Champion CRN25, CRN50, CRN35, CRN75, CRN100 Instruction Manual

SERVICE DEPARTMENT: (724) 746-1100

CRN SERIES

REFRIGERATED

COMPRESSED

AIR DRYERS

INSTRUCTION MANUAL

7610.721.73 1/04

CA18-2-645, 1st Ed.

7610.478.39/040103

INTERNAL USE ONLY

Models: CRN25, CRN35, CRN50,

CRN75, CRN100

®

CONTENTS

GENERAL SAFETY INFORMATION ............................2

RECEIVING, MOVING, UNPACKING ..........................2

1.0 INSTALLATION ...................................................3

2.0 OPERATION.......................................................4

3.0 MAINTENANCE .................................................6

SIZING ......................................................................6

ENGINEERING DATA.................................................7

ELECTRICAL SCHEMATICS ........................................8

DIMENSIONS / WEIGHTS..........................................9

TROUBLESHOOTING...............................................10

PARTS LIST............................................................. 11

WARRANTY............................................................12

GENERAL SAFETY INFORMATION

RECEIVING, MOVING, AND UNPACKING

1. PRESSURIZED DEVICES:

This equipment is a pressure

containing device.

• Do not exceed maximum operating

pressure as shown on equipment serial

number tag.

• Make sure equipment is depressurized before

working on or disassembling it for service.

2. ELECTRICAL:

This equipment requires electricity

to operate.

• Install equipment in compliance

with all applicable electrical codes.

• Standard equipment is supplied with electrical

enclosures not intended for installation in

hazardous environments.

• Disconnect power supply to equipment when

performing any electrical service work.

3. BREATHING AIR:

• Air treated by this equipment

may not be suitable for breathing

without further purification.

Refer to applicable standards and

specifications for the requirements for breathing

quality air.

A. RECEIVING

This shipment has been thoroughly checked, packed

and inspected before leaving our plant. It was received in good condition by the carrier and was so

acknowledged.

Check for Visible Loss or Damage. If this shipment

shows evidence of loss or damage at time of delivery

to you, insist that a notation of this loss or damage

be made on the delivery receipt by the carrier’s

agent.

B. UNPACKING

Check for Concealed Loss or Damage. When a shipment has been delivered to you in apparent good

order, but concealed damage is found upon unpacking, notify the carrier immediately and insist on his

agent inspecting the shipment. Concealed damage

claims are not our responsibility as our terms are

F.O.B. point of shipment.

C. MOVING

In moving or transporting dryer, do not tip dryer onto

its side.

D. STORAGE/SHUT DOWN

Dryer should not be stored outside (either

packed or unpacked) or exposed to the weather. Damage

to electrical and control components may result.

IMPORTANT: Do not store dryer in temperatures above

130°F, 54.4°C.

2

IMPORTANT:

READ PRIOR TO STARTING THIS EQUIPMENT

1.0 INSTALLATION

1.1 Location

A. For typical placement in a compressed air system, see

drawing.

B. Air compressor intake–Locate air compressor so that

contaminants potentially harmful to the dryer (e.g.

ammonia) are not drawn into the air system.

C. Dryer should be installed in a moderately heated, well

ventilated area. Avoid locations immediately adjacent

to cold exterior windows or walls, or adjacent to high

temperature ovens or boilers.

D. Clearances: Minimum requirements for free air flow

and service access

Flows 25 to 100 scfm:

Front 24 inches (610 mm)

Back 24 inches (610 mm)

Sides 12 inches (305 mm)

E. Standard units are designed to operate in ambients:

Air-cooled: 45 to 110°F (7 to 43°C).

Water-cooled: 45 to 130°F (7 to 54°C).

F. Installations in altitudes above 4500 feet (1370

meters) – Dryer is adjusted to operate in altitudes up

to 4500 feet (1370 meters). If dryer is installed in an

altitude above this, and has not been preset at the

factory for this altitude, contact manufacturer’s

Service Department.

NOTE: Outdoor installation–Standard units are designed

for indoor installation. Contact manufacturer if installing

outdoors.

1.2 Mounting

Mount the dryer on a level solid surface. Holes are

provided in the dryer base to permanently mount the

dryer to the floor.

Compressor

Aftercooler

Separator

Dryer

Oil Removal

Filter

1.3 Piping connections

A. Air Inlet - Connect compressed air line from air

source to air inlet. (See callout drawing on page 3 for

air in/outlet connection locations)

Refer to Serial Number Tag for maximum

working pressure. Do not exceed dryer’s Maximum

Working Pressure.

NOTE:

Install dryer in air system at highest pressure possible

(e.g. before pressure reducing valves).

NOTE:

Install dryer at coolest compressed air temperature

possible. Maximum inlet compressed air temperature:

110°F (43°C). If inlet air exceeds this temperature, precool

the air with an aftercooler.

B. Air Outlet—Connect air outlet to downstream

air lines.

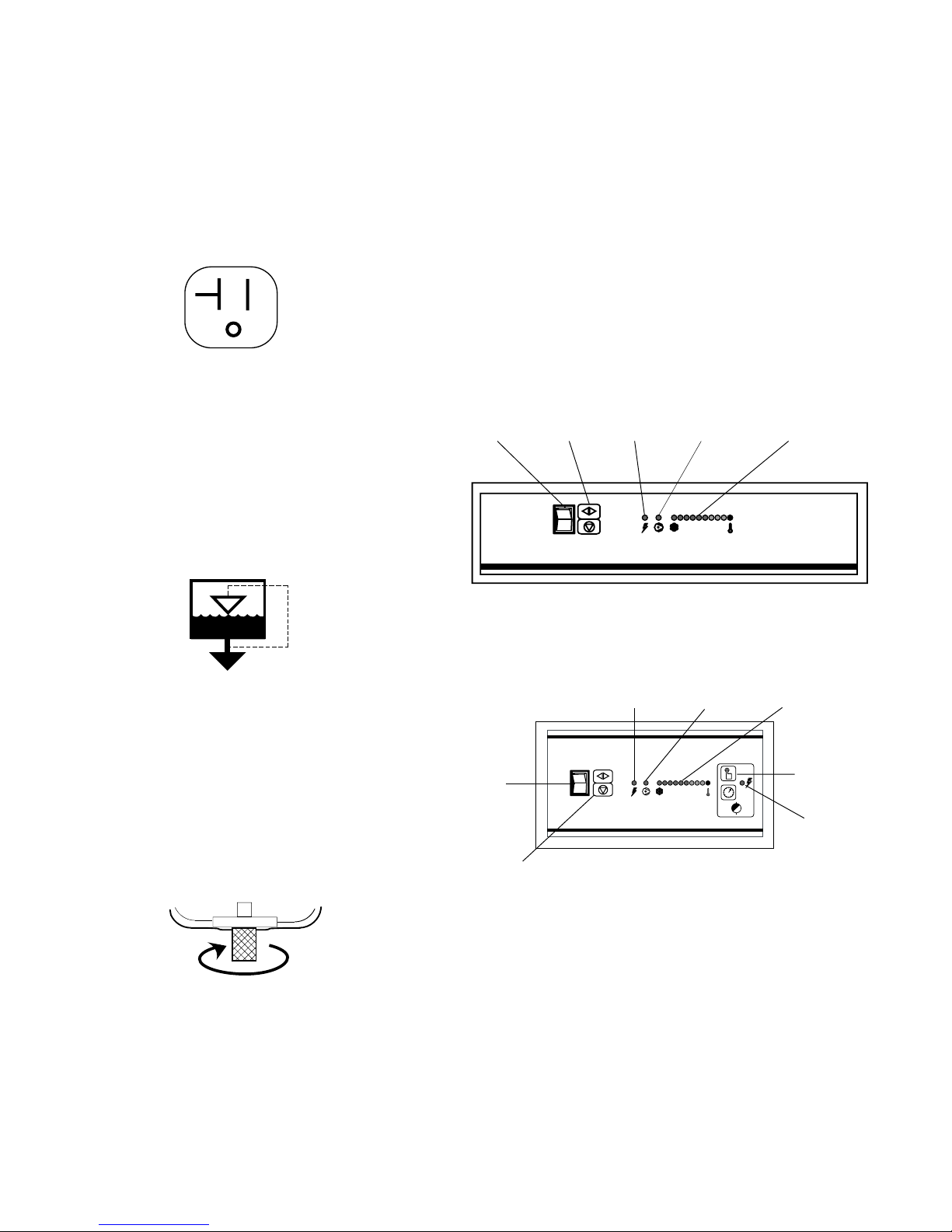

On/Off Switch

Power On-Light

Compressor On-Light

Dew point Temperature Indicator

Separator/Filter

Optional

Cold Coalescing

Filter

C. By-pass piping—

If servicing the dryer without interrupting the

air supply is desired, piping should include

inlet and outlet valves and an air by-pass valve.

Air Outlet

Air Inlet

Power Cord

Air Flow

Drain

3

1.4 Electrical connections

......................39

.......................4

2.0 Operation

A. Dryer is designed to operate on the voltage, phase,

and frequency listed on the serial number tag.

B. If dryer is supplied with a cord and plug, install in a

receptacle of proper voltage.

NOTE:

Refrigeration condensing unit is designed to run continuously and should NOT be wired to cycle on/off with the air

compressor. Excessive cycling of the refrigeration system

could lead to premature failure and void the warranty.

1.5 Moisture separator

A. Separator (and Oil Removal Filter where applicable) has

an internal drain which automatically discharges

collected condensate. It may be desirable to pipe the

condensate from the Automatic Drain outlet to a

suitable drain.

NOTE:

Discharge is at system pressure. Drain line should be

anchored.

2.1 Minimum/Maximum operating conditions

A. Maximum inlet air pressure: refer to dryer serial

number tag

B. Minimum inlet air pressure: 30 psig (2.1 kgf/cm

C. Maximum inlet air temperature: 110°F (43°C)

D. Maximum ambient temperature:

Air-cooled models: 110°F (43°C)

Water-cooled models: 130°F (54°C)

E. Minimum ambient temperature: 45°F (7°C)

I - Controller Level 1 - Standard

On/Off

Switch

Switch

Legend

Power On

Light

Compressor

On Light

33°F......................39°F

1°C.......................4°C

Dew point

Temperature

Indicator

2

)

NOTE:

Condensate may contain oil. Comply with applicable laws

concerning proper disposal.

B. I -Controller Level 1 ONLY:

Separator has a knurled fitting with flexible drain

tubing attached. Be sure knurled fitting is tightened

by turning it counter-clockwise before operating

dryer.

TO CLOSE

TURN COUNTERCLOCKWISE

OptionaI Controller

On/Off

Switch

Switch Legend

Power On

Light

Compressor On

Light

3333°F......................39

°F

°C

1°C.......................4

Dew point

Temperature

Indicator

Push-to-Test

Condensate

Drain

Draining

4

Loading...

Loading...