Page 1

I

400 VETERANS BLVD, CARLSTADT

NJ

07072

Page 2

Page 3

u

Page 4

Page 5

CONTENTS

1.

MAIN

PARTS

2. SPECIFICATIONS··········································································································································1

3. WORK TABLE AND MOTOR ........................................................................................................................ 2

4.

INSTALLATION·············································································································································3

4-1:

Installing the rubber hinge and the corner rubber····

4-2.

Installing the oil pan··· ...... · ...

4--3. Installing

4-4.

installing the spool pin ... ······· .... ···· ... · .....

4-5.

installing the knee lifter

4-6.

Installing the belt······

4-7.

Installing the bobbin winder

4-8.

Installing the belt guard{L)· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·6

4-9.

Installing the thread

4-1

0.

Lubrication···················································

4-11.

Checking the machine pulley rotating direction··

5. PREPARATION BEFORE SEWING .................................................................................................................. g

5-1.

Installing the needle····

5-2.

Removing the bobbin case············

5-3.

Winding the

5-4.

Installing the bobbin case· .. · ..

5-5.

Threading the upper

5-6.

Adjusting the stitch

6. SEWING······················································································································································12

6-1.

Sewing················································································································································12

6--2.

Backtacking·························································-·······

7 .THREAD TENSION···································· ........ ·········· ...... ··········································································

7-1.

Adjusting the thread tension·· .....

7-2.

Adjusting the presser foot

8.STANDARD ADJUSTMENTS········································

8-1.

Adjusting the thread controller

8-2.

Adjusting the height

8-3.

Adjusting the feed dog position (longitudinal)···· ..

8-4.

Adjusting the positions

8-5.

Adjusting the timing the needle

8-6.

Adjusting the height

8-7.

Adjusting the timing between the needle and hook

8-8.

Adjusting the clearance between rotary hook and opener (thread release

Adjusting the clearance between feed forked connection

8--9.

8--10. Adjusting the height

s-·11. Adjusting the presser foot

8-12.

Adjusting the timing

8-13.

Adjusting the

9.SAFETY CLUTCH MECHANISM···· .............................................................................................................. 25

NAMES································································· ..................................................................

........

the machine

lower

thread················-

length·································

L0d

regulator···········································-··············

···········

··

..

······

....

·········

.....

··············

head···············

assembly··············································································································

..

····

..

···

..

..

···················

stand············

..

··

..

··

..

········

········································

thread·············································

pressure·····················

spring···················

of

the feed dog· .....

of

the needle

of

the needle

of

the presser

movement

of

the vibrating presser foot ...

... ······

..

·················

···················

··············

················

with

bar·····································································································

..

················

.. · ..

··············································

..

·············

.... ·

........

.......................................................................................................

and

feed

feet····················:···························

..

················

..

..

··

..

···

..

··· ...... ···· ......

·················

.........

·········

......

···········································································

needle hole

...................................................................................................

amount·······························································

..

···· ... ···

.. ·

..

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 7

···············

..

·····························

..

········································

··········

.....................

..

··············································································14

..

································

······························

of

the feed

......................................................................................

and

·······

..

····

....

··

..

·····

..

··· ..

················

..... ···

..

···················

.. · ..

······················

..

···

..

··············

·····················

..

··········

..

··

... ·

..

·······

....

···········

..................

.........................................................................

.....

···························································

····························································

dog··················

feed fork

..

·····································································

..

..

·····

..

···

..

··············

..

····

..

···· ...... ···

..

···············

················································

...

finger)···············································

collar··················································

........................................................

...... ·

..

··

..

···

..... ·····

··

..

················································

..

·····································

······················

..

······ ...... ···

..

···· .... ·· ...... ····

....

·······································

..

·······································

···························

..

···············································

·········

...

····································

...

···············

.....

···········································

..

..

· .... ···

··· ...

..

······

.... · ..

..

··

....

··············

..

················

..

··

..

··················

···············

..

··········

..

···················

..

...

·········:.·

...............

·······

... ·

..

.. · .. · ..

..

··········

..

··

..

················11

..... ····· ·13

···· ..

......

···

·········22

..

·· .... ·· ·3

·········

···· ·3

....

..

·········

.... ···· ·9

······11

···13

..

···15

······15

··

···21

··· ·5

..

·1

·13

·14

·16

·18

-19

·20

·21

·23

-4

·5

·6

·8

·9

10

12

18

24

-1

·3

-4

0

Page 6

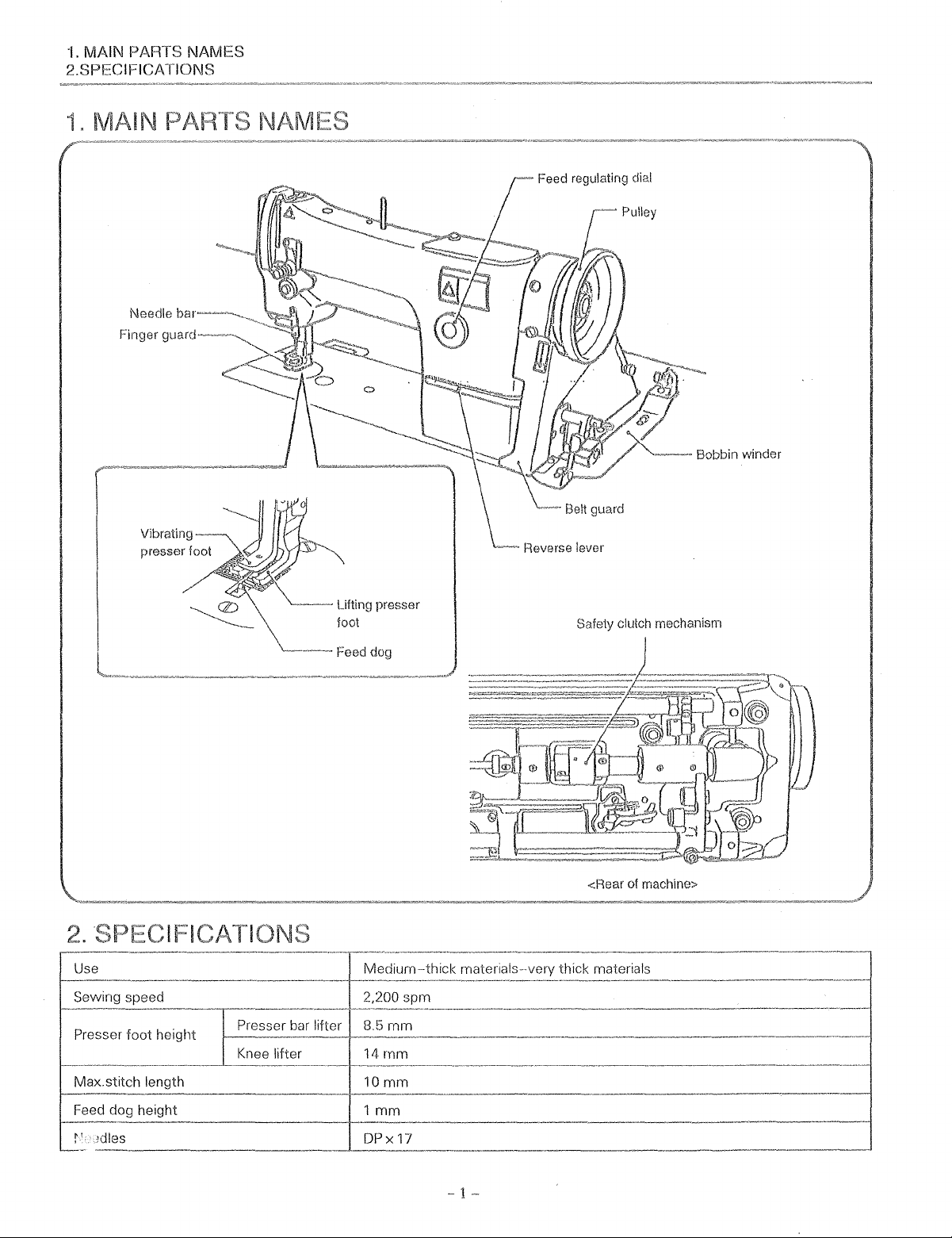

1.

MAIN PARTS NAMES

2.SPECIFICATIONS

1"

MAIN

Feed regulating dial

Vibrating

presser foot

~-

lifting presser

foot

-~Feed

dog

Safety clutch mechanism

of

<Rear

materials--very thick materials

machine>

-

1-

Page 7

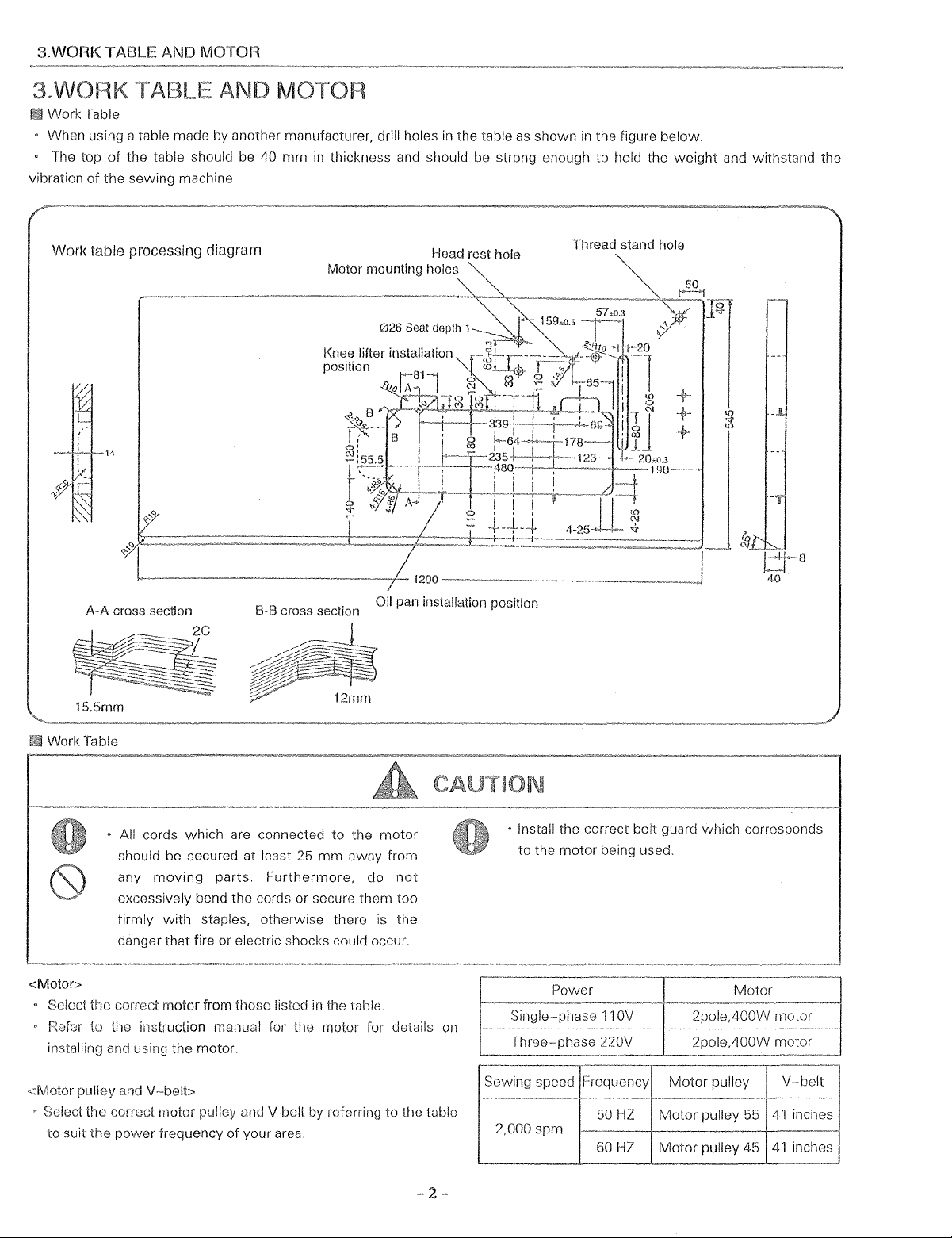

3.WORK TABLE AND MOTOR

3.WORK TABLE AND MOTOR

Work Table

• When using a table made by another manufacturer, drill holes

• The top

vibration

of

the table should be 40

of

the sewing machine.

mm

in

thickness and should be strong enough to hold the

in

the table

as

shown

in

the figure below.

weight

and withstand the

Work

table

processing

14

A-A

cross section

diagram

B-B

cross section

Motor mounting holes

!<:nee

lifter installation

position

Oil pan installation position

Head

Thread stand hole

15.5mm

Work Table

• All cords which are connected to the

should be secured at least 25

moving

any

excessively bend the cords or secure them too

with

firmly

danger that fire or electric shocks could occur.

<Motor>

• Sek;ct

<M0tor pulley and

UiG

correct motor from those listecl

f{,:Jfor

to

the instruction manual for the motor for details on

installing and using the motor.

V-belt>

Select the correct motor pulley and V-belt by referring to the table

to

suit

the

power frequency of your area.

parts.

staples, otherwise them

Furthermore,

mm

in

the table.

motor

away from

do

not

is

the

• Install the correct belt guard which

to the motor being used.

Power

50

HZ

Motor

pulley 55

2,000 spm

60HZ

Motor

pulley 45

Motor

motor

41

inches

41

inches

-2-

Page 8

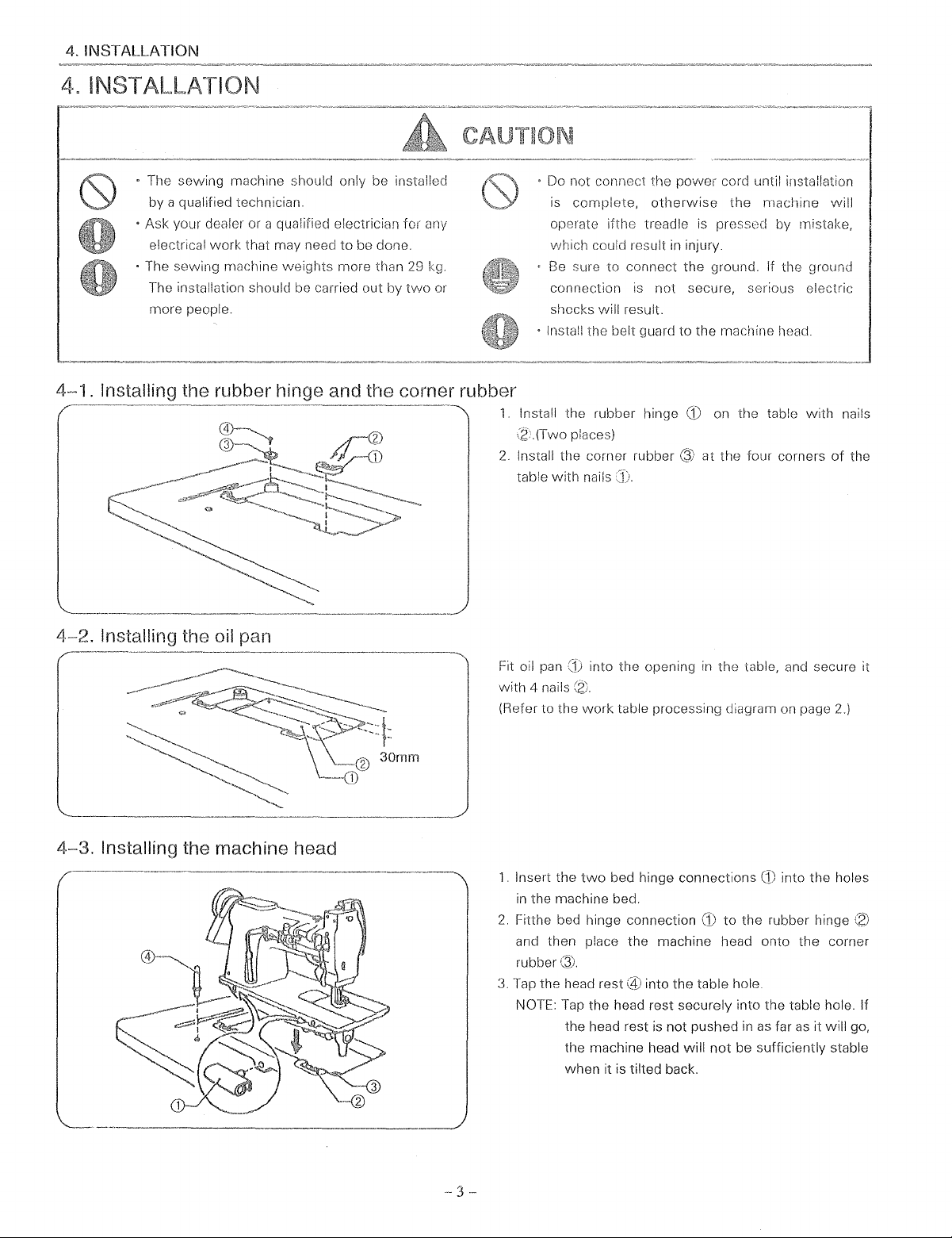

4.

INSTALLATION

4.

INSTALLATION

o The sewing machine should only be installed

by a qualified technician.

• Ask your dealer or a qualified electrician for any

electrical

· The sewing machine

The installation should be

more people.

4-1.

Installing the rubber hinge and the corner rubber

4~2.

Installing the oil pan

work

that may need to be done.

weights

carried out by

more than 29 kg.

two

or

o Do not connect the

is

complete,

oper8te ifthe treadle is

v;hich could result in injury.

Be

sure to connect the ground. If the ground

connection is not secure, serious electric

shocks will result.

• Install the belt guard to the machine head.

1.

Install the rubber hinge

(2

(Two places)

2.

Install the corner rubber Q) at the four corners

table

with

nails

power

otherwise

(1)

cord until installation

the

m8chine

prEJSSt)cl

on the table

by mistake,

with

will

nails

of

the

4-3.

Installing the machine head

Fit oil pan

with

4 nails

(Refer to the

1.

Insert the

in

the machine bed.

2.

Fitthe bed hinge connection to the rubber hinge

and then place the machine head onto the corner

rubber

3.

Tap the head rest into the table hole.

NOTE:

into the opening

work

table processing diagram on page

two

bed hinge connections

Tap

the head rest securely into the table hole. If

the head rest

the machine head will

when

it is tilted back.

is

in

the table, and secure it

not pushed in

not

be sufficiently stable

CD

into the holes

as

far

as

it will go,

2.)

--

3

Page 9

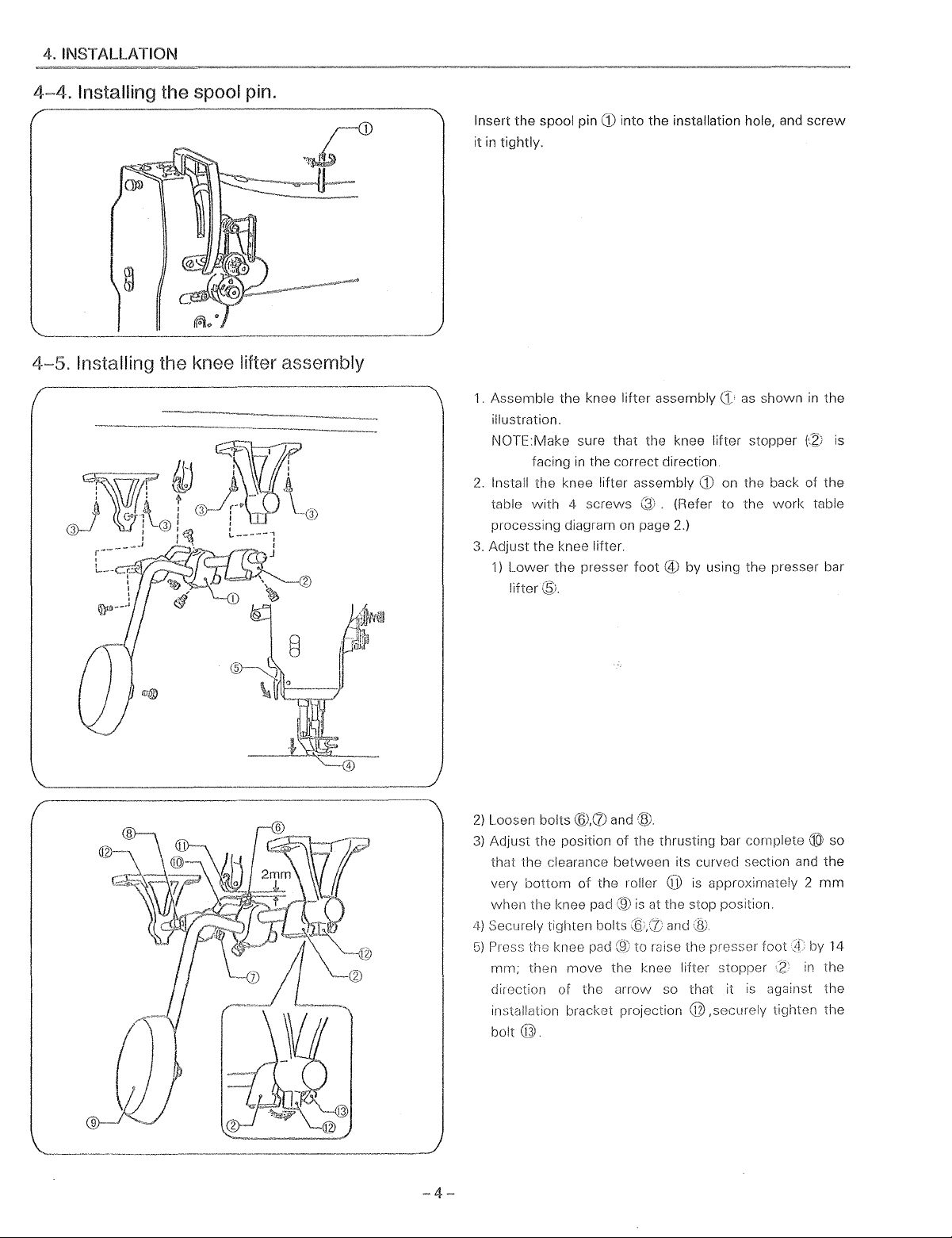

4.

INSTALLATION

4~4.

Installing the spool pin.

4-5.

Installing the knee lifter assembly

Insert

the

spool pin

it

in

tightly.

1.

Assemble

illustration.

NOTE:Make sure that the knee lifter stopper

facing

2.

Install

the

table

with 4 screws

processing diagram on page 2.)

3.

Adjust

the knee lifter.

1)

Lower

lifter®.

CD

into the installation hole, and

the

knee lifter assembly

in

the correct direction.

knee lifter assembly

the

presser

foot @ by

as shown

CD

on the back of

(Refer

to

the

using the presser bar

work

screw

in

the

fZ:;

is

the

table

2)

Loosen bolts

3)

Adjust

the

position

that

the

clearance

very

bottom

when

the

knee pad

4)

Securely tighten bolts and

G)

Press the knee pad

mm;

then

move

direction of the

installation bracket projection

bolt@.

-4-

@.(1)

and

(til

of

the thrusting bar complete ® so

between

of

the

roller @ is approximately 2

(9)

the knee lifter stopper

arrow

its curved section and

is

at the stop position.

to

mise the presser

so that it

is

@,securely

foot

!f

:z

against

tighten

the

mm

by 14

in

the

the

the

Page 10

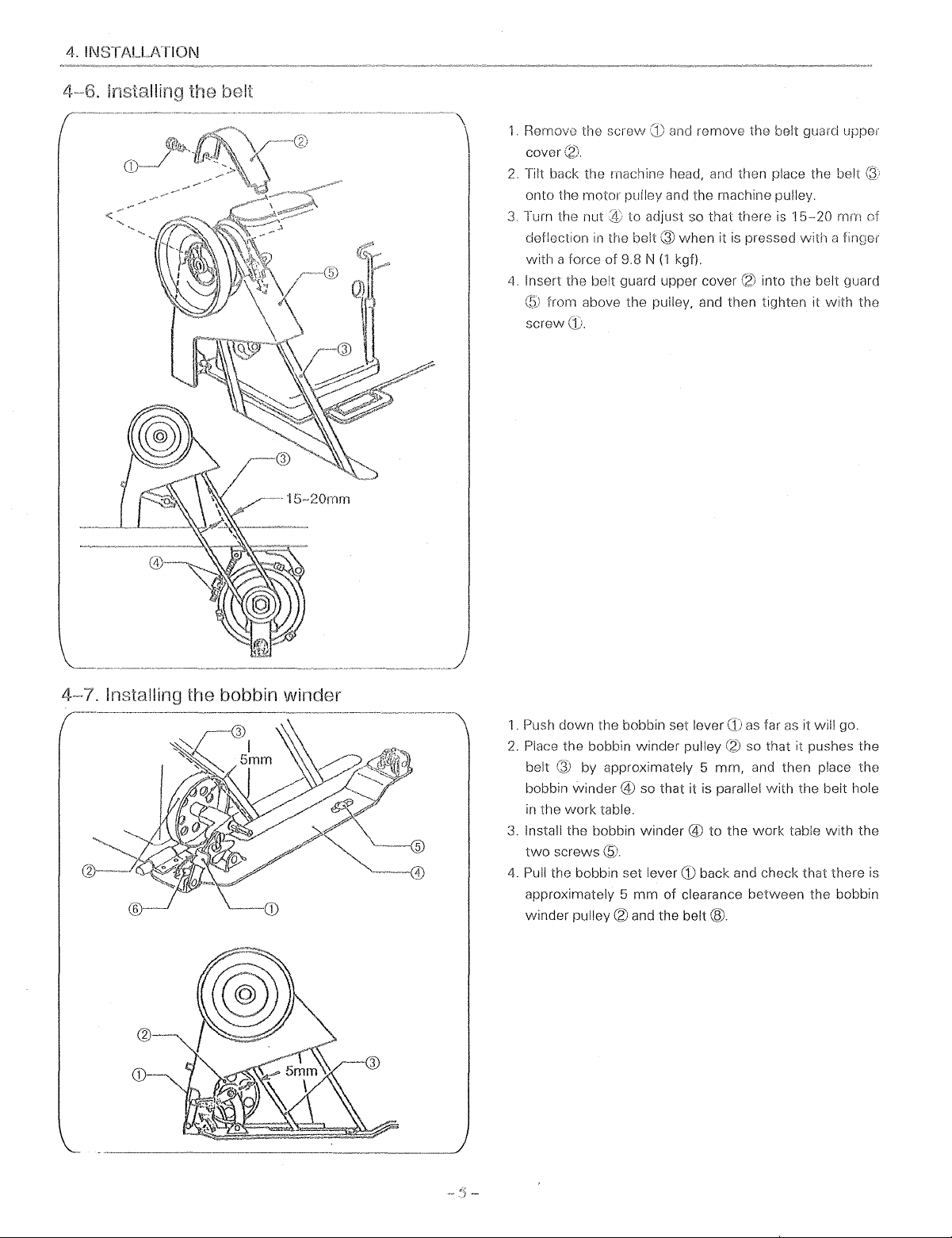

4.

INSTALLATION

ling thH belt

1.

Remove the screw

cover

2.

Tilt back the rnachine head, and then place the belt

onto the

3.

Turn the nut to adjust so that there

deflection

with

4.

Insert the belt guard upper cover into the belt guard

screw

motor

in

a force of 9.8 N

from above the

(1)

and

romove the belt guard upper

pulley and the machine pulley.

is

the belt Q)

when

it

is

pressed

(1

kgf).

pulley, and then tighten it vvith the

15-20

with

a finQer

mm

of

4-7.

Installing the bobbin winder

1.

Push down the bobbin set lever

2.

Place the bobbin winder pulley so that it pushes the

belt by approximately 5 mrn, and then place the

bobbin winder

in

the work table.

3.

Install the bobbin

two

screws

4.

Pull the bobbin set lever

approximately 5

winder pulley

@ so that it is parallel

winder@

@.

GJ

mm

of clearance between the bobbin

(2)

and the

belt®.

as

tar

as

it will go.

with

the belt hole

to the

work

table

with

back and check that there

the

is

Page 11

4. INSTALLATION

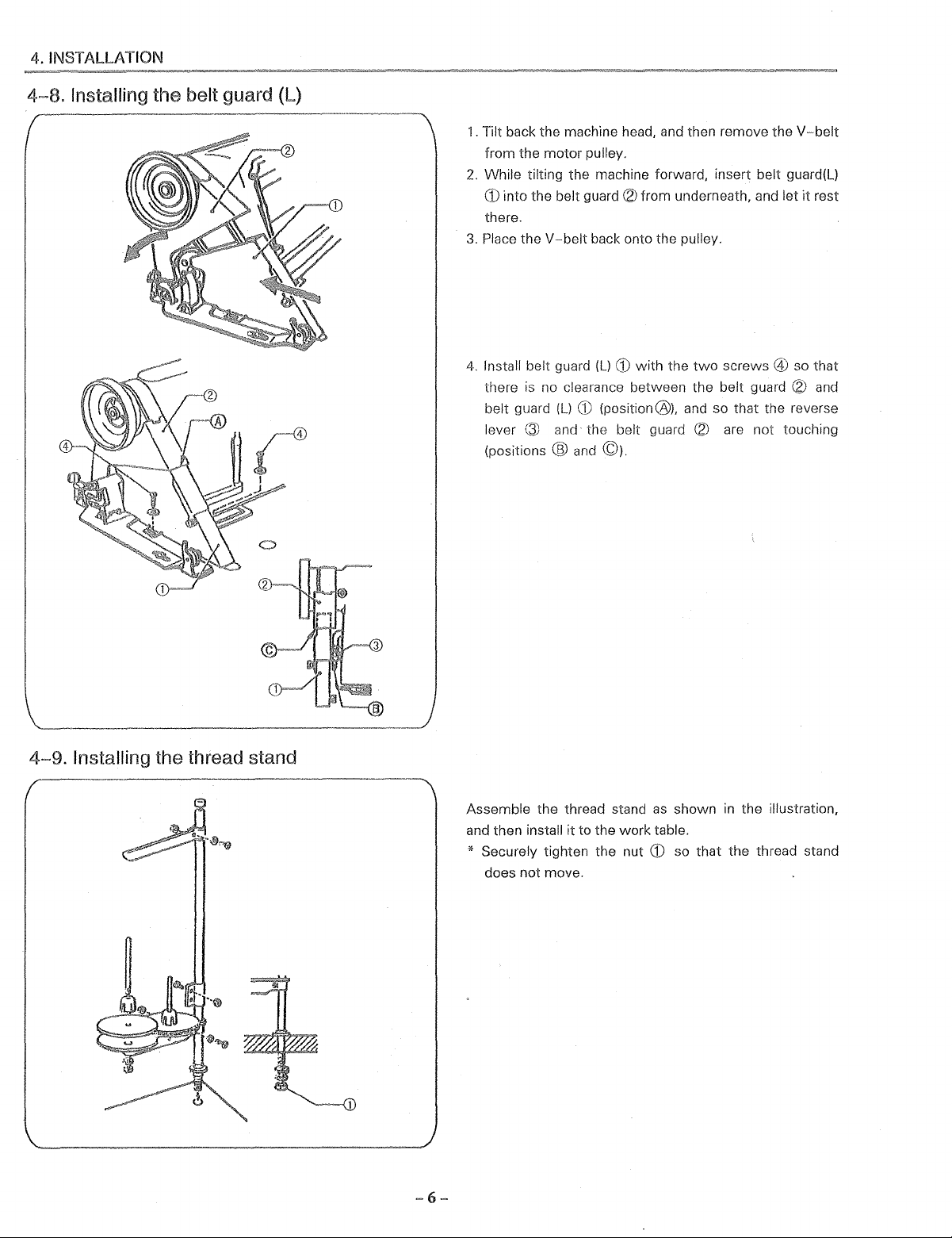

4~8.

Installing the belt guard (L)

1.

Tilt back the machine head, and then remove the

from the

2.

While tilting the machine forward, insert belt guard(L)

G) into the belt guard

there.

3.

Place the

4.

Install belt guard (L) G)

there is no clearance between the

belt guard (L)

lever @ and the belt guard

(positions

motor

pulley.

V-belt

back onto the pulley.

G)

(position@), and so that the reverse

@ and ©).

(2)

from underneath, and let

with

the

two

screws @ so that

belt guard

(2)

are

not

(2)

touching

V-belt

it

rest

and

4-9.

Installing the thread stand

Assemble the thread stand

it

to the

and then install

work

* Securely tighten the nut

does not move.

as

table.

CD

shown

so

that

in

the illustration,

the thread stand

Page 12

4. INSTALLATION

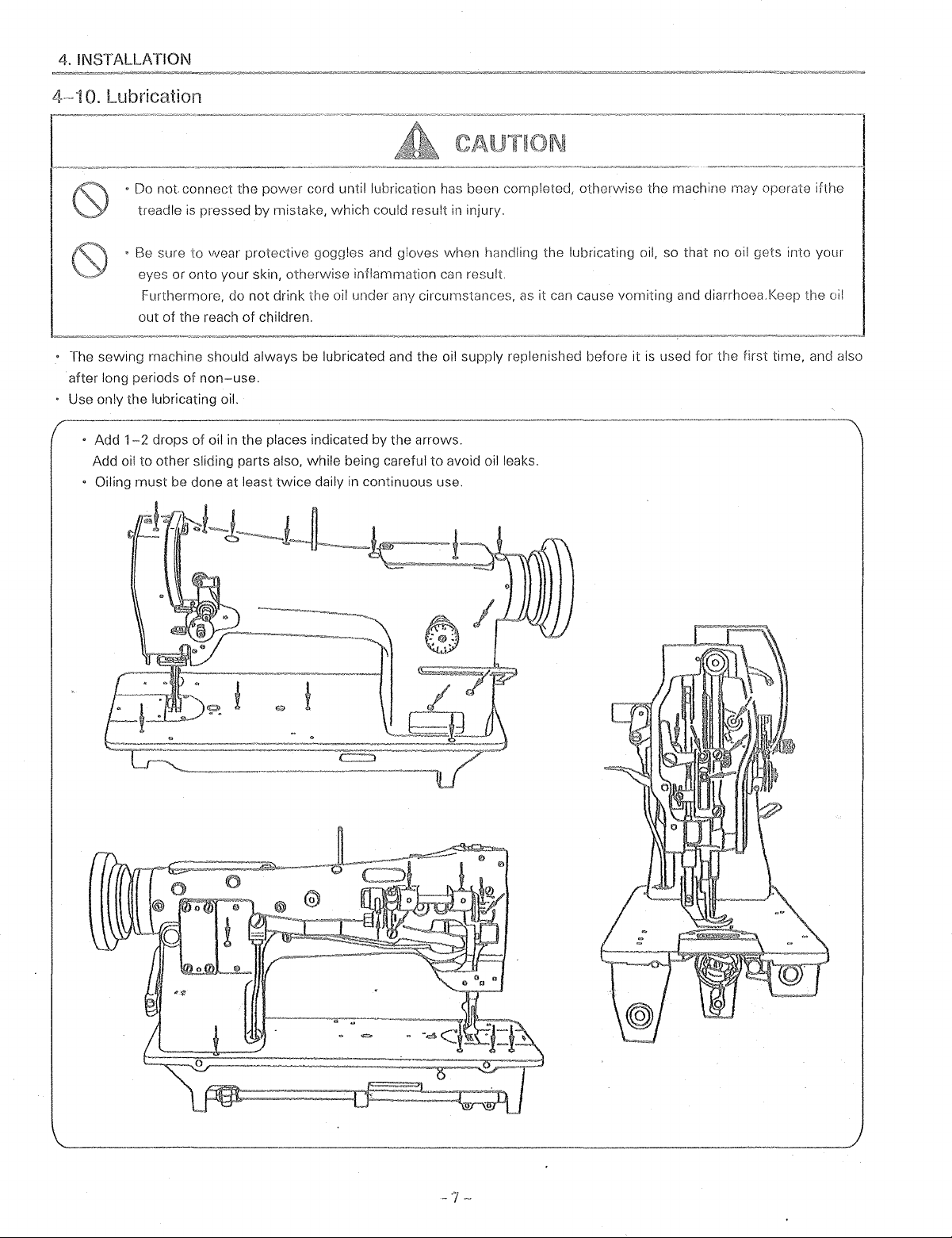

4-" 10. Lubrication

•

Do

not

connect the

treadle

•

Be

eyes or onto your skin, otherwise inflammation can

out

is

sure

to

Furthermore, do not drink the oil under any circumstances,

of

the reach

power

cord until lubrication has been completed, otherwise the machine may operate ifthe

pressed by mistake, which could result

vvear protective goggles

of

children.

and

gloves when handling the lubricating oil, so that no oil gets into your

in

injury.

result

as

it can cause vomiting and diarrhoea. Keep the oil

The sewing machine should always be lubricated and the oil supply replenished before it

after long periods

Use only the lubricating oil.

•

Add

1-2

Add oil to other sliding parts also, while being careful to avoid oil leaks.

Oiling

must

of

non-use.

drops

of

oil

in

be done at least

the places indicated by the arrows.

twice

daily

in

continuous use.

is

used for the first time, and also

-7-

Page 13

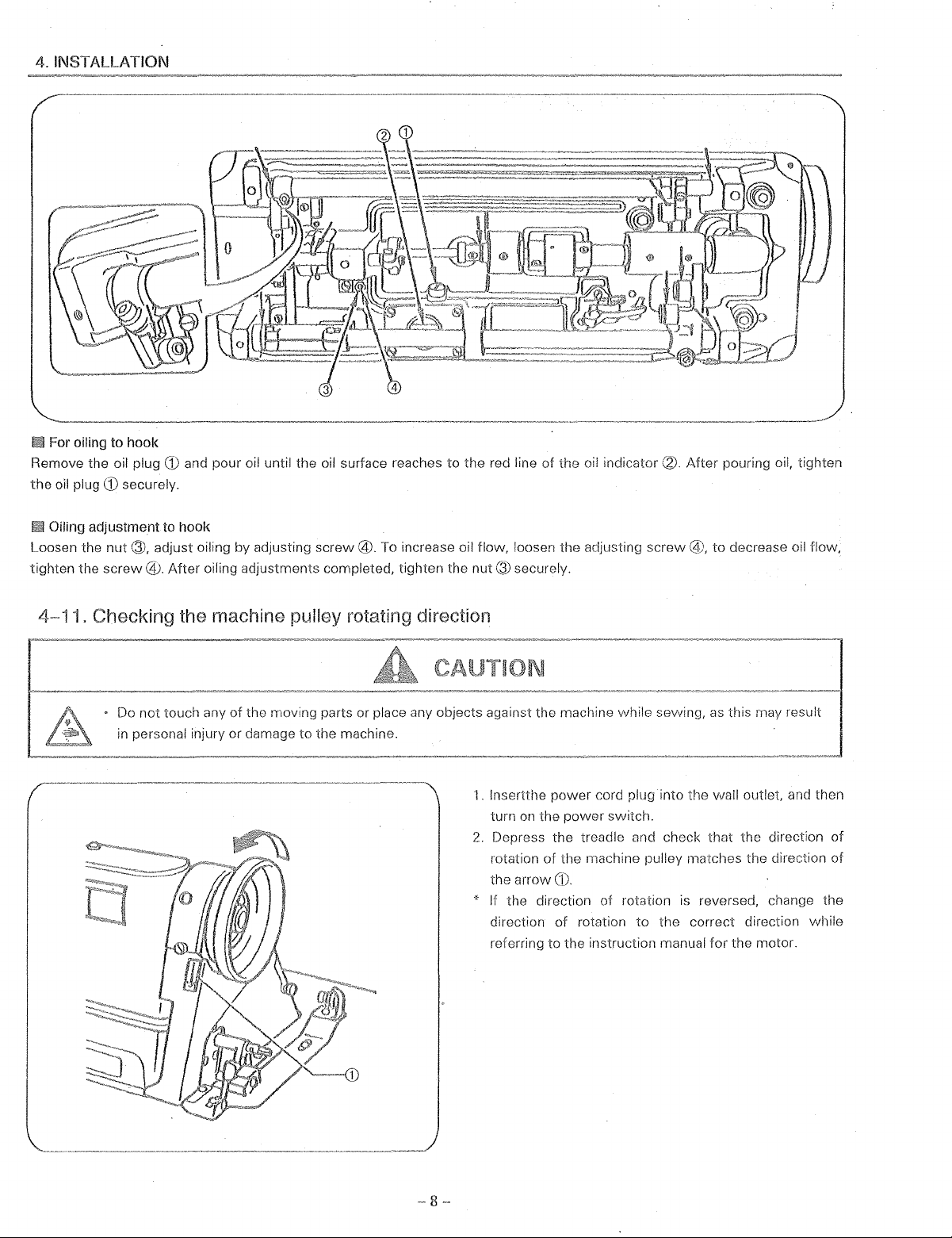

4. INSTALLATION

II

For oiling to hook

Remove the

the

oil plug

oil plug

CD

securely.

CD

and pour oil until the oil surface reaches to the red line of the oil indicator

\2).

After pouring oil, tighten

Oiling adjustment to hook

Loosen the

tighten the

4~

nut®.

adjust oiling by adjusting

screw@.

After

oiling adjustments completed, tighten the

screw@.

To increase oil flow, loosen the adjusting

11. Checking the machine pulley rotating direction

Do

not

touch any

in

personal injury or damage

of

the moving parts or place any objects against the machine while sewing,

to

the machine.

screw@,

nut®

securely.

1.

lnsertthe

turn

2.

Depress the treadle and check that the direction

rotation

the arrow

* If the direction

direction

referring to the instruction manual for the motor.

power

cord plug into the wall

on

the

power

switch.

of

the machine pulley matches the direction

CD.

of

rotation

of

rotation

to

the correct direction while

to

decrease oil flow,

as

this may result

outlet

is

reversed, change the

and then

of

of

-8--

Page 14

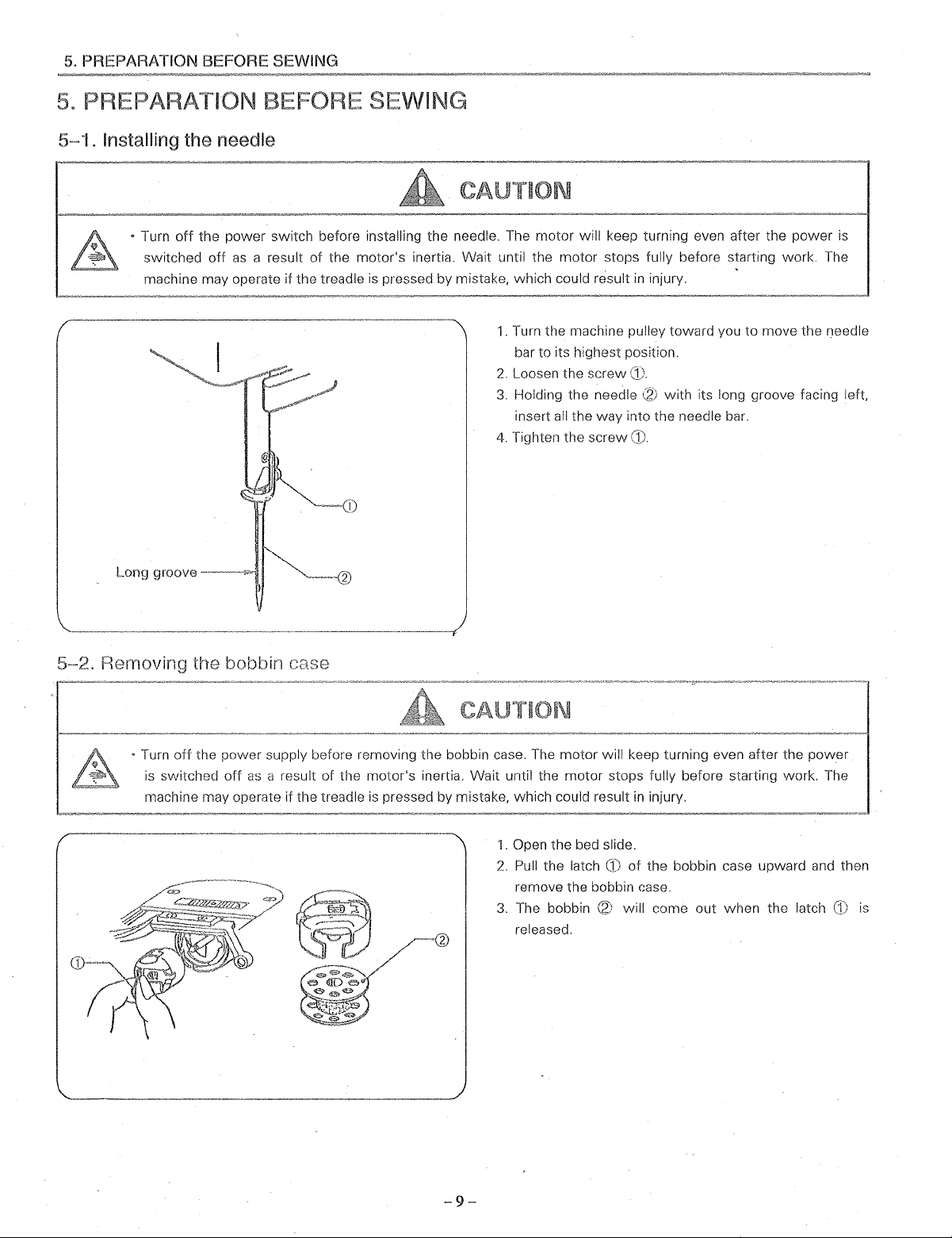

5.

PREPARATION BEFORE SEWING

5.

PR

5-1

PARATION BEFOR SEWING

. Installing the needle

• Turn

off

the

power

switch before installing the needle. The

off

as

switched

machine may operate if the treadle

a result

of

the

motor

motor's

inertia. Wait until the

is

pressed by mistake, which could result

1.

Turn the machine pulley toward you to move the needle

2.

Loosen the

3.

4.

Tighten the

motor

bar to its highest position.

Holding the needle

insert all the way into the needle bar.

will keep turning even after the

stops fully before starting

in

injury.

screw(!).

(2)

with

its long groove facing

screw

CD.

left

Long

5-2.

R£~moving

groove-

~

the bobbin case

• Turn

off

the power supply before removing the bobbin case. The motor will keep turning even after the

is

switched

machine may operate if the treadle

off

as

a result of the motor's inertia. Wait until the

motor

is

pressed by mistake, which could result

1.

Open the bed slide.

2.

Pull the latch

remove the bobbin case.

3.

The bobbin

2

released.

power

stops fully before starting work. The

in

injury.

CD

of

the bobbin case upward and then

(2)

will come

out

when

the latch

CD

is

-9-

Page 15

5.

PREPARATION BEFORE SEWING

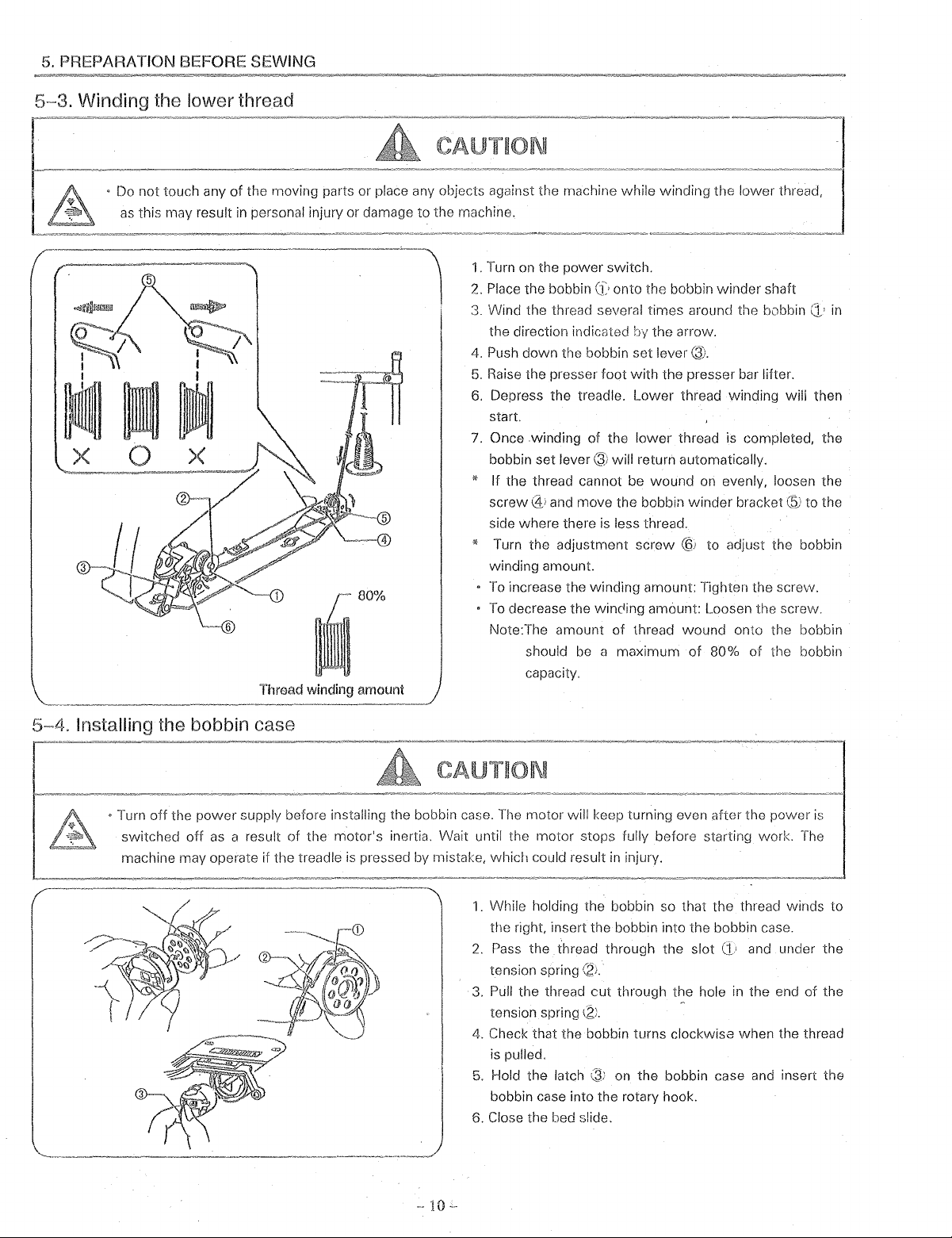

5~3.

Winding the lower thread

• Do not touch any

as

this may result

of

the moving parts or place any objects against the machine while winding the lower

in

personal injury or damage to the machine.

1.

Turn

on

the power switch.

2.

Place the bobbinG:· onto the bobbin winder shaft

3. Wind the thread several times around the bobbin

the direction indicated the arrow.

4.

Push down the bobbin set lever Q).

5.

Raise

Thread winding amount

the presser foot

6.

Depress the treadle. Lower thread winding will then

start.

7.

Once .winding of the

bobbin set

lever®

* If the thread cannot be wound

screw@_~

side where there

* Turn the adjustment screw

winding amount.

To

To

Note:The amount of thread wound onto the bobbin

and move the bobbin winder bracket to the

increase the winding amount: Tighten the screw.

decrease the wincing amount: Loosen the screw.

should

capacity.

be

with

the presser bar lifter.

lower

thread is completed, the

will return automatically.

on

evenly, loosen the

is

less thread.

@j

to adjust the bobbin

a maximum

of

80% of the bobbin

<1·

in

5~4.

Installing the bobbin case

• Turn

off

the

power

switched

machine may operate if the treadle

off

supply before installing the bobbin case.

as

a result of the motor's inertia. Wait until the motor stops fully before starting work. The

is

pressed by mistake, which could result

The

motor will keep turning even after the power

in

injury.

1.

While holding the bobbin so that the thread winds to

the right, insert the bobbin into the bobbin case.

2.

Pass

the thread through the slot

tension spring

3.

Pull the thread

tension spring

4.

Check that the bobbin turns clockwise when the thread

is

pulled.

5.

Hold the latch

bobbin case into the rotary hook.

6.

Close the bed slide.

\21.

cut

through the hole

(2:.

;.3;

on the bobbin case

and

in

the end of the

and

is

under the

insert the

Page 16

5.

PREPARATION BEFORE SEWING

5-5.

Threading

• Turn

switched

machine may operate

the

upper thread

off

the power supply before installing the bobbin case. The motor will keep turning even after the power

off

as

a result of the motor's inertia. Wait until the motor stops fully before starting work.

if

the treadle

CAUTION

is

pressed by mistake, which could result

Turn the machine pulley and raise the thread take up lever

G:·

before threading the upper thread. This will make

threading easier

at

the sewing start.

out

in

injury.

and

it will prevent the thread from coming

is

The

5-6.

Adjusting

the

stitch

length

Stitch length

can

Ci·.

Numeric figures on the dial

mm. The desired numeric figure

set at just above, while depressing the revers lever

slightly.

-11-

be set by turning the feed regulating dial

i.l'

show the stitch length

on

the dial should

be

in

Page 17

6.

SEWING

6.

6~1.

Sewing

"

Attach

"

Turn off the

When

When

When

• Do

all

attached, injury rnay result.

off

JS

a result

rnayoperate if the treadle is

threading the needle

replacing the needle and bobbin

not

not

touch any

personal

injury

devices bofor:1

powe;

switch

of

the

using the machine and

of

the

or

damage

Lower thread

at the

motor's

moving

to

the

inertia.

by mistake,

when

parts

or

machine.

rnachir18. If the rnachine is used vvlthout these devices

times. The

Wait

until the rnmor

leaving

place any objects against

motor

will

which

could

msult

the

machine unattended

1.

While

the machine

thread

2.

Pull the

out

smoothly,

3. Turn on

4. Depress the treadle

slops

turning evon

fully before

in injury.

the

machine

holding

comes

lower

the

power

after

while

sewing,

the

upper thread

pulley by hand

out

onto

the

thread

toward

switch.

to

start

the; pnvver

vvork. The rnachine

as

this may

with

your

toward

feed

you

sewing,

you

dog.

and check

is

sv\'itchcd

fingers, turn

until the

that

lower

it

pulls

6~2.

Backtacking

When

the reverse lever

direction

original position,

normal.

will

be reversed, and

-12-

the

feed

is pushed,

when

direction

the

it

is returned

will

change back

material

feed

to

its

to

Page 18

7.

THREAD TENSION

7.

THREAD TENSION

7 ~ 1.

Adjusting the thread tension

Upper thread

Lower thread

Good even stitches

Upper thread tension too weak or

too strong

lower

thread tension

Lower thread

Upper thread tension too strong or

too weak

II

Upper thread tension

of

The tension

tension thumb nut

To

increase the tension

tension thumb nut

turn the tension thumb nut

II

Lower thread tension

the upper thread

G).

of

the upper thread,

(f1

to the right.

<}1

to the left.

CAUTION

Turn

off

the

power

switch before removing or

inserting the bobbin case.

The motor will keep turning even after the

power

motor's inertia. Wait until the motor stops

fully before starting work. The machine may

operate if

which could result

is

switched

the treadle is pressed by rl'istake,

in

injury.

lower

thread tension

is

adjusted using the

To

decrease tension,

off

as

a result

·~urn

the

of

the

Adjust by turning the thread tension

case will not drop by its

of

the bobbin case is held.

so

that the presser foot can properly hold down

7

~2.Adjusting

the presser foot pressure

---------.

coming out

Adjust the presser foot pressure to

possible

material by turning the

-

13-

own

screw

weight

(f•.

nut

(2J

until the bobbin

while

lower

the thread end

as

much

as

Page 19

8.

STANDARD ADJUSTMENTS

8.

STAN ADJUSTMENTS

Maintenance and inspection

machine should only be carried out by qualified

personnel.

Ask your dealer or a qualified electrician

out

any maintenar.ce and inspection

electrical

If

original positions and check that they

correctly before using the machine.

8-1.

Adjusting the thread controller spring

systern.

any safety devices have been rernoved,be

sure

to

m-install

of

the sewing

to

carry

of

the

them to their

operate

power cord from the wall outlet at the

times, otherwise the machine may operate if

treadle

in

even after the power

the motor's inertia.

fully before starting work.

When carrying out inspection,

maintenance

When replacing consumable parts

rotary hook

If the

carrying

careful to observe

Operating range

The standard operating range for spring

1.

Loosen the

troller spring stop ~ to adjust the operating range.

• For more operating range, move the spring stop

the right.

• For less operating range, move the spring stop

left.

2.

Tighten the

is

injury. However, the motor will keep

power

out

screw

screw

by mistake, which could

is

switched

Wait until the

switch needs

some adjustment. be

all

safety precautions.

of

spring

\2·,

and then turn the thread con

to

(2_:.

off

be

CD

as

left

is

a

5-1

on

Omm.

~~?!

Qi

to the

to

-14-

Tension

The standard tension for spring

1.

Loosen the tension

2.

Turn the tension stud (§l to adjust the tension.

To

stud

To

3.

After adjustment, tighten the tension thumb nut

screw\!?).

of

the spring

is

0.39-0.78

thumb

nut

\4;

and

screw@.

increase the spring tension, slightly turn the tension

®!counterclockwise.

decrease the tension, turn the stud clockwise.

N (40-80g).

0\)

and

Page 20

8. STANDARD

8~2.

Adjusting the height of the feed dog

ADJUSTMENT~;

8~3.

AdjUsting the feed dog position (longitudinal)

The maximum height

of

the needle plate

of

height

1.

2,

3.

4.

the feed dog:

Tilt the machine head away from you. Turn the pulley to

raise the feed dog to its highest position.

Loosen the

Raise or lower the feed dog

Tighten the

screw~.

screw

of

the feed dog from the surface

(2)

is

normally 1 mm.

Q

..

CD

as

necessary,

To

adjust the

31.5mm

1.

Change the feed amount to the smallest possible

setting.

2.

Turn the pulley to raise the feed dog

position.

3.

Tilt the machine head away from you.

4.

Loosen the screw (2), and then move the feed rock

~'

to

shaft crank

32.1

mm

from the edge

of

center

5.

Securely tighten the

the needle hole on the feed dog

adjust so that there

of

the needle plate to the

screw

CZ·.

to its highest

is

a distance

(1•.

of

-

15-

Page 21

3.

WORK TABLE AND fvlOTOR

3.

VVmk

Table

using a table made manufacturer, drill holes

When

The

top

of

ihe

table should be 40

of

vibration

the sewing machine.

mn1

in

thickness

and

in

should

the table

21s

shown

in

bG

strong to hold the

the below.

Thread

and

withstand the

15.5mm

.,

.,

"'""'

cross section

. Oil pan installation position

-16-

Page 22

8.

STANDARD ADJUSTMENTS

3~4.

Adjusting the Positions of the needle and needle hole of the feed dog

Needle

--

eclle

ter

hole

Turning the pulley to lower the needle bar

check whether the needle descends to the center of the

of

needle hole

If the needle does not enter into the center

1.

Remove the cover and loosen the screw

2. Holding the needle bar rock frame

required to get the correct position to the feeder.

3.

Tighten the screw

the feed dog or not.

((2

and close the cover.

;Ji

of

12.·

move it

slowly,

the hole:

slightly.

as

may

be

-Feed

dog

-17-

Page 23

8.

STANDARD ADJUSTMENTS

J'

A

I o;us

t'

mg

timing

tl1e

needle with

It

is

important that the tirning relationship

needle on its

movement

the

needle on the

start

When

procedure to change

1.

Clla:1ge the feed

2.

Loosen the

for oil resc-::voir

and the

3. Normally put the

ditch

4.

Turn the machine pulley

its

lowest

5.

And, pushing

cam and

feed dog

6.

After

positioning completed, tighten the each

securely.

downward

is

maintained at all tirnes.

downward

the

amoum

screw

Q,

oil reservoir

arrow

of

arm

shaft

point.

the

reverse lever up and down, turn

set

this atthe point both

rest

stroke and the · feed dog

rhe feed dog moven1ent

to the largest possible setting.

for cover

and then l"ernove the cover plate

mark

to

the

between

When

the scart

stroke reaches the top

must

use the following

the

mm

screw

the

up

screw

from

'~i

of

the

needle at 1

the

and

earn on

needle and the

the

of

V

the

Adjusting the height of the

<Needle

bar

highest point>

Needle plata

neeclle

When the needle bar

the measurement

plate and the upper end

1.

Loosen the

the needle bar 0

2.

Tighten the

screw

to

screw

G.•

is at its highest point, normally

between

\2' and

get

the

surface

of

the

needle eye is 22.3mm.

move

the setting posi tion

the correct posi tion.

of

the

needle

of

-

18-

Page 24

8.

STANDARD ADJUSTMENTS

8-7.

Adjusting the timing between the needie and the hook

After setting the needle bar height, set stitch length to

minimum, turn the machine pulley toward you

needle bar reaches its

allow the needle bar to raise about

upward stroke. With

of

the sewing hook should be at the center

and normally, the measurement between the hook point

and the upper end

further the

needle hollow should

*If

they are not measured

adjustments below.

II

Adjusting the timing

1.

Loosen the three set screws d

2.

Turn the hook shaft (2; to align the hook point

center

3.

Tighten the three

timing

Adjusting the

1.

Loosen the

2.

Move the hook to the right or to the left

require.

clearance between the hook point and the

of

the needle.

of

the sewing hook.

two

* Please note one

of

ditch

ditch during adjustment.

3.

Tighten the

hook shaft. Therefore, keep the

two

lowest

needle bar

of

the needle eye should be 2.4mm,

be

point. Continue turning

2mm

in

this position, the point

about 0.02 to

0.1

as

above, perform the

'·

set

clearance

screws

of

the

screws

screws

Q·

slightly.

two

~;.

screws

(,3)

and

is

until the

and

while on its

of

the needle,

mm.

with

the

re-check

placed on the V

screw

as

the

may

on V

-19-

Page 25

8.

STANDARD ADJUSTMENTS

8-~~8.

Adjusting

t11e

Clearance between rotary hook and opener

(Thread release finger)

0

L~

The opener facilitates the passage

loop by

rotating movement

instant opens a clearance gap between the notch

inner hook and the tab

needle thread loop to be drawn easily through the gap.

BCiearance between the opener and projection

1 . Loosen the

2.

3. Tighten the screw securely.

slightly nudging the inner hook creating a slight

of

it. This

of

the hook retainer

screw

(1).

Adjust the clearance between projection

~'

and the opener

releasing shaft bushing

may

be

required. The standard clearance between the

two

parts

is

0.7-0.9mm.

by means

@ to the right or to the left

of

the needle thread

movement

permitting

of

movernent

at that very

of

of

hook.

of

hook

of

thread

the

the

as

B Position

Place the one

ditch

B Adjustment

1.

Turn the machine pulley until the opener

projection

2.

Press the opener

make the right side

the bobbin case holder and tab the hook retainer

0.4-0.6mm.

This adjustment can be done by loosening the

3. Tighten the screw

of

the opener cam:

of

of

the hook shaft.

of

of

hook

screws

operation:

~)

(:1·

J_l

securely.

I_Q)

which

is

indicated by "S"

'.3:

extremely on its travel.

to

the projection

clearance

between

of

the notch on

presses the

hook (2: and

screw

01~

V

(§;

-20-

Page 26

8.

STANDARD ADJUSTMENTS

8~9.

Adjusting the cleare.nce between feed forked connection and feed fork collar

Incorrect clearance between the fork

collar

<2'

connection and feed fork

lenoth

or

overheating, etc.

1.

Remove the cover plate

2.

To

increase the clearance, loosen the nut

,(2;

to

the nut

This adjustment should be done

machine

3.

Upon completion

screw

left

pulley toward you to get correct clearance.

(9).

·:3;

or counter-·clockwise.

of

adjustment, tighten the

will bring irregular stitch

and the oil

of

feed forked

reservoir~~'"

CQ;

and

turn

with

turning the

screw

and

8-,1

0.

Adjusting the height of the presser feet

The standard height for the lifting presser foot

mm

when

the presser foot has been raised by the presser

bar

lifter(!.).

1.

Loosen the

then loosen the set

2.

Move the lifting presser

height.

3. Tighten the

4. Tighten the

pressure. (Refer to page 13.)

NOTE: If the height

screw,<~,

screw@.

screw

changed, the movement amount

presser

vibrating presser

movement

to page

raise the presser bar lifter

screw~~).

foot

(2)

up or

down

(,_1)

to

adjust the presser

of

the lifting presser foot

foot·~)

and vibrating presser foot 0 will

Adjust the amount

foot ~ so that it matches the

of

the lifting presser foot (Refer

21.)

of

movement

to adjust its

of

~)

(L;,

the

is

of

8.5

and

foot

is

The

-21-

Page 27

8.

STANDARD ADJUSTMENTS

8~

i 1 .Adjusting the presser foot movement amount

Movement

lifting presser foot

amount

for

Movement

vibrating presser foot

amount

for

Vibrating presser

move up and

Normally,

foot

motions.

• The maximum height

lifting presser

If changing the

presser foot and vibrating presser

use method

only one (thereby decreasing the

use method (8).

Method (A):

amount for both the

presser foot

1.

Loosen nut

2.

Move nut

(Raise the

decreasing motion.)

3.

Tighten the nut

down

vibrating presser

(::;'

operate to the same height

(A);

Simultaneous adjustment of the movement

'~J

nut

foot

alternately.

foot

(2;

movement

if increasing the

lifting presser foot and

(3).

up or

down

for increasing motion; or

and lifting presser

foot

of

vibrating presser

is 5.0

mm.

amounts

as

suitable to the work.

Q\

movement

and lifting presser

in

their vertical

foot

of

both the lifting

foot

simultaneously,

movement

amount for

of the other).

lower

vi

foot

and

brating

it for

(ZJ

4

Method (B): Adjustment

vibrating presser foot

1.

Loosen the vibrating presser bar

the presser bar lifter

2.

While holding the vibrating presser

bolt

1§.:

and then move the presser

as

necGssary.

3.

1-\ftt1r

4.

Tighten the vibrating presser bar screvv

-22-

of

the movement amount for the

screw

•J;ii.

foot

foot

the vibrating presser

@:,

and lower

G , loosen the

up or

down

foot

Page 28

8.

STANDAHD ADJUSTMENTS

8--1

Adjusting the timing of the vibrating presser foot

lifting presser

<When the needle lowers>

Feed

dog

<When

I l

I \

'-;-~~~~,

~~\

foot\--~

the

\ '-.._

\

needle

raises>

Needle

Check the vibrating presser

1.

Lower the presser bar lifter lever, then turn the pulley

At

toward you.

should reach the feed dog before the needle eye does.

2.

When the needle

presser foot

vibrating presser foot rises while

penetrating to the material, it may cause skipped

stitches, etc.

this time, tne vibrating presser foot

is

still holding the material firmly. If the

foot

timing

as

follows:

is

raised, make sure the vibrating

the needle

is

still

Feed

dog

If the timing is not correct

adjustments:

1.

Loosen the

2.

To synchronize the timing

turn the cam

3.

Tighten the

two

screws

C:Z).

screws():.

G_.

..

of

after

you make these

the vibrating presser foot,

-23-

Page 29

8. STANDARD ADJUSTMENTS

8·~

13, Adjusting the feed regulator

If the stitch length

same, make adjustment

1.

Remove the arm rear cover plate

2.

Turn the cover plate

holding upward the reverse lever.

3.

When the mark

rod

<5J

are

alignment, stitch length

will

be

same.

4.

Turn feed regulator rod 0 to the arrow

length

of

reverse is bigger and stitch length of forward

smoller.

5.

Turn feed regulator rod

length of reverse

bigger.

6.

After adjustment,tigthen the

of

forward

of

feed regulator.

\{;;),

of

feed regulator and feed regulator

(g)

is

smoller and stitch length

and

loosen the screw

of

to the arrow

screw

reverse

forward

·JJ.

and

"X"

"Y"

of

forward

are

not

with

reverse

, stitch

,stitch

is

is

-24-

Page 30

9.

SAFETY CLUCH MECHANISM

9.

with

If the thread is

stop the

flelease the

lovver shaft and lot the safcNV clutch

clutch

the rotary

mechanisrn

clutch mecl1anisrn

as

rnentionFJcl

below.

the

the rotary

hook

c1nd

opmatcs

to

off

the

Turn

the

povver

T!1o

machine may operate

power

is

switched

switch

off

before

as

a result the

if

the treadle is mistake, which could result

motor's

clutch rnechanisrn,

inertia.

Wait

until the

1.

Remove the thread, etc. entangled

NOTE:

2.

Slowly turn

button and the safety clutch mechanism returns

original position.

Do

not

hook,

the

The

motor

motor

v,;ill

stops fully before vvork.

in

injury.

with

the

use a

sharp-edged

as

doing so may damage the hook.

machine pulley

tool

while

to

pressing push

rotary hook.

clean the

to

the

Adjustment

If the safety clutch should

spring tension, use the following procedure:

1.

Depress

with

pulley

2.

Tilt back the machine head. Hold the safety clutch (left)

the

3.

To

screw

4.

Upon completion

At

safety clutch

the

your

strongly so that the

and turn the safety clutch (right) until you can see

screw

strengthen the tension

to the right, while

to

the same time, turn

-25-

of

spring tension

become

button in

left

hand.

0 through the hole

the left.

of

re-engages.

the

At

the

to

adjustment, depress

the

of

safety clutch

necessary

bed plate

same time, turn the machine

safety

clutch disengages.

of

spring turn the

lighten

the

tension, turn the

machine pulley until the

to

of

the machine

the

button

adjust

screw

Page 31

THREAD

LATE

13

2

-26-

Page 32

NO.

f--··

I B!9451 l FACE PLATE

']

4

,.

J

6

7 B8040 SCBE\'i' 9/M x 40 L"'8.0

8

9

!0

II

12

13

14

15

16

17

]"

0

19

20 B28206

21

22

23

24

25

26

27

28

29

30 B10690

31

32

33

34 BI80S5

35

36

37

38

39

40

41

42

43

44

45

46

47

-~

PAHT

'-----·~

BR09~

Bl0700

Kl052

B10551 I

nl9452

Bl5054

I

Bl0683

Bl95JO

Bl0759-A

Bl0760

B

1942 i C·--A

Bl9421

I

Bl951l

Bl079l

Bl9531

Bl9532

Bi9533

B!95l3

BI0793

Bl0678

Bl9422

B19512

Bl0689

Bl0694

BBI18319

Bl9534

B8100

B\9518

Bl5062

Bl9501

B18030-S 1 NEEDLE

B6031·-02

B18032C

B6034 I BED SLIDE SPRING

B6035 2 SCREW 3/32 x 56 L=2.7

B18495

B37254 2

B19455 1

B10703

Bl2384

Bl0709

B30046

NO.

~-

··-

l SCHEW 9/64 X 40

l P0:11Tl0\J PfN

l SCHE\V 9/64 x 40

OlLGUAHD

l

I

I

l

I

!

l

l

l

I TENSION

T.\KE~UP

TllHF\D

TIWEAD

I

I

SCHEW 9/61 x 40 L"'6.5

I

Tl!HEAD

THHEAD

I

TENSIO~~

LF:VEH CO\'EH

GUIDE: (UPPER)

GUIDE (MIDDLE)

GiJtDE (LOWEH)

GUIDE

BHACKET

BHACKET

I TENSION STUD

I TENSION

2

l

THHEADDISC

TENSION HELEASE WASHER

BHACKET

1 TENSION SPRING

l TENSION

l

TENSION

THUMB

THUMB

I TENSION RELEASE PLUNGEH

I TENSION HELEASE

2

]

I

I

1 SCHEW 3/32 x 56 L=6.0

1 TENSION

I

1 SCREW 9/64 x 40 L=6.5

J

I

1

1 TENSION RELEASE

2 SCHEW

1

1 EDGE

SCH.EW

THREAD

THH.EAD CONTROLLEH SPHING

THREAD

THHEAD

SCH.EW

THREAD

SCREW 11/64 x 40 L=8.5

BED

SCHEW M4 x 0.7 L=8.0

AH.M

9/64 X 40

CONTROLLEH STUD

CONTH.OLLEH DISC

THUMB

CO

NTH OLLER SPRING

11164

HETAINEB

PLATE

11164

SLIDE COMPLETE

GUIDE PLATE

CAP

1 WASHER

1 SCHEW 3/16 x 32

1

1

SPOOL PIN SCHEW 7/32 x 32

EARTH

WIRE

PARTS

L:o:4.5

FELT

COMPLETE

PIN

NUT

STOPPER

NUT

LEVER

NUT

STOP

x 40

Loo=l4.0

LEVEH

ROD

x 40 b::8.5

SCREW M4 x 0.7 L=4.0

NA:vtE

-----~-----~

'

-

-27-

Page 33

-28-

Page 34

ARM SHAFT, THREAD

TAKE~-U

R

NO.

1 B8009

2

PAHT

Bl0724

NO.

.Qty

l SCREW 15/64 x

I

OILING

3 B 18003C I TIJHEAD

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22 B18486 l

23

24 B18008

25

26

27

28

29

30

31

32 B19528C I

33

34 BJ7041

35

36

37

38

39 BJ7015C

40

41

42

43

44

45

46

47 B19505

1310527

Bl8003

I\!0528

Bl5026

BI0728

Bl9504

BI0724

fll0726

B10523 l NEEDLE

B19418

B19417 l SCREW

Bl9414

Bl9416

B19415

Bl0563

Bl8006

BI7R6

BI0725

B19508

BI0579

Bl0725

Bl9508

B23637

Bl9503-A

BI9503-B

BI9503-·C

Bl9521

B!0827

B23637

B10723

Bl70l7C

1317018

Bl7019

l

1

I

1

l i OILING

l

I

I

1

1

j

TAKE-UP

THREAD

NEEDLE

TAKE-UP

I

OIL

PACKING

OILING

OILING

scrmw

NEEDLE

I SET SCREW

1

1

I

POSITION SCREW

WASHER

ARM

I SCREW 15/64 x 28 L=12.0

I

2

1

j

l

l

2

I

I

l

I FEED

2 SCREW 1/4 x 40 L"'7.5

2

l

1 OILING

1

OILING

LIFTING

SCREW

AHM

SCHEW 15/64 x

OILING

ARM

SCHEW

AHM

AHM

ARM

FEED

SCHEW 1/4 x 28 L=7.5

OILING

AHM

I POSITION SCREW

l SET SCREW 1/4 x 40 L:::7.5

I GEAH COVEH COMPLETE (UPPEH)

BJ7016

Bl7013

Bl0579

Bl3081

Bl8470

Bl0576

Bl0579

2 SET SCHEW 9/64 x 40

l

AHM

1 SCREW 15/64 x 28 L=20.0

1

I

1

OILING

BALANCE

POSITION SCHEW 15/64 x

I SET SCREW 15/64 x 28 L=20.0

1 SCHEW 3/32 x 28

PAHTS

NAME

28

L=

7.5

WICK

TAKE-UP

LEVEH

TAKE-UP

BAH

LEVEH

WICK

\VICK

WICK

BAH

1/4 x

114 x 28

BAR

SHAFT

FELT

ECCENTRIC

114

x 40

SHAFT BUSHING (MIDDLE)

FELT

SHAFT BUSHING COLLAR

l/4

x 28 L=7.5

SHAFT (STANDAHD

SHAFT

SHAFT

LIFTING

DHIVING

FELT

FELT

SHAFT GEAH (SPIHAL) COMPLETE

SHAFT

FELT

WHEEL

LEVER

HINGED

LEVEH

CONNECTING

DRIVING

STOP

CONNECTING

28

L=4.5

L=6.5

CRANK

114

x 28

l/4 x 28

BUSHING (FRONT)

L:~5.5

28

L=20.0

(lR"

MACHINE)

MACHINE)

(25

"

CAM

ECCENTHIC COMPLETE

HETAINEH

114

BUSHING (REAR)

L=

11.0

COMPLETE

STUD

LINK

STUD

SCREW 5/16 X 28 L=6.0

LINK

L=l4.0

L=20.0

MACHINE)

x 40 L=8.0

L=

10.0

28

L=21.0

STUD

.:..

29-

Page 35

NEED

BAR ROCK FRAM

-30-

Page 36

,N

NO.

I

1

3

4

5

6

7

H

9 i

lO

11

12

13

14

15

16

17

18

19

PART

BI0557

B19509 l

Bl0556 l PI\ESSEH

Bl072R l

Bl0728

I

Bi95l7

l l

"'_,,

J.(u)y·

BHYc

I

.\Yy

Jn47U

BI9412C

Bl7104 1

Bl9515 I

Bl9516 I

Bl9514 I

Bl0514

B19420

Bl9419 I

Bl0775

B12136 I

NO.

. ;\

..

1

I

20 B10774

21

22

23

24

25

Bl7114

Bl8485

B37215 l

Bl704l

Bl00446

26 B34712 l

27

28

29

B1761l

B37134

Bl9426

30 Bl9429

31

32

33

B34723 I

B37134

B30078

34 Bl9413

35

B6035

36 RB140553

37 Bl0533

38

39

40

41

BNOI22

Bl

1876C

lll

1877

Bll876

42 Bl0581

43

Bl7048-A

B17048-B

Bl7048-C

44

45

46

B6026-02

Bl9409

Bl8017

47 BI80J8

48

49

50

51

Bl9408

B34722

B34721

B8100

52 Bl0728

Qty

l

I

i

i

!

l

2 LIFTING

l

l HINGE SCREW 7/32 x

LIFTING

LlFTlNC BELL C!L\i\K

OILING

I

~,~~:

l.:'l\AtE

VJ

1

F!U·.s:;F:l{

YfBlL\TlNG

VlBH

PINCH

HINGE

NUT

LIFTING

BELL

CRANK

BAH

CO\\;E(~TINC

\VICK

1

~~

;~~~~

.J/,

TL\r·

l

BAH

.,.,

0 X ,_o

l'H'•'''"FH

\y

L,5J

EXTENSION

Led

'W;

.L

\\

>t,\.

PHESSEH

-\TfNG

PHESSEH

SCREW

SCREW

11/64 x 40 L"'6.0

1/4 x

114 x 28

ROCK

SHAFT

ROCK

SHAFT

PINCH SCREW 1/4 x 28 L=l6.0

CONNECTING

CRANK

WASHER

1

1 NUT7/32 x 32

1 LIFTING

CONNECTING

ECCENTRIC

COLLAR

WASHER

I

I

l NEEDLE

!

I NEEDLE

1

2

2

l

1

1

l

I

1

1

I

l

I

I

1

1 NUT9/32 x

I

I

I HINGE

I

I

I

2

I

OILING

SCREW 15/64 x

HINGE

PINCH

OILING

POSITION

SCHEW

FELT

STUD

BAR

SCREW

BAH

WICK

BHACKET

M4

x 0.7

28

ROOK

M4

CONNECTING

L=

WASHEH

NEEDLE

BAR

SCREW 3/32 x 56 L=2.7

SCHEW

NEEDLE

NEEDLE

SLIDE

SLIDE

HINGE

SCREW

ARM

ARM

ARM

1/8

x 40

BAH

THREAD

DP x 17

BLOCK

COMPLETE

BLOCK

SCREW

7/32 x

7/32 x 32 L=7.0

SHAFT

(STANDARD

SHAFT

(18"

SHAFT

(25 " MACHINE)

L=4.5

#22

28

CONNECTION

CONNECTION

PINCH

VIBRATING

VIBRATING

SCREW

OILING

SCREW

SCHEW

PRESSER

PRESSER

9/64 x 40

WICK

ROD

9/32 x

1/4 x

L=6.5

Ui\K

6.0

B'

P '•'XTE'''""0·'

I

1\..

_\.

L..c

BAR

FOOT

28

BUSHING

32

CONNECTION

L=8.8

FHAME

x 0.7

L=lO.O

10.0

GUIDE

32

MACHINE)

MACHINE)

28

28

L=-17.5

BAR

BLOCK

BAR

BLOCK

PARTS

NAME

LE\K

.....

~,...._)l_

SPHlNG

COi\lPLF:TE

STUD

GUIDE

1

.!_'\

-31-

Page 37

PRESS R BAR,LIFTING PRESS R FOOT

((?~/

I

36

37

/34

32

7\

8

\

~&

\

33

16

-32-

Page 38

RESS

BAR, LIFTING

PR

RFOOT

NO.

I

I B8043

2

3 B9406

4

5

6 B8478

7 B9518 i

8

9 B8479 1 PRESSER

10

11

12

13

14

15

16

17

I8

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

PART

B6729

B0538 1

B5999 1

B4828 1

B0547

B0546-A I

B0659

B9405 I

B8085 2

B8477 I

B0796

B8483

B9403

B18080-A I

Bl8080-B I

B18080-C I

B0548-A

B9408 I

B5111

NO.

Qty

I

I PnESSEH

2

SCREW

SCHEW

PHESSEH

SCHEW

1

PHESSEH

PINCH

SCREW

SCREW

1

SPRING

'f!i:NSION

1 PRESSER BAll LJFTEll

HINGE

SCHEW

SCREW

PRESSER

l

I

1

1

I

LIFTING

SCREW

HINGE

SCREW

ARM

SHAFT

ARM

SHAFT

ARM

SHAFT

BRACKET

PINCH

SCREW

PIN

B6026 I PRESSER

B9519 I

B9404 I

B384

B359-A l

B360

B808! I

B8862

B0539-A l

B4717

B4718

B4719

B6287

B0601

·2

134720

1

2 NUT3/16x

I

l

l

l

2

2

PRESSER

PH.ESSER

HINGE

SCHEW

LIFTING

LIFTING

KNEE

LIFTEH

PHESSEH

LIFTING

LIFTING

LIFTING

WASIIEH

SCHE\\T

SCHEW

M6

xI

L=IO.O

BAH

POSITION

15/64 x 18

BAH

M6

BAH

BUSHING

x 1

L=6.0

POSITION

L=1

11/64 x 40

1 lt64 x

40

BAR

LIFTING

HELEASE

SLIDE

3116 x 32

11/64

x 40

L=8.5

BAH

PHESSEH

FOOT

9/64 x 40 L=9.0

114 x 28

(STANDARD

MACHINE)

(18

"

MACHINE)

(25

"

GUIDE

BLOCK

1/4 x 28

BAR

SPRING

BAH

SPRING

BAR

SPHING

15/64 x 28

LEVEn

CONNECTING

32

LEVER

BELL

BELL

BELL

M5

M6

BAH

x 0.8

x l

BELL

BUSHING

CHANK

CHANK

CHANK

L=12.0

CONNECTING

CRANK

bc!O.O

PARTS

GUIDE

1.0

(UPPEH)

GUIDE

BHACKET

1=:14.0

BRACKET

MACHINE)

L=l7.5

REGULATING

SUI'POHT

SCHEW

ROD

HOD

COMPLETE

(LOWER)

GUIDE

COLLAR

GUIDE

BLOCK

CUIDE

PLATE

NAME

SCREW

JOINT

1/4

1/4 x 28

x 28

-

~

,

-33-

'

-·"""

-

'

Page 39

MECHANISM

-34-

Page 40

NO.

~---~--

MECHANISM

PART

1

B8523

2 B009 1

3 B8065 2

4 B8694

5

6

7

B8696

Bl094 1

Bl8061-A 1

B18061-B

Bl8061-C

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

138702

B009 1

B9526 1

B9535 1

139529

B9530 1

B0230 1

B8031

139525

B8122

138121

B211

B8014

137207

Bl05

139527

138015

13105

131021

27 B7095 1

28

29

138539

B8540

30 B0599 1

31

32

33

34

35

36

Bl412

B8490 1

B8489

B009 1 SCREW 15/64 x

B8492

130066

37 B8488

38

39

B8489

B009

40 B802l

41

B7041

42 B0723

43

B8493

44 B8018

45

46

47

48

Bl05

B8065

B849l

139508

NO.

~---·~~

--·~~~~

Qty

f.--

FEED

1

ROCK

SCREW 15/64 x

PINCH SCREW

FEED

FEED

"E"

AflM

SHAFT

ARM

SHAl•T

AHM

SHAFT

FEED

SCHEW

FEED

FEED

SLIDE

ROCK

BASE

RING

HOCK

15/64 x

BASE

BAR

SLIDE

BLOCK

I

I

1

l

1

1

WASHER

SCREW 3/10 x

FEED

1

2

1

1

2

1

1 FEED

1

1

1

1

1

1

I

DOG

SCREW 1/8 x 40 L=6.0

FEED

FOHKED

HINGE

SCREW

NUT

l\13 X 0.5(SMALL)

SCHEW

HINGE

CONNECTING

NUT9/32 x

FEED

28

ROCK

HINGE SCREW 9/32 x

NUT9/32

PINCH

"E"

HJNGE

x28

SCHEW

lUNG

SCREW

WASHER

WASHER

1

NUTM6x 1

RETAINING

1

1

1 PINCH

l

1

1

1

1 OIUNGFELT

1

1

1

I

1

1

2

FEED LIFTING

FEED LIFTING

SCHEW

FEED LIFTING

FEED LIFTING

SCHEW

CHANK

15/64 x

CONNECTING

RETAINEB

FEED LIFTING

HINGE

SCHEW

NUT9/32 x 28

PINCH

SCHEW

LLVriNG

SCREW

SHAFT

1/4 x 40 L=5.5

SHAFT BUSHING

28

L=7.5

M5

x 0.8 L=d4.0

SHAFT

BASE

SUPPORTING PIN

(STANDAHD

(18

II

(25

11

SHAFT

28

MACHINE)

MACHINE)

MACHINE)

BUSHING

L=7.5

BLOCK

PIN

32

L=5.0

CONNECTION

M3

x 0.5

9/32 x 28

LINK

SHAFT

CRANK

(BACK)

28

M6

x 1 L=18.0

M6

x 1

lUNG

ROCK

SHAFT BUSHING(FHONT)

28

L=7.5

CRANK

M5

HOCK

BOCK

(FRONT)

x 0.8 L=12.0

SHAFT

SHAFT BUSHING

28

L=7.5

HOD

CH.ANK(BACK)

9/32 x

28

M5

x 0.8 L=l4.0

COLLAR

PARTS

(FHONT)

(BACK)

NAME

(BACK)

'

--~----~---~-~~--~-~--

I

-

-35-

Page 41

12-~~

11

14

NO.

1

2

3

4

5

6

7

8

9

10

Jl

12

13

14

15

16

17

!8

19

20

21

22

23

24

25

26

27

28

29

30

31

PART

1319542C

1319542

1319524

1337134

Bl7209

138105

1318506

B18721C

1318507

1318515

1318516

137033

1318574

1319544

1310845

1319546

1318494

1317057

131392

Bl9552

1330066

1350174

1319523

B18496

1313142746

1319!522

1313145502

1313100328

1318420

1319543

1337509

NO.

Qty

FEED

1

1

1

1

1

1 NUT9/32x

1 REVEHSE LEVEH SHAFT

1

1

1

1 SPRING RETAINER

1

1

1 REVERSE LEVER

1

1

1

1 WASHER

1 SCREW 11/64 x 40

1

4

2

1 FEED

1

1

1

1

1

I ORING

1

2

HEGULATOH

FEED

REGULATOH

HEGULATOR

FEED

PINCH

SCHEW

REGULATOR

FEED

REVEHSE

SCHEW

REVERSE

SCREW 9/64 x 40 L=10.8

REVERSE LEVER SHAFT

PINCH

FEED

FEED

SCHEW

SCHEW

POSITION

FEED

WASHER

SCREW

PIN

SPRING

ARM

SCREW

28

BLOCK

15/64 x 28

LEVEH

SCREW

HEGULATING

HEGULATING

11164 x 28

M5

PIN

REGULATING

HEGULATING

3/16 x 32 L=20.0

SIDE

COVER

MS

COMPLETE

HOD

M4

x 0.7 L=10.0

SCHEW

COMPLETE

SPHING

15/64 x 28 1.=18.0

BASE

SUPPOHT

L-=6.5

L=

x 0.8 L=12.0

SCREW

DIAL

x 0.8 L=6.0

11.5

PARTS NAME

9/32 x

CRANK

STUD

---~---

28

-36-

Page 42

ARM SHAFT(UPRIGHT),LOWER SHAFT

51

16

/til

54

-37-

Page 43

NO.

1

2

1

·'

4A

4B

5

/

0

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

PAHT

Bl8096

Bl8034

Bi8033C 1

Bl8033-07

Bl8033-08

]}18035

B6025 1

B18090

B8009

Bll069

Bl8044

B8009 2

Bl8351

B0148-B

BJ8089

Bl8039

Bl8040

BI8041

Bl8042

B8009

B18043

B30066 1

B18053

B18054 1

810674

1318052

NO.

I

26 B19508

27

2R

29

30

31

32

33

B1R038-A 1 HOOK SHAFT BUSHING (HEAR)

B8009

B18047

Bl7019

Bll\056

Bll\046

BIROS!

34 Bl804R

35

36

37

38

Bl8049

Bl8050

Bl7019

B18057-A

Bl8057-B

Bl8057-C

39 B8009

40

41

42

Bl7028C

Bl7022

B17023C

43 B17022

44

45

B17026 1

B10579 1

46 B19553

47

Bl7020

48 B17026

49

50

51

52

Bl0579

B19554

Bl7021C

Bl7022

53 B30750 1

54

55

Bl8058C

B18059 1 PINCH SCREW 15/64 x 28 L=26

Qty PARTS NAME

1 BOBBIN CASE COMPLETE

l BOBBIN

HOTATING BOOK COMPLETE

1 POSITION SCHEW 11/84 x

1

SET SCilEW 11/64 x

40

40

L=7.3

L=8.9

1 IIOOK SUPPORTING PLATE

SCREW 1!164 x

1

HOOK SHAFT BUSHING (F'lWNT)

40

L=l2.0

1 SCREW 15/64 x 28 L=7.5

1 OlLlNG FELT

1 HOOK SHAFT

SCH.E\V

1 \VASHEFt

1

1

1 THHEAD m:LEASING FINGER

1 SCHEW

01UNG

HOOK DRIVING

C:\:V!

1~:18·1

28 L=7.5

F.Er:I'

Sll!UT

M5

x 0.8 L=8.0

1 THHEA!l HELEASING SHAFT

1 THHEAD RELEASING SHAFT BUSHING

1 SCHEW 15/64 x 28 L=7.5

1 THHEAD HELEASING SHAFT FOHK

PINCH SCHEW

1 PUSH

PUSH

1 CLIP

BUTfON

BUTrON

M5

x 0.8 L=12.0

SPHING

1 HOOK SHAFT LOCK RATCHET

2 SCHEW 1/4 x

1

1 SAFETY CLUTCH (LEFT)

SCHEW 15/64 x 28 L=7.5

3 SCHEW 1/4 x

1

1 OILING WICK

1

1

1 STEEL BALL

1 SPHING

3

1 ARM

1

1 ARM SHAFT (25

2

1

LOWEHSHAFT

scrmw

SAFETY CLUTCH (HIGHT)

SCHEW

SHAH

AHM

SHAFT (18

SCREW 15/64 x 28 L'"7.5

LOWER SHAFT GEAR (SPIHAL) COMPLETE

2 SET SCREW 1/4 x

1

ARM SHAFT (UPHIGHT) GEAH (LOWEll) (SPIHAL) COMPLE

2 SET SCHEW 1/4 x

40

L=5.0

40

L=7.5

9/32 x 28

1/4 x

40

L=7.5

(STANDAHD MACHINE)

11

MACHINE)

11

MACHINE)

40

L=5.0

40

L=5.0

OILING FELT

SET

SCHEW 15/64 x 28 L=20.0

AHM

1

SHAFT (UPHIGHT) BUSHING (LOWEH)

1 ARM SHAFT (UPRIGHT)

1 OILING FELT

1

1

1

2

SCREW 15/64 x

ARM

SHAFT (UPIUGHT) BUSHING (UPPEH)

AHM

SHAFT (UPHIGHT) GEAH (SPIHAL) COMPLETE

SET

SCREW 1/4 x

2R

L=20.0

40

L=5.0

BAND

1 GEAH COVER (LOWER) (SPIRAL) COMPLETE

bc~·,•c.

"'"-"'--

-

--38-

~-

Page 44

LUBRICATION

I

I

G

18

16'----g l

17--Q

20

NO.

I

2

3

4

5

6

7

8

9

10

11

12

13

1·1

15

Ho

l7

18

19

20

21

22

n

24

25

26

27

28

29

30

31

32

33

B20!7l

B-~

12

t

B30022

ll3!206

1318112

Bll069

1318110

1311069

B2017l

Bl8ll3

Bl8l09

Bl8111

B18l04

1319106

Bll044

B2017!

Ill 1069

B200ri7

Blill08

Bl\069

BI8100

Bl8Hll

B18094

n

18093

1321104

Bl8095

134137

B

18_'15-l

1319545

Bl8353

1115007

1318092

1318091

PAl{'!'

NO.

--

x 0.7

PAHTS NAME

L=

!6.0

Qly

l

I

l

1

I

I

1

1

1

1

1

1

1

1

!

1

I

l

I

l

1

1

I

I

1

1

1

1

1

1

1

4

1

1

IWBBERPLUG

SCHEW

M4

TUBE

TUBE

TUBE

x 0.7 L=9.5

WICK

160Mi\l

FELT

WICK

FELT

35MM

WICK

75MM

OILING

NUT

OfL

OILING

OILING

OILING

HUBBEHPLUG

OIL

OILING

OIL

FEU

OIL

m:srmvom

SCHLW

i/8 x 40 L=7.0

nt'BBEH PLL;c

.1-u;r

OP

I

IWBBEil

OiLING

OILING

OILTUBI·:

O[L!NC

OIL

OIL

SCREW

HEGULA

NUT

OIL

OIL

OIL HESERVOIR

SCHEW

OIL

SCREW

PLUG

WICK

FELT

80:111\1

WiCK

CONTlWLLEH

COSrROLLEH PLATE

\l/64

Tli\IG

M-tx0.7

HESERVOIR

H.ESEHVOIR

9/64 x 40 L=10.0

PACKING

ll/64

CLAMP

380Mll!

2201\Il\1

IOO~L\l

180m!

x 40

L~7.5

SCREW

M4

GASKET

PLATE

WINDOW

x 40

-39-

Page 45

ACC

SORIES

7

5

/\~

1111~1

17 18 19

~

II

~

i

22 23

25

rm

26

~

20

~

~

I

1

24

21

i i i

9

27

15

-40-

Page 46

ACCESSORIES

NO.

f--

1

2

3 B8123

PART

B8132-B

B6057

NO.

~

Qty

1 ACCESSORIES

1

1

4 B18034 6

5

6

7

8

9

10 B6054-A

BN0122 3 NEEDLE

Bl0734

B35254

Bl9464

Bl9464-14

B6054-B

1

1 SPOOL

1

4

1

1

B6054-C 1

11

12

13

14

1.5

16

17

18

19

136055

Bll866

Bl1885

136055

B 11887

!36055

B19456 1 \\'HENCH 2.0

Bl9457

Bl9458 1

4

2

2

4

4

4 Ni\lL

1

20 B19459 1 WRENCH 4.0

21

B19460

1

22 B19466 1

23 B19467

24

25

Bl9468

Bl9462

I

1 SCREW

l

26 Bl9461 1 SPANNER 6 x 7

27

138180

l SCREW

BAG

VINYL

COVER

OIL

BOBBIN

BOBBIN

DP x 17

WINDER COMPLETE

PIN

#22

COMPLETE

KNEE LIFTEH COMPLETE

SCREW

ARM

SHAFT

(STANDARD

Al\lVI

SHAFT

i\HM SHAVr

(18"

(25"

MACHJNE)

MACHINE)

NAIL

BED

I!INGE

BUBBEH

BED

HINGE

CONNECTION

NAIL

RUBBER

MM

WHENCH

WHENCH

2.5

3.0

l\1M

MM

MM

WHENCH

SCHEW

5.0

MM

DHIVER(LAHCE)

SCREW DBJVEH(MlDDLE)

DIUVER(SMALL)

DOUBLE

IlEAD WRENCH

MM

DIUVEH(+)

PARTS

MACHINE)

NAME

-41-

Page 47

A VAl

CHARG

1

14

I

v

12

13-

· 1

·--~

·r--~-14

13

3

v-.

·~~

6i---.

\,

•-(])

\

5

·-42-

~18

Page 48

PARTS AVAILABLE AT EXTRA CHARG

NO.

1 Bl5098C 1

PART

NO.

2 Bl5099

3 B15098 1

4 B8100 2

5 812418

6 88100 1

7 811142 1

8 B17372

9

10

11

12

13

14

15

16

17

18

19