REV 100152-20221209

DANGER: Not intended for use in critical life support application.

DANGER: Generator must be installed and operated outdoors only.

WARNING

Cancer and Reproductive Harm – www.P65Warnings.ca.gov

DISCLAIMERS

All information, illustrations and specifications in this manual are based on the latest information available at

the time of publishing. The illustrations used in this manual are intended as representative reference views only.

Products are under a continuous improvement policy. Thus, information, illustrations and/or specifications to explain

and/or exemplify a product, service or maintenance improvement may be changed at any time without notice.

ALL RIGHTS RESERVED

No part of this publication may be reproduced or used in any form by any means – graphic, electronic or

mechanical, including photocopying, recording, taping or information storage and retrieval systems – without the

written permission of Champion Power Equipment (CPE).

Have questions or need assistance?

Do not return this product to the store!

WE ARE HERE TO HELP!

Visit our website:

www.championpowerequipment.com

for more info:

• Product Info & Updates

• Frequently Asked Questions

– or –

Call our Customer Care Team Toll-Free at:

1-877-338-0999

This manual must be used with Champion Power Equipment (CPE) manuals:

• Installation Manual, Part No. 101307

• Transfer Switch Manual, Part No. 101111

It is also recommended to refer to the reference materials list on

page 16 of the Installation Manual.

• Tech Bulletins

• Product Registration

*We are always working to improve our products. Therefore, the enclosed product may differ slightly from the image on the cover.

CONTENTS

Model 100152

CONTENTS

INTRODUCTION ...........................5

Home standby generator ....................5

Parts Included ...........................5

General information, Standards and Codes .......6

SAFETY .................................7

Safety Symbol Definitions ...................7

Installation Hazards. . . . . . . . . . . . . . . . . . . . . . . . 8

Before Starting ...........................9

Operating Hazards ........................9

Accidental Starting .......................10

Carbon Monoxide Hazards ..................10

Electrical Shock Hazards ...................11

Fire/Explosion Hazards ....................11

Burn Hazards ...........................12

Entanglement Hazards ....................12

Battery Hazards .........................12

Emission Requirements ....................19

Specifications ...........................20

Fuel System ............................21

Battery Requirements .....................21

Battery Charging ........................21

Model and Serial Number ..................21

OPERATION .............................22

Enclosure and Access .....................22

Pre-Start Checklist .......................22

Turning Off the Generator ..................22

MAINTENANCE ...........................23

Scheduled Maintenance Chart ...............23

Engine Oil .............................23

Engine Oil Requirements .................... 23

Checking the Engine Oil Level ................. 23

Changing the Engine Oil ..................... 24

Safety Labels ...........................12

Safety Labels on Unit ....................... 13

Safety, Serial/Model, Nameplate Label Locations ... 14

GENERAL INFORMATION ...................15

Component Identification –11 kW Generator. . . . . 15

Component Identification – Engine ............16

Control Panel ..........................16

Main Circuit Breaker. . . . . . . . . . . . . . . . . . . . . . . . 16

Exercise Switch ........................... 16

Set Exercise Time .......................... 17

Hour Meter .............................. 17

Engine Control Module ...................... 17

Reset Fault Code(s) ........................ 17

ATS Control Module ........................18

Battery Charger .........................19

Inspect and Clean Engine Air Cleaner ..........25

Spark Plug .............................25

Battery Maintenance ......................26

Corrosion Protection ......................26

Maintenance After Submersion ..............26

Storage ...............................26

Return to Service after Storage ................ 27

Engine Parts Diagram ....................... 28

Engine Parts List .......................... 29

Enclosure and Assemblies Diagram ............. 32

Enclosure and Assemblies Parts List ............ 33

Top Cover Assembly, Left Diagram .............. 34

Top Cover Assembly, Left Parts List ............. 35

Top Cover Assembly, Right Diagram ............. 36

Top Cover Assembly, Right Parts List ............ 37

Part No. 101305

3

Model 100152

CONTENTS

Alternator and Exhaust System Diagram .........38

Alternator and Exhaust System Parts List ......... 39

Control Panel Diagram ...................... 40

Control Panel Parts List ..................... 41

Wiring Diagram ........................... 42

TROUBLESHOOTING .......................43

ADDITIONAL INFORMATION .................45

Identify / Select Standby Circuits .............45

Surge Protection .........................45

Customer Familiarization Summary ...........46

HSB, ATS Model & Serial Reference

Back-Up Circuits ........................47

Maintenance and Service Record .............48

Part No. 101305

4

Model 100152

INTRODUCTION

Congratulations on your purchase of a Champion Power

Equipment (CPE) home standby generator. This generator is

designed and engineered in the USA to exacting standards of the

North American market. This engine-powered generator meets

all Environmental Protection Agency (EPA) Phase 3 requirements

and is approved by CETLUS as tested to UL2200 and CSA22.2 No.

100 in both the USA and Canada.

With proper use and maintenance, this generator will provide

years of satisfying service.

The Champion Staff,

Champion Power Equipment

12039 Smith Ave.

Santa Fe Springs, CA 90670

Toll-free: 1-877-338-0999

Mon-Fri 8:30 AM – 5:00 PM (PST/PDT)

www.championpowerequipment.com

HOME STANDBY GENERATOR

This home standby generator is intended exclusively for outdoor

installation. This generator will operate using either liquefied

petroleum gas (LPG) or natural gas (NG).

PARTS INCLUDED

Your HSB ships with the following:

• Operators Manual

• Installation Manual

• Oil Drain Pan

• Flexible Fuel Line

• HSB Enclosure Keys

• Battery Cable Connection

• LPG Low-speed and Main Converting Jets

• Jet Change Tool

• Lock Nut M6

• Washer, Ø6

• Flange bolt, M6 x 15

This generator is designed to supply typical home load such as:

• Induction motors – sump pumps, refrigerators, air

conditioners, furnaces

• Electronic items – televisions, computers

• Household lighting

• Microwaves

• This generator is not intended for use in critical life

support applications.

Proper sizing of the generator is required to ensure proper

operation of appliances. Some appliances require additional

wattage to start and must be considered.

Part No. 101305

5

Model 100152

INTRODUCTION

GENERAL INFORMATION,

STANDARDS AND CODES

The following information related to General Information and

Standards was gathered from the list of publications related

to installing the HSB generator. A multitude of other materials

related to generators were also used concerning common

practice, knowledgeable installation practices, certified

electrical experience and work related experiences. This

information is not all inclusive and the manufacturer strongly

recommends the owner and installer become familiar with all

pertinent codes, standards and regulations. Always check for

the latest publications date to ensure you are current. Have

only a qualified/certified electrician or installation technician

who is knowledgeable about applicable codes, standards and

regulations install and service the generator.

NFPA NO. 30, FLAMMABLE AND CONBUSTIBLE LIQUID

CODE

National Fire Protection Association

470 Atlantic Avenue, Boston, MA. 02210

NFPA NO. 70, NFPA HANDBOOK OF ELECTRIC CODE

National Fire Protection Association

470 Atlantic Avenue, Boston, Ma. 02210

ARTICLE X, NATIONAL BUILDING CODE

American Insurance Association

85 John Street, New York, N.Y. 10038

AGRICULTURAL WIRING HANDBOOK

Food and Energy Council

909 University Avenue, Columbia, Mo. 65201

ASAE EP-3634, INSTALLATION AND MAINTENANCE OF

FARM STANDBY ELECTRICAL SYSTEMS

American Society of Agricultural Engineers

2950 Niles Road, St. Joseph, Mi. 49085

NFPA NO. 37, STATIONARY COMBUSTION ENGINES AND

GAS TURBINES

National Fire Protection Association

470 Atlantic Avenue, Boston, Ma. 02210

NFPA NO. 76A, ESSENTIAL ELECTRICAL SYSTEMS FOR

HEALTH CARE FACILITIES

National Fire Protection Association

470 Atlantic Avenue, Boston, Ma. 02210

NFPA NO. 54, NATIONAL FUEL GAS CODE

National Fire Protection Association

470 Atlantic Avenue, Boston, Ma. 02210

NFPA NO. 58, AMERICAN NATIONAL STANDARD FOR

STORAGE AND HANDLING OF LIQUID PETROLEUM GAS

National Fire Protection Association

470 Atlantic Avenue, Boston, Ma. 02210

Part No. 101305

6

Model 100152

!

!

!

!

!

!

SAFETY

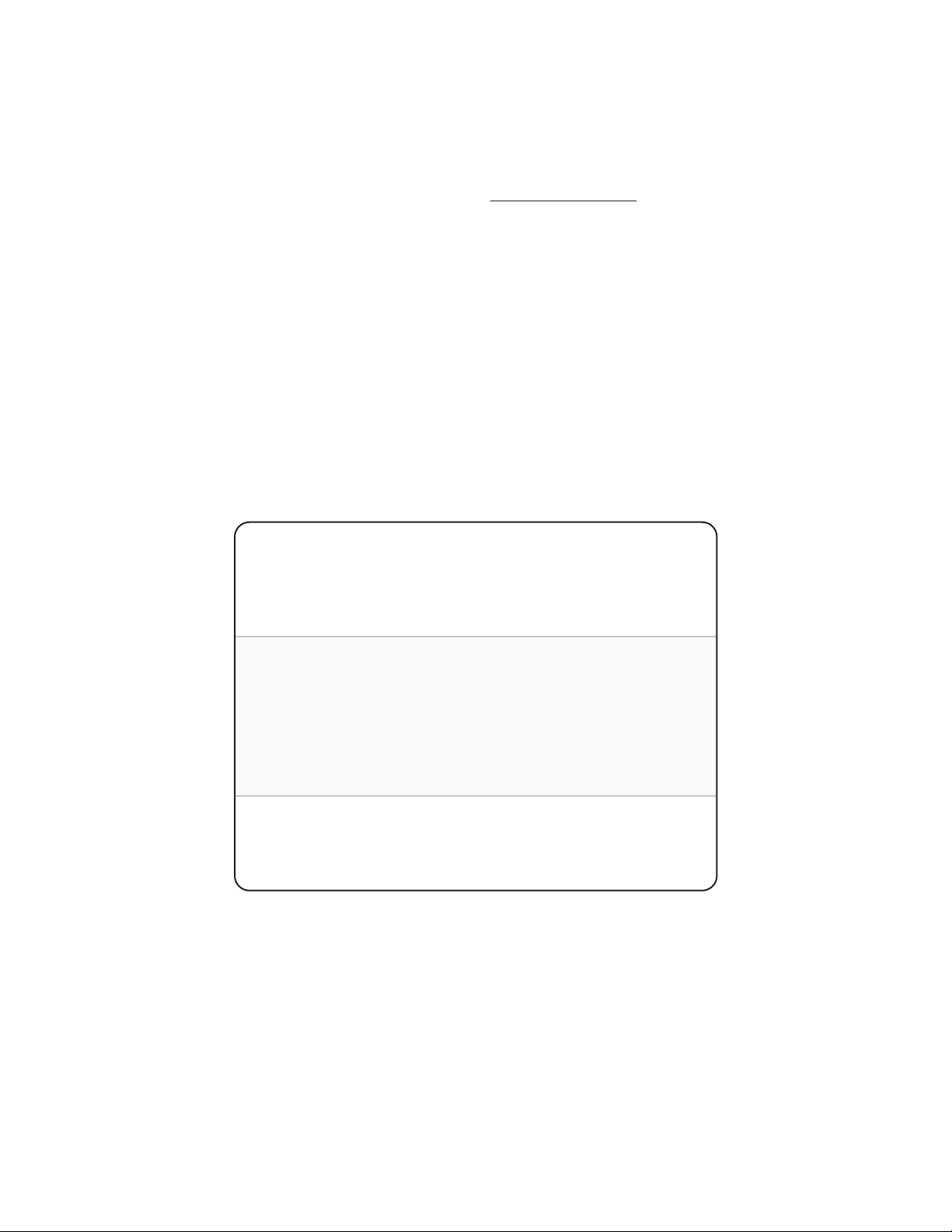

This is the safety alert symbol. It is used to alert

you to potential physical injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

The words DANGER, WARNING, CAUTION and NOTICE are used

throughout this manual to highlight important information.

DANGER

Indicates a hazardous situation that, if not avoided, will

result in death or serious injury.

WARNING

Indicates a hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a hazardous situation that, if not avoided,

could result in minor or moderate injury.

SAFETY SYMBOL DEFINITIONS

Black hazard pictorial on yellow

equilateral triangle enclosed by black

triangular band

Warns that hazard exists and describes

its nature and/or consequences

Black hazard pictorial on white circle

enclosed by red circular band with red

diagonal bar

Depicts action NOT to be taken or

action to be stopped in order to avoid

hazard

White hazard pictorial on blue circle

Depicts action to be taken in order to

avoid hazard

WARNINGS

NOTICE

Indicates a situation that can cause damage to the

equipment, personal property and/or the environment, or

cause the equipment to operate improperly.

OTE: N Indicates a procedure, practice or condition that

should be followed in order for the generator to

function in the manner intended.

Safety alert symbol

Asphyxiation hazard

Electrical shock hazard

Entanglement hazard

Fire hazard

Part No. 101305

7

Model 100152

!

!

!

!

SAFETY

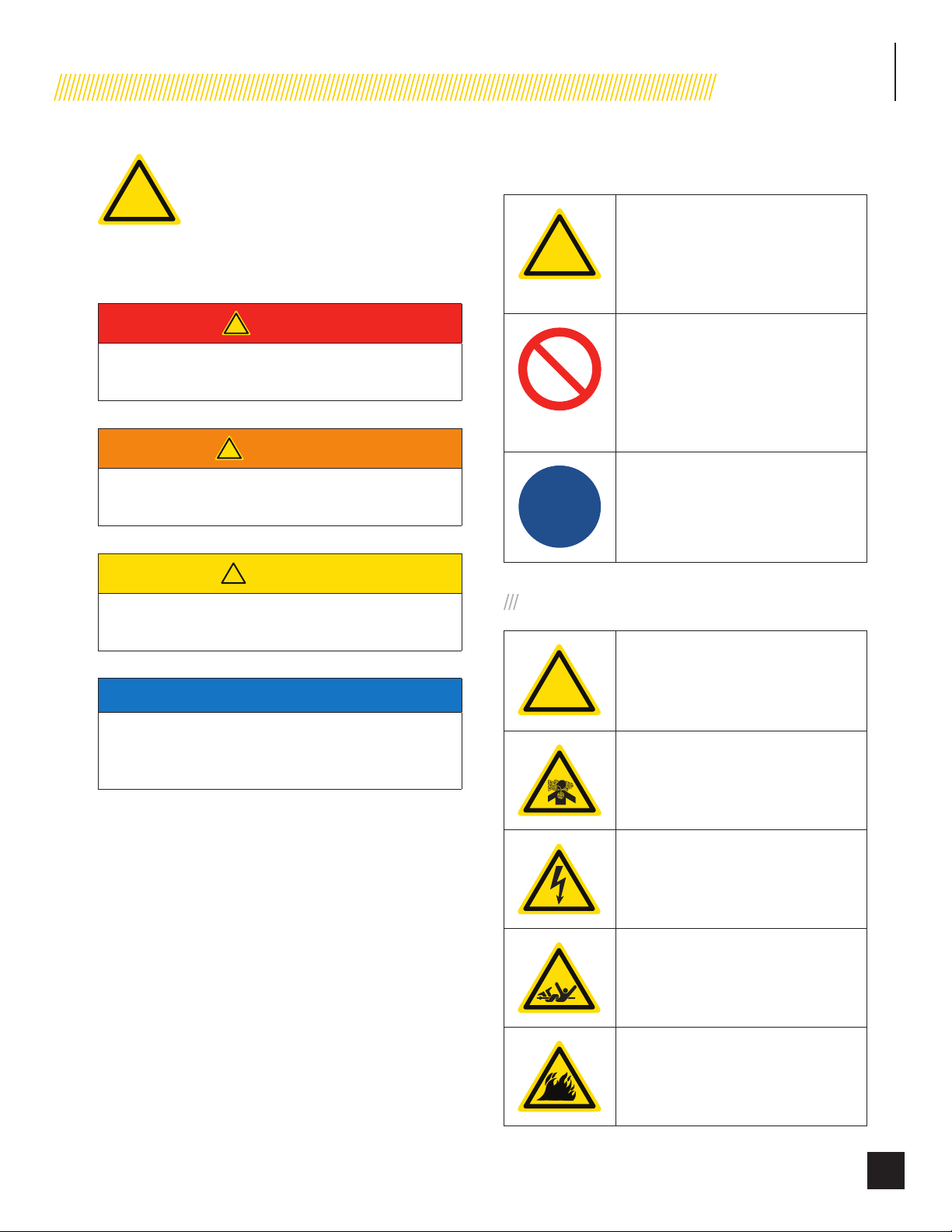

INSTALLATION HAZARDS

Explosion hazard

Burn hazard

Sever hazard (rotating blade)

Crush hazard (top)

MANDATORY ACTIONS

WARNING

Have only a qualified electrician

or installation technician who is

familiar with applicable codes,

standards and regulations install

and service the generator.

ALWAYS comply with local, state

and national electrical and building

codes when installing the generator.

NEVER alter the recommended

installation in a way that would

render the unit noncompliant with

these codes.

ALWAYS comply with regulations

that Occupational Safety and

Health Administration (OSHA) has

established.

ENSURE the generator is installed

following the manufacturer’s

instructions.

Read manufacturer’s instructions

Wear eye protection

Wear personal protective equipment

Do not leave tools in the area

NOTICE

Before welding components on the generator, contact CPE

for recommended welding instructions.

WARNING

Not intended for use in critical life

support applications.

Part No. 101305

8

Model 100152

!

!

!

SAFETY

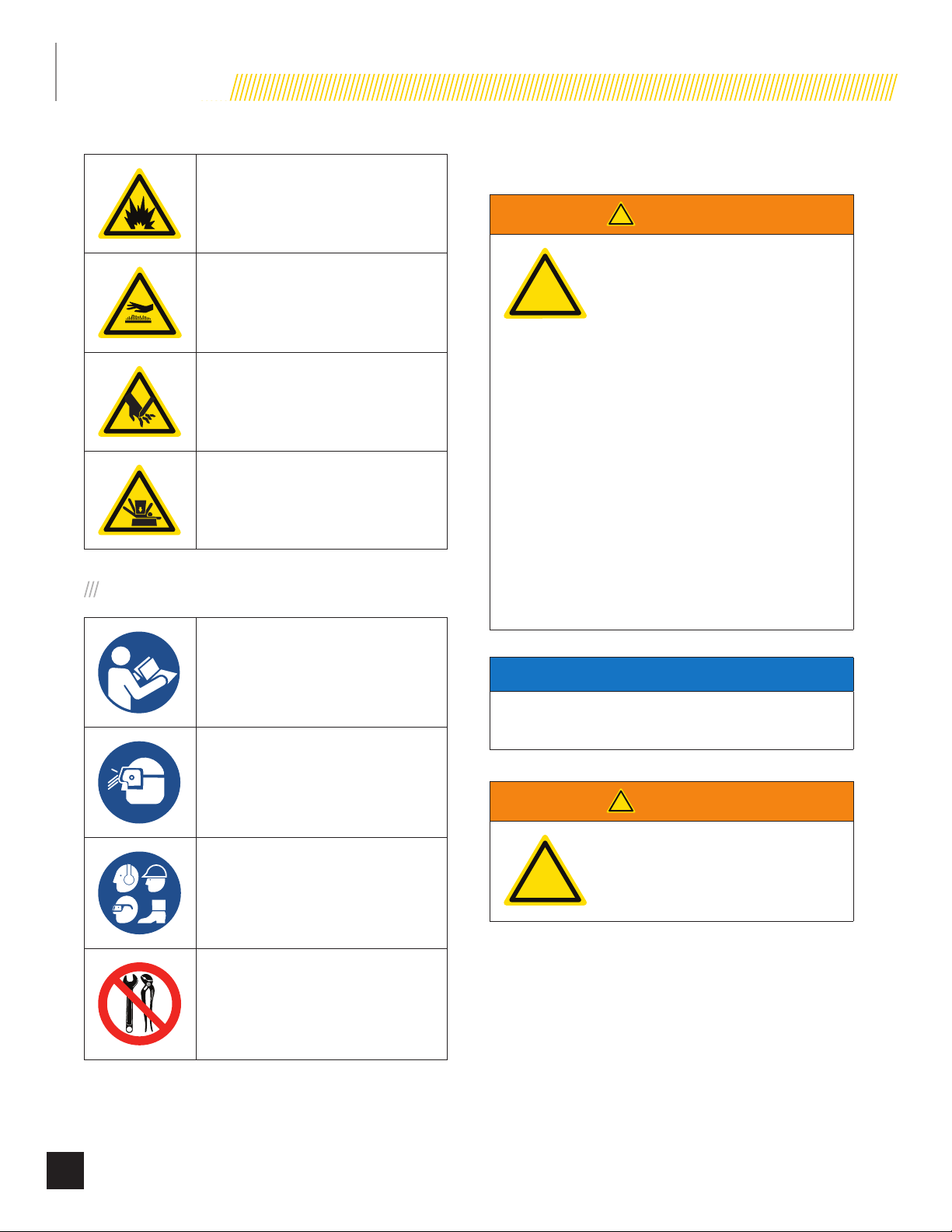

BEFORE STARTING

CAUTION

Before starting, operating and

maintaining this generator, be sure

to read and understand the content

and safety messages in this manual.

The operator is responsible for safe

operation and maintenance of the

generator. Be sure all potential users

of the generator also understand

these instructions. If any portion

of this manual is not understood,

contact your dealer for assistance

before operating the generator.

The operator is responsible for

performing all safety checks, making

sure all maintenance is properly

performed and making sure the

generator is periodically checked by

the dealer.

Inspect the generator regularly.

Contact your dealer if repairs are

needed.

NEVER climb or step on any part or

components of the generator. Doing

so may result in injury and cause

leaking fuel and exhaust.

OPERATING HAZARDS

WARNING

ALWAYS operate the generator

following the manufacturer’s

instructions. Operating the generator

imprudently, neglecting maintenance

or being careless can result in injury

or possible death.

DO NOT allow children or unqualified

persons to operate or service the

generator.

NEVER operate the generator

with the covers open. Operate the

generator only with the covers

closed and secured in place. NEVER

leave the covers unlocked.

Remain alert at all times when

working on the generator. NEVER

work on the generator when

physically or mentally fatigued.

Never operate the generator while

under the influence of alcohol

or drugs. Their effects on vision

and judgment make operating a

generator dangerous.

Part No. 101305

9

Model 100152

!

!

SAFETY

ACCIDENTAL STARTING

WARNING

ALWAYS prevent the generator from

starting while the covers are open.

The generator may crank and start

at any time without notice. Follow

these steps in order:

1. Turn the exercise switch to

the OFF position.

2. Switch the main circuit

breaker to the OFF position.

3. Turn the ATS control module

to the OFF position.

4. Turn the engine control

module switch to the OFF

position.

5. Disconnect the NEGATIVE, NEG

or (-) battery cable first, and

then remove the POSITIVE,

POS or (+) battery cable.

To return the generator to service,

follow these steps in order:

1. Connect the POSITIVE, POS

or (+) battery cable first, and

then connect the NEGATIVE,

NEG or (-) battery cable.

2. Turn the engine control

module switch to the ATS

position.

3. Turn the ATS control module

switch to the AUTO position.

4. Switch the main circuit

breaker to the ON position.

5. Turn the exercise switch to

the ON position.

CARBON MONOXIDE HAZARDS

DANGER

Generator exhaust contains carbon

monoxide, a colorless, odorless,

poisonous gas. Breathing carbon

monoxide will cause nausea,

dizziness, fainting or death. If you

start to feel dizzy or weak, get to

fresh air immediately.

• The generator must be installed

and operated outdoors only.

NEVER install the generator where

exhaust fumes could seep inside

or be drawn into a potentially

occupied building through

windows, air intake vents or other

openings.

• Avoid breathing exhaust fumes

when near an operating generator.

• NEVER alter or add to the exhaust

system or do anything that might

render the system unsafe or in

noncompliance with applicable

codes, standards, laws and

regulations.

• Install a battery-operated carbon

monoxide detector on each

level of any building adjacent

to the generator following the

manufacturer’s instructions.

• NEVER permit even partial

blockage of engine cooling

ventilation air. Doing so can

seriously affect safe operation of

the generator.

Carbon monoxide poisoning symptoms include but are not

limited to the following:

• Light-headedness, dizziness

• Physical fatigue, weakness in joints and muscles

• Sleepiness, mental fatigue, inability to concentrate or

speak clearly, blurred vision

• Stomachache, vomiting, nausea

Part No. 101305

10

Model 100152

!

!

SAFETY

Carbon monoxide poisoning is possible if someone is

experiencing any of these symptoms. Seek fresh air immediately.

DO NOT sit, lie down or fall asleep. Alert others to the possibility

of carbon monoxide poisoning. If the affected person does

not improve within minutes of breathing fresh air, call 911

immediately.

ELECTRICAL SHOCK HAZARDS

WARNING

Use extreme caution when near

the generator while it is operating.

The generator produces dangerous

voltage.

• Avoid contact with bare wires,

terminals and connections while

the generator is operating.

• ALWAYS stand on an insulated dry

surface to reduce shock hazard

if work must be done on an

operating generator.

• NEVER wear jewelry that can

conduct electricity when working

on the generator.

• NEVER handle any kind of

electrical device while hands or

feet are wet, while standing in

water or while barefoot.

• Proper earth grounding of the

frame and external electrical

conductive components is

required by the National Electrical

Code (NEC). State and local codes

for proper grounding may also

apply.

• Avoid direct contact with an

electric shock victim. Immediately

shut down the source of electrical

power. If this is not possible,

attempt to free the victim from

the live conductor using a

nonconducting item such as a

dry board or rope. If the victim is

unconscious, apply first aid and

call 911 immediately.

FIRE/EXPLOSION HAZARDS

WARNING

NG and LPG are extremely explosive.

• NEVER allow any flames or smoke

near the fuel system.

• Wipe up any oil spills immediately.

• NEVER allow any combustible

materials to be near the generator

or to be left in the generator

compartment.

• ALWAYS keep the surrounding

area near the generator clean and

free of debris.

• Be sure to properly purge the fuel

lines and leak-test according to

applicable codes before placing

the generator in service.

• Be sure to regularly inspect the

fuel system for leaks. NEVER

operate the generator if a fuel leak

is present.

• Install a fire extinguisher near

the generator. Keep it properly

charged and be familiar with

its use. An ABC rated National

Fire Protection extinguisher is

appropriate for use on standby

electric systems. Contact your

local fire department with any

questions concerning the fire

extinguisher.

Part No. 101305

11

Model 100152

!

!

!

!

!

!

SAFETY

BURN HAZARDS

WARNING

ALWAYS allow hot surfaces to cool to

the touch. Running engines produce

heat. Severe burns can occur on

contact.

• DO NOT touch hot surfaces.

• Avoid contact with hot exhaust

components and gases.

ENTANGLEMENT HAZARDS

WARNING

Use extreme caution when near

rotating parts. Rotating parts can

entangle hands, feet, hair, clothing

and/or accessories. Traumatic

amputation or severe laceration can

result.

• Keep hands and feet away from

rotating parts.

• Tie up long hair and remove

jewelry.

• Operate equipment with guards in

place.

• DO NOT wear loose-fitting

clothing, dangling drawstrings or

items that could become caught.

WARNING

Batteries contain sulfuric acid and

generate explosive mixtures of

hydrogen and oxygen gases. Keep

any device that may cause sparks

or flames away from the battery to

prevent explosion.

Always wear protective glasses

or goggles and protective clothing

when working with batteries.

You must follow the battery

manufacturer’s instructions on

safety, maintenance and installation

procedures.

SAFETY LABELS

WARNING

All safety labels must be legible to

alert personnel of safety hazards.

• Replace any illegible or missing

label immediately. Missing safety

labels must be replaced in their

original position before the

generator is operated.

• DO NOT operate the generator if

there are missing or badly worn

safety labels.

BATTERY HAZARDS

WARNING

Always read and comply with

the battery manufacturer’s

recommendations for procedures

concerning proper battery use and

maintenance.

Part No. 101305

12

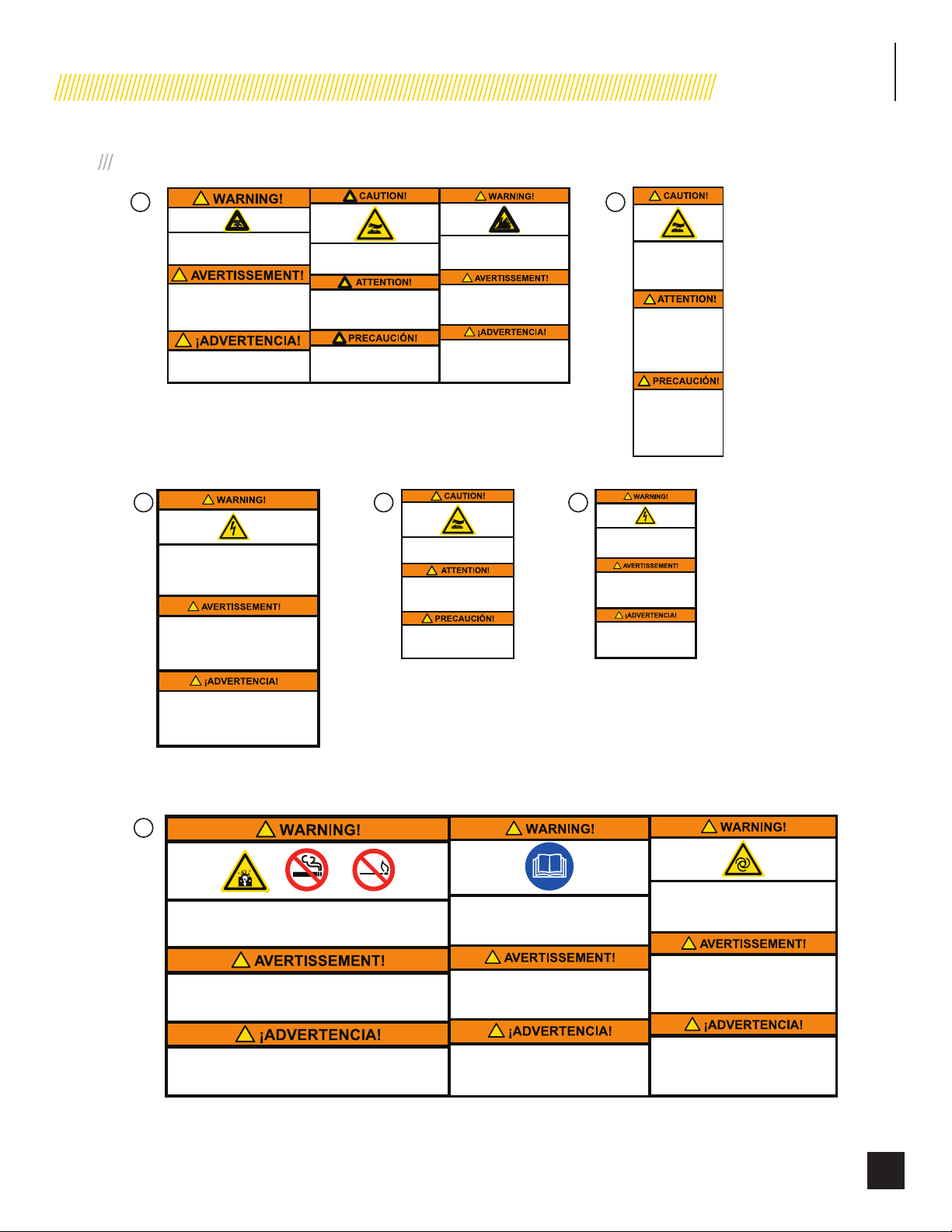

SAFETY LABELS ON UNIT

Model 100152

SAFETY

1

3

!

Poisonous Gas Hazard Generator exhaust

contains carbon monoxide. Breathing carbon

monoxide will cause nausea, dizziness, and

fainting, and it may cause death.

!

Risque d’empoisonnement par le gaz Les gaz

d’échappement de groupe électrogène contiennent

du monoxyde de carbone. Si l’on respire du

monoxyde de carbone, ceci peut provoquer des

nausées, un évanouissement et une perte de

conscience, et ceci peut provoquer la mort.

!

Riesgo de gas venenoso El escape del

generador contiene monóxido de carbono. Aspirar

monóxido de carbono causará náuseas, mareos,

desvanecimiento y hasta la muerte.

!

Electrical Shock Hazard

Do not remove this access panel. The panel

should only be removed by an authorized

Service Dealer or a qualified electrician;

high voltage inside.

!

Risque de choc électrique

N’enlevez pas ce panneau d’accès.

Le panneau ne devrait être enlevé que par

un concess ionnaire d’entretien agréé ou un

électricien qualifié ; haut e tension à l’intérieur.

!

Riesgo de descarga eléctrica

No remueva este tablero de acceso. El tablero

sólo deberá s

de servicio autorizado o un electricista

calificado; alto voltaje al interior.

er removido por un distribuidor

101045

!

Burn Hazard DO NOT touch hot

surfaces. Avoid contact with

exhaust components and gases.

!

Risque de brûlure NE touchez

PAS les surfaces chaudes. Evitez

le contact avec les composants et

les gaz d’échappement.

!

Riesgo de quemaduras NO toque

las superficies calientes. Evite el

contacto con los componentes de

escape y gases.

101500

4 5

101045

!

Fire Hazard ALWAYS keep the surrounding

area near generator clean and free of debris

and/or dry vegetation. The generator may

create sparks while operating.

!

Risque d’incendie Nettoyez TOUJOURS la

surface à proximité du groupe électrogène et

enlevez les débris et/ou la végétation sèche.

Le groupe électrogène peut générer des

étincelles pendant son fonctionnement.

!

Riesgo de incendio SIEMPRE mantenga el

área circundante cerca del generador limpia y

libre de escombros y/o vegetación seca. El

generador puede crear chispas mientras está

en funcionamiento.

!

Burn Hazard DO NOT touch hot

surfaces. Avoid contact with

exhaust components and gases.

!

Risque de brûlure NE touchez

PAS les surfaces chaudes. Evitez

le contact avec les composants et

les gaz d’échappement.

!

Riesgo de quemaduras NO toque

las superficies calientes. Evite el

contacto con los componentes de

escape y gases.

101051

101500

101051 100789

!

2

Burn Hazard DO NOT

touch hot surfaces. Allow

the engine and alternator

to cool to the touch

before servicing.

!

Danger de brulure NE

TOUCHEZ PAS les

surfaces chaudes.

Laissez le moteur et

l’alternateur devenir froid

au toucher avant

d’intervenir.

!

Riesgo de quemaduras

NO toque las superficies

calientes. Deje que el

motor y el alternador se

enfríen para tocarlos

antes de realizarles el

mantenimiento.

100794

!

Electrical Shock Hazard ALWAYS

close and lock generator covers before

operating. The generator produces

dangerous voltage.

!

Risque de choc électrique Fermez et

verrouillez TOUJOURS les capots de

groupe électrogène avant d’utiliser le

groupe. Le groupe électrogène génère

des tensions dangereuses.

!

Riesgo de descarga eléctrica

SIEMPRE cierre y trabe las tapas del

generador antes de ponerlo en

funcionamiento. El generador produce

un voltaje peligroso.

100794

100789

6

!

Explosion Hazard Battery gases are explosive.

Keep sparks and flames away from the battery

compartment.

!

Risque d’explosion Les gaz dégagés par la

batterie peuvent exploser. Ecartez les étincelles

et les flammes du compartiment batterie.

!

Riesgo de explosión Los gases de las baterías

son explosivos. Mantenga las chispas y llamas

alejadas del compartimento de las baterías.

!

Read Operator’s Manual Read,

understand and follow all safety

messages in Installation and Operator’s

manuals.

!

Lisez le manuel d’utilisation Lisez,

comprenez bien et respectez tous les

messages de sécurité dans les manuels

d’installation et d’utilisation.

!

Lea el manual del operador Lea,

comprenda y siga todos los mensajes

de seguridad en los manuales de

instalación y del operador.

Starting Hazard The generator may crank and

start at any time without notice. Prevent the

generator from starting while the covers are open.

See the safety section of the operator’s manual for

further detail.

Risque au démarrage Le groupe électrogène

peut tourner et démarrer à tout moment sans

préavis. Ne démarrez pas le groupe électrogène

lorsque les capots sont ouverts. Consultez la

section sécurité du manuel d’utilisation pour plus

de détail.

Riesgo de inicio El generador puede encenderse

y ponerse en marcha en cualquier momento sin

previo aviso. Evite que el generador se ponga en

marcha mientras las tapas están abiertas. Vea la

sección de seguridad en el manual del operador

para más detalles.

!

!

!

101499

101499

Part No. 101305

13

Model 100152

SAFETY

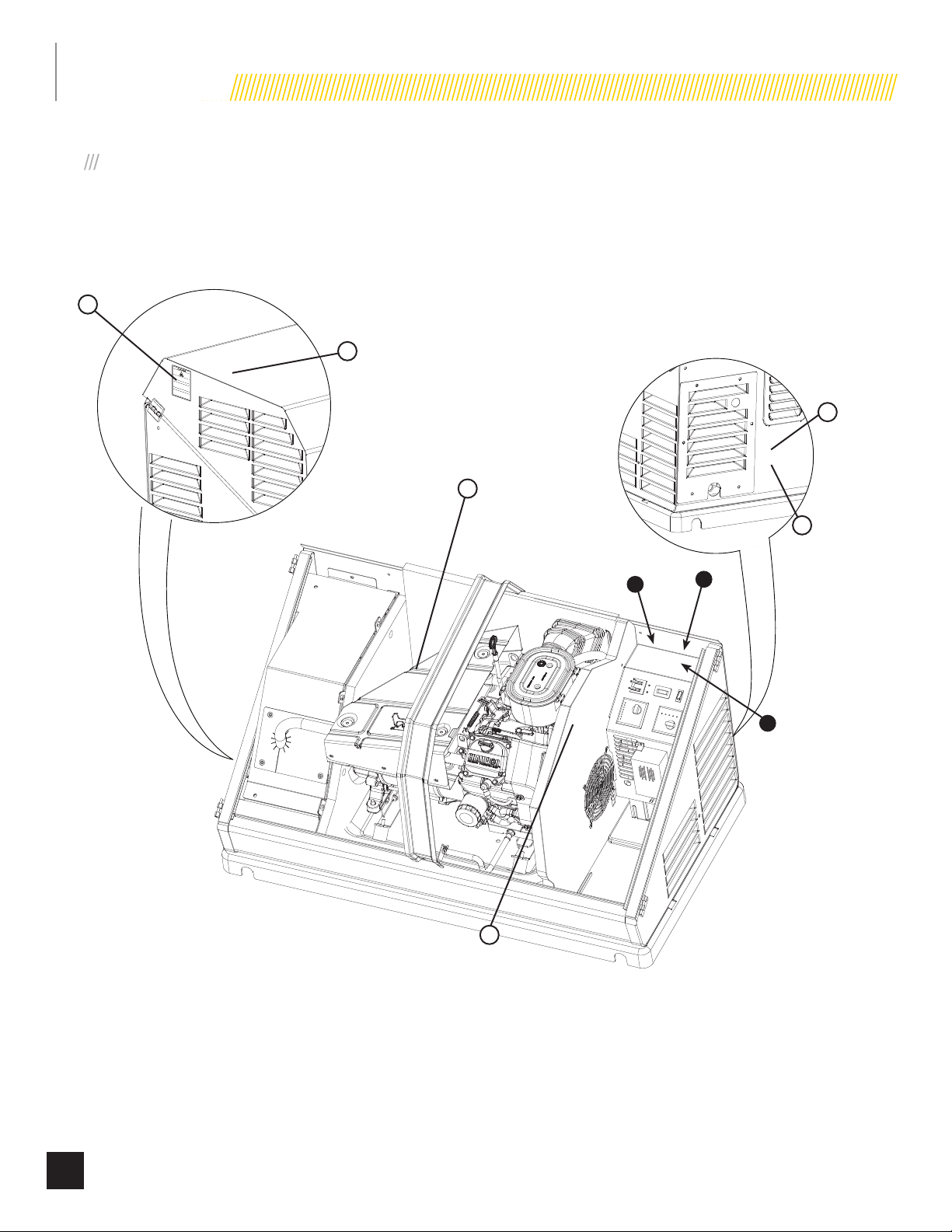

SAFETY, SERIAL/MODEL, NAMEPLATE LABEL LOCATIONS

The safety labels have specific placement and must be replaced if they are unreadable, damaged or missing.

4

!

1

(inner part of cover)

3

2

5

C

A

B

Part No. 101305

14

6

A) Serial number locaon

B) Nameplate

C) NFPA 37 Compliance

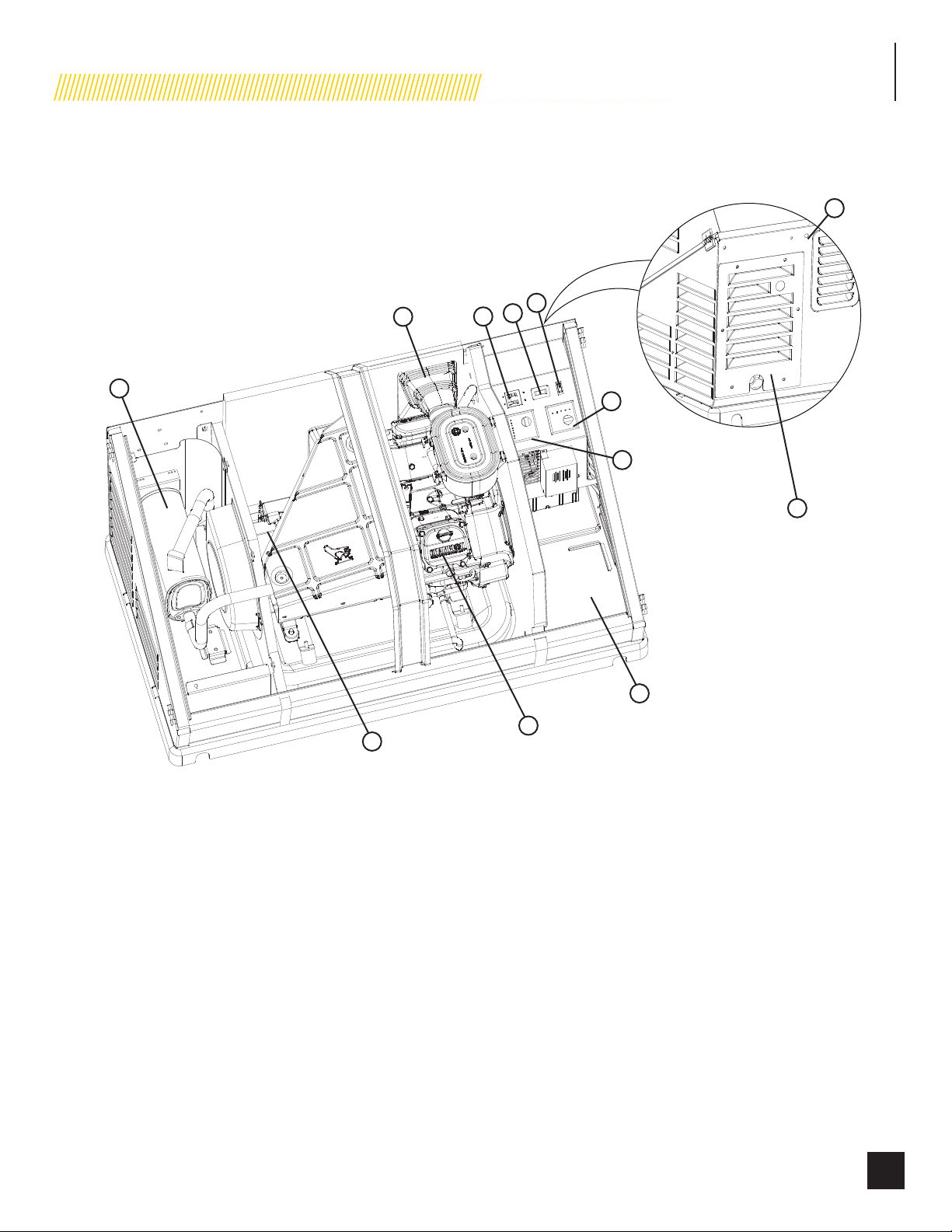

GENERAL INFORMATION

COMPONENT IDENTIFICATION – 11 KW GENERATOR

7

5

2

4

Model 100152

6

1

11

12

Figure 1

8

9

3

10

1. Exhaust System

2. Air Inlet

3. Fuel Regulator/Wire

Connections (behind panel)

4. Main Circuit Breaker

5. Hour Meter

6. Exterior Fault Code Indicator

Light

7. Exercise Switch

8. ATS Control Module

9. Engine Control Module

10. Batteries (not included)

11. Engine

12. Alternator

Part No. 101305

15

Model 100152

ON

MARCHE

ENCENDIDO

OFF

ARRÊT

APAGADO

MAIN CIRCUIT BREAKER

DISJONCTEUR PRINCIPAL

INTERRUPTOR DE CIRCUITO PRINCIPAL

GENERAL INFORMATION

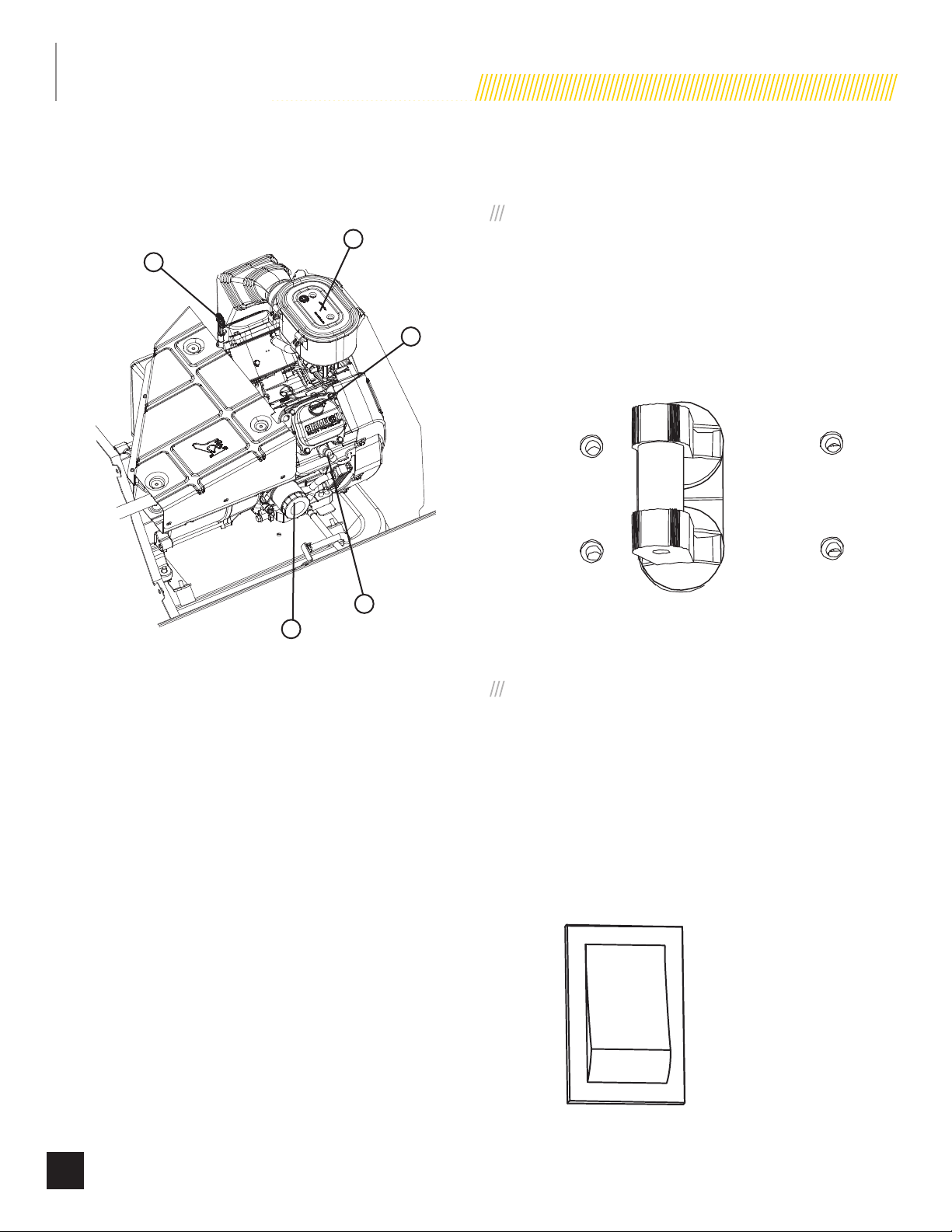

COMPONENT IDENTIFICATION –

ENGINE

2

1

3

4

5

CONTROL PANEL

MAIN CIRCUIT BREAKER

The 46-amp main circuit breaker protects the generator from

circuit overload. The main circuit breaker controls total output of

the generator. (Figure 3)

Figure 3

Figure 2

1. Engine Oil Dipstick

2. Air Cleaner

3. Oil Cap

4. Spark Plug (second on

opposite side)

5. Oil Filter

EXERCISE SWITCH

The exercise switch incorporates a built-in timer. The generator

will automatically perform an exercise period once every

seven days (168 hours). At the start of the exercise period, the

engine will start and run for 15 minutes. Load transfer from the

generator output will not occur unless the utility power is lost.

When the switch is in the OFF position, the exercise function is

disabled. Refer to Set Exercise Time to reset. (Figure 4)

EXERCISE / EXERCICE

EJERCICIO

ON

MARCHE

ENCENDIDO

OFF

ARRÊT

APAGADO

Figure 4

Part No. 101305

16

Model 100152

GENERAL INFORMATION

SET EXERCISE TIME

To set the exercise time, the engine control module switch

must be in the ATS mode. Decide on the desired day and time

to exercise the generator. Press the exercise switch to ON. The

generator will start and run for 15 minutes and then shut off.

The exercise time is now set. The generator will begin the next

exercise period exactly 168 hours from when the exercise switch

was pressed to the ON position.

If you choose to change the current exercise time setting, choose

the new day and time and cycle the exercise switch from off to

on and it will begin the cycle again. (Figure 4)

The exercise time will have to be reset if:

• The battery was disconnected from the generator

• The switch was moved to the OFF position for

maintenance

HOUR METER

The generator is equipped with an hour meter that will display

the generator actual run and exercise times.

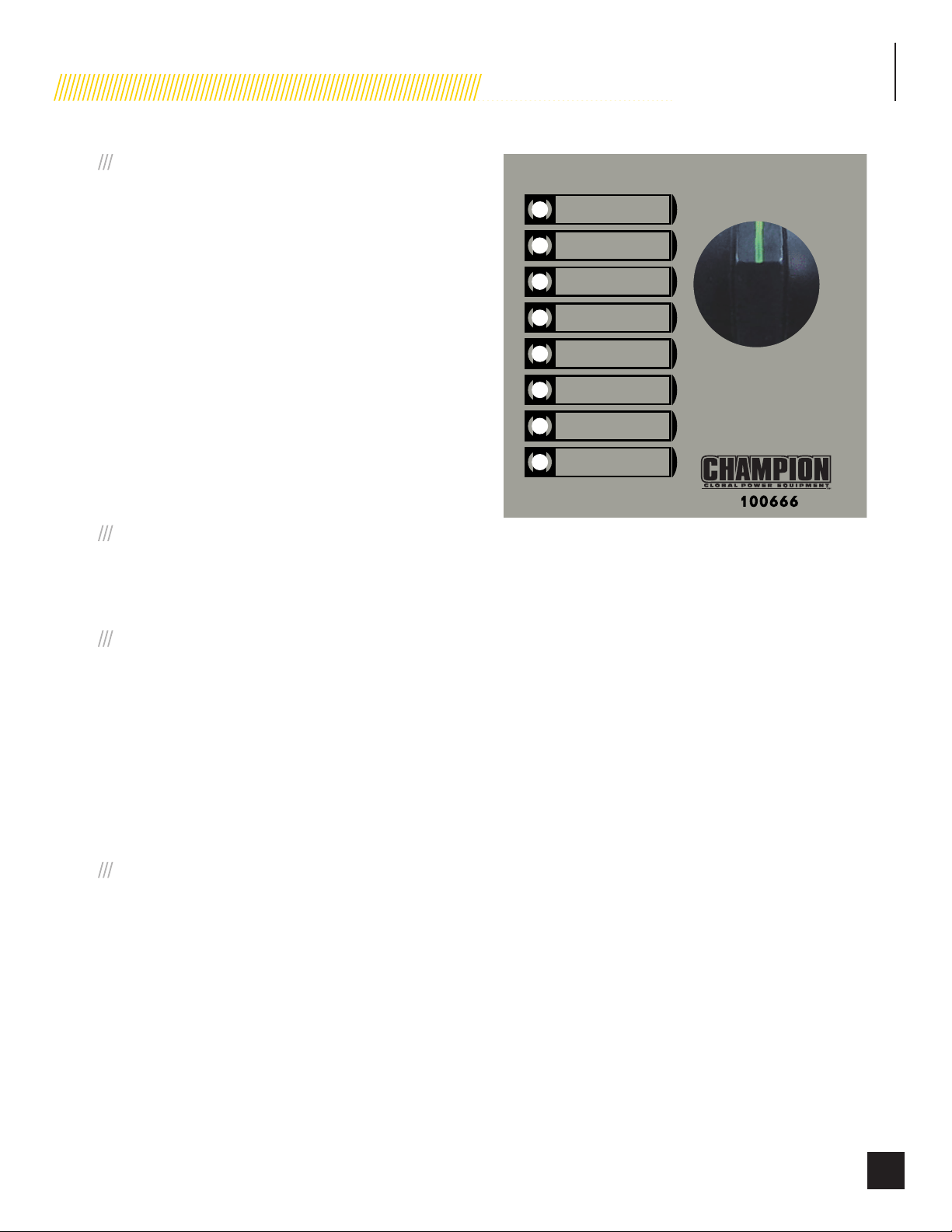

ENGINE CONTROL MODULE

The engine control module contains the ATS/OFF/Manual mode

switch and the LEDs that indicate if a generator operation is

being performed or if there is an active alarm. (Figure 5)

If the exterior fault code indicator light is on, open the enclosure

to view the engine control module. Determine what the fault code

is and remedy the situation or have the generator serviced by an

authorized Service Dealer or contact Champion Customer Service

at 1-877-338-0999.

RESET FAULT CODE(S)

ATS

Exercise / Exercice /

Ejercicio

Low battery /

Batería baja

Hz over/under / Hz plus / sous

Hz Más / Menos

High engine temperature

Surchauffe moteur

Alta temperatura del motor

Low oil / Huile basse

Baja de aceite

Over crank

Surdémarrage

Sobre manivela

Run / Marche

Funcionar

Power / Alimentation

Potencia

MODE SWITCH

• ATS – This position allows for fully automatic operation. If

utility power is lost, the generator will automatically start

up. It also allows the generator to automatically perform

the exercise period.

• OFF – This position shuts down the engine and prevents

automatic operation of the generator.

• Manual – This position allows manual starting of the

engine. Load transfer from the generator output does not

occur unless the utility power is lost.

EXERCISE LED

The GREEN LED will be flashing when the HSB is performing the

weekly exercise cycle. When the exercise period has completed,

the LED will stay lit and the HSB will resume standby monitoring.

Batterie faible

ATS

ATS

Figure 5

OFF

ARRÊT

APAGADO

Manual

Manuel

Manual

There is also an exterior fault code indicator light located on the

back of the enclosure. This should be checked weekly to make

sure there are no active fault codes.

The fault code(s) can be reset by placing the Engine Control

Module (Figure 5) in the OFF position. This will reset fault LED,

however if a fault code(s) re-occurs it must be addressed.

LOW BATTERY LED

The yellow LED will be lit if the battery voltage fell below 21.0

volts for at least one minute while the engine was running. If

battery voltage rises above 21.1 volts, the LED will turn off.

Battery voltage is not monitored when cranking the engine.

Part No. 101305

17

Model 100152

GENERAL INFORMATION

HIGH ENGINE TEMP LED

The red LED will be lit if the engine operating temperature

exceeds the factory preset limits. If excessive operating

temperature is detected, the HSB will shut down and re-start

will be disabled. The RED LEDs on the module and enclosure

exterior are lit.

This failure could be the result of an excessive load or high

ambient temperatures. Should this fault occur do the following;

1. Open the enclosure doors to increase air flow throughout

the unit

2. Check oil level, add oil if required

3. Inspect the interior and exterior of the enclosure for debris,

leaves, ect., and remove them to increase air flow around

and inside the unit.

4. Once the engine temperature falls into the normal

operating range, generally 30 minutes, follow the reset

procedures in the manuals specific to your model to clear

and correct fault.

5. Close the enclosure doors and the unit is ready to run.

HZ OVER / UNDER SPEED LED

The red LED will be lit if the engine was operating above or

below its preset speed limit. The engine will shut down, and the

LED will remain lit until the generator is repaired and operating

correctly. Appliances connected to the generator circuit could be

damaged from high generator output if the engine is allowed to

operate above its preset limit. If this failure occurs, contact an

authorized Service Dealer or contact Champion Customer Service

at 1-877-338-0999.

LOW OIL LED

The red LED will be lit if the engine oil level has dropped below

the safe operating level. When this happens, the engine will shut

down. Check the engine oil level before attempting to restart the

engine. The engine will not start until the problem is corrected.

OVER CRANK LED

The red LED will be lit if the engine tried to start but was

unable to start in the specified time period. The engine will try

to start five times and if unsuccessful the light will turn on. This

may occur on initial start-up, the fuel system needs to be fully

pressurized to start and operate. Follow reset procedure on page

15.

POWER LED

The green LED will be lit indicating the generator is working

correctly and loads can be connected to it.

ATS CONTROL MODULE

The ATS control module contains the TEST/AUTO/OFF switch and

LEDs that indicate type of power delivery. (Figure 6)

UTILITY

UTILITÉ

UTILIDAD

TEST / ESSAI / PRUEBA

AUTO / AUTO / AUTOMÁTICO

OFF / ARRÊT / APAGADO

TEST/AUTO/OFF SWITCH

• TEST – This position allows verification that the generator

power delivery circuit is functional. With the switch in

the TEST position, the engine will start and the ATS will

transfer. The GENSET LED, ATS LED (middle LED) and

LOAD LED should be lit, indicating the generator power

delivery circuit is functional.

• AUTO – This position allows automatic delivery of power

from the generator if there is a utility outage. With the

switch in the AUTO position and the engine not running,

the UTILITY LED, ATS LED (middle LED) and LOAD LED

should be lit, indicating the household is using utility

provided power.

• OFF – This position will not allow any power to be

delivered to the ATS when the engine is running.

LOAD

CHARGER

CARGA

Figure 6

GENSET

GENSET

GENSET

RUN LED

The green LED will be lit indicating the engine is running.

Part No. 101305

18

Model 100152

GENERAL INFORMATION

BATTERY CHARGER

The LEDs on the battery charger indicate the state of the

battery’s charge level. Battery charger rating 24 Vdc 1.6A.

(Figure 7)

NO CHARGE / PAS DE CHARGE /

POWER

ALIMENTATION

RECOGNIZED

COMPONENT

Conforms to UL

Std. 1236

Power: 80-125 Vac 1.0 A 50 / 60 Hz

Alimentation : 80-125 V c.a. 1,0 A 50 / 60 Hz

Potencia: 80 - 125 V C.A. 1,0 A 50 / 60 Hz

POWER / ALIMENTATION /

MODEL / MODÈLE / MODELO : 100482

POTENCIA

L N ADJ

POTENCIA

AUTOMATIC BATTERY CHARGER /

CHARGE AUTOMATIQUE DE BATTERIE /

CARGADOR DE BATERÍA AUTOMÁTICO

Figure 7

SIN CARGA

Output: 24 Vdc 1.6 A

Sortie : 24 V c.c. 1,6 A

Producción: 24 V C.C. 1,6 A

OUTPUT / SORTIE /

PRODUCCIÓN

V

E. O.

EMISSION REQUIREMENTS

This engine-powered generator meets all United States

Environmental Protection Agency (EPA) Phase 3 requirements

and is approved in both the USA and Canada.

This generator is certified to operate on pipeline NG and LPG

(vapor) fuel for use as a stationary engine for standby power

generation. Federal and/or local laws may be violated if it is used

for any other purpose.

The maintenance schedule must be followed to ensure that the

engine complies with the applicable emission standards for the

duration of the engine’s life.

The following components on the engine consist of the emission

control system:

• Fuel metering system – mixer and fuel regulator

• Air induction system – air cleaner housing and element

• Ignition system – spark plug and ignition module

The emissions compliance period for which the engine has been

shown to meet federal emission requirements is stated on the

emission compliance label attached to the engine. Emission

Control System Warranty found at the end of this manual.

POWER Lit to indicate the battery is fully charged.

Small Bar

Lit to indicate the battery is receiving a

trickle charge

Middle Bar Lit to indicate current output is near 50%.

Large Bar

Lit to indicate the charger is operating

above 50% capacity.

Lit to indicate a battery charging problem.

NO CHARGE

If this LED is lit, the LED on the Engine

Controller module, “LOW BATTERY” will

also be lit.

Part No. 101305

19

Model 100152

GENERAL INFORMATION

SPECIFICATIONS

Home standby generator

Maximum continuous power, LPG/NG 11 kW

Rated voltage 120/240

Amps 91.6/45.8 LPG (propane), NG (natural gas)

Harmonic distortion Less than 5%

Main line circuit breaker 46 amp

Phase Single

Frequency 60 Hz

Unit weight 425.5 lb. (193 kg)

Size (L x W x H) 49 x 28 x 28 in. (124.5 x 71 x 71 cm)

Engine

Type Milwaukee Series OHV Commercial V-Twin

No. of cylinders 2

Displacement 717 cc

Cylinder block Aluminum with cast iron sleeves

Ignition system Solid state – magneto

Spark plug F7RTC (NGK BPR7ES)

Governor Mechanical

Starter Electric 24V DC

Oil capacity 1.6 qt (1.5 L)

Oil Type 5W-30 Full Synthetic*

RPM 3600

Controls

Mode switch auto Auto start on utility failure

Mode switch manual Starts on demand

Mode switch off Stops unit/control and charger active

Ready to run/maintenance messages Standard

Programmable start delay Standard

Engine start sequence Standard

Starter lockout Standard

Battery charger/low battery indicator Standard

Charger fault Standard

AVR over voltage protection Standard

Low oil protection Standard

Safety fused Standard

Overcrank/overspeed/underspeed protection Standard

*Unit ships without oil. Add oil before starting the HSB.

Part No. 101305

20

Model 100152

!

GENERAL INFORMATION

FUEL SYSTEM

The engine is fitted with a dual master mixer assembly

carburetion system, which allows it to run on either NG or

LPG. It has been configured at the factory to run on NG. If your

installation requires the engine to run on LPG, orifices in the

master mixer assembly carburetor must be changed.

BATTERY REQUIREMENTS

Two (2) 12 volt Group U1 batteries with a minimum of

350 CCA each. Battery size: 7

(196mm L x 131mm W x 185mm H). This is based on testing

in extreme cold and heat -22° F (-30° C) to 104 ° F (40° C).

Purchase batteries locally. Install positive cable first..

Install a cable from the positive (+) terminal of one battery to the

negative (–) terminal of the other battery. Always connect the

positive (+) battery cable to the generator first. (Figure 8)

3/4

L x 5

3/16

W x 7

5/16

H inches

To Starter

BATTERY CHARGING

The generator is equipped with an automatic battery charger. The

charger will sense the battery’s state of charge and automatically

charge the battery when required. LED lights on the charger display

the battery state of charge. See Figure 7 on page 19.

MODEL AND SERIAL NUMBER

The model and serial number plate is affixed to the generator

above the control panel. Have this information if calling for

service or ordering parts. (Figure 9)

MAX LOAD UNBALANCE MAX DÉSÉQUILIBRE DE CHARGE MAX DESEQUILIBRIO DE LA CARGA50% 50 % 50 %

RATED AMBIENT TEMP TEMPÉRATURE AMBIANTE NOMINALE TEMPERATURA AMBIENTE NOMINAL25-40 ºC 25-40 ºC 25-40 ºC

INSULATION CLASS

FOR STANDBY SERVICE

RAINPROOF ENCLOSURE FITTED

NEUTRAL

H H H

FLOATING NEUTRE FLOTTANT NEUTRO FLOTANTE

BOÎTIER ÉTANCHE À LA PLUIE ÉQUIPÉ

POWER FACTOR 1.0 FACTEUR DE PUISSANCE 1,0 FACTOR DE POTENCIA 1,0

RATED ENGINE SPEED

3600 r/min

RÉGIME MOTEUR NOMINAL

RATED CURRENT 91.6 A / 45.8 A (LPG,NG) COURANT NOMINALE 91,6 A / 45,8 A (GPL,GN) CORRIENTE NOMINAL 91,6 A / 45,8 A (GLP,GN)

RATED FREQUENCY

60 Hz

FRÉQUENCE NOMINALE

RATED VOLTAGE 120/240~,single-phase TENSION NOMINALE 120 / 240~,monophasées

STATIONARY ENGINE DRIVEN GENERATOR / STATIONNAIRE GÉNÉRATEUR ENTRAÎNÉ PAR UN MOTEUR /

GENERADOR ACCIONADO POR MOTOR ESTACIONARIO

To Ground

2

Figure 8

U1 battery post style

CAUTION

For battery installation, maintenance, and safety

requirements refer to purchased manufacturer battery

installation and safety manual.

1

12039 Smith Ave., Santa Fe Springs, CA 90670 USA

CHAMPION POWER EQUIPMENT

CARCASA A PRUEBA DE LLUVIA EQUIPADO

P/N 101502

AISLANTE CLASEISOLATION DE CLASSE

PARA EL SERVICIO SUPLENTEPOUR LE SERVICE DE SECOURS

CAN/CSA Standard

C22.2 No. 100

Certified to

No. 2200

Conforms to UL Std.

Figure 9

3600 r/min

VELOCIDAD NOMINAL DEL MOTOR

3600 r/min

60 Hz

TENSIÓN NOMINAL

FRECUENCIA NOMINAL

120 / 240~,monofásicas

60 Hz

MODÈLE

100152

MODELO

MODEL

Part No. 101305

21

Model 100152

OPERATION

Before operating the generator, review SAFETY section starting

on page 7.

ENCLOSURE AND ACCESS

Open the enclosure to gain access to the generator and its

components. (Figure 10) Unlock the handles. Turn the handles

and lift the hoods up and to the outside.

Figure 10

PRE-START CHECKLIST

To make sure the generator is ready for proper operation, the

following items should be checked:

• Fuel valve is in the ON position

• No fault code LEDs are lit

• Battery is at full charge

• ATS control module is in the AUTO position

• Engine control module is in the ATS position

• Transfer switch lever is in the Utility Power position

TURNING OFF THE GENERATOR

If you need to shut off the generator when it is running, turn

the engine control module switch to the OFF position. This will

shut off the engine. With the engine control module in the OFF

position, the generator will not start, even if there is loss of utility

power.

Part No. 101305

22

Model 100152

MAINTENANCE

Before performing maintenance procedures, review SAFETY

section starting on page 7.

Ensure that the ATS and Engine Switches are in the OFF position

before performing any maintenance or cleaning.

SCHEDULED MAINTENANCE

CHART

Every

Change engine

oil

Change the

engine oil filter

Check engine oil

level

Inspect fuel lines

and connections

Check exterior

fault code

indicator light

Inspect and

clean enclosure

louvers

Inspect and

clean battery

terminals

Inspect and

clean engine air

cleaner

Inspect engine

spark plug

Complete

inspection of

generator and

engine tune-up

First

5Hours of

Operation

√**** √****

Weekly Monthly

√ √**

√*

√

√

√

√

2Years

or 100

Hours of

Operation

√**

√

√***

ENGINE OIL

ENGINE OIL REQUIREMENTS

Use American Petroleum Institute (API) Service Class SN or

better. Do not use special additives. All temperatures full

synthetic 5W-30.

CHECKING THE ENGINE OIL LEVEL

Check the oil level daily when the generator is running for an

extended period of time.

1. If the generator is running during a utility outage, turn off

all household loads.

2. Turn the engine control module switch to the OFF position.

3. Remove the dipstick. Wipe it dry with a clean cloth and

completely reinsert it into the dipstick tube. See figure 12,

page 24.

* Monthly or 24 hours of continuous operation

** Service sooner if operating in high ambient temperatures or a

dusty and dirty environment.

*** Maintenance should be performed by your service dealer.

**** If so equiped

Figure 11

Part No. 101305

23

Model 100152

!

MAINTENANCE

NOTICE

DO NOT overfill the engine with engine oil. Damage to the

engine may occur.

4. Remove the dipstick. The oil level should be at the FULL

mark. If necessary, add oil. DO NOT overfill.

Figure 12

5. Install the dipstick.

6. Turn the engine control module switch to its prior position.

NOTICE

Always be environmentally responsible. Consult the local

authorities or reclamations facility for proper disposal of

engine oil waste.

5. Position drain pan under alternator.

6. Loosen hose clamp on oil drain hose and slide drain hose

off retaining pin. (Figure 13)

3

2

1

CHANGING THE ENGINE OIL

WARNING

Always wear protective glasses

or goggles and protective clothing

when changing hot engine oil.

1. Turn the ATS to the OFF position.

2. Turn the engine control module switch to the MANUAL

position.

3. Allow the engine to run until it reaches operating

temperature.

4. Turn the engine control module switch to the OFF position.

Figure 13

1. Oil Drain Hose

2. Hose Clamp

7. Position drain hose into drain pan and allow crankcase to

empty.

8. With the oil drained, remove oil filter by turning

counterclockwise.

9. Apply a light coat of clean engine oil to the gasket of the

new oil filter.

10. Screw the new oil filter on (turning clockwise) by hand

until the gasket contacts the engine block.

11. Screw the filter an additional 3/4 turn.

12. Reinstall the hose onto the retaining pin and reposition

hose clamp.

13. Fill the engine with the proper amount of engine oil. See

Figure 12.

14. Turn the engine control module switch to its prior position.

15. Turn the ATS to the AUTO position.

3. Retaining Pin

Part No. 101305

24

Model 100152

MAINTENANCE

INSPECT AND CLEAN ENGINE

AIR CLEANER

1. Turn the engine control module switch to the OFF position.

2. Unsnap the clips holding the air cleaner cover in place and

remove the air cleaner cover.

3. Remove the paper element.

1

2

3

SPARK PLUG

1. Turn the ATS to the OFF position.

2. Turn the engine control module switch to the OFF position.

3. Remove the spark plug cable from the spark plug.

4. Clean the area around the spark plug to keep dirt out of

the engine and remove the spark plug.

5. Inspect the spark plug electrode and replace the plug if

the electrode shows signs of deterioration.

6. Check the gap before installing the spark plug. The spark

plug gap should be 0.028 – 0.031 in. (0.7 – 0.8 mm).

Figure 14

1. Air Cleaner Cover

Clips

2. Paper Element

4. Inspect the paper element for any rips or tears. Replace if

damaged.

5. Hold the paper element up to a light. You should be able

to see light through the paper element, if not replace the

element. Inspect air cleaner cover, remove any dirt or

debris.

6. Fit paper element over air cleaner base inlet lip. Push

element gently downward to fully seat element into air

cleaner base.

7. Install the cover and snap the clips in place.

8. Turn the engine control module switch to its prior position.

3. Air Cleaner Base

0.028 - 0.031 in.

(0.7 - 0.8 mm)

Figure 15

7. Carefully thread the spark plug into the engine and tighten

to 20-30 N-m (14.8-22.1 lbf-ft).

8. Re-connect the spark plug cable.

9. Turn the engine control module switch to its prior position.

10. Turn the ATS to the AUTO position.

Part No. 101305

25

Model 100152

!

!

MAINTENANCE

BATTERY MAINTENANCE

1. Turn the engine control module switch to the OFF position.

2. Inspect the battery cables and terminals for corrosion.

3. Check that the cables are securely fastened to the

terminals.

4. Check the ground lug and make sure the connections are

tight.

5. Check the fluid level of the battery, unless sealed. If low,

top off the level using distilled water only.

Follow all battery instructions provided by the battery

manufacture.

CORROSION PROTECTION

NOTICE

Never use a pressure washer to wash the interior of the

generator with water.

Wash the outside of the enclosure using a mild soap and water.

Use an automotive-type wax and wax the outside of the enclosure

to protect it from the elements. If used in a salt water/coastal

area, the enclosure should be washed more frequently to prevent

corrosion. Spray light oil on the hinges for the enclosure doors.

MAINTENANCE AFTER

SUBMERSION

If the house or building has been exposed to a flood, it should

be inspected by a certified electrician for any electrical problems

that may occur if the generator is put back into service or if utility

power is restored.

STORAGE

If the generator is not going to be used for several months and

not exercised every 7 days, it should be prepared for storage.

1. Manually start the engine and run it for several minutes to

allow it to warm up.

2. With the engine running, turn the fuel shutoff valve to the

closed position and let the engine continue to run until it

shuts down.

3. Once the engine has shut down, turn the engine control

module switch and the ATS control module switch to the

OFF position.

4. Switch the generator’s main circuit breaker to the OFF

(OPEN) position.

5. Turn off the utility power to the transfer switch.

6. Disconnect the battery cables. Remove the negative cable

first.

7. Change the engine oil. See CHANGING THE ENGINE OIL on

page 24.

8. Remove the spark plug and spray fogging oil into the

spark plug hole. Install the spark plug and tighten.

9. Thoroughly wash and wax the exterior of the generator

enclosure. Do not use a pressure washer.

WARNING

Never try to start or operate the

generator if it has been submerged

underwater or exposed to a flood.

If the generator has been in conditions where it became

submerged underwater, the generator must be inspected and

maintenance must be performed before returning the generator

to service.

Turn engine control module and ATS control module to the

OFF position. Have a authorized Champion Dealer inspect the

generator and perform any necessary maintenance.

Part No. 101305

26

RETURN TO SERVICE AFTER

!

!

STORAGE

1. Make sure the utility power to the transfer switch is off.

2. The engine control module switch and the ATS control

module switch should be in the OFF position.

3. Check the engine oil level. Add oil if needed.

4. Recharge the batteries to 100% state of charge. If the

batteries will not fully charge, replace the batteries.

WARNING

Always connect the positive

(+) battery cable first. After the

positive cable is connected, then

the negative (-) battery cable can

be attached. This minimizes the

possibility of electrical contact.

Model 100152

MAINTENANCE

5. Connect the positive (+) battery cable to the positive

(+) battery terminal first and then connect the negative

battery cable to the negative (-) battery terminal.

6. Clean and wipe down the generator with mild soap and

water.

7. Turn the fuel shutoff valve to the ON position.

8. Turn the engine control module switch to the manual

position. The engine should start. Run the engine for 15

minutes to allow it to warm up. The fuel system might

require more than one start cycle to fully pressurize the

fuel system for operation.

9. Make sure there are not any active fault codes.

10. Turn the engine control module switch to the OFF position

to shut off the engine.

11. Turn the ATS module switch to the AUTO position.

12. Turn on the utility power to the transfer switch. The utility

LEDs on the ATS module should be lit.

13. Turn the engine control module switch to the ATS position.

14. Set the exercise time. See EXERCISE SWITCH on pages

16 and 17.

Part No. 101305

27

Model 100152

MAINTENANCE

ENGINE PARTS

80

81

82

28

83

84

85

86

87

74

75

88

89

76

90

77

91

78

79

67

117

116

115

114

113

2

1

118

119

120

144

143

142

131

134

135

136

137

138

139

112

111

110

109

121

122

123

124

140

141

129

130

72

71

70

69

66

68

65

64

63

62

61

60

59

108

107

106

105

125

127

126

4

3

2

1

73

58

57

56

55

94

1

2

3

4

5

61

104

103

102

101

100

98

99

128

35

132

333432

31

30

29

54

53

52

51

92

82

93

95

96

97

42

41

40

39

38

36

50

49

48

47

46

43

45

44

43

3

6

2

28

26

27

25

24

23

22

21

20

19

18

17

14

15

13

12

11

10

5

4

16

9

8

7

6

Part No. 101305

28

37

133

2

1

Model 100152

MAINTENANCE

# Part Number Description Qty

101027

1

2.08.083

2

717.070004.00 Bracket, Fuel Pump

3

1. 6 177. 2 0 Nut, M20 x 1.5 Flange

4

1.5789.0 816 Hex Flange Bolt, M8 x 16

5

61.080005.00 Plate, Fan

6

717.080001.00 Fan, Cooling

7

717.123000.03

8

100922 Flywheel Assembly

9

1.5789.0629 Hex Flange Bolt, M6 x 29

10

717.123000.04

11

2.06.009 Clamp, Ø17 x Ø1.5

12

100303 Tube, Breather

13

1.166 74.06 40 Hex Small Flange Bolt, M6 x 40

14

717.130012.00 Intake Manifold

15

717.130011.00 Gasket, Intake Manifold

16

1.166 74.06 2 0 Hex Flange Bolt, M6 x 20

17

100 4 86 Cover, Breather

18

100 504 Gasket, Breather Cover

19

1.82 3.0 410 Screw, Small Pan Head M4 x 10

20

101767 Retainer, Reed Valve

21

100 69 3 Reed Valve

22

101482 Protective Sleeve

23

100 342 Hose, Gaseous Fuel Id 12.7

24

100 825 Clamp Hose Id Ø16-Ø25

25

100 25 8 Gasket, Carburetor

26

61.130001.00 Insulator, Carburetor

27

100 662 Mixer Assembly

28

1 100928 Main Jet - Right

2 100929 Main Jet - Left

NG

3 100910 Slow Jet - Right

4 100910 Slow Jet - Left

1 100909 Main Jet - Right

2 100310 Main Jet - Left

LPG

3 101032 Slow Jet - Right

4 100671 Slow Jet - Left

717.090005.00 Gasket, Ac Assembly

29

101020 Base Assembly, Air Cleaner

30

1.5789.068 8 Hex Flange Bolt, M6 x 88

31

100 275 Air Filter Assembly

32

10100 4 Seal, Ac Base

33

101847 Cover, Ac Base

34

100 829 Pin, Dowel Ø10 x 14

35

101115

36

1.166 74.08 110 Hex Small Flange Bolt, M8 x 110

37

100 937 Switch, Thermal Shutdown

38

1.823.0306.1 Screw, M3 x 6

39

2.08.039 Bolt, Drain, M12 x 1.5 x 15

40

2.03.023

41

10 0 374 Crankcase Component

42

1.5789.0612 Hex Flange Bolt M6 x 12

43

61.120800.00 Diode Assembly, Engine Stop

44

2.12.004 Grommet Ø9.5 x 10

45

100 470

46

Cover, Fan, Rotating Screen With

Oil Cooler Ribs

Bolt, Hex Flange M6 x 12 6

Ignition Coil Assembly,

Cylinder 1, EMC

Ignition Coil Assembly,

Cylinder 2, EMC

Motor Assembly,

24V Solenoid Shift Starter

Washer, Drain Bolt,

Ø12.5 x Ø20 x 2

Air Board, Assembly,

Internal Oil Cooler

12

# Part Number Description Qty

1

1

1

3

1

1

1

1

4

1

2

1

4

1

2

4

1

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

2

1

2

1

2

1

2

1

1

1

1

717.080500.00

47

2.14.005 Key, Flywheel, 4 x 5.5 x 12.5

48

717.051101.04 Assembly, Crankshaft - Taper Pto

49

2.03.026

50

10145 4 Camshaft Assembly

51

717.050200.00 Assembly, Connecting Rod

52

2.09.009 Retainer, Piston Pin, Ø17 x Ø1

53

100 968 Pin, Piston, Ø17 x 53.8 mm

54

102024

55

102289 Ring Assembly, Oil Control

56

10228 6 Ring, Piston, 2nd

57

102285 Ring, Top Piston

58

45.110012.00 Bushing, Governor Gear

59

2.03.053 Washer, Ø6.2 x Ø17 x 0.8

60

21.110011.00 Clip, Retaining

61

61.110100.0 0 Gear Assy, Governor

62

2.03.054 Washer, Ø6.2 x Ø15 x 1

63

45.110013.00 Shaft, Governor Gear

64

1.5789.0620 Hex Flange Bolt, M6 x 20

65

61.150300.00 Oil Filter Component

66

2.04.002 Location Pin Ø8 x 14

67

100 59 6 O-Ring Ø12 x Ø3.5

68

100 261 Gasket, Crankcase Cover

69

100726 Tube, Oil Dipstick Assembly

70

100 26 8 Cover, Crankcase

71

1.5789.0850 Hex Flange Bolt, M8 x 50

72

2.11.010 Seal, Pto Oil, Ø38 x Ø58 x 9

73

61.030011.00 Plug, Crankcase Cover

74

100 69 9 Blade Assembly, Oil Dipstick

75

1.30 8.9.5 Ball Ø9.5, Steel Check Valve

76

61.150004.00 Spring, Compression

77

61.151000.00 Pump Assembly, Oil

78

1.70.0616 Screw, M6 x 16, Socket Head Cap

79

10176 6 Filter, Oil

80

1024 4 6 Switch, Low Oil Shut-Down 0.6 Bar

81

1.166 74.06 2 5 Hex Small Flange Bolt, M6 x 25

82

101719

83

100 8 47 Clamp Ø17, Oil Hose

84

100 942 Hose 2, Oil Line

85

100941 Hose 1, Oil Line

86

2.07.004 O-Ring Ø12 x Ø2.5

87

1.5789.0620 Hex Flange Bolt, M6 x 20

88

10172 3 Oil Cooler Assy, Internal Mount

89

717.080600.00

90

1.5789.0608 Hex Flange Bolt, M6 x 8

91

1.16674.0 616 Hex Small Flange Bolt, M6 x 16

92

2.04.005 Pin, Ø8 x 10, Location

93

101478 Follower Assembly, Camshaft

94

1 101475 Follower Pivot Assembly, Camshaft

2 2.03.021.1

3 1004 85 Follower, Camshaft

4 61.040019.01 Follower, Camshaft

5 61.041001.00 Spring, Support

Air Guide,

Outer Cylinder 1 Assembly

Washer, Crankshaft Thrust,

Ø39 x Ø54 x 1.2

Piston, 78 mm, 2.75 mm,

Dish Ceramic Crown

Base Assembly, Oil Filter With Oil

Cooler And Oil Pressure Switch

Air Guide, Outer,

Cylinder 2 Assembly

Washer, Governor Shaft,

Ø6.4 x Ø13 x 1

1

1

1

1

1

2

4

2

2

2

2

2

1

1

3

1

1

1

3

1

2

1

1

1

1

9

2

1

1

1

1

1

2

1

1

4

1

4

1

1

2

2

1

1

2

1

1

1

1

4

2

2

2

Part No. 101305

29

Model 100152

MAINTENANCE

# Part Number Description Qty

45.030200.00 Retainer, Oil Drain Hose

95

2.06.013 Hose Clamp, Ø13.5 x b10

96

45.032000.00 Hose, Oil Drain

97

1.276.6003.1 Bearing, Roller Ø35 x Ø17 x 10

98

717.030026.01 Plug, Npt1/8-27 Hexagon Socket

99

2.04.004 Pin, Ø12 x 20 Location

100

100170 Bracket, Governor Spring

101

2.01.010 Bolt M8 x 35, Exhaust Stud

102

717.010003.00 Lift Strap

103

1.166 74.08 2 0 Hex Small Flange Bolt, M8 x 20

104

2.0 8 .122 Bolt, Hex Flange M10 x 95

105

100179 Valve, Exhaust

106

717.040015.00 Shim, Valve Spring

107

101881 Oil Seal, Valve Stem

108

45.040003.00 Spring, Valve

109

45.040001.00 Retainer, Intake Valve

110

717.040202.00 Bracket, Rocker Arm

111

1.70.1.0816 Screw, M8 x 16 Socket Head Cap

112

22.040012.00 Adjusting, Lash

113

717.040200.02 Rocker Arm

114

10164 4 Gasket, Rocker Cover

115

1.5789.0625 Hex Flange Bolt, M6 x 25

116

102357 Cap, Oil Fill Assembly

117

1 2.07.001 Seal, Cap Oil Fill, Ø25.5 x Ø3.5

2 101813 Cap, Oil Fill

102261 Rocker Cover Assembly, Oil Fill

118

21.040 021.00 Jam Nut, M6 x 0.5 mm Pitch

119

1.6170. 0 8 Hex Nut, Gb6170, M8

120

717.040016.00 Sleeve, Rocker Arm

121

2.08.086 Bolt, M8 x 1.25 Hhw Special

122

717.040005.00 Push Rod

123

45.040002.00 Valve, Intake

124

2.08.014 Bolt, Hex Flange M10 x 80

125

717.080300.02

126

717.010100.2 0 Head Assembly, Cylinder 2

127

717.030009.00 Gasket Assembly, Cylinder Head

128

717.010100.10 Head Assembly, Cylinder 1

129

717.080300.01

130

2.11.0 0 6 Shaft Oil Seal, Ø7 x Ø14 x 5

131

2.15.0 08 Spark Plug, F7RTC

132

10226 3 Rocker Cover Assembly

133

102428 Spring, Link Take Up

134

100 22 3 Link, Governor

135

2.0 8 .107 Bolt, Governor Arm

136

2.03.019 Washer, Ø8.2 x Ø17 x 0.8

137

61.110008.00 Pin, Shaft

138

1.58 01.0810 Bearing, Roller

139

1.97.1.08 Washer Ø8

140

61.110001.00 Shaft, Governor

141

100 432 Spring, Governor

142

100178 Lever, Governor Arm

143

1. 6 177. 0 6 Nut, M6 Hexagon Flange

144

Air Guide Assembly,

Inner Cylinder 2

Air Guide,

Inner Cylinder 1 Assembly

1

1

1

1

1

4

1

4

2

2

2

2

2

4

4

4

4

4

4

4

2

8

1

1

1

1

4

4

4

4

4

2

6

1

1

2

1

1

1

2

1

1

1

1

1

2

2

2

1

1

1

1

Part No. 101305

30

Model 100152

MAINTENANCE

PAGE INTENTIONALLY LEFT BLANK

Part No. 101305

31

Model 100152

MAINTENANCE

ENCLOSURE AND ASSEMBLIES

1

74

3

73

43

44

42

75

,See Figure B

4

5

6

7

73

8

9

76

10

11

12

13

14

15

16

77

17

18

19

20

36

35

34

41

40

39

53

38

37

54

55

56

59

57

58

45

46

47

48

49

50

51

52

66

65

64

Part No. 101305

32

33

32

,See Figure A

21

22

23

31

30

29

28

27

26

25

24

60

61

41

63

62

67

6869

70

7172

2

Model 100152

MAINTENANCE

# Part Number Description Qty

1.6177.1.06 Lock Nut M6, Flange 24

1

2

1.5789.0615 Flange bolt, M6 x 15

161.200507.00 Curb Chain Assembly, Cover

3

162.200500.61.24

4

161.200110.00 Hook Lock Assembly

5

161.2 0 0021.16 .6

6

1.166 74.08 2 0 Flange bolt, M8 x 20

7

1.166 74.08 12 Flange bolt, M8 x 12

8

161.200402.60.24

9

161.2 0 0109.6 3

10

162.200401.60.24

11

5.14 60.015 Indicator Light, 24 v

12

161.192100.6 0

13

1.862.0 6 Toothed Lock Washer, Ø6

14

5.1560.000 Ground Wire Teminal, Ø6, UL

15

717.090004.21 Pipe, Air Cleaner

16

2.06.036 Clamp, Ø75

17

162.200 021.01.6

18

9.3410. 02 Nylon Cable Ties, 5 x 500 mm

19

161.192300.00 Air Guide, Alternator

20

163.200500.60.24

21

161.20 00 21.17.6

22

161.2 01600.0 2.1 Gutter, Black

23

161.100006.00 Spring, Muffler

24

2.08.119 Flange Bolt M8 x 35, Muffler

25

163.1010005.00.2

26

161.20 00 21.13.6

27

161.20 00 21.18.6

28

2.02.032 Cage Nut, M8

29

161.200017.63.24

30

161.20 00 21.15.6

31

163.200021.03.6

32

1.5789.0612 Flange Bolt, M6 x 12

33

2.03.004 Washer, Ø24 x Ø6.5 x 1.5

34

163.200 017.01 Thermal Baffle

35

163.200017.60.24

36

161.1010005.00.2 Supportor, Muffler, Top, Black

37

Top Cover Assembly, Right,

Silk Grey, Flame Retardant and

textured, See Figure B

Seal, Access Cover, Flame

Retardant

26

Access Cover, Electric Cabinet,

Silk Grey, Flame Retardant and

textured

Rubber Strip, 575 mm, Flame

Retardant

Rear Cover, Silk Grey, Flame

Retardant and textured

Supporter, Air Guide,

Alternator, Flame Retardant

Acoustic Panel, Rear Center

Chamber, Flame Retardant

Top Cover Assembly, Left, Silk

Grey, Flame Retardant and

textured, See Figure A

Seal Strip, Top Cover, Long,

625 x 50 x 25 mm, Flame

Retardant

Supportor, Muffler, Bottom,

Black

Acoustic Panel, Muffler Cover,

Front, Flame Retardant

Seal Strip, Top Cover, Short,

50 x 320 x 25 mm, Flame

Retardant

Muffler Cover, Back, Silk Grey,

Flame Retardant and textured

Foams, Muffler Cover, Back,

Flame Retardant

Acoustic Panel, Muffler Cover,

top, Flame Retardant

Muffler Cover, Top, Silk Grey,

Flame Retardant and textured

# Part Number Description Qty

100152.901 Generator Assembly

38

6

2

1

2

1

9

1

2

1

1

2

5

1

1

1

1

1

1

1

1

1

3

3

1

1

1

4

1

2

1

8

4

1

1

2.06.037 Clamp, Ø28

39

10015 2.9 02 Control Panel Assembly

40

161.20 00 21.02.6

41

161.200300.60.24

42

161.201900.00 Hinge

43

161.130021.02 Galvanized Pipe, NPT 3 /4

44

5.1910.0 0 4 Wiring

45

2.06.015 Cla mp, Ø16 - Ø25

46

161.1360 0 0.04.1

47

161.200018.00

48

1.5789.0629 Flange bolt, M6 x 29

49

1.5783.0825 Bolt, M8 x 25

50

161.20 06 01.60.24

51

2.0 8 .133 Male Female bolt, M5 x 50

52

1.16674.0 516 Flange bolt, M5 x 16

53

161.210018.00 Cover,Terminal Block

54

161.210011.02 Terminal Block, 60A, 90° Angle

55

161.200 017.61.24

56

163.200021.00.6

57

163.200005.61.24

58

1.6177.1.08 Flange Lock Nut, M8

59

163.192300.00.2 Fan Cover, Rotor, Black

60

161.200200.60.24

61

161.2 0 0109.62

62

161.200101.60.24

63

161.20 00 21.11.6

64

161.201800.00 Plastic Pallet, PP

65

163.200021.10.6

66

163 .130021. 01 LPG Hose With NPT3/4 Nipple

67

9.1120.001 Screwdriver, Jet

68

5.19 0 0.0 74

69

161.200023.00.1 Oil Container, Black

70

1.6182.0 6 Lock Nut M6, Flange

71

1.97.1.06 Wa she r, Ø6

72

161.080007.00 Cap, Ø35

73

1.5789.0620 Flange bolt, M6 x 20

74

1.97.1.08 Wa she r, Ø8

75

2.03.065 Insulating Washer, Ø8 × Ø17

76

2.03.064 Insulating Washer, Ø6 × Ø12

77

Seal Strip, Right/Left Cover,

Flame Retardant

Right Cover Assembly, Silk

Grey, Flame Retardant and

textured

Pressure Reducing Valve, LPG/

NG

Supportor, Pressure Reducing

Valve

Base Center, Silk Grey, Flame

Retardant and textured

Muffler Cover, Front, Silk Grey,

Flame Retardant and textured

Acoustic Panel, Left Firewall,

Flame Retardant

Firewall, Left, Silk Grey, Flame

Retardant and textured

Left Cover, Silk Grey, Flame

Retardant and textured

Rubber Strip, 530 mm, Flame

Retardant

Front Cover , Silk Grey, Flame

Retardant and textured

Foams, Front Cover, Flame

Retardant

Foams, Heat Insulation, Flame

Retardant

Battery Jump Wire, 275 mm,

6 AWG

1

1

1

1

2

1

4

1

1

1

1

1

2

8

1

2

2

1

1

1

1

1

21

1

1

2

1

1

1

1

1

1

1

1

4

4

2

4

4

16

4

Part No. 101305

33

Model 100152

MAINTENANCE

TOP COVER ASSEMBLY, LEFT

5

1

14

13

2

1

1

1

16

0

1

9

8

17

7

3

1

6

5

4

3

Part No. 101305

34

2

# Part Number Description Qty

161.200109.00

1

161.200500.00.24 Top Cover, Left 1

2

161.200110.00 Handle Assembly 1

3

2.13.027 Bushing, Ø10.5 × Ø16×7.5 1

4

161.201004.00 Locking Plate 1

5

163.200021.06

6

161.20 00 21.19

7

161.20 00 21.20 Acoustic Panel, Cover, Top 1

8

163.200021.08 Acoustic Panel, Left Cover, Top 1

9

161.20 00 21.01 Seal, Gutter 1

10

161.200110.00.07 Rubber Gasket, Handle 1

11

161.200110.00.02 Locking Washer, Ø5 2

12

161.200110.00.03 Bolt, M5X12 2

13

161.200110.00.04 Wave Washer Ø10 1

14

161.200110.00.05 Locking Washer, Ø10 2

15

161.200110.00.06 Nut, M10 3

16

161.200110. 00.01 Key, Handle 1

17

Seal Strip, 20x1150x8mm,

Gutter

Acoustic Panel, Left Cover,

Side

Seal Strip, Top Cover,

32x560x15mm

Model 100152

MAINTENANCE

1

1

1

Part No. 101305

35

Model 100152

MAINTENANCE

TOP COVER ASSEMBLY, RIGHT

1 5

1 4

3

1

1 2

1 1

1 6

1

1 7

2

8 9 1 0

8

3

4

5

7

Part No. 101305

36

6

# Part Number Description Qty

161.20 0500.01.24 Top Cover Assembly, Right 1

1

161.200109.00

2

163.200021.07

3

161.20 00 21.20 Acoustic Panel, Cover, Top 1

4

161.20 00 21.10

5

161.20 00 21.01

6

161.20 00 21.19

7

161.200110.00 Handle Assembly 1

8

2.13.027 Bushing, Ø10.5 × Ø16×7.5 1

9

161.201004.00 Locking Plate 1

10

161.200110.00.07 Rubber Gasket, Handle 1

11

161.200110.00.02 Locking Washer, Ø5 2

12

161.200110.00.03 Bolt, M5X12 2

13

161.200110.00.04 Wave Washer, Ø10 1

14

161.200110.00.05 Locking Washer, Ø10 2

15

161.200110.00.06 Nut, M10 3

16

161.200110. 00.01 Key, Handle 1

17

Seal Strip, 20x1150x8mm,

Gutter

Acoustic Panel, Right Cover,

Side

Acoustic Panel, Right Cover,

Top

Seal Strip, 20x1150x8mm,

Gutter

Seal Strip Top Cover, 32 x 560

x 15

Model 100152

MAINTENANCE

1

1

1

1

1

Part No. 101305

37

Model 100152

MAINTENANCE

ALTERNATOR AND EXHAUST SYSTEM

1

2

3

31

30

29

28