10006 Santa Fe Springs Road

Santa Fe Springs, CA 90670 USA

Made in China

80003

Rev 80003-200080227

Owner’s Manual and Operating Instructions

30-105A

MIG WELDER

Table of Contents

Introduction ..................................... 1

Portable Welder ........................................ 1

This Booklet .............................................. 1

Manual Conventions ......................... 2

Safety Rules ...................................... 3

Controls and Features ....................... 4

MIG/Flux Welder ..................................... 4

Parts Included .......................................... 5

Assembly .......................................... 6

To load Flux Core Wire Reel ................. 6

Operation ......................................... 7

Welder Location ....................................... 7

Starting the Welder .................................. 7

Power Switches ..................................... 7

Maintenance ..................................... 8

Welder Maintenance ................................ 8

Storage ............................................. 8

Specifications ................................... 9

Rated Input ........................................... 9

Duty Cycle and Overheating ................. 9

Amperage Adjustment .......................... 9

Parts Diagram ......................................... 10

Parts List .................................................. 11

Troubleshooting ............................. 12

Warranty ........................................ 13

Warranty Qualifications ......................... 13

Repair/Replacement Warranty .............. 13

Do not return the unit to the place of

purchase .................................................. 13

Warranty Exclusions ............................... 13

Normal Wear ....................................... 13

Installation, Use and Maintenance ..... 13

Other Exclusions ................................. 13

Limits of Implied Warranty and

Consequential Damage ........................... 13

Contact Information ............................... 13

Address ................................................ 13

Customer Service ................................ 13

Technical Service ................................. 13

Introduction

Introduction

Congratulations on your purchase of a

Champion Power Equipment portable

welder. CPE designs and builds welders to

strict specifications. With proper use and

maintenance, this welder will bring years of

satisfying service.

This Booklet

Every effort has been made to ensure the

accuracy and completeness of the

information in this manual. We reserve the

right to change, alter and/or improve the

product and this document at any time

without prior notice.

Portable Welder

MIG Gas-Protected Welding Machine. It

can also be used for the welding of non-gas

protection Flux welding. It is designed for

medium to light duty welding (up to 1/4”).

Record the model and serial numbers as well as date and place of purchase for future reference.

Have this information available when ordering parts and when making technical or warranty

inquiries.

Champion Power Equipment Support

1-877-338-0999

Model Number

80003

Serial Number

Date of Purchase

Purchase Location

Rev 80003-200080227 1

Manual Conventions

Manual Conventions

This manual uses the following symbols to

help differentiate between different kinds of

information. The safety symbol is used with

a key word to alert you to potential hazards

in operating and owning power equipment.

Follow all safety messages to avoid or reduce

the risk of serious injury or death.

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided,

minor or moderate injury.

may

result in

CAUTION

DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided,

or serious injury.

will

result in death

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided,

death or serious injury.

could

result in

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided,

may

result in property damage.

NOTE

If you have questions regarding your welder, we

can help. Please call our help line at 1-877-338-

0999.

2 Rev 80003-200080227

Safety Rules

Safety Rules

WARNING

Read this manual thoroughly before operating

your welder. Failure to follow instructions could

result in serious injury or death.

DANGER

Breathing welding fumes can be hazardous to

your health

Keep head and face away from welding fumes.

Use enough ventilation to avoid the buildup of

gas and fumes in the immediate area. Do not

breathe in fumes.

Use of a ventilating fan may be necessary.

DANGER

DANGER

Welding can cause fire or explosion.

Do not weld near flammable material.

Welding sparks can cause fires.

It is suggested that you have a fire extinguisher

nearby.

Do not weld on drums, tanks, or other closed

containers

Do not use welder in thermal overload condition

– prevent overheating

DANGER

ARC rays can burn eyes and skin.

Use welding helmet with correct shade of filter

lens.

Wear welders cap and safety glasses underneath

helmet. Use ear protection if welding in an area

with heavy sound reverberation.

Button shirt collar all the way up.

Wear oil-free protective clothing: leather gloves,

heavy shirt, cuff less pants, and high boots

Electric Shock can kill

Electric Shock can occur from wiring or welding

electrode

Do not touch electrode with bare hand.

Wear dry insulating gloves.

Do not touch live electrical parts.

Protect yourself from electric shock by insulating

yourself from work or ground.

Properly install and ground all equipment.

WARNING

Hot parts

Do not touch hot parts bare handed.

Allow cooling period before adjusting gun or

torch

Use proper tools and/or wear heavy, insulated

gloves and clothing to prevent burns

WARNING

Magnetic fields can affect pacemakers.

Pacemaker wearers keep away

WARNING

Noise can damage hearing.

Wear appropriate ear protection if noise level is

high

Rev 80003-200080227 3

Controls and Features

Controls and Features

Read this owner’s manual before operating your 80003 welder. Familiarize yourself with the

location and function of the controls and features. Save this manual for future reference.

MIG/Flux Welder

Handle (1) – For easy mobility and

portability

Thermal Overload Light (2) – Lights

turns on when unit is overheating. Allow

welder to cool for 15 minutes and reduce

duty cycle

On/Off Switch (3) – Power on, Power off.

Amperage Adjustment – Min-Max (4)

– Adjust amperage output here. Minimum

– Maximum.

Amperage Adjustment – 1 - 2 (5) –

Adjust amperage output here. 1 (one) – 2

(two).

4 Rev 80003-200080227

Wire feed speed adjustment (6) – Turn

dial to adjust wire feed speed

Wire Fed Welding Gun (7) – Torch

Handle. Flux Core or Solid Wire feeds

through here. Arc occurs at terminus.

Work Clamp (8) – Also called a “ground

clamp” – clamp onto workpiece near

welding area to complete circuit

Access Panel (9) – Lift panel here to

access wire feed controls and to change

polarity

Wheel (10) – Wheel kit included for easy

mobility

Controls and Features

Parts Included

Your 80003 Welding unit ships with the following parts:

Handheld Welding Mask

Wire Brush/Slag Hammer

Wrench (for contact tip and other small nuts)

Torch Nozzle(1)

Contact Tip (2)

Wire Feed Roller (1)

Flux Core Wire Spool (sample)

Rev 80003-200080227 5

Assembly

Assembly

Your welder requires some assembly.

If you have any questions regarding the

assembly of your welder, call our help line at

1-877-338-0999. Please have your serial

number and model number available.

Connect a 220 VAC plug (not supplied)

to the line cord. This step must be

completed by a licensed electrician.

Depending on the project you are working

on, you will need to decide what size

electrode wire you will need. This welder

can support wire diameters of .6mm, .8mm,

and .9mm

To load Flux Core Wire Reel

1. Press on the cover locking spring, then

lift the cover to expose the wire feed unit

2. Unscrew the wing nut and remove the

reel locking knob

3. Place the wire reel over the shaft and

onto the reel spring. The wire reel

should unwind counterclockwise

4. Replace the reel locking knob and the

wing nut; tighten well

5. Lift the Wire Feed Adjusting Spring to

remove tension

6. Guide at least 12 inches of wire into the

Torch Sheath. If the end of the wire is

crimped or bent, cut it off and remove

any burrs.

7. Replace tension to the Wire Feed

Adjusting Spring

8. Turn the Torch Handle Nozzle

counterclockwise and pull to remove

9. Turn the Contact Tip counterclockwise

and remove

10. Lay the Torch Sheath out in a straight

line so that the wire moves through it

easily

WARNING

The following steps require applying power to the

welder. Do not touch anything with the Torch

Handle or an arc may be ignited

11. Plug the Power Cord into its electrical

outlet, press the Amperage Switch to

High, and turn the welder ON.

12. Lift the Torch Handle and continue

pressing the trigger until the wire feeds

through two inches

NOTE

If the wire does not feed, view the Wire Feed

Unit and see if the wire is being pushed. If it is

not, turn the welder OFF and add more tension

to the Wire Feed Adjusting Spring.

13. Turn the welder on again and press the

trigger.

14. Once the wire is exposed, turn the

welder OFF.

15. Slide the Contact Tip over the wire and

screw it into the Torch Handle.

16. Replace the Nozzle and cut off any

excess wire over 2 inches

17. Secure the cover

.

6 Rev 80003-200080227

Operation

Power Switches

Operation

Welder Location

Place on a flat surface free of vibration.

This unit may be placed on a certified

welding cart (not included) and can be set at

an angle of 10 degrees.

Place the welder in a well-ventilated area.

DO NOT place the welder near vents or

intakes where exhaust fumes could be drawn

into occupied or confined spaces. Carefully

consider wind and air currents when

positioning welder. Place the welder in a

clean, dry place.

Starting the Welder

Before Welding

• Read and understand the safety rules

section of this manual (page 3).

• Be sure all flammable materials are

removed the work area.

• There is good ventilation around the

welding unit and the area that you will be

working.

• Be sure you have fire-extinguisher ready

in-case of an accident

• Put on appropriate protective clothing and

insulated leather gloves

1. Connect work clamp onto metal to be

welded

2. Before plugging in: Adjust amperage and

wire feed speed according to material type

and thickness, and the wire size

3. Cut wire down to ¼” from the tip of the

welding gun

4. Plug in to power source. Then switch on

machine

5. Position tip of welding gun ¼” from the

point where the weld is to begin

6. Hold the mask in front of your eyes

7. Press the trigger, and when the arc

strikes, move the torch slowly in the chosen

direction.

8. If the arc gives a humming sound and

blob begins to form at the end of the wire,

you wire speed must be increased.

If you are having difficulty arriving at the

results you are looking for see

Troubleshooting on page __.

SetPowerSwitches Amps

Min‐1 30

Min‐2 50

Max‐1 75

Max‐2 105

Rev 80003-200080227 7

Maintenance and Storage

Maintenance

The owner/operator is responsible for all

periodic maintenance.

WARNING

Never operate a damaged or defective welder.

WARNING

Improper maintenance will void your warranty.

Welder Maintenance

Make certain that the welder is kept clean

and stored properly. Only operate the unit in

a clean, dry operating environment. DO

NOT expose the unit to extreme conditions,

excessive dust, dirt, moisture or corrosive

vapors.

CAUTION

DO NOT use a garden hose to clean the welder.

Water will enter the welder through the cooling

slots and damage the electrical connections.

Use a soft bristle brush to remove dirt.

Use an air compressor (25 PSI) to clear dirt

and debris from the welder.

Inspect all air vents and cooling slots to

ensure that they are clean and unobstructed.

Every 3 months

Repair or replace cracked cables

Every 6 months

Vacuum or blow out inside. During heavy

service, clean out inside monthly

Storage

1. Allow the welder to cool completely

before storage.

2. Store in a clean, dry place out of direct

sunlight

8 Rev 80003-200080227

Specifications

Specifications

Rated Input

RatedInput

Voltage 230V

Phase 1

Frequency 60Hz

Current 21A

80003

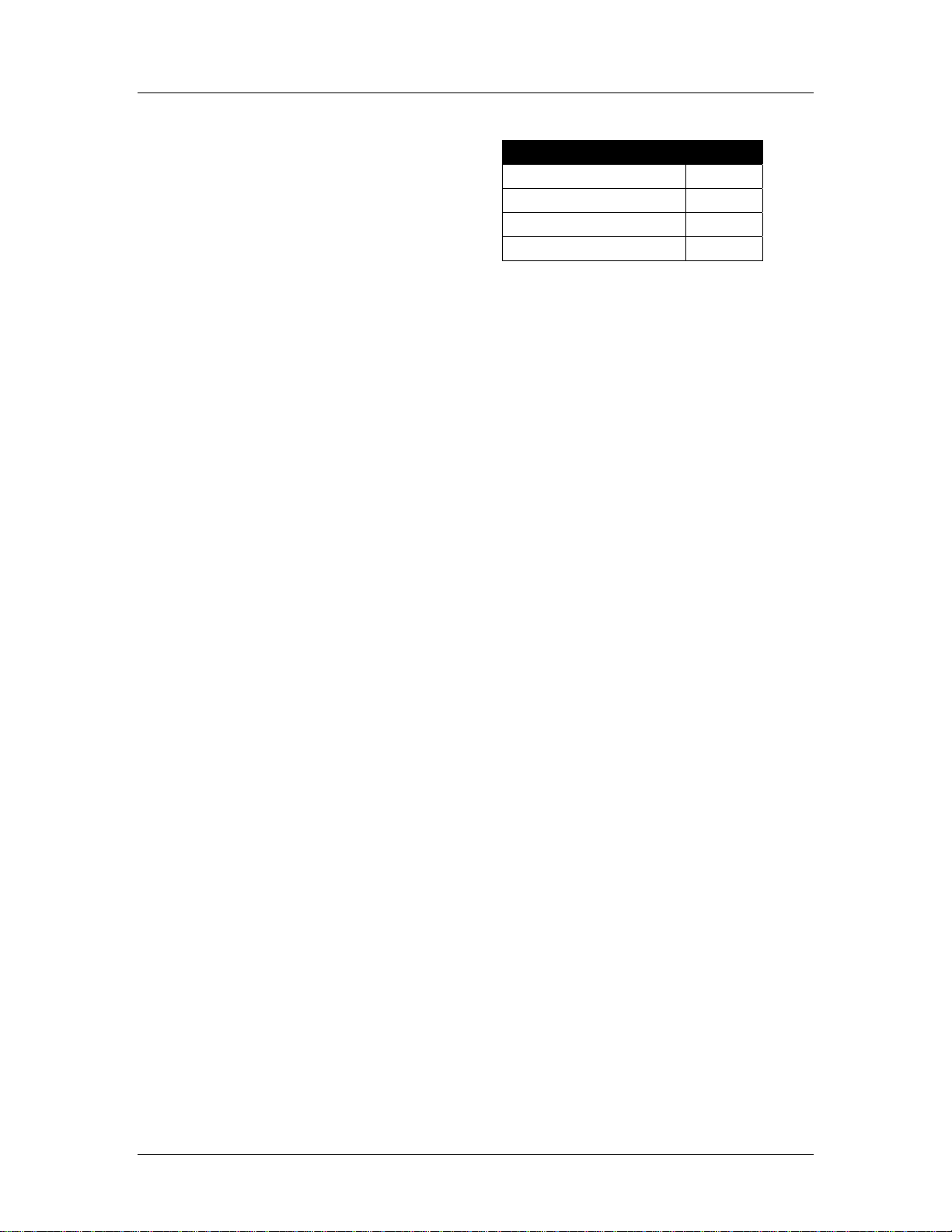

Duty Cycle and Overheating

Duty Cycle is a percentage of 10 minutes that the unit can weld at a given rated load withou t

overheating. For example a 20% duty cycle means 2 minutes welding, 8 minutes resting. If unit

overheats, wait 15 minutes for unit to cool, reduce amperage or duty cycle when welding resumes

RatedOutput 105A(max) 75A 50A 30A

DutyCycle 14% 26% 60% 100%

Voltage 19.2V 17.7V 16.5V 15.5V

Amperage Adjustment

SetPowerSwitches Amps

Min‐1 30

Min‐2 50

Max‐1 75

Max‐2 105

9

Specifications

Parts Diagram

10

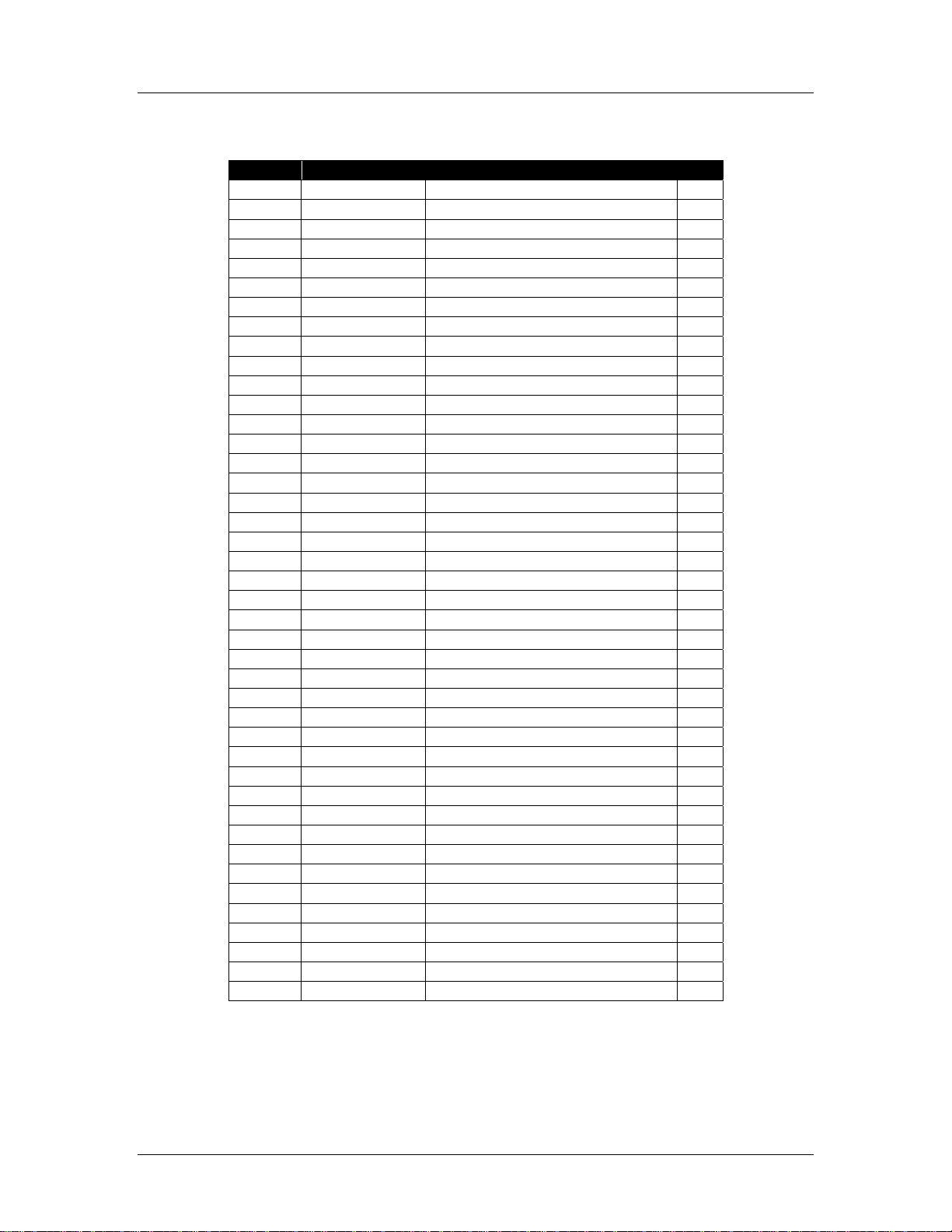

Specifications

Parts List

Item Part Number Description Qty.

0 80003-1 Side Panel B 1

1 80003-2 Hinge 1

2 80003-3 Handle Socket 1

3 80003-4 Straight Handle 1

4 80003-5 Fan 1

5 80003-6 Back Panel 1

6 80003-7 Rectifier Rack 1

7 80003-8 Clap Panel 1

8 80003-9 Wire Spool Axle 1

9 80003-10 Wire Feed Mechanism 1

10 80003-11 Wire Feed Wheel 1

11 80003-12 Side Panel A 1

12 80003-13 Power Cord 1

13 80003-14 Ground Cable With Clamp 1

14 80003-15 Welding Torch/Cable 1

15 80003-16 Cover 1

16 80003-17 Wire Speed Knob 1

17 80003-18 Switch 1

18 80003-19 Overload Light 1

19 80003-20 Cable Nib 1

20 80003-21 Front Panel 1

21 80003-22 Filter Reactor 1

22 80003-23 Main Transformer 1

23 80003-24 Transformer Carriage 1

24 80003-25 Bottom Plate 1

25 80003-26 Plastic Foot 1

26 80003-27 Axle Bracket 1

27 80003-28 Wheel, Plastic 1

28 80003-29 Axle 1

29 80003-30 Temperature Controller 1

30 80003-31 Control Circuit Board Bracket 1

31 80003-32 Control Circuit Board 1

32 80003-33 Potentiometer 1

33 80003-34 Knob 1

34 80003-35 Nut, Copper, M6 1

35 80003-36 Washer, Spring 6

36 80003-37 Washer, Copper, Plain 6

37 80003-38 Washer, Insulating 1

38 80003-39 Screw, Copper, M6 x 35 1

39 80003-40 Washer, Insulating 2

40 80003-41 Brace 1

41 80003-42 Rings 8

Rev 80003-200080227 11

Specifications

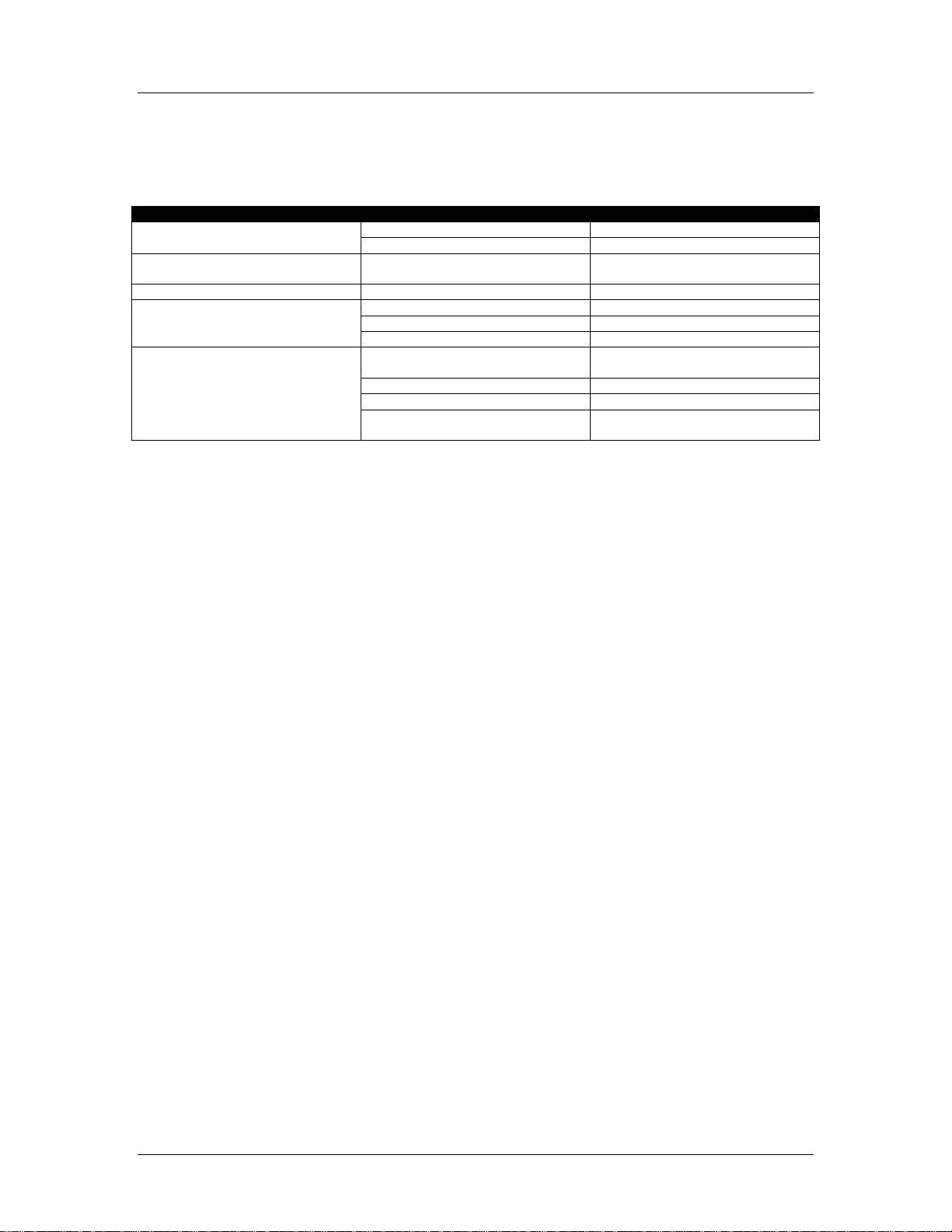

Troubleshooting

Problem Cause Solution

No weld output and fan is not running Power switch is OFF Switch ON

Fuse overload Reset breakers if necessary

Weld output but fan does not run Blocked fan movement Remove item that is blocking fan or

Erratic weld current Loose cable connections Clean and tighten cable connections

Erratic arc with excessive spatter Poor, damaged electrodes Use dry, properly stored electrodes

Long arc length Shorten arc length

High amperage setting Reduce amperage setting

Electrode wire feeding stops during

welding

Gun cable/Gun malfunction Straighten gun cable and/or replace

Poor drive roll pressure Adjust drive roll

Defective contact tip Replace contact tip if blocked

Restricted drive assembly Assess and clear any restrictions at

replace fan motor

damaged parts

drive assembly and liner

12 Rev 80003-200080227

Warranty

improperly or connected incorrectly to any

Warranty

CHAMPION POWER EQUIPMENT

1 YEAR LIMITED WARRANTY

Effective September 1, 2006. Replaces all undated

warranties and all warranties dated before September 1,

2006.

Warranty Qualifications

Champion Power Equipment (CPE) will register

this warranty upon receipt of your Warranty

Registration Card and a copy of your sales receipt

from one of CPE's retail locations as proof of

purchase.

Please submit your warranty registration and

your proof of purchase within ten (10) days of the

date of purchase.

electrical component. Normal maintenance such

as spark plugs, air filters, adjustments, fuel

system cleaning and obstruction due to buildup is

not covered by this warranty.

Other Exclusions

This warranty excludes:

Cosmetic defects such as paint, decals, etc.

Wear items such as filter elements, o-rings, etc.

Accessory parts such as starting batteries, and

storage covers.

Failures to due acts of God and other force

majeure events beyond the manufacturer’s

control.

Problems cause by parts that are not original

Champion Power Equipment parts.

Repair/Replacement Warranty

CPE warrants to the original purchaser that the

mechanical and electrical components will be free

of defects in material and workmanship for a

period of one (1) year from the original date of

purchase (90 days for commercial & industrial

use). Transportation charges on product

submitted for repair or replacement under this

warranty are the sole responsibility of the

purchaser. This warranty only applies to the

original purchaser and is not transferable.

Do not return the unit to the place of

purchase

Contact CPE's Technical Service and CPE will

troubleshoot any issue via phone or e-mail. If the

problem is not corrected by this method, CPE

will, at its option, authorize evaluation, repair or

replacement of the defective part or component

at a CPE Service Center. CPE will provide you

with a case number for warranty service. Please

keep it for future reference. Repairs or

replacements without prior authorization, or at

an unauthorized repair facility, will not be

covered by this warranty.

Warranty Exclusions

This warranty does not cover the following

repairs and equipment:

Normal Wear

Welders need periodic parts and service to

perform well. This warranty does not cover repair

when normal use has exhausted the life of a part

or the equipment as a whole.

Limits of Implied Warranty and

Consequential Damage

Champion Power Equipment disclaims any

obligation to cover any loss of time, use of this

product, freight, or any incidental or

consequential claim by anyone from using this

welder. THIS WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE

A unit provided as an exchange will be subject to

the warranty of the original unit. The length of

the warranty governing the exchanged unit will

remain calculated by reference to the purchase

date of the original unit.

This warranty gives you certain legal rights which

may change from state to state. Your state may

also have other rights you may be entitled to that

are not listed within this warranty.

Contact Information

Address

Champion Power Equipment, Inc.

Customer Service

10006 Santa Fe Springs Rd.

Santa Fe Springs, CA 90670

Customer Service

Mon – Fri 8:30 AM – 5:00 PM (PST/PDT)

Toll Free: 1-877-338-0999

Fax no.: 1-562-236-9429

Installation, Use and Maintenance

This warranty will not apply to parts and/or labor

if this welder is deemed to have been misused,

neglected, involved in an accident, abused, loaded

beyond the welder’s limits, modified, installed

Technical Service

Mon – Fri 8:30 AM – 5:00 PM (PST/PDT)

Toll Free: 1-877-338-0999

tech@championpowerequipment.com

13

Loading...

Loading...