Champion HRU Service Manual

Installation/Operation Guide with Service Replacement Parts

For machines built from 8.21.09 and above

Eseries High Temperature

Heat Recovery Unit

Model:

HRU

3765 Champion Blvd.,

Winston-Salem, NC 27105

336/661-1556 Fax: 336/661-1660

www.championindustries.com

2674 N. Service Road,

Jordan Station Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Issue Date: 2.18.11

Manual P/N 114819 rev.A

Printed in the USA

For future reference, record your dishwasher information in the box below.

Model Number__________________________ Serial Number_______________________

Voltage________________Hertz_____________ Phase__________________

Champion Service Agent __________________________________ Tel:______________________

Champion Parts Distributor _________________________________ Tel:______________________

ATTENTION:

The dishwasher model no., serial no., volt-

age, Hz and phase are needed to identify

your machine and to answer questions.

Please have this information on-hand

if you call for service assistance.

For all models:

The data plate mounts to one

side of the top-mounted

control cabinet.

National Service Department

In Canada: In the USA:

Toll-free: 800/ 263-5798 Toll-free: 800/ 858-4477

Tel: 905/ 562-4195 Tel: 336/ 661-1556

Fax: 905/ 562-4618 Fax: 336/ 661-1660

email: service@moyerdiebellimited.com email: service@championindustries.com

The USGBC and the CaGBC Member Logos are trademarks owned by the U.S. Green Building Council

and The Canadian Green Building Council, respectively, and are used by permission.

The logos signify only that Champion Industries is a

USGBC member and a CaGBC member; USGBC and CaGBC do not review,

certify nor endorse the products or services offered by its members.

COPYRIGHT © 2010 All rights reserved Printed in the USA

Revision History

Revision History

The revision history contains part number changes and instructions not available at the time

of printing. We reserve the right to make any changes without notice and without incurring

any liability by making these changes.

Equipment owners may request a revised manual at no charge, by calling:

1 (800) 858-4477 in the U.S.A. or by calling 1 (800) 263-5798 in Canada.

Revision Revised Serial Number Revision

Date Pages Effectivity Description

8.6.10 All Engineered System Release of First Edition

2.18.11 12-13 J11022850 Added blower junction box

14-21 J11022850 Added 2 amp circuit breaker

31 J10022850 Revised schematic for circuit breaker

i

Limited Warranty

LIMITED WARRANTY

Champion Industries Inc. (herein referred to as Champion), 3765 Champion Blvd., Winston-Salem, North Carolina 27105,

and P.O. Box 301, 2674 N. Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts,

as set out below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name

"Champion" and installed within the United States and Canada to be free from defects in material and workman

ship for a period of one (1) year after the date of installation or fteen (15) months after the date of shipment by

Champion, whichever occurs rst. [See below for special provisions relating to glasswashers.] The warranty

registration card must be returned to Champion within ten (10) days after installation. If warranty card is not

returned to Champion within such period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided;

however, as to glasswashers, Champion's obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs rst. In the event that Champion

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by a Champion authorized service technician. Defective parts become the property of Champion.

Use of replacement parts not authorized by Champion will relieve Champion of all further liability in connection

with its warranty. In no event will Champion's warranty obligation exceed Champion's charge for the machine.

The following are not covered by Champion's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior nish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage

caused by labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION'S WARRANTY IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED, TO ANY WARRANTY OF MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL

NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING MACHINES AND

CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR INCIDENTALS

OR CONSEQUENTIAL DAMAGES.

Champion does not authorize any other person, including persons who deal in Champion Dishwashing machines

to change this warranty or create any other obligation in connection with Champion Dishwashing Machines.

ii

Table of Contents

Table of Contents

Model HRU: Heat Recovery Unit

Revision History.................................................................................................................... i

Limited Warranty

Model Description

.................................................................................................................. ii

................................................................................................................. iv

Installation .............................................................................................................. 1

Receiving ........................................................................ 1

Mounting ......................................................................... 3

Plumbing Connections ................................................... 5

Setting the PRV's ........................................................... 6

Operation Lights and Exhaust Blowers .......................... 8

Operation .............................................................................................................. 9

Cleaning .............................................................................................................. 10

Service Replacement Parts

................................................................................... 11

One Line Piping Diagram

Operation Logic Diagram

....................................................................................... 29

...................................................................................... 33

Electrical Schematic............................................................................................... 34

Model Description

Model: HRU Heat Recovery Unit

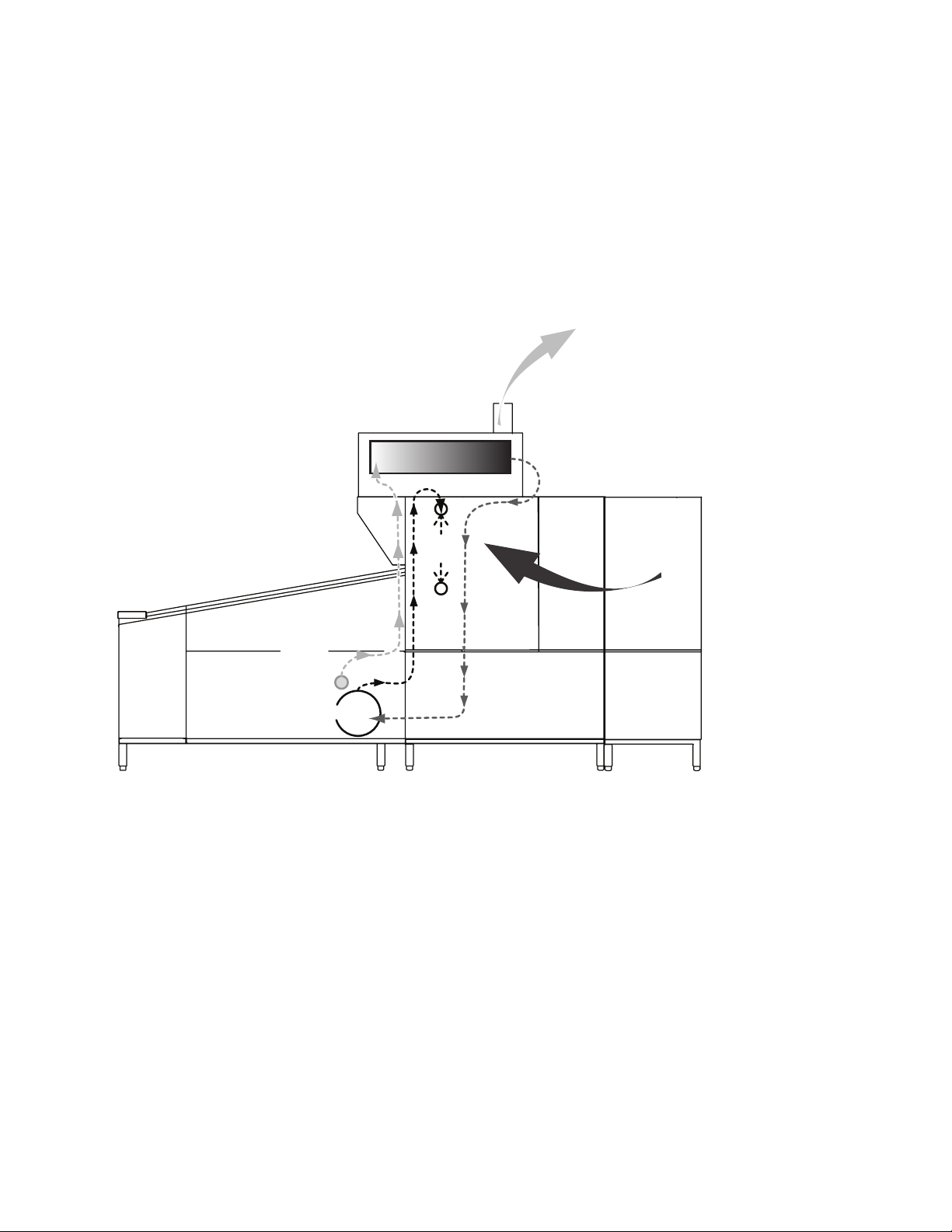

The HRU heats cold water supplied to the dishwasher's built-in heat exchanger which

raises the incoming temperature to approximately 110°F/43°C. The preheated water is

plumbed to the nal rinse water booster which ensures a minimum nal rinse water

temperature of 180°F/82°C to sanitize the clean wares. The HRU signicantly reduces

the energy required to heat water for the nal rinse operations.

Exhaust

Air

HRU

Cold

Water In

Booster

Pre-heated

Water Out

Exhaust

Air

The installation, and initial start-up of your dishwasher must be performed by qualied

electricians, plumbers, and authorized service technicians trained in commercial dishwashers.

Defects and repairs caused by unauthorized installers will not be covered by the dishwasher

warranty.

iv

Installation

Installation

Receiving

NOTE:

The installation of your Heat Recovery Unit (HRU) must be performed by qualified service

personnel. Problems due to improper installation are not covered by the Warranty.

The HRU may have be installed at the factory. Proceed to the operation section of this manual

if your HRU is already attached to the machine.

1. Inspect the HRU for damage due to shipping.

2. Check for any accessories that may have shipped with your dishwasher.

3. Move the HRU near its permanent location.

CAUTION:

Be careful when lifting and moving the HRU to prevent damage to the machine.

NOTE:

The installation of the HRU must comply with local safety and health codes.

4. Compare the installation site utility connections with the dishwasher utility connections and

make sure that they are the same.

5. For new dishwasher installations, install the Dishwasher according to the instructions in the

dishwasher service manual Installation, Operation, and Service Replacement Parts, which

is shipped inside the dishwasher.

WARNING:

Moving Parts may cause INJURY OR DEATH.

USE EXTREME CAUTION WHEN THE CONVEYOR

IS MOVING.

WARNING:

Electrocution or serious injury may result when working on an

energized circuit.

Disconnect power at the main breaker or service disconnect

switch before working on the circuit.

Lock-out and tag the breaker to indicate that work is being

performed on the circuit.

1

Installation

Installation

Receiving

CAUTION:

Metal edges in the HRU may be sharp. Use appropriate caution when

!

NOTE:

The installation of the HRU must comply with local safety and health codes.

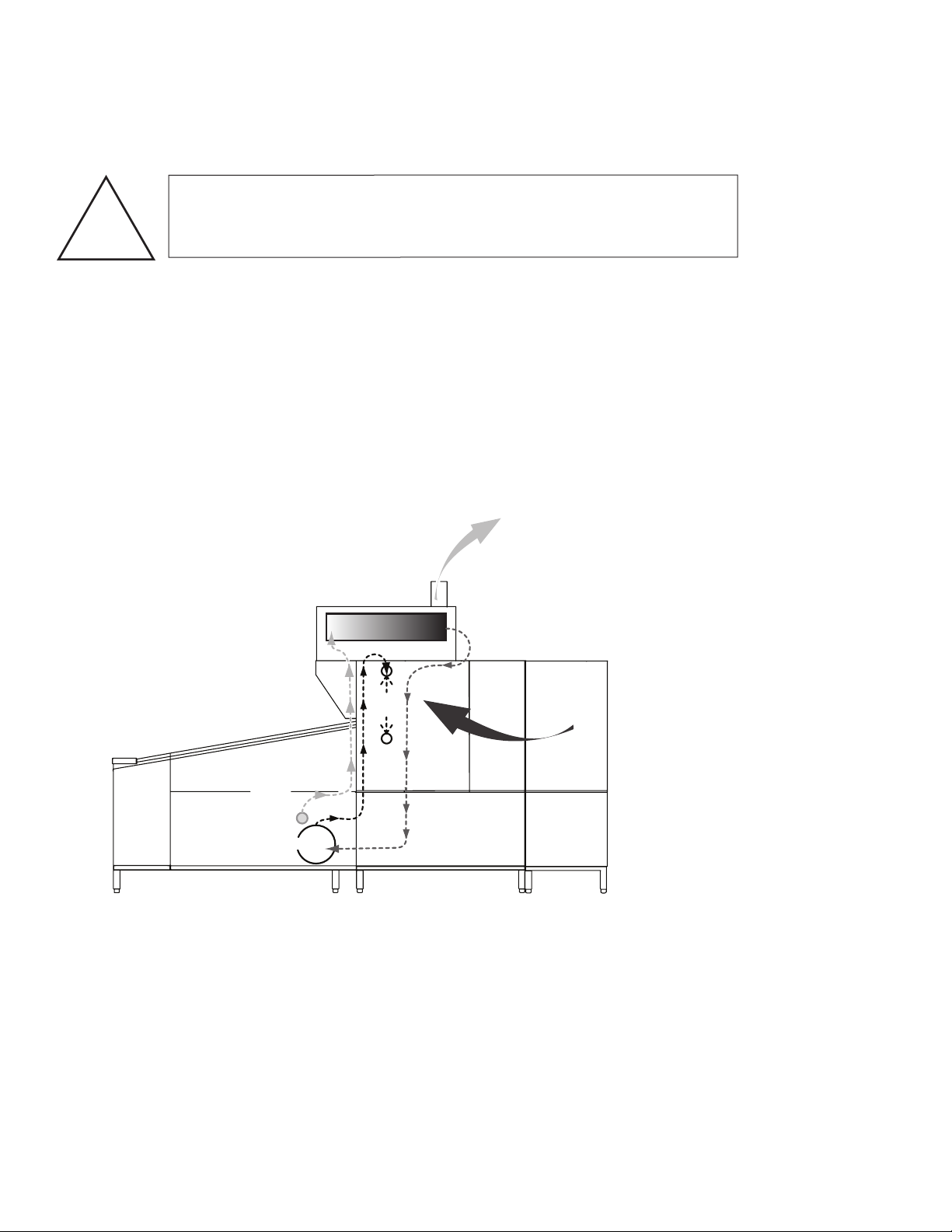

1. The HRU weighs approximately 175 lbs./79.4 Kg and mounts on the top of the unload end

of the dishwasher.

2. The unload exhaust vent of the dishwasher connects to the inlet of the HRU vent and is sealed

with gasket material which has already been installed on the dishwasher.

3. The HRU is attached to the dishwasher by inserting fasteners from inside the dishwasher

into weldnuts mounted in the HRU. Mounting hardware is included in the installation kit.

working on and in the vicinity of metal components

Exhaust

Air

HRU

Cold

Water In

Booster

Heat Recovery Unit (HRU) shown installed on a right-to-left dishwasher

without a Blower Dryer Option

Pre-heated

Water Out

Exhaust

Air

2

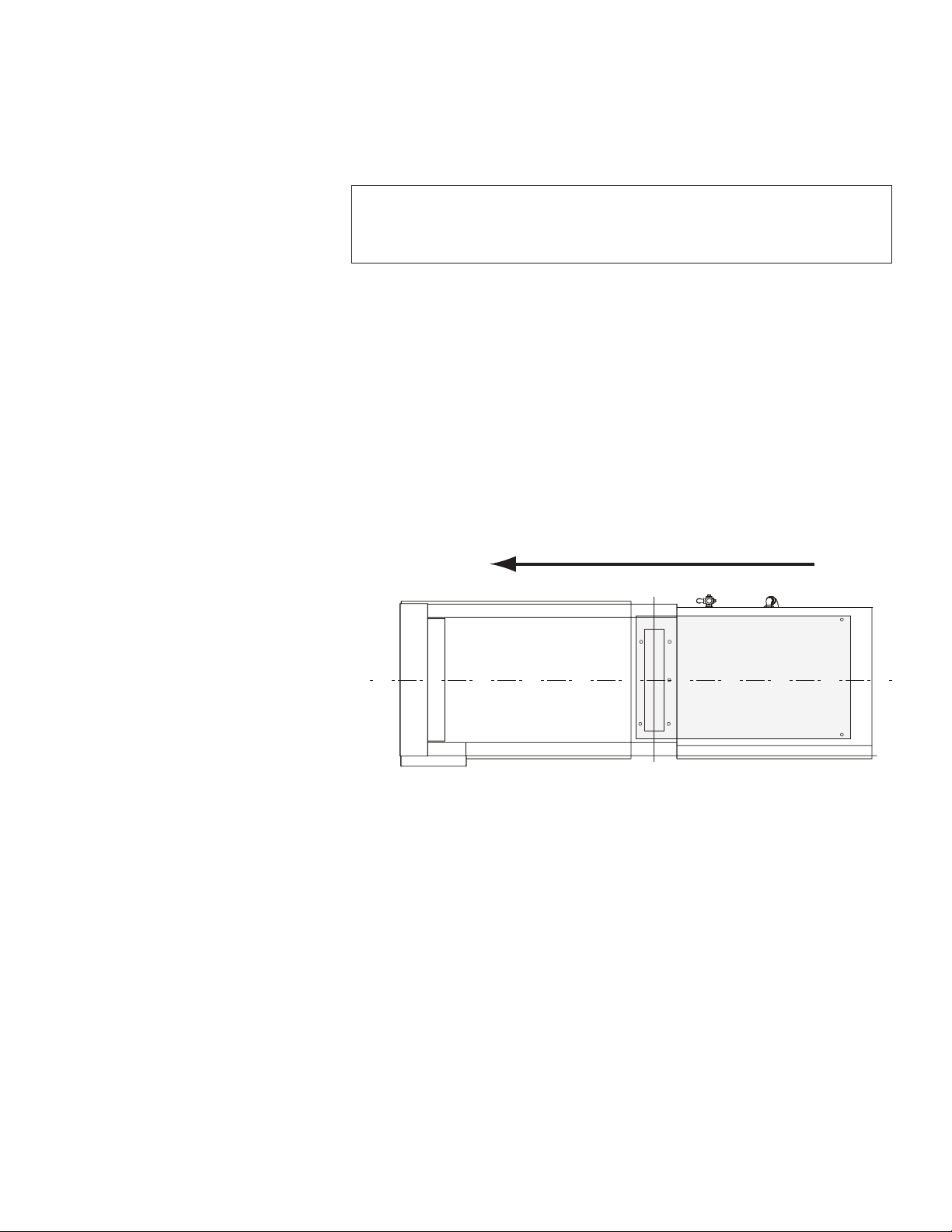

Installation

Dishwasher Direction of Travel

Installation

Mounting

NOTE:

The HRU may have been mounted at the factory so the procedures

described below may not be required.

1. Install the HRU after the dishwasher is completely assembled.

2. Lift the unit with a forklift or a minimum of four persons capable

of positioning and lowering the HRU into its nal position.

3. Make sure the HRU vent inlet (A) is centered on the dishwasher.

4. Install the mounting hardware installed in the installation kit from the

inside of the dishwasher hood to secure the HRU to the machine

5. The mounting hardware (B) includes: (7) Hex hd. bolts 1/4-20 x 5/8",

(7) 1/4" split lock washers, and (7) 1/4" at washers.

C

B

B

L

B

A

B

B

HRU

Top View of the dishwasher unload section.

(HRU shown in gray)

B

B

6. Electrical power is prewired from the heat recovery control box to

the dishwasher main control cabinet to operate the HRU.

3

Blank Page

This Page

Intentionally

Left Blank

4

Installation

Installation

Plumbing Connections

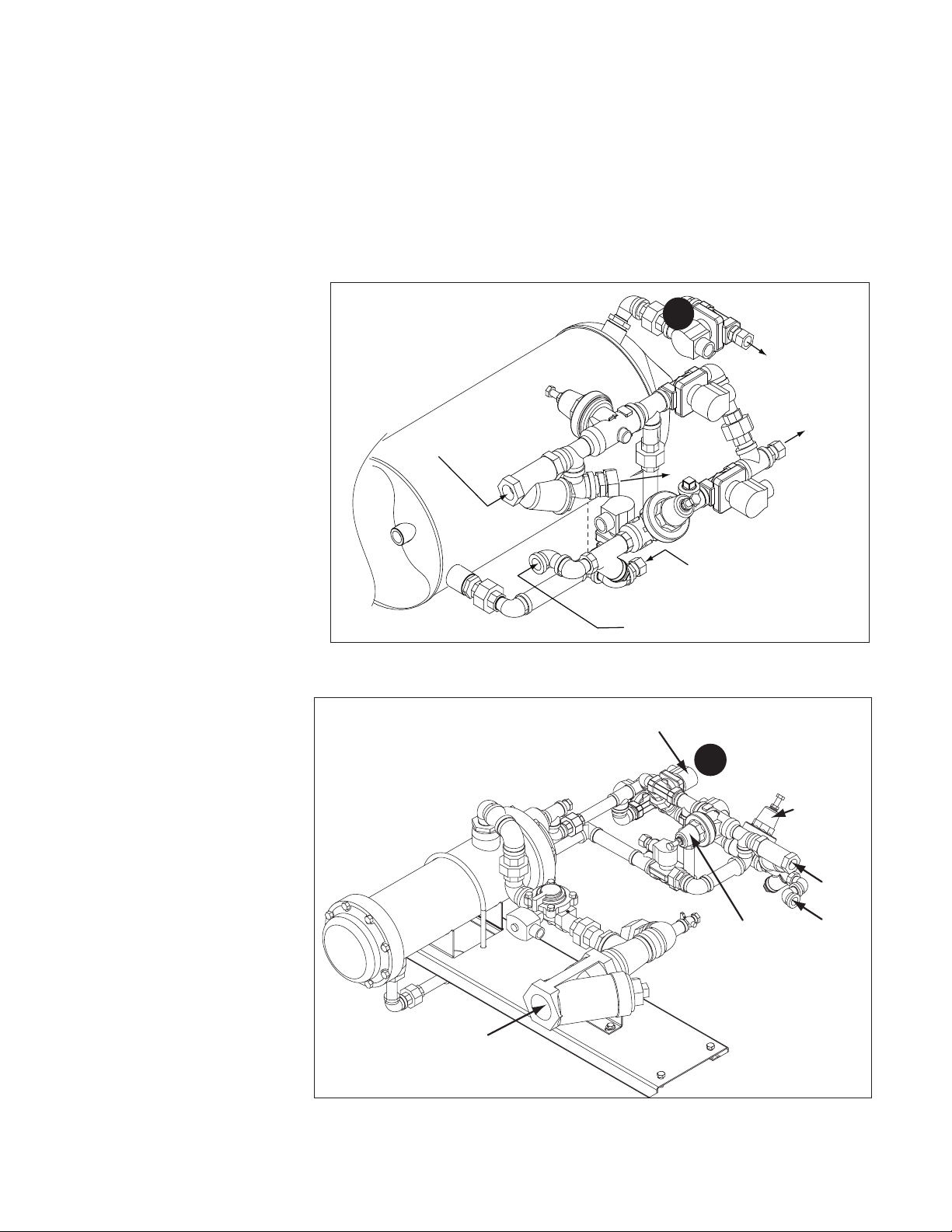

Refer to the photograph below and follow the instructions to connect the

water lines to the HRU.

1. Connect compression ttings from the cold water supply line located

at the base of the dishwasher booster heater to the HRU.

2. Connect compression ttings from the HRU return line at the rear

of the HRU to the booster inlet located at the base of the machine.

3. Connect the red drain hose from the base of the HRU to the

tting on the rear drain line of the dishwasher. The tting is located

directly below the HRU drain line.

HRU WATER

OUT

COLD WATER

IN

HRU DRAIN

OUT

Heat Recovery Unit (HRU) water and drain lines are connected at the rear of the dishwasher.

5

Installation

Installation

Setting the Booster Pressure Reducing Valves (PRV's)

Refer to the illustrations on the next two pages for the location of the water valves and the Green

indicator lights.

1. Ensure that all utility connections are complete.

2. Remove the lower front panel of the unload section.

3. Remove the coil assembly (A) from the multi-rinse valve.

CAUTION:

to prevent damage to the valve coil, energize the multi-rinse valve for as short a

period as needed to make necessary PRV adjustments.

Immediately reinstall the coil assembly when PRV adjustments have been completed.

4. Turn on main water supplies to the dishwasher. Make sure steam supply is OFF.

5. Close all of the drain valves.

6. Remove the main control cabinet cover and set the Auto/Manual switch to the Manual position.

7. Turn ON main breaker power to dishwasher.

8. Turn OFF main breaker power to the booster and optional blower dryer (if equipped).

9. Turn dishwasher main power switch ON.

10. Allow dishwasher tanks to completely ll with water.

11. When dishwasher tanks are full, turn dishwasher main power switch OFF.

12. Turn the Auxiliary wash tank drain handle open and drain the tank (leave the drain open).

(This places the dishwasher in a FILL mode because the tank is empty.)

13. Turn the dishwasher main power switch ON.

14. The Green FILL light in the control cabinet will be ON when the machine is lling.

15. While the machine is lling, adjust the HOT PRV #1 until the nal rinse pressure gauge indicates

20 PSI. Tighten the PRV adjustment lock-nut to hold the setting.

16. Close the drain and allow the dishwasher to ll with water.

17. Turn the dishwasher main power switch OFF.

18. Make sure the main breaker or steam supply to the booster is OFF.

Turn the hot water off.

19. Turn the dishwasher control panel Power Switch on.

20. Press the ENERGY SAVER mode selector switch on the main control cabinet.

The green LED will illuminate and the conveyor will run.

21. While the machine is running, adjust the COLD PRV #2 until the nal rinse pressure gauge indicates 20

PSI. Tighten the PRV adjustment lock-nut to hold the setting.

22. Now set the cold water PRV #2 by adjusting the PRV until the nal rinse pressure gauge indicates 20 PSI

ow pressure. Note that the pressure gauge will cycle on for 15 seconds and then off for 30; therefore, the

pressure gauge will read a owing pressure for 15 secs., then read the no pressure for 30 seconds.

23. The Green FINAL light will be ON when the Cold water valve is ON. The Green REHEAT light will be ON

when the Hot water valve is ON.

24. To complete the settings: Turn the dishwasher main power switch OFF.

25. Turn the main breaker or steam supply to the booster on.

26. Turn the Automatic/Manual switch inside the control cabinet to the Automatic position.

6

Setting the Booster Pressure Regulating Valves (PRV's)

To HRU

From HRU

Cold PRV

Hot PRV

To Tank

Fill

Cold Water In

Hot Water In

Multi-rinse Valve

To Final Rinse

A

#1

#2

1. Reinstall the main control cabinet cover.

2. Reinstall the coil assembly on the multi-rinse valve (A).

3. Open all drain valves and drain the dishwasher.

4. Turn the hot water supply ON.

5. Makes sure the main power supply is ON.

Installation

Installation

Steam In

Electric HRU Booster PRV Locations

(Right-to-left dishwasher installation).

Multi-Rinse Valve

A

Hot

PRV #1

Cold

PRV #2

Hot In

Cold In

Steam HRU Booster PRV Locations

(Right-to-left dishwasher installation).

7

Loading...

Loading...