Page 1

3227486 Rev. H 10/18

CA18-2-635 4th Edition

INSTRUCTION MANUAL

Contents

GENERAL SAFETY INFORMATION ...................................1

1.0 INSTALLATION ..........................................................2

2.0 OPERATION ..............................................................3

3.0 MAINTENANCE ........................................................4

TROUBLESHOOTING GUIDE .............................................6

SPECIFICATIONS ......................................................... 7-8

ELECTRICAL SCHEMATICS ...............................................9

DIMENSIONS AND WEIGHTS ................................... 10-12

PARTS LIST .............................................................. 13-14

WARRANTY ..................................................................16

GENERAL SAFETY INFORMATION

1. Pressurized devices

This equipment is a pressure containing device.

• Do not exceed maximum operating pressure as shown

on equipment serial number tag.

• Make certain equipment is depressurized before servicing.

2. Electrical

This equipment requires electricity to operate.

• Install equipment in compliance with national and local

electrical codes.

• Standard equipment is supplied with NEMA 1 electrical enclosures and is not intended for installation in

hazardous environments.

• Disconnect power supply to equipment before

servicing.

3. Breathing air

• Air treated by this equipment may not be suitable for

breathing without further purification. Refer to OSHA

standard 1910.134 for the requirements for breathing

quality air.

CRH SERIES

HIGH INLET

TEMPERATURE

REFRIGERATED

COMPRESSED

AIR DRYERS

Page 2

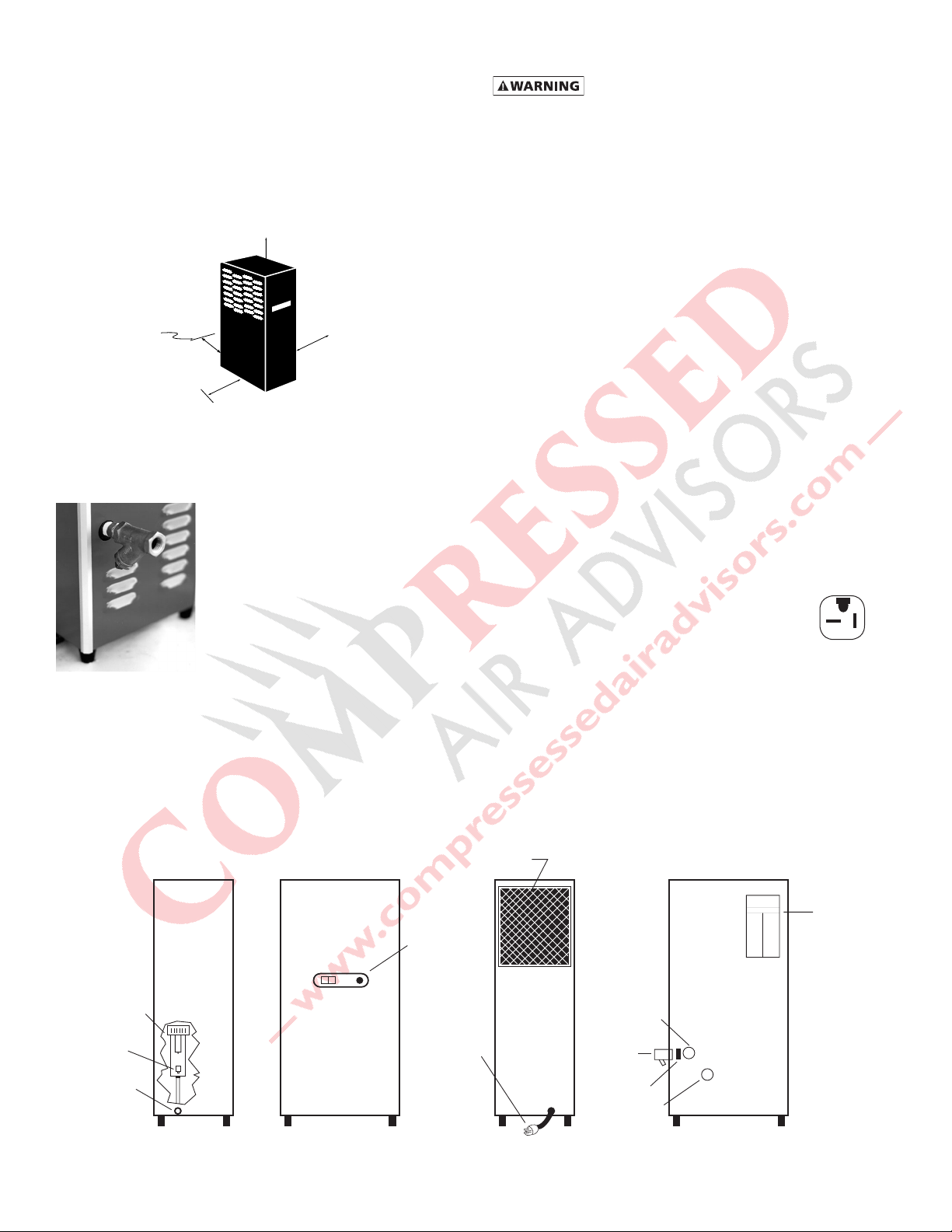

Ambient Air Filter

1.0 INSTALLATION

24"

12"

wall

6"

36"

1.1 Location

A. Air compressor intake - Locate air compressor so that

contaminants potentially harmful to the dryer are not

drawn into the air system.

B. Free air flow - Do not block either side of the cabinet.

Observe minimum installation clearances as shown.

1.2 Mounting

Dryer is suitable for floor or shelf mounting.

2. Location in the compressed air system

A. Maximum working pressure - 250 psig,

17.6 kgf/cm2. Do not exceed unit’s Maximum Working

Pressure.

1) For maximum capacity, install unit in air system at

highest pressure possible (e.g. before pressure reducing valves)

2) For maximum capacity, install unit at coolest compressed air temperature possible. Maximum inlet

compressed air temperature: 180°F, 82°C. If inlet air

exceeds this temperature, precool the air by extending the piping between the compressor and the

dryer.

B. Air Outlet - Connect air outlet to downstream air lines.

C. By-pass piping - If servicing the unit without interrupting

the air supply is desired, piping should include inlet and

outlet isolation valves and an air by-pass valve.

D. Condensate drain - It is advisable to connect drain outlet

to the condensate drainage system.

NOTE: Drain discharge is at system pressure. Drain line

should be anchored to prevent whipping.

1.3 Piping connections

A. Air Inlet - Connect compressed

air line from air compressor to air

inlet using strainer supplied.

1. Install strainer (included in

shipping carton) prior to

dryer inlet using pipe nipple

supplied or other piping as

required.

NOTE: Observe flow direction arrows on strainer.

NOTE: Install strainer where it is easily accessible for cleaning.

NOTE: Use vibration dampener, if vibration exists in air line at

inlet to dryer.

Control

Panel

IO

Separator and

Integral Filter

Drain

Mechanism

Drain

Connection

Electrical

Connection

1.4 Electrical connections

A. Dryer is designed to operate on power supply (voltage)

listed on serial number tag located on the back of the

dryer.

B. Dryer is supplied with an electrical cord. Install in recep-

tacle of proper voltage.

NOTE: Models 50 and 75 (115v only) - Install plug

in receptacle rated for 20 amps. Units are supplied

with 20 amp plug.

Plug

NOTE: Refrigeration system is designed to run continuously

and should NOT be wired to cycle on/off with the air compressor.

Serial Number

Tag

Air Inlet

Connection

Strainer

(shipped

separately)

Pipe Nipple

Air Outlet

Connection

Serial

Number

Tag

2

Left Side Front BackRight Side

Page 3

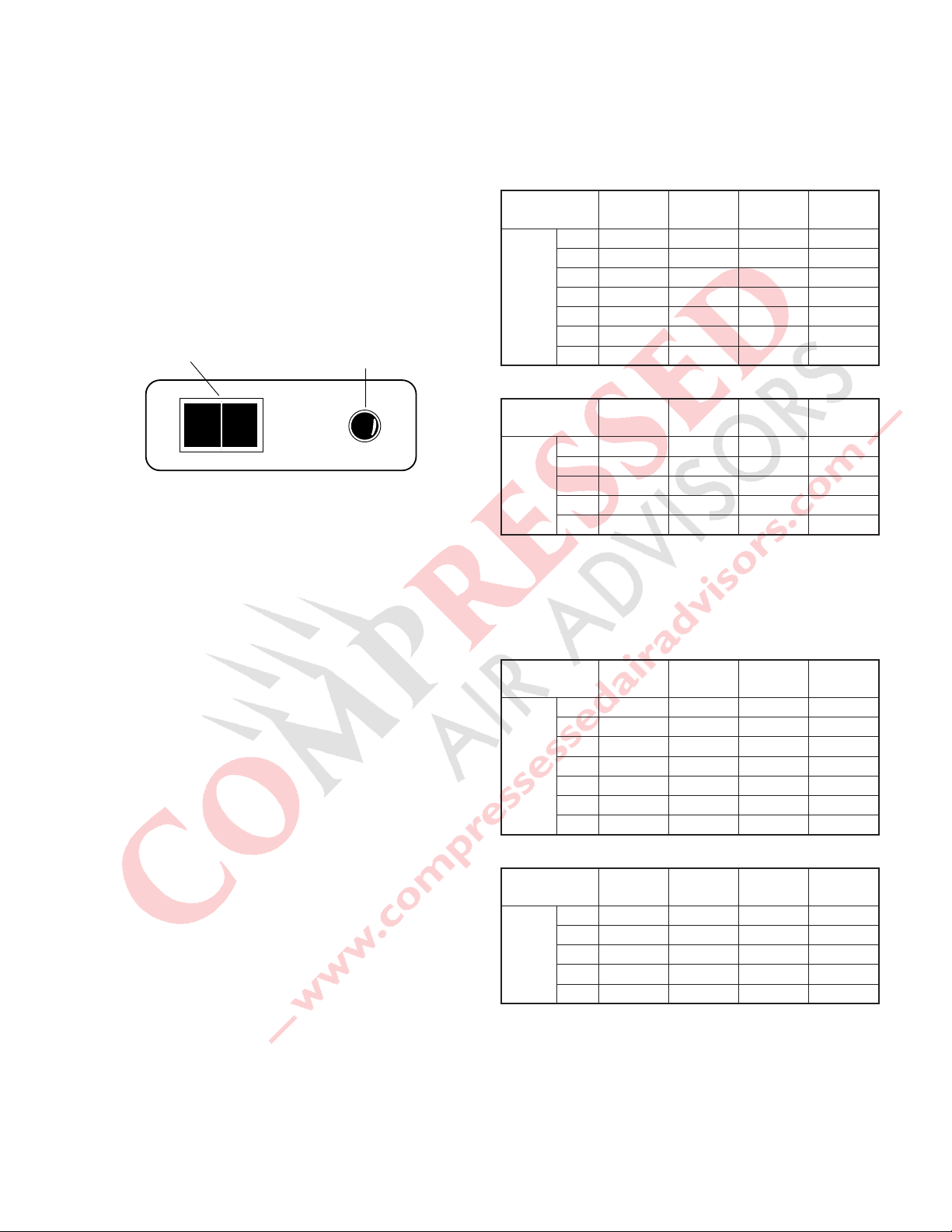

2.0 OPERATION

I

O

On/Off Switch

Fault Light

NOTE: Installations above 6000 feet, 1825 meters

Unit is adjusted to operate in altitudes up to 6000 feet, 1825

meters. If unit is installed in an altitude above this, and has

not been preset at the factory for this altitude, contact

Manufacturer’s Service Department.

2.1 Start-up

Start refrigeration system by pushing the on/off switch to

the ON position (depress rocker switch on side marked “I”).

NOTE: The fault light may illuminate when unit is energized.

Light should go out approximately 5 minutes after start-up.

If light remains lit after 30 minutes or illuminates after going

out, refer to Troubleshooting Guide.

Control Panel

2.2 Operating check points

Check the following on a periodic basis:

A. Rocker switch is in the ON position.

B. Amber fault light is out.

C. Condensate is being regularly discharged.

2.3 Minimum/maximum operating conditions

A. Minimum/Maximum air pressure: 20/250 psig,

1.4/17.6 kgf/cm

B. Maximum inlet air temperature: 180°F, 82°C

C. Minimum/Maximum ambient temperature:

40/110°F, 4/43°C

2

D. Maximum flow capacity

1. For dryers without an aftercooler installed upstream

Flow capacity in scfm (m3/min) @ 180°F, 82°C inlet

temperature, 160°F, 71°C inlet pressure dew point,

95°F, 35°C ambient temperature, and less than

5 psi, 0.35 kgf / cm2 pressure drop.

60 HZ

Inlet Pressure

psig (kgf/cm2)

Model

175 (12.3) 150 (10.6) 125 (8.8) 100 (7.0)

20 23 (0.65) 22 (0.62) 20 (0.57) 18 (0.51)

25 29 (0.82) 27 (0.76) 25 (0.71) 23 (0.65)

35 41 (1.16) 38 (1.08) 35 (0.99) 32 (0.91)

50 58 (1.64) 54 (1.53) 50 (1.42) 45 (1.27)

75 87 (2.46) 81 (2.29) 75 (2.12) 68 (1.93)

100 116 (3.29) 108 (3.06) 100 (2.83) 91 (2.58)

125 145 (4.12) 135 (3.82) 125 (3.54) 114 (3.23)

50 HZ

Inlet Pressure

psig (kgf/cm2)

Model

2. For dryers with an aftercooler installed upstream

Flow capacity in scfm (m3/min) @ 100°F, 38°C inlet

temperature, 100°F, 38°C inlet pressure dew point,

100°F, 38°C ambient temperature, and less than

10 psi, 0.7 kgf / cm2 pressure drop.

175 (12.3) 150 (10.6) 125 (8.8) 100 (7.0)

20 20 (0.57) 18 (0.51) 17 (0.48) 15 (0.42)

25 24 (0.68) 23 (0.65) 21 (0.59) 19 (0.54)

35 31 (0.88) 29 (0.82) 27 (0.76) 24 (0.68)

50 58 (1.64) 54 (1.53) 50 (1.42) 45 (1.27)

75 71 (2.01) 66 (1.87) 61 (1.73) 55 (1.56)

60 HZ

Inlet Pressure

psig (kgf/cm2)

Model

175 (12.3) 150 (10.6) 125 (8.8) 100 (7.0)

20 32 (0.91) 30 (0.85) 28 (0.79) 25 (0.71)

25 40 (1.13) 37 (1.05) 34 (0.96) 31 (0.88)

35 55 (1.56) 51 (1.44) 47 (1.33) 43 (1.22)

50 78 (2.21) 73 (2.07) 67 (1.90) 61 (1.73)

75 118 (3.34) 110 (3.12) 102 (2.89) 92 (2.61)

100 157 (4.45) 146 (4.14) 136 (3.85) 123 (3.48)

125 197 (5.58) 183 (5.18) 170 (4.82) 155 (4.39)

50 HZ

Inlet Pressure

psig (kgf/cm2)

Model

175 (12.3) 150 (10.6) 125 (8.8) 100 (7.0)

20 27 (0.76) 25 (0.71) 23 (0.65) 21 (0.59)

25 33 (0.93) 31 (0.88) 29 (0.82) 26 (0.74)

35 43 (1.22) 40 (1.13) 37 (1.05) 33 (0.93)

50 78 (2.21) 73 (2.07) 67 (1.90) 61 (1.73)

75 96 (2.72) 90 (2.55) 83 (2.35) 75 (2.12)

3

Page 4

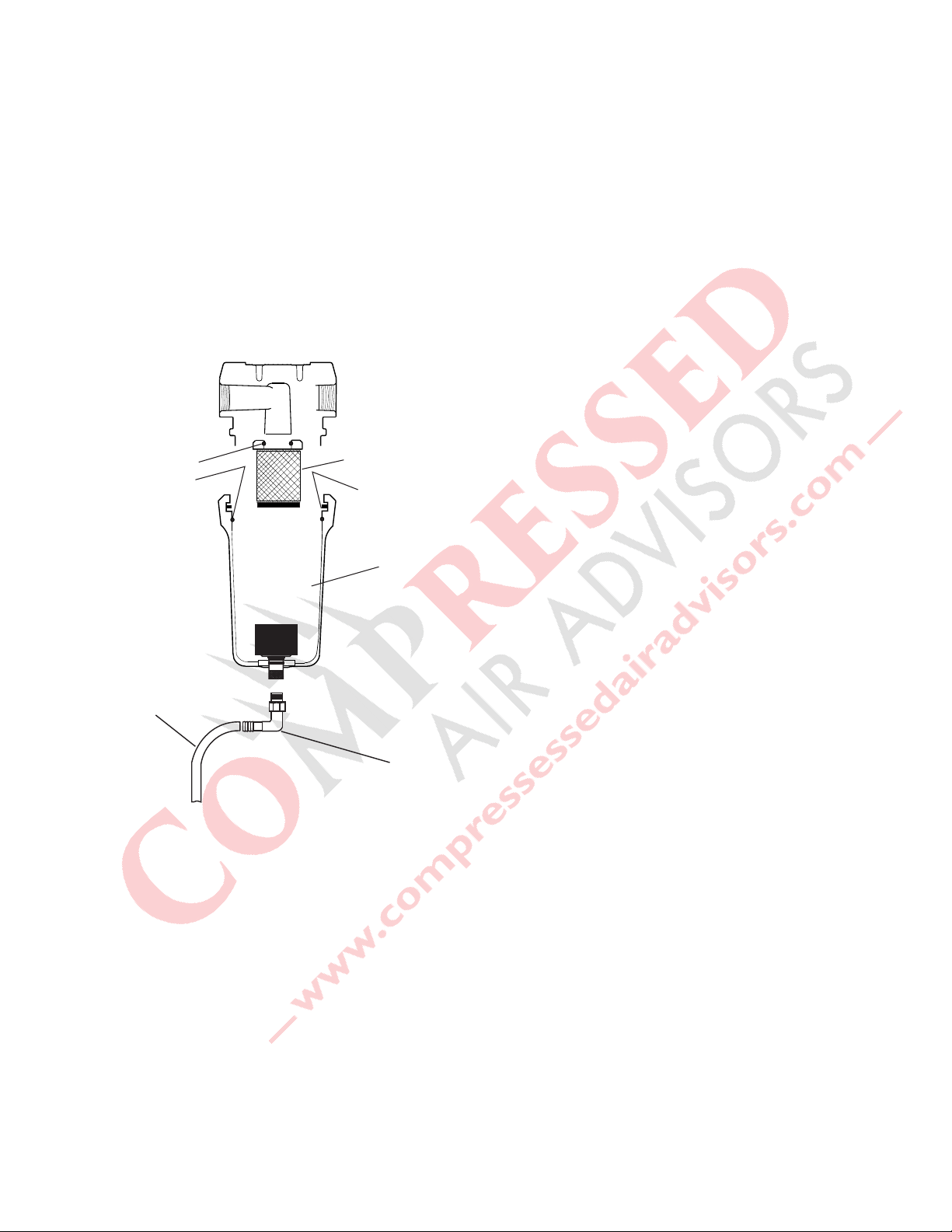

3.0 MAINTENANCE

Screen

DRYER IS A PRESSURE CONTAINING DEVICE.

DISCONNECT POWER AND DEPRESSURIZE DRYER BEFORE

SERVICING.

3.1 Ambient air filter - Clean accumulated dust and

dirt from ambient air filter monthly or more often

if air flow across the condenser is impeded.

A. Remove top panel.

B. Remove ambient air filter by sliding upwards.

3.3 Replace separator/filter element yearly or more

often if pressure drop across the dryer is excessive.

A. Shut-off compressed air supply to the dryer and depres-

surize. Turn off power to the dryer.

B. Remove top panel.

C. Remove two screws holding side panel and remove side

panel by sliding upwards.

D. Disconnect drain tube from bulkhead fitting in cabinet

base. To remove, press the plastic collar in, toward the

fitting, while pulling the tube out of the fitting.

E. Remove bowl - push bowl up, turn bowl 1/8th turn to

your left, and pull straight down.

F. Clean filter bowl.

G. Replace element.

C. Wash with soap and water and allow to dry before re-

installing.

NOTE: Do not use solvents to clean ambient air filter.

D. Reinstall filter and top panel.

3.2 Inlet strainer - clean inlet strainer monthly or

more often if rapid clogging occurs.

A. Shut-off compressed air supply to the strainer and de-

pressurize. Turn off power to the dryer.

B. Remove screen and clean or replace.

C. Reinstall.

1. Replacing complete element

a) Pull off old element and discard.

b) Make certain O-ring inside top of replacement ele-

ment is in place and push element onto filter head.

2. Replacing sleeve only

a) Pull element straight down to remove.

b) Remove bolt and bottom cap and remove disposable

filter sleeve.

c) Clean separator core with soap and water if necessary

d) Slide new filter sleeve over separator core and re-

place bottom cap and hand tighten bolt.

e) Make certain O-ring inside top of element is in place

and push element onto filter head.

4

Page 5

H. After making sure that O-ring and wave spring inside top

Element o-ring

Separator Element

Bowl o-ring

Drain Mechanism

Wave Spring

Tube

Hose

Barb

of bowl are in place, reassemble bowl to head.

NOTE: Make certain O-ring is generously lubricated

NOTE: Wave spring ends should be pointed down to prevent

the wave spring from interfering with reassembly.

I. Reconnect drain tube to bulkhead fitting by pushing

tube into fitting until it locks in position.

J. Reinstall side and top panels.

K. Restore power and repressurize dryer. Resume

operation.

3.4 Automatic condensate drain

• Check daily to be sure automatic drain is discharging.

• Replace drain mechanism yearly.

A. Shut-off compressed air supply to the dryer and depres-

surize. Turn off power to the dryer.

B. Remove top panel.

C. Remove two screws holding side panel then remove side

panel by sliding upwards.

D. Disconnect drain tube from bulkhead fitting in cabinet

base. To remove, press the plastic collar in, toward the

fitting, while pulling the tube out of the fitting.

E. Remove bowl - push bowl up, turn 1/8th turn to your

left, and pull bowl straight down.

F. Remove drain tube fitting from bottom of bowl.

G. Remove old drain mechanism by turning knurled fitting

to the right (clockwise) and remove.

H. Install new drain mechanism. If necessary, use a wire

or pencil to guide the new mechanism into place.

I. Reassemble drain tube fitting to bowl.

J. After making sure that large O-ring in filter head is in

place, reassemble bowl to head.

K. Reconnect drain tube to bulkhead fitting by pushing

tube into fitting until it locks in position.

L. Reinstall top and side panels.

M. Restore power and repressurize dryer. Resume

operation.

5

Page 6

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

A) Water downstream of dryer

B) High pressure drop across

dryer

1. Residual free moisture remaining in

downstream pipelines

2. Air by-pass system is open

3. Inlet and Outlet connections are

reversed

4. Temperatures surrounding air

lines downstream of dryer have

dropped below dryers dew point

rating.

5. Excessive free moisture (bulk liquid)

at dryer inlet

6. Condensate not being automatically drained

Drain mechanism is clogged or

inoperative.

Drain line is restricted or frozen.

7. Dryer overloaded resulting in elevated dew point.

8. Refrigeration system not functioning properly resulting in elevated

dew point.

1. Inlet air strainer clogged

2. Excessive air flow

3. Separator filter clogged.

4. Freezing of moisture in evaporator because of refrigeration

system improperly functioning.

Blow out system with dry air

Check valve positions

Check for correct connection

Insulate or heat trace air lines exposed

to low ambients or dry air to lower

dew point

Install separator ahead of dryer

Replace drain mechanism if inoperative

Open drain line

Check inlet air temperature and pressure, flow rate (compressor capacity)

and ambient air temperature

See D below

Clean inlet air strainer

Check flow rate

Replace filter sleeve

See D below

C) Fault Alarm

D) Refrigeration system not

functioning properly

1. When dryer on/off switch in on

or "I" position

2. Refrigerant compressor cycles on

and off

1. Dryer overloaded resulting in high

air outlet temperature.

2. Refrigeration system not functioning properly resulting in high

air outlet temperature.

3. Unit functioning normally but

thermostatic switch is malfunctioning or not securely mounted.

a. Power failure

b. Line disconnect switch open

c. Blown fuses, open breaker

d. Faulty wiring, loose terminals

a. High or low ambient conditions

b. Ambient air filter clogged

c. Condenser fins clogged

d. Fan motor or fan control

switch malfunction

e. Refrigerant leak

f. Low voltage

See A 7

See D below

Contact qualified refrigeration

repairman or manufacturer’s service

department

Check power to unit

Close disconnect switch

Check for continuity

Have electrician check electrical connections

Check minimum/maximum temperature ranges

Clean ambient air filter

Clean condenser

Replace fan motor or fan control

switch

Contact qualified refrigeration repairman or manufacturer's service

department

Check wiring

6

Page 7

SPECIFICATIONS - Models 20 through 75

Description

20 25 35 50 75

Model

Operating Conditions

Rated Capacity

@125 psig, 8.8 kgf/cm

scfm

2

*

m

3

/min

60 / 50 Hz

60 / 50 Hz

Maximum Working Pressure 250 psig (17.6 kgf/cm

20 / 17

0.57 / 0.48

25 / 21

0.71 / 0.59

35 / 27

0.99 / 0.76

2

)

50 / 50

1.42 / 1.42

Maximum Inlet Temperature 180°F (82°C)

Min/Max. Ambient Temperature 40-110°F (4-43°C)

Pressure Drop @

rated capacity

psi

(kgf/cm

2

)

60 / 50 Hz

60 / 50 Hz

4.5 / 2.9

(0.32 / 0.20)

3.3 / 2.4

(0.23 / 0.17)

4.7 / 2.9

(0.33 / 0.20)

4.5 / 4.5

(0.32 / 0.32)

Refrigeration System Data

Compressor Type Hermetic, Rotary, Permanent Split Capacitor

BTU/HR - Refrigeration Only

@ ASRE-T Conditions

60 / 50 Hz 8720 / 7043 12500 / 9970

Outlet Air Temperature

(nominal @ rated conditions)

155°F (68°C)

Refrigerant Type R-407C

Refrigerant Charge oz (grams)

60 / 50 Hz

Suction Pressure Setting 67 psig (4.7 kgf/cm

Factory Test (design) Pressure

high side/low side

Condenser Fan Switch Setting (in-out) 240-180 psig (16.9-12.7 kgf/cm

Air Flow Across Condenser cfm

3

m

/min

60 / 50 Hz

60 / 50 Hz

280 / 235

(7.9 / 6.7)

See Dryer Serial Tag

2

)

2

330/178 psig (23.2/12.5 kgf/cm

)

2

)

620 /515

(17.6 / 14.6)

Electrical Data

Unit

VAC/phase/Hz

115/1/60

115/1/60

Minimum/maximum volts 104 - 127

Full Load Amps (FLA) 8.7 12.6

Branch Circuit Fuse Size (amps) 15 20

Compressor

Volts/phase/Hz

115/1/60

Rated Load amps (RLA) 7.5 11.0

Locked Rotor amps (LRA) 44.0 67.0

Watts (input) 853 1220

Overload (External) Thermal and Current (Auto Reset)

Condenser fan motor

Volts/phase/Watts (output)

115/1/25 115/1/35

Full Load Amps (FLA) 1.2 1.6

Unit

VAC/phase/Hz

220-240/1/50

220-240/1/50

Minimum/maximum volts 198 - 264

Full Load Amps (FLA) 3.4 6.0

Branch Circuit Fuse Size (amps) 15

Compressor

Volts/phase/Hz

220-240/1/50

Rated Load amps (RLA) 2.8 5.1

Locked Rotor amps (LRA) 18.6 28.0

Watts (input) 690 990

Overload (External)) Thermal and Current (Auto Reset)

Condenser fan motor

Volts/phase/Watts (output)

220-240/1/18.3 220-240/1/25.6

Full Load Amps (FLA) 0.6 0.8

75 / 61

2.12 / 1.7

3.8 / 2.2

(0.27 / 0.15)

* Capacity @ 180°F, 82°C inlet temperature, 160°F, 71°C inlet pressure dew point, 95°F, 35°C ambient temperature, and less than

5 psi, 0.35 kgf / cm2 pressure drop.

7

Page 8

SPECIFICATIONS - Models 100 and 125

Description

100 125

Model

Operating Conditions

Rated Capacity

@125 psig, 8.8 kgf/cm

2

scfm

3

m

*

/min

60 Hz

60 Hz

Maximum Working Pressure 250 psig (17.6 kgf/cm

100

2.83

125

3.54

2

)

Maximum Inlet Temperature 180°F (82°C)

Min/Max. Ambient Temperature 40-110°F (4-43°C)

Pressure Drop @

rated capacity

psi

(kgf/cm

60 Hz

2

)

60 Hz

3.5

(0.25)

4.6

(0.32)

Refrigeration System Data

Compressor Type Hermetic, Scroll, Permanent Split Capacitor

BTU/HR - Refrigeration Only

@ ARI (60 Hz) Conditions

60 Hz 22500

Outlet Air Temperature

(nominal @ rated conditions)

155°F (68°C)

Refrigerant Type R-407C

Refrigerant Charge oz (grams)

60 Hz

Suction Pressure Setting 67 psig (4.7 kgf/cm

Factory Test (design) Pressure

high side/low side

Condenser Fan Switch Setting (in-out) 240-180 psig (16.9-12.7 kgf/cm

Air Flow Across Condenser cfm

m

3

/min

60 Hz

60 Hz

See Dryer Serial Tag

2

)

2

330/178 psig (23.2/12.5 kgf/cm

)

2

)

830

(23.5)

Electrical Data

Unit

VAC/phase/Hz

230/1/60

230/1/60

Minimum/maximum volts 207 - 253

Full Load Amps (FLA) 15.75

Branch Circuit Fuse Size (amps) 20

Compressor

Volts/phase/Hz

230/1/60

Rated Load amps (RLA) 14.9

Locked Rotor amps (LRA) 68.0

Watts (input) 2280

Overload (Internal) Thermal and Current (Auto Reset)

Condenser fan motor

Volts/phase/Watts (output)

230/1/60

Full Load Amps (FLA) 0.85

* Capacity @ 180°F, 82°C inlet temperature, 160°F, 71°C inlet pressure dew point, 95°F, 35°C

ambient temperature, and less than 5 psi, 0.35 kgf / cm2 pressure drop.

8

Page 9

ELECTRICAL SCHEMATICS

LINE

G

LINE

L2 L1

Models 20, 25, and 35

SW

2

1

G

4

2

3

3

3

3 1

14

OLT

HTS

FPS

WIRING SCHEMATIC

C S

5

M

LT

7

A

8

FM

RC

6

R

4

REFRIGERANT

COMPRESSOR

4

4

HIGH

TEMPERATURE

4

CONDENSER

FAN MOTOR

Models 50 and 75

LEGEND

Models 100 and 125

SW - On/Off Switch

OLT - Thermal Overload

3

SW

L2

L1

G

TB

3

3

4

4

FPS

8

LT

HTS

7

3

FM

4

A

4

C

3

5

4

4

10

S

2

PR

11

1

12R9

RC

SC

C

S

M

R

M - Compressor Motor

RC - Run Capacitor

HTS - High Temperature Switch

LT - Fault Light

FPS - Fan Pressure Switch

FM - Fan Motor

TB - Terminal Block

CT - Contactor w/115V Coil

SC - Start Capacitor

PR - Potential Relay

Models 20, 25, 35, 100, and 125

Front of Dryer

Right Side of Dryer

(Outside)

SW

LT

FPS

COMPONENT LOCATIONS COMPONENT LOCATIONS

(Inside)

FM

HTS

OLT

M

TB

SC, PR

(CRH 100/125 Only)

RC

Models 50 and 75

Front of Dryer

(Outside)

SW

LT

Right Side of Dryer

(Inside)

FM

HTS

OLT

M

RC

FPS

CT

9

Page 10

DIMENSIONS AND WEIGHTS

Models 20, 25, 35

Model Weight

20 79 lbs (36 kg)

25 80 lbs (36 kg)

35 81 lbs (37 kg)

28.1/4"

(718 mm)

1.9/16"

(40 mm)

12.1/2"

(317 mm)

DRAIN CONNECTION

CONEXION DEL DREN

VIDANGE AUTOMATIQUE

1" (25 mm)

4.1/8"

(105 mm)

1/4" NPT(F)

DRAIN CONNECTION

3/16"

(5 mm)

LEFT SIDE VIEW FRONT VIEW

5.1/16"

(128 mm)

10.1/8"

(257 mm)

8.9/16"

(217 mm)

FAULT

INDICATOR

INDICADOR

DE FALLA

INDICATEUR

DE BRIS

1/4"

(6 mm)

AIR FLOW

FAU LT

INDICATOR

LIGHT

ON/OFF SWITCH

13/16"

(21 mm)

(TYP)

POWER CORD

REPLACEABLE AMBIENT

AIR FILTER

12.7/8"

(327 mm)

11.5/16"

(287 mm)

4.1/8”

(105 mm)

1.1/2”

(38 mm)

AIR INLET

1/2" NPT(F)

8.1/2"

(216 mm)

1.11/16"

(41 mm)

5.1/8"

(130 mm)

BACK VIEWRIGHT SIDE VIEW

10.1/8"

(257 mm)

AIR OUTLET

1/2" NPT(F)

6.5/8"

(168 mm)

SERIAL

NUMBER

TAG

10

Page 11

DIMENSIONS AND WEIGHTS

Models 50 and 75

Model Weight

50 150 lbs (68 kg)

75 155 lbs (70 kg)

36.3/4"

(933 mm)

1.1/2"

(38 mm)

4.5/8"

(117 mm)

DRAIN CONNECTION

CONEXION DEL DREN

VIDANGE AUTOMATIQUE

1/4" NPT(F)

DRAIN CONNECTION

1"

(25 mm)

16.1/2"

(419 mm)

3/16"

(5 mm)

8.7/16"

(213 mm)

16.7/8"

(425 mm)

15.1/4" (TYP)

(387 mm)

FRONT VIEWLEFT SIDE VIEW

1/4"

(6 mm)

AIR FLOW

FAULT INDICATOR

LIGHT

ON/OFF SWITCH

13/16" (TYP)

(21 mm)

16.7/8"

(429 mm)

5'-20 AMP POWER CORD

REPLACEABLE AMBIENT

AIR FILTER

1.9/16"

(39 mm)

5.1/16"

(129 mm)

SERIAL NUMBER

TAG

AIR OUTLET

3/4" NPT(F)

AIR INLET

3/4" NPT(F)

9.1/8"

(232 mm)

6.5/16"

(160 mm)

2.15/16"

(59 mm)

6.7/8"

175 mm)

BACK VIEWRIGHT SIDE VIEW

11

Page 12

DIMENSIONS AND WEIGHTS

Models 100 and 125

Model Weight

100 191 lbs (86.6 kg)

125 192 lbs (87.1 kg)

45.3/4"

(1162 mm)

1.9/16"

(39 mm)

5.3/4"

(146 mm)

LEFT SIDE VIEW

DRAIN CONNECTION

CONEXION DEL DREN

VIDANGE AUTOMATIQUE

1/4" NPT (F)

DRAIN CONNECTION

1"

(26 mm)

17.5/16"

(440 mm)

1/8"

(4 mm)

8.7/16"

(214 mm)

15.1/4" ( T YP. )

(388 mm)

FRONT VIEW

16.7/8"

(429 mm)

FAULT

INDICATOR

INDICADOR

DE FALLA

DE BRIS

1/4"

(6 mm)

AIR FLOW

FAULT INDICATOR

LIGHT

ON/OFF SWITCH

13/16"

(21 mm)

REPLACEABLE AMBIENT

16.7/8"

(429 mm)

AIR FILTER

SERIAL NUMBER

AIR OUTLET

1" NPT (F)

AIR INLET

1" NPT (F)

10.7/8"

(276 mm)

8.1/8"

(206 mm)

5'-20 AMP POWER CORD

5.1/16"

(129 mm)

(38 mm)

1.1/2"

2.3/4"

(70 mm)

7.5/16"

(186 mm)

RIGHT SIDE VIEW BACK VIEW

12

Page 13

PARTS LIST

PARTS DESCRIPTION 20 25 35 50 75

Separator

*Separator/Filter Cartridge

Filter Sleeve C35BEL C35BEL C35BEL C60BEL C100BEL

*Drain Mechanism C3152270 C3152270 C3152270 C3152270 C3152270

Bowl C3240333 C3240333 C3240333 C3223457 C3241108

*O-ring Bowl C3154585 C3154585 C3154585 C3162913 C3162913

Inlet (Compressed Air) Strainer

Strainer, inlet

*Screen, Strainer C3230672 C3230672 C3230672 C3230673 C3230673

Electrical

Switch On/Off

Light, Fault (amber)

Light, Fault (amber)

Cord Set

Cord Set

Capacitor, Run

Capacitor, Run

Switch, fault light w/conn. C3240331 C3240331 C3240331 C3240597 C3240597

115/1/60

220-240/1/50

115/1/60

220-240/1/50

115/1/60

220-240/1/50

Condenser Fan

Fan Motor

Fan Motor

Fan Blade

Fan Blade

115/1/60

220-240/1/50

115/1/60

220-240/1/50

Refrigeration System

Compressor

Compressor

Condenser C3221323 C3221323 C3221323 C3221324 C3221324

Hot Gas By-Pass Valve C3232549 C3232549 C3232549 C3232526 C3232526

Filter/Dryer C3223809 C3223809 C3223809 C3223809 C3223809

Fan Pressure Switch C3230755 C3230755 C3230755 C3230756 C3230756

115/1/60

220-240/1/50

Cabinet

*Filter, Ambient Air

Grommet (light & switch, front panel) C3224016 C3224016 C3224016 C3224016 C3224016

Foot, mounting C3223838 C3223838 C3223838 C3223838 C3223838

* Maintenance kits for the above models are available "*" indicates items included in the kits.

C35BE C35BE C35BE C60BE C100BE

C4009634 C4009634 C4009634 C4009635 C4009635

C3230775 C3230775 C3230775 C3230775 C3230775

C3227423 C3227423 C3227423 C3227423 C3227423

C3227424 C3227424 C3227424 C3227424 C3227424

C3221571 C3221571 C3221571 C3221572 C3221572

C3221422 C3221422 C3221422 C3221422 C3221422

C3220878 C3220878 C3220878 C3220878 C3220878

C3220872 C3220872 C3220872 C3220878 C3220878

C3228001 C3228001 C3228001 C3227992 C3227992

C3228002 C3228002 C3228002 C3227986 C3227986

C3219394 C3219394 C3219394 C3219395 C3219395

C3219394 C3219394 C3219394 C3219399 C3219399

C3221265 C3221265 C3221265 C3221267 C3221267

C3221266 C3221266 C3221266 C3221268 C3221268

C3223805 C3223805 C3223805 C3223806 C3223806

Maintenance Kits

For Dryer Models Kit Number

20, 25, 35 CRHMK4

50 CRHMK6

75 CRHMK5

13

Page 14

PARTS LIST

PARTS DESCRIPTION 100 125

Separator

*Separator/Filter Cartridge

Filter Sleeve C100BEL C100BEL

*Drain Mechanism C3152270 C3152270

Bowl C3241108 C3241108

*O-ring Bowl C3162913 C3162913

Strainer, inlet C4009636 C4009636

*Screen, Strainer C3230662 C3230662

Electrical

Switch On/Off

Light, Fault 230v C3227424 C3227424

Cord Set C3221573 C3221573

Capacitor, Run

Capacitor, Start

Relay, Potential

Switch, Fault Light w/conn. C3240597 C3240597

230/1/60

230/1/60

230/1/60

Condenser Fan

Fan Motor C3227986 C3227986

Fan Blade C3219404 C3219404

Refrigeration System

Compressor

Condenser C3221325 C3221325

Hot Gas By-Pass Valve C3232526 C3232526

Filter/Dryer C3223814 C3223814

Fan Pressure Switch C3230756 C3230756

230/1/60

Cabinet

*Filter, Ambient Air

Grommet (light & switch, front panel) C3224016 C3224016

Foot, mounting C3223838 C3223838

* Maintenance kits for the above models are available "*" indicates

items included in the kits.

C100BE C100BE

C3230775 C3230775

C7439986 C7439986

C7439985 C7439985

C7439984 C7439984

C7426401 C7426401

C3223807 C3223807

Maintenance Kits

For Dryer Models Kit Number

100 CRHMK3

125 CRHMK3

14

Page 15

NOTES

15

Page 16

WARRANTY

The manufacturer warrants the product it manufactures, when properly installed, operated, applied, and maintained in accordance with

procedures and recommendations outlined in manufacturer’s instruction manuals, will be free from defects in material or workmanship

for a period as specified below, provided such defect is discovered and brought to the manufacturer’s attention within the aforesaid

warranty period.

The manufacturer will repair or replace any product or part determined to be defective by the manufacturer within the warranty period,

provided such defect occurred in normal service and not as a result of misuse, abuse, neglect or accident. Normal maintenance items

requiring routine replacement are not warranted. The warranty covers parts and labor for the warranty period unless otherwise specified.

Repair or replacement shall be made at the factory or the installation site, at the sole discretion of the manufacturer. Although not required

for warranty consideration, it is recommended that the manufacture be contacted prior to doing any warranty related service work. This

action will provide guidance and instruction on the repair often times authorization to perform the work. NOTE: The manufacture reserves

the right to repair, replace in the case of warranty approval or reject the warranty claim once submitted.

Unauthorized service and use of unauthorized or pirated parts voids the warranty and any resulting charges or subsequent claim will

not be paid. Products repaired or replaced under warranty shall be warranted for the unexpired portion of the warranty applying to the

original product.

The foregoing is the exclusive remedy of any buyer of the manufacturer’s product. The maximum damages liability of the manufacturer

is the original purchase price of the product or part.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR STATUTORY, AND IS EXPRESSLY

IN LIEU OF THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

THE MANUFACTURER SHALL NOT BE LIABLE FOR LOSS OR DAMAGE BY REASON OF STRICT LIABILITY IN TORT OR ITS NEGLIGENCE IN WHATEVER

MANNER INCLUDING DESIGN, MANUFACTURE OR INSPECTION OF THE EQUIPMENT OR ITS FAILURE TO DISCOVER, REPORT, REPAIR, OR MODIFY

LATENT DEFECTS INHERENT THEREIN. THE MANUFACTURER, HIS REPRESENTATIVE OR DISTRIBUTOR SHALL NOT BE LIABLE FOR LOSS OF USE OF

THE PRODUCT OR OTHER INCIDENTAL OR CONSEQUENTIAL COSTS, EXPENSES, OR DAMAGES INCURRED BY THE BUYER, WHETHER ARISING FROM

BREACH OF WARRANTY, NEGLIGENCE OR STRICT LIABILITY IN TORT.

Please note that the manufacturer’s warranty for this product is intended to cover manufacturing defects and therefore does not cover

consumable components (desiccants, filter elements, soft goods, standard maintenance kit wear items, etc.) or components that require

periodic user adjustment (expansion valve, hot gas bypass valve or cooling water regulating valve) or calibration (dew point elements/

sensors, gauge calibration, etc.)

Warranty Period

Parts and labor for two (2) years from the date of shipment from the factory.

An extended warranty of up to 5 years from the date of purchase may be available for your dryer. Please contact your local distributor for

more details of the requirements for activation of warranty extension

.

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY BEFORE MATERIAL IS

RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

For Service: (724) 746-1100

Or visit Sales and Service at www.championpneumatic.com

Loading...

Loading...