Champion CPG2500, CPG2500EU, CPG3500EU, CPG3500, CPG4000 E1-EU Owner's Manual & Operating Instructions

...Page 1

This manual covers the following models:

CPG2500 (EU) / CPG3500 (EU) / CPG4000 E1 (EU)

CPG6500 E2 (EU) / CPG 9000 E2 (EU)

OWNER’S MANUAL & OPERATING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Important Safety Instructions

are included in this manual.

PORTABLE GENERATOR

Frame Type

T

h

r

e

e

Y

e

a

r

L

i

m

i

t

e

d

W

a

r

r

a

n

t

y

G

a

r

a

n

t

í

a

l

i

m

i

t

a

d

a

d

e

t

r

e

s

a

ñ

o

s

T

h

r

e

e

Y

e

a

r

L

i

m

i

t

e

d

W

a

r

r

a

n

t

y

G

a

r

a

n

t

í

a

l

i

m

i

t

a

d

a

d

e

t

r

e

s

a

ñ

o

s

Page 2

1

2

MANUAL CONVENTIONSINTRODUCTION

Please familiarize yourself with the following symbols. The safety symbol and key words are safety warnings. Follow all

safety messages to avoid accidents or injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in m inor

or moderate injury.

CAUTION

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, may result in property damage.

CAUTION

DANGER indicates an imminently hazardo us

situation which, if not avoided, will result in death

or serious injury.

DANGER

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

WARNING

If you have questions regarding your generator, we can

help. Please contact yor local dealer.

NOTE

Record the model and serial numbers as well as date and place of purchase for future reference. Have this

information available when ordering parts and when making technical or warranty inquiries.

Champion Power Equipment Support

Model Number

Serial Number

Date of Purchase

Purchase Location

For Oi l Type see ‘Add Engine Oil‘ section. For Fue l Type see ‘Add Fuel‘ section.

Introduction

Congratulations on purchasing your generator. Please

and maintain correctly.

Portable Power Generator

This unit is a petrol engine driven AC generator used for

supply electrical pow er.

Accessories

CPE manufactures and supplies a serie s of accesso ries.

See local dealer for more information.

This Booklet

We reserve the right to change, alter or improve the

product and this manual without prior notice.

Page 3

3

4

SAFETY RULES SAFETY RULES

Improper treatment or use of the generator can

damage it, shorten its life and void your warranty.

Use the generator only for intended uses.

Operate only on level surfaces.

DO NOT expose generator to excessive moisture,

dust, or dirt.

DO NOT allow any material to block the cooling slots.

If connected devices overheat, turn them off and

disconnect them from the generator.

DO NOT use the generator if:

– Electrical output is lost

– Equipment sparks, smokes or emits flames

– Equipment v ibrate s exces sively

CAUTION

Rapid retraction of the starter cord will pull hand and

arm towards the engine faster than you can let go.

Unintentional startup can result in serious injury.

Broken bones, fractures, bruises or sprains could result.

When starting engine, pull the starter cord slowly

until resistance is felt and then pull rapidly to avoid

kickback.

DO NOT start or stop the engine with electrical

device s plugg ed in.

WARNING

Exceeding the generator’s running capacity can

damage the generator and/or electrical devices

connected to it.

DO NOT overload the generator.

Start the generator and allow the engine to stabilize

before connecting electrical loads.

Connect electrical equipment in the off position,

and then turn them on for operation.

Turn electrical equipment off before stopping the

generator.

DO NOT tamper with the governed speed.

DO NOT modify the generator in any way.

CAUTION

Generator exhaust contains carbon monoxide, a

colorless, odorless, poison gas. Breathing carbon

monoxide will cause nausea, dizziness, fainting or

death. If you start to feel dizzy or weak, get to fresh

air immediately.

Operate generator outdoors only in a well ventilated

area.

DO NOT operate the generator inside any building,

including garages, basements, crawlspaces and

sheds, enclosure or compartment, including the

generator compartment of a recreational vehicle.

DO NOT allow exhaust fumes to enter a confined

area through windows, doors, vents or other

opening s.

DANGER CARBON MONOXIDE: using a generator

indoor s CAN KILL YOU IN MINUTES.

DANGER

Rotating parts can entangle hands, feet, hair,

clothing and/or accessories.

Traumatic amputation or severe laceration can result.

Keep hands and feet away from rotating parts.

Tie up long hair and remove jewelry.

Operate equipment with guards in place.

DO NOT wear loose-fitting clothing, dangling

drawstrings or items that could become caught.

DANGER

Generator produces powerful voltage.

DO NOT touch bare wires or receptacles.

DO NOT use electrical cords that are worn, damaged

or frayed.

DO NOT operate generator in wet weather.

DO NOT allow children or unqualified persons to

operate or service the generator

Use a ground fault circuit interrupter (GFCI) in damp

areas and areas containing conductive material such

as metal decking.

Use approved transfer equipment to isolate generator

from your electric utility and Notify your utility

company before connecting your generator to your

power system.

DANGER

Sparks can result in fire or electrical shock.

When servicing the gener ator:

Disconnect the spark plug wire and place it where it

cannot contact the plug.

DO NOT check for spark with the plug removed.

Use only approved spark plug testers.

WARNING

Running engines produce heat. Severe burns can

occur on contact.

Combustible material can catch fire on contact.

DO NOT touch hot surfaces.

Avoid contact with hot exhaust gases.

Allow equipment to cool before touching.

Maintain at least 3 ft. (91.4 cm) of clearance on all

sides to ensure adequate cooling.

Maintain at least 5 ft. (1.5 m) of clearance from

combustible materials.

WARNING

Medical and Life Support Uses.

In an emergency, call emergency services immediately.

NEVER use this product to power life support

devices or life support appliances.

NEVER use this product to power medical devices

or medical appliances.

Inform your electricity provider immediately if you

or anyone in your household depends on electrical

equipment to live.

Inform your electrical provider immediately if a

loss of power would cause you or anyone in your

household to experience a medical emergency.

WARNING

The engine exhaust from this product contains

chemicals that are known to cause serious health

problems and even death.

WARNING

Read this manual thoroughly before operating your

generator. Failure to follow instructions could result

in serious injury or death.

WARNING

Operation of this equipment may create sparks that

can start fires around dry vegetation.

A spark arrestor may be required. The operator

should contact local fire agencies for laws or

regulations relating to fire prevention requirements.

WARNING

Fuel and fuel vapors are highly flammable and

extremely ex plosive.

Fire or explosion can cause severe burns or death.

Unintentional startup can result in entanglement,

traumatic amputation or laceration.

When adding or removing fuel:

Turn the generator off and let it cool for at least two

minutes before removing the fuel cap. Loosen the

cap slowly to relieve pressure in the tank.

Only fill or drain fuel outdoors in a well-ventilated area.

DO NOT pump gas directly into the generator at the

gas station. Use an approved container to transfer

the fuel to the generator.

DO NOT overfill the fuel tank.

Always keep fuel away from sparks, open flames,

pilot lights, heat and other sources of ignition.

DO NOT light or smoke cigarettes.

When starting the generator:

DO NOT attempt to start a damaged generator.

Make certain that the gas cap, air filter, spark plug,

fuel lines and exhaust system are properly in place.

Allow spilled fuel to evaporate fully before

attempting to start the engine.

Make certain that the generator is resting firmly on

level ground.

When operating the genera tor:

DO NOT move or tip the generator during operation.

DO NOT tip the generator or allow fuel or oil to spill.

When transporting or servicing the generator:

Make certain that the fuel shutoff valve is in the off

position and the fuel tank is empty.

Disconnect the spark plug wire.

When storing the genera tor:

Store away from sparks, open flames, pilot lights,

heat and other sources of ignition.

DANGER

Page 4

5

6

ASSEMBLY

Your generator requires some assembly. This unit ships

from our factory without oil. It must be properly serviced

with fuel and oil before operation.

If you have any questions regarding the assembly of your

generator, contact yor local dealer. Please have your serial

number and model number available.

Remove the Generator from the Shipping Car ton

1. Set the shipping carton on a solid, flat surface.

2. Remove everything from the carton except the

generator.

3. Carefully cut each corner of the box from top to

bottom. Fold each side flat on the ground to provide a

surface area to install the wheel kit and support leg.

Install the Wheel Kit (Optional Extra)

You will need the following tools to install the wheels:

• 17 mm wrench OR adjustable wrench (not included)

• Socket wrench with a 16 mm socket (not included)

• Plier s (not includ ed)

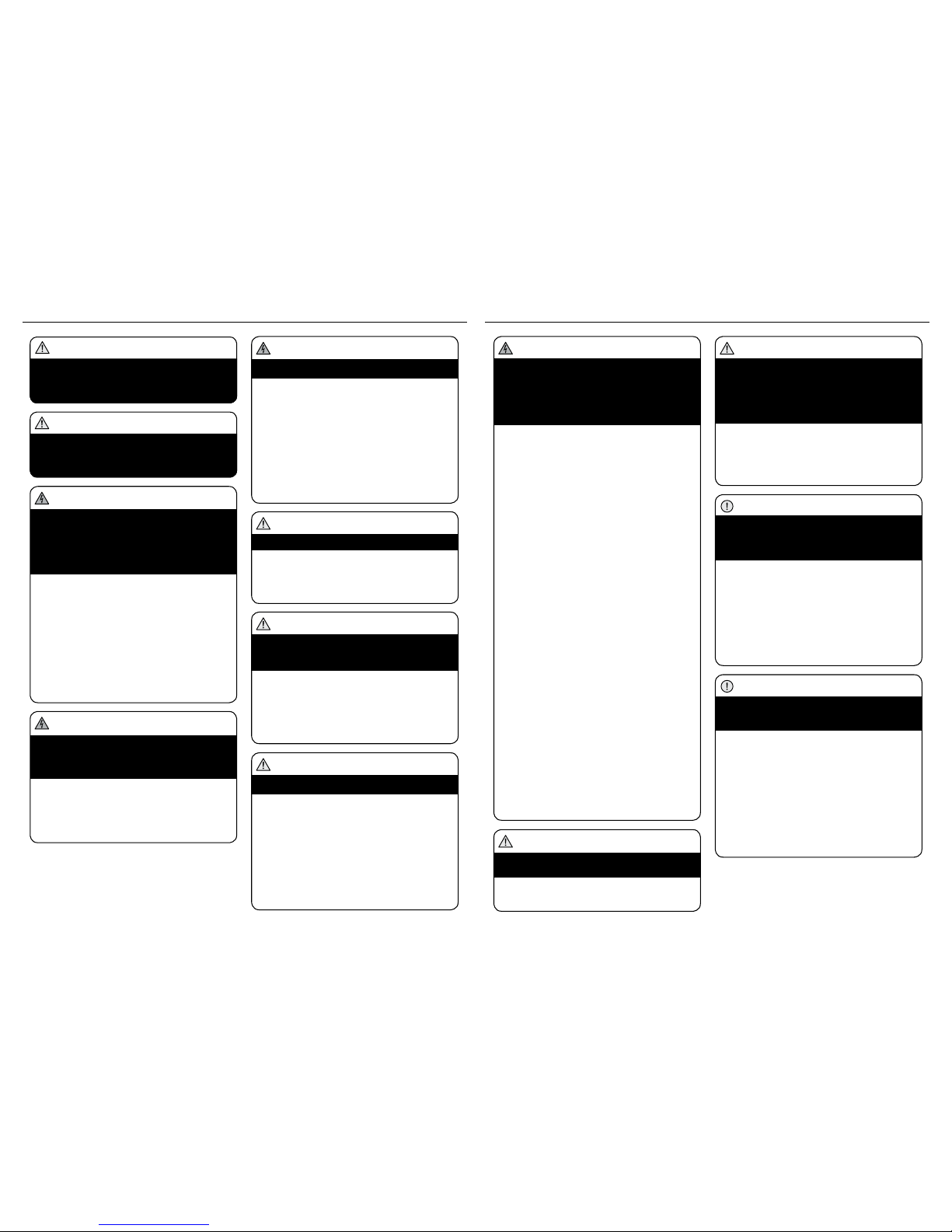

1. Before adding fuel and oil, tip the generator on it’s side.

2. Slide the M10x120 flange bolt through the washer,

sleeve and wheel.

3. Slide the bolt through the mount point on the frame.

4. Fasten securely with the M10 lock nut.

5. Repeat steps 2-4 to attach the second wheel.

Install the Support Leg

1. Attach the vibration mounts to the support leg with

a flange bolt M8 x 25 and flange lock nuts.

2. Attach the support leg to the generator frame with

flange bolts M8 x 16 and flange lock nuts and

fasten securely. DO NOT over tighten the lock nuts.

3. Tip the generator slowly so that it rests on the

wheels and support leg.

The wheel kit is not intended for over-the-road use.

CAUTION

Connect the Batter y (Electric Start Models

only)

1. Remove the protective cover from the red (+) lead on

the bat ter y.

2. Attach the red (+) lead to the red (+) terminal on the

battery with the cap screw (M5x10) and secure with

the lock washer (M5).

3. Repeat steps 1-2 for the black (–) battery lead.

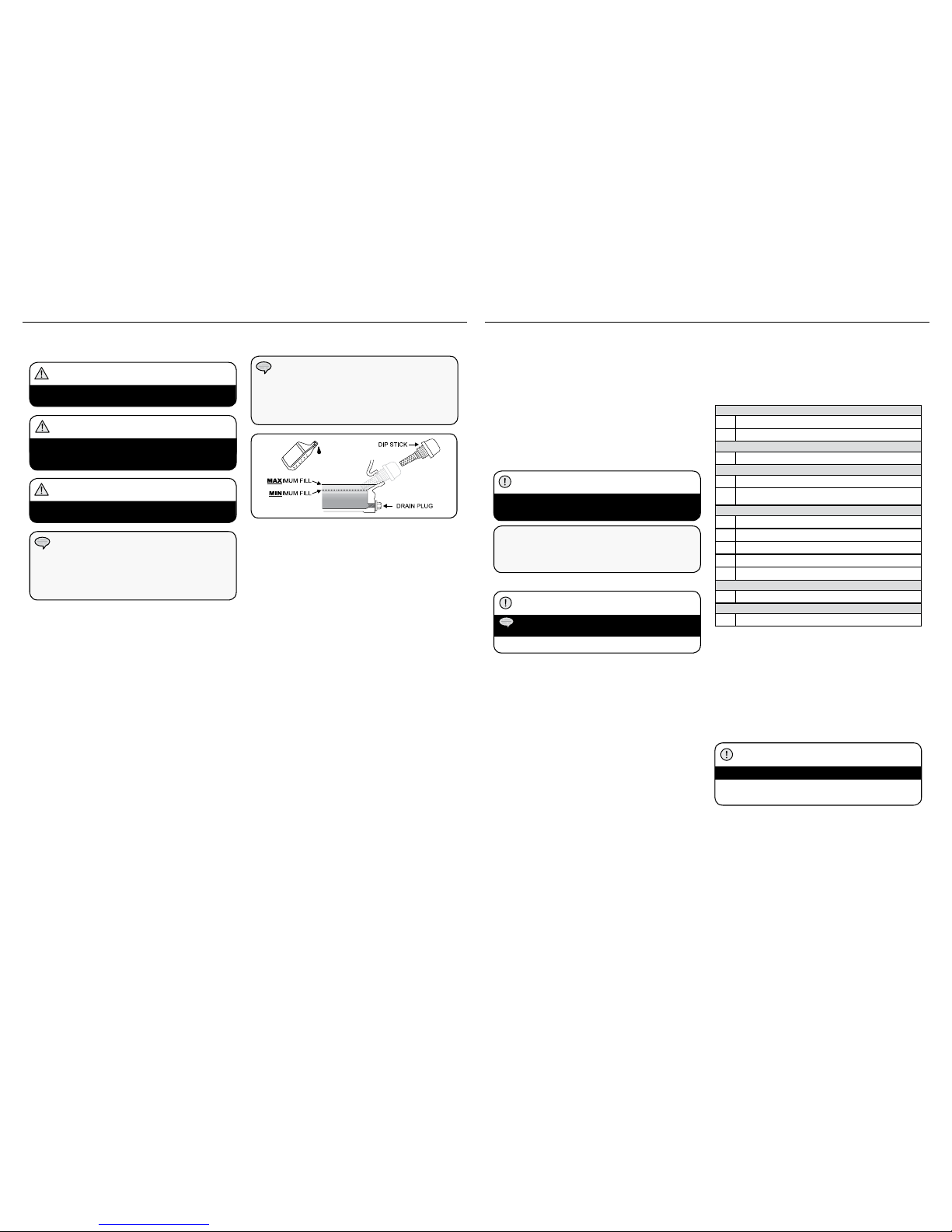

1. Place the generator on a flat, level surface.

2. Remove oil fill cap/dipstick to add oil.

3. Add oil and replace oil fill cap/dipstick. DO NOT

OVERFILL .

4. Check engine oil level daily and add as needed.

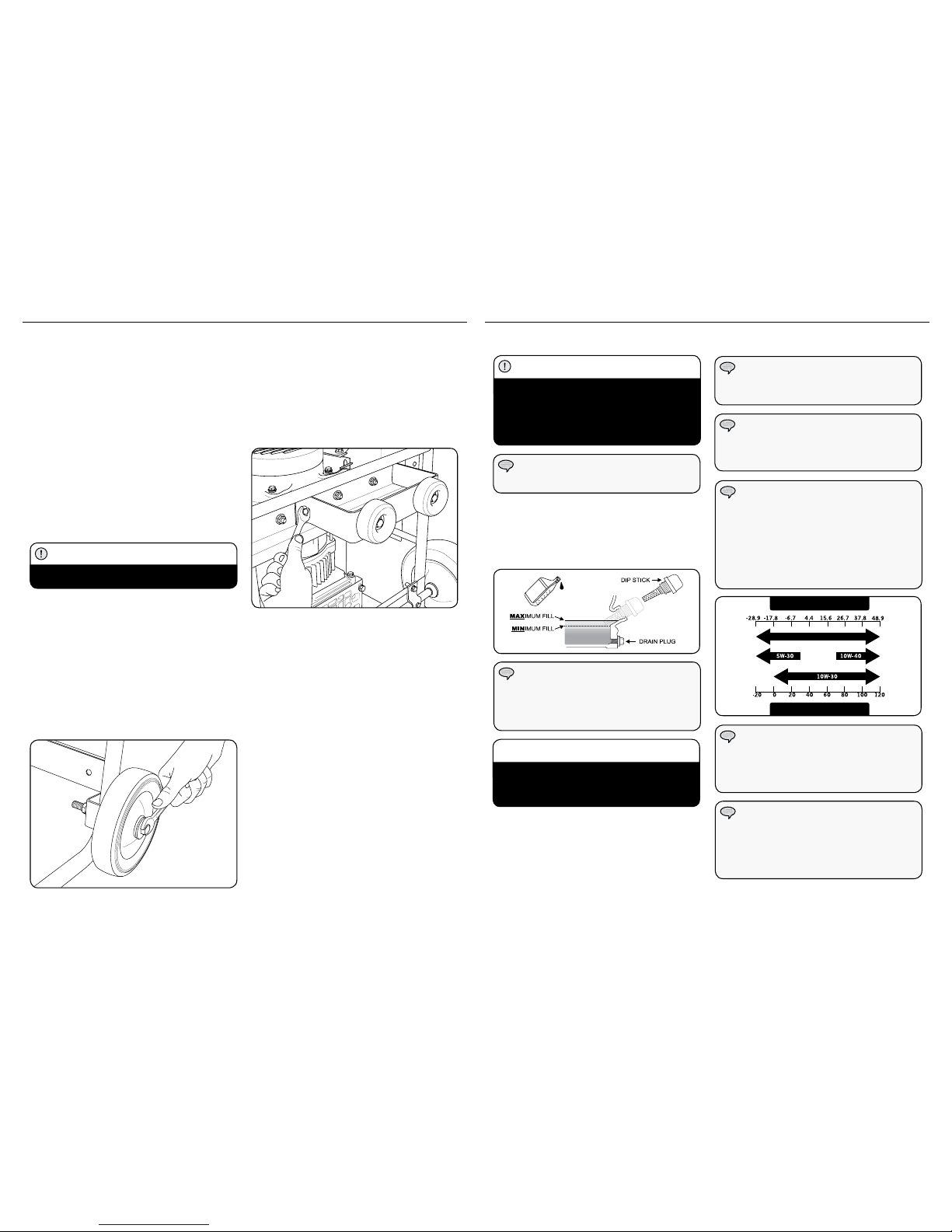

The recommended oil type is 10W-30 automotive oil.

NOTE

The engine is equipped with a low oil shut-off and

will stop when the oil level in the crankcase falls

below the threshold level.

CAUTION

Add Engine Oil

DO NOT attempt to crank or start the engine before

it has been properly filled with the recommended

type and amount of oil. Damage to the generator as

a result of failure to follow these instructions will

void your warranty.

CAUTION

ASSEMBLY

Check oil often during the break-in period. Refer to the

Maintenance section for rec ommended servic e intervals.

NOTE

The generator rotor has a sealed, pre-lubricated ball

bearing that requires no additional lubrication for

the life of the bearing.

NOTE

Add Engine Oil Cont’d.

Synthetic oil may be used after the 5 hour initial

break-in period. Using synthetic oil does not

increase the recommended oil change interval.

Full synthetic 5W-30 oil will aid in starting in cold

ambient <5ºC (41ºF)

NOTE

We consider the first 5 hours of run time to be

the break-in period for the unit. During the break

in period stay at or below 50% of the running

watt rating and vary the load occasionally to allow

stator windings to heat and cool. Adjusting the

load will also cause engine speed to vary and help

seat piston rings. After the 5 hour break-in period,

change the oil.

NOTE

Weather will affect engine oil and engine

performance. Change the type of engine oil used

based on weather conditions to suit the engine

needs.

NOTE

Once oil has been added, a visual check should show

oil about 1-2 threads from running out of the fill hole.

If using the dipstick to check oil level, DO NOT screw

in the dipstick while checking.

NOTE

Full Synthetic 5W-30

Degrees Celsiusº

(Outside)

(Outside)

Degrees Fahrenheitº

Page 5

7

8

ASSEMBLY

Add Fuel Cont’d.

Grounding

Your generator must be properly connected to an

appropriate ground to help prevent electric shock.

A ground terminal connected to the frame of the generator

has been provided on the power panel. For remote

grounding, connect of a length of heavy gauge

(12 AWG minimum) copper wire between the generator

ground terminal and a copper rod driven into the ground.

We strongly recommend that you consult with a qualified

electrician to ensure compliance with local electrical codes.

Failure to properly ground the generator can result

in electric shock.

WARNING

Our engines work well with 10% or less ethanol

blend fuels. When using blended fuels there are

some issues worth noting:

– Ethanol-gasoline blends can absorb more water

than gasoline alone.

– These blends can eventually separate, leaving

water or a watery goo in the tank, fuel valve and

ca rbu re to r.

– With gravity-fed fuel supplies, this compromised

fuel can be drawn into the carburetor and cause

damage to the engine and/or potential hazards.

– There are only a few suppliers of fuel stabilizer

that are formulated to work with ethanol blend

fuels.

– Any damages or hazards caused by using

improper fuel, improperly stored fuel, and/

or improperly formulated stabilizers, are not

covered by manufacture’s warrant y.

It is advisable to always shut off the fuel supply,

run the engine to fuel starvation and drain the tank

when the equipment is not in use for more than 30

days.

NOTE

Add Fuel

1. Use clean, fresh, regular unleaded fuel with a

minimum octane rating of 85 and an ethanol content

of less than 10% by volume.

2. DO NOT mix oil with fuel.

3. Clean the area around the fuel cap.

4. Remove the fuel cap.

5. Slowly add fuel to the tank. DO NOT OVERFILL. Fuel

can expand after filling. A minimum of

¼ in. (6.4 mm) of space left in the tank is required

for fuel expansion, more than ¼ in. (6.4 mm) is

recommended. Fuel can be forced out of the tank as

a result of expansion if it is overfilled, and can affect

the stable running condition of the product. When

filling the tank, it is recommended to leave enough

space for the fuel to expand.

6. Screw on the fuel cap and wipe away any spilled fuel.

Use regular unleaded gasoline with a minimum

octane rating of 85.

Do not mix oil and gasoline.

Fill tank to approximately ¼ in. (6.4 mm) below the

top of the tank to allow for fuel expansion.

DO NOT pump gas directly into the generator at the

gas station. Use an approved container to transfer

the fuel to the generator.

DO NOT fill fuel tank indoors.

DO NOT fill fuel tank when the engine is running or hot.

DO NOT overfill the fuel tank.

DO NOT light cigarettes or smoke when filling the

fuel tank.

CAUTION

Pouring fuel too fast through the fuel screen may

result in blow back of fuel at the operator while filling.

WARNING

OPERATION

Generator Location

Never operate the generator inside any building! (See

safety warnings section). In some areas generators must

be registered with the local utility company. Generators

used on construction sites may be subject to local

rules and regulations. Keep on a flat, level surface.

Generators must have at least 5 ft (1.5m) clearance

from all combustible material. In addition they must

have at least 3 ft (91.4cm) of clearance on all sides to

allow for adequate cooling, maintenance and servicing.

Generators should never be started or operated in ant

location that will not allow for adequate cooling of

the generator and/or the muffler. Allow generators to

cool before storage or transportation. Do not place the

generator near any vents or intakes. Carefully consider

wind and air currents when placing generator.

Failure to follow proper safety precautions may void

manufacturer’s warranty.

Do not operate or store the generator in rain, snow,

or wet weather.

Using a generator or electrical appliance in wet

conditions, such as rain or snow, or near a pool or

sprinkler system, or when your hands are wet, could

result in electrocution.

WARNING

WARNING

During operation the muffler and exhaust fumes

produced will become hot. If adequate cooling and

breathing space are not supplied, or if the generator

is blocked or contained, temperatures can become

extremely heated and may lead to fire.

Surge Protection

Electronic devices, including computers and many

programmable appliances use components that are

designed to operate within a narrow voltage range and

may be affected by momentary voltage fluctuations.

While there is no way to prevent voltage fluctuations, you

can take steps to protect sensitive electronic equipment.

1. Install UL1449, CSA-listed, plug-in surge suppressors

on the outlets feeding your sensitive equipment.

Surge suppressors come in single- or multi-outlet

styles. They’re designed to protect against virtually

all short-duration voltage fluctuations.

Voltage fluctuation may impair the proper

functioning of sensitive electronic equipment.

CAUTION

Starting the Engine

1. Make certain the generator is on a flat, level surface.

2. Disconnect all electrical loads from the generator.

Never start or stop the generator with electrical

devices plugged in or turned on.

3. Turn the Fuel Valve to the “ON” position.

4. Move the choke lever to the “CHOKE” position.

5. Flip the ignition switch to the “ON” position.

6. For models that have an ELECTRIC START: Press

and hold the ignition switch to the “START” position.

Release as the engine begins to roll over. If the engine

fails to start within five seconds, release the switch

and wait at least ten seconds before attempting to

start the engine again.

7. RECOIL START: Pull the starter cord slowly until

resistance is felt and then pull rapidly

8. Do not over-choke. As as soon as engine starts, move

the choke lever to the “RUN” position.

Grounding

The generator system ground connects the frame to the

ground terminals on the power panel. The system ground is

connected to the AC neutral wire.

Page 6

9

10

Connecting Electrical Loads

1. Let the engine stabilize and warm up for a few

minutes after starting

2. Plug in and turn on the desired 120/240 Volt AC

single phase, 50 Hz electrical loads.

– DO NOT connect 3-phase loads to the generator.

– DO NOT connect 60 Hz loads to the generator.

– DO NOT overload the generator.

Connecting a generator to your electric utility company’s

power lines or to another power source may be against

the law. In addition this action, if done incorrectly, could

damage your generator and appliances and could cause

serious injury or even death to you or a utility worker

who may be working on nearby power lines. If you plan

to run a portable electric generator during an outage,

please notify your electric utility company immediately

and remember to plug your appliances directly into the

generator. Do not plug the generator into any electric

outlet in your home. Doing so could create a connection

to the utility company power lines. You are responsible

for ensuring that your generator’s electricity does not

feed back into the electric utility power lines.

If the generator will be connected to a building electrical

system, consult your local utility company or a qualified

electrician. Connections must isolate generator power

from utility power and must comply with all applicable

laws and codes.

NOTE

OPERATION

Stopping the Engine

1. Turn off and unplug all electrical loads. Never start

or stop the generator with electrical devices plugged

in or turned on.

2. Let the generator run at no-load for several minutes

to stabilize internal temperatures of the engine and

generator.

3. Turn the Fuel Valve to the “OFF” position.

4. Let the engine run until fuel starvation has stopped

the engine. This usually takes a few minutes.

5. Press the Ignition Switch to the “OFF” position.

Important: Always ensure that the Fuel Valve and the

Ignition Switch are in the “OFF” position when the

engine is not in use.

If the engine will not be used for a period of two (2) weeks

or longer, please see the Storage section for proper engine

and fuel storage.

NOTE

If the engine starts but does not run make certain

that the generator is on a flat, level surface. The

engine is equipped with a low oil sensor that will

prevent the engine from running when the oil level

falls below a critical threshold.

NOTE

Keep choke lever in “Choke” position for only 1

pull of the recoil starter. After first pull, move

choke lever to the “Run” position for up to the next

3 pulls of the recoil starter. Too much choke will

cause the engine not to start.

NOTE

When the battery switch is in the “ON” position,

the switch will light up if the battery is sending

out a charge. If the switch does not light up while

in the “ON” position, check that the battery

connection is still good.

NOTE

The supplied 12V 15AH battery does re-charge

while the engine is running, but it is also

recommended that the battery be fully charged at

least once per month.

NOTE

Starting the Engine Cont’d. Connecting Electrical Loads Cont’d.

Do Not Overload Generator

Capacity

Follow these simple steps to calculate the running and

starting watts necessary for your purposes.

1. Select the electrical devices you plan on running at

the same time.

2. Total the running watts of these items. This is

the amount of power you need to keep your items

running.

3. Identify the highest starting wattage of all devices

identified in step 1. Add this number to the number

calculated in step 2. Surge wattage is the extra

burst of power needed to start some electric driven

equipment. Following the steps listed under “Power

Management” will guarantee that only one device will

be starting at a time.

Power Management

Use the following formula to convert voltage and

amperage to w atts:

Volts x Amps = Watts

To prolong the life of your generator and attached

devices, follow these steps to add electrical load:

1. Start the generator with no electrical load attached

2. Allow the engine to run for several minutes to stabilize.

3. Plug in and turn on the first item. It is best to attach

the item with the largest load first.

4. Allow the engine to stabilize.

5. Plug in and turn on the next item.

6. Allow the engine to stabilize.

7. Repeat steps 5-6 for each additional item.

Never exceed the specified capacity when adding

loads to the generator.

NOTE

OPERATION

Operation at High Altitude

Be aware that engine efficiency can reduce and exhaust

emissions increase when working at high altitude.

Other high altitude issues can include hard starting,

increased fuel consumption and spark plug fouling.

This is a natural trend and cannot be altered by engine

adjustm ent.

Page 7

11

12

Adjustments

The air-fuel mixture is not adjustable. Tampering with

the governor can damage your generator and your

electrical devices and will void your warranty. CPE

recommends that you contact your local dealer for all

other service and/or adjustment needs.

Maintenance Schedule

Follow the service intervals indicated in the following

maintenance schedule.

Service your generator more frequently when operating

in adverse conditions.

Use a damp cloth to clean exterior surfaces of the engine.

Use a soft bristle brush to remove dirt and oil.

Use an air compressor (25 PSI) to clear dirt and debris

from the engine.

Cleaning

DO NOT spray engine with water.

CAUTION

Water can contaminate the fuel system.

Spark Arrester

1. Allow the engine to cool completely before servicing

the spark arrester.

2. Remove the screws holding the cover plate which

retains the end of the spark arrester to the muffler.

3. Remove the spark arrester screen.

4. Carefully remove the carbon deposits from the spark

arrester screen with a wire brush.

5. Replace the spark arrester if it is damaged.

6. Position the spark arrester in the muffler and attach

with the three sc rews.

Failure to clean the spark arrester will result in degraded

engine performance.

CAUTION

MAINTENANCE AND STORAGE

Federal and local laws and administrative requirements

indicate when and where spark arresters are required.

NOTE

*To be performed by knowledgeable, experienced owners or

Champion Power Equipment certified dealers.

MAINTENANCE AND STORAGE

Generator Maintenance

Make certain that the generator is kept clean and stored

properly. Only operate the unit on a flat, level surface in

a clean, dry operating environment. DO NOT expose the

unit to extreme conditions, excessive dust, dirt, moisture

or corrosive vapors.

Use a damp cloth to clean exterior surfaces of the generator.

Use a soft bristle brush to remove dirt and oil.

Use an air compressor (25 PSI) to clear dirt and debris

from the generator.

Inspect all air vents and cooling slots to ensure that they

are clean and unobstructed.

DO NOT use a garden hose to clean the generator.

Water can enter the generator through the cooling

slots and damage the generator windings.

CAUTION

Every 8 hours or daily

Check oil level

Clean around air intake and muffler

First 5 Hours

Change oil

Every 50 hours or every season

Clean air filter

Change oil if operating under heavy load or in hot

environments

Every 100 hours or every season

Change oil

Clean/Adjust spark plug

Check/Adjust valve clearance*

Clean spark arrester

Clean fuel tank and filter*

Every 250 hours

Clean combustion chamber*

Every 3 years

Replace fuel line

The owner/operator is responsible for all periodic

maintenance.

Complete all scheduled maintenance in a timely manner.

Correct any issue before operating the generator.

Never operate a damaged or defective generator.

Tampering with the factory set governor will void

your warranty.

Engine Maintenance

To prevent accidental starting, remove and ground spark

plug wire before performing any service.

Oil

Change oil when the engine is warm. Refer to the oil

specification to select the proper grade of oil for your

operating env ironment.

1. Remove the oil drain plug with a 15 mm socket and

extension (no t included ).

2. Allow the oil to drain completely.

3. Replace the d rain plug.

4. Remove oil fill cap/dipstick to add oil.

5. Add oil and replace oil fill cap/dipstick. DO NOT

OVERFILL .

6. Dispose of used oil at an approved waste

manag ement facilit y.

Air Filter

1. Remove the snap-on cover holding the air filter to

the assembly.

2. Remove the foam element.

3. Wash in liquid detergent and water. Squeeze

thoroughly dry in a clean cloth.

4. Saturate in clean engine oil.

5. Squeeze in a clean, absorbent cloth to remove all

exce ss oil.

6. Place the filter in the assembly.

7. Reattach the air filter cover and snap in place.

Spark Plugs

1. Remove the spark plug cable from the spark plug.

2. Remove the plug.

3. Inspect the electrode on the plug. It must be clean and

not worn to produce the spark required for ignition.

4. Refer to spark plug information located in the

“specification” page for this model.

5. Carefully thread the plug into the engine.

6. Use the spark plug tool (not included) to firmly install

the plug.

7. Attach the spark plug wire to the plug.

Maintenance, replacement, or repair of emission

control devices and systems may be performed

by any non-road engine repair establishment or

individual.

NOTE

WARNING

WARNING

Improper maintenance will void your warranty.

WARNING

Oil Cont’d.

Once oil has been added, a visual check should show

oil about 1-2 threads from running out of the fill hole.

If using the dipstick to check oil level, DO NOT screw

in the dipstick while checking.

NOTE

Page 8

13

14

MAINTENANCE AND STORAGE

Storage

The generator should be started at least once every 14

days and allowed to run for at least 20 minutes. For

longer term storage, please follow these guidelines.

Generator Storage

1. Add a properly formulated fuel stabilizer to the tank.

2. Be sure all appliances are disconnected from the

generator.

3. Run the generator for a few minutes so the treated

fuel cycles through the fuel system and carburetor.

4. Turn the fuel valve to the “Off” position.

5. Let the generator run until fuel starvation has

stopped the engine. This usually takes a few minutes.

6. The generator needs to cool acompletely before

cleaning a nd stor age.

7. Clean the generator according to the maintenance

section.

8. Change the oil.

9. Remove the spark plug and pour about 1⁄ 2 ounce

(14.8 mL) of oil into the cylinder. Crank the engine

slowly to distribute the oil and lubricate the cylinder.

10. Reattach the spark plug.

11. Store the unit in a clean, dry place out of direct

sunlight .

Battery

Some frame type generators are equipped with an

automatic battery charging circuit. The battery will

receive charging voltage when the engine is running. The

battery will maintain a proper charge if the unit is used

on a regular basis (about once every two weeks). If it is

used less frequently, the battery should be connected

to a trickle charger or battery maintainer to keep the

battery properly charged. If the battery is not able to

start the engine, it can be started by manually pulling

the engine recoil cord. If the battery voltage is extremely

low, the charging circuit may not be able to re-charge

the battery. In this case, the battery must be connected

to a standard automotive style battery charger for re-

charging before it can be used.

Disconnect the Battery

1. Remove the protective cover from the black/negative

battery lead.

2. Disconnect the black/negative lead from the black/

negative terminal on the battery and store the cap

screw and lock washer.

3. Repeat steps 1-2 for the red/positive battery lead.

4. Store the battery in a cool, dry place.

A Float Charger will maintain the battery condition

over long storage periods.

NOTE

Charge the Batter y

For generators equipped with batteries for electric

starting, proper battery maintenance and storage should

be followed. An automatic battery charger (not included)

with automatic trickle charging capability should be used

to charge the battery. Maximum charging rate should not

exceed 1.5 amps. Follow the instructions included with

the battery charger. The battery should be fully charged

at least once per month.

Generator exhaust contains odorless and colorless

carbon monoxide gas.

To avoid accidental or unintended ignition of your

electric start generator during periods of storage,

the following precautions should be followed:

– When storing the generator for short periods of

time make sure that the Ignition Switch and the

FuelValve are set in the OFF position.

– When storing the generator for extended periods

of time make sure that the Ignition Switch and

the Fuel Valve are set in the OFF position and

the battery leads have been disconnected from

the bat ter y.

DANGER

TROUBLESHOOTING

Problem Cause Solution

Generator will not start

No fuel Add fuel

Faulty spark plug Replace spark plug

Unit loaded during start up Remove load from unit

Generator will not start;

Generator starts but runs roughly

Low oil level

Fill crankcase to the proper level

Place generator on a flat, level surface

Choke in the wrong position. Adjust choke.

Spark plug wire loose Attach wire to spark plug

Generator will not start electrically Generator battery is dead Recharge generator battery

Generator shuts down during operation

Out of fuel Fill fuel t ank

Low oil level

Fill crankcase to the proper level. Place

generator on a flat, level surface

Generator cannot supply enough power or

overheating

Generator is overloaded

Review load and adjust. See “Power

Management”

Insufficient ventilation

Check for air restriction. Move to a well

ventilated area

No AC output

Cable not properly connected Check all connections

Connected device is defective Replace defective device

Circuit breaker is open Reset circuit breaker

Faulty brush assembly Replace brush assembly (Service Center)

Faulty AVR (auto voltage regulator) Replace AVR (Service Center)

Loose w iring Inspect and tighten wiring connections

Other Contact the help line.

Generator gallops Engine governor defective Contact the help line

Repeated circuit breaker tripping

Overload

Review load and adjust. See “Power

Management”

Faulty cords or device

Check for damaged, bare or frayed wires.

Replace defective device

Page 9

15

16

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS CPG2500 (EU) CPG3500 (EU) CPG4000 E1 (EU)

Gasoline Starting Watts 2300W 2800W 3750W

Gasoline Running Watt s 1900W 250 0W 3000W

Gasoline Starting Amps at 120V 10 .45 A 12.73A 17. 05 A

Gasoline Running Amps at 120V 8.64A 11.36 A 13.64A

Volts 220 220 220

Frequency 5 0Hz 50Hz 50Hz

Outlets 220V 16A Euro 2Pin 220V 16A Euro 2Pin 220V 16A Euro 2Pin

GFCI Outlets No No No

Covered Outlets Yes Yes Yes

Gasoline Run Time at 1/2 Load 10.0 h. 10.0 h. 10.0 h.

Noise Level 65.0 dBA 65.0 dBA 68.0 dBA

Inverter No No No

Parallel C apability No No No

DC Operation No Ye s Yes

Voltmeter No Ye s Intelligau ge

Automatic Voltage Regulation Yes Ye s Ye s

Battery No No Yes

Sta rt Typ e Recoil Recoil Recoil/Electric Star t

Engine Brand Champion Champion Champion

Engine Size 196c c 196c c 224cc

Engine Type 4-stro ke 4-stro ke 4-stro ke

Engine Speed 3000 3000 3000

Fue l Typ e Gasoline Gas oline Gasolin e

Fuel Gauge Yes Yes Yes

Gasoline Capacity 15L 15 L 15L

Gasoline Tank Material Steel Steel Steel

Engine Oil Type 10W-30 10W-30 10W-30

Engine Oil Capacity 0.6 L 0.6 L 0.6 L

Engine Oil Included No No No

Low Oil Shut-Off Yes Yes Yes

Wheels No No No

CE Certified Yes Ye s Ye s

SPECIFICATIONS CPG6500 E2 (EU) CPG9000 E2 (EU)

Gasoline Starting Watts 6250W 9375W

Gasoline Running Watt s 5000W 7500W

Gasoline Starting Amps at 120V 2 8.41A 42. 61A

Gasoline Running Amps at 120V 22.73 A 3 4.09A

Volts 220 220

Frequency 5 0Hz 50Hz

Outlets

220V 16A Euro 2Pin

220V 32A Euro 3Pin

220V 16A Euro 2Pin

220V 32A Euro 3Pin

GFCI Outlets No No

Covered Outlets Yes Yes

Gasoline Run Time at 1/2 Load 8.0 h. 8.0 h .

Noise Level 73.0 dBA 74. 0 d BA

Inverter No No

Parallel C apability No No

DC Operation Yes Yes

Voltmeter Intelligau ge Intelligau ge

Automatic Voltage Regulation Yes Yes

Battery Yes Yes

Sta rt Typ e Recoil/Electric Start Recoil/Electric Start

Engine Brand Champion Champion

Engine Size 389cc 459c c

Engine Type 4-stro ke 4-s troke

Engine Speed 3000 3000

Fue l Typ e Gasoline Ga soline

Fuel Gauge Yes Yes

Gasoline Capacity 25L 25L

Gasoline Tank Material Steel Ste el

Engine Oil Type 10W-30 10W-30

Engine Oil Capacity 1.1 L 1.1 L

Engine Oil Included No No

Low Oil Shut-Off Yes Yes

Wheels Ye s Ye s

CE Certified Yes Yes

Page 10

17

18

TECHNICAL DIAGRAMS

CPG2500 (EU) PARTS DIAGRAM

TECHNICAL DIAGRAMS

CPG2500 (EU) PARTS LIST

1

2

3

4

5

6

7

8

9

10

12

13

25

26

27

29

30

32

35

37

38

12

40

41

42

43

44

46

47

21

22

23

24

31

34

36

39

53

52

45

51

50

49

55

56

57

58

54

60

62

61

63

65

66

67

68

69

70

71

72

74

25

75

1

93

94

95

92

91

90

97

78

79

80

82

83

84

85

86

87

88

76

M

o

d

e

l

C

P

G

2

5

0

0

59

12

77

96

33

81

73

15

20

48

14

101

51

100

64

16

99

89

19

11

18

17

19

28

98

26

No. Part Number Description Qty. No. Part Number Description Qty.

1 1.5789.0608 Flange Bolt M6 x 8 5 52 21.110001.00 Shaft, Governor Arm 1

2 22.061100.00.2 Cover, Recoil Starter, Black 1 53 22.123000.01 Ignition Coil, Silicon Rubber 1

3 21.061005.00 Spring, Recoil Starter 1 54 1.5789.0625 Flange Bolt M6 x 25 2

4 2.10.003 Rope Ø5 x 1550 1 55 23.110005.01 Spring, Throttle Return 1

5 21.061001.01 Reel, Recoil Starter 1 56 23.110007.00 Spring, Governor 1

6 45.060003.00 Spring, Ratchet 2 57 2.08.040 Bolt M6 x 21, Governor Arm 1

7 45.060002.00 Starter Ratchet, Steel 2 58 21.110008.00 Pin, Shaft 1

8 45.060009.00 Spring, Ratchet Guide 1 59 23.111000.20 Control Assembly 1

9 45.060007.00 Ratchet Guide 1 60 25.040013.00 Lifter, Valve 2

10 45.060008.00 Screw, Ratchet Guide 1 61 2.04.001 Dowel Pin Ø9 x 14 2

11 24.040004.00 Guide Plate, Push Rod 1 62 26.041000.00 Camshaft 1

12 1.5789.0612 Flange Bolt M6 x 12 8 63 2.14.012 Woodruff Key 4 x 7.5 x 19 1

13 24.080100.01.48 Fan Cover, Yellow 1 64 2.08.037 Drain Bolt M10 x 1.25 x 25 2

14 24.091100.20 Base, Air Cleaner 1 65 26.050005.00 Piston 1

15 21.061300.00 Handle, Recoil, Soft 1 66 23.050003.00 Pin, Piston 1

16 24.130004.20 Gasket, Air Cleaner 1 67 2.09.001 Circlip Ø18 x Ø1 2

17 22.061000.00 Recoil Assembly 1 68 26.050303.00 Ring, Oil 1

18 24.091000.20 Air Cleaner Assembly 1 69 26.050302.00 Ring, Second Piston 1

26.131000.20 70 26.050301.00 Ring, First Piston 1

26.131000.21 71 26.030009.00 Gasket, Cylinder Head 1

20 2.03.016 Washer Ø10 x Ø16 x 1.5, Drain Bolt 2 72 2.04.003 Dowel Pin Ø10 x 14 2

21 2.02.006 Nut M14 x 1.5 1 73 23.040002.00 Valve, Intake 1

22 21.060001.01 Pulley, Starter 1 74 23.040006.00 Valve, Exhaust 1

23 23.080001.00 Cooling Fan 1 75 26.080400.00 Air Guide, Lower 1

24 24.120100.06 Flywheel 1 76 2.15.001(F6TC) Spark Plug F6TC 1

25 2.11.001 Oil Seal Ø25 x Ø41.3 x 6 2 77 1.5789.0860 Flange Bolt M8 x 60 4

26 2.03.020.1 Washer Ø6.2 x Ø15 x 0.5, Black 2 78 23.040017.00 Oil Seal, Valve, Iron

2

27 21.110100.00 Gear, Governor 1 79 21.040003.00 Spring, Valve 2

28 23.130100.20 Choke Lever 1 80 21.040007.00 Retainer, Exhaust Valve Spring 1

29 21.110013.00 Shaft, Governor Gear 1 81 21.040001.00 Retainer, Intake Valve Spring 1

30 21.110011.00 Clip, Governor Gear 1 82 21.040008.00 Rotator, Exhaust Valve 1

31 22.130003.00 Gasket, Carburetor 1 83 24.040202.00 Shaft, Rocker Arm 1

32 21.110012.01 Bushing, Govornor Gear, Steel 1 84 22.040009.00 Rocker Arm, Intake Valve 2

33 24.130002.00 Gasket, Insulator 1 85 22.040012.00 Screw, Valve Adjustment 2

34 23.130001.00 Insulator, Carburetor 1 86 21.040021.00 Nut M6 x 0.5, Lock 2

35 23.080600.00 Air Guide, Right Side 1 87 1.97.1.06 Washer Ø6 2

36 2.01.003 Stud Bolt M6 x 90 2 88 1.6177.1.06 Flange Nut M6 2

37 26.030100.00 Crankcase 1 26.131017.20 Main Jet, Standard 1

38 21.127000.02 Oil Level Sensor 1 26.131017.20.01 Main Jet, Altitude /

39 26.010100.00 Cylinder Head 1 90 24.040201.00 Retainer, Rocker Arm 1

40 23.050200.00 Connecting Rod 1 91 23.040010.00 Bolt, Rocker Arm 2

41 25.050100.11 Crankshaft 1 92 23.040005.00 Push Rod 2

42 1.276.6205 Bearing 6205 2 93 21.020002.01 Gasket, Cylinder Head Cover 1

43 24.030008.00 Gasket, Crankcase Cover 1 94 24.021000.00 Cover, Cylinder Head 1

44 22.031000.00.48 Oil Dipstick Assembly, Yellow 1 95 23.020001.02 Breather Tube 1

45 2.03.021.1 Washer Ø6.4 x Ø13 x 1, Black 1 96 1.5789.0615 Flange Bolt M6 x 15 4

46 23.030007.01 Cover, Crankcase 1 97 2.01.010 Stud Bolt M8 x 35 2

47 1.5789.0832.0.8 Flange Bolt M8 x 32 6 98 1.5789.0620 Flange Bolt M6 x 20 1

48 23.091002.21 Seal, Air Cleaner 1 99 24.091200.20 Cover, Air Cleaner 1

49 23.110006.00 Rod, Governor 1 100 23.091003.21 Element, Air Cleaner 1

50 21.110003.00 Arm, Governor 1 101 23.091001.21 Separator, Air Cleaner 1

51 1.6177.06 Flange Nut M6 3

CPG2500

89

Carburetor19 1

Page 11

19

20

TECHNICAL DIAGRAMS TECHNICAL DIAGRAMS

CPG2500 (EU) PARTS DIAGRAM CPG2500 (EU) PARTS LIST

M

o

d

e

l

:

C

P

G

2

5

0

0

1

25262728293031

323334

36

39

40

414243

74

75

76

2

3

4

5

6

7

8

9

10

13

14 15 16

17

19

20

4546

47

515253

54

55

57

59

60

62636465

61

21

22

24 23

44

56

73

77

6869 70

71

66

72

58

49

50

67

37

38

35

11

12

18

48

10

No Part Number Description QTY No Part Number Description QTY

1 CPG2500 Engine 1 41 2.06.007 Clamp Ø8 x b6 2

2 122.190005.00 Rubber, Fore-Cover, B 1 42 122.070011.04 Fuel Pipe Ø4.5 x Ø8.5 x 140 mm 1

3 122.190005.01 Rubber, Fore-Cover, A 1 43 122.070400.04 Fuel Valve 1

4 122.191100.00 Rotor Assembly, Cu, Ø95 x 85 mm 1 44 1.6177.1.08 Lock Nut M8, Flange 12

5 2.08.017 Flange Bolt M8 x 208 1 45 62337.2.2.2 Frame 1

6 122.191200.08 Stator Assembly, Cu, Ø160 x 85 mm 1 46 122.201200.00 Mount 2, Motor 2

7 122.191002.00 Cover, Stator 1 47 122.201200.01 Mount 1, Motor 2

8 122.190002.00 End Housing 1 48 122.201400.01 Rubber 4

9 2.08.050 Flange Bolt M6 x 133 4 49 1.62.06 Butterfly Type Nut M6 1

10 1.16674.0512.2 Flange Bolt M5×12 3 50 1.93.06.2 Lock Waher Ø6 1

11 122.190600.00 Rectifier 1 51 1.97.1.06.2 Washer Ø6 2

12 1.16674.0520 Flange Bolt M5×20 1 52 1.6177.1.06 Lock Nut M6, Flange 1

13 122.190400.00 Terminal Block 1 53 5.1900.026 Grounding Line 150 mm 1

14 1.5783.0516 Bolt M5 x 16 3 54 1.862.06 Lock Washer Ø6, Toothed 1

15 122.190200.00 AVR 1 55 122.210007.26 Control Box 1

16 1.16674.0516 Flange Bolt M5 x 16 2 56 1.5789.0615.1 Bolt M6 x 15, Black 4

17 122.190003.00.48 End Cover, Generator, Yellow 1 57 1.818.0514.2 Screw M5 x 14 1

18 1.9074.15.0520 Washer Assembly M5 x 20 1 58 5.1810.001 Over Voltage Protector 1

19 122.190004.01 Pinch, Carbon Brush 1 59 122.20.11.48 Control Panel, Yellow 1

20 122.190300.00 Carbon Brush Assembly 1 60 5.1000.004.3 Ignition Switch, Red 1

21 1.5789.0615 Flange Bolt M6 x 15 3 61 1.9074.4.0512.1 Screw/Washer Assembly M5 x 12, Black 5

22 27.100100.10 Bracket, Muffler 1 62 5.1400.003 Voltage Meter 1

23 1.823.0406 Screw M4 x 6 3 63 1.848.03.2 Washer Ø3 4

24 27.101300.00 Spark Arrester Assembly 1 64 1.859.03.2 Lock Washer Ø3 4

25 27.101000.01.2 Muffler Assembly 1 65 1.6175.03.2 Nut M3 4

26 1.6175.08 Nut M8 2 66 5.1240.091 Double Pole Circuit Breaker 1

27 1.93.08 Lock Washer Ø8 2 67 5.1120.009 Receptacle L14-30R 1

28 1.848.08 Washer Ø8 2 68 5.1120.008 Receptacle L5-30R 1

29 21.100001.00 Gasket, Exhaust 1 69 1.6177.1.04.1 Nut M4 6

30 1.5789.0608 Flange Bolt M6 x 8 1 70 5.1120.010 Receptacle 5-20R, Duplex 1

31 23.090006.21 Holder, Air Cleaner 1 71 5.1200.110 10Amp Circuit Breaker, Push Button 1

32 122.071000.45.48 Fuel Tank, Yellow 1 72 5.1110.001 Receptacle 1

33 1.93.06 Lock Washer Ø6 4 73 CPG2500.21.10 Wire Assembly 1

34 122.070015.01 Mount Vibration, Fuel Tank 4 74 122.210003.01 Wire Jacket, Control Box 1

35 2.03.004.1 Washer Ø24 x Ø6.5 x 1.5, Black 4 75 5.1330.001 Sheath, Wire 1

36 1.5789.0620.1 Flange Bolt M6 x 20, Black 4 76 122.210003.03 Plug, End Cover 1

37 122.070300.02 Fuel Filter, Fuel Tank 1 77 CPG2500.21 Control Panel Assembly 1

38 122.070100.02 Cap, Fuel Tank 1

39 1.819.0510 Screw M5×10 2

40 122.072000.01 Fuel Meter Assembly 1

CPG2500

Page 12

21

22

TECHNICAL DIAGRAMS TECHNICAL DIAGRAMS

CPG3500 (EU) PARTS DIAGRAM CPG3500 (EU) PARTS LIST

1

2

3

4

5

6

7

8

9

10

12

13

25

26

27

29

30

32

35

37

38

12

40

41

42

43

44

46

47

21

22

23

24

31

34

36

39

53

52

45

51

50

49

55

56

57

58

54

60

62

61

63

65

66

67

68

69

70

71

72

74

25

75

1

93

94

95

92

91

90

97

78

79

80

82

83

84

85

86

87

88

76

M

o

d

e

l

C

P

G

3

5

0

0

59

12

77

96

33

81

73

15

20

48

14

101

51

100

64

16

99

89

19

11

18

17

19

28

98

26

No. Part Number Description Qty. No. Part Number Description Qty.

1 1.5789.0608 Flange Bolt M6 x 8 5 52 21.110001.00 Shaft, Governor Arm 1

2 22.061100.00.2 Cover, Recoil Starter, Black 1 53 22.123000.01 Ignition Coil, Silicon Rubber 1

3 21.061005.00 Spring, Recoil Starter 1 54 1.5789.0625 Flange Bolt M6 x 25 2

4 2.10.003 Rope Ø5 x 1550 1 55 23.110005.01 Spring, Throttle Return 1

5 21.061001.01 Reel, Recoil Starter 1 56 23.110007.00 Spring, Governor 1

6 45.060003.00 Spring, Ratchet 2 57 2.08.040 Bolt M6 x 21, Governor Arm 1

7 45.060002.00 Starter Ratchet, Steel 2 58 21.110008.00 Pin, Shaft 1

8 45.060009.00 Spring, Ratchet Guide 1 59 23.111000.20 Control Assembly 1

9 45.060007.00 Ratchet Guide 1 60 25.040013.00 Lifter, Valve 2

10 45.060008.00 Screw, Ratchet Guide 1 61 2.04.001 Dowel Pin Ø9 x 14 2

11 24.040004.00 Guide Plate, Push Rod 1 62 26.041000.00 Camshaft 1

12 1.5789.0612 Flange Bolt M6 x 12 8 63 2.14.012 Woodruff Key 4 x 7.5 x 19 1

13 24.080100.01.48 Fan Cover, Yellow 1 64 2.08.037 Drain Bolt M10 x 1.25 x 25 2

14 24.091100.20 Base, Air Cleaner 1 65 26.050005.00 Piston 1

15 21.061300.00 Handle, Recoil, Soft 1 66 23.050003.00 Pin, Piston 1

16 24.130004.20 Gasket, Air Cleaner 1 67 2.09.001 Circlip Ø18 x Ø1 2

17 22.061000.00 Recoil Assembly 1 68 26.050303.00 Ring, Oil 1

18 24.091000.20 Air Cleaner Assembly 1 69 26.050302.00 Ring, Second Piston 1

26.131000.20 70 26.050301.00 Ring, First Piston 1

26.131000.21 71 26.030009.00 Gasket, Cylinder Head 1

20 2.03.016 Washer Ø10 x Ø16 x 1.5, Drain Bolt 2 72 2.04.003 Dowel Pin Ø10 x 14 2

21 2.02.006 Nut M14 x 1.5 1 73 23.040002.00 Valve, Intake 1

22 21.060001.01 Pulley, Starter 1 74 23.040006.00 Valve, Exhaust 1

23 23.080001.00 Cooling Fan 1 75 26.080400.00 Air Guide, Lower 1

24 24.120100.06 Flywheel 1 76 2.15.001(F6TC) Spark Plug F6TC 1

25 2.11.001 Oil Seal Ø25 x Ø41.3 x 6 2 77 1.5789.0860 Flange Bolt M8 x 60 4

26 2.03.020.1 Washer Ø6.2 x Ø15 x 0.5, Black 2 78 23.040017.00 Oil Seal, Valve, Iron

2

27 21.110100.00 Gear, Governor 1 79 21.040003.00 Spring, Valve 2

28 23.130100.20 Choke Lever 1 80 21.040007.00 Retainer, Exhaust Valve Spring 1

29 21.110013.00 Shaft, Governor Gear 1 81 21.040001.00 Retainer, Intake Valve Spring 1

30 21.110011.00 Clip, Governor Gear 1 82 21.040008.00 Rotator, Exhaust Valve 1

31 22.130003.00 Gasket, Carburetor 1 83 24.040202.00 Shaft, Rocker Arm 1

32 21.110012.01 Bushing, Govornor Gear, Steel 1 84 22.040009.00 Rocker Arm, Intake Valve 2

33 24.130002.00 Gasket, Insulator 1 85 22.040012.00 Screw, Valve Adjustment 2

34 23.130001.00 Insulator, Carburetor 1 86 21.040021.00 Nut M6 x 0.5, Lock 2

35 23.080600.00 Air Guide, Right Side 1 87 1.97.1.06 Washer Ø6 2

36 2.01.003 Stud Bolt M6 x 90 2 88 1.6177.1.06 Flange Nut M6 2

37 26.030100.00 Crankcase 1 26.131017.20 Main Jet, Standard 1

38 21.127000.02 Oil Level Sensor 1 26.131017.20.01 Main Jet, Altitude /

39 26.010100.00 Cylinder Head 1 90 24.040201.00 Retainer, Rocker Arm 1

40 23.050200.00 Connecting Rod 1 91 23.040010.00 Bolt, Rocker Arm 2

41 25.050100.11 Crankshaft 1 92 23.040005.00 Push Rod 2

42 1.276.6205 Bearing 6205 2 93 21.020002.01 Gasket, Cylinder Head Cover 1

43 24.030008.00 Gasket, Crankcase Cover 1 94 24.021000.00 Cover, Cylinder Head 1

44 22.031000.00.48 Oil Dipstick Assembly, Yellow 1 95 23.020001.02 Breather Tube 1

45 2.03.021.1 Washer Ø6.4 x Ø13 x 1, Black 1 96 1.5789.0615 Flange Bolt M6 x 15 4

46 23.030007.01 Cover, Crankcase 1 97 2.01.010 Stud Bolt M8 x 35 2

47 1.5789.0832.0.8 Flange Bolt M8 x 32 6 98 1.5789.0620 Flange Bolt M6 x 20 1

48 23.091002.21 Seal, Air Cleaner 1 99 24.091200.20 Cover, Air Cleaner 1

49 23.110006.00 Rod, Governor 1 100 23.091003.21 Element, Air Cleaner 1

50 21.110003.00 Arm, Governor 1 101 23.091001.21 Separator, Air Cleaner 1

51 1.6177.06 Flange Nut M6 3

CPG3500

89

Carburetor19 1

Page 13

23

24

TECHNICAL DIAGRAMS TECHNICAL DIAGRAMS

CPG3500 (EU) PARTS DIAGRAM CPG3500 (EU) PARTS LIST

M

o

d

e

l

:

C

P

G

3

5

0

0

1

25262728293031

323334

36

39

40

414243

74

75

76

2

3

4

5

6

7

8

9

10

13

14 15 16

17

19

20

4546

47

515253

54

55

57

59

60

62636465

61

21

22

24 23

44

56

73

77

6869 70

71

66

72

58

49

50

67

37

38

35

11

12

18

48

10

No Part Number Description QTY No Part Number Description QTY

1 CPG3500 Engine 1 40 122.072000.01 Fuel Meter Assembly 1

2 122.190005.00 Rubber, Fore-Cover, B 1 41 2.06.007 Clamp Ø8 x b6 2

3 122.190005.01 Rubber, Fore-Cover, A 1 42 122.070011.04 Fuel Pipe Ø4.5 x Ø8.5 x 140 mm 1

4 123.191100.04 Rotor Assembly, Cu, Ø160 x 110 mm 1 43 122.070400.04 Fuel Valve 1

5 2.08.021 Flange Bolt M8 x 233 1 44 1.6177.1.08 Lock Nut M8, Flange 12

6 123.191200.04 Stator Assembly, Cu, Ø160 x 110 mm 1 45 62337.2.5.2 Frame 1

7 122.191002.00 Cover, Stator 1 46 122.201200.00 Mount 2, Motor 2

8 122.190002.00 End Housing 1 47 122.201200.01 Mount 1, Motor 2

9 2.08.020 Flange Bolt M6 x 158 4 48 122.201400.01 Rubber 4

10 1.16674.0512.2 Flange Bolt M5×12 3 49 1.62.06 Butterfly Type Nut M6 1

11 122.190600.00 Rectifier 1 50 1.93.06.2 Lock Waher Ø6 1

12 1.16674.0520 Flange Bolt M5×20 1 51 1.97.1.06.2 Washer Ø6 2

13 122.190400.00 Terminal Block 1 52 1.6177.1.06 Lock Nut M6, Flange 1

14 1.5783.0516 Bolt M5 x 16 3 53 5.1900.026 Grounding Line 150 mm 1

15 122.190200.00 AVR 1 54 1.862.06 Lock Washer Ø6, Toothed 1

16 1.16674.0516 Flange Bolt M5 x 16 2 55 122.210007.26 Control Box 1

17 122.190003.00.48 End Cover, Generator, Yellow 1 56 1.5789.0615.1 Bolt M6 x 15, Black 4

18 1.9074.15.0520 Washer Assembly M5 x 20 1 57 1.818.0514.2 Screw M5 x 14 1

19 122.190004.01 Pinch, Carbon Brush 1 58 5.1810.001 Over Voltage Protector 1

20 122.190300.00 Carbon Brush Assembly 1 59 122.20.11.48 Control Panel, Yellow 1

21 1.5789.0615 Flange Bolt M6 x 15 3 60 5.1000.004.3 Ignition Switch, Red 1

22 27.100100.10 Bracket, Muffler 1 61 1.9074.4.0512.1 Screw/Washer Assembly M5 x 12, Black 5

23 1.823.0406 Screw M4 x 6 3 62 5.1400.003 Voltage Meter 1

24 27.101300.00 Spark Arrester Assembly 1 63 1.848.03.2 Washer Ø3 4

25 27.101000.01.2 Muffler Assembly 1 64 1.859.03.2 Lock Washer Ø3 4

26 1.6175.08 Nut M8 2 65 1.6175.03.2 Nut M3 4

27 1.93.08 Lock Washer Ø8 2 66 5.1240.117 Double Pole Circuit Breaker 1

28 1.848.08 Washer Ø8 2 67 5.1120.009 Receptacle L14-30R 1

29 21.100001.00 Gasket, Exhaust 1 68 5.1120.008 Receptacle L5-30R 1

30 1.5789.0608 Flange Bolt M6 x 8 1 69 1.6177.1.04.1 Nut M4 6

31 23.090006.21 Holder, Air Cleaner 1 70 5.1120.010 Receptacle 5-20R, Duplex 1

32 122.071000.45.48 Fuel Tank, Yellow 1 71 5.1200.110 10Amp Circuit Breaker, Push Button 1

33 1.93.06 Lock Washer Ø6 4 72 5.1110.001 Receptacle 1

34 122.070015.01 Mount Vibration, Fuel Tank 4 73 CPG3500.21.10 Wire Assembly 1

35 2.03.004.1 Washer Ø24 x Ø6.5 x 1.5, Black 4 74 122.210003.01 Wire Jacket, Control Box 1

36 1.5789.0620.1 Flange Bolt M6 x 20, Black 4 75 5.1330.001 Sheath, Wire 1

37 122.070300.02 Fuel Filter, Fuel Tank 1 76 122.210003.03 Plug, End Cover 1

38 122.070100.02 Cap, Fuel Tank 1 77 CPG3500.21 Control Panel Assembly 1

39 1.819.0510 Screw M5×10 2

CPG3500

Page 14

25

26

TECHNICAL DIAGRAMS TECHNICAL DIAGRAMS

CPG4000 E1 (EU) PARTS DIAGRAM CPG4000 E1 (EU) PARTS LIST

1

2

3

4

5

6

7

8

9

10

12

13

25

26

27

29

30

32

37

38

12

40

41

42

43

44

21

22

23

24

31

34

36

39

53

52

45

51

50

49

55

56

57

58

54

60

62

61

63

65

66

67

68

69

70

71

72

74

93

94

95

92

91

90

97

78

79

80

82

83

84

85

86

87

88

76

59

12

77

96

33

81

73

106

54

108

109,110

111

107

15

48

14

101

51

100

99

89

19

11

18

17

26

105

77

35

1

113

112

104

16

19

28

75

1

46

47

25

46

47

25

20

64

103

102

98

No. Part Number Description Qty No. Part Number Description Qty

1 1.5789.0608 Flange Bolt M6 × 8 6 58 21.110008.00 Pin, Shaft 1

2 22.061100.00.2 Cover, Recoil Starter, Black 1 59 27.111000.20 Control Assembly 1

3 21.061005.00 Spring, Recoil Starter 1 60 25.040013.00 Lifter, Valve 2

4 2.10.003 Rope Ø5 × 1550 1 61 2.04.001 Dowel Pin Ø9 × 14 2

5 21.061001.01 Reel, Recoil Starter 1 62 27.041000.00 Camshaft 1

6 45.060003.00 Spring, Ratchet 2 63 2.14.012 Woodruff Key 4 × 7.5 × 19 1

7 45.060002.00 Starter Ratchet, Steel 2 64 2.08.037 Drain Bolt M10 × 1.25 × 25 2

8 45.060009.00 Spring, Ratchet Guide 1 65 27.050005.00 Piston 1

9 45.060007.00 Ratchet Guide 1 66 23.050003.00 Pin, Piston 1

10 45.060008.00 Screw, Ratchet Guide 1 67 2.09.001 Circlip Ø18 × Ø1 2

11 24.040004.00 Guide Plate, Push Rod 1 68 27.050303.00 Ring, Oil 1

12 1.5789.0612 Flange Bolt M6 × 12 8 69 27.050302.00 Ring, Second Piston 1

13

27.080100.01.48

FanC

over,Yello

w

17027.050301.00

Ri

ng,Firs

t Pist

on

1

14 24.091100.20 Base, Air Cleaner 1 71 27.030009.01 Gasket, Cylinder Head 1

15 21.061300.00 Handle, Recoil, Soft 1 72 2.04.003 Dowel Pin Ø10 × 14 2

16 24.130004.20 Gasket, Air Cleaner 1 73 23.040002.02 Valve, Intake 1

17 22.061000.00 Recoil Assembly 1 74 23.040006.02 Valve, Exhaust 1

18 27.091000.01 Air Cleaner Assembly 1 75 26.080400.00 Air Guide, Lower 1

27.131000.01 76 2.15.001(F6TC) Spark Plug F6TC 1

27.131000.06 77 1.5789.0865 Flange Bolt M8 × 65 3

20 2.03.016 Washer Ø10 × Ø16 × 1.5

,

Drain Bolt 2 78 23.040017.00 Oil Seal, Valve, Iron

2

19 Carburetor 1

20

2.03.016

Washer Ø10 Ø16 1.5, Drain Bolt

27823.040017.00

Oil Seal, Valve, Iron

2

21 2.02.006 Nut M14 × 1.5 1 79 21.040003.00 Spring, Valve 2

22 83.060001.01 Pulley, Starter 1 80 21.040007.00 Retainer, Exhaust Valve Spring 1

23 27.080001.00 Cooling Fan 1 81 21.040001.00 Retainer, Intake Valve Spring 1

24 24.120100.07 Flywheel 1 82 21.040008.00 Rotator, Exhaust Valve 1

25 2.11.001 Oil Seal Ø25 × Ø41.3 × 6 2 83 24.040202.00 Shaft, Rocker Arm 1

26 2.03.020.1 Washer Ø6.2 × Ø15 × 0.5, Black 2 84 22.040009.00 Rocker Arm, Intake Valve 2

27 21.110100.00 Gear, Governor 1 85 22.040012.00 Screw, Valve Adjustment 2

28 23.130100.20 Choke Lever 1 86 21.040021.00 Nut M6 × 0.5, Lock 2

29 21.110013.00 Shaft, Governor Gear 1 87 1.97.1.06 Washer Ø6 2

30 21.110011.00 Clip, Governor Gear 1 88 1.6177.1.06 Flange Nut M6 2

31 22.130003.00 Gasket, Carburetor 1 27.131017.01 Main Jet, Standard 1

32 21.110012.01 Bushing, Govornor Gear, Steel 1 27.131017.01.01 Main Jet, Altitude /

33 24.130002.00 Gasket, Insulator 1 90 24.040201.00 Retainer, Rocker Arm 1

34 27.130001.00 Insulator, Carburetor 1 91 23.040010.00 Bolt, Rocker Arm 2

35 27.080600.01 Air Guide, Right Side 1 92 27.040005.00 Push Rod 2

36 2.01.003 Stud Bolt M6 × 90 2 93 21.020002.01 Gasket, Cylinder Head Cover 1

89

37

27.030100.00

Crankcase

19424.021000.00

Cover,Cylinder Head

1

38 21.127000.02 Oil Level Sensor 1 95 23.020001.02 Breather Tube 1

39 26.010100.01 Cylinder Head, 224cc 1 96 1.5789.0615 Flange Bolt M6 × 15 4

40 27.050200.00 Connecting Rod 1 97 2.01.010 Stud Bolt M8 × 35 2

41 27.050100.00 Crankshaft 1 98 21.120400.00 Diode Comp 1

42 1.276.6205 Bearing 6205 2 99 27.091200.01 Cover, Air Cleaner 1

43 24.030008.00 Gasket, Crankcase Cover 1 100 23.091003.21 Element, Air Cleaner 1

44 46.031000.00 Oil Dipstick Assembly, Black 1 101 23.091001.21 Separator, Air Cleaner 1

45 2.03.021.1 Washer Ø6.4 × Ø13 × 1, Black 1 102 122.070011.04 Pi

p

e, Fuel 140 1

5

03 0

as e Ø6 Ø 3 , ac

0

0 00 0

pe, ue 0

46 23.030007.01 Cover, Crankcase 1 103 2.06.007 Clamp Ø8 × b6 2

47 1.5789.0832.0.8 Flange Bolt M8 × 32 6 104 152.070031.01 Sheath, Wire 1

48 23.091002.21 Seal, Air Cleaner 1 105 2.08.121 Flange Bolt M10 × 65 1

49 23.110006.00 Rod, Governor 1 106 1.5789.0629 Flange Bolt M6 × 29 1

50 27.110003.00 Arm, Governor 1 107 2.04.005 Dowel Pin, Ø8 × 10 2

51 1.6177.06 Flange Nut M6 3 108 27.125100.00 Starter Motor Assembly 1

52 21.110001.00 Shaft, Governor Arm 1 109 1.93.05 Lock Washer Ø5 2

53 22.123000.01 Ignition Coil, Silicon Rubber 1 110 1.16674.0516 Flange Bolt M5 × 16 2

54 1.5789.0625 Flange Bolt M6 × 25 5 111 23.125200.03 Relay, Starter 1

55 23.110005.01 Spring, Throttle Return 1 112 45.121000.00 Coil, Charging 1

56 23.110007.00 Spring, Governor 1 113 23.030006.00 Plate, Coil 1

57 2.08.040 Bolt M6 × 21, Governor Arm 1

Page 15

27

28

TECHNICAL DIAGRAMS TECHNICAL DIAGRAMS

CPG4000 E1 (EU) PARTS DIAGRAM CPG4000 E1 (EU) PARTS LIST

1

4

5

6

7

8

9

10

21

13

14

16 17

18

19

20

22

232425

293025

31

32

33

34

35

36

25

49

51

52

575859

19

50

56

373839

40

414244

45

46

47

48

11

12

262728

53

545532

62

50

63

57

64

65

36

66

67

68

2

3

60

61

25

70

71

72 73 59 74 75 76 77

78

7981828384

86

87

88

89

90

91

80

85

43

15

25

69

No Part Number Destription QTY No Part Number Destription QTY

1 CPG4000E1-EU Engine 1 47 122.070300.02 Fuel Filter 1

2 122.190005.00 Rubber, Fore-Cover, B 1 48 122.070100.03 Fuel Tank Cap 1

3 122.190005.01 Rubber, Fore-Cover, A 1 49 62294.2.15.2 Frame 1

4 124.191100.00 Rotor Assembly 1 50 1.6177.1.08 Nut M8 12

5 2.08.022 Flange Bolt M8 x 242 1 51 122.201200.01 Motor Mount 1 1

6 124.191200.00 Stator Assembly 1 52 122.201200.00 Motor Mount 2 1

7 123.191002.00 Stator Cover 1 53 1.5789.0835 Flange Bolt M8 x 35 2

8 122.190002.00 End Housing 1 54 1.96.08 Big Whashe φ82

9 2.08.065 Flange Bolt M6 x 168 4 55 152.201200.00 Motor Mount 2

10 122.190300.00 Carbon Brush Assembly 1 56 122.201400.01 Rubber 4

11 122.190600.00 Diode Assembly 1 57 1.6177.1.06 Nut M6

3

12 1.5783.0520 Bolt M5 x 20 1 58 5.1900.026 Grounding Line 1

13 1.93.05 Spring Washer φ5 2 59 1.862.06 Lock Washer Φ62

14 1.5783.0516 Bolt M5 x 16 1 60 1.9074.3.0510 Bolt And Washer Assembly M5 x 10 2

15 1.9074.17.0516 Screw/Washer Assembly M5 x 16 2 61 1.6177.1.05 Flange Lock Nut M5 2

16 122.190200.00 AVR 1 62 9.1000.075 Battery 12V 7.5AH 1

17 1.16674.0516 Flange Bolt M5 x 16 2 63 122.200901.02 Supporter,Battery 1

18 122.190003.00.48 Generator End Cover Yellow 1 64 122.200902.01 Lock,Battery 1

19 1.16674.0512.2 Flange Bolt M5 x 12 3 65 1.5789.0845 Flange Bolt M8 x 45 2

20 122.190400.00 Terminal Block 1 66 5.1900.009 Black Wire,Battery 1

21 122.190004.01 Pinch 1 67 5.1900.010 Red Wire,Battery 1

22 122.190018.00 Bracket,Muffler 1 68 152.200013.01.3 Jacket, Red 2

23 1.16674.0820 Flange Bolt M8 x 20 3 69 152.200013.01 Jacket, Black 1

24 122.190018.01 Bracket,Muffler 1 70 122.159.9.2 Control Panel 1

25 1.5789.0612 Flange Bolt M6 x 12 13 71 5.1000.001.3 Switch 1

26 1.9074.4.0514 Screw And Washer Assembly M5 x 14 2 72 5.1120.013.1 Receptacle 2

27 46.101503.08 Plate, Spark Arrester 1 73 1.819.0414.2

Screw M4 x 14

8

28 46.101300.08 Spark Arrester Assembly 1 74 1.5783.0622.2 Bolt M6 x 22

1

29 26.101000.00 Muffler 1 75 1.6175.06.2 Nut M6

2

30 23.102000.03.2 Muffler Cover 1 76 1.93.06.2 Spring Washer Φ62

31 1.6175.08 Nut M8 2 77 1.97.1.06.2 Washer Φ62

32 1.93.08 Spring Washer φ8 4 78 5.1110.001

Receptacle(DC.12V)

1

33 1.848.08 Washer Φ8 2 79 5.1200.110.1

AC.10A Breaker

1

34 21.100001.00 Muffler Gasket 1 80 1.6177.1.04.2 Flange Nut M4 10

35 23.090006.21 Holder,Air Cleaner 1 81 5.1220.130 AC.13A Breaker 1

36 1.5789.0608 Flange Bolt M6 x 8 4 82 1.9074.4.0306.2 Bolt and Washer Assembly M3 x 6 2

37

122.070011.05 Pipe,Fuel(5.5in) 1

83 1.9074.4.0414.2 Bolt and Washer Assembly M4 x 14 2

38

2.06.007 Clamp 2

84 5.1430.002 Intelligauge 1

39

122.070400.03 Fuel Cock 1

85

5.1800.002 Rectifier 1

40 122.071000.06.48 Fuel Tank Yellow 1 86 122.210002.14 Control Box 1

41 122.070015.01 Mount Vibration, Fuel Tank 4 87 1.9074.1.0538.2 Bolt and Washer Assembly M5 x 38 3

42 2.03.004 Washer Φ6 4 88 122.210003.00 sheath,wire 1

43 1.93.06 Spring Washer φ6 4 89

122.210003.01 Plug, Control Box 1

44 1.5789.0620.2 Flange Bolt M6 x 20 4 90 5.1330.214 Plug 1

45 122.072000.02 Fuel Meter Assembly 1 91 122.210003.03 Plug, End Cover 1

46 1.819.0510 Screw M5 x 10 2

Page 16

29

30

TECHNICAL DIAGRAMS TECHNICAL DIAGRAMS

CPG6500 E2 (EU) PARTS DIAGRAM CPG6500 E2 (EU) PARTS LIST

1 2 3 4 5

6

7

8

9

10

11

12

1314151617

23 2 4 2 5 2 6 2 7

28

29

25 30 31323332

34

35

36

37

38

39

40

41

42

25

31

43

45

46

47

48

78

51 90 91 9 2 93888 9

94

99

67

707172

73

75

76

77

79

495214

53

54

55

56

57

58

59

60

61

62

63

64

65

66

68

16

10 1

10 3

10 4

10 5

11 5

11 7

11 8

11 9

74

69

69

81

82

83

18

19

20

21

2250

44

44

50

51

42

84

10 0

95

98

10 8

10 9

11 0

11 1

11 2

11 3

11 4

10 6

10 7

11 6

858 6

87

10 2

969 7

80

No Part Number Destription QTY No Part Number Destription QTY

1 122.070100.03 Fuel Tank Cap 1 61 152.201200.01 Motor Mount 1

2 122.070300.02 Fuel Filter 1 62 1.5182.10120 Bolt M10 x 120 2

3 1.819.0510 Screw M5 x 10 2 63 253.200016.00 Bush Φ 16 x Φ 10.5 x 69.5 2

4 152.072000.03 Fuel Meter Assembly 1 64 152.201701.04.48 10 in Wheel 2

5 1.5789.0620.2 Flange Bolt M6 x 20 4 65 1.6182.10 Nut M10 2

6 1.93.06 Spring Washer Φ 6 4 66 152.201200.02 Motor Mount 1

7 2.03.004 Washer Φ 6 4 67 1.5789.0835 Flange Bolt M8 x 35 2

8 122.070015.01 Mount Vibration, Fuel Tank 4 68 1.96.08 Washer Φ 82

9 152.071000.03.48 Fuel Tank 1 69 1.6177.1.08 Nut M8 8

10 122.070400.03 Fuel Cock 1 70 1.5789.0816 Flange Bolt M8 x 16 2

11 2.06.007 Clamp 2 71 152.200002.01.2 Support Leg 1

12 152.070011.06 Pipe,Fuel 170 mm 1 72 152.201400.00 Rubber, Support 2

13 45.090006.20 Holder, Air Cleaner 1 73 1.5789.0825 Flange Bolt M8 x 25 2

14 1.6177.1.06 Nut M 6 2 74 1.9074.3.0510 Bolt And Washer Assembly M5 x 10 2

15 1.848.08 Washer Φ 8 2 75 1.6177.1.05 Nut M5 2

16 1.93.08 Spring Washer Φ 8 4 76 9.1000.150 Battery 12V15 AH 1

17 1.6175.08 Nut M8 2 77 152.200904.00 Pinch, Rubber 1

18 46.100001.07 Muffler Gasket 1 78 5.1900.025 Black Wire, Battery 1

19 46.101000.01.2 Muffler Assembly 1 79 5.1900.024 Red Wire, Battery 1

20

1.9074.4.0510 Bolt And Washer Assembly M5 x 10

3 80 152.200013.01.3 Jacket, Red 2

21 46.101300.00 Arrester Assembly, Spark 1 81 152.200013.01 Jacket, Black 1

22 1.16674.0825 Flange Bolt M8x25 2 82 152.159.049.2 Control Panel 1

23 152.190300.00 Carbon Bursh Assembly 1 83 5.1000.001.3 Switch 1

24 122.190004.01 Pinch 1 84 5.1120.013 Receptacle 2

25 1.93.05 Spring Washer Φ 5 5 85 1.819.0414.2 Bolt and Washer Assembly M4 x 14 8

26 1.5783.0520 Bolt M5 x 20 1 86 1.6177.1.04.2 Nut M4 8

27 122.190400.00 Terminal Block 1 87 5.1210.920

20Amp Circuit Breaker, Push Button

2

28 152.190003.00.48 Generator End Cover 1 88 1.819.0516.2 Bolt and Washer Assembly M5 x 16

4

29 1.16674.0512.2 Flange Bolt M5 x 12 2 89 1.6177.1.05.2 Nut M5 4

30 1.5783.0516 Bolt M5 x 16 2 90 1.5783.0622.3 Bolt M6 x 22 1

31 1.97.1.05 Washer Φ 5 4 91 1.6175.06.3 Nut M6 2

32 1.16674.0516 Flange Bolt M5 x 16 3 92 1.93.06.3 Spring Washer Φ62

33 153.190200.05 AVR 1 93 1.97.1.06.3 Washer Ø6, Green 2

34 152.190002.00 End Housing 1 94 5.1430.002 Intelligauge 1

35 2.08.032 Flange Bolt M6 x 179 4 95 5.1000.000.3 Switch 1

36 2.08.035 Bolt M5 x 214 2 96 1.9074.4.0414.2 Screw And Washer Assembly M4 x 14 2

37 1.6175.05 Nut M5 2 97 1.6177.1.04.2 Flange Lock Nut M4 2

38 152.191002.00 Stator Cover 1 98 1.9074.4.0306.2 Bolt M3 x 6 2

39 152.191200.00 Stator Assembly 1 99 5.1230.217

21.7Amp Circuit Breaker

1

40 2.08.034 Flange Bolt M10 x 265 1 100 5.1110.001 Receptacle 1

41 1.7244.10 Spring Washer Φ 10 1 101 5.1200.110.1 Breaker 1

42 1.96.10 Washer Φ 10 3 102 5.1120.014 Receptacle 1

43 152.191100.00 Rotor Assembly 1 103 122.210003.01

Plug

1

44 1.5789.0608 Flange Bolt M6 x 8 3 104 5.1330.007 Sheath, Wire 1

45 152.192300.00 Air Guide 1 105 152.210003.02

Plug

1

46 152.190005.00 Rubber, Fore-Cover 1 106 CPG6500E2-EU.21 Control Panel Assembly 1

47 152.190005.01 Rubber, Fore-Cover 1 107 CPG6500E2-EU.21.10 Wire Assembly 1

48 CPG6500E2-EU Engine 1 108

122.210003.00 Plug 1

49 5.1900.026 Grounding Line 1 109

5.1280.003 Fuse(10A) 1

50 1.5789.0612 Flange Bolt M6 x 12 5 110

5.1830.001 Remote Control Module 1

51 1.862.06 Lock Washer Φ 6 2 111 5.1040.004 Switch

1

52 152.201200.00 Motor Mount 2 112 5.1460.003 Indicator light

1

53 1.894.1.10 Circlip Φ 10 2 113

152.210002.11 Control Box 1

54 152.200703.04 Pin,Handle 2 114

5.1820.000 Charger 1

55 1.894.1.08 Circlip Φ8 2 115 5.1800.000 Rectifier 1

56 152.200703.02 Pin, Handle 2 116 1.823.0514.2 Screw M5 x 14 4

57 152.200701.02.2 Handle 1 117 122.210003.00

Plug

1

58 152.200702.02 Cover, Handle 1 118 1.9074.1.0538.2 Bolt and Washer Assembly M5 x 38 5

59 65212.0.5.2 Frame 1 119 152.210002.09 Control Box 1

60 1.6177.1.10 Nut M10 2

Page 17

31

32

TECHNICAL DIAGRAMS TECHNICAL DIAGRAMS

CPG6500 E2 (EU) PARTS DIAGRAM CPG6500 E2 (EU) PARTS LIST

45

64

40

102

103

104

10591106

107

110

109

108

85

10

1

2

3

4

5

6

7

8

9

11

12

13

14

15

16

17

18

19

20

16

24

25

26

27

28

29

30

31

33

34

35

12

36

30

37

38

23

39

41

42

43

44

46

47

48

49

50

51

52

53

12

54

55

57

58

59

60

61

62

65

66

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

86

87

88

67

83

84

56

94

95

96

111

89

97

98

99

100

101

2

21

22

23

93

89

112

63

32

92

113

114

90

91

115

117

118

119

120

121

116

No. Alias Description Qty. No. Alias Description Qty.

1 21.061300.00 Handle, Recoil, Soft 1 62 45.020100.00 Bolt, Cylinder Head Cover 1

2 1.5789.0608 Flange Bolt M6 × 8 4 63 2.08.039 Drain Bolt M10 × 1.25 × 25 2

3 46.061100.00.2 Cover, Recoil Starter, Black 1 64 46.041000.00 Camshaft 1

4 45.060005.00 Spring, Recoil Starter 1 65 45.040013.00 Lifter, Valve 2

5 45.061102.00 Reel, Recoil Starter 1 66 45.040002.00 Valve, Intake 1

6 2.10.003 Rope Ø5 × 1550 1 67 45.040006.00 Valve, Exhaust 1

7 45.060003.00 Spring, Ratchet 2 68 46.040005.00 Push Rod 2

8 45.060002.00 Starter Ratchet, Steel 2 69 45.040015.00 Retainer, Valve Spring Down 2

9 45.060009.00 Spring, Ratchet Guide 1 70 45.040017.00 Oil Seal, Valve 2

10 45.060007.00 Ratchet Guide 1 71 45.040003.00 Spring, Valve 2

11 45.060008.00 Screw, Ratchet Guide 1 72 23.040010.00 Bolt, Rocker Arm 2

12 1.5789.0612 Flange Bolt M6 × 12 12 73 45.040001.00 Retainer, Intake Valve Spring 1

13 2.05.005

C

lampØ6 2 74 45.040007.00 Retainer, Exhaust Valve Spring 1

14 46.080100.01.48 Fan Cover, Yellow 1 75 45.040008.00 Rotator, Exhaust Valve 1

15 2.02.007 Nut M16 × 1.5 1 76 46.040004.00 Guide Plate, Push Rod 1

16 1.5789.0629 Flange Bolt M6 × 29 4 77 46.040016.00 Shaft, Rocker Arm 1

17 45.060001.00 Pulley, Starter 1 78 46.040201.00 Retainer, Rocker Arm 1

18 46.123000.03 Ignition Coil, Silicon Rubber 1 79 46.040009.00 Rocker Arm, Intake Valve 1

19 45.080001.00 Cooling Fan 1 80 46.040018.00 Rocker Arm, Exhaust Valve 1

20 46.120100.04 Flywheel 1 81 1.97.1.06 Washer Ø6 2

21

45.030006.00

Plate,Coil182

22.040012.00

Screw,Valve Adjustment

2

22 45.121000.00 Coil, Charging 1 83 1.6177.1.06 Flange Nut M6 2

23 2.11.007 Oil Seal Ø35 × Ø52 × 8 2 84 21.040021.00 Nut M6 × 0.5, Lock 2

24 2.05.050 Wire Clip, 100 mm 1 85 2.01.008 Stud Bolt M6 × M8 × 105 2

25 45.030032.00 Sheath, Wire 1 86 46.130002.20 Gasket, Insulator 1

26 2.03.023 Washer Ø12.5 × Ø20 × 2, Drain Bolt 2 87 45.130001.00 Insulator, Carburetor 1

27 46.030100.01 Crankcase 1 88 46.130003.20 Gasket, Carburetor 1

28 45.127000.02 Oil Level Sensor 1 89 46.131000.22 Carburetor 1

29 1.5789.0615 Flange Bolt M6 × 15 2 90 46.130004.20 Gasket, Air Cleaner 2

g

,

30 1.276.6202 Bearing 6202 2 91 1.6177.06 Flange Nut M6 3