Page 1

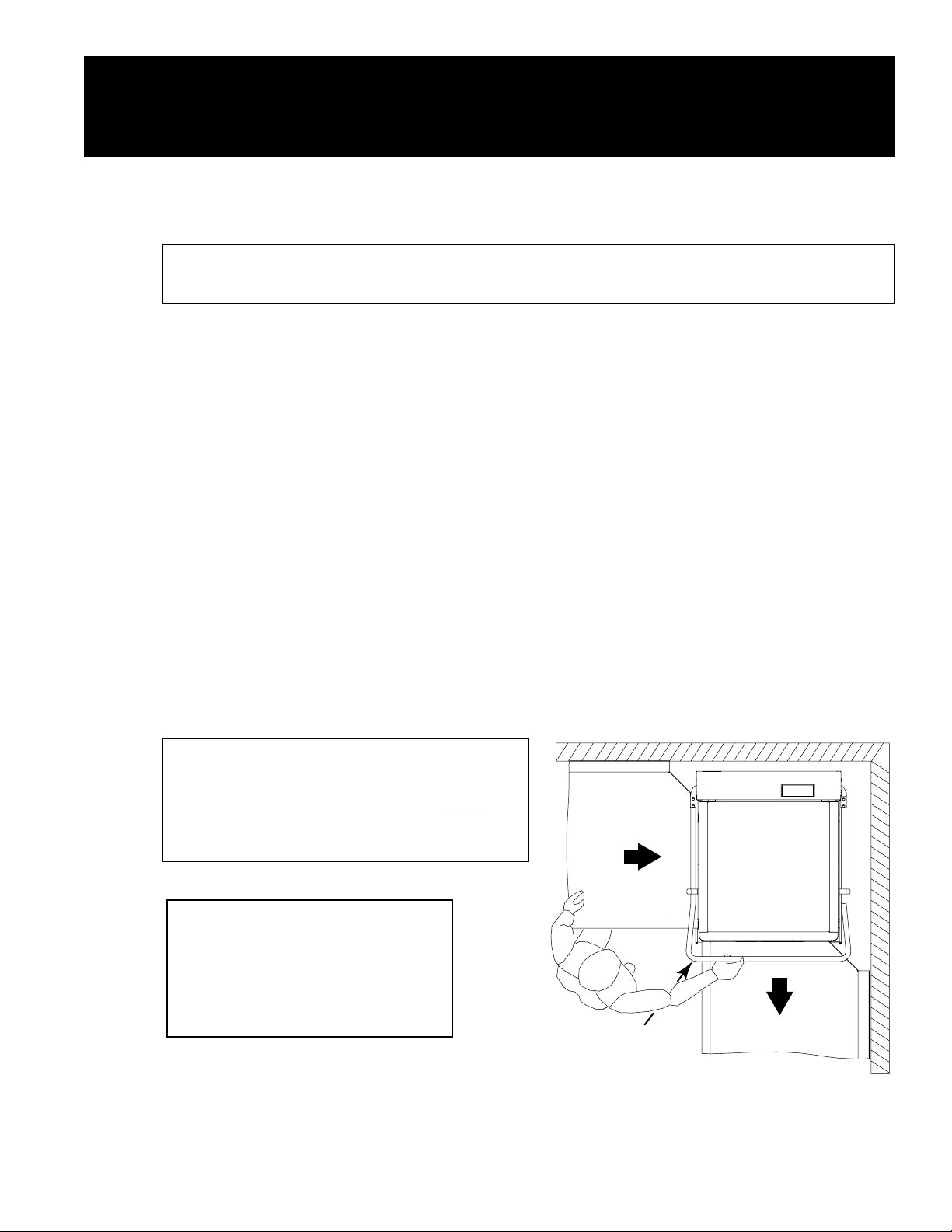

DH5000 Straight-through to Corner Operation

Conversion Instructions

Converting Straight-through Operation to Corner Operation

! ATTENTION !

The clean-end dish table must be modified if the backsplash is more than 3” [76mm] high.

Refer to the illustration below and the next page to convert a straight-through operation machine to

a corner operation machine.

To convert the dishwasher:

1. Place the dishwasher as shown below so the control panel faces into the room

and is accessible to the operator.

2. Refer to the illustrations on the next page and cut a notch in the dish table backsplash

if it is higher than 3" [76 mm].

3. Position the rear of the machine a minimum of 1-7/8" [48mm] from the back wall and a

minimum of 5-1/8" [130 mm] from the right side wall.

4. Make the utility connections as described in this manual and in accordance with all

local codes and regulations.

5. Install the dish tables so the edge of each table fits over the inner wall of the dishwasher

tank.

6. Secure the dish tables to the dishwasher

7. Seal each dish table joint with a food-grade sealant to prevent leakage.

! IMPORTANT !

An optional Splash Shield, P/N 334630, is

available for corner operation and must be

installed before the machine is placed in its

permanent location.

NOTE:

DH5000 Splash Shield Installation

Kit P/N 901156 installation

instructions f

prior to S/N D140911960 are on

page 4.

or machines built

Control

Panel

Corner Operation Shown

1Form No. 114907 rev. C

Page 2

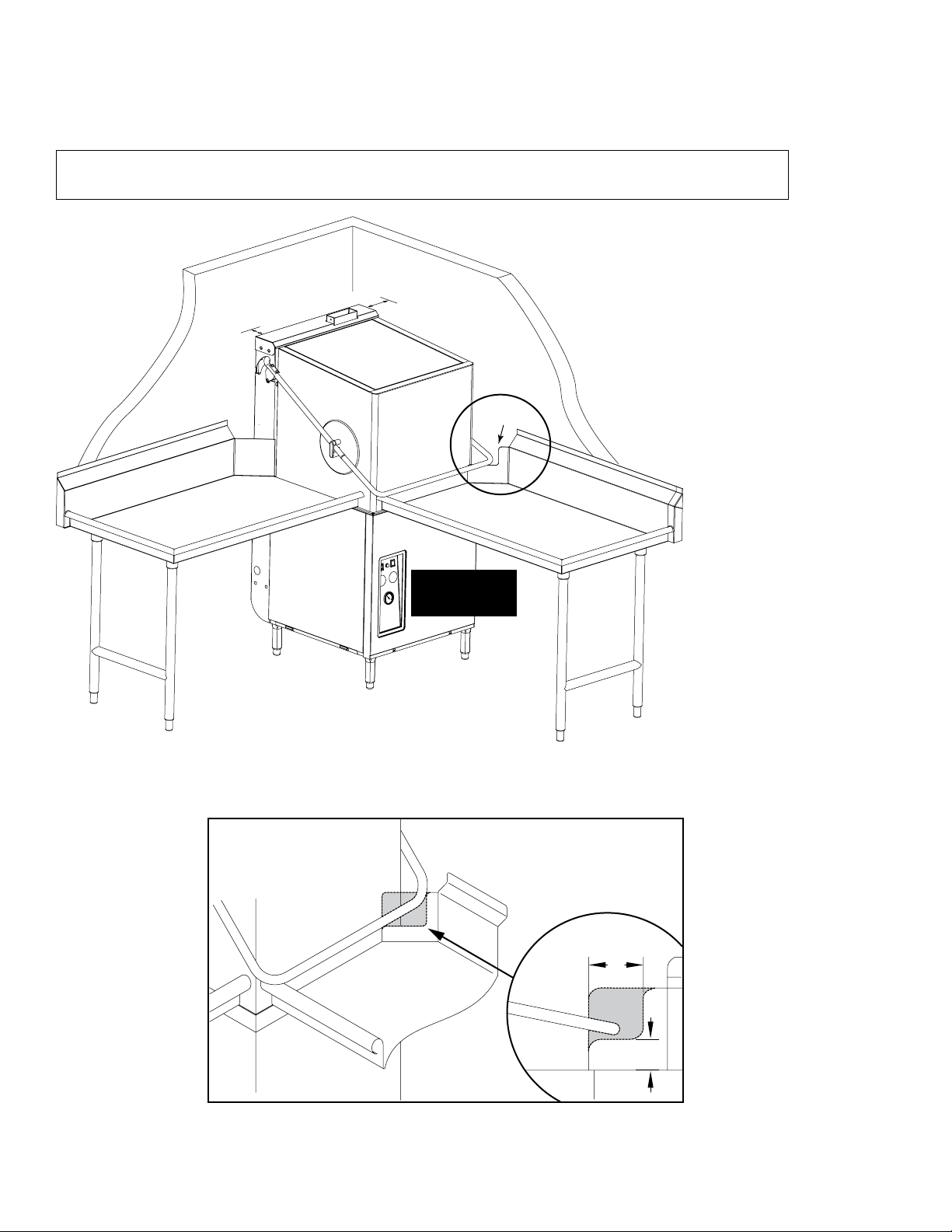

Converting Straight-through Operation to Corner Operation (continued)

! ATTENTION !

If the backsplash is more than 3" [76mm] high, then it must be notched for handle clearance.

1-7/8"

[48]

MIN.

5⅛"

[130]

MIN.

Controls must

be accessible.

CORNER CONFIGURATION

See Detail

HANDLE CLEARANCE CUTOUT

FOR CORNER OPERATION

Detail

2 Form No. 114907 rev. C

5"

[127]

3" [76]

Page 3

Converting Straight-through Operation to Corner Operation

Track Assembly

Guide

! IMPORTANT !

An optional Splash Shield, P/N 334630, is available for corner operation and must be installed

before the machine is placed in its permanent location.

Track Assembly Conversion:

Step 1: Open the hood and remove the

track assembly. Pull straight up and lift out

of the machine.

Step 2: Rotate the track assembly 180°

and reinstall it in the machine.

Step 3: The guide that was at the back of

the machine is now at the front. Remove

the fasteners holding the guide in place.

Save the fasteners.

Step 4: Rotate the guide counter-clockwise

to the right-side of the track assembly.

Use the fasteners to secure the guide.

Optional Splash Shield Installation for S/N D140911960 and above:

The splash shield reduces splash-out whenever the hood is raised.

IMPORTANT:

The splash shield must be installed before the machine is placed in its

permanent location.

Step 1: Remove the two 1/4-20 x 1/2" hex head bolts

located on the right-hand side of the machine as shown

in the illustration “Splash Shield (outside view)”.

Save the bolts.

Step 2: Raise the hood and fit the splash shield channel

guide over the edge of tank. Refer to illustration

“Splash Shield (inside view).

Step 3: Reinstall the bolts removed in step 1.

Step 4: Open and close the hood to ensure it

operates smoothly.

Step 5: Conversion is complete.

Bolts

1/4-20 X 1/2"

Splash

Shield

(inside view)

Channel

Guide

Splash

Shield

Right-side

of machine

Note:

See page 4 for splash shield installation instructions

for machines built prior to S/N D140911960.

Corner

Wall

Splash Shield (outside view)

3Form No. 114907 rev. C

Page 4

Kit 901056 - DH5000 Splash Shield Installation Kit

For machines built prior to S/N D140911960.

! IMPORTANT !

The splash shield must be installed before the machine is placed in its permanent

location.

Step 1: Check the contents of the kit.

Qty. (1) P/N 334630, DH5000 Splash Shield

Qty. (2) P/N 100734, 1/4-20 x 1/2” Hex Hd. Bolt

Qty. (2) P/N 106482, Washer, Lock 1/4”

Qty. (2) P/N 106026, Washer, Flat 1/4”

Step 2: Refer to the illustration at right. Raise the hood and fit the

splash shield channel guide over the right hand edge of tank.

Step 3: Refer to the the illustration below. Using the splash shield as a

template, mark the location for the mounting holes on the right-hand

side of the machine.

Step 4: Use a 5/16” drill bit and drill two mounting holes.

Step 5: Install the panel using two stainless steel 1/4-20 x 1/2” bolts

nuts, flat washers, and lock washers supplied in the kit.

Step 6: Raise and lower the hood to ensure it operates smoothly.

Step 7: The conversion is complete.

Splash

Shield

(inside view)

Channel

Guide

Splash

Shield

Bolts

1/4-20 X 1/2"

nuts, flat washers

and lock washers

4 Form No. 114907 rev. C

Right-side

of machine

Corner

Wall

Splash Shield (outside view)

Loading...

Loading...