25 Ton Full Beam Log Splitter

model number 060-0550-6 | contact us: 1.866.523.5218

IMPORTANT:

Read and follow all safety rules and operating

instructions before using this product.

Instruction

Manual

2

model no. 060-0550-6 | contact us: 1.866.523.5218

SAFETY INSTRUCTIONS 3

SAFETY SYMBOLS 7

SPECIFICATIONS 9

KNOW YOUR LOG SPLITTER 11

ASSEMBLY 16

OPERATION 36

MAINTENANCE 40

STORAGE 46

EXPLODED VIEW PRODUCT 48

PARTS LIST PRODUCT 49

EXPLODED VIEW ENGINE 52

TABLE OF CONTENTS

PARTS LIST ENGINE 53

TROUBLESHOOTING 58

WARRANTY 59

For problems or questions, DO NOT RETURN TO STORE.

Please contact one of our Customer Service Agents

who would be happy to assist you.

For Customer Assistance Please Call:

1.866.523.5218

3

– DANGER: Log splitter engine

exhaust contains carbon monoxide,

a colourless, odourless, poison gas.

Breathing carbon monoxide will cause

nausea, dizziness, fainting or death. If

you start to feel dizzy or weak, get to

fresh air immediately.

• Operate log splitter outdoors only in a

well-ventilated area.

• DO NOT operate the log splitter

inside any building, including

garages, basements, crawlspaces

and sheds, enclosures or

compartments.

• DO NOT allow exhaust fumes

to enter a confined area through

windows, doors, vents or other

openings.

– DANGER: Using an engine indoors

can kill you in minutes. Engine exhaust

contains carbon monoxide. This is a

poison you cannot see or smell.

• Never use inside a home or garage,

even if doors and windows are open.

• Only use outside and far away from

windows, doors, and vents.

• Install battery-operated carbon

monoxide alarms or plug-in carbon

monoxide alarms with battery backup according to the manufacturer’s

instructions.

– DANGER: Rotating parts can entangle

hands, feet, hair, clothing and/or

accessories. Traumatic amputation or

severe laceration can result.

• Keep hands and feet away from

rotating parts.

• Tie up long hair and remove

jewellery.

• Operate equipment with guards in

place.

• DO NOT wear loose-fitting clothing,

dangling drawstrings or items that

could become caught.

– WARNING: Operation of this

equipment may create sparks that can

start fires around dry vegetation.

• A spark arrestor may be required.

The operator should contact

local fire agencies for laws or

regulations relating to fire prevention

requirements.

– WARNING: Sparks can result in fire or

electrical shock.

• When servicing the engine:

– Disconnect the spark plug wire and

place it where it cannot contact the

plug.

– DO NOT check for spark with the

plug removed.

– Use only approved spark plug

testers.

– WARNING: Running engines produce

heat. Severe burns can occur on

contact. Combustible material can

catch fire on contact.

• DO NOT touch hot surfaces.

• Avoid contact with hot exhaust gases.

• Allow equipment to cool before

touching.

• Maintain at least 3’ (91.4 cm) of

clearance on all sides to ensure

adequate cooling.

SAFETY INSTRUCTIONS

4

model no. 060-0550-6 | contact us: 1.866.523.5218

• Maintain at least 5’ (1.5 m) of

clearance from combustible

materials.

– WARNING: Only one person should

operate the log splitter and load the

logs.

– WARNING: Crush Hazard

• Wedge can cut through skin and

break bones. Keep all limbs away

from wedge and endplate.

– WARNING: Projectile Hazard

SAFETY INSTRUCTIONS

• Pieces of log may be ejected from

the splitter while operating. Wear

ANSI-approved safety glasses when

operating. Be alert.

– WARNING: Keep Operator Work Zone

Clear

• Keep work zone clear of debris while

working to ensure safe footing.

– WARNING: Before removing the pin

installed into the front support leg

make sure hitch is installed onto

vehicle. Releasing the pin before will

cause support leg to slide up and

possibly cause injury.

– WARNING: Skin Injection Hazard. High

pressure hydraulic oil can inject under

your skin.

• Make sure all fittings are tightly

secure before applying pressure.

Relieve system of pressure before

servicing.

– WARNING: Towing Hazard

• ALWAYS check all local and

provincial regulations regarding

towing, licensing and lights before

towing your log splitter. Review

towing safety warnings in your towing

vehicle manual.

• Drive safely. Be aware of the added

length of the log splitter. NEVER ride

or transport cargo on the log splitter.

Choose a level surface to operate the

log splitter.

• NEVER EXCEED Maximum Towing

Speed 45 mph (72 km/h)

– WARNING: Rapid retraction of the

starter cord will pull hand and arm

towards the engine faster than you can

let go. Unintentional startup can result

in entanglement, traumatic amputation

or laceration. Broken bones, fractures,

bruises or sprains could result.

• When starting engine, pull the starter

cord slowly until resistance is felt and

then pull rapidly to avoid kickback.

– CAUTION: Parts of the hydraulic circuit

(cylinder, pump, valve-body, hoses)

can become very hot during operation.

– WARNING: In most provinces towing

on public streets is either prohibited

or would require further licensing or

modifications. Please check with your

local authorities regarding regulations,

restrictions and registration.

– CAUTION: Improper treatment or

use of the log splitter can damage it,

shorten its life and void your warranty.

• Use the log splitter only for intended

uses.

• Operate only on level surfaces.

• DO NOT expose log splitter to

excessive moisture, dust, or dirt.

5

• DO NOT allow any material to block

the cooling slots.

• DO NOT use the engine if:

– Equipment sparks, smokes or

emits flames.

– Equipment vibrates excessively.

FUEL SAFETY

– DANGER: Gasoline and gasoline

vapours are highly flammable and

explosive.

• Fire or explosion can cause severe

burns or death.

– Gasoline and gasoline vapours:

• Gasoline is highly flammable and

explosive.

• Gasoline can cause a fire or

explosion if ignited.

• Gasoline is a liquid fuel but its

vapours can ignite.

• Gasoline is a skin irritant and needs

to be cleaned up immediately if

spilled on skin or clothes.

• Gasoline has a distinctive odour.

This will help detect potential leaks

quickly.

• In any petroleum gas fire, flames

should not be extinguished unless by

doing so the fuel supply valve can be

turned OFF. This is because if a fire

is extinguished and a supply of fuel

is not turned OFF, then an explosion

hazard could be created.

• Gasoline expands or contracts with

ambient temperatures. Never fill the

gasoline tank to full capacity, as

gasoline needs room to expand if

temperatures rise.

– When adding or removing gasoline:

• Turn the engine off and let it cool for

at least two minutes before removing

the gasoline cap. Loosen the cap

slowly to relieve pressure in the tank.

• Only fill or drain gasoline outdoors in

a well-ventilated area.

• DO NOT pump gasoline directly into

the engine at the gas station. Use an

approved container to transfer the

fuel to the engine.

• DO NOT overfill the gasoline tank.

• Always keep gasoline away from

sparks, open flames, pilot lights, heat

and other sources of ignition.

• DO NOT light or smoke cigarettes.

– When starting the engine:

• DO NOT attempt to start a damaged

engine.

• Make certain that the gasoline cap,

air filter, spark plug, fuel lines and

exhaust system are properly in place.

• Allow spilled gasoline to evaporate

fully before attempting to start the

engine.

• Make certain that the log splitter is

resting firmly on level ground.

– When operating the log splitter:

• DO NOT move or tip the log splitter

during operation.

• DO NOT tip the log splitter or allow

fuel or oil to spill.

SAFETY INSTRUCTIONS

6

model no. 060-0550-6 | contact us: 1.866.523.5218

– When transporting or servicing the log

splitter:

• Make certain that the fuel valve is in

the OFF position and the gasoline

tank is empty.

• Disconnect the spark plug wire.

– When storing the log splitter:

• Store away from sparks, open

flames, pilot lights, heat and other

sources of ignition.

SAFETY INSTRUCTIONS

• Do not store log splitter or gasoline

near furnaces, water heaters, or any

other appliances that produce heat or

have automatic ignitions.

– WARNING: Never use a gasoline

container, gasoline tank or any other

fuel item that is damaged or appears

damaged.

SYMBOL MEANING

Read Operator’s Manual. To reduce the risk of injury, user must

read and understand operator’s manual before using this product.

Eye and Ear Protection. Always wear safety goggles or safety

glasses with side shields, and as necessary a full face-shield as

well as full ear protection when operating this product.

Footwear. Always wear safety shoes or heavy boots when

operating the machine.

Gloves. Always wear nonslip, heavy-duty protective gloves when

operating this product.

7

SAFETY SYMBOLS

Safety Alert. Precautions that involve your safety.

Risk of Fire. Fuel and its vapours are extremely flammable and

explosive. Fire can cause severe burns or death. Do not add fuel

while the product is operating or still hot.

Skin Injection Hazard. High pressure hydraulic oil can inject under

your skin.

Make sure all fittings are tightly secure before applying pressure.

Relieve system pressure before servicing.

Always keep hands away from the wedge and the ram. Moving

parts can crush or cut.

Always keep feet away from the wedge and the ram. Moving parts

can crush or cut.

8

model no. 060-0550-6 | contact us: 1.866.523.5218

SYMBOL MEANING

Hot Surface. To reduce the risk of injury or damage, avoid contact

with any hot surface.

Open Flame alert. Fuel and its vapours are extremely flammable

and explosive. Keep fuel away from smoking, open flames,

sparks, pilot lights, heat, and other ignition sources.

Hold logs on sides when loading. Keep hands and feet away from

cylinder, wedge, and partially split logs.

SAFETY SYMBOLS

Never place hands or any part of the body between a log and any

part of the log splitter.

Do not split logs against the grain. Split logs end to end in the

direction of the grain only.

Toxic Fumes. The engine exhaust from this product contains

chemicals known to cause cancer and birth defects and other

reproductive harm.

Risk of Asphyxiation. This engine emits carbon monoxide, an

odourless, colourless poison gas. Breathing carbon monoxide

can cause nausea, fainting or death. Use only in a well-ventilated

area.

Clearance. Keep all objects including others at least 10’ (3 m)

from this machine. Only one person should operate the log splitter

and load the logs.

Never operate on an incline. Make sure the splitter is on a level

surface. Block tires and ensure support leg is secure to prevent

unintended movement of the log splitter during operation.

LOG SPLITTER SPECIFICATIONS

Ram Force 25 Ton

Cycle Time 11 Seconds

Hydraulic Tank Capacity 4 gal (15.1 L)

Total Hydraulic Oil System

Capacity

4.5 gal (17 L)

Max Log Length 23 3/4” (60.3 cm)

Max Log Weight 100 lb (45 kg)

Coupler Ball Size 2” (5.1 cm)

Tire Size 16” (40.6 cm)

Max Towing Speed 45 mph (72 km/h)

Cylinder Size 3 15/16 x 22 5/8” (10 x 57.5 cm)

Cylinder Rod Size 1 9/16” (4 cm)

Gear Pump 2-stage

Max Pressure 3900 PSI

Max Flow Capacity 11 GPM (41.6 LPM)

Control Valve Detent (auto-return)

Gross Weight 498 lb 4 oz (226 kg)

Net Weight 429 lb 14 oz (195 kg)

Height 39 5/16” (99.8 cm)

Width 51 1/4” (130.2 cm)

Length 89 1/2” (227.3 cm)

9

SPECIFICATIONS

ENGINE SPECIFICATIONS OIL SPECIFICATIONS

Model YF172F-000

Displacement 224 cc

Type 4-Stroke OHV

Start Type Manual

NOTE: Weather will affect engine oil and engine

!

performance. Change the type of engine oil used based

DO NOT OVERFILL.

Type See chart below

Capacity 0.6 qt (0.6 L)

Recommende d Engine Oil Type

5W-30 Synthetic

-20 0 20 40 60

°F

-28.9

°C -17.8 -6.7 4.4 15.6 26.7 37. 8 4 8.9

Ambient temperature

on weather conditions to suit the engine needs.

10W-30

10W-4 05W-30

80 100 120

10

model no. 060-0550-6 | contact us: 1.866.523.5218

HYDRAULIC OIL SYSTEM

Capacity 4.5 gal (17 L)

For year-round use in warmer climates

(always ABOVE 32˚F/ 0˚C):

– ISO 32

– Universal Hydraulic Oil

For year round use in colder climates

(BELOW 32˚F/ 0˚C):

– Automatic Transmission Fluid

Replacement filters:

SPECIFICATIONS

– Fram PH9342

– K&N HP-2008

– Wix 51361

FUEL SPECIFICATIONS

Use regular unleaded gasoline with a

minimum octane rating of 85 and an

ethanol content of less than 10% by

volume. DO NOT USE E15 or E85.

DO NOT OVERFILL.

Gasoline Capacity 0.9 gal (3.4 L)

SPARK PLUG SPECIFICATIONS

OEM Type NHSP F6RTC

Replacement Type

Gap

VALVE SPECIFICATIONS

Intake Clearance

Exhaust Clearance

IMPORTANT MESSAGE ABOUT

TEMPERATURE

Your product is designed and rated

for continuous operation at ambient

temperatures up to 40°C (104°F). When

your product is needed it may be operated

at temperatures ranging from 2°F (-10°C)

to 122°F (50°C) for short periods of time. If

exposed to temperatures outside this range

during storage, it should be brought back

within this range before operation. In any

event, the product must always be operated

outdoors, in a well-ventilated area and

away from doors, windows and vents.

NGK BPR6ES or

equivalent

0.028–0.031”

(0.7–0.8 mm)

0.005–0.007”

(0.13–0.17 mm)

0.007–0.009”

(0.18–0.22 mm)

NOTE: When temperature is below 32ºF (0ºC) use

!

Automatic Transmission Fluid (Dexron-III or similar).

11

4

3

2

1

12

13

1. 2” (5.1 cm) Ball Coupler For towing the log splitter behind your vehicle.

2. Hydraulic Cylinder

3. Control Valve Handle Controls the movement of the cutting wedge.

4. Wedge

5. Splitting Beam

6. Log Cradle Prevents logs from rolling off beam.

7. Log Catchers

8. Engine 224 cc, OHV.

9. Tires Maximum travel speed is 45 mph (72 km/h).

10. Beam Lock Pin Secures in either horizontal or vertical position.

11. Beam Bracket Holds splitting beam in place.

12. Support Leg Supports log splitter while operating. Raise leg for towing.

13. Safety Chains For use while towing.

1011

3 15/16” (10 cm) bore × 22 5/8” (57.5 cm) stroke.

Rated to 3900 PSI.

5

6

7

8

9

KNOW YOUR LOG SPLITTER

12

model no. 060-0550-6 | contact us: 1.866.523.5218

Parts Included

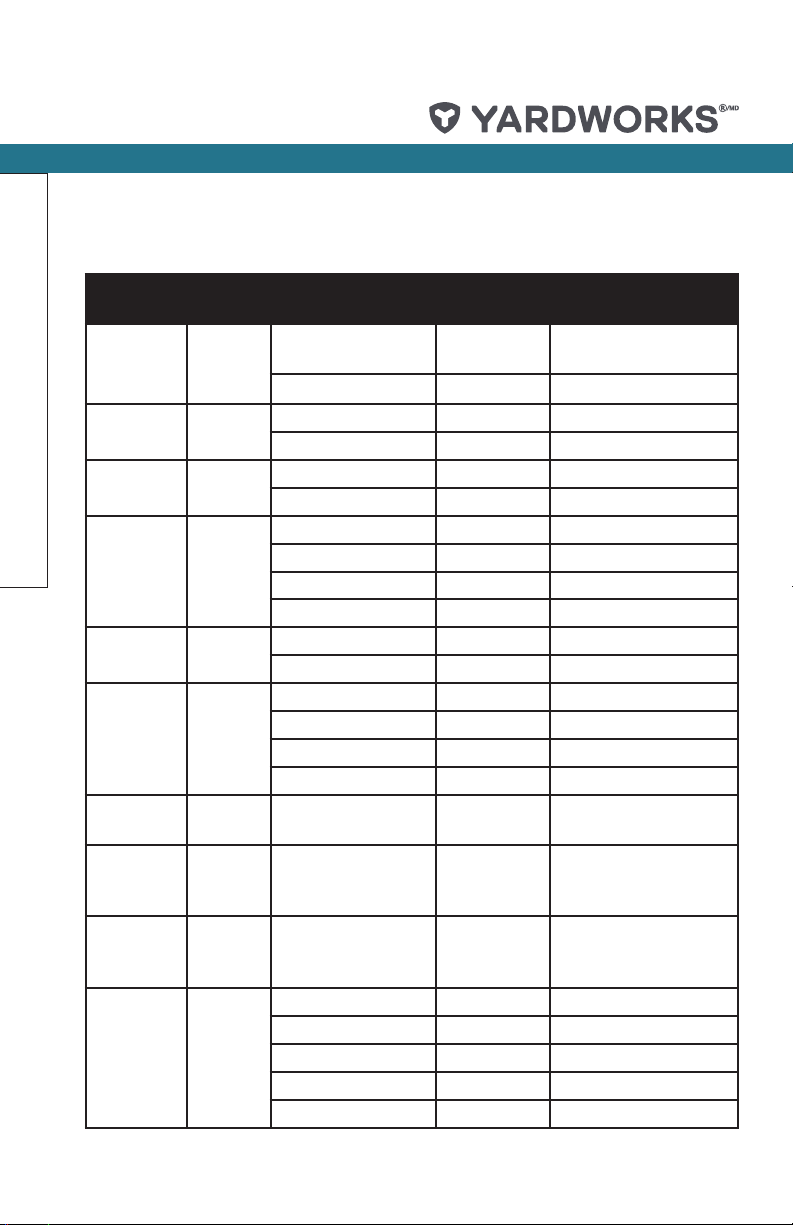

Part Part Qty. Hardware Needed

Wheels 2

Support

Leg

Tow Bar 1

KNOW YOUR LOG SPLITTER

Engine 1

Beam 1

Fenders 2

Oil Return

Hose

High

Pressure

Hose

Suction

Hose

Log

Catchers

Hardware

Qty.

Castle Nut 2

Axle Cap 2 Mallet

Pin 1

1

R-Pin 1

Bolt M12 × 85 2 18mm wrench or socket

Nut M12 2 19mm wrench or socket

Bolt M8 × 40 4 13mm wrench

Nut M8 4 14mm wrench

Lock Washer 4

Flat Washer 4

Bolt M18 × 115 1 27mm wrench or socket

Nut M14 1 22mm wrench or socket

Bolt M10 × 25 4 16mm wrench or socket

Nut M10 4 17mm wrench

Lock Washer 4

Flat Washer 4

1

1

1 C-Clamp 2

Bolt M10 × 30 2 6mm allen wrench

Bolt M10 × 20 4 16mm wrench or socket

2

Nut M10 2 17mm wrench

Lock Washer 6

Flat Washer 6

Tool Needed

30mm open-end

27mm open-end

27mm open-end

Flat head screw driver

8mm socket

wrench

wrench

wrench

or

13

TRAINING

1. Read the Operator’s Manual

completely before attempting to use

this log splitter.

2. Do not allow anyone to operate your

log splitter who has not read the

Operator’s Manual or has not been

instructed on the safe use of the log

splitter.

3. Never allow children or untrained

adults to operate this machine.

4. Many accidents occur when more

than one (1) person operates the

log splitter. If a helper is assisting in

loading logs to be split, never actuate

controls until helper is clear of the

area.

5. Never allow anyone to ride on the

machine.

6. Never transport cargo on the log

splitter.

7. High fluid pressures are developed

in hydraulic log splitters. Pressurized

hydraulic fluid escaping through a

pin hole opening can puncture skin

and cause severe blood poisoning.

Therefore, the following instructions

should be heeded at all times.

7a. Do not operate the unit with

frayed, kinked, cracked or

damaged hoses, fittings, or

tubing.

7b. Stop the engine and relieve

hydraulic system pressure before

changing or adjusting fittings,

hoses, tubing, or other system

components.

7c. Do not adjust the pressure

settings of the pump or valve.

7d. Do not check for leaks with your

hand. Leaks can be detected

by passing cardboard or wood

over the suspected area. Look

for discolouration. If injured by

escaping fluid, see a doctor

at once. Serious infection or

reaction can develop if proper

medical treatment is not

administered immediately.

8. Keep the operator zone and adjacent

area clear for safe, secure footing.

9. If your log splitter is equipped with

an internal-combustion engine and

intended for use near any unimproved

forest, brush, or grass covered

land, the engine exhaust should

be equipped with a spark arrestor.

Make sure you comply with local,

provincial, and federal codes. Take

appropriate fire-fighting equipment

with you.

10. Log splitters should be used only for

splitting wood. Do not use for other

purposes unless the manufacturer

provides attachments and

instructions.

11. Only split wood WITH the grain.

NEVER split perpendicular to the

grain

KNOW YOUR LOG SPLITTER

14

model no. 060-0550-6 | contact us: 1.866.523.5218

PREPARATION

1. Be thoroughly familiar with all

controls and with proper use of the

equipment.

2. Safety Gear:

2a. Always wear safety shoes or

heavy boots when operating the

machine.

2b. Always wear safety glasses or

goggles when operating the

machine.

2c. Never wear jewelery or loose-

KNOW YOUR LOG SPLITTER

fitting clothing that might become

entangled in moving or rotating

parts of the machine.

3. Make sure the splitter is on a level

surface. Block tires and ensure

support leg is secure to prevent

unintended movement of the log

splitter during operation.

3a. Always operate the splitter from

the manufacturer’s indicated

operator zone.

4. Logs to be split on ram-type units

should be cut as squarely as

possible.

5. Fuel:

5a. Use an approved fuel container.

5b. Never add fuel to a running or hot

engine.

5c. Fill fuel tank outdoors with

extreme care. Never fill fuel tank

indoors.

5d. Replace gasoline cap securely

and clean up any spilled fuel.

OPERATION

1. Before starting this log splitter, review

all safety rules. Failure to follow these

rules may result in serious injury to

the operator or bystanders.

2. Be sure to confirm all hose

connections and hose clamps are

tight before each use. It is possible

for connections to vibrate loose over

time.

3. Never leave the machine unattended

with the power source operating.

4. Never operate the machine when

under the influence of alcohol, drugs

or medication.

5. The machine owner should instruct

all operators in safe log splitter

operation.

6. Always operate the log splitter with

all safety equipment in place and all

controls properly adjusted for safe

operation.

7. Always operate the log splitter at

manufacturer’s recommended speed.

8. Always keep hands and feet clear of

moving parts.

9. When loading a ram-type log splitter,

place your hands on the sides of

the log, not the ends. Never place

your hands or any part of your body

between a log and any part of the log

splitter.

10. On ram-type log splitters, never

attempt to split more than one (1) log

at a time unless the ram has been

fully extended and a second log is

needed to complete the separation of

the first log.

11. On ram-type log splitters on which

the logs are not cut square, the

longest portion of the log should be

rotated down and the most square

end placed against the ram.

12. Only split logs with the grain of the

wood.

13. Use only your hand to operate the log

splitter controls.

14. Do not refuel the engine until it has

cooled for several minutes.

MAINTENANCE AND STORAGE

1. Always shut off the power source

while repairing or adjusting the

splitter except as recommended by

the manufacturer.

2. Clean debris and chaff from the

engine cylinder, cylinder head fins,

recoil starter cover, and muffler

areas. If the engine is equipped

with a spark arrestor muffler, clean

and inspect it regularly (follow

manufacturer’s service instructions).

Replace, if damaged.

3. Never store the unit indoors with fuel

in the tank. Fumes might reach an

open flame spark. Allow the engine to

cool before storing in any enclosure.

4. Clear debris from movable parts, but

only when the power source is shut

off.

5. Check to be sure all nuts and bolts

are tight to assure the equipment is in

safe working condition.

15

KNOW YOUR LOG SPLITTER

16

model no. 060-0550-6 | contact us: 1.866.523.5218

If your log splitter is already assembled, skip the assembly instructions in this manual.

If unassembled, please read and follow these instructions.

If you have any questions regarding the assembly of your log splitter, call our

Technical Support Team at 1.866.523.5218. Please have your serial number and model

number available.

TOOLS NEEDED

– Ratchet wrench

– 17 mm socket

– 17 mm wrench

ASSEMBLY

– Adjustable wrench (to 1 1/4”)

– 13 mm socket

– 13 mm wrench

– Rubber mallet

– 10 mm socket

– 10 mm wrench

– Standard/flathead screwdriver

OPEN SHIPPING CRATE

1. Set the shipping crate on a solid, flat surface.

2. Carefully cut the shipping bands and remove lid of shipping crate.

3. Locate all hardware before beginning assembly.

1 INSTALL THE TOW BAR

Attach the tow bar (55) with the support leg

facing down to the bracket on top of the

hydraulic oil tank (43) with two M12 × 85

bolts (34), M12 washers (3) and M12 lock

nuts (2).

17

2

3

34

55

43

ASSEMBLY

WARNING: Over-tightening the castle nut will cause the

!

bearings to run hot and fail prematurely.

NOTE: Keep dirt and debris away from the wheel

!

bearings during assembly.

18

model no. 060-0550-6 | contact us: 1.866.523.5218

2 INSTALL THE FENDERS

1. Attach the fender (35) to the side of

the hydraulic oil tank with an M10 ×

25 bolt (36), M10 washer (22), M10

lock washer (21) and M10 nut (26).

The safety reflector should be facing

the back of the hydraulic oil tank.

2. Repeat with second fender on

opposite side.

ASSEMBLY

35

36

21

22

26

19

3 INSTALL THE WHEELS

1. Remove the two plastic shipping caps

from the wheel hubs.

2. Slide the wheel (40) onto the axle.

3. Be sure the tire valve stem is facing

out.

4. Thread the castle nut (38) on the axle

and tighten by hand. Use a wrench to

tighten another ¼ turn.

5. Spin the wheel (40) to distribute the

bearing grease.

6. Loosen the castle nut (38) and

re-tighten by hand.

7. Install the cotter pin (42) through the

axle and castle nut (38).

8. Wheel should spin freely but when

grasped on both sides, should not

move from side to side (40).

9. Install the axle cap (37) using a softfaced mallet or hammer and wood

block.

10. Repeat for the other wheel.

40

38

42

37

ASSEMBLY

Loading...

Loading...