Champion CGM7.5 Installation Manual

Installation/Operation and Service Parts Manual

Rotary-type

Conveyor Glasswasher

Model:

CGM7.5

Clockwise Rotation

3765 Champion Boulevard

Winston-Salem, NC 27105

(336) 661-1992 Fax: (336) 661-1660

Toll-free: (800) 858-4477

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

(905) 562-4195 Fax: (905) 562-4618

Toll-free: (800) 263-5798

Issue Date: 11.29.16

Manual P/N 0514433 rev. -

For machines beginning with S/N G016052106

Printed in the USA

National Service Department

In Canada: In the USA:

Toll-free: 800/ 263-5798 Toll-free: 800/ 858-4477

Tel: 905/ 562-4195 Tel: 336/ 661-1992

Fax: 905/ 562-4618 Fax: 336/ 661-1660

email: service@moyerdiebellimited.com email: service@championindustries.com

ATTENTION:

The glasswasher model no., serial no.,

voltage, Hz and phase are needed to

identify your machine and to answer

questions.

Please have this information on-hand

if you call for service assistance.

COPYRIGHT © 2016 All rights reserved Printed in the USA

Product Registration

REGISTER YOUR PRODUCT to

ACTIVATE YOUR WARRANTY.

4:34 PM 44%

Three ways to register:

• Use your mobile device to scan the QR code located on the front panel

of your machine or enter our URL http://www.champdw.us/CG.

• Visit our website at:

http://www.championindustries.com/warranty-registration

• Use the FAX FORM on the next page.

PRODUCT REGISTRATION

BY FAX

COMPLETE THIS FORM AND FAX TO:

(336) 661-1660 in the USA

1-(800) 204-0109 in Canada

PRODUCT REGISTRATION CARD

Model

Date of Installation:

Company Name:

Address:

Telephone #: ( ) ---

Serial #

(Street) Province Postal Code

Contact:

Installation Company:

Address:

Telephone #:

Contact:

FAILURE TO REGISTER YOUR PRODUCT MAY VOID YOUR WARRANTY

IMPORTANT IMPORTANT

Revision History

Revision History

We reserve the right to make changes to this manual without notice and without incurring any

liability by those changes. Equipment owners may request a revised manual, at no charge, by

calling 1 (800) 858-4477 in the USA or by calling 1 (800) 263-5798 in Canada.

Revision Revised Serial Number Revision

Date Pages Effectivity Description

11.29.16 All G016052106 Released CGM7.5 version

i

Limited Warranty

LIMITED WARRANTY

Champion Industries. (herein referred to as The Company), 3765 Champion Blvd., Winston-Salem, North Carolina 27105,

and 2674 N. Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts, as set out below.

Warranty of Machines: The Company warrants all new machines of its manufacture bearing the name "Champion"

and installed within the United States and Canada to be free from defects in material and workmanship for a period of one

(1) year after the date of installation or fifteen (15) months after the date of shipment by The Company, whichever occurs

first. [See below for special provisions relating to glasswashers.] Warranty registration must be submitted to Champion within

ten (10) days after installation either online at http://www.championindustries.com/warranty-registration or by fax on the

form provided at the front of this manual. If warranty registration is not returned to The Company within such period, the

warranty will expire after one year from the date of shipment. The Company will not assume any responsibility for extra costs

for installation in any area where there are jurisdictional problems with local trades or unions. If a defect in workmanship or

material is found to exist within the warranty period, The Company, at its election, will either repair or replace the defective

machine or accept return of the machine for full credit; provided; however, as to glasswashers, The Company's obligation

with respect to labor associated with any repairs shall end (a) 120 days after shipment, or (b) 90 days after installation,

whichever occurs first. In the event that Champion elects to repair, the labor and work to be performed in connection with

the warranty shall be done during regular working hours by The Company's authorized service technician. Defective parts

become the property of The Company. Use of replacement parts not authorized by The Company will relieve The Company of

all further liability in connection with its warranty. In no event will The Company's warranty obligation exceed The Company's

charge for the machine. The following are not covered by The Company's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or interior finish

as a result of the above, (2) Use with utility service other than that designated on the rating plate, (3) Improper connection to

utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from chemicals dispensed in excess of recommended

concentrations, (6) Failure of electrical components due to connection of chemical dispensing equipment installed by others,

(7) Leaks or damage resulting from such leaks caused by the installer, including those at machine table connections or by

connection of chemical dispensing equipment installed by others, (8) Failure to comply with local building codes,

(9) Damage caused by labor dispute.

Warranty of Parts: The Company warrants all new machine parts produced or authorized by The Company to be

free from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in material and

workmanship is found to exist within the warranty period The Company will replace the defective part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. THE COMPANY'S

WARRANTY IS ONLY TO THE EXTENT REFLECTED ABOVE. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION INDUSTRIES SHALL NOT BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE THE

EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN THE COMPANY'S DISHWASHING

MACHINES AND THE COMPANY'S PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED,

INCLUDING ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Champion Industries does not authorize any other person, including persons who deal in Champion Industries dishwashing machines to

change this warranty or create any other obligation in connection with Champion Industries Dishwashing Machines.

ii

Table of Contents

Table of Contents

Revision History

Limited Warranty

Specifications

................................................................................................................ i

............................................................................................................. ii

..................................................................................................................iv

Installation ......................................................................................... 1

Unpacking ................................................................................................ 1

Utility Connections ..................................................................................... 3

Chemicals ................................................................................................. 4

Flow Diagram ........................................................................................... 6

Quick Operation Guide .............................................................................. 7

Operation ......................................................................................... 8

Assembling the Glasswasher ....................................................................... 8

Filling the Wash Tank ................................................................................. 8

Operating Instructions ................................................................................ 8

Cleaning ............................................................................................15

Daily Cleaning or after 8 hours of operation ............................................... 15

Weekly Cleaning or 56 hours of operation ................................................. 10

Troubleshooting ..................................................................................12

Service Replacement Parts ....................................................................17

Electrical Schematic

.............................................................................42

iii

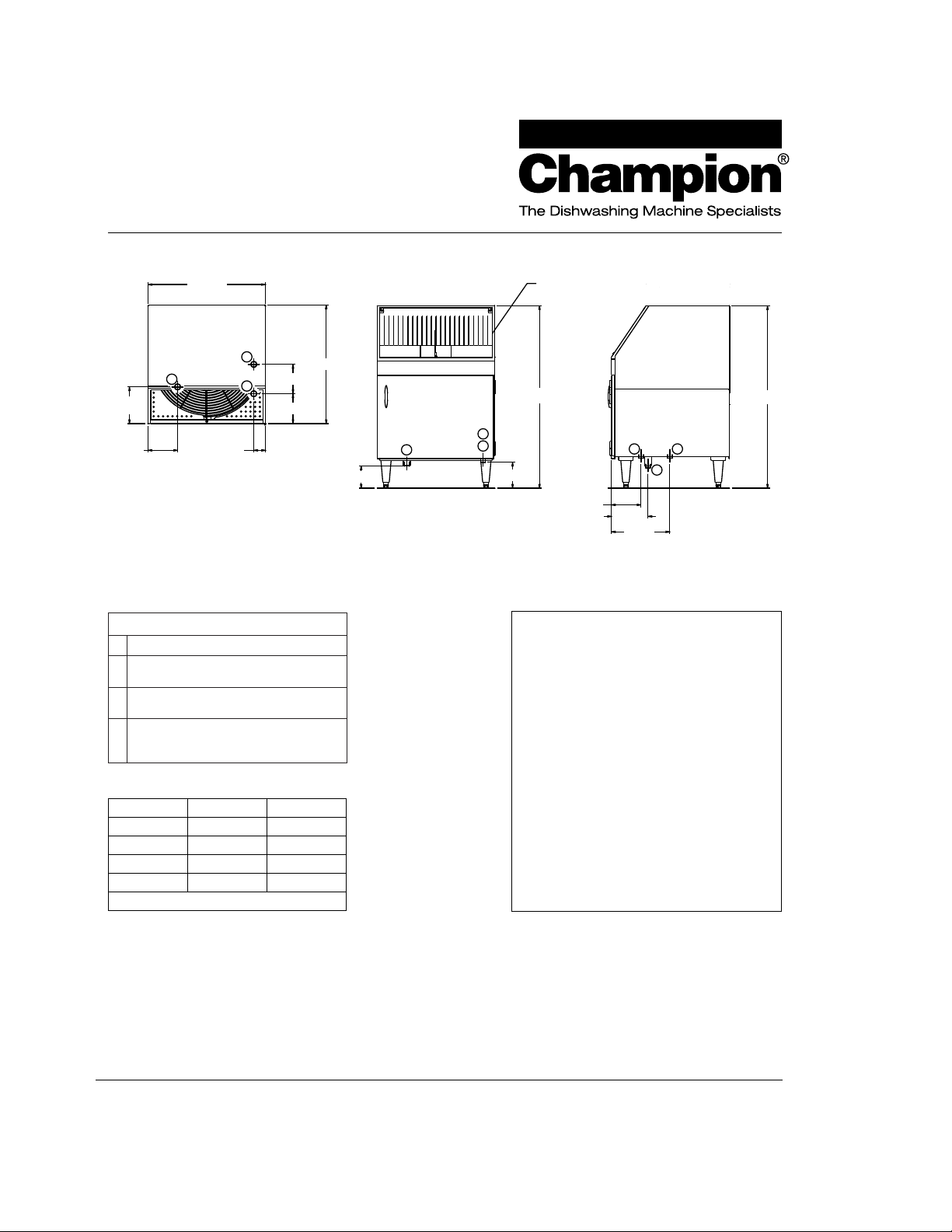

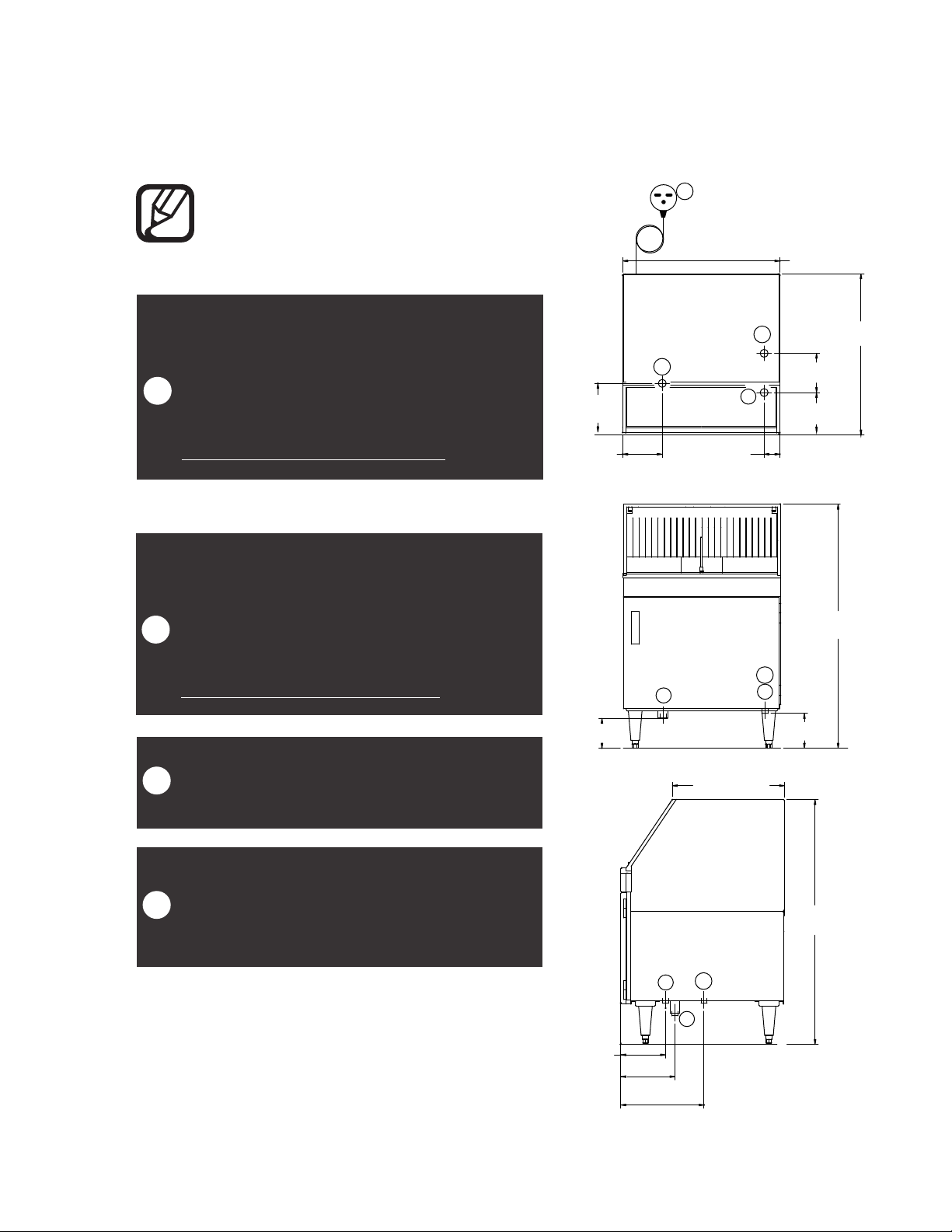

Specifications

CG

Rotary Type Series

Fully Automatic

Glasswashing Machine

Dimensions shown in inches and [millimeters]

25" [635]

CG GLASSWASHER

2

3

7-3/4"

[197]

6-1/4"

[159]

Plan View

Utilities

*Electrical 208 - 230/60/1, 15 amp

1

Hot water

1/2" IPS. Flow pressure 25-95 psi

2

Cold water

1/2" IPS. Flow pressure 25-95 psi

3

Drain

1-1/2" tailpiece. Connect to drain size

according to local plumbing code.

Height 39" 46-1/2"

Width 25-1/4" 27"

Depth 26" 27-1/2"

Ship Wt.

lbs/kg 156 176

* Adjustable foot height - 1-1/4"

1

2-1/2" [64]

Uncrated Crated

6-1/4" [156]

6-1/4" [156]

26" [660]

4-3/4" [121]

* NOTE: CG models supplied

with 6 ft. plug-in cord

(NEMA 6-15P).

Warning: Plumbing and

electrical connections

should be made by qualied

personnel who will observe

all the applicable plumbing,

sanitary and safety codes.

3

Front View

2

1

5-1/2" [140]

12" [305]

Vertical Clearance

39" [991]

6-1/4" [156]

1 2

7-3/4"

[197]

12-1/2"

[318]

17-3/4" [451]

3

SPECIFICATIONS

Capacity (hr.)

2-1/2" glasses/hr. 1200

Conveyor Movement

CG Clockwise

Water consumption

Cold Water (approx.) 2.5 gpm

Hot Water (initial ll) 3 gpm

(Max. use – approx. 10 gph)

Temperatures °F

Inlet water (hot) 140-160

Inlet water (cold) 75

Heating

Tank heat, electric, (kW) 3

Clearance

Through machine (inches) 12

39" [991]

Side View

iv

Due to an ongoing value analysis program at Champion, specications contained in this catalog are subject to change without notice.

Champion Industries, Inc., 3765 Champion Blvd., Winston-Salem, NC 27105 • 336/661-1556 • Fax: 336/661-1979 • www.championindustries.com

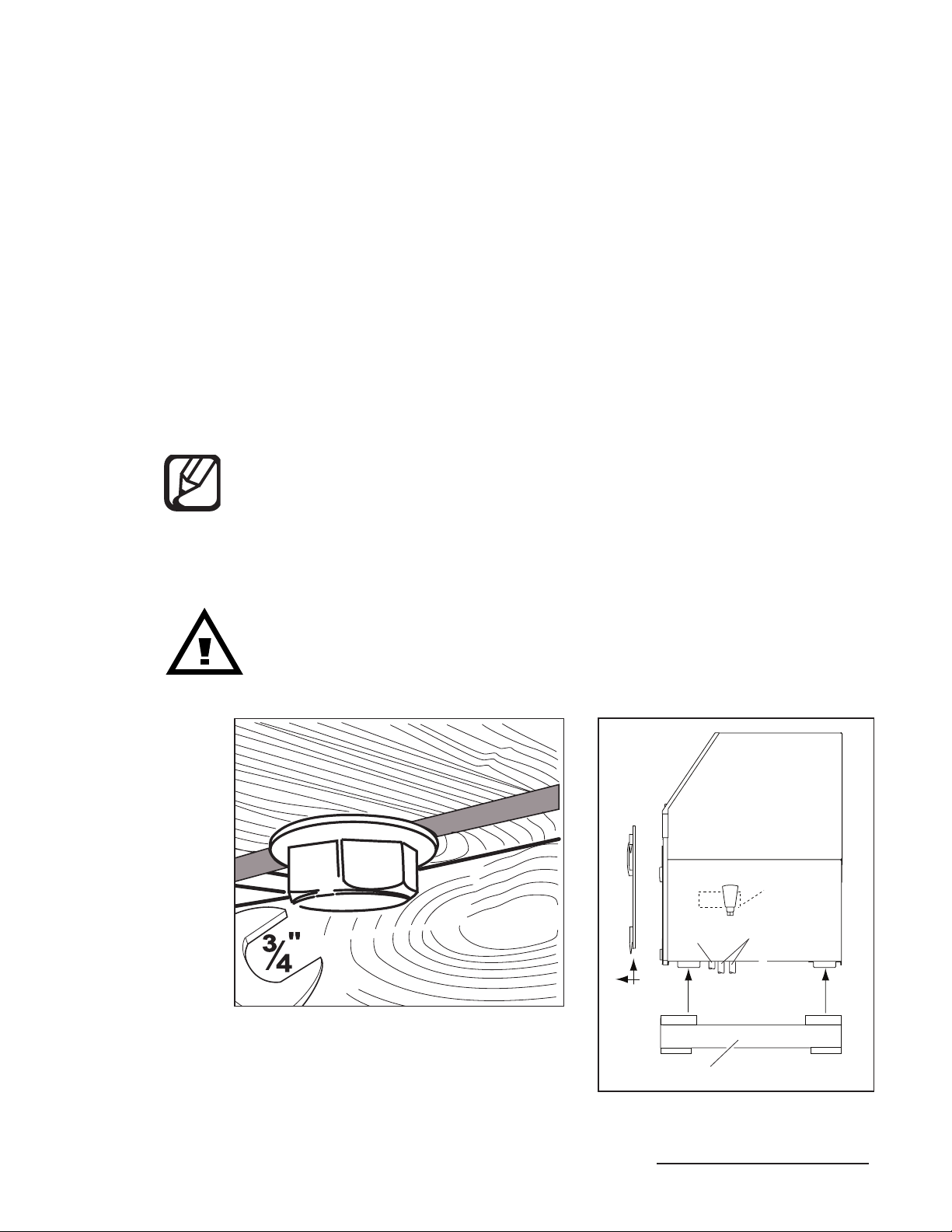

Installation

Unpacking

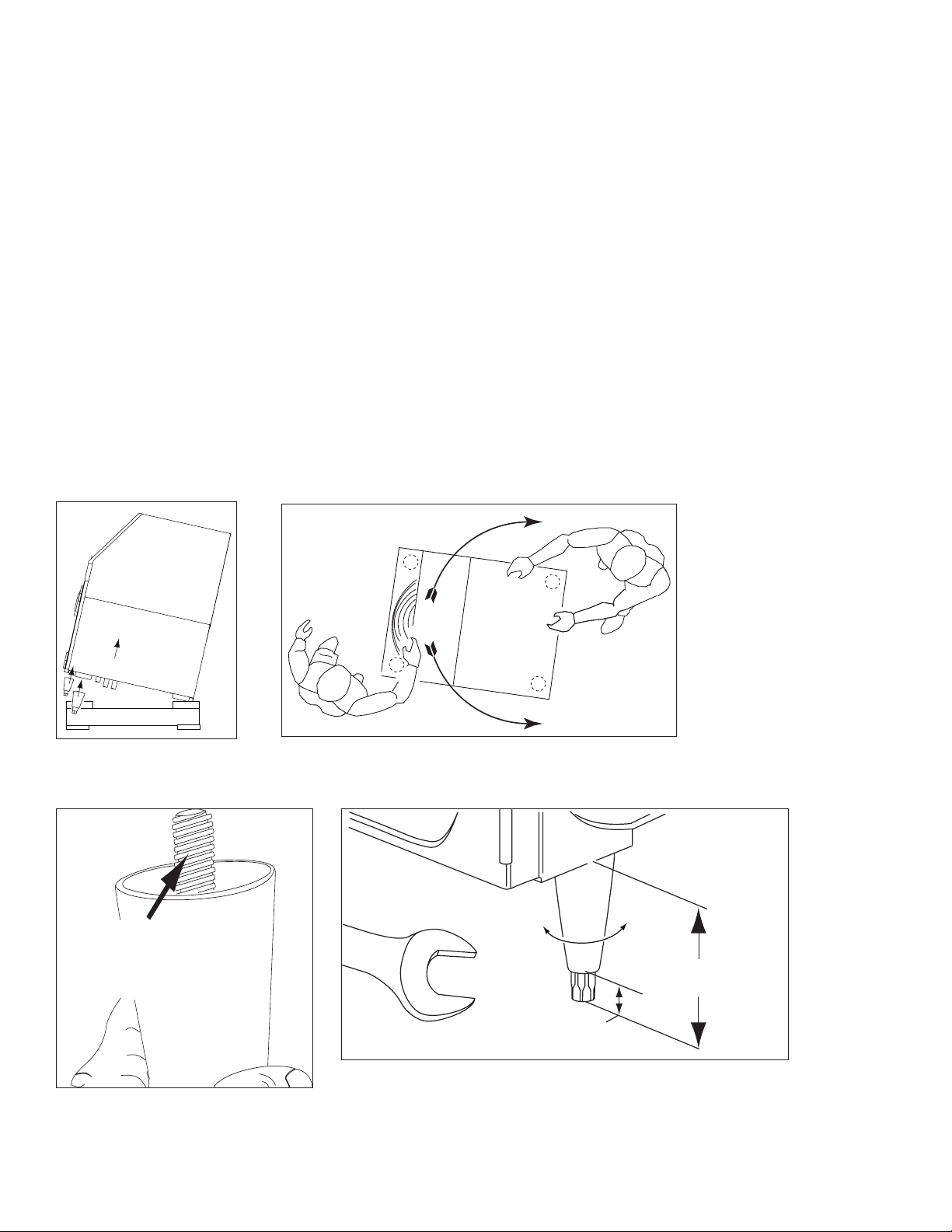

1. Move the glasswasher to its permanent location.

2. Open the door and remove the box marked "LEGS".

The box contains (4) 6" [152cm] screw-in legs.

These legs are threaded tightly into the base of the machine.

3. Remove (2) 1/2-13 x 2" bolts holding the glasswasher

to the pallet.

4. Lift the front door off the bottom hinges and set carefully aside.

5. The illustrations below show one method to install the legs

without lifting the glasswasher completely off the pallet.

NOTE:

The installation of the dishwasher must comply with all local electrical, plumbing, health

and safety codes or in the absence of local codes, installed in accordance with the

applicable requirements in the National Electrical Code, NFPA 70, Canadian Electrical

Code (CEC), Part 1, CSA C22.1; and the Standard for Ventilation Control and Fire

Protection of Commercial Cooking Operations, NFPA 96.

Installation

CAUTION:

The glasswasher water inlet plumbing and the drain piping extend below the

pallet. Use extreme care when moving the glasswasher to prevent damage to the

glasswasher plumbing.

Boxed Legs

Water

Drain

Remove the (2) pallet bolts holding

the glasswasher to the pallet.

Connections

Pallet

Glasswasher plumbing connections extend

below the pallet.

Continued on the next page.

1

Installation

Thread (1) leg in each

corner of the

machine base

Installation

Unpacking (continued)

6. Use two people to move the machine in order to install the legs.

7. Have one person behind the glasswasher tilt it back as the person in front twists the machine

to the right. This makes the front left leg mounting hole accessible.

8. Screw one of the legs tightly into place. Repeat this process for the remaining legs.

9. Lift the glasswasher off the pallet, and re-install the front door..

10. Level the glasswasher front-to-back and side-to-side by adjusting the leg bullet feet in or out.

11. Compare the site utilities with the data plate specifications. If they

agree, then proceed with the installation according to the diagrams on the next page.

12. Remove the packing material in the glasswasher and discard, then

remove any protective film on the machine.

Tilt the machine back to clear

plumbing connections.

Twist the

glasswasher

to the right,

then to the left.

Twist the machine to the right until the front right leg mounting

hole is accessible.

TILT

1"

6"-7½"

Make sure to install the legs tightly.

2

1½"

Level front-to-back and side-to-side

Utility Connections

Installation

The installation of this machine must be performed

by personnel who will follow all safety, electrical,

plumbing, and sanitation codes.

HOT WATER CONNECTION:

140-160°F/60-71°C

½" IPS

Flow Pressure 25-95 PSI [173-655 kPa]

1

Install water shut-off valves and check-valves in

the water inlet supply lines and

as close to the machine as possible.

COLD WATER CONNECTION:

75°F/24°C

½" IPS

Flow Pressure 25-95 PSI [173-655 kPa]

2

Install water shut-off valves and chack-valves in

the water inlet supply lines and

as close to the machine as possible.

7¾"

[197]

6¼" [156]

4

6 ft.

(1.5M)

Plan View

3

Front View

3

25" [635]

2

1

2

1

26-1/4" [667]

6¼" [156]

6¼" [156]

2½" [64]

39" [991]

DRAIN CONNECTION:

Gravity

3

1-½" Tailpiece (slip-fit)

Maximum drain flow 3 US gallons/min [11L/min].

ELECTRIC CONNECTION:

208-230VAC/50-60Hz/1PH

Min/Max 15A

4

6ft./1.5m flexible cord and plug supplied

NEMA 6-15P electric outlet.

4¾" [121]

6¼" [156]

7¾" [197]

12½" [318]

1

5½" [140]

17¾" [451]

Side View

39" [991]

2

3

3

Installation

RED

CLEAR

BLUE

Installation (continued)

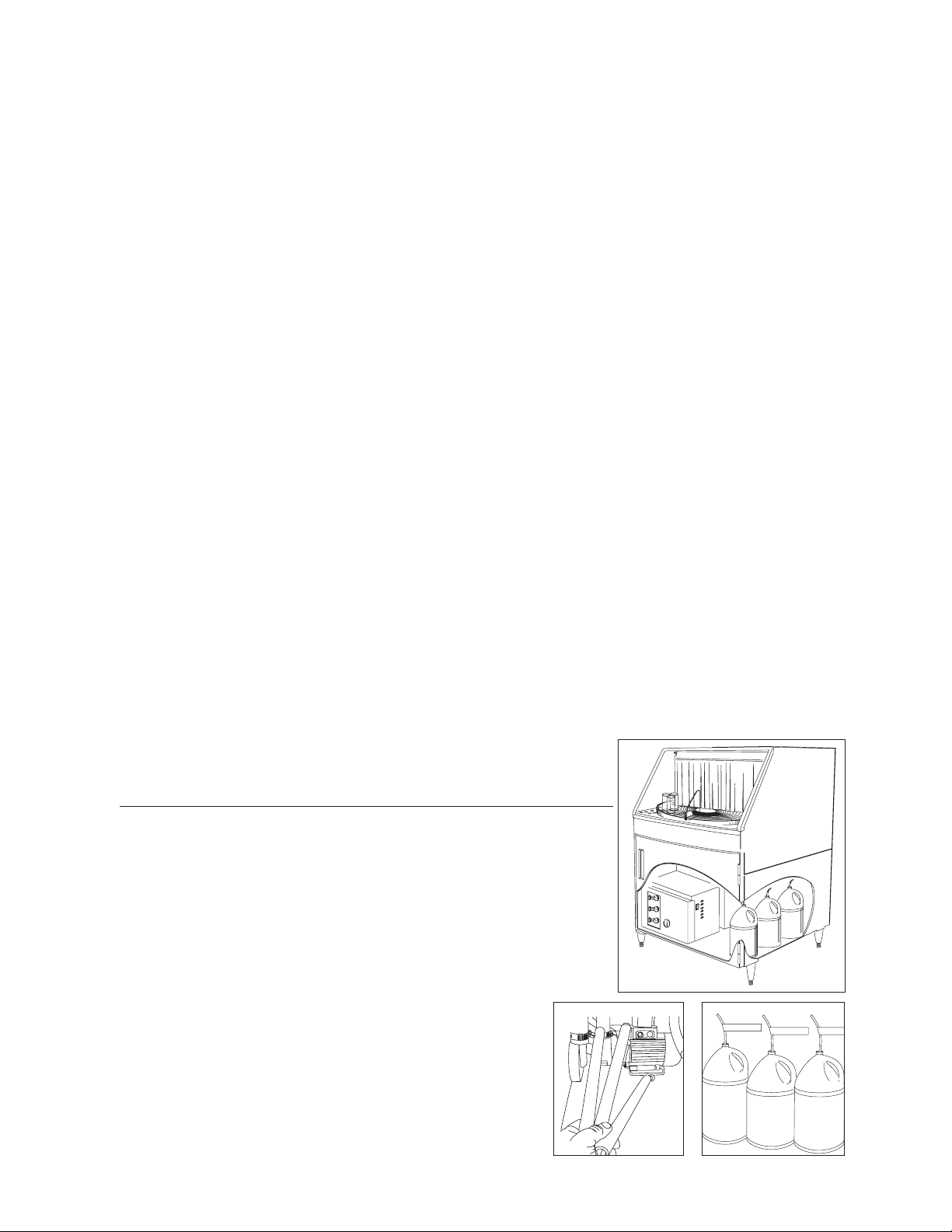

Chemicals

Glassware cleaning chemicals

1. A qualified chemical supplier should supply liquid detergent, sanitizer and rinse-aid for the

glasswasher. The glasswasher manufacturer does not sell glassware washing chemicals.

2. A chemical's formulation and strength vary depending on the chemical supplier; therefore,

the specifications given below are approximations only.

3. The glasswasher has 3 built-in chemical dispensing pumps for

Detergent - Use a commercial grade non-chlorinated detergent specifically made for

glasswashers. The recommended concentration of detergent should be .35%

Sanitizer - 2 types of sanitizer may be used.

(5.25%) Sodium hypochlorite (chlorine bleach) to provide a minimum

concentration of 50 ppm in the final rinse. The 50 ppm concentration must

be checked using test strips to make sure the proper concentration is maintained.

Iodophor (Iodine formulated with a rinse agent), to provide a minimum

concentration of 12.5ppm in the final rinse. The 12.5 ppm concentration must be

checked using test strips to make sure the proper concentration is maintained.

Rinse-aid -

Consult your chemical supplier for the proper type of rinse-aid to use in the

glasswasher.

Installing chemical supply containers and chemical pick-up tubes

1. There is enough space inside the lower compartment to hold

3 one gallon containers for detergent, sanitizer, and rinse-aid.

The contents of each container must be marked clearly.

2. The glasswasher comes equipped with 3 gray tubes, called

stiffener tubes, and tubing for each chemical pump.

The tubing inserted in the chemical container has a strainer.

3. The outlet tubes from the supply containers to the chemical

pumps are marked with color-coded labels, they are:

DET

SAN

RED - Detergent (DET)

CLEAR - Sanitizer (SAN)

BLUE - Rinse-aid (R/A)

4. Pull the stiffener tubes and chemical tubing forward and

DETERGENT

out of the compartment. Make sure the tubing is not

tangled or kinked.

DET

5. Insert the stiffener tube and pick-up tubing into its

container and stow the supply containers in the lower

compartment as shown to the right.

SANITIZER

SAN

R/A

RINSE

R/A

4

Installation

DET

SAN

R/A

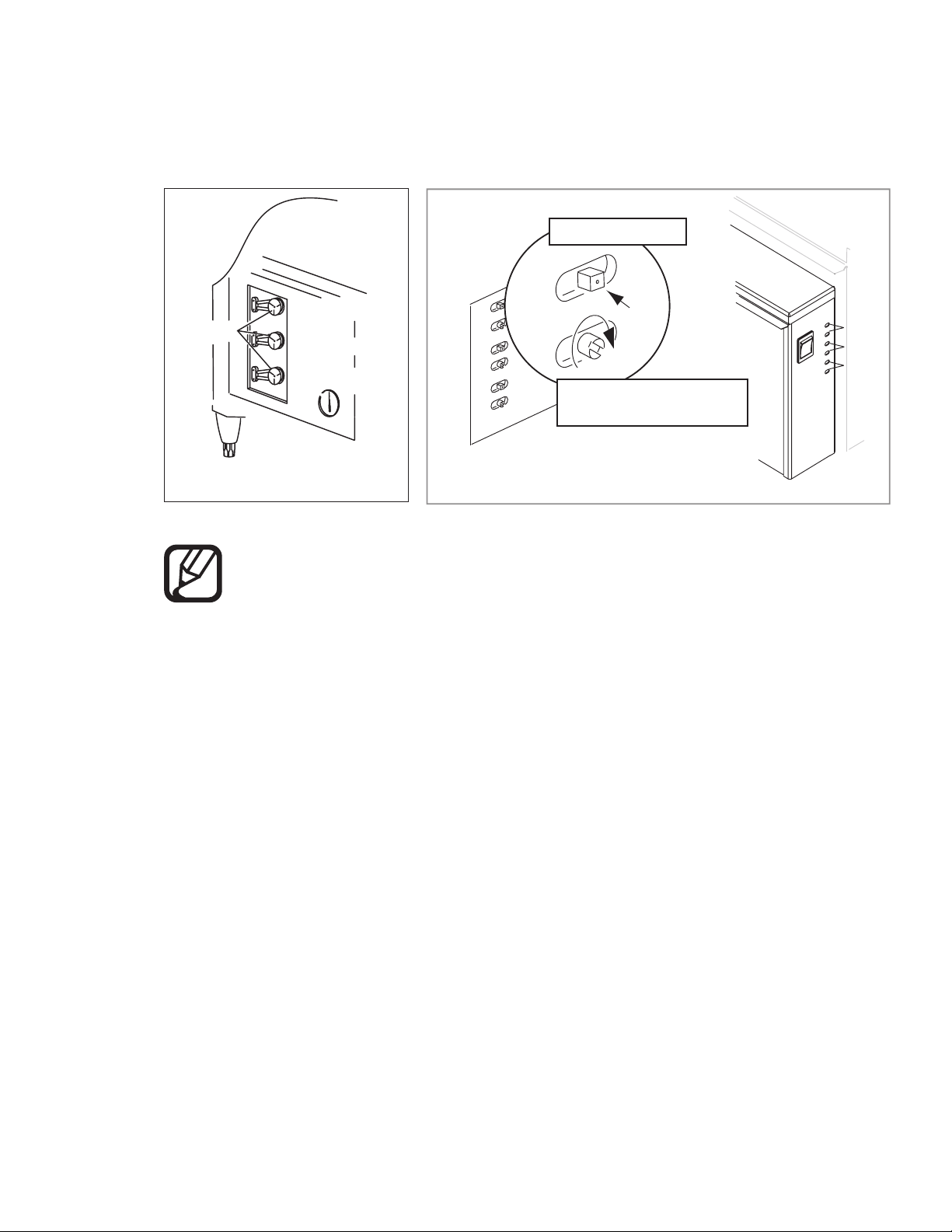

Priming the Chemical Injectors and Approximate Chemical Settings

Each chemical injector can be adjusted using its prime button and concentration adjusting screw.

These controls are located on the right side of the control box located in the lower compartment of the

glasswasher. The white injector rotors are visible through the control box window.

Push to prime

Rinse-aid

Rotor

Sanitizer

+

Detergent

-

Turn CW to increase(+)

CCW to decrease (-)

Chemical Injector Prime and Concentration Controls

NOTE:

1. Priming the Pumps:

Make sure the proper chemical pick-up tube is in its supply container, then

push and hold the prime button until the detergent, sanitizer and rinse-aid feed tubes are

full of chemicals. Release the Prime button.

2. Approximate Chemical Settings:

The approximate chemical volume dispensed by the chemical injectors can be

determined by counting the number of revolutions of the injector rotor.

Detergent - 1 revolution in 1-second of the detergent pump rotor ~ 0.35% concentration.

Sanitizer - 1 revolution in 5-seconds ~ 12.5 ppm of Iodophor or 50 ppm of chlorine.

Rinse-aid - 1 revolution in 8-seconds ~ the median volume recommended.

Turn the Injector Concentration screws clockwise to increase or counter-clockwise

to decrease the volume of dispensed chemical.

All of the chemical settings below are approximations.

Consult a qualified chemical representative trained in the use of the test equipments

required for taking samples and performing adjustments.

3. The detergent chemical setting must be performed when the hot-water fill solenoid valve

is open. The hot-water valve is open when the power switch is in the ON position during

initial fill and when the detergent tank float assembly calls for hot water

The sanitizer and the rinse-aid setting can be performed whenever the cold-water fill

solenoid valve is open. The cold-water fill valve is open whenever the glasswasher power

switch is ON and the conveyor is turning. A separate rinse-aid is not needed when

Iodophor is used as a sanitizer. Turn the Injector Concentration Screw fully

counter-clockwise until the rinse-aid injector rotor stops turning.

5

Operation

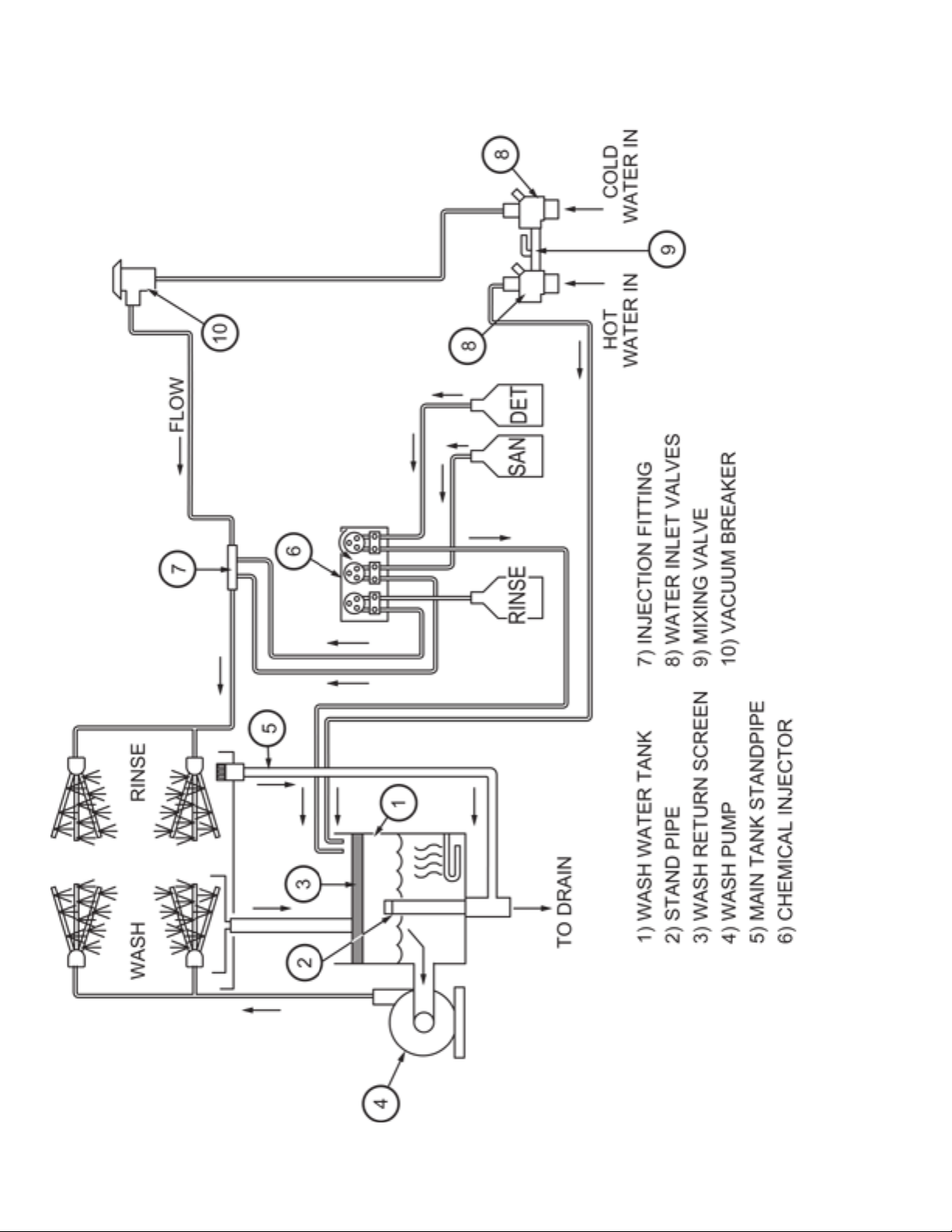

Flow Diagram

The diagram below shows the major components

of the CGM7.5 glasswasher and the flow of

water and chemicals during normal operation.

6

MIX

Plug machine power cord into a

208-230VAC/60/1,15 A wall recep-

tacle. Turn main power and water

service ON.

Remove lower wash tank scrap screen.

Make sure a glass

is against the conveyor

stop switch, Push the rocker

switch UP to the ON

position until the wash

tank is full of water.

Then, push and hold each

chemical Prime button

until chemical supply

tubes are full.

The incoming cold water

supply temperature must

be a minimum temperature of 75°F/24°C.

Adjust the temperature of

the incoming cold water temperature

by opening or closing the mixing valve

located between the hot water and the

cold water solenoid valves.

Check the cold water temperature

gauge and the cold water pressure

gauge as you adjust the mixing valve.

The minimum temperature should be

75°F/24°C. The pressure gauge should

read a flowing pressure

of 4-6 psi/24-36 kPa.

Check the wash tank

temperature gauge

for 140°F/60°C160°F/71°C.

Place glassware on

the conveyor.

The conveyor

stops automatically

when when

the clean glassware

operates the conveyor

stop switch.

Install the drain/

overflow tube into

the drain located

at the front of the

wash tank bottom.

Re-install the

scrap screen

removed

in Step 2.

Pull the chemical

pick-up tubes out

of the machine

Colored labels I.D. each tube

Place tube into its supply container.

On

Off

Flush

MIX

Pressure

Temperature

Wash Tank Heat

Prime

Prime

Prime

Label

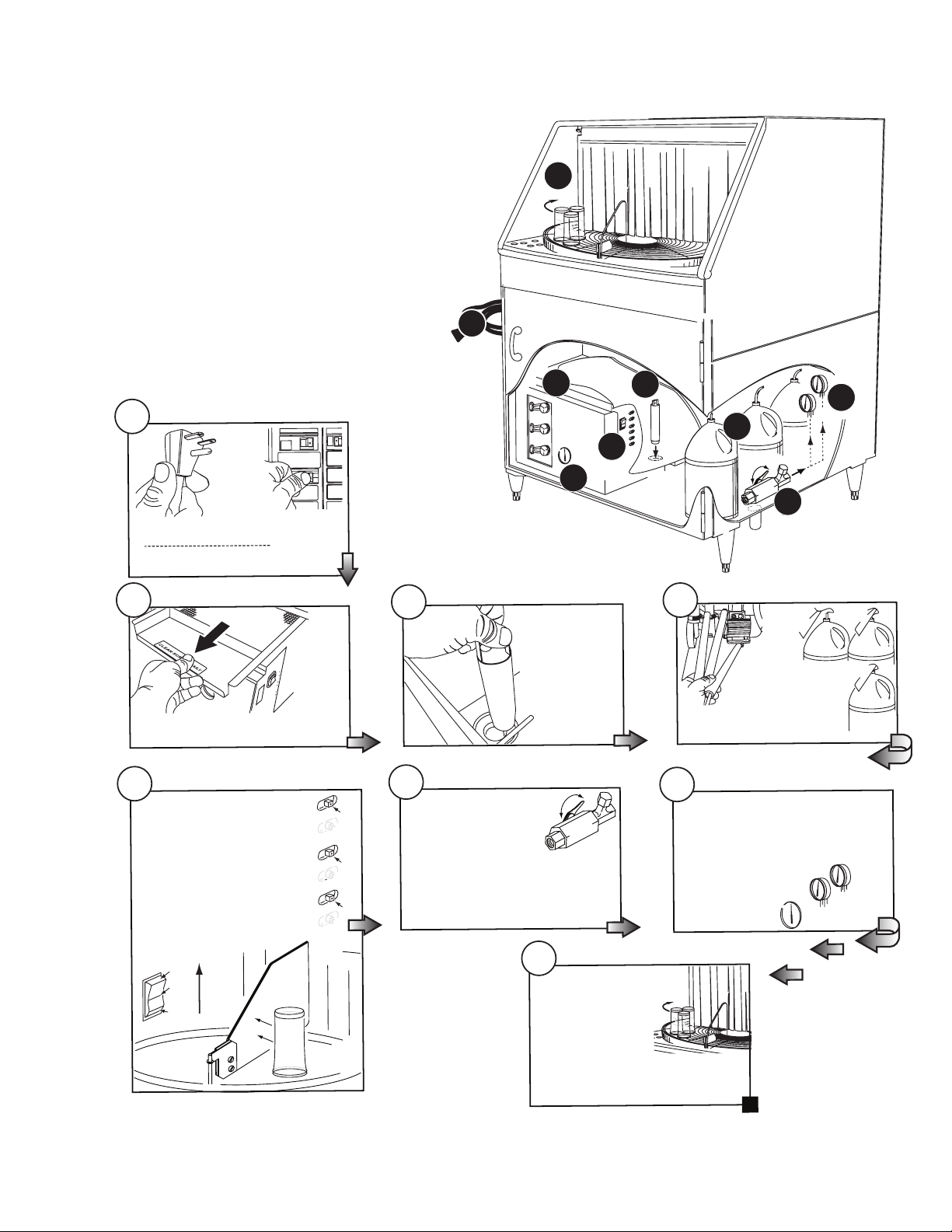

Quick Operation Guide

The glass washing machine is designed

to automatically wash a wide variety of glassware.

The glass washer consists of a wash section and

rinse section. Glasses rotate on a conveyor

through each section. A wash tank in the lower

compartment holds heated wash water. The water

level in the wash tank is maintained by a float and

cam-operated switch. The wash tank water

temperature is controlled by a heater and a

thermostat. The rinse water is supplied from

the cold water supply. Chemicals are automatically dispensed by built-in chemical pumps

1

2

3

4

6

5

7

8

7

4

6

7

8

1

2

3

5

Red

Label

Detergent

Sanitizer

White

Blue

Label

Rinse-aid

Det.

Sani

R/A

Operation

7

Loading...

Loading...