Page 1

REGISTER YOUR PRODUCT ONLINE

at championpowerequipment.com

INSTALLATION MANUAL

aXis CONTROLLER HOME

STANDBY GENERATOR

All aXis Controller™ Models

4010077

or visit championpowerequipment.com

SAVE THESE INSTRUCTIONS. This manual contains important safety precautions which should be read and understood before operating the product. Failure to do

so could result in serious injury. This manual should remain with the product.

No part of this publication may be reproduced or used in any form by any means – graphic, electronic or mechanical, including photocopying, recording, taping or

information storage and retrieval systems – without the written permission of Champion Power Equipment (CPE).

RE V 2 021010 6

Champion Power Equipment, Inc., Santa Fe Springs, CA USA

Page 2

Have questions or need assistance?

Do not return this product to the store!

WE ARE HERE TO HELP!

Visit our website:

www.championpowerequipment.com

for more info:

– Product Info & Updates

– Tech Bulletins

– Frequently Asked Questions

– or –

Call our Customer Care Team Toll-Free at:

1-877-338-0999

– Product Registration

This manual must be used with Champion Power Equipment (CPE) manuals:

Installation Manual, Part No. 101951

Transfer Switch Manual, Part No. 101948

* We are always working to improve our products. Therefore, the enclosed product may differ slightly from the image on the cover.

Page 3

aXis CONTROLLER HOME STANDBY GENERATOR

TABLE OF CONTENTS

TABLE OF CONTENTS

Introduction ................................................... 4

Home Standby Generator

Parts Included ..................................................... 4

Safety ............................................................ 5

Safety Definitions ................................................. 5

Safety Symbols .................................................... 6

Important Safety Instructions ....................... 8

Installation Hazards ............................................... 8

Before Starting .................................................... 8

Operation Hazards ................................................ 9

Accidental Starting ................................................ 9

Carbon Monoxide Hazards ........................................ 9

Electrical Shock Hazards ........................................ 10

Fire/Explosion Hazards .......................................... 10

Burn Hazards ..................................................... 10

Entanglement Hazards ........................................... 10

Battery Hazards .................................................. 10

Safety Labels and Hang Tags ....................... 11

Safety, Serial/Model, Nameplate Label Locations .............. 13

............................... 4

Installation

Placement & Installation Guidelines for Champion Home Standby

Generators to Reduce the Risk of Fire ............................ 17

Intertek Group PLC Label ........................................ 18

Site Selection, Preparation and Placement ..................... 19

Installation Preparation .......................................... 21

Surge protection ................................................. 28

AVR = Automatic Voltage Regulator ............................. 28

Engine Relay Module ............................................. 29

Exterior Warning LED ............................................ 30

Generator ON/OFF Switch ....................................... 30

aXis Controller™ Module ........................................ 30

Programming aXis Controller™ ................................. 34

Battery Charger .................................................. 35

Automatic Transfer Switch (ATS) ................................ 36

aXis Controller™ Module ........................................ 36

ATS Installation ................................................... 36

Commissioning the ATS .......................................... 37

HSB Te st .......................................................... 37

Checking Automatic Operation .................................. 39

Installing Standby Generator to non-aXis Controller ™ ATS ... 39

Customer Familiarization Summary .............................40

.................................................. 17

Specifications .............................................. 14

14kW HSB Specifications ........................................ 14

Champion 754cc Engine ......................................... 15

Champion 754cc Engine Torque Specifications ................. 15

Master Mixing Assembly Jets (Carburetor System) ............ 15

Alternator Overview .............................................. 16

Unpacking .................................................... 16

Troubleshooting HSB ...................................40

HSB, ATS Model & Serial Reference ATS Back-up Circuits .....42

3

Page 4

aXis CONTROLLER HOME STANDBY GENERATOR

INTRODUCTION

INTRODUCTION

Congratulations on your purchase of a Champion Power Equipment

(CPE) product. CPE designs, builds, and supports all of our

products to strict specifications and guidelines. With proper

product knowledge, safe use, and regular maintenance, this

product should bring years of satisfying service.

Every effort has been made to ensure the accuracy and

completeness of the information in this manual at the time of

publication, and we reserve the right to change, alter and/or

improve the product and this document at any time without prior

notice.

CPE highly values how our products are designed, manufactured,

operated, and serviced as well as providing safety to the operator

and those around the generator. Therefore, it is IMPORTANT to

review this product manual and other product materials thoroughly

and be fully aware and knowledgeable of the assembly, operation,

dangers and maintenance of the product before use. Fully

familiarize yourself, and make sure others who plan on operating

the product fully familiarize themselves too, with the proper safety

and operation procedures before each use. Please always exercise

common sense and always err on the side of caution when

operating the product to ensure no accident, property damage,

or injury occurs. We want you to continue to use and be satisfied

with your CPE product for years to come.

When contacting CPE about parts and/or service, you will need to

supply the complete model and serial numbers of your product.

Transcribe the information found on your product’s nameplate

label to the table below

HOME STANDBY GENERATOR

This home standby generator is intended exclusively for outdoor

installation. This generator will operate using either liquified

petroleum gas (LPG) or natural gas (NG).

This generator is designed to supply typical home load such as:

Induction motors – sump pumps, refrigerators, air conditioners,

furnaces

Electronic items – televisions, computers

Household lighting

Microwaves

This generator is not intended for use in critical life support

applications.

Proper sizing of the generator is required to ensure proper

operation of appliances. Some appliances require additional

wattage to start and must be considered.

Parts Included

Your HSB ships with the following:

– Operators Manual

– Installation Manual

– Oil Drain Pan

– Flexible Fuel Line

– HSB Enclosure Keys

– Battery Cable Connection

CPE TECHNICAL SUPPORT TEAM

1-877-338-0999

MODEL NUMBER

SERIAL NUMBER

DATE OF PURCHASE

PURCHASE LOCATION

– LPG Low-speed and Main Converting Jets

– Jet Change Tool

Battery Hardware

– 4 pieces - lock nut M6

– 4 pieces - washer, Ø6 mm

– 4 pieces - flange bolt, M6 x 1.0-15

4

Page 5

aXis CONTROLLER HOME STANDBY GENERATOR

SAFETY

Safety Definitions

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols, and their explanations,

deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes for proper

accident prevention measures.

DANGER

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

SAFETY

CAUTION

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE

NOTICE indicates information considered important, but not

hazard-related (e.g., messages relating to property damage).

5

Page 6

aXis CONTROLLER HOME STANDBY GENERATOR

!

SAFETY

Safety Symbols

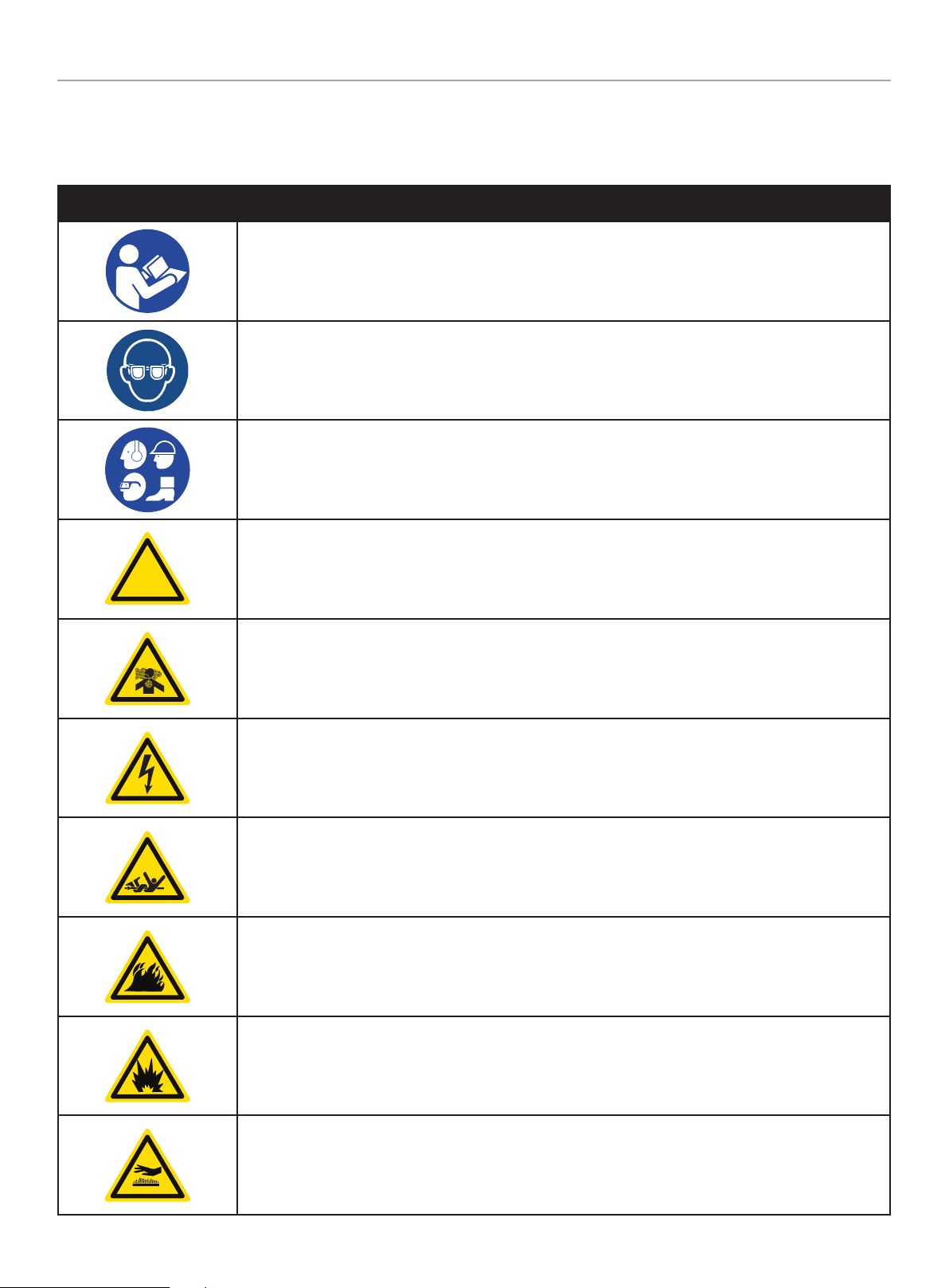

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these

symbols will allow you to more safely operate the product.

SYMBOL MEANING

Read Operator’s Manual. To reduce the risk of injury, user must read and understand operator’s manual

before using this product.

Eye protection. Always wear eye protection with side shields marked to comply with ANSI Z87.1

Wear personal protective equipment

Safety alert symbol

Asphyxiation hazard

Electrical shock hazard

Entanglement hazard

Fire hazard

Fire/Explosion. Fuel and its vapors are extremely flammable and explosive. Fire or explosion can cause

severe burns or death.

Hot Surface. To reduce the risk of injury or damage, avoid contact with any hot surface.

6

Page 7

aXis CONTROLLER HOME STANDBY GENERATOR

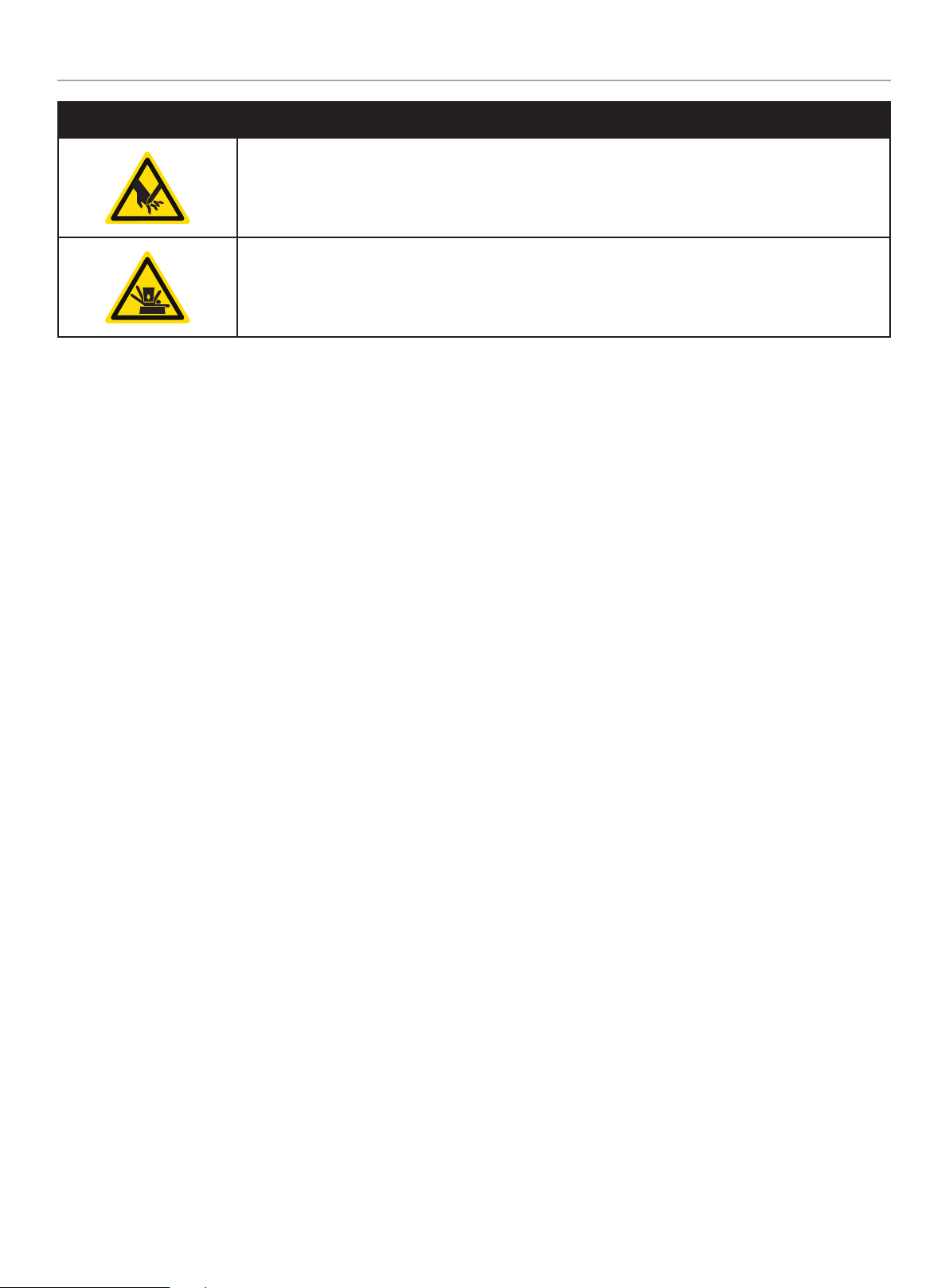

SYMBOL MEANING

Sever hazard (rotating blade)

Crush hazard (top)

SAFETY

7

Page 8

aXis CONTROLLER HOME STANDBY GENERATOR

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Cancer and Reproductive Harm – www.P65Warnings.ca.gov

DANGER

Generator exhaust contains carbon monoxide, a colorless,

odorless, poisonous gas. Breathing carbon monoxide will

cause nausea, dizziness, fainting or death. If you start to feel

dizzy or weak, get to fresh air immediately.

GENERATOR MUST BE INSTALLED AND OPERATED

OUTDOORS ONLY.

Carbon monoxide (CO) poisoning symptoms include but are not

limited to the following:

– Lightheadedness, dizziness, blurred vision

– Physical fatigue, weakness in joints and muscles

– Mental fatigue, sleepiness, inability to concentrate or

speak clearly,

– Stomachache, vomiting, nausea

In the event of carbon monoxide (CO) poisoning:

– Seek fresh air immediately

– DO NOT sit, lie down or fall asleep.

– Alert others to the possibility of carbon monoxide (CO)

poisoning.

– If the affected person does not improve within minutes

of breathing fresh air, call 911 immediately for medical

assistance.

WARNING

Do not use generator for medical and life support uses.

In case of emergency, call 911 immediately.

NEVER use this product to power life support devices or life

support appliances.

Installation Hazards

WARNING

Have only a qualified electrician or installation technician who

is familiar with applicable codes, standards and regulations

install and service the generator.

ALWAYS comply with local, state and national electrical and

building codes when installing the generator. NEVER alter the

recommended installation in a way that would render the unit

noncompliant with these codes.

ALWAYS comply with regulations that Occupational Safety and

Health Administration (OSHA) has established.

ENSURE the generator is installed following the manufacturer’s

instructions.

Before Starting

CAUTION

Before operation, read and understand the features and

controls of the generator, including the safety information of

this manual.

The owner/operator is responsible for safe operation and

maintenance of the generator. Be sure all potential users of the

generator also understand these instructions. If any portion

of this manual is not understood, contact your dealer for

assistance before operating the generator.

The operator is responsible for performing all safety checks,

making sure all maintenance is properly performed and

making sure the generator is periodically checked by the

dealer.

Inspect the generator regularly. Contact your dealer if repairs

are needed.

NEVER climb or step on any part or components of the

generator. Doing so may result in injury and cause leaking fuel

and exhaust.

NEVER use this product to power medical devices or medical

appliances.

Inform your electricity provider immediately if you or anyone in

your household depends on electrical equipment to live.

Inform your electrical provider immediately if a loss of power

would cause you or anyone in your household to experience a

medical emergency.

8

Page 9

aXis CONTROLLER HOME STANDBY GENERATOR

IMPORTANT SAFETY INSTRUCTIONS

Operation Hazards

WARNING

ALWAYS operate the generator following the manufacturer’s

instructions. Operating the generator improperly or neglecting

maintenance can result in serious injury or possible death.

DO NOT allow children or unqualified persons to operate or

service the generator.

NEVER operate the generator with the covers open. Operate

the generator only with the covers closed and secured in

place. NEVER leave the covers unlocked.

Remain alert at all times when working on the generator.

NEVER work on the generator when physically or mentally

fatigued.

NEVER operate the generator while under the influence of

alcohol or drugs.

Accidental Starting

WARNING

Carbon Monoxide Hazards

DANGER

– Generator must be installed and operated outdoors only.

– NEVER allow exhaust fumes to enter a confined area

through windows, doors, air intake vents or other openings

of the building

– ALWAYS avoid breathing exhaust fumes when near an

operating generator.

– NEVER alter the generator or modify the exhaust system

thereby creating noncompliance with Federal and State

emissions regulations, local applicable codes, standards

and laws.

– NEVER allow blockage of the engine’s air intake cooling

ventilation system. Doing so can seriously affect

performance and safe operation of the generator.

– Install a battery-operated carbon monoxide (CO) detector

on each level of any building adjacent to the generator

location following the manufacturer’s CO detector

installation instructions.

ALWAYS prevent the generator from starting while the covers

are open. The generator may crank and start at any time

without notice. Follow these steps in order:

1. Pull fuse from aXis Controller™ panel and secure with

tape to the panel.

2. Disconnect the NEGATIVE, NEG or (-) battery cable first,

and then remove the POSITIVE, POS or (+) battery cable.

To return the generator to service, follow these steps in order:

1. Connect the POSITIVE, POS or (+) battery cable first, and

then connect the NEGATIVE, NEG or (-) battery cable.

2. Remove taped fuse from the panel and reinstall into the

aXis Controller™ module.

NOTICE

In many States it is required by law to have a Carbon Monoxide

(CO) detector on each level of any building in operating

condition.

Carbon Monoxide (CO) is a colorless, odorless, poisonous gas.

Breathing carbon monoxide will cause nausea, dizziness, fainting

or death.

A Carbon Monoxide (CO) detector is a device that detects elevated

hazardous levels of CO and will alert the occupants by flashing a

visual light indicator and an audible alarm.

9

Page 10

aXis CONTROLLER HOME STANDBY GENERATOR

IMPORTANT SAFETY INSTRUCTIONS

Electrical Shock Hazards

WARNING

Use extreme caution when near the generator while it is

operating. The generator produces dangerous voltage.

– Avoid contact with bare wires, terminals and connections

while the generator is operating.

– ALWAYS stand on an insulated dry surface to reduce shock

hazard if work must be done on an operating generator.

– NEVER wear jewelry that can conduct electricity when

working on the generator.

– NEVER handle any kind of electrical device while hands or

feet are wet, while standing in water or while barefoot.

– Proper earth grounding of the frame and external electrical

conductive components is required by the National

Electrical Code (NEC). State and local codes for proper

grounding may also apply.

– Avoid direct contact with an electric shock victim.

Immediately shut down the source of electrical power. If

this is not possible, attempt to free the victim from the live

conductor using a nonconducting item such as a dry board

or rope. If the victim is unconscious, apply first aid and call

911 immediately.

Burn Hazards

WARNING

DO NOT touch hot surfaces.

– ALWAYS avoid contact with hot exhaust components and

gases. Running engines produce heat. Severe burns can

occur on contact.

– ALWAYS allow hot surfaces to cool to the touch.

Entanglement Hazards

WARNING

Use extreme caution when near rotating parts. Rotating parts

can entangle hands, feet, hair, clothing and/or accessories.

Traumatic amputation or severe laceration can result.

– Keep hands and feet away from rotating parts.

– Tie up long hair and remove jewelry.

– Operate equipment with guards in place.

– DO NOT wear loose-fitting clothing, dangling drawstrings

or items that could become caught.

Fire/Explosion Hazards

WARNING

Natural Gas (NG) and Liquefied Petroleum Gas (LPG) are

extremely explosive.

– NEVER allow any flames or smoke near the fuel system.

– Wipe up any oil spills immediately.

– NEVER allow any combustible materials to be near the

generator or to be left in the generator compartment.

– ALWAYS keep the surrounding area near the generator

clean and free of debris.

– Be sure to properly purge the fuel lines and leak-test

according to applicable codes before placing the generator

in service.

– Be sure to regularly inspect the fuel system for leaks.

NEVER operate the generator if a fuel leak is present.

– Install a fire extinguisher near the generator. Keep it

properly charged and be familiar with its use. An ABC

rated National Fire Protection extinguisher is appropriate

for use on standby electric systems. Contact your local

fire department with any questions concerning the fire

extinguisher.

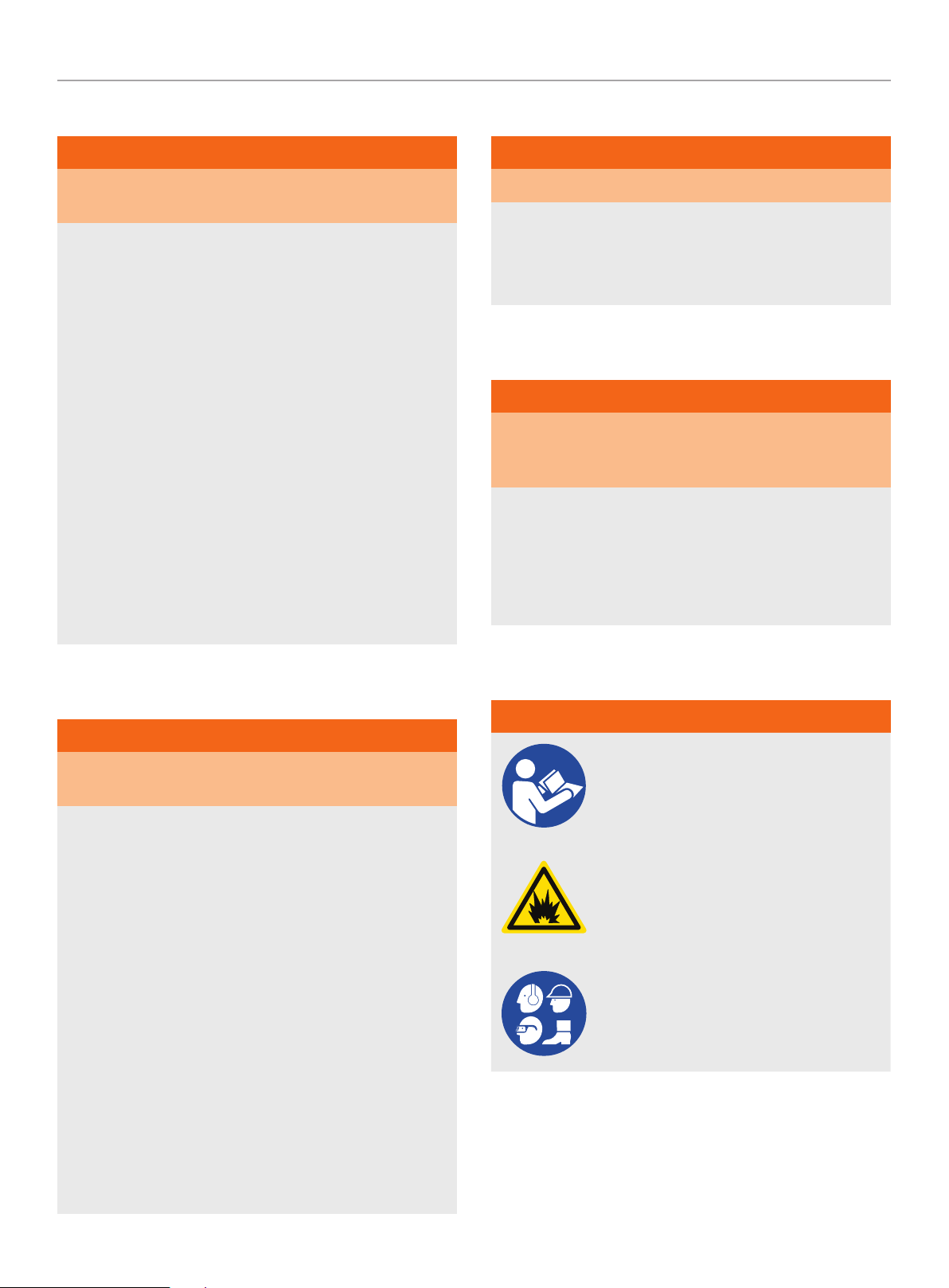

Battery Hazards

WARNING

Always read and comply with the battery

manufacturer’s recommendations for

procedures concerning proper battery use

and maintenance.

Batteries contain sulfuric acid and generate

explosive mixtures of hydrogen and oxygen

gases. Keep any device that may cause

sparks or flames away from the battery to

prevent explosion.

Always wear protective glasses or goggles

and protective clothing when working with

batteries. You must follow the battery

manufacturer’s instructions on safety,

maintenance and installation procedures.

10

Page 11

aXis CONTROLLER HOME STANDBY GENERATOR

Poisonous Gas Hazard - Generator exhaust conta ins

carbon monoxide. Bre athing carbon mon oxide will

cause nausea, dizzin ess, and faintin g, and it may

cause death.

Risque d’empoisonnement par le gaz - Les gaz

d’échappement de groupe électrogène contiennent

du monoxyde de carbone . Si l’on respire du

monoxyde de carbone, c eci peut provoque r des

nausées, un évanouissement et une perte de

conscience, et ceci peu t provoquer la mor t.

Riesgo de gas venenoso - El escape del generador

contiene monóxido de ca rbono. Respira r monóxido de

carbono causará náuseas, mareos, desvanecimiento

y hasta la muerte.

DANGER

DANGER

PELIGRO

2510-L-SF-A

Fire Hazard - ALWAYS keep th e surrounding ar ea

near generator clean a nd free of debris an d/or dry

vegetation. The gene rator may create s parks while

operating.

Risque d’incendie - Nettoyez TOUJOURS la su rface à

proximité du groupe éle ctrogène et enle vez les débris

et/ou la vegétation s èche. Le groupe éle ctrogène

peut générer des étinc elles pendant son

fonctionnement.

Riesgo de incendio - SIEMPRE mantenga el área

circundante cerca de l generador limpi a y libre de

escombros y/o vegetaci ón seca. El genera dor puede

crear chispas mientras está en funcionamiento.

WARNING

AVERTISSEMENT

ADVERTENCIA

Burn Hazard - DO NOT touch hot surfaces.

Avoid contact with exhaus t components

and gases.

Risque de brûlure - NE touchez PAS les

surfaces chaudes. Evit ez le contat avec les

composants et les gaz d’échappement.

Riesgo de quemaduras - NO to que las

superficies calientes . Evite el contacto con

los componentes de escape y gases.

WARNING

AVERTISSEMENT

ADVERTENCIA

2483-L-SF-A

Burn Hazard - DO NOT touch

hot surfaces. Allow the

engine and alternator to cool

to the touch before servicing.

Danger de brulure - NE

TOUCHEZ PAZ les surfaces

chaudes. Laissez le moteur

et l’alternateur devenir froid

au toucher avant d’intervenir.

Riesgo de quemaduras -

NO toque las superficies

calientes. Deje que el motor

y el alternador se enfríen

para tocarlos antes de

realizarles el mantenimiento.

WARNING

AVERTISSEMENT

ADVERTENCIA

Electrical Shock Hazard

Do not remove this access panel. The panel should

only be removed by an authorized Service Dealer

or a qualified electrician; high voltage inside.

Risque de choc élect rique

N’enlevez pas ce panneau d’accès. Le panneau ne

devrait être enlevé que par un concessionnaire

d’entretien agréé ou un électricien qualifié; haute

tension à l´’intérieur.

Riesgo de descarga eléctrica

No remueva este tablero de acceso. El tablero sólo

deberá ser removido por un distribuidor de

servicio autorizado o un electricista calificado;

alto voltaje al interior.

2396-L-SF-A

DANGER

DANGER

PELIGRO

2473-L-SF-A

Burn Hazard - DO NOT touch hot surfaces.

Avoid contact with exhaus t components

and gases.

Risque de brûlure - NE touchez PAS les

surfaces chaudes. Evit ez le contat avec les

composants et les gaz d’échappement.

Riesgo de quemaduras - NO to que las

superficies calientes . Evite el contacto con

los componentes de escape y gases.

WARNING

AVERTISSEMENT

ADVERTENCIA

2474-L-SF-A

Electrical Shock - ALWAYS close and lock

the generator covers before operating.

The generator produces dangerous voltage.

Risque de choc électrique - Fermez et

verrouillez TOUJOU RS les capots de gro upe

électrogène avant d’ut iliser le groupe. Le

groupe électrogène génère des tensions

dangereuses.

Riesgo de descarga elé ctrica - SIEMPRE

cierre y trabe las tapa s del generador ant es

de ponerlo en funcionamiento. El generador

produce un voltaje peligroso.

DANGER

DANGER

PELIGRO

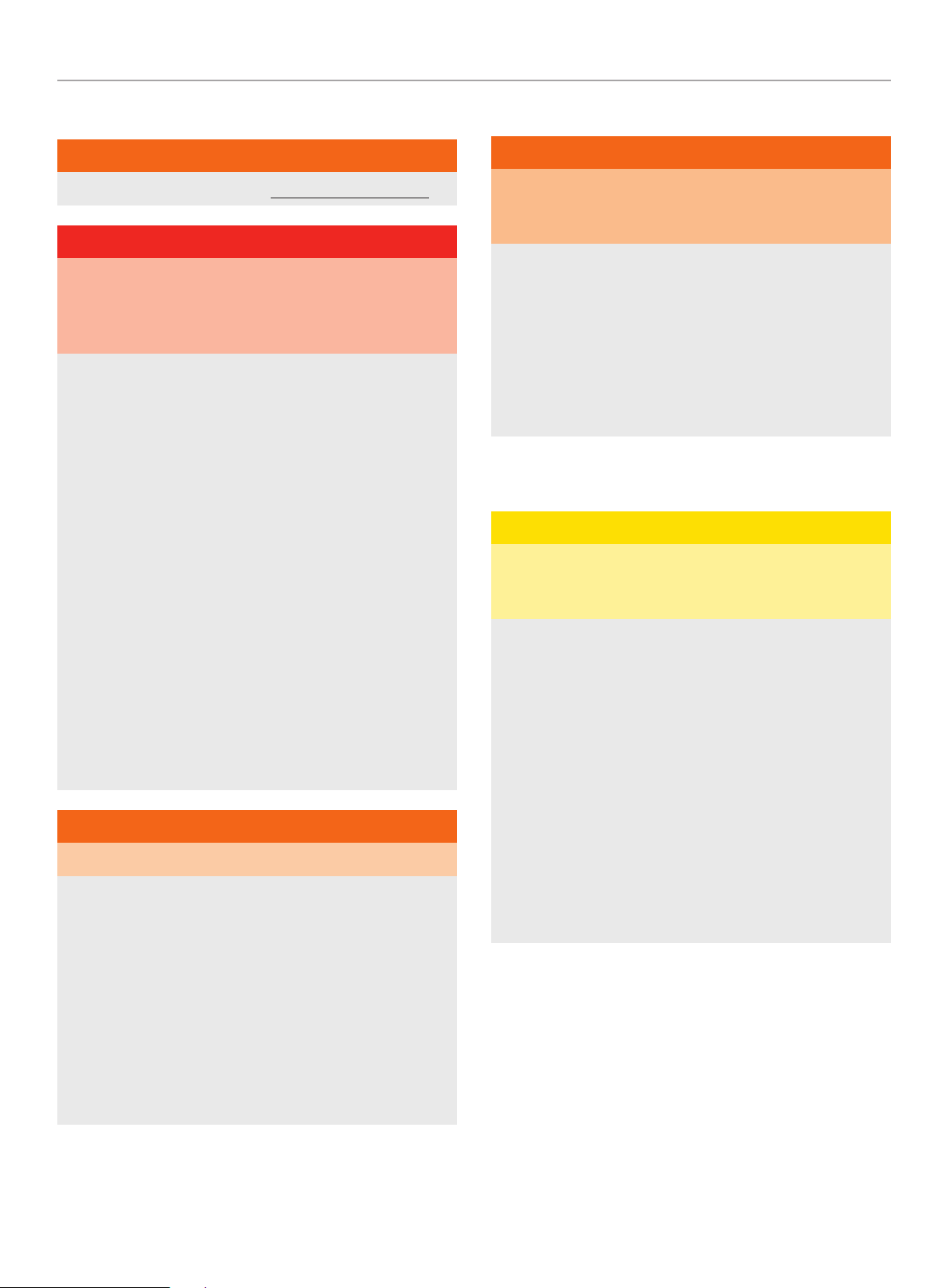

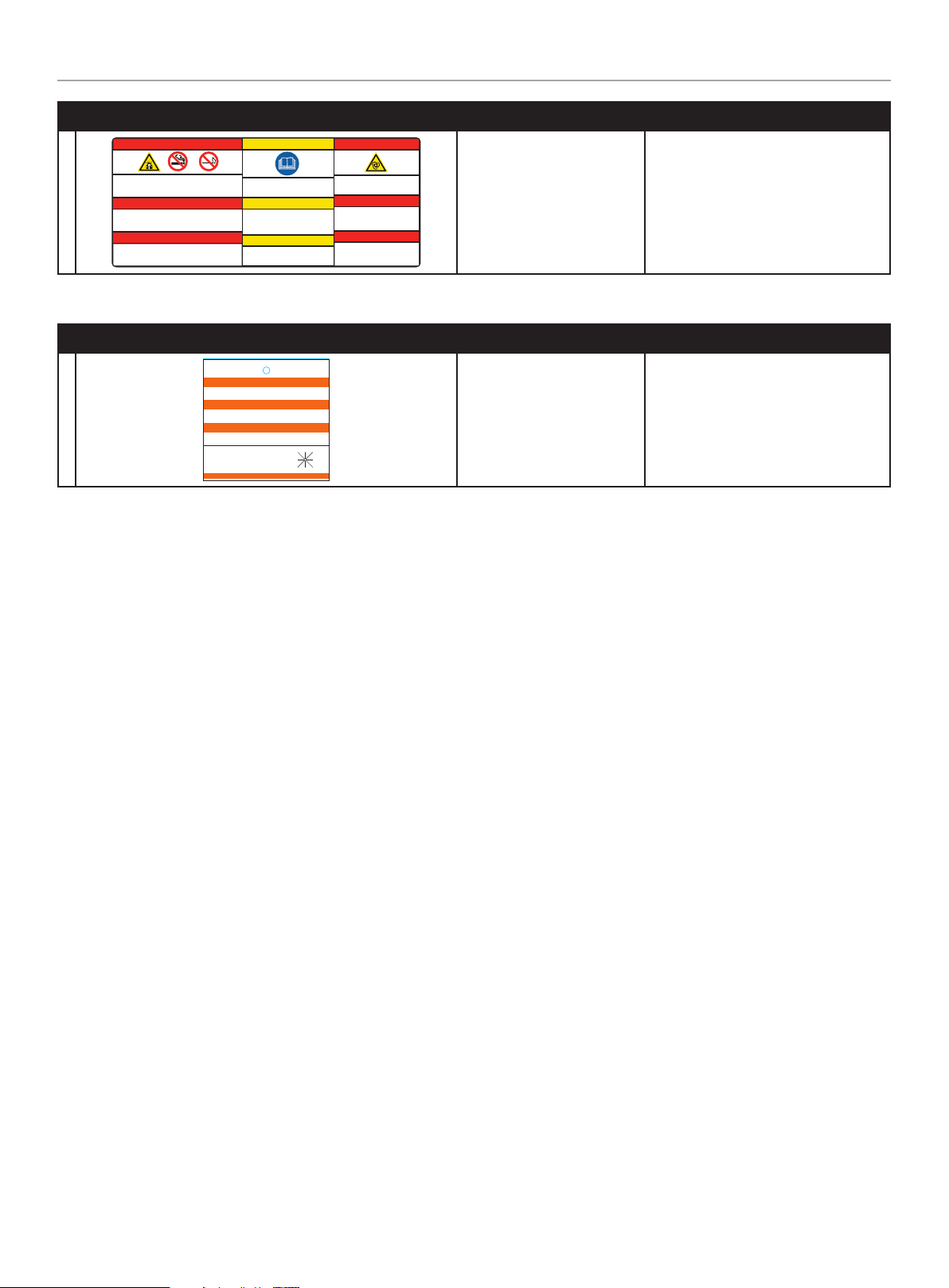

SAFETY LABELS AND HANG TAGS

WARNING

DO NOT operate the generator if there are missing or badly

worn safety labels. Safety labels must be legible to alert

personnel of safety hazards.

– Replace any illegible or missing label immediately. Missing

safety labels must be replaced in their original position

before the generator is operated.

Labels

LABEL DESCRIPTION PART NO.

SAFETY LABELS AND HANG TAGS

A

B

C

Poison, Burn and Fire

Warning

2510 -L-S F

Burn Warning 24 8 3- L-S F

Electrocution Warning 2396-L-SF

D

E

Burn Warning 24 7 3- L- SF

Electrocution Warning 2474-L-SF

11

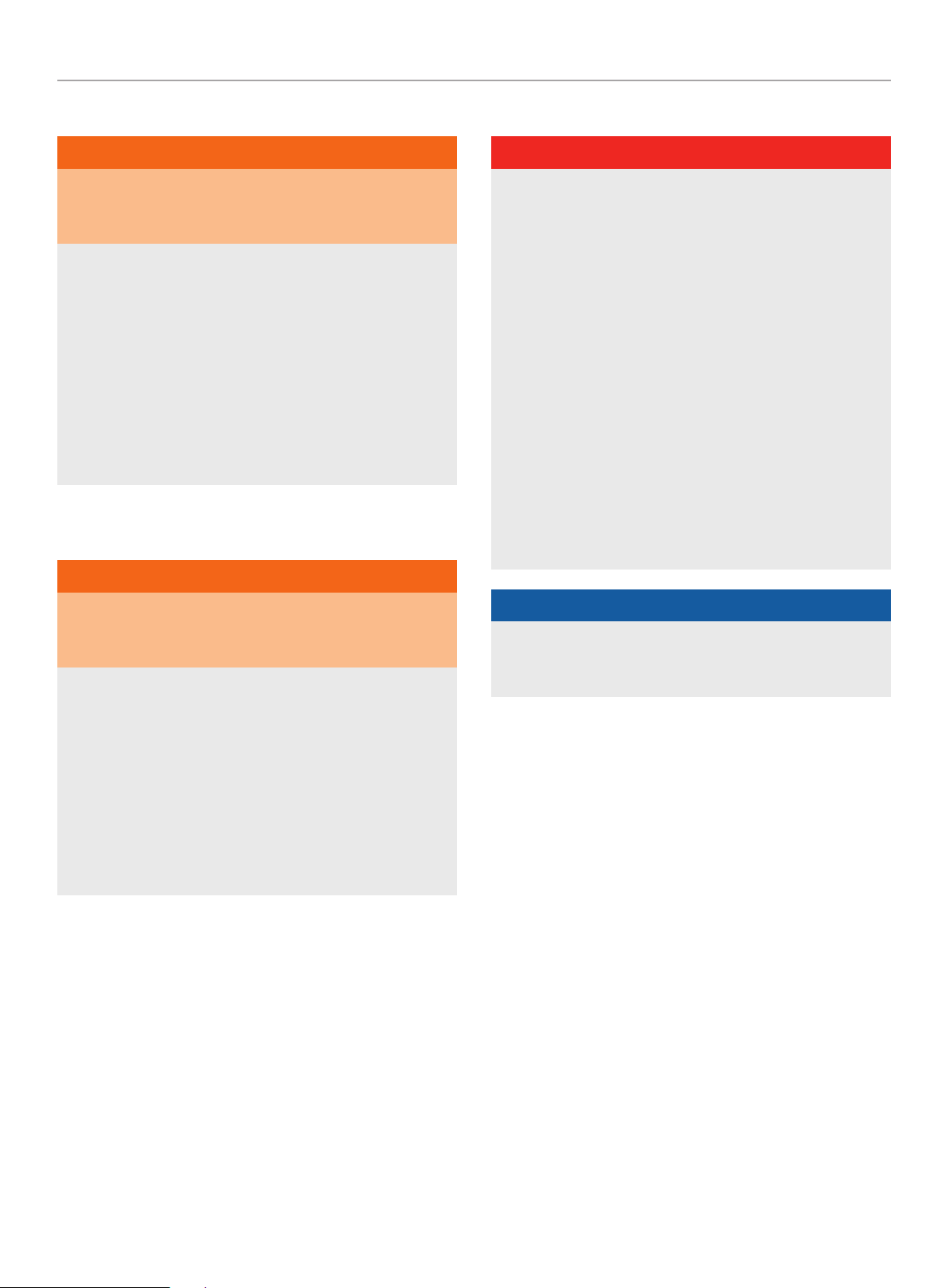

Page 12

aXis CONTROLLER HOME STANDBY GENERATOR

Explosion Hazard - Battery gases are explosive.

Keep sparks and flames away from the battery

compartment.

Risque d’explosion - Les gaz dégagés par la batterie

peuvent exploser. Ecartez les étincelles et les

flammes du compartiment batterie.

Riesgo de explosión - Los gases de las baterías son

explosivos. Mantenga las chispas y llamas alejadas

del compartimento de las baterías.

DANGER

DANGER

PELIGRO

Read Operator’s Manual - Read, understand

and follow all safety messages in Intallation

and Operator’s manuals

Lisez le manuel d’utilisation - Lisez

comprenez bien et respectez tous les

messages de sécurité dans les manuels

d’installation et d’utilisation.

Lea el manual del operador - Lea, comprenda

y siga todos los mensajes de seguridad en los

manuales de instalación y del operador.

CAUTION

MISE EN GARDE

PRECAUCIÓN

2470-L-SF-A

Starting Hazard - The generator may crank and start any

time without notice. Prevent the generator from starting

while the covers are open. See the safety section of the

operator’s manual for further detail.

Risque au démarrage - Le groupe électrogène peut tourner

et démarrer à tout moment sans préavis. Ne démarrez pas

le groupe électrogène lorsque les capots sont ouverts.

Consultez la section sécurité du manuel d’utilisation pour

plus de détail.

Riesgo de inicio - El generador puede encenderse y

ponerse en marcha en cualquier momento sin previo aviso.

Evite que el generador se ponga en marcha mientras las

tapas están abiertas. Vea la sección de seguridad en el

manual del operador para más detalles.

DANGER

DANGER

PELIGRO

1681-T-PR

1681-T-PR

ATTENTION

ALTERNATE POWER SOURCE AVAILABLE -

STANDBY GENERATOR ON PREMISES.

ATTENTION

AUTRE SOURCE DE COURANT DISPONIBLE -

GENERATEUR SUR SITE.

ATEN CIÓN

FUENTE DE CORRIENTE ALTERNA DISPONIBLE -

GENERADOR DE RESERVA EN EL SITIO.

GENERATOR LOCATION:

UBICACIÓN DEL GENERADOR:

EMPLACEMENT DU GENERATEUR:

DO NOT REMOVE \ NO REMUEVA \ NE PAS ENLEVER

NW

W E

N NE

SW S SE

FRONT BACK

LABEL DESCRIPTION PART NO.

SAFETY LABELS AND HANG TAGS

F

Hang Tags

1

Explosion Warning, Read

OM, Starting Warning

HANG TAG DESCRIPTION PART NO.

ATTENTION

ALTERNATE POWER SOURCE AVAILABLE -

STANDBY GENERATOR ON PREMISES.

ATEN CIÓN

FUENTE DE CORRIENTE ALTERNA DISPONIBLE -

GENERADOR DE RESERVA EN EL SITIO.

ATTENTION

AUTRE SOURCE DE COURANT DISPONIBLE -

GENERATEUR SUR SITE.

GENERATOR LOCATION:

UBICACIÓN DEL GENERADOR:

EMPLACEMENT DU GENERATEUR:

DO NOT REMOVE \ NO REMUEVA \ NE PAS ENLEVER

NW

W E

SW S SE

N NE

Alternate Power Source 1681-T-O P

2470 -L- S F

12

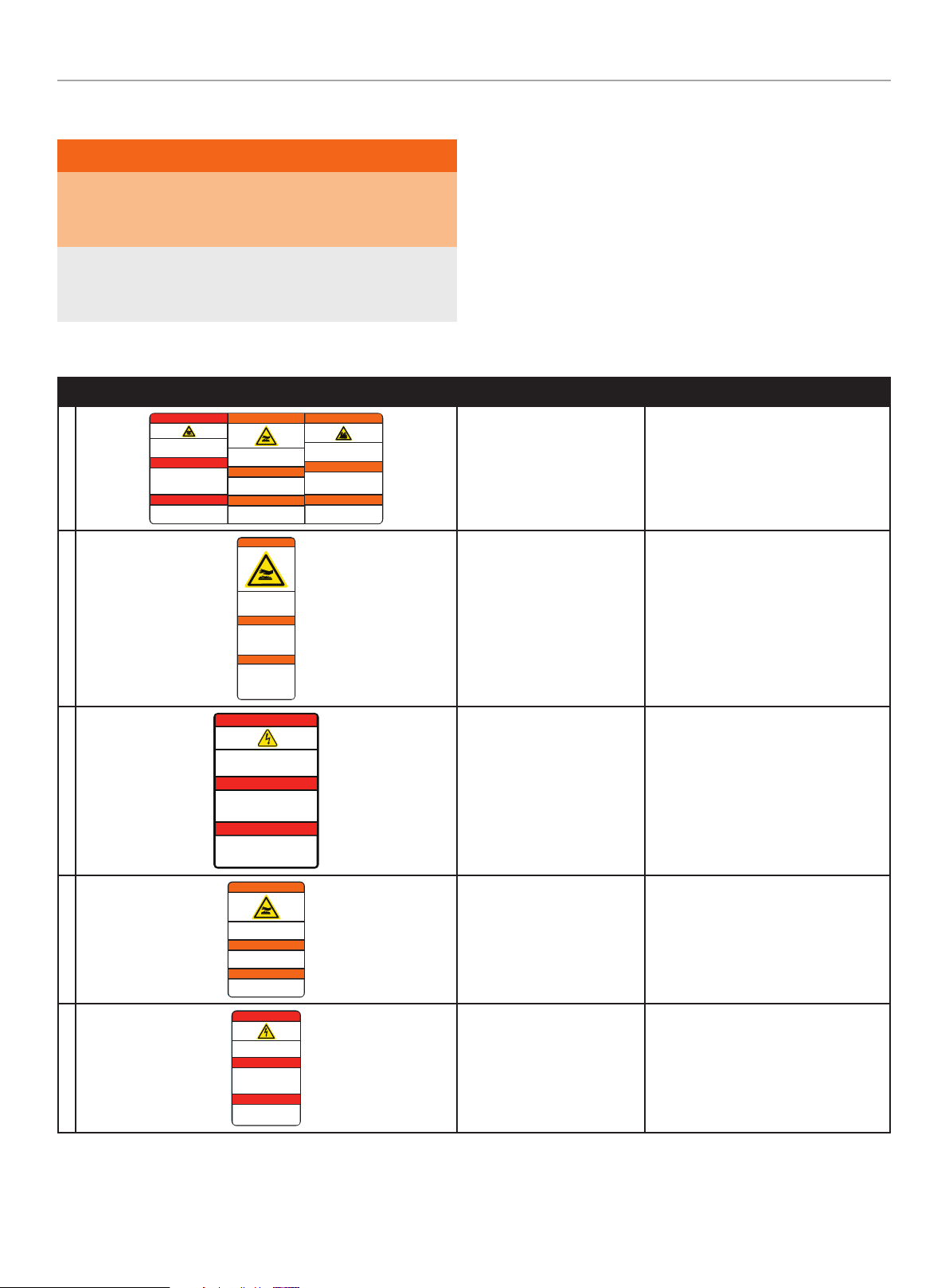

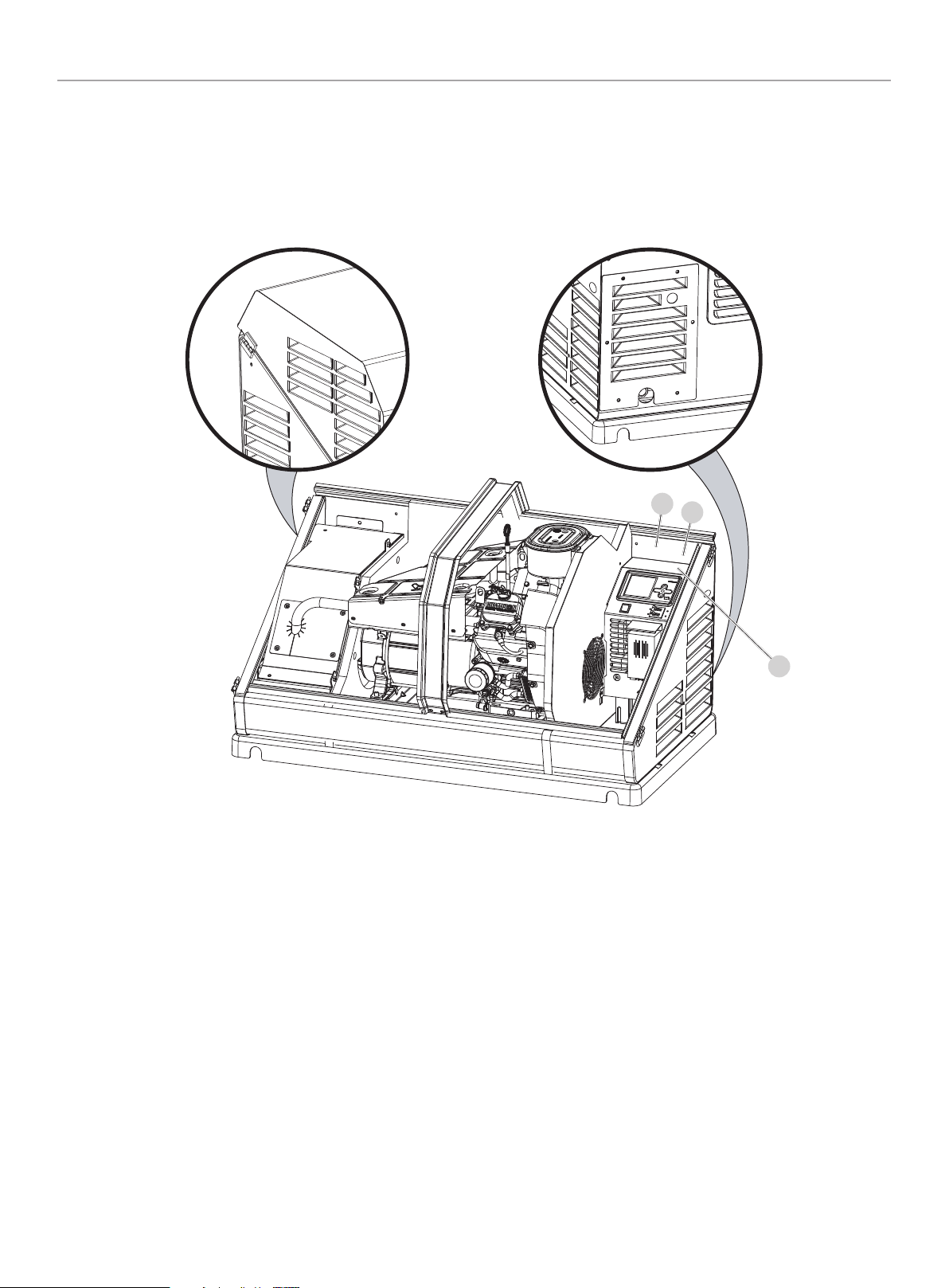

Page 13

aXis CONTROLLER HOME STANDBY GENERATOR

SAFETY LABELS AND HANG TAGS

Safety, Serial/Model, Nameplate Label Locations

The safety labels have specific placement and must be replaced if they are unreadable, damaged or missing.

C

A

a. Serial number location

b. Nameplate

c. NFPA 37 Compliance

B

13

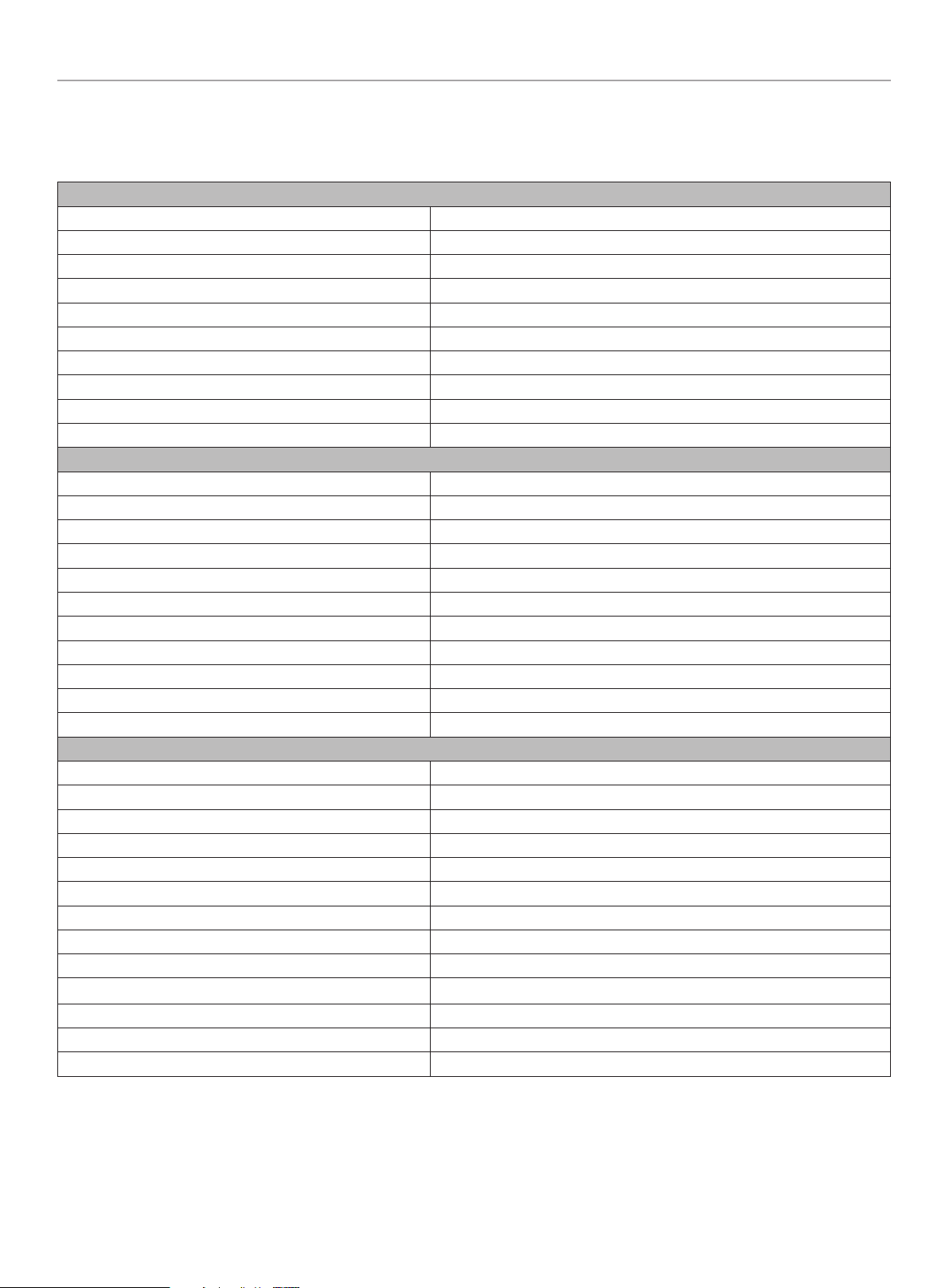

Page 14

aXis CONTROLLER HOME STANDBY GENERATOR

SPECIFICATIONS

14kW HSB Specifications

Home Standby Generator

Maximum continuous power, LPG 14 kW

Maximum continuous power, NG 12.5 kW

Rated voltage 120/240

Amps 116.6/58.3 LPG (propane), 104/52 NG (natural gas)

Harmonic distortion Less than 5%

Main line circuit breaker 65 amp

Phase Single

Frequency 60 Hz

Unit weight 438.7 lb. (199 kg)

Size (L x W x H) 49 x 28 x 28 in. (124.5 x 71 x 71 cm)

Engine

Type Milwaukee Series OHV Commercial V-Twin

No. of cylinders 2

Displacement 754 cc

Cylinder block Aluminum with cast iron sleeves

Ignition system Solid state – magneto

Spark plug F7RTC (NGK BPR7ES)

Governor Mechanical

Starter Electric 24V DC

Oil capacity 1.6 qt (1.5 L)

Oil Type 5W-30 Full Synthetic*

RPM 3600

Controls

Mode switch auto Auto start on utility failure

Mode switch manual Starts on demand

Mode switch off Stops unit/control and charger active

Ready to run/maintenance messages Standard

Programmable start delay Standard

Engine start sequence Standard

Starter lockout Standard

Battery charger/low battery indicator Standard

Charger fault Standard

AVR over voltage protection Standard

Low oil protection Standard

Safety fused Standard

Overcrank/overspeed/underspeed protection Standard

SPECIFICATIONS

* Unit ships without oil. Add oil before starting the HSB.

14

Page 15

aXis CONTROLLER HOME STANDBY GENERATOR

SPECIFICATIONS

Champion 754cc Engine

The 754cc engine was developed by Champion Engine Technology for use in Champion home standby generators. The V-Twin cylinder

design provides high output, efficient operation, low maintenance and demonstrated long life.

Based on the engine’s power, performance and reliability, it was selected to power the 14 kW Champion Home Standby Generator. This

engine design has been used in production since 2015.

The following are the engine specifications:

Type ................... Milwaukee Series OHV Commercial V-Twin

No. of Cylinders ....................................................2

Displacement ................................................. 754cc

Cylinder Block .................... Aluminum with cast-iron sleeve

Cylinder Head ............... Automotive harden valves and seats

Ignition System .............................. Solid state – magneto

Governor ................................................ Mechanical

Starter .............................................. Electric 24V DC

RPM ............................................................3,600

Oil Capacity ........................................... 1.6 qt. (1.5 L)

Champion 754cc Engine Torque Specifications

Crankcase Cover Bolts ...........................27 Nm (20 lbf-ft)

Connecting Rod Bolts ............................. 12 Nm (9 lbf-ft)

Rocker Cover Screws .............................. 10 Nm (7 lbf-ft)

Cylinder Head Bolts ........................... 40 Nm (29.5 lbf-ft)

Intake Manifold Screws .......................... 9.5 Nm (7 lbf-ft)

Carburetor to Intake Manifold .................... 9.5 Nm (7 lbf-ft)

Blower Housing ................................... 9 Nm (6.6 lbf-ft)

Flywheel Nut ................................... 196 Nm (145 lbf-ft)

Ignition Coil Bolts ................................. 9.5 Nm (7 lbf-ft)

Starter Motor Bolts ............................. 24.4 Nm (18 lbf-ft)

Spark Plug ......................................18 Nm (13.3 lbf-ft)

Air Cleaner box to Carb ........................... 9 Nm (6.6 lbf-ft)

Exhaust pipe nuts ..............................18 Nm (13.3 lbf-ft)

Master Mixing Assembly Jets (Carburetor System)

Idle/low-speed Jet .............................. 1.9 Nm (1.4 lbf-ft)

Main Jet ......................................... 3.9 Nm (2.9 lbf-ft)

Fuel Inlet Chamber Screws .................... 2.9 Nm (2.1 lbf-ft)

15

Page 16

aXis CONTROLLER HOME STANDBY GENERATOR

UNPACKING

Alternator Overview

The alternator is made up with the following major components;

1. Brush holder assembly

2. Rear bearing carrier

3. 2 pole rotor (all copper wire)

4. Stator assembly (all copper wire)

5. Engine adapter

ROTOR ASSEMBLY

The alternator has a 2-pole rotor, which means the rotor has a

single south magnetic pole and a single north magnetic pole.

As the rotor spins, its magnetic field passes through the stator

assembly windings and voltage is induced into the stator windings.

This is known as induction. The rotor shaft has a negative (-) slip

ring and a positive (+) slip ring, with the negative (-) nearest the

bearing carrier. The rotor shaft is held in place with single through

bolt.

STATOR ASSEMBLY

The stator houses, AC power windings and excitation windings.

It is held in place with 4 bolts that pass through the bearing

carrier and engine adapter, then attached to the engine mounting

flange. In combination with the rotor assembly, they generate the

electrical out-put of the HSB.

BRUSH HOLDER AND BRUSHES

The brush holder is a component that holds the brushes in a

stationary position enabling them to maintain contact with the

rotating surface commutator rings on the rotor. The brush holder

is attached to the rear bearing carrier by means of a M5 x 20 bolt

and a location tab. A negative (-) brush and a positive (+) brush

are retained in the brush holder. The negative (-) brush rides on

the slip ring nearest the bearing carrier. The brushes are spring

loaded to maintain contact.

UNPACKING

WARNING

The HSB weighs more than 500 lbs. (227 kg).

Use the aid of additional assistants and exercise caution during

installation.

Inspect the generator for damaged or loose parts. DO NOT operate

the generator if any components are damaged or loose. Contact

your dealer for assistance.

1. Cut banding straps.

2. Remove top lid.

3. Remove center cardboard supporting rib.

4. Lift cardboard housing and set aside with all other trash.

5. Remove plastic covering and discard.

6. Remove 4 securing clamps. Save if going to use anchor bolts

to secure to concrete pad (not supplied).

7. Insert 2 lifting rods (not supplied) into lifting notches at each

end of the base.

8. Discard all shipping materials and recycle if possible.

NOTICE

– If you know length of run for wires you may want to install

the ATS communication wires and voltage wires now

before setting unit to industry 1st 17.7 in. from fire rated

wall and when code permits. Install the wires, some of the

gas delivery pipes and flex hose now while you have ample

room and at tailgate height is much easier than when in

place

– Cardboard can be used for kneeling

A RED wire connects to the positive (+) brush and a BLACK wire to

the negative (-) brush. Rectified and regulated excitation current,

as well as current from the field boost circuit, are delivered to the

rotor windings via the RED wire, and the positive (+) brush and

slip ring. The excitation and field boost current passes through the

windings and to the frame ground via the negative (-) slip ring and

brush, and the BLACK wire.

The current flow creates a magnetic field around the rotor having

a flux concentration that is proportional to the amount of current

flow.

16

Page 17

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

INSTALLATION

Placement & Installation Guidelines for Champion Home Standby Generators to Reduce the

Risk of Fire

NATIONAL FIRE PROTECTION ASSOCIATION (NFPA)

STANDARD NFPA 37 REQUIREMENTS AND TESTING

Requirements:

NFPA 37 2010, section 4.1.4, Engines Located Outdoors.

Engines, and their weatherproof housings if provided, that are

installed outdoors shall be located at least 1.5 m (5 ft.) from

openings in walls and at least 1.5 m (5 ft.) from structures having

combustible walls. A minimum separation shall not be required

where either of the following conditions exist:

1. The adjacent wall of the structure has a fire resistance rating

of at least 1 hour.

2. The weatherproof enclosure is constructed of noncombustible

materials and has been demonstrated that a fire within the

enclosure will not ignite combustible materials outside the

enclosure.

Annex A Explanatory Material

A.4.1.2 (2) Means of demonstrating compliance are by means of

full-scale fire tests or by calculating procedures, such as those

given in NFPA 555, Guide on Methods for Evaluating Potential for

Room Flashover.

To comply with condition 2 the weatherproof enclosure has

been constructed of non-combustible materials and full-scale

fire tests have been performed to demonstrate that a fire within

the enclosure will not ignite combustible materials outside the

enclosure.

Based on this testing and the requirements of NFPA 37, Sec.

4.1.4, the guidelines for installation of the Champion home

standby generator are changed to 17.7 inches (45 cm) from the

backside of the generator to a combustible wall. All other location

and distances remain the same as noted in the Operators and

Installation manuals.

These guidelines are based upon fire testing of the generator

enclosure and Champion’s requirement for air flow for proper

operation. Local codes may be different and more restrictive.

17

Page 18

aXis CONTROLLER HOME STANDBY GENERATOR

102358 1193-L-PR-A

ID: 170800364HZH-001

Conforms to / Conforme à:

NFPA 37 4.1.4 CL. 2

INSTALLATION

Intertek Group PLC Label

Located inside the generator, next to the generator’s data label

NFPA® 37 Standard for the Installation and Use of Stationary Combustion Engines and Gas Turbine

The National Fire Protection Association (NFPA) standard NFPA 37 establishes criteria for minimizing the hazard of fire during the

installation and operation of stationary combustion engines. NFPA 37 limits the spacing of an enclosed generator from openings in walls,

structures and combustible materials outside the enclosure.

NFPA 37 (2015): Section 4.1.4 stipulates that engines installed outdoors shall be located at least 5 ft. (1.5 m) from structures having

combustible walls. Further, a minimum separation shall not be required where the following conditions exist:

All walls of the structure that are closer than 5 ft. from the engine enclosure have a fire resistance rating of at least 1 hr., or

The weatherproof engine enclosure is constructed of noncombustible materials, and it has been demonstrated that a fire within the

enclosure will not ignite combustible materials outside the enclosure.

Intertek Group PLC performed a full-scale fire test under a worst-case fire scenario within the stationary generator enclosure to determine

the ignitability of combustible material near the stationary generator. The enclosure is made of non-combustible materials and the results

and conclusions of the test indicate that a fire within the enclosure would not pose any risk of ignition to nearby combustible materials

or structures. Intertek Group PLC is certifying that this model complies with clause (2) of Section 4.1.4 of NFPA 37 when installed at a

minimum distance of 450 mm (17.7 in.) from a combustible wall.

18

Page 19

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

Champion HSB units have been run and tested at the factory prior

to shipment. They do not require any type of break-in period.

Site Selection, Preparation and Placement

These items are important to the overall performance of the HSB

generator. Many items covered in this section are not optional and

are requirements under Federal, State and Local codes. As with

all generators, your generator must be installed in accordance

with current NFPA-37, NFPA 54, NFPA 58 and NFPA-70 standards.

Contact your local electrical inspector or city hall to insure you

are aware of all codes and regulations. Install the equipment in

compliance with the National Electric Code (NEC). For Canada

installations, refer to Canadian Electrical Code (CEC). Contact your

natural gas supplier to verify that increased BTU gas demand can

be handled with the existing NG meter. The same should done for

LPG fueled generators. This generator in the enclosure is designed

to be installed outdoors only.

Champion HSB units are run and tested at the factory prior to

being shipped. They do not require any type of break-in period.

SUGGESTED SITE SELECTION

The installation of the HSB must comply strictly with NFPA 37,

NFPA 54, NFPA 58 and NFPA 70 standards.

Always install your generator within 20 feet of the NG meter, the

closer the better. This will reduce expensive costs of running fuel

line. In some cases longer runs of fuel line, when not properly

sized may cause inadequate fuel delivery. This could result in

poor starting, lower outputs and diminished overall performance

of the unit. The Champion HSB is shipped from the factory set

up for natural gas (NG) fuel. The HSB can be converted to LPG

if required. Orifices in the master mixer assembly (carburetor)

MUST be changed. The LPG orifices are shipped with the unit and

include installation instructions.

Install the unit in a location where the sump pump discharge,

rain gutter downspouts, roof run off, landscape irrigation, natural

ponding or water sprinklers will not flood the unit or spray the

enclosure entering any inlet or outlet opens.

Position the unit in an area where prevailing winds will carry

the exhaust gas away from any potentially occupied building or

structure.

Install the unit where leaves, grass, snow, ect., will not obstruct

air inlet and outlet openings. If prevailing winds cause blowing or

drifting, you may consider building a windbreak, planting trees or

shrubs within the guidelines and codes applicable.

Watch out for roof overhangs. Snow, ice or rain shouldn’t be

permitted to accumulate on the roof and then cascade onto the

unit.

DANGER

Engine exhaust from the unit is hot, poisonous and dangerous.

Exhaust must be allowed to dissipate into a free air zone as

listed in the applicable codes with no obstructions.

Direct the HSB exhaust away from or parallel to the building or

structure. DO NOT direct the HSB exhaust toward a potentially

occupied building, structure, windows, doors, ventilation intakes,

soffit vents, crawl spaces, open garage doors or other openings

where exhaust gas could accumulate and enter inside or be drawn

into potentially occupied buildings or structures.

Install the unit on higher ground where water levels will not rise

and endanger it. This unit shouldn’t be operated in standing water.

DO NOT place HSB waterproof enclosure under a deck or other

type of structure that may confine or restrict airflow. Operate

HSB only outdoors, where adequate ventilation and air movement

is available. Avoid installations under decks, inside garages or

carports, in basements, along home exterior within 5 feet (1.5m)

of home vent, roof overhang vents, a window that can be opened,

or other such home invasion points. Use the same precautions

when installing HSB at property line, close to a neighbor’s home,

or any building or structure that houses animals.

DANGER

Running engines give off carbon monoxide, an odorless,

colorless, invisible, poison gas.

Breathing carbon monoxide will cause fatigue, headache,

dizziness, vomiting and in prolonged conditions, even death.

Carbon monoxide detectors MUST be installed and maintained

indoors according to the manufacturer’s instructions/

recommendations. Smoke alarms cannot detect carbon

monoxide gas.

The back of the HSB locates the fuel and wire entry points. When

placement/mounting is done this side generally faces the closest

point to each of those sources.

It is always recommended to prepare a drawing showing location

of HSB, typical gas utility approach, circuit connections and full

load connections.

Similar considerations should be given to the location of the ATS

(automatic transfer switch) in relationship to the HSB generator.

The closer to both the fuel meter and the main utility panel

the better. The key point here is, the closer to fuel meter is the

suggested direction to go, wire is cheaper to run and more flexible.

19

Page 20

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

SUGGESTED PREPARATION

A concrete pad can be poured or purchased through Champion

(model 100616) and the HSB secured to it. In some areas a

concrete pad is required due to high wind potential. Check

local codes to see what type of mounting base is required. If a

concrete pad is required, all federal, state and local codes should

be followed. Unless mandated by federal, state or local code, a

concrete pad is not required.

If no concrete pad is being used, Champion recommends using a

mixture of pea gravel and sand or crushed stone for placement of

the mounting pad. The mounting pad MUST be level. The gravel

mixture or crushed stone is to permit water runoff, drainage and

reduce ponding of water around the HSB.

Dig an area 5 inches (12.7 cm) deep that is 6 inches (15.2 cm)

longer and wider than the foot print of the HSB. The HSB is 49

inches long × 28 inches wide (124.5 cm long × 71 cm wide).

Cover the dugout area with a weed barrier or landscape cloth if

desired.

Fill the area with pea gravel and sand mixture or crushed stone.

Final stone level must be 2 or 3 inches higher than the original

ground level to ensure water run-off and drainage.

Unbox the unit, by removing the exterior shipping carton. The ATS

is included, remove the packaging and lift it out. Remove the 4

shipping brackets, 2 on each end that hold the HSB to the wood

shipping pallet. This pallet is for shipping/transportation only and

cannot be used as a mounting pad in any form. Exercise caution

when removing the HSB from the wood pallet, dragging it off the

wood pallet will damage the HSB base. The HSB must be lifted

from the wood pallet to separate.

Contact your natural gas (NG) supplier about the meter size. Most

meters must be replaced with a larger BTU size, due to a larger

demand of BTU’s from the HSB and appliances during operation

(utility outage). This also applies to HSB utilizing LPG.

SUGGESTED PLACEMENT

The Site Selection has been completed, all federal, state and local

codes have been reviewed and applied as mandated by the NFPA

standards and all other related codes/standards.

Preparation has been completed and everything has been properly

prepared to place the HSB.

The rear right side of the HSB locates the fuel and wire entry

points. When placement is done this side generally faces the

closest point to each of those sources for fuel and wire entry.

Compact the fill, this is to provide a firm base for the HSB.

Remember the final stone level must be 2 or 3 inches higher than

the original ground level to ensure water run-off and drainage.

Tools required

1. General SAE and Metric hand tools, wrenches, sockets and

screwdrivers.

2. Standard electrician’s hand tools, drill and bits.

3. Monometer (for checking fuel pressures).

4. Meter capable of measuring AC/DC Voltage and Frequency

5. Safety apparel

Inspect the unit. Carefully inspect the HSB for any damage

that may have occurred during shipment and delivery. If loss

or damage is noted at the time of delivery, have the person(s)

making delivery note all damage on the freight bill and affix their

signature under the consignor’s memo of loss or damage. If loss

or damage is noted after delivery, separate the damaged materials

and contact the carrier for claims procedures. Parts damaged in

shipping are not covered under Champion warranty.

WARNING

HSBs weigh approximately 300-500 lbs (136-227 kg)

depending on the model. Proper tools, equipment and qualified

personnel should be used in all phases of handling and moving

the HSB. Do not lift or move the HSB without assistance. Do

not lift the unit by the roof structure or any other enclosure

component as damage to the HSB may occur, including

possible injury of persons when handling and or moving the

HSB in this manner.

Two (2) 5 foot (1.5 m) lengths of ¾ “steel pipe (supplied by the

installer), are required to lift the HSB. Insert the steel pipes

through the lifting holes located near the HSB base in the

composite pad, on each end.

20

Page 21

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

You may also lift the HSB using a properly rated strap, lift, hook

and hoist procedure attached to both steel lifting pipes, provided

that you use spreader bars to ensure that the belts, chains or

cables DO NOT touch/contact the HSB.

Once the HSB has been placed, check to make sure it is level. If it

isn’t, make adjustments prior to installation procedures start.

Installation Preparation

WARNING

Improper installation can result in personal injury and damage

to the generator. It may also result in the warranty being

suspended or voided. All the instructions must be followed

including location clearances and pipe size.

Once Site Selection, Preparation and Placement has been

completed, you can proceed to Installation Preparation. Without

these in place you may encounter problems moving forward.

There are a number of key items that MUST be addressed prior

to the physical installation of the HSB. The installation of the HSB

must comply strictly with all applicable codes, standards and

regulations (NFPA 37, NFPA 54, NFPA 58, and NFPA 70).

Check and confirm that the HSB on board controls are in the

“OFF” position. It is recommended to pull the control module fuse

located on the front panel and turn the circuit breaker to the OFF

position.

Champion HSB units have been run and tested at the factory prior

to being shipped. They do not require any type of break-in period.

7. Sediment Tr ap

8. Checking Pressure with a Manometer

9. Battery Requirements, Installation & Service

10. Wiring of the HSB

1. FUEL REQUIREMENTS AND RECOMMENDATIONS

The following NG and LPG fuel information is provided to assist

the fuel installer. This information should not be deemed to be

all inclusive or to conflict with local dry fuel codes. Consult your

local fuel supplier or Fire Marshall for guidance on proper local

codes and installations. Local codes will mandate correct routing

of gaseous fuel line piping around gardens, shrubs and other

landscaping to prevent any damage.

Special considerations should be given when installing the

HSB where local conditions include might flooding, tornadoes,

hurricanes, earthquakes and unstable ground. These are

considerations for the flexibility and strength of piping and their

connections.

NG is lighter than air and will collect in high areas. LPG is heavier

than air and will settle in low areas.

DANGER

Gaseous fuels such as NG and LPG are highly explosive.

Even the slightest spark can ignite such fuels and cause an

explosion, which could cause burns, fire or explosion resulting

in serious injury, property damage or even death. NO leakage

is permitted.

CAUTION

The HSB is shipped without oil in the engine. Add oil to full

capacity as stated in the specification section before starting

the HSB.

Never operate the HSB with the engine oil level below the

“ADD” mark on the dipstick, doing so could damage the

engine. Check the oil level and add the appropriate viscosity

and amount indicated on the oil dipstick full line. The

recommended oil type for typical use is 5W-30 full synthetic

oil. Refer to Owner’s manual.

In the this segment, “Installation Preparation, the following will be

covered;

1. Fuel Requirements and Recommendations

2. Fuel Consumption

3. NG Pipe Sizing, flexible fuel line

4. LPG Vapor Pipe Sizing, flexible fuel line

5. Converting to LPG

6. Full Flow Shut Off Valve

Recommended fuels should have a BTU content of at least 1,000

BTU’s per cubic foot for NG, or at least 2,500 BTU per cubic foot

for LPG. Ask the fuel supplier for the BTU content of the fuel.

Before NG fuel lines plans are made, call your NG supplier, provide

them information on the amount cubic feet/hour and the BTU’s/

hour that the HSB will use, and ask if the NG meter and primary

regulator can accommodate the addition of the NG generator. NG

companies have different meters for increased BTU demands.

Utilize the “Fuel Consumption (BTU) Chart” contained in this

manual or the Installation Manual for your specific HSB model.

Verify that the current gas meter is capable of providing enough

fuel flow to include household appliances and other loads

including the addition of the HSB. Check the NG primary regulator,

connected at the NG meter output. The correct primary regulator

is set at 5 to 7 inches water column. The existing primary

regulator may be undersized once the HSB is added.

The HSB engine can run on either NG or LPG. The HSB comes

equipped from the factory to run on NG. If your installation

requires the engine to run on LPG, orifices in the master mixer

assembly (carburetor) MUST be changed. The LPG orifices are

shipped with HSB. Refer to “Converting to LPG” in this manual or

the “Installation Manual” for your specific HSB model.

21

Page 22

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

14 kW Fuel System Requirements

Fuel System

Requirements

Fuel Supply Inlet 3/4 in. NPT

Fuel Supply

Pressure

Maximum flow

rate @ 14kW

LPG 2500 BTU/ft3

NG 1000 BTU/ft3

Install the fuel system in accordance with NEC and local codes.

The HSB is EPA Phase 3 certified for LPG and NG fuels.

2. FUEL CONSUMPTION

Air density is less at high altitudes, resulting in less available

engine power. Engine power will decrease 3.5% for each 1,000

feet (300 m) above sea level and 1% for each 10° F (5.5° C) above

77° F (25° C). Make sure these factors are considered when

determining total HSB load.

The gas supply and pipe MUST be sized at 100% load BTU rating.

Understand that as a specific fuel supply line pipe diameter is

extended in length, its ability to carry the volume of gas diminishes

in direct proportion. Improper fuel pipe sizing is the number one

reason for poor operating performance (hard starting, output).

Required fuel pressure for NG is 5 – 7 inches water column.

Required fuel pressure for LPG vapor is 10 – 12 inches water

column. These are estimated fuel supply requirements listed.

Refer to “Fuel Consumption Chart” above.

14 kW Fuel Consumption

Fuel Type Percent of load l/hr – m3/hr

LPG

NG

3. NG PIPE SIZING

The HSB leaves the factory set up for NG, no changes or alteration

need to be made if NG is the fuel source you are going to use

The following NG fuel information is provided to assist the fuel

installer. This information should not be deemed to be all inclusive

or to conflict with local dry fuel codes. Consult your local fuel

supplier or Fire Marshall for guidance on proper local codes and

installations. All piping must comply with NFPA 54 and related

codes. Gas line connections should be made by a certified

plumber familiar with local codes.

10 – 12 inch-H20.

(2.5 – 3.0 kPa W.C.)

LPG NG

5 – 7 inch-H2O

(1.2 – 1.7 kPa W.C.)

10.1 l/ h r 5.3 m3/hr

Nominal Fuel Rating

0% 3.09 l/hr

50% 5.93 l/hr

100% 9.91 l/hr

0% 1.8 m3/hr

50% 3.3 m3/hr

100% 5.1 m3/hr

Always use AGA approved gas pipe and a quality pipe sealant or

joint compound. The piping should conform to federal and local

codes, rigidly mounted and protected from vibration. Piping should

be black iron or steel to avoid reacting with the sulfur in the fuel.

DANGER

NG is highly explosive. Even the slightest spark can ignite and

cause an explosion, which could cause burns, fire or explosion

resulting in serious injury, property damage or even death. NO

leakage is permitted. Safety is important.

Gas pipe sizing is critical to the proper operation of the HSB. The

HSB fuel inlet size has no bearing on the proper gas pipe size

running to the HSB. Gas supply and pipe MUST be sized at 100%

load BTU rating. Understand that as a specific fuel supply line pipe

diameter is extended in length, its ability to carry the volume of

gas is diminished in direct proportion.

Pipe sizes are measured by inside diameter (ID) to include any

fittings, valves, elbows, tees or angles. Add 2.5 feet (.76 m) per

bend, tee or angle in the pipe line to the overall distance, for each

90 degree elbow, add 8 feet (2.4 m) to the measurement. Use a

pipe sealant or joint compound approved for use with LPG/NG on

all threaded fittings to assure zero leakage.

A dedicated NG fuel supply line pipe and primary gas regulator is

mandatory for proper operation. A minimum of one (1) approved,

external manual full flow shutoff gas valve must be installed in the

fuel supply line pipe leading to the HSB. This line must be easily

accessible.

FLEXIBLE FUEL LINE

A flexible fuel line (enclosed with the HSB) is to be installed

between the stationary fuel supply line pipe and the fuel inlet

pipe to the HSB. The purpose of the flexible fuel line is to ensure

that vibration from the HSB does not cause a gas leak at one of

the connection points. The flexible fuel line is not to be installed

underground, in contact with any enclosure parts or contact with

the ground. The entire flexible fuel line must be visible for periodic

inspection and must not be concealed within nor contact nor run

through any wall, floor, partition or fence. Never bend flexible

fuel line to avoid using an elbow. Bending the flexible fuel line

decreases its ability to absorb vibrations and could restrict the

actual fuel flow. Because a HSB engine is prone to vibration, a

flexible piping connection to the gas supply is required. Connect

the HSB to the gas supply piping with an approved flexible gas line

according to local codes. The flexible gas line also protects against

settlement between the HSB pad and the ridged gas supply piping.

22

Page 23

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

CAUTION

Check for leaks by spraying all connection points with a soap

solution made of dishwashing liquid and water. If you see

bubbles, this indicates a leak and the connection should be

corrected. Check each connection point, there should not be

a visible bubbling when soap solution applied. Installed piping

must be properly purged and leak tested, in accordance with

applicable codes and standards. A sediment trap should be

placed in the fuel supply pipe line to drain any condensation.

Refer to the “Fuel Pipe Sizing Chart” contained in this manual or

the Installation manual for your specific HSB model. Champion

HSB units have been run and tested at the factory prior to

shipment. They do not require any type of break-in period.

4. LPG VAPOR PIPE SIZING

The HSB leaves the factory set up for NG. If you are going to fuel

the HSB with LPG you MUST change the Master Mixer Assembly

(carburetor system) for LPG usage. The HSB will not perform on

LPG if the carburetor system is not changed from NG to LPG. Refer

to “Converting to LPG” in this manual or the Installation Manual

of your specific HSB model. If your installation requires the engine

to run on LPG, a set of orifices in the Master Mixer Assembly

(carburetor system) MUST be changed. The LPG set of orifices are

enclosed (shipped) with the HSB.

The following LPG information is provided to assist the fuel

installer. This information should not be deemed to be all inclusive

or to conflict with local dry fuel codes. Consult your local fuel

supplier or Fire Marshall for final answers on proper local codes

and installation. All piping must comply with NFPA 54 and related

codes. Gas line connections should be made by a certified

plumber familiar with local codes.

DANGER

LPG is highly explosive. Even the slightest spark can ignite and

cause an explosion, which could cause burns or fire resulting

in serious injury, property damage or even death. No leakage

is permitted. Safety is important.

Gas pipe sizing is critical to the proper operation of the HSB. The

HSB fuel inlet size has no bearing on the proper gas pipe size

running to the HSB. Gas supply and pipe MUST be sized at 100%

load Btu rating.

Pipe sizes are measured by inside diameter (ID) to include any

fittings, valves, elbows, tees or angles. Add 2.5 feet (.76 m) per

any bend, tee or angle in the pipe to the overall distance. For each

90 degree elbow, add 8 ft. (2.4m) to the measurement. Use a pipe

sealant or joint compound for use with LPG/NG on all threaded

fitting to assure zero leakage.

The LPG must be a vapor withdrawal system. The HSB will not

work on a liquid withdrawal system. Gas line connections should

be made by a certified plumber familiar with local codes.

New LPG tanks and existing LPG tanks already located at the

installation site, have a primary fuel regulator set and intended for

home heating and cooking. This regulator might not be properly

sized to accommodate the addition of the HSB. Contact the local

LPG supplier to properly size the fuel regulator.

Make sure the tank is sized large enough to provide the required

Btu’s for the HSB and all connected appliances.

The LPG fuel tank must have a dedicated primary fuel regulator

mounted at the tank fuel outlet point and set for 6 ounce pressure,

10 -12 inch water column. A direct, dedicated fuel line connected

directly to the HSB mounted secondary regulator, also set at

6 ounce pressure, 10 -12 inch water column. When sizing the

secondary regulator for LP applications be sure to note the

maximum individual load capabilities. This could impact HSB

starting performance if sized to small. It is not recommended to

reduce the fuel supply line pipe exiting the secondary regulator

unless to accommodate the flexible fuel line required to install and

shipped with the unit. The may result in starting or performance

issues with the HSB.

Make sure fuel supply line pipe includes an on/off external manual

full flow shut off gas valve at both the LPG tank and at the point of

connection to the HSB.

A sediment trap should be installed into the fuel supply pipe line to

drain any condensation.

23

Page 24

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

FUEL PIPE SIZING CHART

NOTICE

Reduced pipe size will affect fuel delivery and performance.

Measure the pipe length from the generator fuel inlet to the

primary gas pressure regulator.

Pipe Length* NG LPG

25 ft (8 m) 3/4 in. NPT 3/4 in. NPT

50 ft (15 m) 1 in. NPT 3/4 in. NPT

100 ft (30 m) 1 in. NPT 1 in. NPT

150 ft (46 m) 1-1/4 in. NPT 1 in. NPT

200 ft (61 m) 1-1/4 in. NPT 1 in. NPT

* Add 2.5 ft (0.76 m) per bend, tee or angle in the pipe line to overall distance, for

each 90 degree elbow, add 8 feet (2.4 m) to the overall measurement.

5. CONVERTING TO LPG

The engine is fitted with a dual Master Mixer Assembly (carburetor

system), which allows the HSB to run on either NG or LPG. It has

been configured at the factory to run on NG. If your installation

requires to run on LPG, an orifice in the Master Mixer Assembly

(carburetor system) must be changed. The LPG orifices are

shipped with the HSB.

3. Remove left side main jet (7), right side main jet (8), left side

slow jet (9) and right side slow jet (10). Recommend tool

for removing main jet: Special Tool (Part number 100908).

Recommend tool for removing slow jet: Driver Bit, 7/32 Slot Flat Head

4. Install LPG jets and gasket (6) to fuel inlet chamber.

– Left side main jet: Size #410 (11)

– Right side main jet: #430 (12)

– Left side slow jet: Size #130* (13)

– Right side slow jet: #120* (14)

– Main Jet Tightening Torque: 34.7 lb.-in (3.92Nm)

– Slow Jet Tightening Torque: 17.3 lb.-in (1.96Nm)

* No slow jet required for NG.

Jet Change Procedures

1. Remove breather tube (1) by loosening breather tube clamp

(2).

2. Remove fuel inlet chamber screws (3). Remove fuel inlet

chamber (4) along with fuel hose (5) and gasket (6).

5. Install fuel inlet chamber to mixer body. Tighten fuel inlet

chamber screws (3). Screw Tightening Torque: 26.0 lb.-in

(2.94Nm).

24

Page 25

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

6. Connect breather tube (1) to breather port and put clamp (2)

on breather tube.

7. SEDIMENT TRAP

A sediment trap should be installed into the fuel supply line pipe

when using either NG or LPG to drain any condensation. Always

make sure the HSB is completely in the OFF position and the full

flow fuel shut off valve is closed before removing the sediment

trap for drainage. Use a pipe sealant or joint compound approved

for use with LPG/NG on all threaded fittings to reduce the

possibility of leakage. Install a sediment trap downstream of the

HSB shut-off valve as close to the inlet as possible in accordance

with local codes.

8. CHECKING PRESSURE WITH A MANOMETER

6. FULL FUEL SHUT OFF

A minimum of one accessible, approved manual full fuel shutoff

valve shall be installed in the fuel supply line of the HSB. A manual

full fuel shut off valve should be installed inside the building, for

those locations with inside gas meters. The full flow shut off valve

should be installed in accordance with all applicable codes and

standards.

This check should only be done when the HSB and ATS have been

installed, properly inspected and ready for testing.

A Manometer is a general term for any device that measures

pressure. A gas Manometer measures gas pressure. It’s important

to make sure the correct amount of fuel is being delivered to the

HSB when it starts and at full load usage, the Manometer provides

the ability to check the fuel pressure throughout the operation of

the HSB. A Manometer port should be placed in the fuel supply

pipe line.

CAUTION

Remove the plug, install the Manometer. Open the gas

supply valve check to make sure the pressures are within the

specified values for NG or LPG. This is always a good starting

point for evaluations related to poor performance.

25

Page 26

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

After all appliances have been turn on, start the HSB. If the

Manometer stays within 5 -7 inches of water column for NG,

10 -12 inches of water column for LP, with full load applied to a

proper running HSB, the installation is good.

If the Manometer reading falls below the listed inches of water

column for either specific gas rating while the HSB engine is

starting or running. It may be an indication that the gas meter or

primary regulator is undersized.

If the Manometer reading stays within the specific gas rated

inches water column, but the HSB engine will not start, run erratic,

it may indicate insufficient fuel volume due to long fuel supply pipe

line, incorrect full pipe diameter. Recheck you initial calculations to

ensure where the problem might exist. Champion HSB units have

been run and tested at the factory. They do not require any type of

break-in period.

9. BATTERY REQUIREMENTS, INSTALLATION & SERVICE

Battery sizing is a topic that is discussed and debated for a

number of reasons. The battery size, cold cranking amps (CCA),

starting cycle or deep cycle are all items for consideration. The

following will assist you to better understand the battery, the

codes and the purpose of the battery. It is extremely important

to follow all cautions and warnings per the battery manufacturer

concerning installation, service, maintenance and replacement

procedures.

Battery Council International (BCI) is an association of battery

industry companies whose members establish policy and

standards for the industry.

Battery Size is the physical dimensions of a battery. BCI assigns

letters and numbers for North American battery size types.

Cold Cranking Amps (CCA) is a rating that is used to define

the batteries ability to start an engine under low-temperature

conditions. BCI defines it as “the number of amps a lead-acid

battery at 0 degrees F can deliver for 30 seconds”.

Starting (cranking) Cycle Battery is designed to deliver large

bursts of power for a short time, as needed to start an engine.

Starting batteries are intended to have a low depth of discharge on

each use.

1. Place the batteries in the front right corner of the HSB

enclosure. Features on the floor of the enclosure locate

batteries.

2. Connect the black jumper cable (included) from negative (-)

terminal of battery 1 to the positive (+) terminal of battery 2.

3. Connect the red cable (included) to the positive (+) terminal of

battery 1.

4. Connect the black cable (included) to the negative (-) terminal

of battery 2.

5. Install both battery post covers.

6. Dielectric grease should be applied on the battery

connections to aid in the prevention of corrosion.

7. Inspect, clean or re-grease battery connections every two

months.

This HSB is equipped with an automatic float type battery trickle

charger powered by utility power, to maintain full battery power

while in standby (non-running) mode. This trickle charger will not

recharge a fully discharged or defective battery.

When doing any work on the batteries always make sure the HSB,

ATS and transfer switch from utility are in the “OFF” position

or sparking may occur at the battery posts as the cables are

attached and cause an explosion.

DANGER

Servicing of batteries are to be performed or supervised

by personnel knowledgeable of batteries and the required

precautions. Keep unauthorized personnel away from

batteries.

– Always follow the battery manufacturer’s directions.

– When replacing batteries, use the same number and the

following type batteries: Two (2) 12 volt Group U1 batteries

with a minimum of 350 CCA each (cold cranking amps).

WARNING

The starting system is a 24-volt DC system. The two 12-volt

batteries MUST be wired in series to achieve the correct

voltage.

Damage will result if the battery connections are made in

reverse, refer to owner manual or installation manual for

typical installation. Dielectric grease should be applied on

battery posts to aid in prevention of corrosion. Cables supplied

with the HSB.

26

Page 27

aXis CONTROLLER HOME STANDBY GENERATOR

INSTALLATION

CAUTION

A battery presents a risk of electrical shock and high short

circuit current.

The following precautions are to be observed when working on

batteries:

1. Remove watches, rings, or other metal objects,

2. Use tools with insulated handles,

3. Wear rubber gloves and boots,

4. Do not lay tools or metal parts on top of the battery

5. Disconnect charging source prior to connecting or

disconnecting battery terminals,

6. Determine the battery is inadvertently grounded. When

inadvertently grounded, remove source of ground. Contact

with any part of a grounded battery is capable of resulting

in electrical shock. The risk of such a shock is reduced

when such grounds are removed during installation and

maintenance (applicable to a generator not having a

grounded supply circuit.

WARNING

Do not dispose of battery or batteries in a fire. The battery is

capable of exploding.

CAUTION

The electrolyte is a diluted sulfuric acid that is harmful to the

skin and eyes. It is electrically conductive and corrosive.

The following procedures are to be observed:

1. Wear full eye protection and protective clothing,

2. Where electrolyte contacts the skin, wash it immediately

with water,

3. Where electrolyte contacts the eyes, flush thoroughly and

immediately with water and seek medical attention, and

40 Spilled electrolyte is to be washed down with an acid

neutralizing agent. A common practice is to use a solution

of one pound (500 grams) bicarbonate of soda to one

gallon (4 liters) of water. The bicarbonate of soda is to be

added until the evidence of reaction (foaming) has ceased.

The resulting liquid is to be flushed with water and the

area dried.

WARNING

Lead-acid batteries present a risk of fire because they

generate hydrogen gas.

The following procedures are to be followed:

1. DO NOT SMOKE when near batteries.

2. DO NOT cause flame or spark in battery area, and

WARNING

Do not open or mutilate the battery or batteries. Released

electrolyte has been known to be harmful to the skin and eyes

and can be toxic.

Vented Batteries

The installation of the engine generator shall provide enough

ventilation to ensure that all gases generated by vented batteries

during charging, or caused by equipment malfunction are

removed.

3. Discharge static electricity from body before touching

batteries by first touching a grounded metal surface.

10. WIRING OF THE HSB

Wire Sizing

All installations must comply with National, State and Local codes.

It is the responsibility of the installer to perform an installation that

will pass the final electrical inspection. Conductor wire sizes must

be adequate to handle the maximum current to which they will be

subjected. The installation must comply fully with all applicable

codes, standards and regulations.

All power cables must enter the enclosure through the knockouts

provided. If not using knockouts, conduit entry into the enclosure

must be at or below knockouts to maintain the Type 3R rating.

NEMA 3R enclosures are rated and tested for outside installation,

they are water proof enclosures and only come with knockouts on

the bottom side of the enclosure. If a NEMA 3R enclosure in used

for an inside installation, a greenlee type punch will be required to

make a knockout(s) on the side or top of the enclosure. Conduits

should be arranged to provide separation between the Utility

Source and HSB Source supply conduits inside the enclosure.

Conductor wires must be properly supported, of approved

insulated qualities, protected by approved conduit and of the

correct wire gauge size in accordance with all applicable codes.

27

Page 28