Champion Power Equipment PP-3 User Manual

Technical Manual

Taskmaster

Power Wash Sink System

Model

PP-3

Machine Serial No.

P.O. Box 4149 2674 N. Service Road

Winston Salem, NC 27115-4149 Jordan Station, Ontario, Canada L0R 1S0

336/661-1556 Fax:: 336/661-1660 905/562-4195 Fax: 905/562-4618

www.championindustries.com

This Page

Intentionally

Left Blank

USER MANUAL

Operation & Installation Guide

Champion Industries

PO Box 4149

Winston Salem, NC 27115

336/661-1556

www.championindustries.com

T ABLE OF CONTENTS

NOTES.......................................................................................ERROR! BOOKMARK NOT DEFINED.

INITIAL START UP...........................................................................................................................6

FILL TANKS WITH WATER...................................................................................................................6

ADD SOAP / CHEMICALS .....................................................................................................................6

APPROVED CHEMICALS.......................................................................................................................7

OPERATION INSTRUCTIONS........................................................................................................8

PRE-SCRAPPING ..................................................................................................................................8

LOADING WASH TANK........................................................................................................................8

Pots and Pans..................................................................................................................................8

Utensils and Silver Ware.................................................................................................................9

Sheet Pans.......................................................................................................................................9

START THE WASH CYCLE....................................................................................................................9

UNLOAD WASH TANK....................................................................................................................... 10

NOTES.............................................................................................................................................11

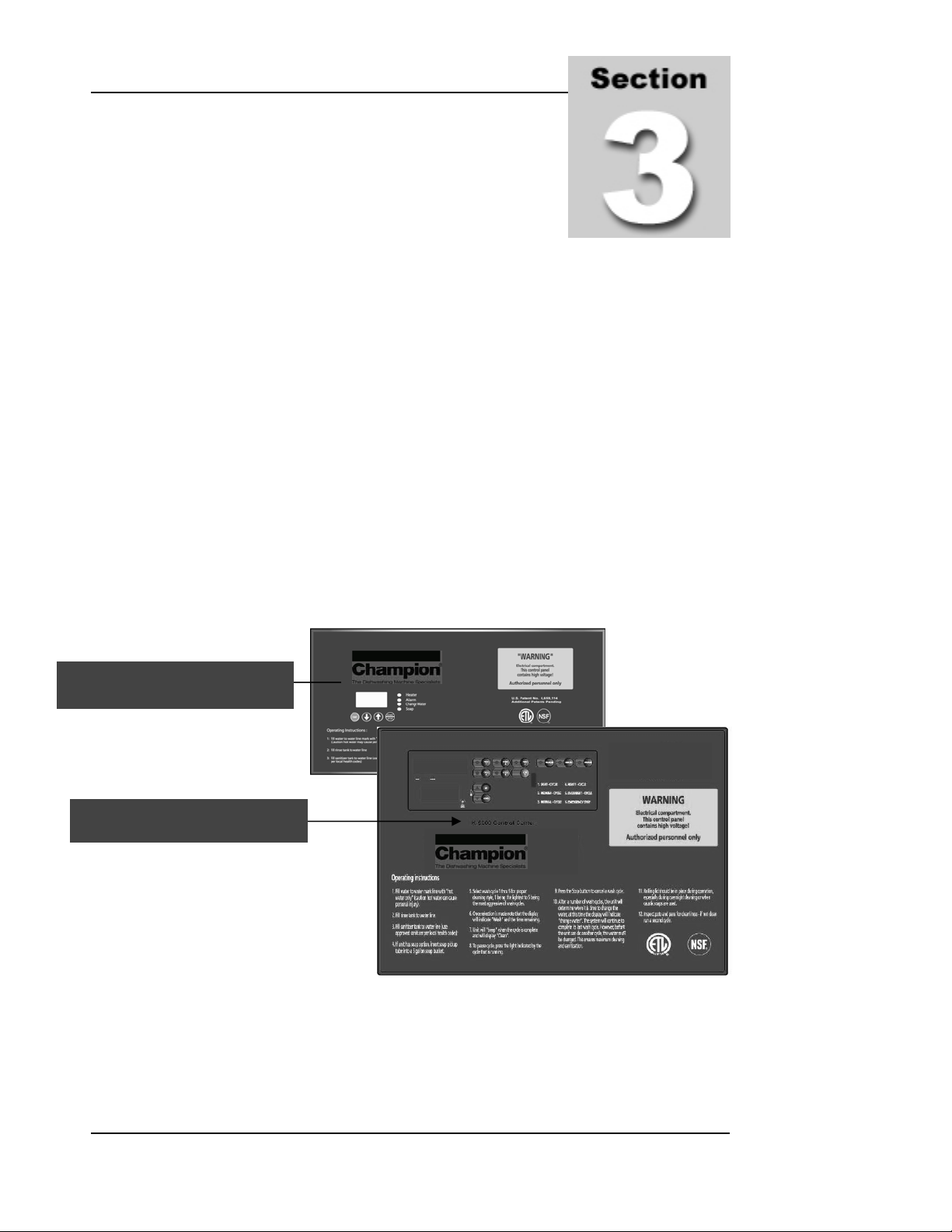

CONTROL PANELS........................................................................................................................12

IDENTIFYING YOUR CONTROL PANEL ................................................................................................12

STANDARD CONTROL CENTER ......................................................................................................13

Mylar Buttons................................................................................................................................13

Mylar Indicator Lights.................................................................................................................. 14

Basic Operation ............................................................................................................................14

Advanced Operation......................................................................................................................15

Changing Temperature Set Point................................................................................................................15

Supervisor Mode ................................................................................................................ ........................15

Setup Mode – OP.S.......................................................................................................................................15

Configuration Mode –Cn F...........................................................................................................................16

Loading Celsius or Fahrenheit Tables........................................................................................................17

Display Software Version...........................................................................................................................18

Alarms........................................................................................................................................................18

Display Sheath Temperature.......................................................................................................................18

Reset Change Water...................................................................................................................................18

Display Lamp Test......................................................................................................................................18

Temperature Sensor Fault...........................................................................................................................18

Timer Operation.........................................................................................................................................19

Keypad Operation.......................................................................................................................................19

Wire Diagrams..............................................................................................................................20

STANDARD – 208V..................................................................................................................................20

STANDARD – 480V..................................................................................................................................21

Operational Details and Engineering Diagram............................................................................22

Operation Modes...........................................................................................................................23

Fill State .....................................................................................................................................................23

Run State ....................................................................................................................................................23

Drain State..................................................................................................................................................23

Drain State..................................................................................................................................................24

Stop State....................................................................................................................................................24

AL2 State....................................................................................................................................................24

Trouble Shooting...........................................................................................................................25

DELUXE CONTROL CENTER............................................................................................................26

Display.......................................................................................................................................... 26

Mylar Buttons................................................................................................................................26

Cycle Buttons .............................................................................................................................................26

Stop Button.................................................................................................................................................27

Language Buttons .......................................................................................................................................27

Up/Down Buttons.......................................................................................................................................27

Mylar Indicator Lights................................................................................................................................28

Basic Operation ............................................................................................................................28

Time Display.................................................................................................................................29

Wash Cycles.................................................................................................................................. 29

Change Settings..........................................................................................................................................29

Step Duration..............................................................................................................................................30

Step Temperature........................................................................................................................................30

Step Pump Speed........................................................................................................................................30

Step Soap Quantity.....................................................................................................................................31

System States.................................................................................................................................31

Power up State............................................................................................................................................31

Off State .....................................................................................................................................................32

Wash State..................................................................................................................................................32

Hold/Clean State.........................................................................................................................................33

Additional System Features...........................................................................................................33

Internal Buzzer ...........................................................................................................................................33

Soap Injection Algorithm ...........................................................................................................................33

Soap Level Detection..................................................................................................................................34

Dry Fire Detection......................................................................................................................................34

Change Water Feature................................................................................................................................34

Auto-Drain / Fill.........................................................................................................................................35

Manual Drain..............................................................................................................................................35

Sanitize Tank..............................................................................................................................................35

Diagnostics ...................................................................................................................................35

Temperature Probe Error............................................................................................................................36

External DC Error.......................................................................................................................................36

Omron Messages........................................................................................................................................36

Omron Inverter Control................................................................................................................37

Low Level programming...............................................................................................................37

Temperature Units......................................................................................................................................38

Low Speed Frequency................................................................................................................................38

Medium Speed Frequency..........................................................................................................................38

High Speed Frequency................................................................................................................................38

Hold Pump Speed.......................................................................................................................................38

Hold Temperature.......................................................................................................................................39

Soap Minimum........................................................................................................................................... 39

Soap Intermediate .......................................................................................................................................39

Soap Maximum ..........................................................................................................................................39

Sanitize Soap..............................................................................................................................................39

Sanitize Heater Temperature......................................................................................................................40

Buzzer Time...............................................................................................................................................40

Key Press Buzzer Volume..........................................................................................................................40

Dry Fire Period...........................................................................................................................................40

Dry Fire Duty.............................................................................................................................................40

Dry Fire Threshold.....................................................................................................................................41

Change Water Time....................................................................................................................................41

Drain Time .................................................................................................................................................41

Fill Time.....................................................................................................................................................41

Operational Details and Engineering Diagram............................................................................42

Wire Diagrams..............................................................................................................................43

DELUXE – 208V w/Communications.......................................................................................................43

DELUXE – 480V w/Communications.......................................................................................................43

DELUXE – 480V w/Communications.......................................................................................................44

Wash Cycle Defaults.....................................................................................................................45

NOTES.............................................................................................................................................47

INSTALLATION..............................................................................................................................48

PRE-INSTALLATION........................................................................................................................... 48

PLACEMENT ......................................................................................................................................48

PLUMBING REQUIREMENTS...............................................................................................................49

ELECTRICAL REQUIREMENTS............................................................................................................49

WARRANTY INFORMATION......................................................................................................50

WARRANTY.......................................................................................................................................50

NOTES.............................................................................................................................................51

MAINTENANCE..............................................................................................................................52

ROUTINE MAINTENANCE ..................................................................................................................52

Heater ...........................................................................................................................................52

Wash Tank.....................................................................................................................................52

REPLACING HEATER .........................................................................................................................52

REPLACING THERMOCOUPLE ............................................................................................................53

REPLACING STANDARD ELECTRONICS ..........................................................................................54

REPLACING DELUXE CONTROLLER ................................................................................................55

REPLACING PUMP .............................................................................................................................56

REPLACING SOAP PUMP....................................................................................................................57

PARTS LIST......................................................................................................................................58

Heater / Thermocouple .................................................................................................................58

Soap Pump / STANDARD / DELUXE...........................................................................................59

Water Pump ..................................................................................................................................60

NOTES.............................................................................................................................................64

START UP

p

INITIAL ST ART UP

Fill T anks with Water

¾ WASH TANK – Fill wash tank with hot water to the marked Fill Line. The water

temperature ought to be approximately

110˚ to 120˚ F (43˚ to 49˚ C).

¾ RINSE TANK – If equipped, fill the rinse

tank with hot water to the marked Fill Line.

The water temperature ought to be

approximately 75˚ to 80˚ F (24˚ to 27˚ C).

¾ SANITIZE TANK – If equipped, fill the

sanitize tank with hot water to the marked Fill Line. The water temperature ought to

be approximately 75˚ to 80˚ F (24˚ to 27˚ C).

Add Soap / Chemicals

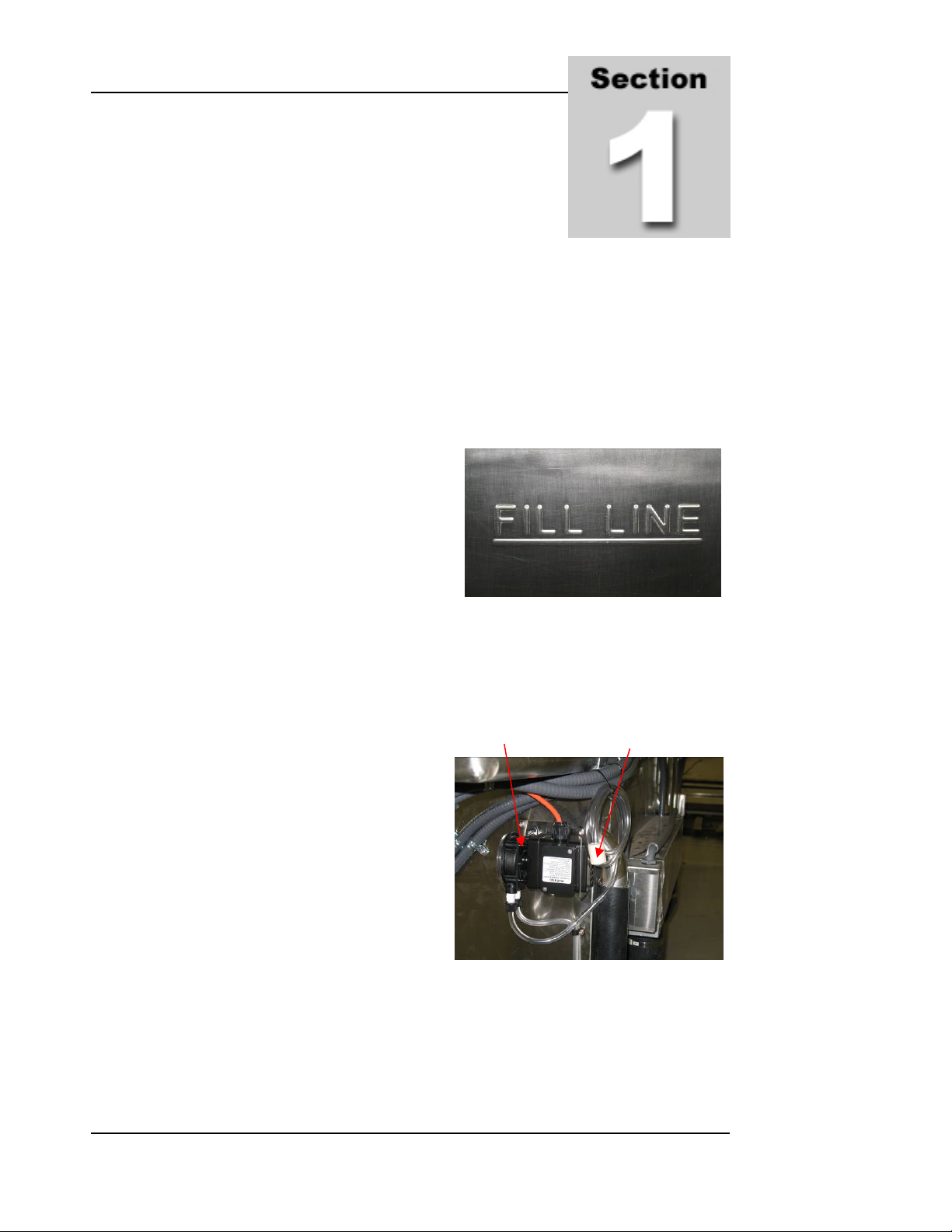

¾ WASH TANK – If your unit is equipped

with the soap injection option, then make

sure that the soap pump pick up tube is

inserted into the soap container. The soap

will automatically be injected into the

wash tank. Otherwise, manually add the

soap into the wash tank.

¾ SANITIZE TANK – If equipped, add

the appropriate sanitizing chemical to the

sanitize tank. Consult your local health

code.

Soap Pum

6

START UP

Approved Chemicals

It is recommended that chemicals that are low to non foaming, metal safe, and noncaustic be used in the wash and sanitize tank.

Caustic chemicals are capable of burning, corroding, or destroying living tissue and

should not be used. If you plan on using caustic chemicals, then a rolling lid is required.

If your unit did not come with a rolling lid, one can be ordered from the factory.

Contact information is provided on the inside cover of this manual.

WARNING

- Chemicals used in the wash tank that do not have de-foaming

capabilities will not run properly and could damage the machine. Consult your chemical

manufacturer before use.

WARNING

– Chemical Hazard - could result in serious injury or death. Always consult

with your chemical manufacturer and read all warning labels before handling new

chemicals.

7

OPERATION INSTRUCTIONS

OPERA TION

INSTRUCTIONS

Pre-Scrapping

It is recommended that any loose or excess soils be

removed from the item to be washed prior to

placing it into the wash tank. This will ensure a faster

and more efficient cleaning operation and will also

cut down on the number of times that the water will

have to be changed.

This pre-scrapping process should be done in the

scrapping sink. If your unit does not include a

scrapping sink, then you can typically scrap into a

waste area close to the wash tank.

Loading Wash T ank

Pots and Pans

Pots, pans, mixing bowls, etc. can be placed into the

wash tank in any order.

NOTE – Pots and Pans that are stacked or nested

together during the wash cycle will not be cleaned

properly. Pause the cycle and move them apart from

one another.

8

OPERATION INSTRUCTIONS

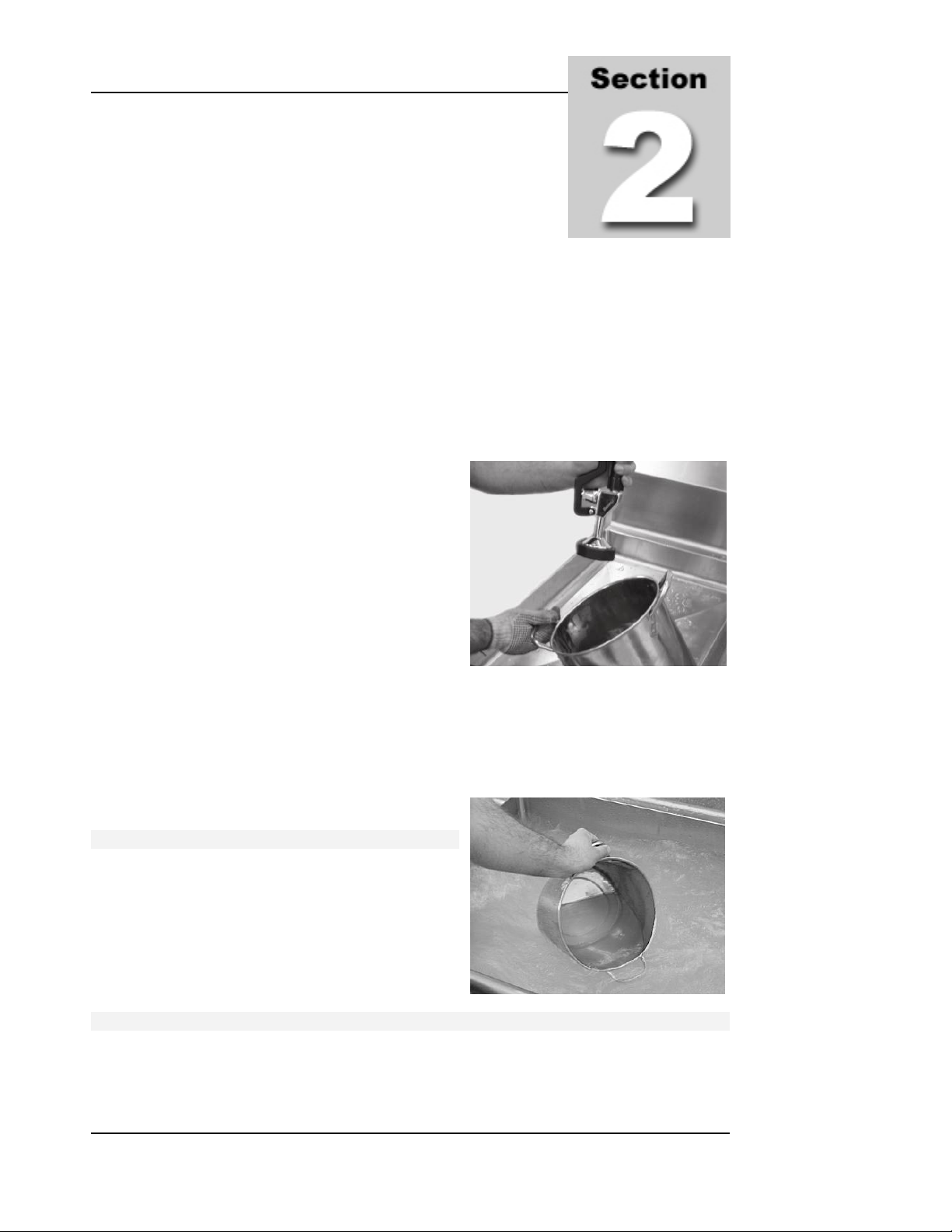

Utensils and Silver Ware

Utensils and Silver Ware must be placed in a utensil basket.

If your unit was not supplied with a utensil basket, one can

be ordered from the factory. Contact information is

provided on the inside cover of this manual.

To use the utensil basket, simply hang the basket over the

side of the wash tank, place the utensils and silver ware in

the basket, and run a wash cycle.

WARNING

– Never load sharp objects or silver ware into

the machine. This could cause serious bodily injury.

Sheet Pans

Some simple steps must be followed when washing sheet pans to ensure that proper

cleaning can be achieved.

If your unit was supplied with a sheet pan rack, place the rack into the wash tank in a vertical

position (opening on top). Load the rack with sheet pans, and then pivot the rack to a

horizontal position.

To load sheet pans without the rack, insert the sheet pans into the wash tank one at a time

with the baking side up. Place the pans in an opposite or alternating crisscross pattern, so as

not to have them stacked inside of each other.

It is recommended that 10 to 12 pans be placed in the wash tank during a wash cycle.

If your unit did not come with a sheet pan rack, one can be ordered from the factory.

Contact information is provided on the inside cover of this manual.

Start the Wash Cyc le

After the wash tank has been loaded, press the cycle start button. Which button you press

will be determined by which controller that has been installed on your unit. See the section

on controllers for more details.

9

OPERATION INSTRUCTIONS

Unload Wash T ank

The display will indicate that the items are clean when a

wash cycle has been completed. At this time the system

will switch to a holding cycle. This cycle has slower water

movement that will keep grease and soiled sediments

from falling back onto the items that were just cleaned.

Remove the clean items from the wash tank and dip into

the rinse tank to rinse off any soap or soiled residue.

Place items into the sanitize tank. When done soaking in

the sanitize tank, remove item and allow to air dry.

10

OPERATION INSTRUCTIONS

NOTES

11

CONTROL PANELS

Control Panels

Identifying your control panel

There are two types of control panels used, the STANDARD and the DELUXE. Your

control box type is printed on the front cover. Use the diagrams below to determine which

control box you have.

control box you have.

the diagrams below to determine which

STANDARD CONTROL CENTER

DELUXE CONTROL CENTER

Champion

12

CONTROL PANELS

ST ANDARD Co ntrol Center

Mylar Buttons

115

¾

Temp Button

, press to set or display the wash tanks

running temperature. When pressed, the display will

toggle between sp and 115 (115 represents a temperature

set point value and may be different from your display),

at this time you can press the Up and Down Arrow keys

to change the set point temperature. Once changed, press

the Temp button again to lock in the new value.

¾

Down Arrow Button

, pressing this button, while not in

the temperature set point mode, will display the time

remaining before a mandatory water change. Pressing this

button while in the temperature set point mode, will

lower the temperature set point setting.

UP Arrow Button

¾

, pressing this button, while in the

temperature set point mode, will raise the temperature set

point value. Pressing this button while in the wash mode

will display the heaters sheath temperature.

¾

Start / Stop Button

and off the circulation pumps.

13

, pressing this button will toggle on

CONTROL PANELS

Mylar Indicator Lights

The heater light will illuminate whenever the wash

tank’s heater is powered on.

The alarm light will illuminate whenever an alarm has

occurred.

The change water indicator light will flash when it is

time to change water. The display will show drn.

The soap indicator light will illuminate whenever the

soap pump is powered on.

Basic Operation

When you first power up to use your wash tank, the display will show fil, fill the wash tank

to the water fill line (see the INITIAL START UP section).

Once the tank has been filled, press the Start/Stop button to start the continuous wash cycle.

Soap will be dispensed automatically into the wash tank.

During the wash operation, the display will show current water temperature and the heater

light will cycle on and off as the heater is maintaining the preset water temperature.

The Start/Stop button can be used to toggle on and off the circulation pumps. During a

pause state, the heater is still in operation and maintaining the water temperature.

After a certain amount of time, the water is considered dirty and the circulation pumps will

turn off, the display will show drn, and the change water indicator light will flash.

Note

: Pressing the down arrow key will display the time remaining before a water change is required.

After the water has been drained, the display will show fil. You are now ready to start

another wash cycle.

14

CONTROL PANELS

Advanced Operation

Changing Temperature Set Point

The temperature set point is the water temperature setting for the wash tank and is the only

parameter that can be set by the operator. If the TEMP button is pressed once, the display

will switch back and forth from sp and 115 (115 represents the temperature setting and may

be different from your display).

Use the UP or DOWN buttons to change the temperature setting. Once set, press the

TEMP button to lock in the new value.

NOTE:

If no key is pressed within three seconds, then your display will revert back to the way it was before

the TEMP button was pressed. If the temperature setting was changed and the TEMP button was not

pressed, then the temperature setting will remain unchanged.

Supervisor Mode

The supervisor mode can be accessed by holding the TEMP and START/STOP buttons

simultaneously for 3 seconds. The display will toggle opr and op.b. Pressing the UP or

DOWN buttons will toggle between “op.b”, “op.s”, “cpi.”, and “cnf.”.

To exit the supervisor mode, press the UP or DOWN buttons until op.b is displayed, then

press the TEMP button.

NOTE

: You may need to hold the TEMP and START/STOP buttons in

for 3 seconds to get to the menu.

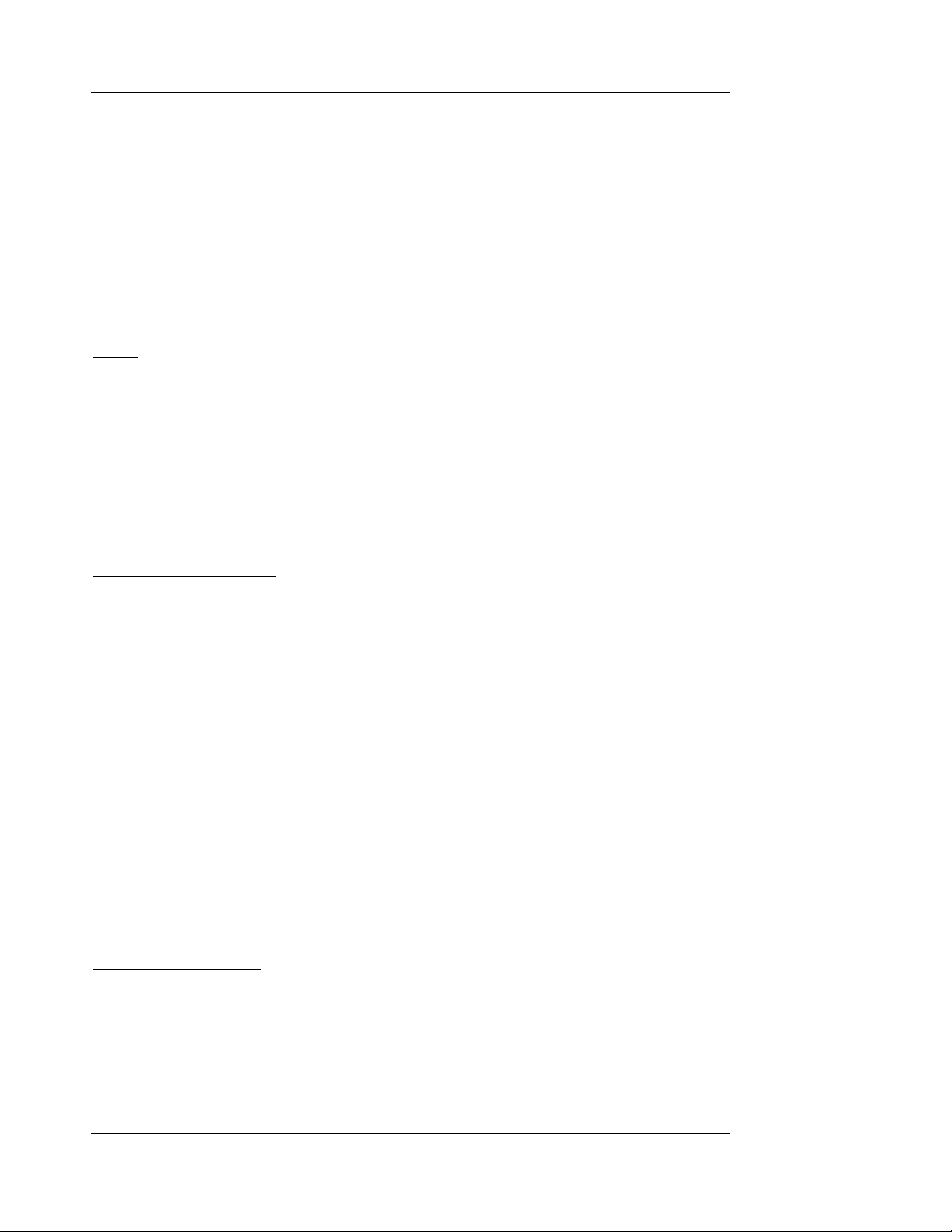

Setup Mode –

ΟΠ.Σ

Enter the supervisor mode and press the UP or DOWN buttons until op.s is displayed. Press

the TEMP button to select.

When prompted for a password (pss), use the UP and DOWN buttons to select 55. Press

the TEMP button to enter in the value.

Press the TEMP button to toggle between the parameters that are available, see parameter

table below.

The parameter name and its value will be swapped in and out of the display. Press the UP

and DOWN button to change the parameters value. Once a value has been changed, press

the TEMP key to lock in this value and move on to the next parameter. If you do not press

the TEMP key within three seconds after changing a parameters value, the new value will

not be saved.

Exit the supervisor mode when done with the setup mode.

NOTE:

See Supervisor Mode section

on how to exit.

15

CONTROL PANELS

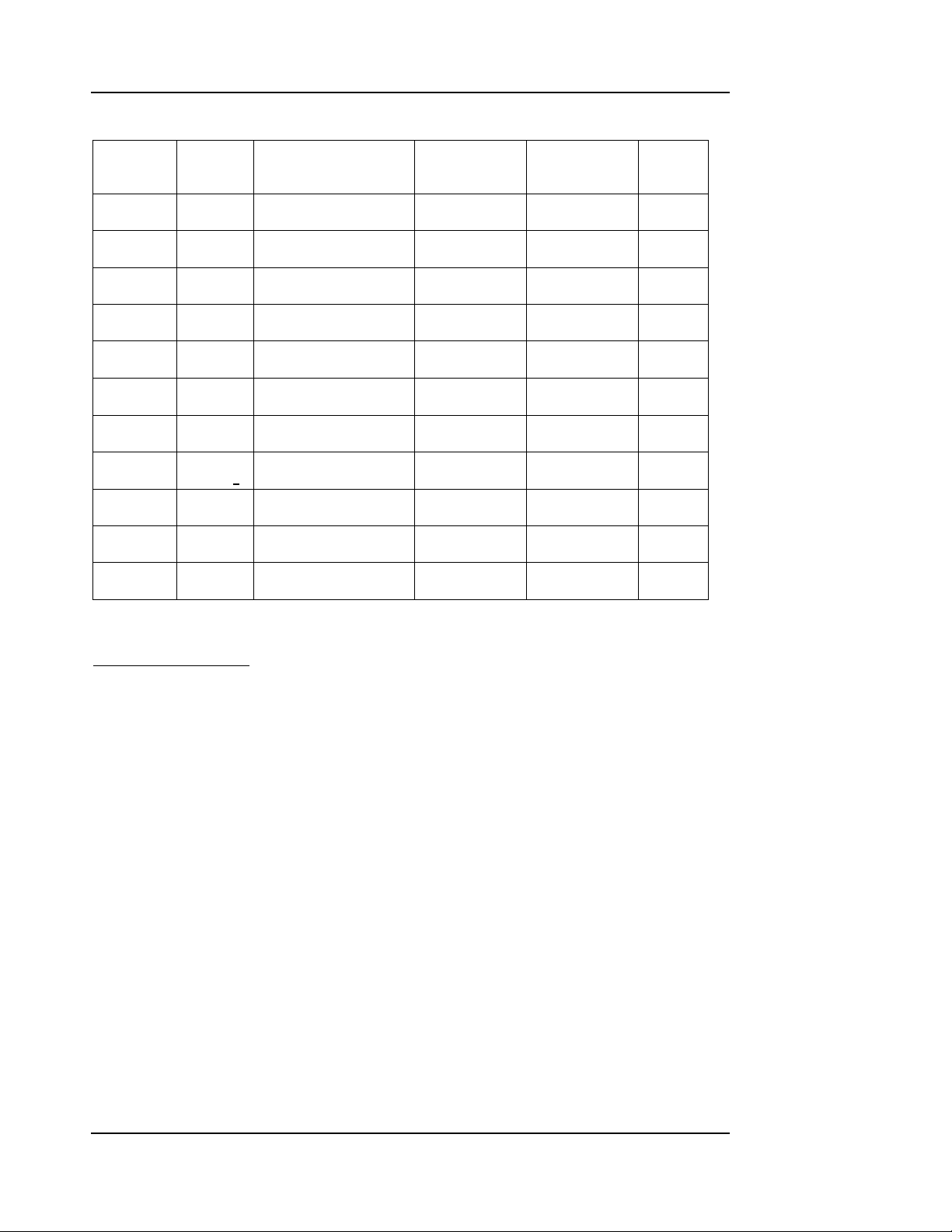

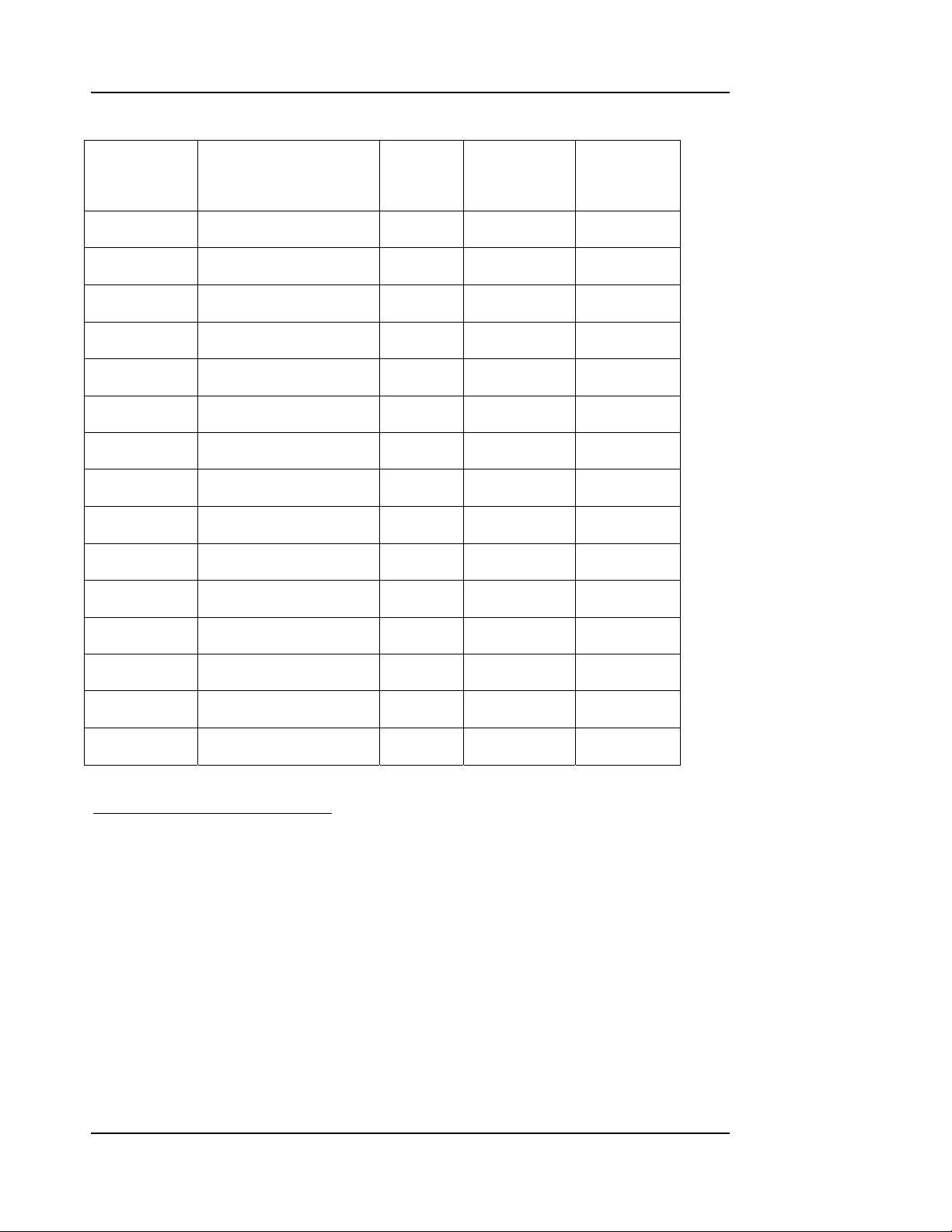

Parameter

Mnemonic

sp

t

t2

t3

Al.1

Hs.1

Al..2

Hs..2

hs

rl

rh

Setup Mode Parameter Table

Parameter

Name

Setpoint Temperature Set Point

Timer 1

Timer 2

Timer 3 Soap Dispensing Time

Alarm 1 Alarm 1 Set Point

Hysteresis Alarm 1 Hysteresis

Alarm 2 Alarm 2 Set Point

Hysteresis

Hysteresis On/Off Hysteresis

Range

Low

Range

High

Description

Change Water Cycle

Time

Soap Dispensing Delay

Time

Alarm 2 Hysteresis

Set Point Low Limit

Set Point High Limit

Table 1 Default

Value

(Celsius)

Table 2 Default

Value

(Fahrenheit)

46ºc 115 ºF

4.00 4.00

2.00 2.00

0.30 0.30

107 ºc

225

ºF

0.1 0.1

72 ºc 160 ºf

0.1 0.1

0.1 0.1

38 ºc 100 ºf

52 ºc 125 ºf

Units

Degrees

H:MM

M:SS

M:SS

Degrees

%

Degrees

%

%

Degrees

Degrees

Configuration Mode –

cnf

Enter the supervisor mode and press the UP or DOWN buttons until cnf is displayed.

Press the TEMP button to select.

When prompted for a password (p55), use the UP and DOWN buttons to select 415. Press

the TEMP button to enter in the value.

Press the TEMP button to toggle between the parameters that are available, see parameter

table below.

The parameter name and its value will be swapped in and out of the display. Press the UP

and DOWN button to change the parameters value. Once a value has been changed, press

the TEMP key to lock in this value and move on to the next parameter. If you do not press

the TEMP key within three seconds after changing a parameters value, the new value will

not be saved.

Exit the supervisor mode when done with the setup mode.

NOTE:

See Supervisor Mode section

on how to exit.

16

CONTROL PANELS

Parameter

Mnemonic

P 1

P 2

P 3

P 4

P 5

P 6

P 8

P11

P1 2

P22

P23

P25

P33

P35

P36

Configuration Mode Parameter Table

Description

Input table

Low scale range of sensors

High scale range of sensors

Output 1 control action

Output 2 function

Output 2 alarm type

Alarm 1 standby function

Auto-ranging display

Filter sensor values

Output 3 function

Output 3 alarm type

Alarm 2 standby function

Access to op.5 mode

Access to cnf mode

Access to I .cl mode

Table 1

Default

Value

(Celsius)

Table 2 Default

Value

(Fahrenheit)

2 10

0 ºc 0 ºf

282 ºc 540 ºf

reu reu

1 1

h.r. h.r.

Off Off

Off Off

On On

1 1

h.r. h.r.

Off Off

55 55

415 415

415 415

Units

Degrees

Degrees

Loading Celsius or Fahrenheit Tables

The controller contains two default parameter tables. Table 1 is used for Celsius operation,

and Table 2 is used for Fahrenheit.

To load one of the default tables, enter the configuration mode (See instructions listed in the

Configuration Mode – cnf section listed above). When cnf is displayed, press both the UP

and DOWN buttons simultaneously. The display will show d l.f. Press the UP or DOWN

buttons to display d l.1 for table 1 (Celsius), or d l.2 for table 2 (Fahrenheit).

Press the TEMP key to enter in your selection. The display will show d l.t . This indicates

that the loading procedure has been initiated and after approximately 1 second, the loading

will be finished and the display will revert back to cnf.

Exit the supervisor mode when done.

NOTE:

See Supervisor Mode section on how to exit.

17

CONTROL PANELS

Display Software Version

To display the software version, enter the configuration mode (See instructions listed in the

Configuration Mode – cnf section listed above). When cnf is displayed, press the DOWN

button. The software version number will be displayed and should look something like

d.17.

Press the DOWN arrow key again to return back to the cnf display.

Exit the supervisor mode when done.

Alarms

NOTE:

See Supervisor Mode section on how to exit.

Alarm 1 is associated with the heater’s sheath temperature, and is triggered when the

temperature rises above the value set in al.1 (see chart above).

Alarm 2 is associated with the wash tanks water temperature, and is triggered when the

temperature rises above the value set in al.2 (see chart above).

When one of these alarms is activated, the circulation pump will turn off and the alarm

indicator light will be illuminated. The controller will enter the fil state.

Display Sheath Temperature

During normal operation, pressing the UP button will display the heater’s sheath

temperature. The sheath temperature will be displayed for about six seconds and then switch

back to the original display that was shown before the UP button was pressed.

Reset Change Water

The Change Water flag is cleared whenever the heaters sheath temperature rises above its set

point. In the case of a heater failure this flag cannot be reset automatically. To manually reset

this flag you will need to hold down the UP button and START/STOP button

simultaneously for approximately 15 seconds. The controller will then enter the fil state.

Display Lamp Test

A lamp test can be started by pressing the DOWN and TEMP buttons simultaneously.

During the lamp test, the controller functions normally, but all display segments and status

lights flash. Pressing the DOWN and TEMP buttons again will return back to the normal

operation display.

Temperature Sensor Fault

If the water or heater sheath temperature sensors should fail, the controller will indicate the

fault by taking the controller to the fil state. The alarm light will be on, the heater will be

disabled, and the circulation pump will be off.

After the sensor(s) have been replaced, normal operation is resumed by exiting the fil state.

18

CONTROL PANELS

N

:

Timer Operation

The change water timer (t) will retain its current count when the washer is stopped or when

power has been disconnected from the controller.

The soap delay timer (t2) allows for a delay before soap is dispensed into the wash tank.

This will allow the soap to be added to a wash tank when it is full of water and the

circulation pumps are running.

The soap dispensing timer (τ3) determines the time for soap dispensing. A time of 0.00 will

bypass the soap dispensing process.

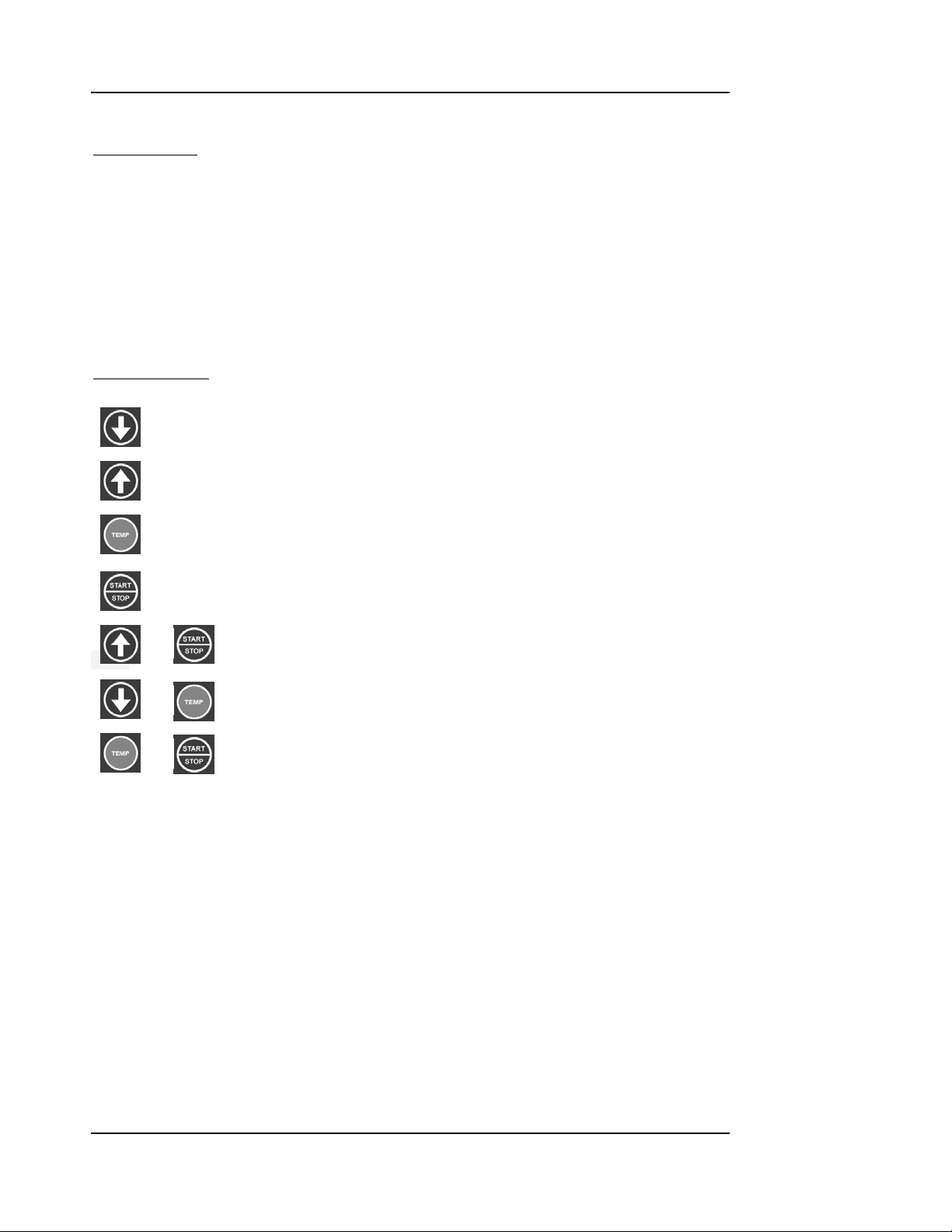

Keypad Operation

Used to decrement or modify a parameter value, or to show the software version when in configuration/calibration mode.

Used to decrement or modify a parameter value, or to show the software version when in configuration/calibration mode.

Used to increment or modify a parameter value, or to show the heater sheath temperature

Used to scroll the display to the next parameter and to store a modified parameter value

Used to cycle the circulation pumps and to restart the washer after a change water cycle has been completed

+

+

+

Used to bypass the change water status, this resets the change water timer and advances the controller

to the fil state.

Used to enable / disable the display lamp test.

Used to access the supervisor mode.

Note

: Buttons must be pressed in the order shown, and held for roughly 15 seconds.

OTE

Buttons must be pressed in the order shown.

NOTE

: Buttons must be pressed in the order shown, and held for roughly 3 seconds.

19

CONTROL PANELS

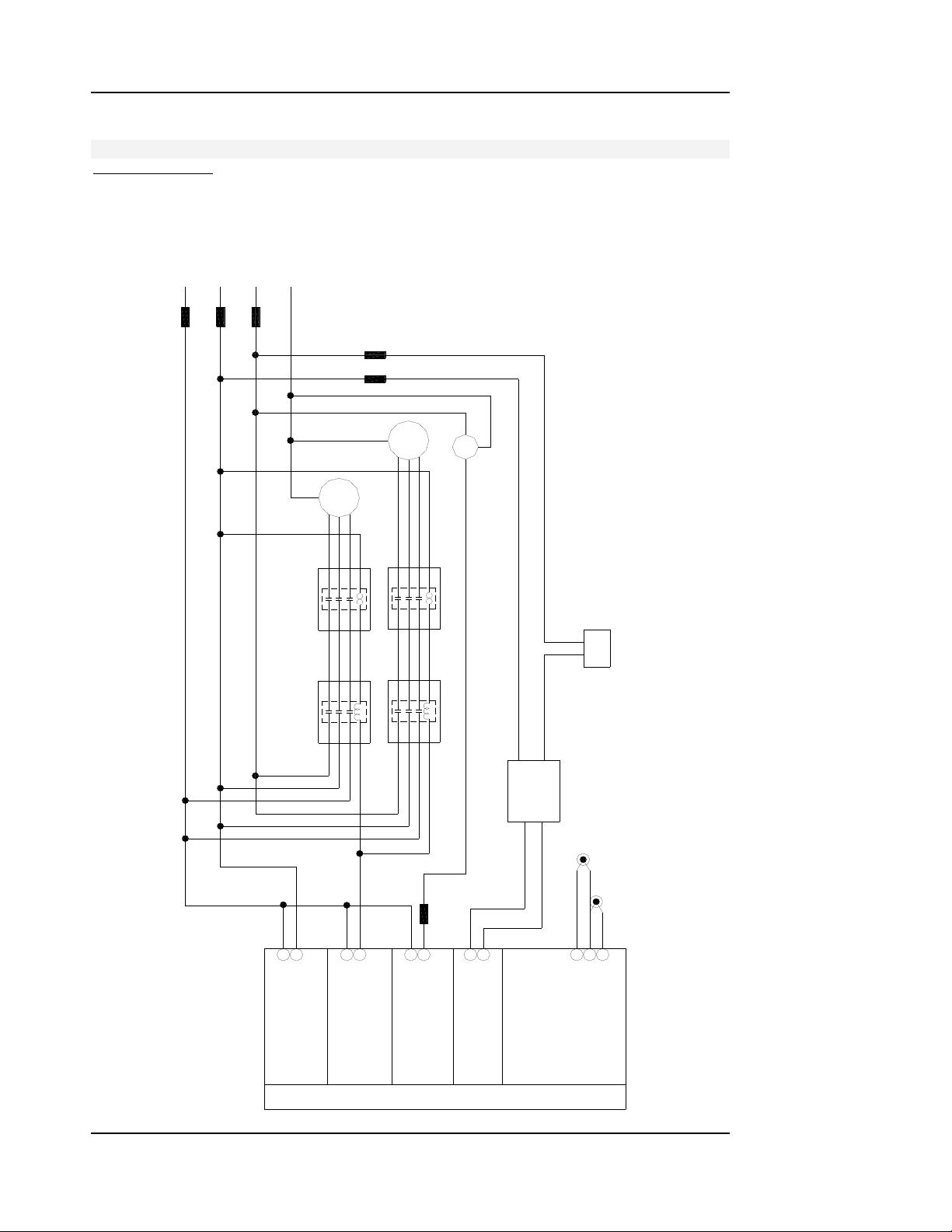

Wire Diagrams agrams

STANDARD – 208VSTANDARD – 208V

INCOMING POWER

208 VOLT 3 PHASE

LINE 3

30 AMP

LINE 1

LINE 2

30 AMP

GROUND

30 AMP

Pump

2T1

4T2

1L1

3L2

2T1

4T2

15 AMP

15 AMP

#2

Pump

#1

Soap Pump

2T1

4T2

6T3

L3

A1

5

T3

A2 A2

6

6T3

MT03M

1L1

2T1

MT03M

L3

A1

5

3L2

T3

A2 A2

4T2

6

Heater

MC1A 10E

L3

A1

1L1

3L2

5

1

2

POWER

100/240VAC

3

SUPPLY

OUTPUT 2

1L1

4

CIRCULATION

PUMPS

MC1A 10E

1

K1A Z361403GE

2

SSR

3+

TYPE K

THERMOCOUPLE

RVDA/6V25

4-

Water T emp. Sensor

Temp. Sensor

Heater Sheath

9

11

10

- (RED)

+ (YELLOW)

+ (YELLOW)

INPUTS

L3

A1

3L2

5

1 AMP

7

5

6

SOAP

OUTPUT 3

8

-

+

DISPENSER

OUTPUT 1

HEATER

20

Loading...

Loading...