Page 1

Project

Item No.

Quantity

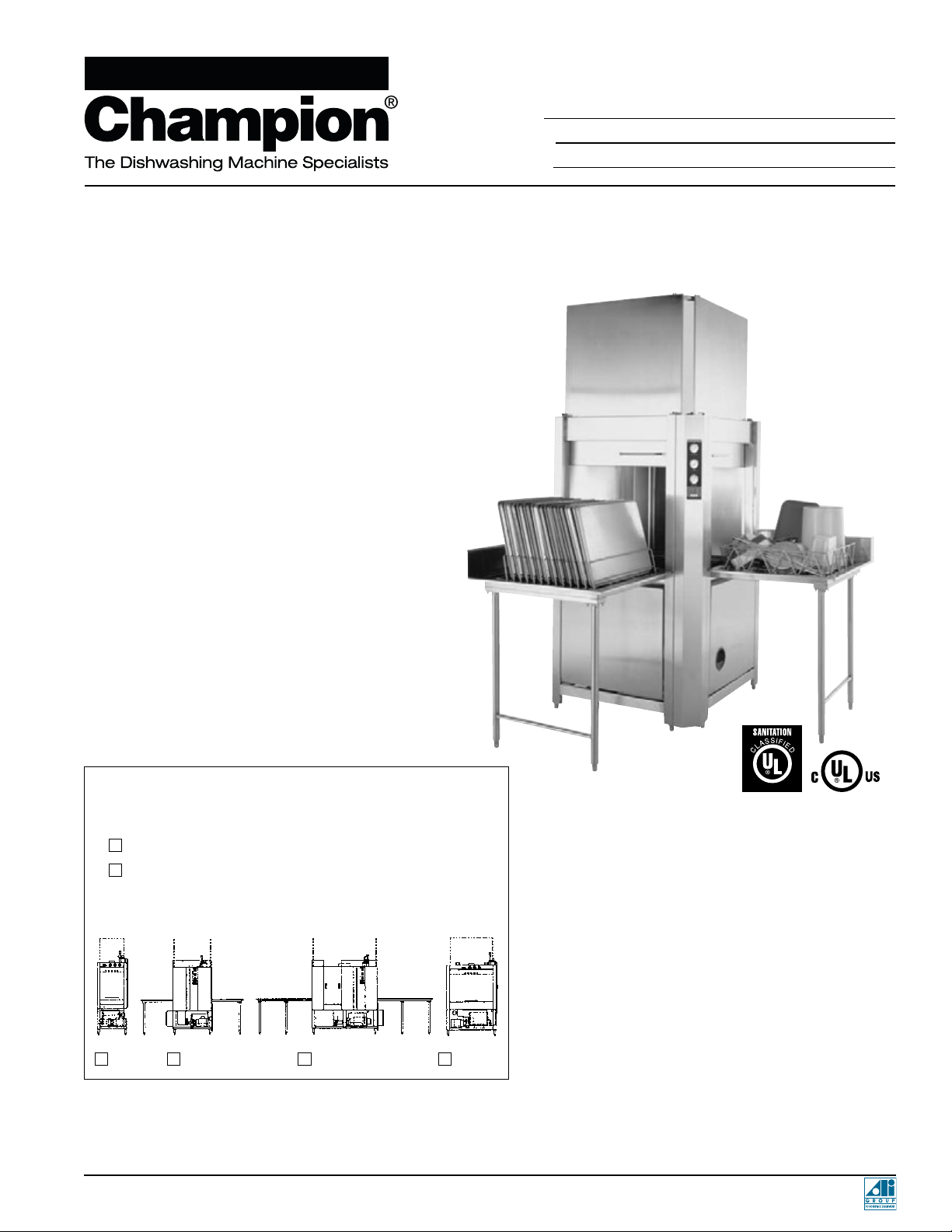

LD-12-cpt washer

stanDarD Features

• Heavy-duty stainless steel construction

• External rinse hose & spray gun

• Self-contained water heating

• Moisture resistant control gauges

• Recirculating wash water

• Adjustable wash and rinse cycles

• Digital Control & Information Center

• Versatile racking system

• Precision engineered spray patterns

• Removable, dual filtration system

• Complete with load/unload tabling

• One year parts and labor warranty

LD-12-cpt

Pot, Pan and

Utensil Washer

options

Tank Heat

Steam

Gas

Additional Lift Door and Split Door Models:

LD-20-PTLD-10 LD-12-CPT LD-20

DG006

(1M) 10/06 Printed in U.S.A.

Champion Industries, Inc.

P. O. Box 4149, Winston-Salem, NC 27115

Tel: 336/661-1556 Fax: 336/661-1979

2674 N. Service Road,

Jordan Station, Ontario, Canada L0R 1S0

Tel: 800/263-5798 Fax: 905/562-4618

www.championindustries.com

Page 2

LD-12-cpt

75"

41"

87"

105"

Drain Valve

27"

Door

Opening

30"

Door

Opening

34"

Lift

Height

Electrical

Control

Panel

Rinse Tank

Wash Pump

75"

41"

41"

87"

105"

Wash Thermometer

Pressure Gauge

Rinse Thermometer

Digital Control and

Information Center

Wash Down Hose

With Spray Nozzle

Drain Valve

27"

Door

Opening

30"

Door

Opening

34"

Lift

Height

Hot Water

Connection

6" Dia. Vent

Overflow

Connection

30"

Door

Opening

Electrical

Control

Panel

Rinse Tank

Wash Pump

Adjustable Legs

42-1/2"

Pot, Pan and

Utensil Washer

LD-12-cpt washer

Dimensions shown in inches

speciFications

Machine Construction

12, 14, & 16 gauge stainless steel. All seams

tig welded.

Door

Stainless steel, counter-balanced with self-

lubricating guides. Stainless steel cables on

nylon rollers with guards to prevent jumping.

Spray Arm Assembly

Stainless steel spray arm assembly with

stainless steel jets, removable end caps and

hand operated quick release mechanism for

easy cleaning and reassembly.

Filter

Perforated, removable, stainless steel baskets.

Water Pump

7-1/2 Hp, 208/240 or 480 volt, 1 phase or

3 phase, 60 cycle with output of 120 gallons

per minute at 35 to 45 P.S.I.

Digital Control & Information Center

110 volt control circuit with push pad

operation of “Power On”, Stop” and “Short,

Medium or Long Wash Cycles”. A digital

display indicates “Time Remaining” for each

cycle. LED’s indicate wash, rinse and unload

functions. A buzzer is also included to

provide an audible indication of time to

unload. A pre-programmed circuit board

allows the push pad to be used as

a “Diagnostic Center” by displaying “Error

Codes” for ease of troubleshooting.

Due to an ongoing value analysis program at Champion, specifications contained in this catalog are subject to change without notice.

Champion Industries, Inc., P. O. Box 4149, Winston-Salem, NC 27115 • 336/661-1556 • Fax: 336/661-1979 • www.championindustries.com

2674 N. Service Road

Jordan Station, Ontario, Canada L0R 1S0

•

Gauges

Special moisture resistant design to measure

wash temperature, wash pressure, and rinse

temperature.

Wash Tank

Stainless steel with electric, infrared gas,

steam or steam coil eating, thermostatically

controlled, low-water protected, sloped to

drain with a 25-gallon capacity.

Racks

Customized to hold your specific items.

Standard bakery racks include utensil basket

with hold-down lid and bun/sheet pan rack

designed to hold twelve (12) pans, constructed

of stainless steel rod, mig welded.

800/263-5798

•

Fax: 905/562-4618

•

Page 3

speciFications

LD-12-cpt pot, pan &

utensiL washer

Washer Automatic washing machine designed to wash all pots, pans and utensils commonly

used in baking and cooking operations. Machine is pass-thru, corner type with tabling

on each end.

Cabinet 41” wide x 41” deep x 75” high. Overall height with door open: 105”.

Door opening: 30” wide x 27” high. Constructed of 12, 14 & 16 gauge, Type 304

#3 finish, stainless steel . All seams tig-welded, cleaned and polished.

Door Lift-up door type. Two doors, single control handle. Counter balanced with self-

lubricating guides, stainless steel cables on nylon rollers with cable guards to insure

tracking. Doors are interlocked with limit switch to prevent machine operation while

doors are open. Door construction: 16 gauge, type 304 #3 finish, stainless steel.

Recirculating Wash Tank Heated by 208/240 at 480 volt electric immersion heaters, 12 kW total.

Thermostatically controlled wash temperature and low water protection system.

25 gallons, 14 gauge stainless steel, sloped to drain. Infrared gas and steam heating

options available.

Wash Tank Filter Perforated, stainless steel basket type. Double filter system designed for increased

effectiveness and easy cleaning without emptying wash tank.

Wash Tank Fill Valve Size 1/2” brass material, solenoid type, automatic.

Wash Tank Drain Valve Size 1-1/4” brass material, gate type for manual or electrically operated ball valve

for automatic option.

Wash Pump 7-1/2 Hp, 208/240 or 480 volt, 1 or 3 phase, 60 cycle. Close coupled; 120 gallons per

minute at 35 to 45 psi, mounted on 12 gauge stainless steel formed channel base.

Rotating Wash Hub & Water driven, stainless steel base with stainless steel jets, removable end caps

Spray Arm Assembly for quick and easy cleaning without the use of tools.

Sanitizing Rinse Tank Stainless steel 6 gallon capacity, with one (1) 6 kW 208/240 or 480 volt electric

booster heater to provide 180°/190°F hot sanitizing rinse. Uses 2.8 gallons per

22 second cycle. Infrared gas and steam coil heating options available.

Water Supply Valve Size 1/2” brass material, solenoid type, automatic.

Final Rinse Piping Type 304 stainless steel tubing with brass compression fittings and brass or optional

stainless steel full cone rinse jets.

Control & Information Center 120 volt control circuit with push pad operation of “Power On,” “Stop” and “Short,

Medium or Long Wash Cycles.” A digital display indicates “Time Remaining” for each

cycle. LED’s indicate wash, rinse and unload functions. A buzzer is also included

to provide an audible indication of time to unload. A pre-programmed circuit board

allows the push pad to be used as a “Diagnostic Center” by displaying “Error Codes”

for ease of troubleshooting. Moisture resistant gauges measure wash temperature,

wash pressure and rinse temperature.

External Rinse Hose Externally mounted rinse hose with spray gun for easy cleaning and maintenance of

machine.

Steam Exhaust Vent Steam exhaust vent 6-3/4" diameter, consisting of 16 gauge rolled collar for PVC

pipe connection bolted to the top of the machine. Machine pre-wired with control

timer for the addition of a fan.

Optional Exhaust Fan Draft inducer fan side mounted on exhaust duct to extract excess steam after final

rinse cycle. 300 CFM @ .05" statis pressure. 1/10Hp, 110 volt motor, 1550 RPM.

2674 N. Service Road,

Jordan Station, Ontario, Canada L0R 1S0

Tel: 800/263-5798 Fax: 905/562-4618

(1M) 10/06 Printed in U.S.A.

Champion Industries, Inc.

P. O. Box 4149, Winston-Salem, NC 27115

Tel: 336/661-1556 Fax: 336/661-1979

www.championindustries.com

Page 4

speciFications

LD-12-cpt pot, pan &

utensiL washer

Racks Customized to hold your specific items. Standard bakery racks include utensil basket

with hold-down lid and bun/sheet pan insert designed to hold ten pans, constructed

of stainless steel rod, mig-welded.

Connections Water Inlet: 120°F, 3/4" NPT

Water Drain and Overflow: 1-1/4" NPT

Electrical: Two point connection through knock out on electrical enclosure.

Steam Heating Option: 1/2" NPT

Natural or Propane Gas Heating Option: 1/2" NPT

Utilities 120 Volt -1 phase, 5 running amps, 15 amp service, plus one of the following:

Running Amps

Elec. Spec.

208 Volt

3 phase

240 Volt

3 phase

480 Volt

3 phase

Electric Wash

Electric Booster

69 19 19

63 18 18

32 9 9

Steam Wash

Steam Booster

1

Infrared Gas Wash

Infrared Gas Booster

2

1

Steam Supply: Consumption: 69 lbs./hr. @ 15 psi minimum

2

Gas Supply: Consumption: 60,000 BTU/hr.

Certifications UL and UL Sanitation Listed (all). CUL Listed (electric and steam only).

2674 N. Service Road,

Jordan Station, Ontario, Canada L0R 1S0

Tel: 800/263-5798 Fax: 905/562-4618

Champion Industries, Inc.

P. O. Box 4149, Winston-Salem, NC 27115

Tel: 336/661-1556 Fax: 336/661-1979

www.championindustries.com

Loading...

Loading...