Page 1

er

•

DARNING &

MENDING MCH.

INSTRUCTION

PARTS

THE

CLASSES:

140,

BOOK

FOLLOWING

136,

144,

146,

&

FOR

138,

671.

•

'

f

I

'

chandter

ayer,

u.s.a.

tel:

mass.

61

7-77

machine

0

143

2-3393

co.

2

Page 2

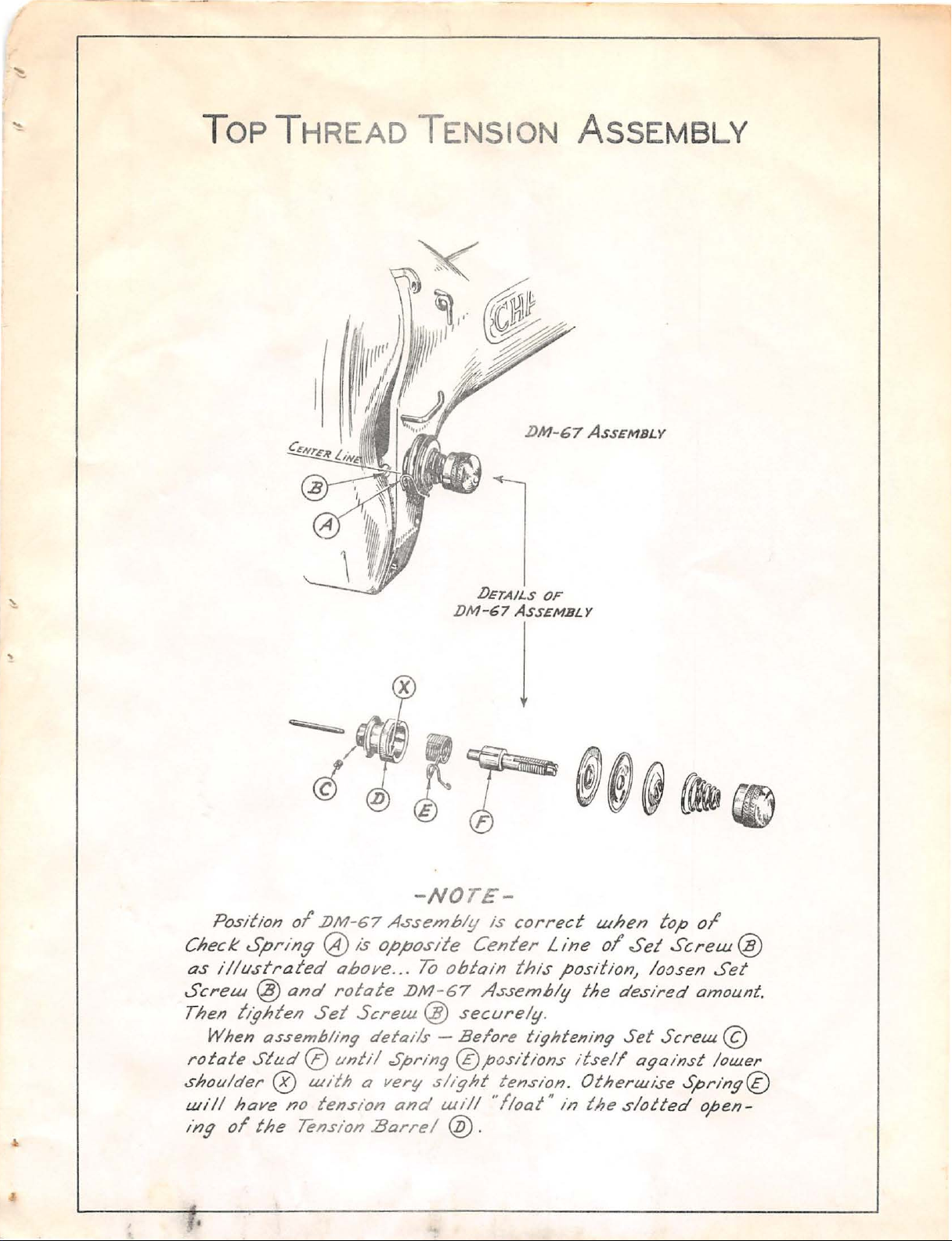

TOP TH

READ

TENSIO

N

ASS

EMBLY

lJETAILS

IJ

M-67

t

r@~

IJM-67

OF

AssEMBLY

1

AssEMBLY

@~

~

-N

OTE-

Position of

Check

as

Screw

Then

rotate Stud

shoulde

will ha

t"ng

Spr

illllstrate

@

lighten

When as

r @ u

Ye

of

the

.lJM

-67

ing 0

and rotate

semhling

0 u

no

Tens

d

Set

nlh

ten

/s

abol/e

Scre

deta

ntil

a ver(l

sion

ion

.Ba

A.ssemb

opposite

...

.l)M-67

w@

ils

Spring @JJ

and ULi!l ,.

rrel

l!f

To

o

btain this position)

securely .

- Be fore t igh

sli

ght tension.

@ .

is

Ce

nter

Asse

os;fions

float"

cor

m61!f

rect

Line

ten

in

when

of

the

ing

itself against

Otherwise

the

fop

Set

Screw@

loosen

desired

Set

ScreUL@

slotted

Spring({)

of'

Set

amount.

lower

open-

Page 3

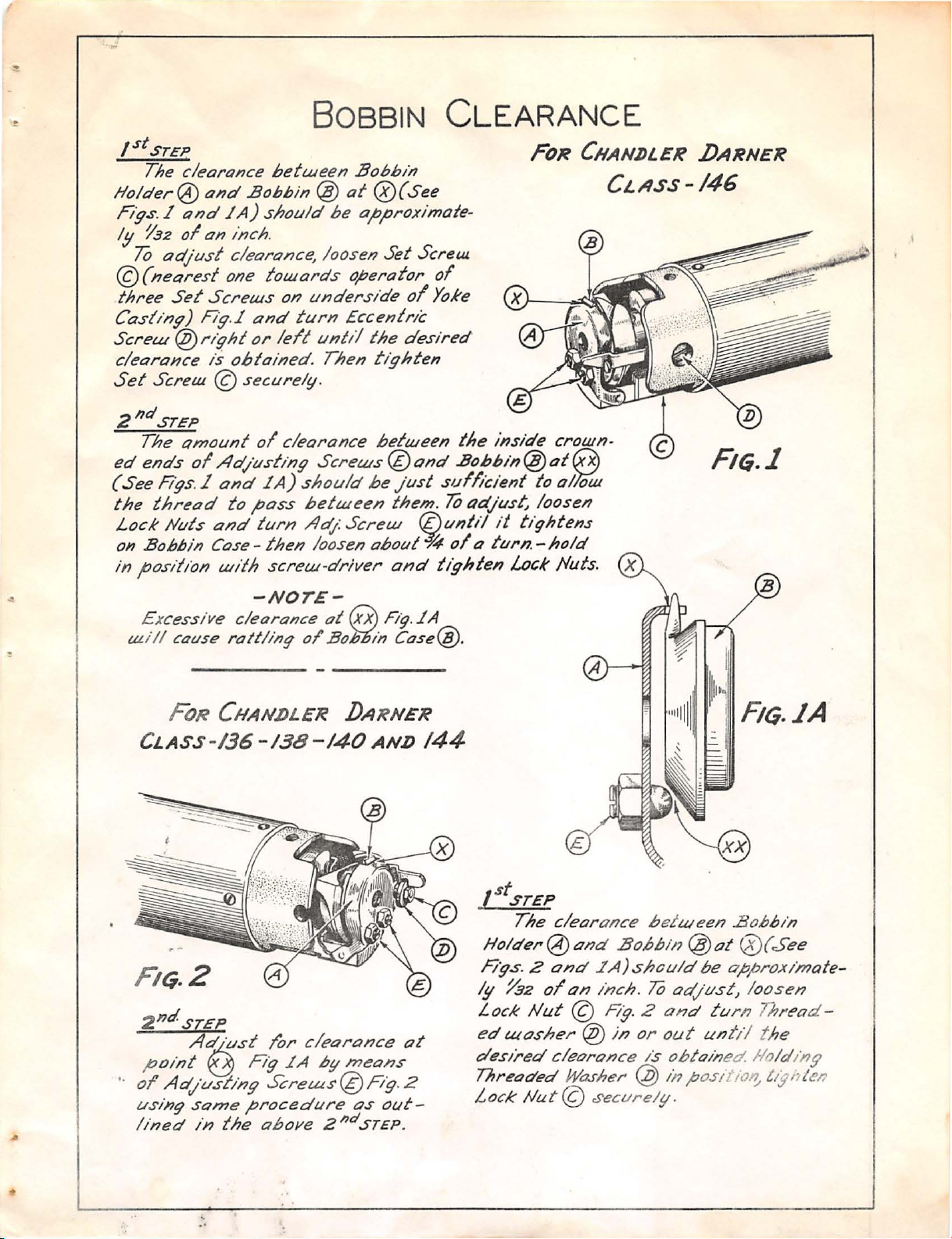

/st

STEP

The clearance

flolder@

Fig.s.l

ly

13z

To

©

(nee~rest

three

Caslin5')

Screw

cleare~nce

Set

Screw

1

2

":1

STEP

The

ed

ends

(See

Figs.l

the

thread

Lock

on Bohhin

in

posd/on

and

and

ol

an

adjust

Set

Screws

Fig.l

@right

is

amount

of

Nuts

.Bohhin@

.1

A)

inch.

clearonc~

one

e~nd

or

ootained.

©secure/~.

of

Ad.;usling

and

lA)

to

pass

and

turn

Case-

with

-Nor£-

Ex

(.Lt.

/

cessive

II

cause

clearance

ratt

ling

BOBBIN CLEARANCE

oetween

should

towards

on

turn

!ell

clearance

s

hetween

Ad,;:

then

screw-driver

of

.Bobbin

of

be

approximate-

loosen

operator

understde

£ccenlrtc

unttl

Then

Screws

hould

Screw

loosen

at

(xX)

.Bo'btftn

(g){See

Set

Screw.

ol

the

desired

tighten

oetween

@and

he just

them.

©unit/

ahout

and

Fig . .1

Case@.

FoR

of

Yoke

t11e

instde

.Bohhin@atCXXJ

s1..1llicient

To

adjus~

~

o/ a turn.-hold

tighten

A

it

fi9htens

LocJ:

to

loosen

CHAN.DLE~

.DARNER

CLASS-/46

crown-

AG.l

ol'lo:u

Nuts.

B

FoR

CLASS-/36

---=.

FI

G.2

11

2

dSTEP

A14;sf

p

oint

'·

of

AdJus"ting

vsin

q SClme

lined

/n

CHANIJLE~

-13

8-

!Or

1(1

Fig

LA

Scre~s@Fig

procedure

the

a6ore

./)A

140

AND

clee~rance

bf!

means

as

11

2

dSTEP

~N

.

out-

£~

/44

at

2

.

/sf

STEP

The

flolder@an

Figs. 2

/3z

l!f

Lock

ed

desired

Threaded

Lock

of

Nut

washer@

Nut@

£

clear

ance

d

..Bo,Obin @at

and

..!A)

an

inch.

©

Fig.

in

clearance

Washer @

cSecurelf!·

between

should

To

acl

2

and

or ot.d

is

obt

in

.Bohhin

@(..-

be

appro.ximate-

,/u

stj loosen

turn lh

tLnl

;/ the

aine

d.

p os

/l

/O.J'l./

See

rea

I/o/din

t

ignler,

d -

g

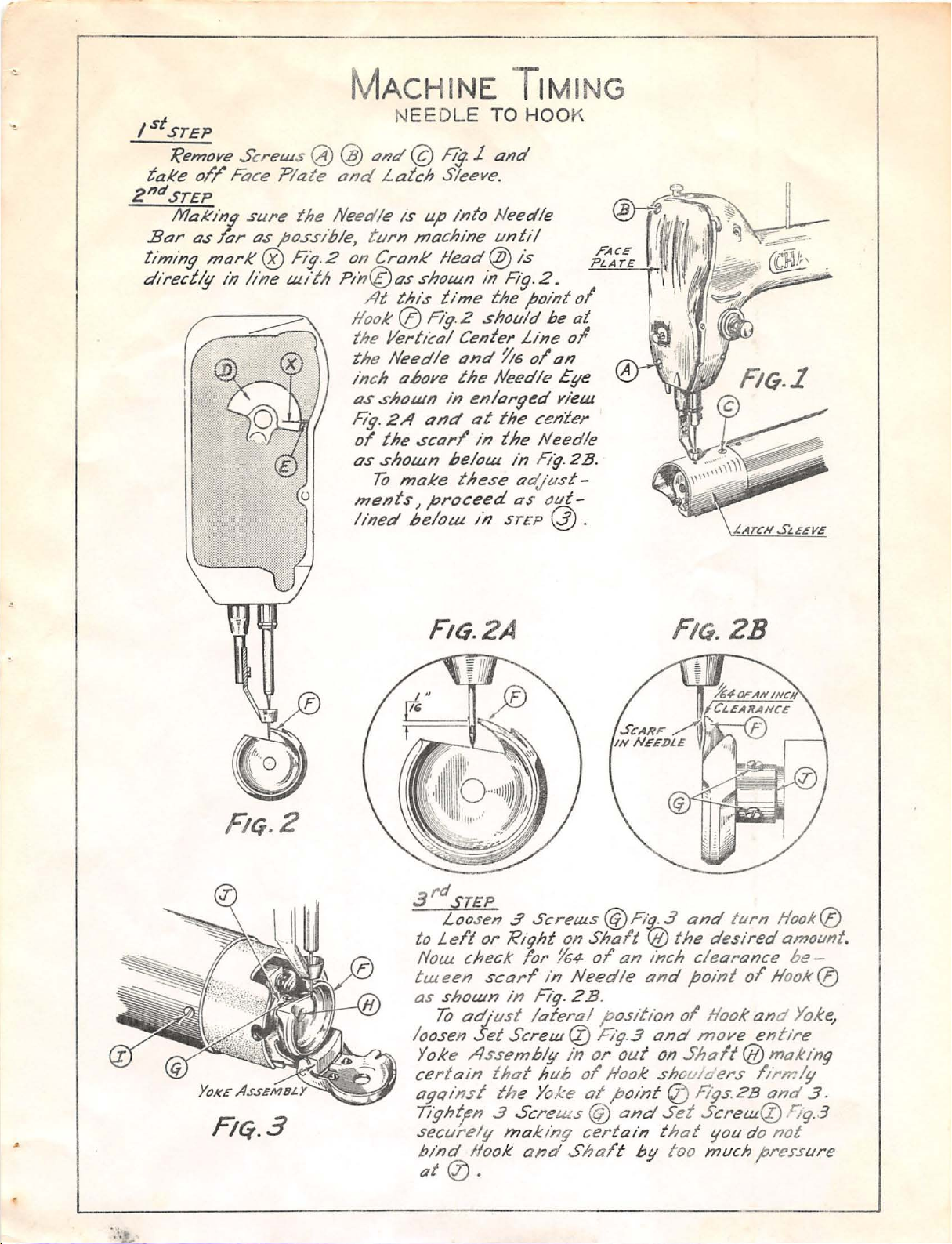

Page 4

/st

STEP

Remove

take

ol'/

zn"sr£P

Makinfl.sure

Bar

a.s

timing

directlg

marK

Screws

Face

l'ar a.s

® Fig. 2

in

line

M ACH INE T IMING

@ @

Plate

possible,

tt.Lith Pin@

the

and

Needle

on Crank

!look 0

the

the Needle

in

as

Fig.

ol

as

ments

lined

N

EEDLE

and@

Latch

turn machine until

At

Fig

Sleeve

is up into N

f/ead@

as

shou.tn in Fig.

this

time

Fig.

J/ert/col Center

ch a.6oYe

shomn

2A

t~nd

the

.scar/

shown

To

make

"'

~roceed

beloLLL

TO

1

and

.

eedle

is

the

2

shou

and

1/

6

the

Needle £!/e

in

enlar~ed

at

the

in

the Need

befoUL

these adjust-

in

in

as out -

STE

HOO

2.

point

ld

he

Line

ol

an

vietJJ

center

Fig. 213.

P @ .

K

ol

at

ol

le

Flc;.2

.3rd

STE

P

Loosen 3

to

Left

or

Now

check

tll.l.

een

as

shown

To

adjust latera

lo

osen Set

Yoke As.seml;/!1

certain

against

Ti"gh'fn

secure/!/

hind

at

1/ook and Sha

0.

Sc

Right

for

scarf

in

Fig.

Scre

that

hul;

the Yoke

.3

Sc

reu.ts@

ma

kin9

ret.Us

on

JIG4

in

w 0

in

FIG.

@Ftg_.

Shalt

of'

Need

2 B .

l p

ostfion

Fig.3

or

of

!look shvt./laers lirrr.l!f

af

poin

cert

l"t h!f

3

{jj)

the

an

inch

le

and

ol

and

out

on

t 0 Figs.2B

and Set S

ain that

too

2B

and

turn

desired

clearance

point

Hook an

move entire

Shalt@

crew

~ou

much

Hool<(l)

amount.

be-

of Hook®

d

Yok~

making

an

d

3.

0 0q.3

do

not

pressu

re

Page 5

DAR

NING 8 MEND

CH

AIIIX..~AC,HINE

WHEN

ORO~""'

COMP

UNITS

ON

THIS PAGE ONL

..., ...

LET

u

ING

ANY

OF

E

' R£F£R TO

Y.

MACHINE

CO.

THE

SE

NUMBER

2 DLS-3

2 DL

8-5

2 DL

8-6

2

DL8

- 7

2

DL8

-4

2 DL

8-8

Page 6

DARNING 8 MENDING

T

op

>fA-

Arm

MActt

NE

CHANDLER

MACHIN

CO

E

'-

543-1013

~~

2DL3-52

"-

2DL6-

93

2DL3-

51

r

L.A''e:r

----

--

---

----

-

---

- 2

5

43-1

2DL32DL

DL5

2 DLG-

6 -

008

15

67

-172

92

Page 7

.

~

,

..

~

...

D

ARNING

8 ME

Mi

ddle 8 Bottom Bose

CHANOI.ER I<AcitHE

-'-

NDING

MACHINE

CO

..•

··

...

•.,

.

,-·~

.......

.

~.

:·l,

......

..

'•'

···-~.

...

••

I

!

t-. , ...

2DLG-10

:

7

•

'I

0

.:

} j I

:'

f:i

t/

r

•:

I •

''

-...

.....

-

Page 8

2DLNI-J

2DLN3-I

DARNING

2

DLNI-4

543-1015

2DLN3-2

2DLI

-I

2DLI-4

8 M

ENDING

Long Nose Darner

CHANDLER

-----------

MACH

~

..............................

MACHINE

INE CO.

__

~

-

2DL

1-2

2DLN3-3

2DL3-I

2DL5-7

543-1237

~

2DLN5-I

2DLNI-5

2

DLN

1-2 2DL6-95 2DL

2DLNI-3

2DLI-3

1-2

Page 9

..

DARN

ING

Flat Work

8

MENDING

Plate

CHANDLER

MACH

8(p.t_

2DL7-160

MACHINE

Assembly

INE

CO.

2DL6-87

' .

WHEN

ORDERING

REFER TO

THIS UNIT COMPLETE

IT

AS 2

\ .

DL 8 -I

~·

..

,.,.

PG-2101

Page 10

DARNING a MENDING

MACHIN

Bobbin Winder a Motor Ass

CHAN

DLER MACHINE CO.

~

WHEN

REFER

ORDERING

TO

IT

AS

THIS

2

UNIT

DL

COMPLETE

8-2

E

embly

3N

G-3000

2

DLG-1

56

2DL7-136

2DL6-

157

2DLG-185

2DLI-8

2DL3-178

.

l

. .

,·

..

Page 11

;

1

MODEL 217-25

ZIG-ZAG

Now

This

workmanship.

LEATHERWORK:

Th

e excellent results obtained

also extend

leather

oilskin, foam rubbe

from cotton

and

designed roller

ZIG-ZAG

AND

PLAIN SEWER

one of the finest Zig-Zag machines made.

is

a well made excellent piece

to

s.

without

work

materials difficult

or

synthetics slide through easily

difficulty when the specially

foot

with artificial and real

r,

or rubberized products

is used.

to

with

pass,

model

such

of

217

as

COMPLETEMachine, tabl

bobbin winder, ready

NOW

AVAILABLE

e,

light, chair, thread stand,

to

go-

ready

to

sew.

SAIL

AND

Sailcloth, awnings, canv

impregnated (waterproof)

can be sewn

• and zig

CORSET

Model 217 is the ideal machine for sewing

stretch fabrics and material

LINGERIE:

For all straight and

hemming, lace insets and trimmings.

CLOTHING TRADE:

For all kinds

CURTAINS

Yo

u can sew curtains and drapes in all fabrics.

SPECIFICATIONS:

Standard bed size, 8mm (5/16) inch zig-zag

wid1:1,

2700 spm, pressure

STRETCHED

MODEL

Designed especially for sail

long reach is often necessary. Th

medium

sewing, zig-zag sewing

The machine will

this requires a very heavy machine (See Model

166-1

England, Chesapeake Bay ar

Gulf States, and West Coast report

•

machine

jobs.

Ne

brown,

CANVAS:

four

zag

with the 217.

AND

BRASSIERE:

of

straight and zig-zag stitch.

AND

medium brown finish,

217

-50-25

duty

machine capable of straight

).

However. manv satisified users in

is

in u

se

edle

16

x 231, reverse stitch, color light

20"

clearance underarm. 2500 RPM.

as

or

the most heavily

to

DRAPERIES:

foot lift

not

5-6 hours per day on varied

cotton

six

ply

in straight stitch

s.

zig-zag

16 x 231

3.5mm (3/8 inch)

work

or

wave sewing.

sew the points

ea,

CHANDL

materials

sewing wor

i;leedle

where that

is

is

simply a

of

sails

Great L

that

ER

MACHINE

k,

MODEL 217-25Z

Auxiliary programmed stitching-

Cam driven linkage box attached

machine automatically programs needle bar

stitch a wide variety

One

of

the

of

most

seam.

s,

as

New

akes,

the

serpentine stitch used in sailwork for greater

strength

Other patterns such

half circles, etc., are used mainly in decorative

color threads on clothing

. ...

CO. INC., AYER, MASS. 01432

of

patterns.

popular patterns is

as

diamond

or

leather.

USA

TELEX

to

rear

of

to

the

s,

wedges,

c::J,andlar

928448

TEL~PHONE:

617

772-0522

Page 12

INTERNAL

TOP VIEW:

gearbox shows

Into

tion housing. Please also note auxilliary cam housing

grammed stitching. Avai lable only on "Z" machines

cost. You

easier

matic program stitching.

FRONT VIEW:

Shows

that ensures quiet smooth running

higher speeds and heavier materials.

Reverse stit

ground on right.

action-automatic return.

ca

to

order a

crank type link take

top

main

nnot

make a fi

"Z"

machine complete

ch lever visable in back-

Simple push

WORKING

shaft gea

e1d

up

r drive

installation

motion

at

down

with

gear lubrica-

of

cam housing.

if

you need the auto-

at

for

pro-

extra

MECHANISMS-MODEL

It

is

HOOK:

Full

signed

Produced from the finast qua

alloy steels and precisioned

machined

ance and

reasonably

217-25

rotary

hoo

k specially de-

for

zig-zag stitching.

for

maximum perform-

long lif

e.

priced.

lity

Replacements

""'

J

.

. -

BOTTOM VIEW:

Illustrat

es

and rig

in front

stitch

This

zag machine the best performer on the

market today.

SUMMARY:

We hope you are or

performan

lowest priced zig-zag

are in business,

gear shatt driven

ht

angle gearing to position hook

of

nee

dle thereby building better

loops when the sewi

un

ique design makes the 217-25 zig-

ce

is unsurpassed. It can

will

bottom

ng

gets tough.

wi

ll shortly

but

in analizing

be

in busine

CHANDLER

shaft

be

a proud

work

what

ss,

or

MACHINE

owner of the model217-

on the lightest materials

want

money buy

to sell yo

s,

ur

assets

CO.

INC., AYER, MASS. 01432

25

zig-zag machin

this is

with gentl

the most economical investment. If you just

at

some later time, thi s is the machine

e s

wift

e.

This brochu

precision

USA TEL

re

could nev

or

sew heavy canv

to call yours.

er

as

want

in and out,

EX

928448 TEL

describe

binding

what

a handsome machine this is to

work

by

altering the

do

not

buy

EPHONE:

fitt

this machin

617

772-0522

ings. Certainly

e.

If, however, you

own

not

. Its

the

•

Loading...

Loading...