Page 1

Parts and Operator’s Manual

Ci 40 - Ci 110

Read this manual prior to installation and operation of this machine.

Manual No.: 975203 Rev. H

Effective: July 2002

Model : _____________

Serial Number: _____________

Page 2

Page 3

Champion Compressors Ltd. Manual No. 975203 Rev H

CONTENTS

1.0 PARTS ORDERING PROCEDURE.....................................................1

2.0 RECOMMENDED SPARE PARTS LIST.............................................2

3.0 INTRODUCTION.................................................................................3

4.0 SAFETY..............................................................................................4

4.1 General Safety Notes................................................................4

5.0 GENERAL DESCRIPTION AND OPERATION....................................6

5.1 General Description of the Dominator Ci Series........................6

5.2 Principle of Operation ...............................................................7

5.3 Control System .........................................................................8

5.4 Operating Temperature .............................................................8

6.0 TECHNICAL DATA..............................................................................9

7.0 INSTALLATION AND PRE START CHECKS....................................10

7.1 Location..................................................................................10

7.2 Connection To Air System ......................................................10

7.3 Electrical Connection..............................................................11

7.3.1 Ci 40 - 75 (Stop / start control).......................................11

7.3.2 Ci 75 / 110 (Star-delta, CSU).........................................12

7.3.3 Motor Rotation Direction................................................12

7.4 Mechanical Checks.................................................................13

7.4.1 Airend Check.................................................................13

7.4.2 Oil Level Check .............................................................13

7.4.3 Vee Belt Check ..............................................................13

7.4.4 System Isolating Gate Valve Check...............................14

8.0 OPERATION.....................................................................................15

8.1 Start-Up Procedure.................................................................15

8.2 Function Of Controls...............................................................15

8.2.1 Stop / Start (Standard Ci 40 - 75):.................................15

8.2.2 Star-delta, CSU (Option Ci75, Standard Ci 110):...........16

8.3 Control Pressure Switch..........................................................17

8.4 Protection Devices..................................................................18

8.5 Thermo Bypass-Valve.............................................................18

9.0 OPTIONS..........................................................................................19

Page 4

Champion Compressors Ltd. Manual No. 975203 Rev H

9.1 Lead/Lag, Remote Monitoring & Control.................................19

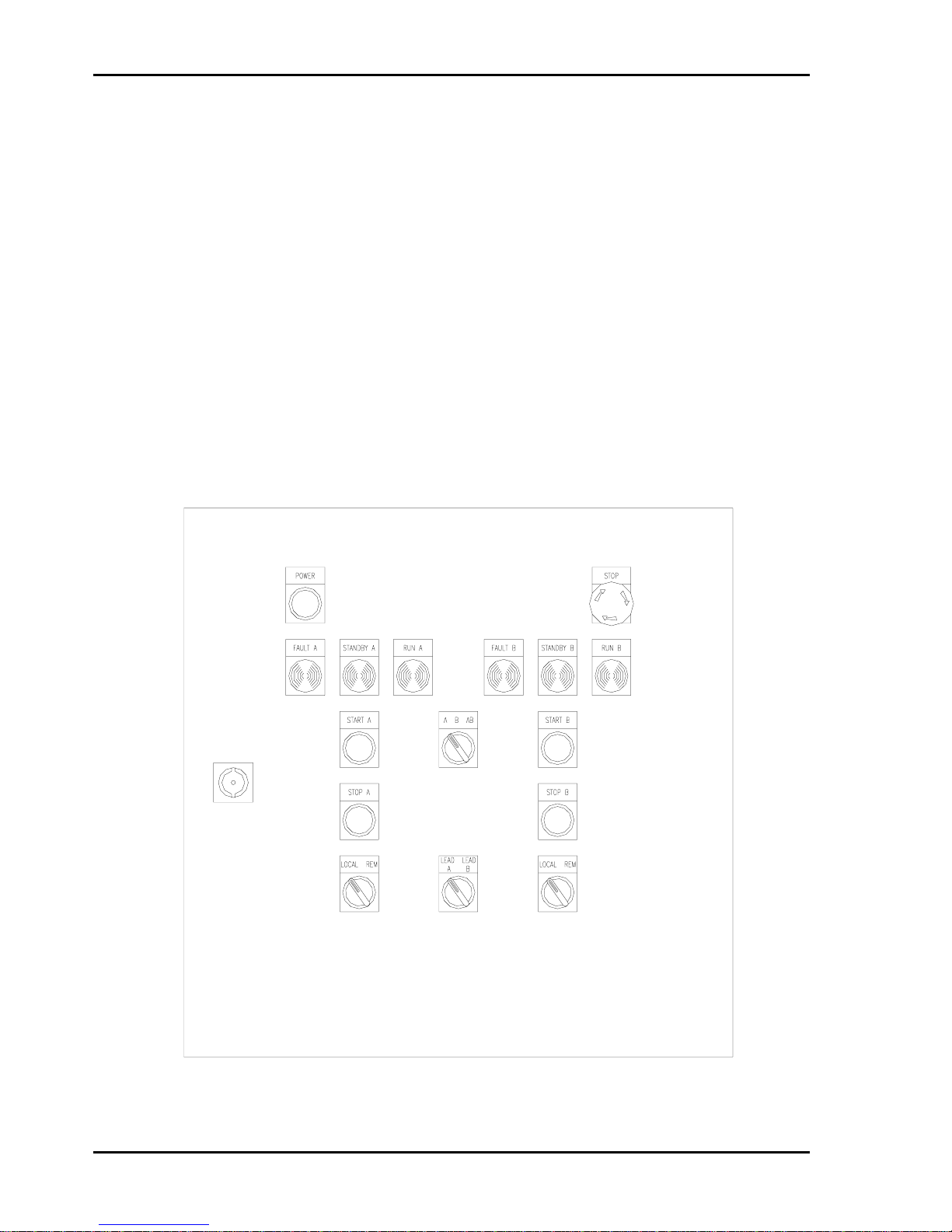

9.1.1 Central Control Box Operation...................................... 20

9.2 Lead/Lag Control.................................................................... 22

9.2.1 Lead / Lag Control Box Operation.................................22

9.3 Lead / Lag Pressure Switches................................................ 23

9.4 Acoustic Hood (Ci 40/55)........................................................24

9.5 Clean Air Pack (Dryer)............................................................24

9.6 Dirty Environment Filter (Cyclopac)........................................ 24

9.7 No Neutral & Hour-meter (Ci 40/55/75)..................................24

9.8 Duplex....................................................................................24

9.9 Base-mount............................................................................25

9.10 Sump Heater and Thermal Fan..............................................25

9.11 Auto Restart Option................................................................25

9.12 Phase Failure Relay (Ci 75/110 only)..................................... 25

10.0 MAINTENANCE ................................................................................ 26

10.1 General .................................................................................. 26

10.2 Daily Operation.......................................................................26

10.3 Maintenance Schedule........................................................... 27

10.3.1 Initial Service - 250 hours............................................27

10.3.2 Every 1,500 Hours....................................................... 27

10.3.3 Every 3,000 Hours (Or Yearly)....................................27

11.0 GENERAL ASSEMBLY COMPONENTS - Ci 40 / 55........................ 30

12.0 GENERAL ASSEMBLY COMPONENTS- Ci 75................................ 34

13.0 GENERAL ASSEMBLY COMPONENTS- Ci 110.............................. 40

14.0 INTEGRATED SCREW COMPONENTS- Ci 40 / 55.........................44

15.0 INTEGRATED SCREW COMPONENTS- Ci 75 / 110....................... 46

16.0 ELECTRICAL STARTER ASSEMBLY - Ci75SD/110........................48

17.0 CLEAN AIR PACK ASSEMBLIES.....................................................52

18.0 CYCLOPAC AIR INTAKE ASSEMBLIES.......................................... 56

19.0 ACOUSTIC HOOD ASSEMBLY........................................................58

20.0 AUTODRAIN ASSEMBLY.................................................................60

21.0 CONTROL BOX DOOR ASSEMBLY................................................62

22.0 CENTRAL CONTROL BOX ASSEMBLY..........................................64

23.0 LEAD / LAG CONTROL BOX DOOR ASSEMBLY............................ 66

Page 5

Champion Compressors Ltd. Manual No. 975203 Rev H

24.0 LEAD / LAG CONTROL BOX ASSEMBLY........................................68

25.0 DUPLEX ASSEMBLIES ....................................................................70

26.0 TROUBLESHOOTING.......................................................................72

27.0 GENERAL ARRANGEMENT DRAWINGS........................................73

29.0 CHAMPION NETWORK....................................................................91

APPENDIX A DN - METRIC NOMINAL SIZES..........................................94

Page 6

Page 7

Champion Compressors Ltd. Manual No. 975203 Rev H

1

1.0 PARTS ORDERING PROCEDURE

When ordering parts always indicate the Serial No. and Model No. of the

compressor.

The parts should be ordered from the nearest Champion Branch or Champion

Distributor from whom the compressor was purchased (see 29.0 Champion

Network). If for any reason parts cannot be obtained in this manner, please

contact Champion Compressors Head Office directly.

When ordering parts, please be careful to check with your part number

selection for either assembly or kit. If you have any questions, please contact

your nearest Champion Branch.

Page 8

Champion Compressors Ltd. Manual No. 975203 Rev H

2

2.0 RECOMMENDED SPARE PARTS LIST

Description Repair Kit

No.

Qty.

2.1 Parts required per 1,500 hour (Type B)

Service

Standard Air Filter Element - Ci 40-55 278766 1

Standard Air Filter Element - Ci 75-110 278767 1

Oil Filter Element Cartridge - Ci 40-110 278877 1

Cyclonic Air Filter Element - Ci 40-110(Optional) 270092 1

Lubricant - Shell Corena CH46 (See Section 6) 831015

2.2 Parts required per 3,000 hour (Type C)

Service (As above plus:)

Separator Element - Ci 40-55 278773 1

Separator Element - Ci 75-110 278765 1

Microfilter Element - Ci 40-55 (If fitted) 211756 1

Microfilter Element - Ci 75-110 (If fitted) 211760 1

Vee Belts (Refer Section 9.0 / 10.0) 2

2.3 Machine Spares

Thermo Valve Repair Kit - 70ºC - Ci 40-110 278875 1

Thermo Valve Repair Kit - 80ºC - Ci 40-110 278876 1

Minimum Pressure Valve Repair Kit - Ci 40-110 278775 1

Inlet Controller - Ci 40-55 278905 1

Inlet Controller - Ci 75-110 278830 1

Airend Seal Kit - Ci 40-110 278763 1

Sight Glass Kit - Ci 40-110 278780 1

O-ring Kit - Ci 40-110 278874 1

Tensiometer 270965 1

2.4 Upgrade Kits

Cyclonic Air Filter Kit - Ci 40-55 159022

Cyclonic Air Filter Kit - Ci 75-110 159023

No Neutral, Hour Meter - Ci 40-55 159021

Clean Air Pack (CRD006) - Ci 40 159036

Clean Air Pack (CRD009) - Ci 55 159037

Clean Air Pack (CRD012) - Ci 75 159038

Clean Air Pack (CRD018) - Ci 110 159039

Acoustic Hood - Ci40-55 159017

Auto Drain Kit 159041

Spare parts Warranty: Type B Service items are warranted f or 1000 hours. ULTIMIZER is warranted for 4000 hours (or 1 year,

whichever occurs first). CHAMPION Vee belts are warranted for 6000 hours, if installed by a Champion approved technician. The parts

subjected to warranty must be returned (freight pre-paid), with proof of purchase to Champion Compress ors. In general, machine spare

parts are warranted for six months from the date of invoice and subject to Champion Compress ors Ltd. standard Warranty P ol i cy, and

Terms and Conditions of Sale of Goods.

Page 9

Champion Compressors Ltd. Manual No. 975203 Rev H

3

3.0 INTRODUCTION

The Dominator range of rotary screw compressors provides efficient

compressed air in a modular design, which allows for customisation and future

expansion of air requirements.

The standard Dominator range of air compressors has many features and

innovations.

Some of these advanced features are as follows:

• Advanced, modified profile screw element.

• Integrated machine componentry for less connections, eliminating oil leaks.

• Simplified intake controller.

• Integrated spin-on separator element for easy servicing and very low oil

carry-over.

• Integrated oil filter, air filter and over pressure protection.

• Minimum noise emission through innovative design.

• Simple machine control and adjustment.

• Easy access to service components.

• Compact modular design which allows for flexible installation and complete

package models, with air receiver and refrigerant dryer, all mounted on the

one unit.

• Integrated thermovalve optimised for ambient conditions.

This operator's manual is written to assist the end user in gaining maximum

use from their compressor unit. Please familiarise yourself with the contents

before placing the unit into service. Correct installation and on going

maintenance using the Champion Maintenance Program and Service Contract

will provide years of trouble-free service.

A copy of this manual should be given to the personnel responsible for

operating the machine within your organisation.

All requests for information, service and spare parts should be directed to

your nearest Champion Compressors’ Customer Support Division, or your

Authorised Champion Compressors’ Service Agent.

Page 10

Champion Compressors Ltd. Manual No. 975203 Rev H

4

4.0 SAFETY

4.1 General Safety Notes

Champion Compressors manufacture the Dominator Ci series so that they

can be operated safely. Persons operating the compressor are ultimately

responsible for their own safety. The following safety precautions are

suggested as a guide to reduce the risk of injuries throughout the life of your

compressor.

• Do not operate the compressor in an unsafe condition. Tag the

compressor with an appropriate Warning Tag and render it inoperative by

disconnecting the power at the source. This will prevent others from being

able to operate it until it is repaired.

• Correct hearing protection must be worn by person(s) working on or around

the compressor whilst the compressor is in operation.

• Before removing the oil filler cap ensure the compressor is not running and

is not pressurised. Shut down the compressor, isolate and bleed the

compressor air receiver before attempting to remove the oil filler cap. Vent

all internal pressure before opening any line, fitting, valve, drain plug,

connection or other component. If you are unsure how to do this contact

your nearest Champion Service Agent.

• Do not vary pressure switch setting from those listed in Section 8.3 without

prior approval from Champion Compressors’ Engineering Department.

Failure to comply to this may void your warranty.

• Do not tamper with or remove the integrated screw or air receiver safety

valves.

• Clean up spills of lubricant or other combustibles immediately. Keep

sparks and other ignition sources at a safe distance. Do not allow smoking

near the compressor.

• Keep electrical wiring and connections clean, free from dust, oil and tightly

clamped.

• Do not operate compressor or optional dryer with any protective guards or

panels removed. This includes the Ci 75 & 110 cabinet, fan & belt guards

or motor fan cowlings. Keep loose clothing and parts of the body away

from fans and other moving parts at all times.

Page 11

Champion Compressors Ltd. Manual No. 975203 Rev H

5

Avoid touching hot fluid, hot surfaces and points of air discharge. The

surfaces of the cooler, motor and airend can become very hot in high ambient

conditions.

• Do not directly breathe the air from this compressor.

• Do not direct compressed air at any part of a person’s body.

When making adjustments or repairs to exposed live parts of the system

maintain dry footing, stand on insulating surfaces and do not contact any

other portion of the compressor. Make adjustments with one hand only so as

to minimise the possibility of creating a current path through the heart. Do not

leave the compressor unattended with open electrical enclosures. If

necessary to do so, disconnect and lock out all power at the source.

All electrical service or installation work must be carried out by a

qualified / certified electrician.

Page 12

Champion Compressors Ltd. Manual No. 975203 Rev H

6

5.0 GENERAL DESCRIPTION AND OPERATION

5.1 General Description of the Dominator Ci Series

Your new Dominator rotary screw compressor will provide you with product

reliability and greatly reduced maintenance, if maintained and operated in

accordance with this manual.

The protection devices fitted to this compressor are provided to offer safety of

operation. The operator is solely responsible for personal safety at all times.

These devices should not be adjusted except by an authorised Champion

Compressors service agent.

The machines can be adjusted to operate at maximum capacity at pressures

of 780,1000 & 1300 kPa, but are supplied as standard at 780 kPa.

For pressure other than standard, check with Champion Compressors’

Support Division should you wish to vary the operating pressure of your

machine.

As standard, each compressor is mounted on an air receiver. The Ci 40 & 55

is mounted on one 150L air receiver, and the Ci 75 & 110 are mounted on

twin tank 220L air receivers.

Optionally, each model can be accompanied by a clean air package

consisting of a refrigerated dryer and microcoalescing filter. Each model is

also available in a version mounted on rubber feet, for applications where a

receiver already exists. The innovative modular design of the Ci series allows

for easy configuration changes, (See Section 9 for full option descriptions).

The Ci 40 - Ci 75 machines all employ three phase direct-on-line starting

(DOL) via a combination pressure switch / off-auto control / starter and motor

overload. These machines will start and stop automatically depending on

system pressure requirements, while the lever control on the pressure switch

is set to ‘Auto’ mode. The Ci 75 is also supplied with an hour meter indicating

hours of operation for service intervals.

Page 13

Champion Compressors Ltd. Manual No. 975203 Rev H

7

The Ci 110 uses a three phase star-delta starter panel mounted in the lid of

the compressor cabinet. This machine runs continuously, loading and

unloading as required to meet system pressure needs. An Off/Auto switch

mounted in the lid panel of the compressor is provided as a means of control.

An hour meter is provided indicating hours of operation for service intervals.

The Star-delta, Constant Speed Unload (CSU) option is available on the

Ci 75 by customer request.

Service access for your machine is excellent, with ample space provided to

allow for easy servicing of components. All the serviceable components on

the machine are located in convenient positions requiring minimum

disturbance to your compressor package. All models employ a vertical fan

mounted oil cooler, and on the Ci 75 and Ci 110, an air aftercooler is also

provided as standard.

5.2 Principle of Operation

The main functional components of a Dominator rotary screw air compressor

are the integrated rotary screw airend, the drive motor and cooler assemblies.

Unlike other rotary screw air compressors, the integrated rotary screw airend

performs the task of multiple system components. This has the advantage of

reducing the number of connections between components, and also reducing

system complexity.

The integrated screw rotors draw air through the air filter and intake controller.

Oil is injected into the compression space to provide cooling, sealing and

lubrication of the rotors and bearings as they turn, compressing the air. The

compressed air/oil mixture is discharged into the integrated separator vessel,

where most of the oil is removed from the air/oil mixture by mechanical

separation. The glass fibre spin-on separator element removes the remaining

oil.

The oil that is removed by the separator element is returned to the airend

sump via the purge line sight glass. The oil is collected in the separator

vessel and piped to the oil filter, where oil is cleaned before being cooled in

the oil cooler and re-injected into the airend.

After the separator element, the compressed air then flows through the

minimum pressure valve to the air receiver (via the air aftercooler on Ci 75 &

110). The moisture condensation is accumulated in the air receiver and

removed by means of the receiver drain valve or auto drain.

Page 14

Champion Compressors Ltd. Manual No. 975203 Rev H

8

The minimum pressure valve maintains pressure in the integrated screw

during start-up and during off-load operation to assist oil circulation. Backflow of compressed air from the air mains into the separator is prevented by a

non-return valve which is incorporated in the minimum pressure valve.

5.3 Control System

The purpose of the control system is to regulate the compressor air intake to

match the amount of air being used. The major components of the control

system are the intake controller, solenoid valve and pressure switch.

As the compressor starts (Stop / Start control only) or switches into DELTA (or

run) mode (Star-delta, CSU Only), the solenoid valve is energised, allowing

the air to enter the compressor. The system pressure rises.

The compressor pumps until the pre-set UN-LOAD pressure switch setting is

reached. The pressure switch then de-energises the solenoid valve, closing

the intake valve and allowing the integrated screw to reduce sump pressure.

On the stop/start models (standard on Ci 40, 55, 75) the compressor will

come to a stop. The load/unload models (standard Ci 110) will continue to

unload (producing no air) for a set time, governed by the setting of the run-on

timer, after which the compressor will enter standby mode, ready to

automatically start when air demand exists.

When mains pressure falls to the pre-set LOAD pressure switch setting, the

solenoid valve is energised, signalling for the inlet valve to open, thus allowing

the compressor to build up pressure to the pre-set level again. This cycle

continues as long as air demand is present.

5.4 Operating Temperature

This unit is designed to work from 0°C to temperatures in excess of 40°C.

Where site ambient temperatures will exceed 40°C (for example in a boiler

room), then it is better to duct the cooling air to the compressor. The oil

temperature is regulated by a thermo-bypass valve. For details on thermobypass valve operation refer to Section 8.5.

Page 15

Champion Compressors Ltd. Manual No. 975203 Rev H

9

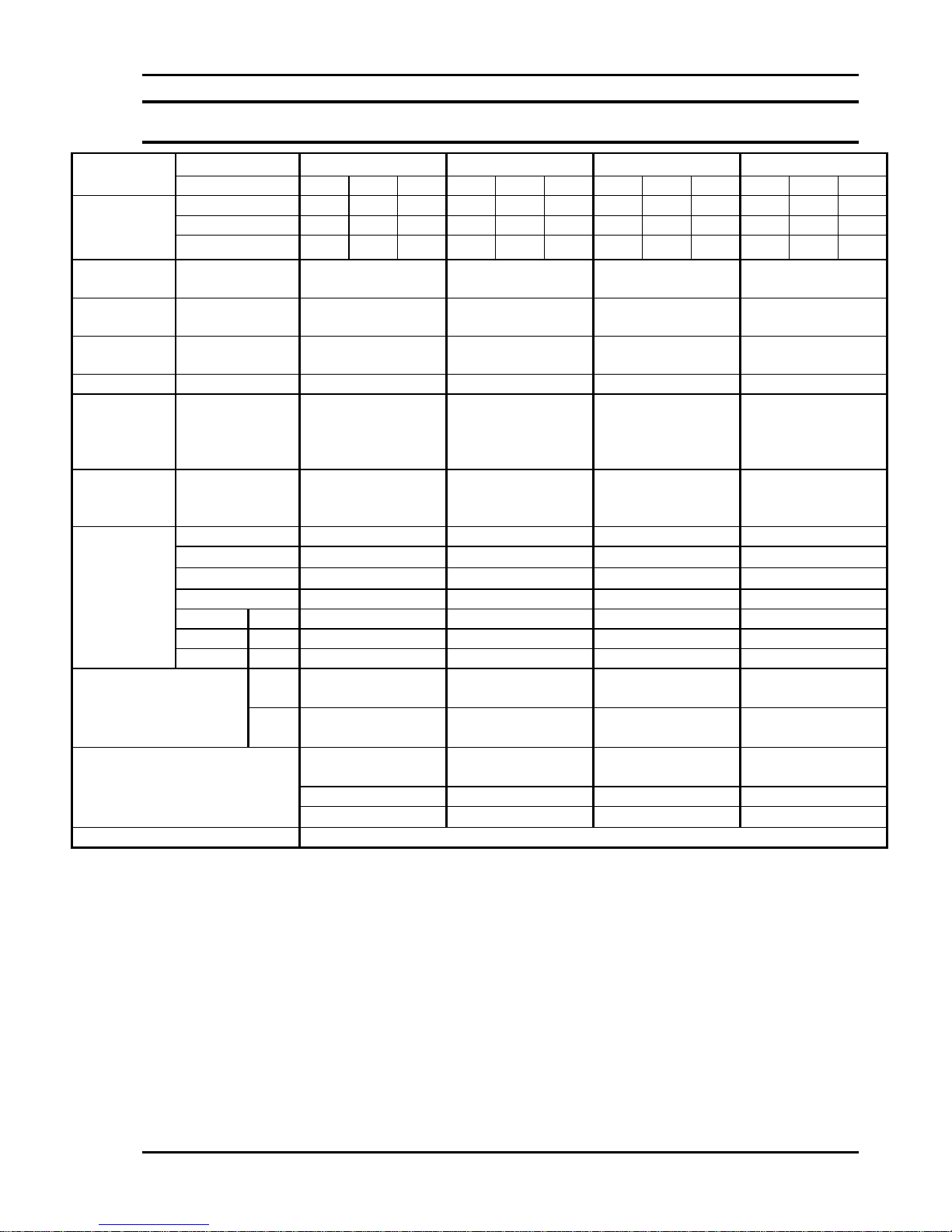

6.0 TECHNICAL DATA

UNIT

Ci 40 Ci 55 Ci 75 Ci 110

Pressure BAR 7 10 13 7 10 13 7 10 13 7 10 13

cfm 19 16 14 28 21 18 42 34 29 60 50 42

l/s 9.0 7.6 6.6 13.2 9.9 8.5 19.8 16.0 13.7 28.3 23.6 19.8

FAD

(Capacity)

m

3

/min 0.54 0.45 0.40 0.79 0.59 0.51 1.19 0.96 0.82 1.70 1.41 1.19

Drive

System

BELTS 2XPZ 2XPZ 2XPZ 2XPZ

Cooling Air

Vol.

L/Sec 250 250 1000 1000

Heat

Rejection

kW 5.1 7.0 9.5 13.4

Oil Fill Litres 3.5 3.5 4.0 4.0

Av. Sound

Pressure

Level

(10 Bar)

dB(A)

@ 1m

71

72

74

75

Air Outlet

Discharge

Size

DN

BSP ‘F’

DN20

3/4”

DN20

3/4”

DN25

1”

DN25

1”

Motor kW 4.0 5.5 7.5 11.0

RPM 50Hz

2890 2930 2930 2955

RPM 60Hz

3440 3480 3450 3545

IP 55 55 55 55

FLC / 380/50

A

8.5 / 9.4 11.8 / 12.9 15.7 / 17.3 (9.9) 22.8 / 14.3

o/load 415/50

A

8.1 / 8.9 11.1 / 12.2 14.7 / 16.2 (9.3) 21.2 / 13.4

Setting † 440/60

A

8.8 / 9.7 11.8 / 12.9 15.4 / 16.0 (9.7) 22.3 / 14.1

Australia:

Cable Size *

mm²

1.0 1.5 1.5 2.5

Fuse Size ♦

(MOTOR START)

A

25 32 35 35

Oils:

Factory Fill (Mineral)

SMARTLUBE CH46 SMARTLUBE CH46 SMARTLUBE CH46 SMARTLUBE CH46

High Ambient (Mineral)

SHELL CORENA S68 SHELL CORENA S68 SHELL CORENA S68 SHELL CORENA S68

Synthetic ♣

SULLUBE 32

SULLUBE 32 SULLUBE 32 SULLUBE 32

Motor Bearings SEALED BEARINGS - NO SERVICE REQUIRED

* Example as per AS3008.1.1 Selection of cables Table 12 (Column 4). Note that no

de-rating factors have been applied. Refer to AS3008.1.1 for correct selection and

installation.

♦ If circuit breakers are to be used, use only circuit breakers equivalent to MOTOR

START FUSE.

♣ Refer Champion Service if a change from mineral based oil to

synthetic is required.

† Overload settings in brackets are for Ci-75 with Star-delta starter.

Page 16

Champion Compressors Ltd. Manual No. 975203 Rev H

10

7.0 INSTALLATION AND PRE START CHECKS

WARNING: Incorrect Installation May Void War ranty.

Before installing your Champion Compressor check carefully for any transport

damage. Contact Champion Compressors immediately if any such damage is

found.

7.1 Location

The compressor cabinet as supplied is not weather-proof, and the compressor

should be installed inside (or in a sheltered location outside). The compressor

should be installed in such a way that the locations with respect to walls and

ceiling meet the requirements of the model general assembly diagrams.

(Refer Section 27).

The compressor must be placed on a flat surface and it must remain level at

all times. Packing shims should be used to level the compressor. The unit

must not be securely bolted down. When the need exists location pins should

be used.

IMPORTANT: Locate the compressor in an adequately ventilated area. Hot

air from the discharge duct must not recirculate to the air intake. Do not install

in an area where exhaust fumes from other equipment can be drawn into the

intake (or other toxic, noxious or corrosive fumes, chemicals or substances).

Where more than one compressor is installed in one location, not only must

proper care be taken with regard to access to each individual machine, but

special attention should be taken to ensure that there is no possibility of the

heated cooling air discharge from any one machine being directed into the

intake of another machine.

7.2 Connection To Air System

The compressor is supplied with either a 3/4” Gate valve (Ci 40/55) or 1” Gate

Valve (Ci 75/110) loose for installation into to ends of the compressor’s air

receiver. The connecting plant airline connection should be at least the size

of the prescribed gate valve, and if the pipe run is of any great length, the pipe

sizes should be increased by one size to minimise any pressure drop.

Note

: In base mount option configuration, the pressure switch is

supplied loose (on a 2m fly lead). This must

be fitted into the air supply

to provide a control signal for correct compressor operation.

Page 17

Champion Compressors Ltd. Manual No. 975203 Rev H

11

7.3 Electrical Connection

The electrical installation must be checked by a licensed electrician to ensure

that it is adequate for starting and running the compressor. Refer to Section 6

- ‘Technical Data’.

NEUTRAL CONNECTION IS REQUIRED ON SOME MODELS.

Champion Compressors has provided a circuit diagram at the rear of this

operator’s manual

.

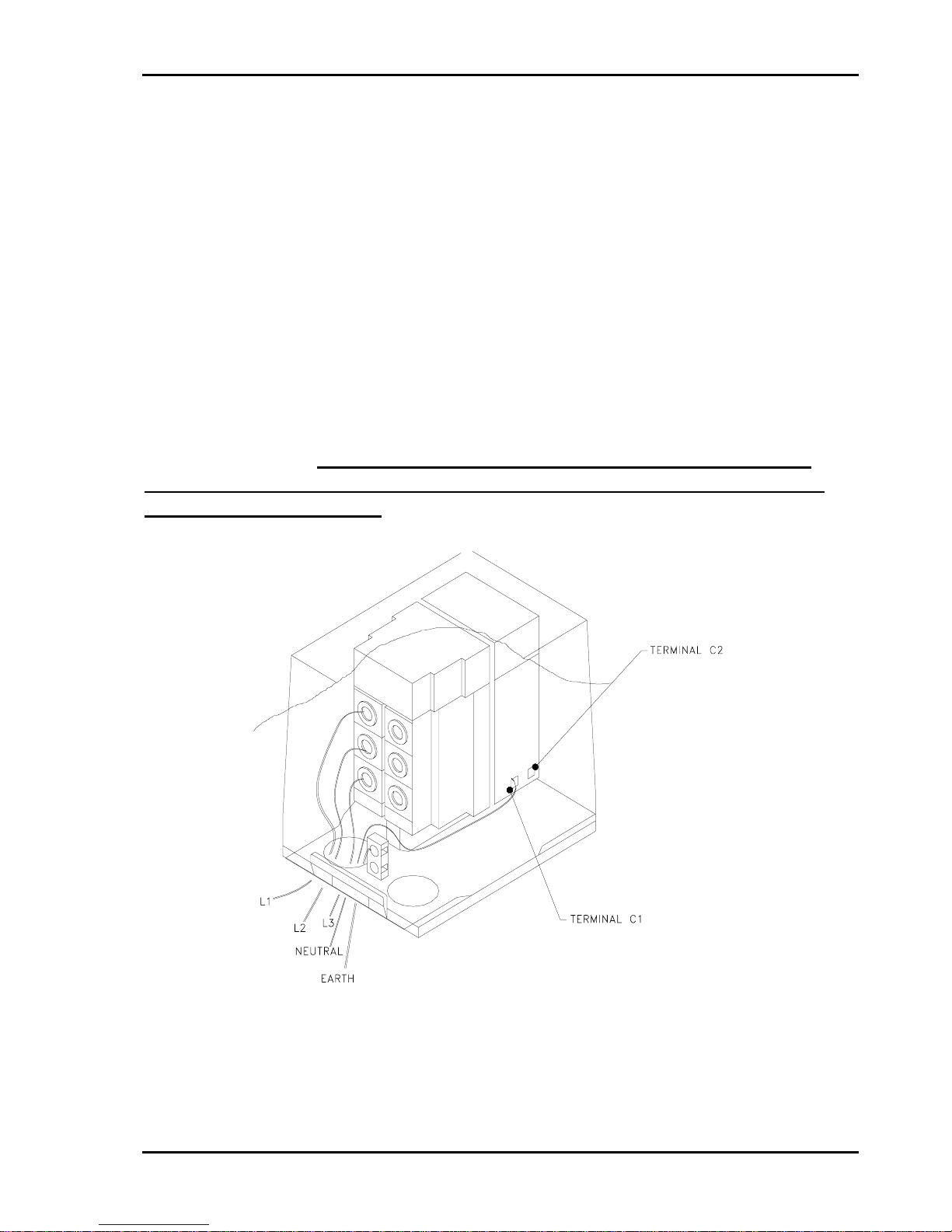

7.3.1 Ci 40 - 75 (Stop / start control)

All the mains supply leads connect to the compressor within the cover of the

combination pressure switch and starter. There is connection for 3 phases,

earth and neutral. Note: The neutral connection is made on the shunt

relay contact block (located inside pressure switch cover), at terminal

‘C1’ marked on the relay. Please refer to circuit diagram supplied with your

machine.

Note:- A No-Neutral option is available for your compressor. Please contact

Champion Compressor’s customer support department for assistance.

Fig. 1 - Electrical Connection Ci 75 (Stop / Start Control)

Page 18

Champion Compressors Ltd. Manual No. 975203 Rev H

12

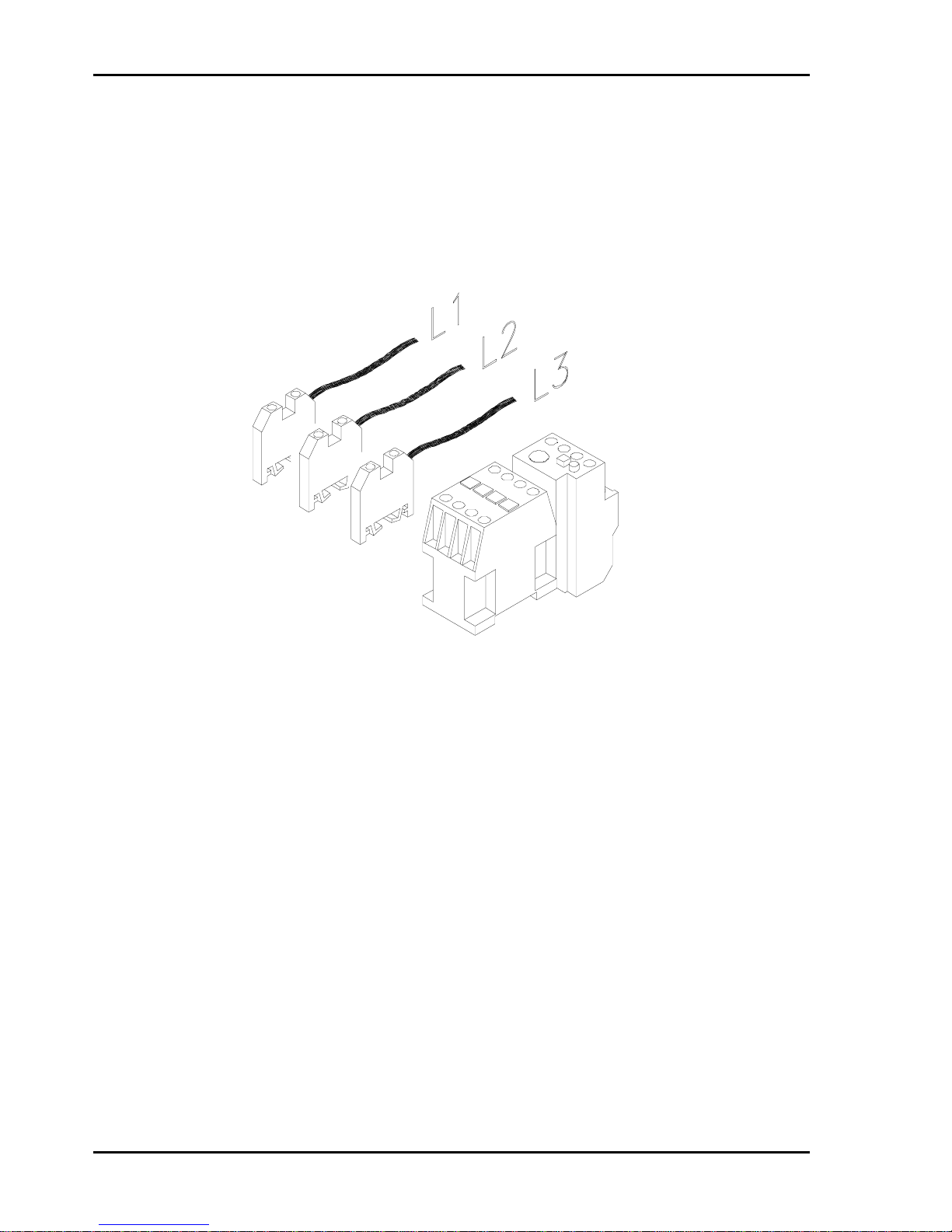

7.3.2 Ci 75 / 110 (Star-delta, CSU)

The main supply leads connect to the compressor through conduit entry

points on both the cabinet panels and electrical enclosure. The three phase

wires connect directly to terminals marked. Connection of the earth wire

should be bolted to the starter enclosure using the M6 earthing bolt provided.

Please refer to the circuit diagram supplied with your machine.

Fig. 2 - Electrical Connection - Ci75SD - 110

7.3.3 Motor Rotation Direction

The power supply must be correctly connected for the motor to rotate in the

correct direction. This can be checked by toggling the Off/Auto switch located

on the pressure switch / starter (Stop / Start) or the compressor lid (StarDelta, CSU). Note that if your machine is fitted with an auto restart facility,

there may be a delay of up to 30 seconds after toggling the Off/Auto switch.

The motor and airend rotate in the direction indicated by the arrow marked ‘D’

on the airend and motor fan cowling (anti-clockwise viewed from drive shaft

end). In the event that the motor has been disconnected or removed for

service reasons, ensure that the power supply is reconnected in the correct

sequence prior to start-up.

Change incoming power leads only. Refer to Work instruction Q36-34a

for correct wiring sequence.

WARNING: Rotation in the wrong direction will damage the airend and

will void warranty.

Page 19

Champion Compressors Ltd. Manual No. 975203 Rev H

13

7.4 Mechanical Checks

WARNING: Ensure that the machine is electricall y isolated before

checks are made.

7.4.1 Airend Check

Ensure that the airend is not hydro-locked by rotating the driven pulley by

hand through two complete revolutions.

7.4.2 Oil Level Check

Sight glasses are used to check both dynamic and static oil levels on these

models. The upper sight glass is used to check the static oil level, whilst the

lower sight glass is used to check the dynamic level.

Top-ups: Add prescribed grade of oil. Ensure that the oil filler cap is firmly

secured and seated properly on the seal, do not over tension.

7.4.3 Vee Belt Check

Pulley alignment must be checked by using a straight edge to confirm that the

pulley faces are flush, and drive shafts parallel. The maximum misalignment

allowable is 0.5mm.

Check that all belts are seated in their grooves. The belt tension is

maintained by sliding the motor, via adjusting jacking bolts located at the feet

of the motor. Correct belt tension is achieved with the use of a Tensiometer

(Champion Part No. 270965). Refer to Figure 3. Set the large o-ring so that

the o-ring bottom is at the 7mm mark. Ensure that the small o-ring is set at

the zero mark. Hold the top of the Tensiometer and press it at right angles to

the belts, midway between the airend pulley and motor pulley into one of the

v-belts. When the bottom of the large o-ring is level with the top of the other

belts stop pressing it in and read the kilogram figure off the bottom of the

small o-ring. Move the small o-ring back to the zero mark and repeat the

operation for the other belts. Record the results.

Rotate the motor pulley through one complete revolution and measure the

belts again, recording the results. Once again rotate the motor pulley and

take another set of readings. Average three sets of readings to ascertain a

belt tension figure.

Page 20

Champion Compressors Ltd. Manual No. 975203 Rev H

14

The belt tension must be adjusted between the minimum, maximum and initial

values (1.3 x Maximum) listed in the table below:

Model Minimum Maximum Initial

Ci 40 1.3 kg 1.8 kg 2.3 kg

Ci 55 1.4 kg 2.0 kg 2.6 kg

Ci 75 1.5 kg 2.1 kg 2.7 kg

Ci 110 1.9 kg 2.7 kg 3.6 kg

New belts should be initially tensioned to 1.3 times the maximum running

tension settings outlined above. Belt tension needs to be adjusted five

minutes after these belts are fitted and the compressor is run, then again ten

minutes later. This will ensure that the belts have completed their initial

“stretch”. After this first fifteen minutes of operation, the belts should be

correctly tensioned to the table above.

Fig. 3 - Belt Tensiometer Part Number 270965

7.4.4 System Isolating Gate Valve Check

Check that the isolating gate valve fitted to the compressor is open.

Page 21

Champion Compressors Ltd. Manual No. 975203 Rev H

15

8.0 OPERATION

8.1 Start-Up Procedure

If the compressor has not been started for a period of two months or longer,

carry out all the pre-start checks outlined in Section 7 prior to starting

machine.

1. Drain moisture from the compressors’ air receiver.

2. Drain any water that has condensed in the oil sump, (See Section 10.2)

3. Check that the proper oil level is visible in the upper oil sight glass.

Top up if necessary. Warning : Allow five minutes for oil level to settle

before opening the filler plug.

4. Ensure the isolating valve is opened.

5. Turn the ‘Off-Auto’ switch to auto (located on the lid on Star-delta

models) or adjust the lever to the ‘Auto’ position indicated on the

pressure switch (Stop/Start models).

Warning : Do not restart the unit within 30 seconds of shutdown. This allows

the separator vessel to fully vent, and prevents starting against load.

Should the machine show any excessive vibration, shut down and

contact the Champion Customer Support Division immediately.

To shut the compressor down, turn the ‘Off-Auto’ switch to the Off position

(Star-delta models) or move the lever on the pressure switch to the OFF

position (Stop/Start Models).

8.2 Function Of Controls

8.2.1 Stop / Start (Standard Ci 40 - 75):

The On / Off control, and system pressure gauge for the Ci 40 - 75 machines

is located on the pressure switch / starter assembly. While the switch is in the

‘Auto’ position, the machine will start and stop according to system pressure.

For directions on setting the pressure switch cut-in and cut-out pressures,

refer to section 8.3.

Page 22

Champion Compressors Ltd. Manual No. 975203 Rev H

16

8.2.2 Star-delta, CSU (Option Ci75, Standard Ci 110):

The ‘Off-Auto’ switch, emergency stop button and hour meter are located on

the lid of the machine. Unlike the Ci40 and 55 Dominators, the Ci 110 has

constant speed unloading as standard. The compressor runs off load rather

than stopping when the upper pressure setting has been reached. There is a

run on timer fitted to ensure that during periods of low air usage, the

compressor does not run unnecessarily. The factory setting of this timer is six

minutes, but it may be adjusted with specific installation requirements. Please

refer to Champion Compressors prior to any adjustments being made, as an

incorrect setting may result in damage to the compressor.

The compressor may start at any time whilst the compressor is in ‘Auto’ mode.

Please note that if your machine is fitted with Auto Restart option, there may

be a starting delay of up to 30 seconds after powering up the compressor. If

the emergency stop button is used to stop the compressor or to cut power to

the compressor, the Auto/Off switch must be toggled to restart the

compressor.

Warning : Do not remove covers or attempt any service without first ensuring

the compressor is isolated from the mains power supply, as the compressor

could start at any time.

Page 23

Champion Compressors Ltd. Manual No. 975203 Rev H

17

8.3 Control Pressure Switch

The control pressure switch (tank mounted or supplied loose on base mounts

for line mounting) has been set prior to leaving the factory with the following

settings:

Nominal

Operating

Pressure

(kPa)

Nominal

Pressure

Differential

(kPa)

Load

Pressure

(kPa)

Unload

Pressure

(kPa)

780 120 660 780

1000 120 880 1000

1300 120 1180 1300

If the settings have “drifted” during transport, it will be necessary to adjust

them on site. This is accomplished as follows (refer Figure 4):

1. Remove the protective cover from the pressure switch assembly.

2. (a) To increase pressure - turn range screw clockwise

(b) To reduce pressure - turn range screw anticlockwise

3. (a) To increase differential - turn differential screw clockwise

(b) To reduce differential - turn differential screw anticlockwise

For safety reasons, under no circumstances adjust the setting differently

to the ones listed above. If different pressure settings are desired refer

to your Champion Compressors Service Agent

.

Adjust under pressure

Fig. 4 - Control Pressure Switches

Page 24

Champion Compressors Ltd. Manual No. 975203 Rev H

18

8.4 Protection Devices

The Dominator range is protected by a high oil temperature switch (set at

100°C) and a motor thermal overload (settings detailed in Section 6). On the

Stop / Start models, the temperature switch trips the motor overload (located

in the pressure switch) and this requires manual resetting (switch off / switch

on). The Star-delta, CSU models’ temperature switch disconnects power from

the starter coils, stopping the compressor. The temperature switch will

automatically reset once the unit has cooled down. The Star-delta, CSU

models motor overload (located in the enclosure) once tripped, must be

manually reset. After any fault, the Off/Auto switch must be toggled to start

the compressor.

In all instances of compressor stopping due to a protecti on tr ip, urgent

action must be taken to rectify the fault prior to the compressor being

restarted.

8.5 Thermo Bypass-Valve

All the Dominator series compressors are fitted with thermo bypass valves.

This valve insures optimum oil temperature (approx. 70°C) during periods of

low load cycles or on cold days. This valve will prevent excessive

condensation build up in the oil. For export machines, an 80ºC thermoslide

may be fitted to reduce water condensation in humid environments.

Page 25

Champion Compressors Ltd. Manual No. 975203 Rev H

19

9.0 OPTIONS

The following is a selection of options, which may have been ordered with

your compressor.

9.1 Lead/Lag, Remote Monitoring & Control.

A pair of compressors may be controlled by a central control box, equipping

the package with ‘Lead / Lag’, ‘Duty / Standby’, and ‘Remote monitoring and

control’ capabilities.

Lead/Lag controls allow two compressors to operate in tandem. One unit is

selected to be the lead unit and the other the lag unit. In this situation, the

lead unit will provide the base air supply for the plant requirement. The lag

unit will provide any additional air as required during peak demands. The lead

and lag functions should be alternated between the two units by regularly

reversing the selector switch on a periodic (daily or weekly) basis.

Duty/Standby operation may be selected as an alternative to Lead/Lag.

Power is supplied to one compressor only (the ‘duty’ compressor). In the

event that the ‘duty’ compressor must be stopped, (eg. routine service), the

‘standby’ compressor may be called upon so that there is no interruption to

the plant’s supply of compressed air.

NOTE:

When more than one compressor is installed with a parallel connection, care

must be taken when piping the discharge air. Incorrect piping may result in

condensate accumulating in the mains piping and draining back to a

compressor that remains idle or on Standby for a period of time. Generally,

having the compressor discharge pipework higher than the junction to the

mains piping at some point will avoid the problem.

Page 26

Champion Compressors Ltd. Manual No. 975203 Rev H

20

Remote monitoring of the compressor status, (“Fault”, “Standby”, “Run”), is

achieved by utilising the voltage-free contacts contained within the control

box.

Remote Control of the compressors is achieved by connecting a remote

switch to the terminals contained within the control box.

Two Hour Meters to record ‘hours run’ for each compressor are mounted

inside the control box. No mains neutral wire is required for compressors

fitted with this option unless the Clean Air Pack is included.

(Refer Section 9.5).

9.1.1 Central Control Box Operation.

The control box offers a number of configurations in which to operate the two

compressor units. (Refer Fig.5):

Fig. 5 - Control Panel, Central Contr ol Box

Page 27

Champion Compressors Ltd. Manual No. 975203 Rev H

21

‘Compressor A or Compressor B’ - Set the “A / B / AB” selector switch to

either ‘A’ or ‘B’ to run one compressor only. The other compressor will not

run, it can be switched to run in the event of the primary compressor being out

of service, i.e. a true ‘Duty / Standby’ application.

‘Compressor A and

Compressor B’ - Set the “A / B / AB” selector switch to

‘AB’ to supply power to both compressor units. The compressors will now run

in Lead / Lag mode, with the ‘Lead A / Lead B’ selector switch determining

which compressor will supply the base air supply for the demand. As stated

above, the Lead and Lag functions should be alternated between the two units

by regularly reversing the selector switches on a periodic (daily or weekly)

basis.

Note : The control box does not have the facility to set both units to Lead or

both to Lag. This configuration is neither useful or advisable.

‘Local or Remote Control’ - Set the “LOCAL / REM” Selector switch for each

compressor unit to start or stop the machine either locally or at a remote

location. (Refer Electrical Circuit Diagram at rear of manual).

The “EMERGENCY STOP” button will isolate power from both compressors

irrespective of the control mode selected.

Page 28

Champion Compressors Ltd. Manual No. 975203 Rev H

22

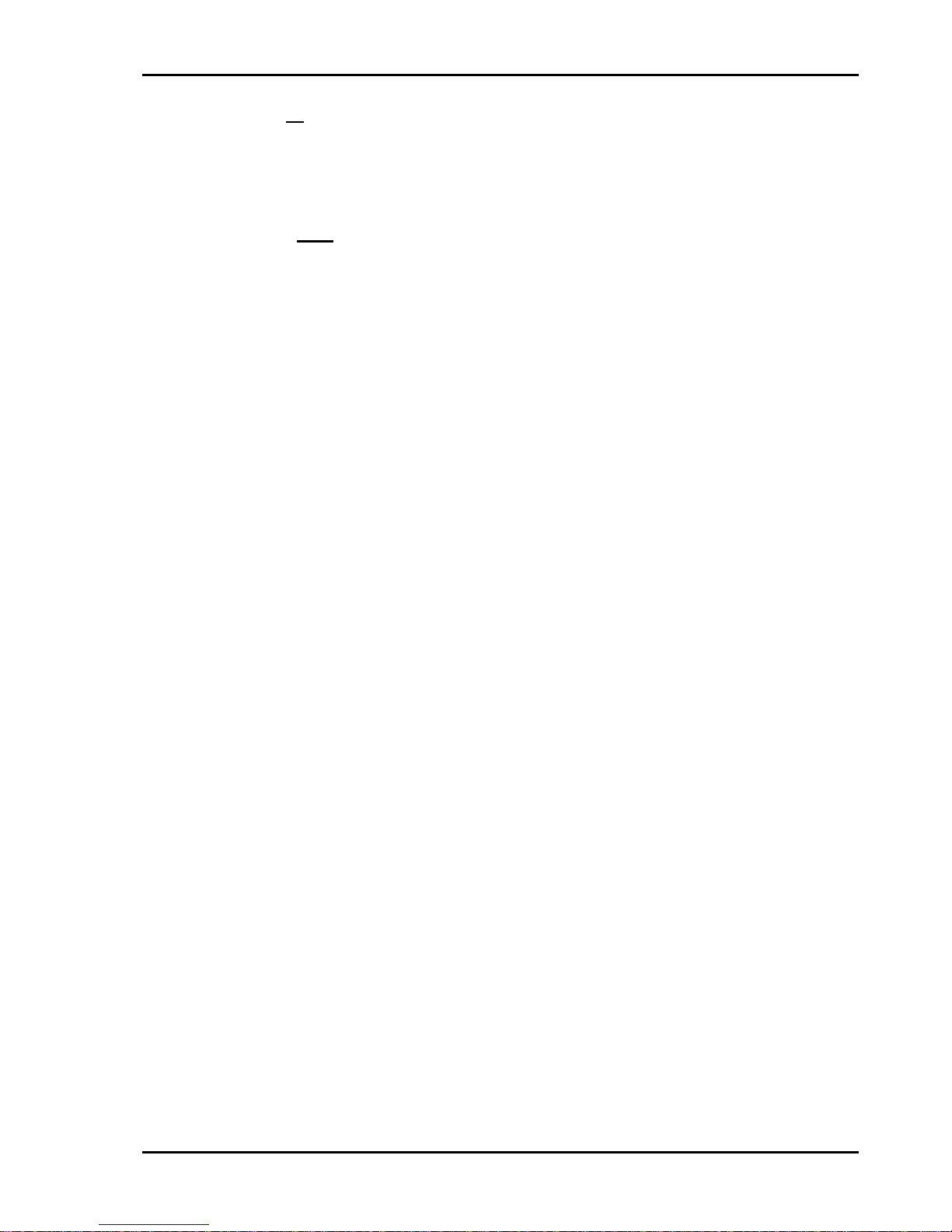

9.2 Lead/Lag Control.

Similar to the central control box, a pair of compressors may be controlled by

a lead/lag control box, equipping the package with ‘lead / lag’ capability.

Lead/Lag controls allow two compressors to operate in tandem. One unit is

selected to be the lead unit and the other the lag unit. In this situation, the

lead unit will provide the base air supply for the plant requirement. The lag

unit will provide any additional air as required during peak demands. The lead

and lag functions should be alternated between the two units by regularly

reversing the selector switch on a periodic (daily or weekly) basis.

9.2.1 Lead / Lag Control Box Operation.

The lead / lag control box offers lead / lag only in which to operate the two

compressor units. (Refer Fig.6):

Fig. 6 - Control Panel, Lead/Lag Control Box

The ‘Lead A / Lead B’ selector switch determines which compressor will

supply the base air supply for the demand. As stated above, the Lead and

Lag functions should be alternated between the two units by regularly

reversing the selector switches on a periodic (daily or weekly) basis.

Individual Start / Stop selector switches enable electrical isolation of the

motors only of one or both units.

Page 29

Champion Compressors Ltd. Manual No. 975203 Rev H

23

When a fault is detected, or the Emergency Stop button is depressed, the

machine will not start until the fault is removed and the Fault Reset button is

pressed.

9.3 Lead / Lag Pressure Switches

The central and lead / lag control boxes contain two pressure switches, (lead

and lag), which have been factory set as listed below.

Lead / Lag Pressure Switch Settings

Nominal Operating

Pressure

(kPa)

Nominal Pressure

Differential

(kPa)

Lead

Load

Pressure

(kPa)

Lead

Unload

Pressure

(kPa)

Lag

Load

Pressure

(kPa)

Lag

Unload

Pressure

(kPa)

780 80 700 780 650 730

1000 80 920 1000 870 950

If the settings have “drifted” during transport, it will be necessary to adjust

them on site. This is accomplished as follows (refer Figure 7):

1. (a) To increase pressure - turn range screw anticlockwise

(b) To reduce pressure - turn range screw clockwise

2. (a) To increase differential - turn differential screw clockwise

(b) To reduce differential - turn differential screw anticlockwise

For safety reasons, under no circumstances adjust the setting differently

to the ones listed above. If different pressure settings are required refer

Champion Compressors.

Fig. 7 - Control Pressure Switch (Central Control Box)

Page 30

Champion Compressors Ltd. Manual No. 975203 Rev H

24

9.4 Acoustic Hood (Ci 40/55).

The Ci 40/55 Dominators are available with an acoustic hood. This cabinet

helps to reduce the noise level, as well as acting as a protective cover for the

compressor. Ci75 / 110 models have the hoods fitted as standard.

9.5 Clean Air Pack (Dryer).

The clean air pack provides clean, moisture free air. A refrigerant dryer is

teamed in series with a microcoalescent filter or filters to remove any moisture

and oil carry-over in the discharge air supply.

NOTE: A 240V connection must be available for wiring of the refrigerant

dryer. The dryer must be individually wired to the supply, as it is not hardwired to the compressor electrics.

9.6 Dirty Environment Filter (Cyclopac).

For operation in dirty environments, a heavy-duty Cyclonic air filter is offered

as an externally mounted option. (Refer Section 18).

9.7 No Neutral & Hour-meter (Ci 40/55/75)

Where no neutral facility exists at the installation location, the no neutral

option may be fitted, allowing connection with three phase power leads and an

earth lead. Also included is an hour meter to record hours run, not standard

on Ci40 / 55. As stated above, if a refrigerant dryer is incorporated, a 240V

connection for single phase power supply to the dryer is necessary.

9.8 Duplex

The Duplex is a pair of Dominators mounted on a common twin air receiver,

approximately three times the volume of a standard air receiver. The

compressor units are controlled by either the 'Lead / Lag' Control box

providing ‘lead / lag’ operation (Refer Section 9.2) or the ‘Lead / Lag, Remote

Monitoring and Control’ box providing ‘duty / standby’ or ‘lead / lag’ operation

(Refer Section 9.1).

Page 31

Champion Compressors Ltd. Manual No. 975203 Rev H

25

When incorporated with the Clean Air Pack, the receivers will operate in a ‘wet

and dry’ configuration, i.e. two individual receivers separated by dryer /

filter(s). Discharge air enters the ‘wet’ receiver where some condensation

takes place, additional filtration is provided by the dryer / filter(s) before

entering the ‘dry’ receiver. An additional filter may be fitted at the discharge of

the ‘dry’ receiver.

The Dirty Environment Filter and Acoustic Hood (Ci 40 / 55) options are

available in conjunction with the Duplex option.

9.9 Base-mount

Where an air receiver or equivalent exists at the installation location, a

Dominator may be ordered without an integrated receiver. The pressure

switch is supplied loose (on a 2m fly lead) to be fitted into the air supply to

provide a control signal for correct compressor operation.

9.10 Sump Heater and Thermal Fan

A sump heater is available to enable the machine to stay warm when not in

operation and to prevent condensation from mixing with oil. This option is

advisable in the cases of a low load cycle, low ambient temperature and a

humid environment. The sump heater option requires a dedicated 240V

connection.

The thermal fan switch option is designed to suit machines with very low load

cycle operation. A temperature switch monitors oil temperature and only

switches the cooling fan on when the oil is at a minimum temperature. This

ensures the compressor achieves desired operating temperatures within a

minimum time.

9.11 Auto Restart Option

The auto restart option allows the machine to automatically restart after a 30

second delay upon the reinstatement of power following a power interruption.

9.12 Phase Failure Relay (Ci 75/110 only)

The phase failure relay option can be fitted to provide protection against

phase imbalance, phase dropout and incorrect phase sequence.

Page 32

Champion Compressors Ltd. Manual No. 975203 Rev H

26

10.0 MAINTENANCE

10.1 General

Your Dominator air compressor will give years of trouble free performance if

you ensure that it is correctly maintained. Proper maintenance will increase

the productive life of the unit and can result in large savings as a direct result

of reduced down time.

Champion Compressors offers a variety of Maintenance Management

solutions which provide regular maintenance to ensure long life and trouble

free service from your compressor. Contact your Champion Compressors

representative to arrange this service.

10.2 Daily Operation

Prior to starting drain any water from oil sump through drain valve until oil

begins to flow (Oil floats on water).

Check the oil level via the appropriate sight glass located on the integrated

screw.

Drain any water from receiver(s) where applicable.

Page 33

Champion Compressors Ltd. Manual No. 975203 Rev H

27

10.3 Maintenance Schedule

Refer to Section 2 and the ‘Parts section’ for all part numbers of items

mentioned here.

10.3.1 Initial Service - 250 hours

The oil should be changed after the first 250 hours of service, and then after

every 1,500* hours of service. Use only Champion recommended oil. (See

Section 6 for 'Recommended Lubricants')

10.3.2 Every 1,500 Hours

Change the compressor oil and oil filter (use prescribed grade only)*.

Replace the air intake filter element.

Check & adjust the belt tension. Replace as required.

Check purge line recovery pipe for blockage by observing the purge line sight

glass. If no flow is visible, the purge line should be inspected and unblocked.

Access is gained by removing the purge line sight glass.

Drain all air receivers.

* Except with long-life lubricant (synthetic), analyse sample and change if

required.

10.3.3 Every 3,000 Hours (Or Yearly)

Perform all checks listed for ‘Every 1,500 hours’ as well as the following:

Replace separator element.

Check condition of inlet controller, service if necessary.

Check condition of Minimum Pressure Valve, service if necessary.

Check condition of Thermo By-pass Valve, service if necessary.

Check that all electrical connections are tight.

Inspect all

safety devices.

Check general tightness of nuts, bolts and pipe fittings.

Check condition of Microfilter Element, replace if necessary. (Where Fitted)

WARNING - Do not attempt any maintenance when the compressor is

running or pressurised. Stop the compressor, relieve all internal

pressure and isolate the power supply before per f or ming maintenance.

Page 34

Champion Compressors Ltd. Manual No. 975203 Rev H

28

THIS PAGE HAS BEEN

LEFT BLANK

Page 35

Champion Compressors Ltd. Manual No. 975203 Rev H

29

A.R. = As Required

N.S.S. = Not Sold Separately

Page 36

Champion Compressors Ltd. Manual No. 975203 Rev H

30

11.0 GENERAL ASSEMBLY COMPONENTS - Ci 40 / 55

Page 37

Champion Compressors Ltd. Manual No. 975203 Rev H

31

11.0 GENERAL ASSEMBLY COMPONENTS - Ci 40 / 55 - (9800660 Rev G)

Item Part No. Description Qty.

1 511132 Air Receiver - 380 Dia x 1200 Long 1

2 872267 Belt Guard - 500 x 250 x 85 1

3 872364 Bracket - Belt Guard - 245 x 150 x 15 1

4 741061 Pressure Switch - MDR3RM - Ci 40 - 7 & 10 bar 1

741062 Pressure Switch - MDR3RM - Ci 55 - 7 & 10 bar 1

741049 Pressure Switch - MDR3RM - Ci 40 - 13 bar 1

740150 Pressure Switch - MDR3RM - Ci 55 - 13 bar 1

5 521295 Platform W.A. - 745 X 320 X 120 1

6 491390 Cooler / Fan Assembly - Oil 1

6a 491399 Cooler - Part of Item 6 1

6b 481236 Fan - Part of Item 6 1

Motors - 380/415 50Hz, 440V 60Hz

7 351253 Motor - 5.5 kW - 2P - IP55 - TOP - Multivoltage - Ci 55 1

351276 Motor - 4.0 kW - 2P - IP55 - TOP - Multivoltage - Ci 40 1

8 301023 Integrated Screw - Ci 40 & 55 1

9 681718 Hose Assy - 3/8” - Cooler to Airend Oil Injection 1

9a N.S.S Elbow - 9/16” JIC x 1/2” BSPP - Part of Item 9 1

9b N.S.S Nipple - 9/16” JIC x 3/8” BSPP - Part of Item 9 1

10 681717 Hose Assy - 3/8” - Airend Oil Discharge to Cooler 1

10a N.S.S Elbow - 9/16” JIC x 1/2” BSPP - Par t of Item 10 1

10b N.S.S Nipple - 9/16” JIC x 3/8” BSPT - Part of Item 10 1

11 681495 Hose Assy - 1/2” - Airend Air Discharge to Receiver 1

11a N.S.S Nipple - 3/4” JIC x 1/2” BSPT - Part of Item 11 2

12 601079 Taptite - M6 x 16 A.R

13 601037 Bolt - Hex Hd - M10 x 30 12

14 601091 Washer - M10 Mudguard 8

15 601086 Washer - M10 Spring 4

16 621010 Plug - Hex - Gal - ¼” BSP 2

17 371004 Clamp Plate - Motor - Ci 55 2

371005 Clamp Plate - Motor - Ci 40 2

18 721029 Over Temperature Switch - Oil Cooler - IP65 1

19 621066 Plug - Hex - Black - 1/2” BSPT 1

20 671004 Dowty Seal - 1/2” 1

21 601009 Washer - M10 Flat 8

22 781002 Gauge - Air Pressure - 63 Dia / 1600 kPa 1

23 541268 Valve - Safety - 1335 kPa - 1/4” BSP 1

24 601395 Grommet - 16mm 1

25 541025 Gate Valve - 3/4” 1

26 621469 Nipple - Gal - Hex Red - 1.1/2” BSPT x 3/4” BSPT 1

27 601053 Bolt - M12 x 75 - Tensioner Adjustment - Ci 55 3

601282 Bolt - M12 x 100 - Tensioner Adjustment - Ci 40 1

28 601007 Nut - ZP - M10 4

29 601017 Nut - Nyloc - M10 4

30 711079 Gland - PVC - M20 2

31 541173 Valve - Ball - 1/4"BSP M & F 1

32 711078 Reducer - PVC - 25 to 20mm 1

33 621571 Adaptor - Swivel - ¼” BSPF x 1/4” BSPM 1

33a 621609 Nipple - Hex - plt - ¼" BSPT - Seated 30 deg 1

Page 38

Champion Compressors Ltd. Manual No. 975203 Rev H

32

11.0 GENERAL ASSEMBLY COMPONENTS - Ci 40 / 55

(Continued)

Page 39

Champion Compressors Ltd. Manual No. 975203 Rev H

33

11.0 GENERAL ASSEMBLY COMPONENTS- Ci 40 / 55 (9800660 Rev G) - Continued

Item Part No. Description Qty.

Airend Pulleys

34 401312 Pulley - 2 SPZ x 106 - 1610 T/L - Ci 40 - 7 & 10 bar 1

401284 Pulley - 2 SPZ x 118 - 1610 T/L - Ci 40 - 13 bar 1

401304 Pulley - 2 SPZ x 95 - 1610 T/L - Ci 55 - 7,10 & 13 bar 1

35 411036 Taperlock Bush - Airend - 1610-25 - Ci 40 & 55 1

35a N.S.S Grub Screw - Part of Item 33 2

Motor Pulleys

36 401304 Pulley - 2 SPZ x 95 - 1610 T/L - Ci 40 - 7,10 & 13 bar 1

401312 Pulley - 2 SPZ x 106 - 1610 T/L - Ci 55 - 13 bar 1

401284 Pulley - 2 SPZ x 118 - 1610 T/L - Ci 55 - 7 & 10 bar 1

37 411172 Taperlock Bush - Motor - 1610-28 - Ci 40 1

411164 Taperlock Bush - Motor - 1610-38 - Ci 55 1

37a N.S.S Grub Screw - Part of Item 32 2

38 421101 Vee Belt - XPZ 937 - 7,10 & 13 bar 2

39 712331 Sleeving - Black - 10mm A.R.

40 631173 Bush - Reducing - ½"BSP M to 1/4"BSP F 1

Page 40

Champion Compressors Ltd. Manual No. 975203 Rev H

34

12.0 GENERAL ASSEMBLY COMPONENTS- Ci 75

Page 41

Champion Compressors Ltd. Manual No. 975203 Rev H

35

12.0 GENERAL ASSEMBLY COMPONENTS - Ci 75 - (9800657 Rev H)

Item Part No. Description Qty.

1 511135 Air Receiver 1

2 301020 Airend - Integrated Screw 1

Motors - 380/415 V 50 Hz, 440V 60Hz

3 351274 Motor - 7.5kW - 2P - TOP - IP55 - Multivoltage 1

4 491394 Cooler / Fan Assembly - Air / Oil - Emmegi 1

4a 491398 Cooler - Part of Item 4 1

4b 481235 Fan - Part of Item 4 1

5 521321 Platform W.A. 1

6 621609 Nipple - 1/4” BSPT - 30 deg Seated 1

7 601091 Washer - ZP - M10 Mudguard 4

8 681695 Hose Assembly - 1/2” - Oil Cooler to Airend Oil

Injection

1

8a N.S.S Elbow - 3/4” JIC x 1/2” BSPP 1

8b N.S.S Nipple - 3/4” JIC x 1/2” BSPP 1

9 681534 Hose Assembly - 3/4” - Airend Discharge 1

9a N.S.S Elbow - 1.1/16 JIC x 3/4” BSPT 1

9b N.S.S Elbow - 1.1/16 JIC x 1/2” BSPT 1

10 681654 Hose Assembly - 3/4” - Air Aftercooler to Receiver 1

10a N.S.S Nipple - 1” BSPT x 1” BSPT 1

10b N.S.S Elbow - 1.1/16” JIC x 3/4” BSPT 1

11 681696 Hose Assembly - 1/2” - Oil Discharge to Cooler Inlet 1

11a N.S.S Elbow - 3/4” JIC x 1/2” BSPP 1

11b N.S.S Nipple - 9/16” JIC x 1/2” BSPP 1

12 872539 Panel - Belt Guard Cover 1

15 601037 Bolt - Hex Hd - M10 x 30 8

16 872538 Panel - Belt Guard 1

17 872442 Angle - Door 2

18 872391 Panel - Rear 1

19 872313 Panel - Compressor Lid 1

20 872315 Panel - Door 1

21 872390 Panel - Front 1

22 601079 T aptite - M6 x 16 A.R

23 781009 Hour Meter - 48 Sq. - 240V 1

23a N.S.S Bracket - Hourmeter 1

24 9800673-4 Sound Foam - Front Panel - Cut Out 1

25 9800673-3 Sound Foam - Front Panel - Large 1

26 9800673-2 Sound Foam - Front Panel - Small 1

27 741063 Pressure Switch - MDR 3RM- 7 & 10 bar 1

741056 Pressure Switch-MDR 3RM - 13 bar 1

28a 861018 Seal Strip - 15 mm wide 2

28b 861018 Seal Strip - 15 mm wide 2

29 861035 Door Catch Kit - Black - 1000-V349 1

30 601086 Washer - ZP - Spring - M10 8

31 721029 Over Temperature Switch - Oil Cooler - IP65 1

Page 42

Champion Compressors Ltd. Manual No. 975203 Rev H

36

12.0 GENERAL ASSEMBLY COMPONENTS- Ci 75

(Continued)

Page 43

Champion Compressors Ltd. Manual No. 975203 Rev H

37

12.0 GENERAL ASSEMBLY COMPONENTS - Ci 75 - (9800657 Rev H) - Continued

Item Part No. Description Qty.

32 9800673-5 Sound Foam - Roof Panel - Rear 1

33 9800673-7 Sound Foam - Roof Panel - Front 1

34 9800673-1 Sound Foam - Rear Panel 1

35 541173 Valve - Ball - 1/4"BSP M & F 2

36 631173 Bush - Reducing - 1/2"BSP M to 1/4"BSP F 2

37 9800673-8 Sound Foam - Right End Panels 2

38 9800673-6 Sound Foam - Service Door 1

39 9800673-9 Sound Foam - Lef t End Panels 2

40 371004 Clamp Plate - Motor 2

44 601007 Nut - ZP - M10 4

45 861089 Handle - Pocket - Ci Series 2

46 601129 Nut - Nyloc - M10 4

47 601007 Washer - Flat - M10 8

48 621220 Nipple - Gal - 1” 1

49 541026 Gate Valve - 1” BSP 1

50 621067 Plug - Hex Blk - 3/4” BSPT 1

51 621064 Plug - Hex Blk - 1/8” BSPT 2

52 781002 Gauge - Air Pressure - 63 Dia/1600 kPa - Rear Entry 1

53 601053 Bolt - ZP - M12 x 75 2

54 601282 Bolt - ZP - M12 x 100 2

58 541268 Valve - Safety - 1/4” BSP - 1335 kPa - 6mm orifice 1

59 601395 Grommet - 16mm 1

60 621571 Adaptor - Swivel - 1/4” BSPF x 1/4” BSPM 1

61 711078 Reducer - PVC - 25/20 2

62 711079 Cable Gland - PVC - M20 2

63 601035 Bolt - Hex Hd - M10 x 20 4

Motor Pulleys

70 401313 Pulley - 2 SPZ x 160 PD - 2012 T/L 1

Airend Pulleys

71 401319 Pulley - 2 SPZ x 112 PD - 1610 T/L - 7 bar 1

401315 Pulley - 2 SPZ x 125 PD - 1610 T/L - 10 bar 1

401307 Pulley - 2 SPZ x 132 PD - 1610 T/L - 13 bar 1

72 421107 Vee Belt - XPZ1080 2

73 411002 Taperlock - Motor - 1210-38 1

73a N.S.S Grub Screw - Part of Item 63 2

74 411036 Taperlock - Airend - 1610-25 1

74a N.S.S Grub Screw - Part of Item 74 2

Star Delta Option (replaces items 19, 28, 32, 33 &

45)

75 872441 Panel - Compressor Top 1

Page 44

Champion Compressors Ltd. Manual No. 975203 Rev H

38

12.0 GENERAL ASSEMBLY COMPONENTS- Ci 75

(Continued)

Page 45

Champion Compressors Ltd. Manual No. 975203 Rev H

39

12.0 GENERAL ASSEMBLY COMPONENTS - Ci 75 - (9800657 Rev H) - Continued

Item Part No. Description Qty.

76 861018 Seal Strip - 15mm wide A.R

77 861089 Handle - Pocket - Ci Series 1

78 861099 Gas Strut - 200N - 210 Stroke 1

79 872440 Panel - Electrical Door 1

80 9800747-5 Sound Foam - Roof Panel - Front 2

81 9800747-3 Sound Foam - Roof Panel - Top Large 2

82 9800747-9 Sound Foam - Roof Panel - Top Small 1

Page 46

Champion Compressors Ltd. Manual No. 975203 Rev H

40

13.0 GENERAL ASSEMBLY COMPONENTS- Ci 110

Page 47

Champion Compressors Ltd. Manual No. 975203 Rev H

41

13.0 GENERAL ASSEMBLY COMPONENTS - Ci 110 - (9800745 Rev E)

Item Part No. Description Qty.

1 511135 Air Receiver 1

2 301020 Airend - Integrated Screw 1

Motors - 380/415/440 V 50 Hz, 440V 60Hz

3 351259 Motor - 11kW - 2P - TOP- IP55 - Multivoltage 1

4 491394 Cooler / Fan Assembly - Air / Oil - Emmegi 1

4a 491398 Cooler - Part of Item 4 1

4b 481235 Fan - Part of Item 4 1

5 521302 Platform W.A 1

6 872441 Panel - Compressor Top 1

7 872391 Panel - Rear 1

8 872390 Panel - Front 1

9 872538 Panel - Belt Guard 1

10 872539 Panel - Belt Guard Cover 1

11 872315 Panel - Door 1

12 872440 Panel - Electrical Door 1

13 872316 Angle - Door 2

14 861076 Hinge Set 2

15 861035 Door Catch Kit - Black - 1000-V349 1

16 9800747-5 Sound Foam - Roof Panel - Front 1

17 9800747-3 Sound Foam - Roof Panel - Top Large 1

18 9800747-9 Sound Foam - Roof Panel - Top Small 1

19 9800747-6 Sound Foam - Right End Panels 2

20 9800747-7 Sound Foam - Left End Panels 2

21 9800747-4 Sound Foam - Service Door 1

22 9800747-1 Sound Foam - Rear Panel 1

23 9800747-2 Sound Foam - Front Panel - Cut Out 1

23a 9800747-8 Sound Foam - Front Panel - Large 1

24 9800747-10 Sound Foam - Front Panel - Small 1

25 601091 Washer - ZP - M10 Mudguard 4

26 601053 Bolt - ZP - M12 x 75 2

27 601007 Nut - ZP - M10 4

28 601129 Nut - Nyloc - M10 4

29 601007 Washer - Flat - M10 8

30 891089 Handle - Pocket Compressor Cover 1

31a 861018 Seal Strip - 15 mm wide 2

31b 861018 Seal Strip - 15 mm wide 2

32 421107 Vee Belt - XPZ1080 - Ci 75/110 - All pressures 2

33 861099 Gas Strut - 200 N - 210 Stroke 1

34 621067 Plug - Hex Blk - 3/4” BSPT 1

35 371007 Clamp Plate - Motor - 254 mm 2

36 541268 Valve - Safety - 1/4” BSP - 1335 kPa - 6mm orifice 1

37 721029 Over Temperature Switch - Oil Cooler - IP65 1

38 541173 Valve - Ball - 1/4"BSP M & F 2

Page 48

Champion Compressors Ltd. Manual No. 975203 Rev H

42

13.0 GENERAL ASSEMBLY COMPONENTS - Ci 110

(Continued)

Page 49

Champion Compressors Ltd. Manual No. 975203 Rev H

43

13.0 GENERAL ASSEMBLY COMPONENTS - Ci 110 - (9800745 Rev E) - Continued

Item Part No. Description Qty.

38a 631173 Bush - Reducing - 1/2"BSP M to 1/4"BSP F 2

39 541026 Gate Valve - 1” BSP 1

40 621220 Nipple - Gal - 1” 1

41 621064 Plug - Hex Blk - 1/8” BSPT 2

42 681596 Hose Assembly - 1/2” - Oil Cooler to Airend Oil

Injection

1

42a N.S.S Elbow - 3/4” JIC x 1/2” BSPP 1

42b N.S.S Nipple - 3/4” JIC x 1/2” BSPP 1

43 681534 Hose Assembly - 3/4” - Airend Discharge 1

43a N.S.S Elbow - 1.1/16 JIC x 3/4” BSPT 1

43b N.S.S Elbow - 3/4” JIC x 1/2” BSPP 1

44 681533 Hose Assembly - 3/4” - Air Aftercooler to Receiver 1

44a N.S.S Nipple - 1” BSPT x 1” BSPT 1

44b N.S.S Elbow - 1.1/16” JIC x 3/4” BSPT 1

45 681535 Hose Assembly - 1/2” - Oil Discharge to Cooler Inlet 1

45a N.S.S Nipple - 9/16” JIC x 1/2” BSPT 1

45b N.S.S Nipple - 9/16” JIC x 1/2” BSPP 1

46 741005 Pressure Switch - XMP 1

741013 Pressure Switch - XMP - 13 bar 1

47 621609 Nipple - 1/4” BSPT 2

48 621011 Tee - Gal - 1/4” BSP 1

49 781002 Gauge - Air Pressure - 63 Dia/1600 kPa - Rear

Entry

1

50 621571 Adaptor - Swivel - 1/4” BSPF x 1/4” BSPM 1

51 601079 Taptite - M6 x 16 A.R

52 601037 Bolt - Hex Hd - M10 x 30 8

53 601035 Bolt - Hex Hd - M10 x 20 4

54 601086 Washer - ZP - Spring - M10 8

55 711263 Reducer - PVC - 32/25 2

56 711078 Reducer - PVC - 25/20 2

57 711079 Cable Gland - PVC - M20 2

Airend Pulleys

58 401318 Pulley - 2 SPZ x 90 PD - 1610 T/L - 7 bar 1

401314 Pulley - 2 SPZ x 100 PD - 1610 T/L - 10 bar 1

401312 Pulley - 2 SPZ x 106 PD - 1610 T/L - 13 bar 1

59 411036 Taperlock - Airend - 1610-25 1

59a N.S.S Grub Screw - Part of Item 59 2

Motor Pulleys

60 401305 Pulley - 2 SPZ x 180 PD - 2012 T/L 1

61 411032 Taperlock - Motor - 1210-42 1

61a N.S.S Grub Screw - Part of Item 61 2

Page 50

Champion Compressors Ltd. Manual No. 975203 Rev H

44

14.0 INTEGRATED SCREW COMPONENTS- Ci 40 / 55

Page 51

Champion Compressors Ltd. Manual No. 975203 Rev H

45

14.0 INTEGRATED SCREW COMPONENTS - Ci 40 / 55 (98001013 Rev A)

Item Part No. Description Qty.

1 301023 Airend - Integrated Screw 1

2 278780 Sight Glass - Oil 2

3 N.S.S. Cap Screw 4

4 621064 Plug - 1/8” BSP Black 2

5 N.S.S. Grub Screw - 3/8” BSP 1

6 541113 Oil Drain Tap - 3/8” BSP 1

7 278905 Inlet Controller Kit 1

8 278766 Element - Air Filter 1

9 278773 Element - Separator - Spin On 1

10 N.S.S. Cover - Air Filter 1

11 278879 Oil Return Orifice 1

12 278783 Safety Valve - Integrated Screw - 1500 kPa - Ci

Series

1

13 278664 Solenoid Valve - 240V - H Class Coil 1

14 278780 Sight Glass - Purge Line - Part of Sight Glass Kit 1

15 278775 Minimum Pressure Valve 1

16 N.S.S. Oil Filler Cap 1

17 N.S.S. Element - Thermovalve - 70º C 1

N.S.S. Element - Thermovalve - 80º C - Export 1

18 N.S.S. O-ring 1

19 N.S.S. Cover - Thermovalve 1

20 N.S.S. Slide - Thermovalve 1

21 N.S.S. Spring 1

22 278877 Element - Oil Filter Cartridge 1

23 N.S.S. Oil Filter Base 1

24 N.S.S. O-ring 1

25 N.S.S. O-ring 1

26 N.S.S. O-ring 1

27 N.S.S. Copper Washer 2

28 N.S.S. Copper Washer 1

29 N.S.S. Copper Washer 1

30 278859 Gasket - Inlet VV - Lower 1

31 278858 Gasket - Inlet VV - Upper 1

32 N.S.S. Plug 1

Repair Kits

278875 Kit - Thermovalve 70º-Includes Items 17,18, 20 1

278876 Kit - Thermovalve 80º-Includes Items 17,18, 20 1

278763 Kit - Airend Seals Ci 40-110 1

278874 Kit - O-rings - Includes Items 18, 24, 25, 26 1

Page 52

Champion Compressors Ltd. Manual No. 975203 Rev H

46

15.0 INTEGRATED SCREW COMPONENTS- Ci 75 / 110

Page 53

Champion Compressors Ltd. Manual No. 975203 Rev H

47

15.0 INTEGRATED SCREW COMPONENTS - Ci 75 / 110 - (9800879 - Rev A)

Item Part No. Description Qty.

1 301020 Airend - Integrated Screw 1

2 278780 Sight Glass - Oil 2

3 N.S.S. Cap Screw 4

4 621064 Plug - 1/8” BSP Black 2

5 N.S.S. Grub Screw - 3/8” BSP 1

6 541113 Oil Drain Tap - 3/8” BSP 1

7 278830 Inlet Controller Kit 1

8 278767 Element - Air Filter 1

9 278765 Element - Separator - Spin On 1

10 N.S.S. Cover - Air Filter 1

11 601163 Wing Nut - M6 1

12 278783 Safety Valve - Integrated Screw - 1500 kPa - Ci

Series

1

13 278770 Solenoid Valve - 240V - H Class Coil 1

14 278780 Sight Glass - Purge Line - Part of Sight Glass Kit 1

15 278775 Minimum Pressure Valve 1

16 N.S.S. Oil Filler Cap 1

17 N.S.S. Element - Thermovalve - 70º C 1

N.S.S. Element - Thermovalve - 80º C - Export 1

18 N.S.S. O-ring 1

19 N.S.S. Cover - Thermovalve 1

20 N.S.S. Slide - Thermovalve 1

21 N.S.S. Spring 1

22 278877 Element - Oil Filter Cartridge 1

23 N.S.S. Oil Filter Base 1

24 N.S.S. O-ring 1

25 N.S.S. O-ring 1

26 N.S.S. O-ring 1

27 N.S.S. Copper Washer 2

28 N.S.S. Copper Washer 1

29 N.S.S. Copper Washer 1

30 278859 Gasket - Inlet VV - Lower 1

31 278858 Gasket - Inlet VV - Upper 1

32 671155 O-ring - BS137 Viton 1

33 671156 O-ring - BS012 Viton 1

34 N.S.S. Plug 1

35 278879 Oil Return Orifice 1

Repair Kits

278875 Kit - Thermovalve 70º-Includes Items 17,18, 20 1

278876 Kit - Thermovalve 80º-Includes Items 17,18, 20 1

278763 Kit - Airend Seals Ci 40-110 1

278874 Kit - O-rings - Includes Items 18, 24, 25, 26 1

Page 54

Champion Compressors Ltd. Manual No. 975203 Rev H

48

16.0 ELECTRICAL STARTER ASSEMBLY - Ci75SD/110

Page 55

Champion Compressors Ltd. Manual No. 975203 Rev H

49

16.0 ELECTRICAL STARTER ASSEMBLY - Ci75SD / 110 - (9800746 Rev C)

Item Part No. Description Qty.

Internal Electrical

1 712184 Transformer - 415/240V - 60 VA 1

712396 Transformer - 60VA Multi-Input To 240V - Export

Option Only

1

2 712116 Timer - Run On Timer - Off Delay - Mode D 1

3 711063 Relay Base - 2 Pole 2

711063 Relay Base - 2 Pole - Auto Start Option 1

712247 Relay Base - 8 Pin - Auto Start Option 1

4 711062 Relay - 240V AC - 2 Pole 2

711062 Relay - 240V AC - 2 Pole - Auto Start Option 1

712218 Relay - 240V AC - Latching - Auto Start Option 1

5 712359 Phase Failure Relay - Export Option 1

6 712116 Timer - Auto Start - Mode A - Auto Start Option 1

7 711349 Terminal Block - Earth 2

8 711048 Terminal Block 4

9 601079 Taptite - M6 X 16 2

10 711137 Din Rail - 35 x 8 - Omega A.R.

11 712029 Contactor - Line/Delta - CL03 - A301MR - GE 2

12 712044 Overload - 10-16 A - GE - Ci 110 1

712043 Overload - 8-12 A - GE - Ci 75SD 1

13 712205 Interlock - Mechanical - Electrical - bela 1

14 712027 Contactor - Star - CL02 - A301TR - GE 1

15 712162 Timer - Star Delta 1

16 711075 Fuse Holder 3

17 N.S.S Cover - Fuse Holder - Part of Item 17 3

18 711222 Fuse Link - 4A 1

19 711221 Fuse Link - 2 A 2

20 711075 Fuse Holder - Export Option 1

21 N.S.S Cover - Fuse Holder - Part of Item 4 - Export Option 1

22 711221 Fuse Link - 2A - Export Option 1

23 711221 Fuse Link - 2A - Heater Pad Option 1

24 712255 Terminal Block - Suit 4 mm Cable 3

25 711048 Terminal Block - Heater Pad Option 4

26 711046 Terminal End Cover 2

711046 Terminal End Cover - Heater Pad Option 1

27 711462 Cable Gland - M16 4

27a N.S.S. Nut - Cable Gland 4

28 711079 Cable Gland - M20 2

28a N.S.S. Nut - Cable Gland 2

29 711140 Duct - Grey PVC - 30 x 60 A.R

29a N.S.S. Duct - Grey PVC - Cover A.R

External Electrical

30 712157 Contact Block - Power Supply 1

31 712002 Contactor - N/O 2

32 712003 Contactor - N/C 3

Page 56

Champion Compressors Ltd. Manual No. 975203 Rev H

50

16.0 ELECTRICAL STARTER ASSEMBLY - Ci75SD/110

(Continued)

Page 57

Champion Compressors Ltd. Manual No. 975203 Rev H

51

16.0 ELECTRICAL STARTER ASSEMBLY - Ci75SD / 110 - (9800746 Rev C) Continued

Item Part No. Description Qty.

33 712004 Emergency Stop Button 1

33a N.S.S Locknut - Button 1

34 712067 On/Off Switch - 2 Position 1

34a N.S.S Locknut - Button 1

35 712160 Reset Button - Auto Restart Option 1

35a N.S.S Locknut - Button 1

36 781009 Hour Meter 1

36a N.S.S. Hour Meter Bracket 1

37 671139 Gasket Hour Meter 1

Page 58

Champion Compressors Ltd. Manual No. 975203 Rev H

52

17.0 CLEAN AIR PACK ASSEMBLIES

Page 59

Champion Compressors Ltd. Manual No. 975203 Rev H

53

17.0 CLEAN AIR PACK ASSEMBLIES - (9800668 Rev E)

Item Part No. Description Qty.

Clean Air Pack Components - Ci 40 & Ci 55

*1 182006 Refrigerated Dryer - Champion CRD006 1

182009 Refrigerated Dryer - Champion CRD009 1

2 521326 Mount W.A - Dryer 2

521329 Mount W.A - Dryer 2

3 681699 Hose Assy - ¾” - Receiver to Dryer 1

3a N.S.S Nipple - 3/8” BSPT x ½” BSPT - Part of Item 3 1

3b N.S.S Elbow - ½” BSP x ¾” JIC - Part of Item 3 1

4 211556 Micro Filter - Champion G5ZD 1

211756 G5ZD Filter Element 1

5 621561 Nipple - Hex Red - 3/8” BSPT x ½” BSPT -

CRD009

1

621700 Nipple - Hex - 3/8” BSPT - CRD006 1

6 621559 Elbow - ½” BSPF Swivel x ½” BSPT - CRD009 1

621819 Elbow -3/8” BSPF Swivel x 3/8” BSPT - CRD006 1

7 541025 Gate Valve - ¾” - CRD009 1

541024 Gate Valve - ½” - CRD006 1

8 621562 Nipple - Hex Red - ¾” BSPT x ½” BSPT - CRD009 1

621561 Nipple - Hex Red - ½” BSPT x 3/8” BSPT -

CRD006

1

9 601147 Taptite - Hex - Washer Face - M8x36 4

10 601037 Bolt - M10 x 30 4

11 601091 Washer - M10 Mudguard 4

12 601086 Washer - M10 Spring 4

Clean Air Pack Components - Ci 75 & Ci 110

*15 182012 Refrigerated Dryer - Champion CRD012 1

182018 Refrigerated Dryer - Champion CRD018 1

16 521327 Dryer Mount W.A - CRD012 2

521328 Dryer Mount W.A - CRD018 2

17 681700 Hose Assy - ¾” 2

18 621593 Elbow - 1/2” BSPT X 1.1/16”JIC 2

19 621592 Elbow - ¾” BSPT X 1.1/16”JIC 1

20 621593 Elbow - 1/2” BSPT X 1.1/16”JIC - CRD012 1

621592 Elbow - ¾” BSPT X 1.1/16”JIC - CRD018 1

21 621562 Nipple - Hex Red - ¾” BSPT x ½” BSPT - CRD012 1

621566 Nipple - Hex Red - 1” BSPT x ¾” BSPT - CRD018 1

22 872540 Bracket - Micro Filter 1

23 601440 Screw - Socket Head - M8x110 2

24 601004 Washer - M8 Flat 2

25 601157 Nut - Nyloc - M8 2

26 601002 Taptite - Cross Recess - Pan Hd - M6 2

27 601037 Bolt - M10 x 30 4

28 601091 Washer - M10 Mudguard 4

*: For Service and spares instruction - Refer to separate dryer manual supplied with compressor

Page 60

Champion Compressors Ltd. Manual No. 975203 Rev H

54

17.0 CLEAN AIR PACK ASSEMBLIES

(Continued)

Page 61

Champion Compressors Ltd. Manual No. 975203 Rev H

55

17.0 CLEAN AIR PACK ASSEMBLIES - (9800668 Rev E) - Continued

29 601086 Washer - M10 Spring 4

30 601147 Taptite - Hex - Washer Face - M8x36 4

31 211560 Micro Filter - Champion G7ZD 1

211760 G7ZD Filter Element 1

32 541025 Gate Valve - ¾” - CRD012 1

541026 Gate Valve - 1” - CRD018 1

Various Filter Arrangements Available

211551 Micro Filter - Champion G3V

211751 G3V Filter Element

211552 Micro Filter - Champion G3ZP

211752 G3ZP Filter Element

211553 Micro Filter - Champion G3XP

211753 G3XP Filter Element

211554 Micro Filter - Champion G3A**

211754 G3A** Filter Element

211555 Micro Filter - Champion G5V

211755 G5V Filter Element

211556 Micro Filter - Champion G5ZP

211756 G5ZP Filter Element

211557 Micro Filter - Champion G5XP

211757 G5XP Filter Element

211558 Micro Filter - Champion G5A**

211758 G5A** Filter Element

211559 Micro Filter - Champion G7V

211759 G7V Filter Element

211560 Micro Filter - Champion G7ZP

211760 G7ZP Filter Element

211561 Micro Filter - Champion G7XP

211761 G7XP Filter Element

211562 Micro Filter - Champion G7A**

211762 G7A** Filter Element

*: For Service and spares instruction - Refer to separate dryer manual supplied with compressor

**: Series A filters are supplied with manual drain and no differential pressure gauge

Page 62

Champion Compressors Ltd. Manual No. 975203 Rev H

56

18.0 CYCLOPAC AIR INTAKE ASSEMBLIES

Page 63

Champion Compressors Ltd. Manual No. 975203 Rev H

57

18.0 CYCLOPAC AIR INTAKE ASSEMBLIES - (9800688 Rev D)

Item Part No. Description Qty.

Ci 40 - 55

1 561354 Clamp - Hose - Worm Drive - 40 to 60 mm 4

2 561096 Rubber - 90 Deg Elbow 1

3 681570 Tube - Aluminised - 2” - 300 X 270 1

4 681582 Hose - Rubber - 2” id x 105 Long 1

5 561051 Mounting Band - Cyclopac - 5.21 id 2

6 561049 Filter - Air - Cyclopac - FWA05-2526 1

6a N.S.S. Air Filter Body - 5” 1

6b 270092 Element - Air Filter - 5” 1

6c N.S.S. Filter Body Clamp 1

6d N.S.S. Standard Cup Assembly 1

7 601004 Washer - Flat - Zinc PL 4

8 601086 Washer - Spring - Zinc PL 4

9 601003 Nut - Hex - Zinc PL - M8 4

10 601006 Bolt - Hex Hd - Zinc PL - M8 x 20 4

11 631025 Tube Fitting - Str Conn - ¼” x 1/8” BSPM 1

12 681002 Tube - ¼” Nylon A.R.

13 631024 Tube Fitting - Elbow - ¼” x 1/8” BSPM 1

Ci 75 - 110

14 861077 Seal Strip - P. Mould - Nitrile 1

15 N.S.S. Air Filter Cover 1

16 561200 Clamp - Hose - Worm Drive - 35 to 53 mm 1

17 561354 Clamp - Hose - Worm Drive - 40 to 60 mm 3

18 561454 Reducer - Rubber - 2” to 1 ½” 1

19 681583 Tube - Aluminised - 2” - 80 x 80 1

20 681582 Hose - Rubber - 2” id x 80 Long 1

21 561049 Filter - Air - Cyclopac - FWA05-2526 1

21a N.S.S. Air Filter Inlet Hood 1

21b N.S.S. Air Filter Body - 5” 1

21c 270092 Element - Air Filter - 5” 1

21d N.S.S. Filter Body Clamp 1

21e N.S.S. Standard Cup Assembly 1

22 561051 Mounting Band - Cyclopac - 5.21 id 2

23 601006 Bolt - Hex Hd - Zinc PL - M8 x 20 4

24 601004 Washer - Flat - Zinc PL 4

25 601086 Washer - Spring - Zinc PL 4

26 601003 Nut - Hex - Zinc PL - M8 4

Page 64

Champion Compressors Ltd. Manual No. 975203 Rev H

58

19.0 ACOUSTIC HOOD ASSEMBLY

Page 65

Champion Compressors Ltd. Manual No. 975203 Rev H

59

19.0 ACOUSTIC HOOD ASSEMBLY - (9800689 Rev E)