

tension

and

then

to

slotofthe

alongtothe

tension

slotofthe

the

guide

the

top

post

holeofthe

pin

of the face plate.

outlining the

we

outline

through

very

rearofthe

discs

the

RIGHT of

discs.

front disc

and

then

discs

and

performance

the

the

to

the

keeping

to

(sameas2).

thread

proper

following

first

guide

top

LEFT

the

the

RIGHT

slack

arm.

of

small

it to

pull

7.

Then

lock

which

plate

down

8.

From

guide

underneath.

9. Insert the

needle

10.

Then

endofthe

eye

of

1-6

push

the

thread

is

(making

as

the

plate

located

sure

otherwise

thread

by

thread

bar

passingitthrough

guide

the

face

the

needle

6-10

the

the

lock

merely

through

thread

plate

from

see

tig.

2

through

on

clamp

thread

catch

the

the

left

that

lockisclosed).

the

pulling

the

thread

centerofthe

thread

the

from left to right.

through

and

FRONTtoBACK.

see

pass

fig. 3

the

the

center

holds

of

the

in

thread

take-up

holeinthe

thread

through

the

button

the

up

on the

thread

face

lower

from

lower

the

is

Page 8

yj

Fig.

3

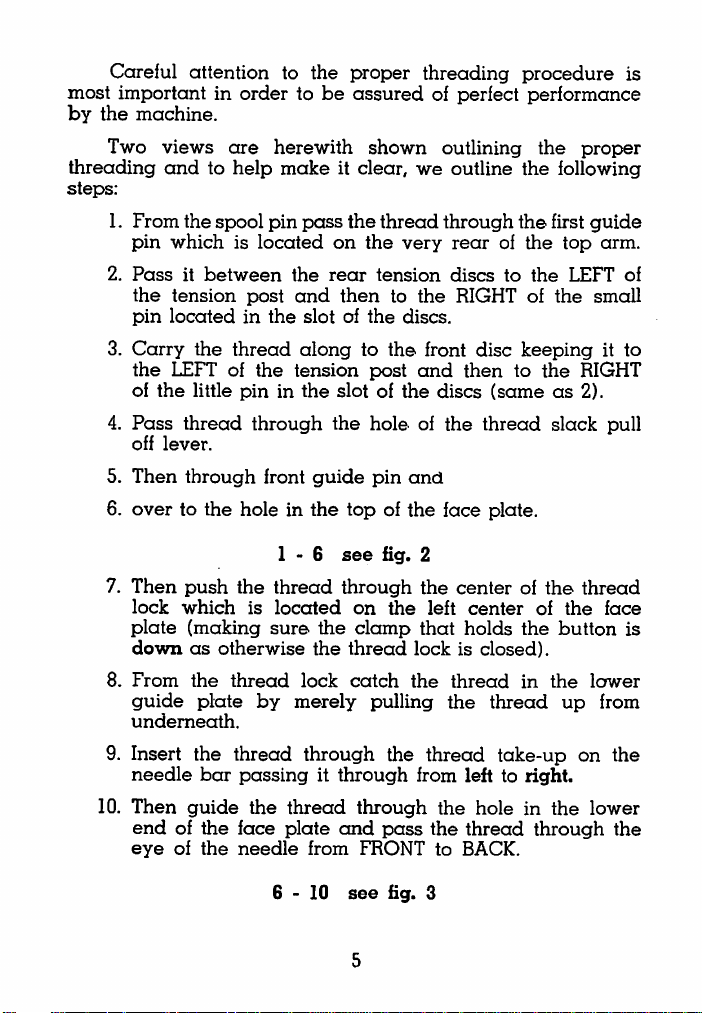

TENSIONS

There

are

only two

thread

tension adjustments,

both

are

at the top of the machine. The rear thread tension "B"

vFig.

1) is

an

light. (This

set

screw

do not

change

intermittent tension

rear

tension is locked in position

on

the

sideofthe

it for

thumb

adjusting

and

must

nut.

It is

tension on

be

by

means

"factory

the

thread.

kept

set"

very

of a

so

This

Page 9

rear

adjustment

stitch to

cone

of

keep

insteadofpullingupthe

The

iront

the

stitch

shouldbelight

until it

position

released.

thread

stops

you

lockonthe

Then pull the

onlyaslight

the

FIRST

merely

the

looper

tension

and

is

and

(hand

will

note

At

the

same

face

threadatthe

tension.

tension,

holds

the

the

"A"

from

(Fig. 1)

most

thread

stealing

loop

important

more

under

regulates

before

thread

the

button).

one.

the

the

This

canbedeterminedbyturning the

wheelisup

the

time

plateisopen

needletobe

When

"A",ahalf

rear

lower

tension

against

tension is

the

(center

is too tight,

turn

atatime

stop

pin). In this

raised

button

clamp

plunger

sure

it pulls free with

until

then

end

of a

from

the

tightness

tension

machine

and

thus

so

the

is loose).

loosen

thread

pulls freely through the needle. If too loose tighten it slowly.

the

button

If first

thread.

BE

tension

If

too

willbeloose,

SURE

YOU

"A"

is

too

tight

loose

the

knots

makingaloosely

MAKE

THESE

the

on

the

sewed

THREAD

looper

under

button.

TENSION

will

side

of

snap

the

AD-

lUSTMENTS ONLY WHEN THE HAND WHEEL IS BLOCKED

BY

THE

PIN

AND

THE

BUTTON

SEWING

Before the operator

control

as

button

(red

faraspossible so

lever on top of the

when

the

clamp

provided.

At

the

least

2V2"ofthread

IF

THEREISNO

THE

MACHINE

OF

THE NEEDLE, THE LOOPER WILL

THREAD

sewing

and

without

is lowered, the

same

time,

AND

the

even

can

color,

see

that

the

machine

the

projecting from

SLACK

machine

NO

IN

EXTRA

making

CLAMP

LOWERED.

PROCEDURE

sew

on a button, the right

Fig. 1)

thread

shouldbepulled

forward

slack pull off (see Fig. 1)

is kicked over to the left. Then

proper

operator

THE

will

go

a stitch. (See Fig. 3,

slack

must

the

THREAD

THREAD

through

see

eye

AT

NOT

in the

that

of

THE

FROM

CATCH

the

thread

thereisat

the

needle.

TOP

THE

full

cycle

Page

6).

hand

OF

EYE

THE

of

is

Page 10

BUTTON

The

button

clamp

small lever E, (Fig. 10,

plate

is to

set

the

openingofthe

you

may

use.

The

jaws

a

trifle

smaller

is

inserted,

and

thus

On

Page

23),

ment

clear

two

hole

hole

button.

thumb

screwsothe

Needles

TOWARDS

way

up

the

old

needle

should

LER

become

THE

AS

the

SHOWN

than

the

jaws

hold

it in

left

and

its locking

forward

button.

After

must

THE

into

the

remains

NEEDLES

place.

2

HOLE

sideofthe

towards

Moving it

moving

be

FRONT.

needle

bent,

RECOMMENDED

BELOW

CLAMP

can

Page

ADJUSTMENT

be

openedtoany

23), on

the

jawstothe

should

the

sizeofthe

will

clamp

be

the

adjusted

button

button

AND4HOLE

machine

thumb

the

operator

is a

screw. Moving this

cleartothe

this

adjustment

setting

NEEDLES

inserted

Be

bar.

when

will

not

move

with

the

sure

to

insert

Make

sure

insertinganew

replaceitwithanew

ARE

size

button.

The

top of the button clamp

so

so

with

lever

smallest

that

when

a little

button

they

close

the

button

tension

A, (Fig. 10,

adjust

sets

the

back

sets

be

suretotighten

while

groove

the

no

broken

one.Ifthe

machine

it for a four

sewing.

of

needle

the

for a

needle

all

part

needle

the

the

one.

GENUINE

CHAND

of

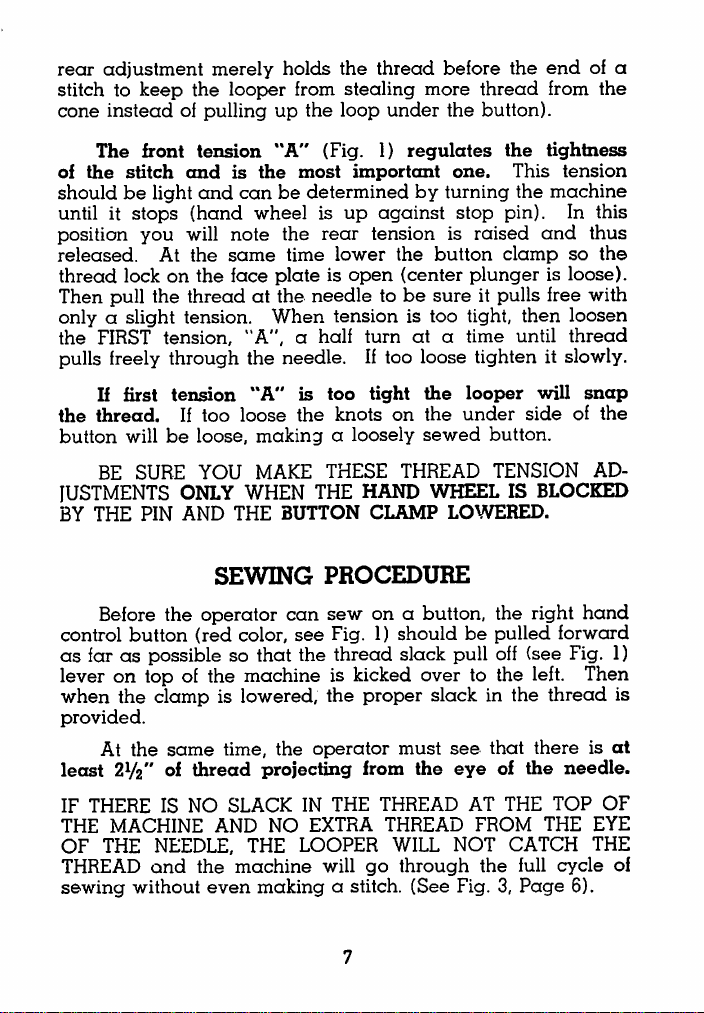

A

B

B

are,

suit

buttons.

B

buttons

supply

The

Check

needles

needles

needles

therefore,

needles

on

or

heavy

overall

needles

your

are

used

for

are

for

472P

have

spear

recommended

canbeused

or highly

work.

illustrated

needle

with

all

Chandler

and

475P

Machines.

point,

are

for cuff

on the

are

hand

starched

exact

illustrationifin

8

material

length.

Hand

one

size

tacking

machines

Button

heavier

and

such

doubt.

for

Sewers.

sewing

sewing

as

linen

and

Page 11

THREAD

A

coneofthe

suggest

a soft

slippage

Chandler

stitches

usingastrong

thread

and

Button-Sewing

We

suggest

over

machineamuch

crowd

all

the

button.Afour

the

of

area

all

the

or

original

the

of

Use

sizes.

spacing

break.

We

button

the

buttons

Watch

may

button

material.

you

missed

the

a

wider

better

stitches

hole

pulling

where

out

is

greater

caution

proper

will

threadissent

glazed,

get

poor

stilches.

Thread.

BUTTONS

hard

results

Best

useof4-hole

area

on

chancetoworkasyou

between

button

on

the

oh,asthe

the

for

very

and

against

is a

shirt

two

good

and

buttonisheld

spacingofthe

largeorvery

may

the

finished

results

buttons.

the

selling

helps

cause

use

with

the

thread.Ifyou

and

experience

canbeobtained

They

material

and

are

holes

as

inatwo

point,itduplicates

eliminate

on

holesisthe

small

buttons

the

needle

of

cheap,

machine.

We

use

thread

with

spread

gives

not

trying

hole

the

danger

overawider

same

where

to

bend

low

price

the

the

to

for

bone or pearl buttons. These buttons have razor sharp edges

at

the

holes

and

making

The

holes

or

deflection

one

think

are

of

would

thereissomething

apttobe

the

needle.

cause

unevenly

the

thread

spaced,

wrong

also

to

cut

with

causing

and

the

break,

machine.

burring

TO

The

left

machine

this

the

but

repeat

this will

much

it.

for

button

buttonasecond

merely

the

Do

not

putintoo

thread

START

hand

control

the

next

sewing

forwards.Inthe

time,

pull

back

sewing

repeat

cycle.

this

many

that

the

needle

on

cycle

THE

button

cycle. To

event

do

not

the

blue

too

stitches

will

MACHINE

(blue, J Fig. 1)

release

that

you

pull

back

and

turn

oftenona

and

two

plug

releases

the

machine,

wishtosew

on

the

the

hole

the

holes

bendintryingtogo

red

button,

machine

button

with

through

the

pull

over

to

as

so

Page 12

ADDITIONAL

CLASS

INSTRUCTIONS

472-P

&

475-P

't

FOR

MACHINE

THE

Thisisdone

jaws.

strike

of

with

made

besttotack

nesses

the

Be

the

On

cuff

the

invisible.

For

of

light

fingers

extremely

CUFF

by

placing

suretospread

top

jaw

clips,

weight

rightinthe

off

material.

so

the

trousers

that

heavy

seam

seam.

TACKING

the

the

jaws

(See

Fig

the

The

the

tackisdrawn

trousers

where

cuff

under

so

that

A.).

tack

can

operator

or

there

the

the

be

can

into

extra

are

notsomany

regular

needle

made

spread

the

heavy

will

at

the

seam

cuffs

button

the

seam

and

it is

thick

not

top

Page 13

When

and

placeitunder

the

cuff

and

itself. This is

the

exact

catch

the

show

throughtothe

This

method

the

needle

tral

grey

trousers.

tacking off the seam, fold

the

jaws

so that the tack is

halfinthe

called

location

tackatthe

is

from

bending

thread

For

can

this

single

"blind"

under

tacking.Ittakes

the

edgeofthe

front of

preferrable

and

be

used

"blind"

cloth

jaw

the

cuff.

on

causing

regardless

tacking

back

the top of the cuff

thicknessofthe

practicetolearn

so

that

the

fold so that the

heavy

trouserstoprevent

thread

breakage.

of the color of

operation

made

operator

tack

(See

half in

trouser

will

will

not

Neu

the

Fig. B.).

In

the

stitches

Cleaners

BLIND

many

thisisvery

SEWING

cases

showing

it is

desirable

on

the

important

OF

to

underside

on

suit

11

A

BUTTON

sew

onabutton

of

coats.

the

cloth. To

without

some

Page 14

Fig.

C

(See

turned

Place

only,

sewing

show

than

halfway

some

will

take

be

successfully

and

suspender

under

Fig. C.)

underatthe

the

folded

or,inother

will

through

partofthe

a little

side

This

will

illustrateasuit

point

where

material

words,

under

under

thenbedoneinthe

the

into

of

material.

the

stitches

practice.

used

bands

the

material.

button

for

If

there

may

Onceithas

attaching

without

the

the

the

fold of

the

show

any

button

front

first

two

the

material

is a

slight

through.

been

buttons

stitches

coat

that

has

is to

be

attached.

half

of

the

holes

only.

cloth

and

will

is

inserted

possibility

This

operation

mastered,itcan

onto

suit

showing

been

button

more

coats

on

The

not

that

the

Page 15

INSTRUCTIONS

lor

TIMINa

THE

All

strictly

with.

The

that

must

that

have

their

machine

on

the

machine

Important

ADJUSTma

MECHANICAL

mechanical

alone,

and

following

replace

experienced

and

mechanical

is

properly

replaceable

the

end

settings

should

pages

essential

wish

settings

of

these

and

checking

SETTINGS.

should

not

be

are

only

be

tampered

for

partsorfor

troubleinoperating

to

double

to

see

adjusted.

Parts

illustrated

instructions

left

those

those

check

if

the

at

13

Page 16

(1)

Turn

thread

finger,

TAKE

(2)

Check

has

PARE

Make

(3)

Check

(4)

EXAMINE

PUT

TROUBLE.

(5)

WithaNEW

see

needle.

trouble.

sults. Poor

cut

needle.

the

machine

that

never

OUT

the

threadingofthe

not

jumped

IT

WITH

sure

the

your

YOUR

IN

WRONG

When

whether

Evenasmall

Try

qualityofpearl

the

thread

THREAD

may

be

over

wound

BREAKAGE

and

remove

around

any

the

loose

looper.

strands

Use

a screw driver. BUT NEVER LOOSEN OR

THE

LOOPER

outorwound

ILLUSTRATIONS

thread-pulls

thread

tensions

NEEDLEIFIT

SIDE

in

doubt

needleinyour

the

buttons

amount

other

typesofbuttons

and

unevenly

TO

REMOVE

machinetosee

around

through

as

outlined

IS

TO,

IT

WILL

always

putina

machine,

you

are

using

of

deflection

buttons

have

spaced

TIfflEAD.

that

the

thread

some

part.

COM

FIG.

2 &

FIG.

the

needle

smoothly.

previously.

BENT, BURRED, OR

SURELY

new

CAUSE

needle.

crankitslowly

are

deflecting

can

cause

and

holes

compare

sharp

that

the

edges

deflect

of

your

3.

to

the

much

re

that

the

In

the

experienced

suggestions:

1. LooF>er

loopertohook

(see

2.

Needle

(see

3.

Needle

(See

may

hole.

may

4.

Needle

(see

event

while

striking

paragraph

striking

paragraph

striking

paragraph

not

Clean

be

leftinthe

may

paragraph

NEEDLE

that

considerable

using

be

inserted

out

not

BREAKAGE

the

machine,

the

needle

the

needle

"Setting

finger,

finger

"Timing

looper.

Needle

"Setting

full

any

part

hole.

lineupwith

"Aligning

14

Needle

check

or

being

uponaslight

the

Looper").

may

the

finger").

Bar

the

Needle

depth

of

the

Button

into

an

holesinthe

Clamp").

Breakage

too

the

close,

is

following

causing

deflection—

be

out

of

time—

may

be

too

Bar"),orNeedle

the

Needle

old

needle

button—

being

low—

Bar

that

Page 17

5.

6.

Improper

Needle,

Clamp

Cams").

Needle,

any

other

Movement

may

not

be

needle

maybetoo

outofTime—(see

Genuine

short

paragraph

Chandler

or too

long.

"The

The

adjustments

ment

will

cause

no

thread

in

cause

end

TIMING

finger

the

the

of

trouble.

timingisone

machine.

machine

THE

An

to

IN

FINGER

improperly

break

thread,

of

the

most

important

set

finger

miss

stitches

adjust

and

This

view

shows

and

all

the

To

turn

made

proper

reveal

iurthest

check

the

from

Finger.

stroke.

this

machine

underneath.

direction

Needle

Note

adjustment,

over

(careful;

Finger

loosen

on

its

Rotate

not

Plate

pulled

position

the

base

hinges

the

machine

backwards)

as

away

at

clamping

this

adjustment

very

until

to

its

slowly

the

screw

in

finger

is

Page 18

cam

point,

the

the

1/16".

throws

plate

back

the

the

finger

so

that

curveofthe

See

Fig. 4

Cutaway

to

finger

should

the

and

Needle

itselfasfar

have

needle

finger

should

Fig. 5.

Fig.

view

showing

when

Fingerisclear

forwardasit will go. At this

gone

comes

5

beyond

down

clear

position of

the

toward

the

needle

Finger

Forward.

needle

the

hole

looper,

by

about

Should the finger go too far beyond needle, or not far

enough, loosen clamp screw 8, Fig. 6

correct

adjustment.

THE FINGER ADJUSTMENT.

needle

position,

tightening

THIS IS THE FIRST STEP

The finger must be

and

needle plate hole. Proper adjustment is when the

clamp

adjusted

and

screw

TO

sideways

move finger into

after

making

TAKE IN MAKING

the

in relation to the

needle is about 1/16" from the flat face or side of the finger.

(The curve at the front of the finger should center with the

needle

set

bly

lower

2nd STEPIN

plate

hole)

Should the finger

screw

holding the finger

need

sideway

bushing

adjustment, loosen the

and

tap

the

whole

in the direction desired, making certain that the

does

not

rideorcontact

THE

ADJUSTMENTOFTHE

the

hubofthe

cam.

FINGER.

assem

cam

fol

THIS IS THE

See Fig. 6

of

Page 19

5.

2.

3.

4.

1.

Thread

Finger

Finger

Cam

Rnger

Shait

Cam

Follower

Bushing

Follower

Spring

6.

Finger

Finger

7.

8.

Looper

Cam

Cam

Support

Follower

Clamp

Screw

Page 20

After

machine

needle

should

begins

fast,

bend,

If

up

past

of

the

To

the

finger

set

screws

controlled

proper

slowly

must

be

be

passing

to move-

the

backofthe

burrorscratch

the

finger

the

needle

finger

adjust

may

the

cam

h.old

by

this

positioning

watching

on

through

its

finger

upstroke

the

backward.

finger will hit

the

smooth

moves

according

the

too

slowly

plate,

the

snap

the

thread.

oscillationofthe

to

camtothe

cam.

THISISTHE

IN ADJUSTING THE FINGER.

To

repeat:

trolledbyadjusting

the

of

adjusting

ment

bearing

POSITION of finger to

cam

finger to

is

controlled

block.

finger

the

strokeofthe

cam

on

by

the

needle

Should

thread

the

shaft.

See

linger

and

needle

and

the

finger

the

needle

finger

the

needle

willbetight

finger,

adjustment

THIRD

Fig. 6.

as

shown,

very

point

of

plate

holeasthe

move

backward

causing

surface.

will

have

and

retard

required.

Timingofthe

OR

FINAL

the

needle

closely. The

the

needle

finger

needle

moved

the

or

advance

Three

finger

is

follower on finger shaft. TIMING

needleiscontrolled

main

moving

shaft. SIDEWAYS

entire

assembly

adjust

in

turn

too

to

hook

is

STEP

con

by

the

TO

TIME

Should it

that

the

looperisprovided

looper. The looper set screw must

this flat

timing of

needle

partofthe

There

and

are

the

looper.

the

AND

become

looper

SET

necessary

with

shank.

THE

to

replace

a flat

always

LOOPER

the looper, note

on

the

shank

bear

and

seat

of

against

two adjustments to consider in checking the

One

is in

otheristhe

relationtothe

distance,

18

sideways,

upstroke of the

from

the

needle

the

Page 21

The

hand

wheel

until

the

needle

scale

on the top

projects through the long slot in the faceplate) so that a

ing

may

be

obtained

faceplate) then

takeup

eye

has

point of the looper should

behind

relation

or

the

running

spotted

by

justing

the

needle

For

Class

between

retarding

back

the

of

the

through

on the shaftatthe factory,

anyone

these

other

machines.

should

barisat

its

sideofthe

(usually

continue

moved

(see

401

and

looper

small

machine.

the

to

5/32"

figure

461

and

spiral

This

upper

thanamechanic

be

turned

lowest

thread

in

the

proper

pointofstroke.

take-up

eye

direction

Place

(one

that

read

against

turn

the

the top

hand

edge

wheel

of

until

Upwctrd. At this position the

be

just

7).

machines

beginning

the

actual

to

show

"timing"

from

needleiscontrolledbyadvancing

gear

on

the

main

shaft

towards

gear

drives

armofthe

and

thoroughly

the

machine.

should

vertical

The

not

be

shaft

gear

moved

trainedinad

the

the

of

is

a

Page 22

For

Class

471

modernized)

the

retardingaseparate

on

the

front

endofthe

Two

small

set

sleeve

bearing

screws

after

the

justsothat

looper

the

In

very

(located

to

setting

and

on

supports)

time

the

proper

the

pointofthe

there

the

needle.

machine

actual

"timing"

looper

main

screws

inside

hold

looper,

adjustment

clearance

looper

is a

space

See

(or

holder

shaft.

on

face

this

Fig. 8.

previous

the

enlarged

of front

sleeve

securely

was

made.

between

about

of light

models

is

made

sleeve

in

retightening

looper

1/64"

between

that

have

by

advancing

attached

separately

shoulderofthe

bearing

place.

and

Loosen

the

and

needle,

from

the

needle,

the

pointofthe

been

or

disc

finger

both

screws

have

or

Fig.

8

IN

BE

SURE

CHECK

CHECKING

TO

THESE

THE

USE

A

SETTINGS

LOOPER

NEW

WITH

AGAINST

STRAIGHT

THE

NEEDLE.

A BENT NEEDLE IN THE

NEEDLE—

DO

NOT

MACHINE. MAKE SURE THE NEEDLE IS ALL THE WAY UP

IN

THE

NEEDLE

BAR

HOLE.

Page 23

SETTING

THE

e1

®

iJ

NEEDLE

The

needle

replacing

event

the

replaced

justment

tiontothe

The following

be

observed:

1.

Insert

way

bar

that

an

in

2.

Providing

properly

tion

the

ing

and

the

tion,

needle

mined

machine

point

ject

then

needle

top

needle

3/64")

edge

figure

BAR

bar

and

in

new

one

with

the

andinproper

other

mechanism.

pointers

new

needle

up

in

hole,

making

thereisno

old

needle

the

needle

the

timed

to

the

upstroke

needle

proper

behind

of

(see

pages

Set

the

height,

or

position

bar

by

until

just

beginstopro

raise

or

bar

the

turning

the

so

eye

is

below

of

the

looper

7).

may

such

must

proper

the

needle

part

stuck

hole.

looper

in

preced

"To

Looper")

is

the

needle,

lower

that

1/32"

the

need

an

be

ad

rela

must

all

the

sure

up

rela

Time

loca

of

the

deter

the

looper

the

the

of

the

(or

lower

(see

of

is

of

Page 24

3.

4.

Needle

is in

rub

on

and

down.

to

turn

Tighten

bar

must

line

with

the

sidesofthe

Otherwiseitmay

hard.

set

screwinneedle

beinlinesothat

the

slotinthe

slotasthe

face

bind

bar

thread

plate,

needle

causing

clamp

and

bar

stud.

take-up

does

moves

hand

eye

not

up

wheel

BUTTON

At

some

timeitmay

the

button

holes

In

clamptoaccommodate

in

buttons.

suchacase,

backwardsiscontrolledbyadjustment

and

marked

and

moving

the

clamp

machine

nut

after

The

"C"

towards

whereas

decreases

irjoving to

strokeofthe

onlyiscontrolled

first

cover.

stop

suretotighten

nut

Should

back

and

stop

BUTTON

At some time it

soasto

position

CLAMP

be

ADJUSTMENTS

necessary

larger

strokeofthe

button

in Fig. 10. Loosening

centerofthe

machine

movingittowards

the

strokeofthe

desired

by

greater

away

nut

may

the

the

button

position.

clamp

stop

sideways

nut

cross

from

securely

CLAMP

be

necessary

perfectlyinline

"B" Fig. 10,

strokebenecessary,

the

front of

after

ALIGNMENT

to

change

clamp

under

the

increases

the

clamp.

for

the

or

smaller

forwards

rear

cover

adjustment

outer

edgeofthe

Tighten

the4hole

stroke

stroke

adjusting

located

move

the

machine.

making

the

adjustment.

to re-align the clamp

with

the

spaced

and

plate,

nut

on

button

under

the

Be

needle.

The needle should enter the center of all holes without striking

the

sides

or

solid

part

of

the

hard

hole,

the

holeofthe

on

the

button

the

clampisoutofline

button

itself

with

and

button.Ifthe

must

bend

in

and

shouldbeadjustedtocenter

the

needle

as

order

outlined

needle

to

below.

enter

strikes

the

of

22

Page 25

mi

iWHjlTlI'OlWr11-'ir...

Fig.

10

Before

sure

any

adjustments

Omit

made

The

head

these

2

hole

needle

the

needleiscentered

proceeding

to

insert

a

BRAND

to line

threading

without

button

the

the

clampisheld

screws ''D" Fig.

screws

enters

button

just

enough

in

the

the

holeofthe

needle

thread

"*10

with

jaws

both

any

NEW

up

with a

so

being

at the

to

and

ways,

button

NEEDLE

that

in

the

firmly in

rearofthe

loosen

turn

button.

see

clamp

so

adjustment

as

not

crookedorbent

the

adjustments

way.

place

by2hexagon

top plate. Loosen

the

plate.

the

Move

Fig.10and

Then

machine

the

clamp

Fig.

to

make

needle.

can

insert

until

so

11.

be

be

the

that

a

Page 26

**

Then tighten

over

slowly

centeroithe

any

sideofthe

causing

needles.

missed stitches,

When you

both

holding

When

it

should

automatically

fc

by

this

hand,

other

hole,

are

screws.

clamp

Fig.

one

clamp

binding

m.aking

hole.Besure

otherwise

thread

assured

clamp is properly

adjustmentismade

line

up

24

11

sure

that

that

the

the

breakage

the

clamp

screw

needle

the

needle

and

and

needle

does

will

possibly

turn

be

adjusted

on

the2hole

for a 4 hole button.

1

machine

enters

not

touch

deflected,

broken

tighten

button

the

Page 27

has

does

of

the

The

cams

completed

not

begintomove

button.

THE

mustbeadjusted

its

shift

before

until

after

CAMS

so

the

that

needle

the

needle

the

enters

clamp

the

has

and

button

button

or

comeupout

These

cams

setting, turn the

At

this

point

the

or

be

opposite

frame.

AUTOMATIC

In

the

top

the

automatic

Function

in first

BEFORE

To

shaft

left

not

drop

the

to

room

set

paragraph

The

proper

the

advance

of

hand

move

or

the

machine.

sideofmachine

cam

outoftension

The

cam

3rd,

holditwith

adjust

backwards

for fingers, so

screw

and

are

setatthe

hand

wheel until it is blocked by

lineonthe

the

line

arm

of

releaseofthe

of

this

automatic

under

timing is

needle

bar

retard

sideways,

this

A

post.

has3set

screw

and

cam

adjusted

factory

outer

rimofthe

stamped

on

TENSION

the

machine

rear

intermittent

"Tensions."

when

the

reaches

timing

hole

for

close

as

screws.

driver,

by

otherwise

Loosen2and

and

forwards.

mustbeheld

accordingly.

buttodouble

cam

the

edgeofthe

RELEASE

is a

Cam

tension

B—^Fig.

tension

threadisreleased

its

highest

adjust

screw

the

turn

Space

by

point

the

Cam

driver

Arm

the

release

machine

does

screw

is

hole

after

check

the

should

their

stop pin.

match

machine

that

controls

1.

is

described

5/32"

of stroke.

on

the

located

cover.

pin

will

loosening

handwheel

not

allow

driverin3rd

top

on

Do

to

make

When

make

thread

thread

cam

is

release

release

loose—turn

late

earlier.

or

25

handle

turn

in

operating

handwheel

direction

backward

to

Page 28

BS-93-W

BS-95-T

BS-93

BS-I44-B

f)

BS-35

BS-97

BS-I44-A

¥

BS-)69

BS-163

BS-96

BS-166

Page 29

BS-

BS-

BS-

BS-

93W

93

94

95

Thread

Rear

Rear

Front

Tension

Thread

Thread

Tension

PARTS

Tension

Tension

Stud.

UST

Release

Washer.

Release

Release

Stud.

Pin.

BS- 95T

BS-

97

BS- 96

BS-144A

BS-144B

BS-

35

BS-

169

BS-163 Button

BS-166

Thread

Thread

Thread

Thread

Thread

Cam

Needle

Button

Tension

Tension

Tension

Tension

Tension

Roller.

Set

Clamp

Clamp

Spring.

Bottom

Top

Thumb

Thumb

Screw.

Lifter Lever

Lifter

27

Disc.

Disc.

Nut—Front.

Nut—Rear.

Spring.

Lever

Lock

Spring.

Page 30

cn

o ^

V^ip*

Page 31

BS-

88

Needle

Hole

PARTS

Plate.

LIST

BS- 99

BS-105

Thread

Needle Bar Thread Guide

BS- 122 Button

BS- 47

BS- 48

BS- 82

BS- 181

BS- 44

BS-160

Thread

Thread

Hand

Stop

Thread

Thread

Slack Take-up Lever.

Clamp

Jaw Spring.

Finger.

Looper.

Wheel Stop Pin.

Arm Spring.

Finger

Finger

Cam

Follower.

Cam

Follower Spring.

and

Take -up

29

Page 32

SOLt**'

MRkaP

'

*»>

CHANDLER

A

large

supplyofspecial

convenience

have

difficultyinsecuring

A

special

general

6M

and

Prices

We

thread

Button

of

our

soft

mercerized

repairingisstocked

12M

yd.

conesinblack

and

thread

also

stockalarge

which

Sewing

mustbeused

Machine.

andisstockedinthree

khaki.

Prices

on

application.

CHANDLER

Manufacturers

of

many

SEWING

customers,

color

This

different

Ayer,

the

Famous

sewing

the

thread

in 2000

card

supply

with

is a

MFG.

Mass.

threadisstocked

especially

proper

for

yd.

and

white.

mailed

of

the

Chandler

special

sized

conesinwhite,

COMPANY

CHANDLER

THREAD

thread.

darning,

spoolsin32

on

application.

special

Hand

glazed-finish

for

those

mending

colors

Button

DARNER

for

Sewing

Operated

thread

black

the

who

and

and

and

Page 33

> -CHANDLER

A

complete

at

any

location

A

flexible

FEATURE

edgeofthe

be

expanded

The

Chandler

can

alsobeused

You will find

winter

not

when

well

It

pays

big

Manufacturers

socket

li'ght

table

the

lighted,

dividends.

SAVE

to fit a

Light

Chandler

unit

which

the

operator

attached

adjustment.

by

means

although

on

other

this

lightisweak.

by

all

EYESTRAIN

Write

CHANDLER

of

Sewing

clamps

finds

to a

The

ofanadjustable

table

withamaximum

designed

typesofsewing

light

indispensable

means

—

for

current

MFG.

AVER,

the

famous

Light

on

any

convenient,

flexible

for

If

your

NEATER

price.

COMPANY

CHANDLER

sewing

arm

unitisheld

the

equipment.

on

sewing

most

complete

orderaChandler

DO

MASS.

machine

gives

clamp

thickness

Chandler

rainy

WORK

DARNER

DOUBLE

which

Darner

days

equipment

Light

table

to

can

of 2".

or in

todayl

the

is

Page 34

CHANDLER

^

4-

4

4

DARNING

FLUTING

HAND

SEWING

AND

MACHINES,

OH

POWER

THREADS

MENDING

HAND

BUTTON

MACHINES

OH

POWER

SEWERS

4 REBUILT TAILORING

4

PLEATING

4

RUFFLE

4

CUFF

4 LABEL

MACHINES

IRONERS

TACKERS

TAGGERS

MACHINES

1

Loading...

Loading...