REGISTER YOUR PRODUCT ONLINE

at championpowerequipment.com

OPERATOR'S MANUAL

MODEL #200947

WALK BEHIND BLOWER

or visit championpowerequipment.com

WARNING

To reduce the risk of injury, the user must read and understand the operator’s manual before using this product. If you do not

understand the warnings and instructions in the operator’s manual, do not use this product.

READ AND SAVE THIS MANUAL. This manual contains important safety precautions which should be read and understood before operating the product. Failure to

do so could result in serious injury. This manual should remain with the product.

Specifications, descriptions and illustrations in this manual are as accurate as known at the time of publication, but are subject to change without notice.

REV 20201106 Champion Power Equipment, Inc., Santa Fe Springs, CA USA

200947 - WALK BEHIND BLOWER

TABLE OF CONTENTS

TABLE OF CONTENTS

Introduction ................................................... 3

Safety Definitions

Important Safety Instructions

Fuel Safety .........................................................6

Safety And Dataplate Labels/ Tags ................................7

Safety Symbols .....................................................9

Operation Symbols ............................................... 11

Quickstart Label Symbols........................................ 11

Controls and Features ................................. 12

Blower ............................................................ 12

Engine ............................................................ 12

Parts Included .................................................... 13

Parts Not Included ............................................... 13

Assembly ..................................................... 14

Remove the Blower from the Shipping Carton .................. 14

Assemble Front Wheel ........................................... 14

Assemble Upper Handle ......................................... 14

Assemble Throttle Control ....................................... 14

.......................................... 3

....................... 4

Storage ........................................................ 24

Short Term Engine Storage (Up to 30 Days) .................... 24

Long Term Engine Storage (30 Days – 1 Year) .................. 24

Specifications .............................................. 26

Blower Specifications ............................................ 26

Engine Specifications ............................................ 26

Spark Plug Specifications ........................................ 26

Valve Specifications .............................................. 26

Oil Specifications ................................................. 26

Fuel Specifications ............................................... 26

Important Message About Temperature......................... 26

Parts Diagram - Figure A ........................................ 27

Parts List - Figure A .............................................. 28

Parts Diagram - Figure B ........................................ 29

Parts List - Figure B .............................................. 30

Engine Parts Diagram ............................................ 31

Engine Parts List ................................................. 32

Troubleshooting ........................................... 34

Operation ..................................................... 15

Add Engine Oil .................................................... 15

Add Fuel .......................................................... 16

Starting the Engine ............................................... 17

Stopping the Engine .............................................. 18

Blower Operation ................................................. 19

Before Each Use Inspect the Blower ............................ 19

Adjust the Handle Height ......................................... 19

Vertical Air Flow Adjustment ..................................... 20

Forward Air Flow Attachment ................................... 20

Front Wheel Swivel ............................................... 21

Operation at High Altitude ....................................... 21

Maintenance ................................................ 21

Cleaning the Blower .............................................. 22

Engine Oil Services ............................................... 22

Cleaning and Adjusting the Spark Plug(s) ....................... 23

Cleaning the Air Filter ............................................ 23

Cleaning the Spark Arrestor ..................................... 23

Adjusting the Governor ........................................... 24

Maintenance Schedule ........................................... 24

2

200947 - WALK BEHIND BLOWER

INTRODUCTION

INTRODUCTION

Congratulations on your purchase of a Champion Power Equipment

(CPE) product. CPE designs, builds, and supports all of our

products to strict specifications and guidelines. With proper

product knowledge, safe use, and regular maintenance, this

product should bring years of satisfying service.

Every effort has been made to ensure the accuracy and

completeness of the information in this manual at the time of

publication, and we reserve the right to change, alter and/or

improve the product and this document at any time without prior

notice.

Since CPE highly values how our products are designed,

manufactured, operated and are serviced, and also highly value

your safety and the safety of others, we would like you to take the

time to review this product manual and other product materials

thoroughly and be fully aware and knowledgeable of the assembly,

operation, dangers and maintenance of the product before use.

Fully familiarize yourself, and make sure others who plan on

operating the product fully familiarize themselves too, with the

proper safety and operation procedures before each use. Please

always exercise common sense and always err on the side

of caution when operating the product to ensure no accident,

property damage, or injury occurs. We want you to continue to use

and be satisfied with your CPE product for years to come.

SAFETY DEFINITIONS

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols, and their explanations,

deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger.

The instructions or warnings they give are not substitutes for

proper accident prevention measures.

DANGER

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE

When contacting CPE about parts and/or service, you will need to

supply the complete model and serial numbers of your product.

Transcribe the information found on your product’s nameplate

label to the table below

CPE TECHNICAL SUPPORT TEAM

1-877-338-0999

MODEL NUMBER

200947

SERIAL NUMBER

DATE OF PURCHASE

PURCHASE LOCATION

NOTICE indicates information considered important, but not

hazard-related (e.g., messages relating to property damaged).

3

200947 - WALK BEHIND BLOWER

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Cancer and Reproductive Harm – www.P65Warnings.ca.gov

DANGER

The blower engine exhaust contains carbon monoxide,

a colorless, odorless, poison gas. Breathing carbon monoxide

will cause nausea, dizziness, fainting or death.

If you start to feel dizzy or weak, get to fresh air immediately.

Operate the blower outdoors only in a well ventilated area.

DO NOT operate the blower inside any building, including

garages, basements, crawlspaces and sheds, enclosure or

compartment.

DO NOT allow exhaust fumes to enter a confined area through

windows, doors, vents or other openings.

DANGER

Using an engine indoors CAN KILL YOU IN MINUTES. Engine

exhaust contains carbon monoxide. This is a poison you cannot

see or smell.

DANGER

DO NOT allow children or untrained individuals to use this unit.

WARNING

Maintain a firm grip on the handle with both hands while using

the blower.

WARNING

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in objects

being thrown into your eyes and other possible serious injuries.

WARNING

Always wear sound protection (ear mufflers or ear plugs) to

protect your hearing. Long term blower noise exposure may

damage your hearing.

WARNING

Keep all bystanders, children, and pets at least 50’ (15m) away

when operating the blower.

NEVER use inside a home or garage, EVEN IF doors and

windows are open.

ONLY use OUTSIDE and far away from windows, doors,

and vents.

Install battery-operated carbon monoxide alarms or plug-in

carbon monoxide alarms with battery back-up according to the

manufacturer’s instructions.

DANGER

Rotating parts can entangle hands, feet, hair, clothing and/or

accessories. Traumatic amputation or severe laceration can

result.

Keep hands and feet away from rotating parts.

Tie up long hair and remove jewelry.

WARNING

Wear heavy long pants, long sleeves, boots, and gloves. Do not

wear loose fitting clothing, short pants, sandals, jewelry of any

kind, or go barefoot.

WARNING

To reduce the risk of injury associated with objects being

drawn into rotating parts, do not wear loose clothing, scarves,

neck chains, and the like.

WARNING

Secure long hair so it is above shoulder level to prevent

entanglement in any rotating parts.

WARNING

Do not operate this unit when you are tired, ill, or under the

influence of alcohol, drugs, or medication.

Operate equipment with guards in place.

DO NOT wear loose-fitting clothing, dangling drawstrings or

items that could become caught.

WARNING

Do not operate in poor lighting.

4

200947 - WALK BEHIND BLOWER

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Wear a face filter mask in dusty conditions to reduce the risk

of injury associated with the inhalation of dust.

WARNING

Check the work area before each use. Remove all objects such

as rocks (where possible), broken glass, nails, wire, or string

which can be thrown or become entangled in the machine.

WARNING

Keep firm footing and balance. Do not overreach. Overreaching

can result in loss of balance or exposure to hot surfaces.

WARNING

The engine is equipped with a spark arrestor. Never operate

the unit without a spark arrestor screen.

WARNING

Use only identical manufacturer’s replacement parts and

accessories.

WARNING

Spark from a removed spark plug wire can result in fire or

electrical shock.

When servicing the engine:

Disconnect the spark plug wire and place it where it cannot

contact the plug or any other metal object.

DO NOT check for spark with the plug removed.

Use only approved spark plug testers.

WARNING

Running engines produce heat. Severe burns can occur on

contact. Combustible material can catch fire on contact.

DO NOT touch hot surfaces.

Avoid contact with hot exhaust gases.

Allow equipment to cool before touching.

Maintain at least 3 ft. (91.4 cm) of clearance on all sides to

ensure adequate cooling.

Maintain at least 5 ft. (1.5 m) of clearance from combustible

materials.

WARNING

Inspect the unit before each use for loose fasteners, fuel leaks,

etc. Replace damaged parts.

WARNING

Rotating impeller blades can cause severe injury. Stop the

engine and ensure impeller blades have stopped rotating

before installing/changing parts or diverters.

WARNING

Do not point the blower nozzle in the direction of people or

pets when in operation.

5

200947 - WALK BEHIND BLOWER

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Rapid retraction of the starter cord will pull hand and arm

towards the engine faster than you can let go. Unintentional

startup can result in entanglement, traumatic amputation or

laceration. Broken bones, fractures, bruises or sprains could

result.

When starting engine, pull the starter cord slowly until

resistance is felt and then pull rapidly to avoid kickback.

CAUTION

Prolonged exposure to vibrations, also known as vibration

white finger, through use of gasoline-powered equipment,

such as this blower, could cause blood vessel or nerve damage

in fingers, hands, and joints. If symptoms occur such as

numbness, or loss of feeling in the fingers, hands, or joints,

discontinue the use of this blower and seek medical attention.

Fuel Safety

– DO NOT pump gasoline directly into the blower at the gas

station. Always use an approved fuel container to transfer the

fuel to the gasoline tank.

– DO NOT overfill the gasoline tank.

– Always keep gasoline away from sparks, open flames, pilot

lights, heat and other sources of ignition.

– Mix and store fuel in a container approved for gasoline.

When starting the blower:

– DO NOT attempt to start a damaged engine.

– Always make certain that the gasoline cap, air filter, spark

plug, fuel lines and exhaust system are properly secured,

connected and in place.

– Always allow spilled gasoline to evaporate fully before

attempting to start the engine.

– Make certain that the blower is resting firmly on level ground.

When operating the blower:

– DO NOT move or tip the blower during operation.

– DO NOT tip the blower or allow fuel or oil to spill.

DANGER

GASOLINE AND GASOLINE VAPORS ARE HIGHLY

FLAMMABLE AND EXPLOSIVE.

Fire or explosion can cause severe burns or death.

Gasoline and gasoline vapors:

– Gasoline is highly flammable and explosive.

– Gasoline can cause a fire or explosion if ignited.

– Gasoline is a liquid fuel but its vapors can ignite.

– Gasoline is a skin irritant and needs to be cleaned up

immediately if spilled on skin or clothes.

– Gasoline has a distinctive odor, this will help detect potential

leaks quickly.

– In any petroleum gas fire, flames should not be extinguished

unless by doing so the fuel supply valve can be turned OFF.

This is because if a fire is extinguished and a supply of fuel is

not turned OFF, then an explosion hazard could be created.

– Gasoline expands or contracts with ambient temperatures.

Never fill the gasoline tank to full capacity, as gasoline needs

room to expand if temperatures rise.

When storing the blower:

– Store away from sparks, open flames, pilot lights, heat and

other sources of ignition.

– Do not store the blower or gasoline near furnaces, water

heaters, or any other appliances that produce heat or have

automatic ignitions.

WARNING

NEVER use a gasoline container, gasoline tank, or any other

fuel item that is broken, cut, torn or damaged.

When adding or removing gasoline:

– DO NOT light or smoke cigarettes.

– Always turn the blower off and let cool for minimum of two

minutes before removing the gasoline cap. Afterwards, loosen

gasoline cap to relieve pressure from the gasoline tank.

– Only fill or drain gasoline outdoors in a well-ventilated area.

6

200947 - WALK BEHIND BLOWER

2233-L-SF-A

DANGER DANGER PELIGRO

50 ft.

15m

2222-L-SF-A

DANGER PELIGRO DANGER PELIGRO

50 ft.

15m

2018-L-OP-A

ESSENCE SAN S PLOM SEULEMENT.

Indice d’octane minimal d e

87. Maximum 10 % d'éthanol.

La clasificación mínimo de 87

octano. Máxim o de etanol de 10%.

GASOLINA SIN P LOMO SOLAMENTE.UNLEADED FUEL ONLY.

Minimum octane rat ing of 87.

Maximum 10% ethanol.

IMPORTANT SAFETY INSTRUCTIONS

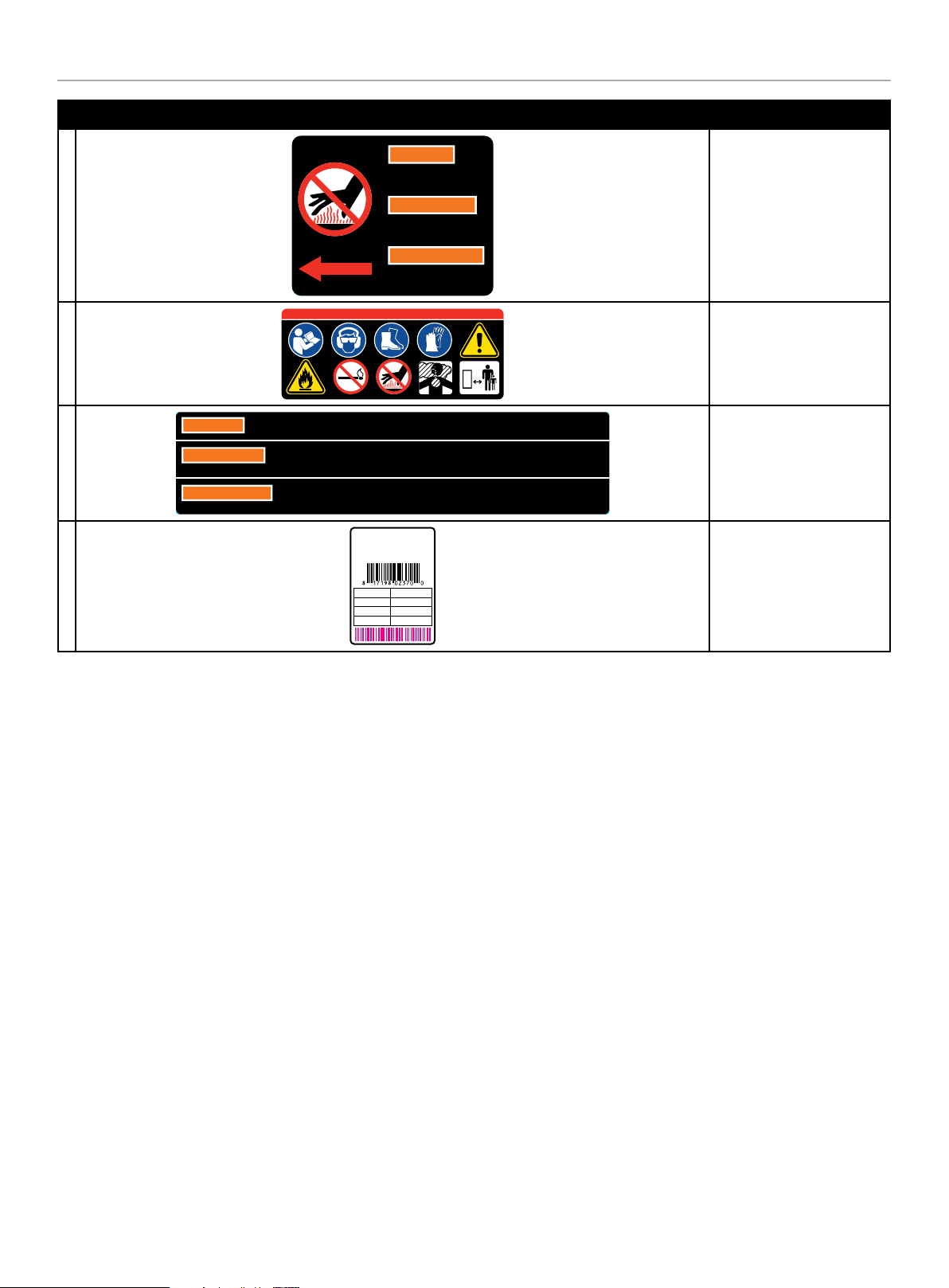

Safety And Dataplate Labels/Tags

These labels warn you of potential hazards that can cause serious injury. Read them carefully.

If a label comes off or becomes hard to read, contact Technical Support Team for possible replacement.

D

E

F

C

G

A

B

Top viewFront view Back view

LABEL DESCRIPTION

A

Blower Housing Danger

Label

B

C

Blower Discharge Danger

Label

Fuel Requirements Label

7

200947 - WALK BEHIND BLOWER

1966-L-SF-A

DO NOT TOUCH!

Hot surface.

WARNING

¡NO TOCAR!

Superficie caliente.

ADVERTENCIA

AVERTISSEMENT

NE TOUCHEZ PAS!

Surface chaude.

1253-L-SF-A

DANGER PELIGRO DANGER

WARNING

Operati on of this equipmen t may create spar ks that can star t fires around d ry vegetatio n. A spark arres tor may be required .

The operator should contact local fire agencies for laws or regulations relating to fire prevention requirements.

AVERTISSEMENT

Le fonctionnement de cet équipement peut créer des étincelles qui peuvent déclencher des incendies autour de

la végétat ion sèche. Un par e-étincell es peut être néce ssaire. L'utilisate ur doit communiq uer avec le servi ce

d'incendi e local pour les loi s et les règlement s relatifs à la p révention des in cendies.

2303-L-SF-A

ADVERTENCIA

Operación de este equipo puede crear chispas que pueden iniciar incendios en vegetación seca.

Un parach ispas puede ser re querido. El opera dor debería cont actar las agenc ias locales de inc endios para

leyes o regulaciones relacionadas con requisitos de prevención de incendios.

CHAMPION POWER EQUIPMENT, INC.

12039 SMITH AVENUE

SANTA FE SPRINGS, CA 90670

USA / É.-U.

1-877-338-0999

WWW.CHAMPIONPOWEREQUIPMENT.COM

MADE IN CHINA / FABRIQUÉ EN CHINE

Manufactured to meet ANSI B71.6-2000

2223-L-PR-A

MANUFACTURE DATE

DATE DE FABRICATION

SOUND PRESSURE

PRESSION SONORE

SERIAL NO.

N° DE SÉRIE

MODEL

MODÈLE

200947

85 dB(A)

@ 20 ft. (6 m)

XXXX

XXXXXXXXXXXX

IMPORTANT SAFETY INSTRUCTIONS

LABEL DESCRIPTION

D

E

F

G

Hot Surface Warning Label

Engine Danger Label

Spark Arrestor Warning

Label

Product Data Plate Label

8

200947 - WALK BEHIND BLOWER

IMPORTANT SAFETY INSTRUCTIONS

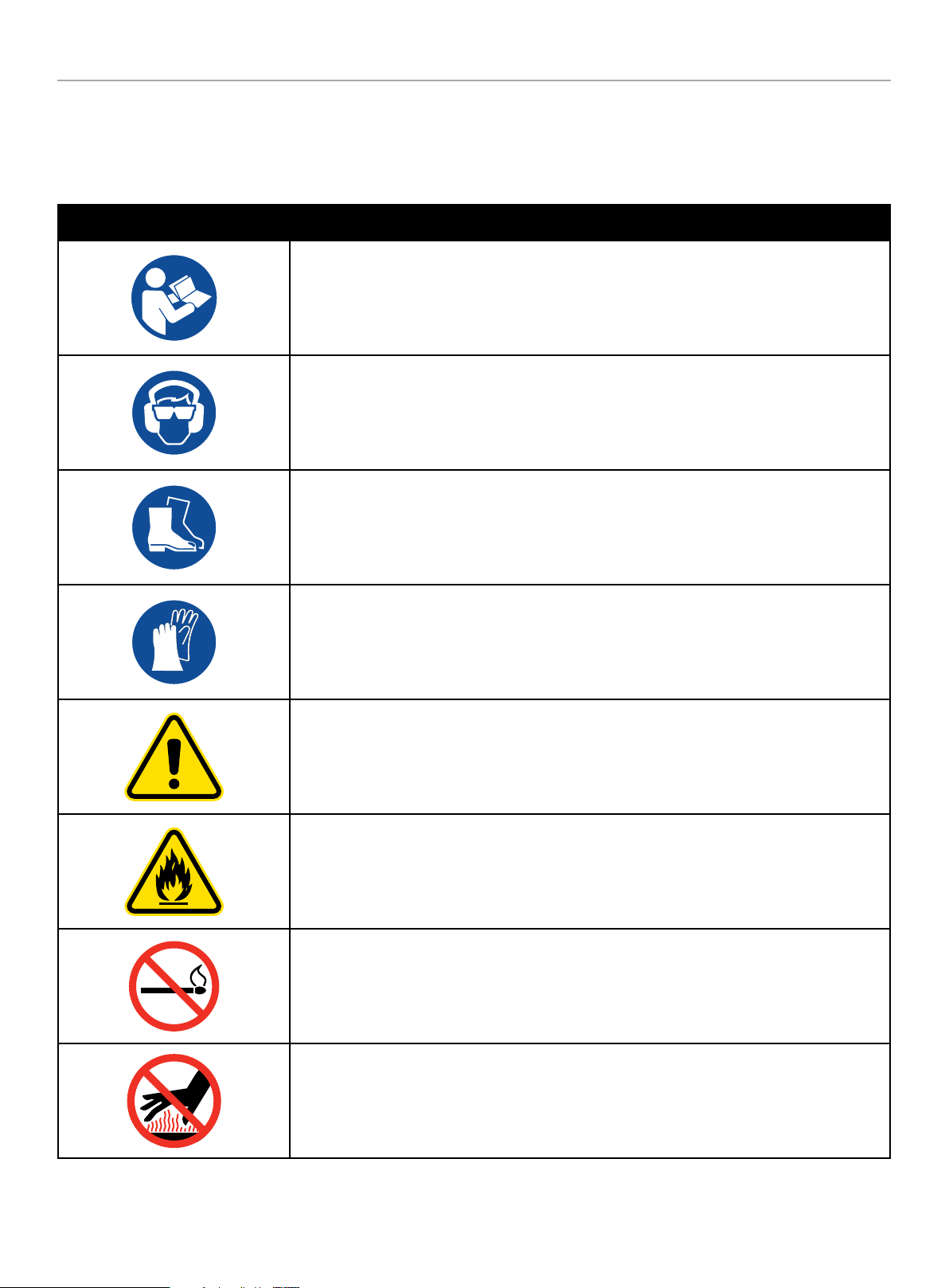

Safety Symbols

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these

symbols will allow you to more safely operate the product.

SYMBOL MEANING

Read Operator’s Manual. To reduce the risk of injury, the user must read and understand

the operator’s manual before using this product. If you do not understand the warnings and

instructions in the operator’s manual, do not use this product.

Eye and Ear Protection. Always wear eye protection with side shields marked to comply with

ANSI Z87.1. Failure to do so could result in objects being thrown into your eyes and other possible

serious injuries.

Always wear sound protection (ear mufflers or ear plugs) to protect your hearing. Long term

blower noise exposure may damage your hearing.

Footwear. Always wear safety shoes or heavy boots when operating the machine.

Gloves. Always wear nonslip, heavy-duty protective gloves when operating this product.

Safety Alert. Precautions that involve your safety.

Risk of Fire. Fuel and its vapors are extremely flammable and explosive. Fire can cause severe

burns or death. Do not add fuel while the product is operating or still hot.

Open Flame alert. Fuel and its vapors are extremely flammable and explosive. Keep fuel away

from smoking, open flames, sparks, pilot lights, heat, and other ignition sources.

Hot Surface. To reduce the risk of injury or damage, avoid contact with any hot surface

9

200947 - WALK BEHIND BLOWER

SYMBOL MEANING

IMPORTANT SAFETY INSTRUCTIONS

Amputation Hazard. Rotating parts can entangle hands, feet, hair, clothing and/or accessories.

Traumatic amputation or severe laceration can result.

Toxic Fumes. The engine exhaust from this product contains chemicals known to the state of

California to cause cancer and birth defects and other reproductive harm.

Risk of Asphyxiation. This engine emits carbon monoxide, an odorless, colorless poison gas.

Breathing carbon monoxide can cause nausea, fainting or death. Use only in a well ventilated

area.

Thrown Objects. This machine may pick up and throw objects which can cause personal injury.

Check the work area before each use. Remove all objects such as rocks (where possible), broken

glass, nails, wire, or string which can be thrown or become entangled in the machine.

50 ft.

15m

Clearance. Keep all bystanders, children, and pets at least 50’ (15m) away when operating the

blower.

Never run the unit without the blower fan cover installed. Use of an improperly assembled unit

could result in serious personal injury.

Serious Personal Injury or Property Damage. Before inspecting, cleaning, or servicing the

blower, shut off the engine. Wait for all moving parts to stop, disconnect spark plug wire and

move it away from the spark plug. Failure to follow these instructions could result in personal

injury or damage to the blower.

10

200947 - WALK BEHIND BLOWER

2197-L-OP-A

1

10W-30

5

1

2

3

7

42

6

IMPORTANT SAFETY INSTRUCTIONS

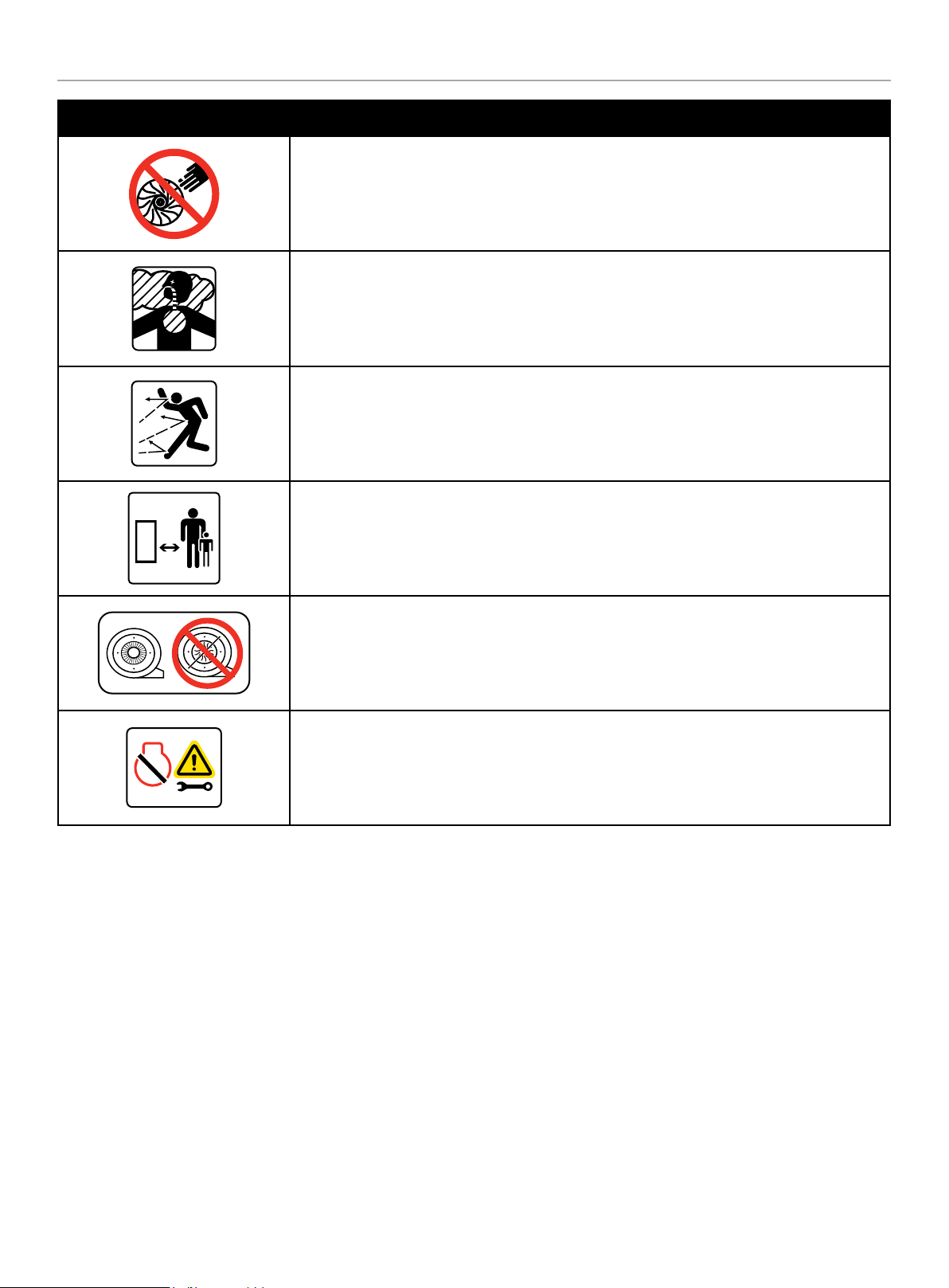

Operation Symbols

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these

symbols will allow you to more safely operate the product.

SYMBOL MEANING

Choke/Run

Fuel Valve: CLOSED/OPEN

Throttle Lever

FAST: forward position

SYMBOL MEANING

Fuel Gauge: Full

Fuel Gauge: Empty

Stop

Throttle Lever

SLOW: rear position

Quickstart Label Symbols

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these

symbols will allow you to more safely operate the product.

Starting the Engine

1. Check Oil Level. Recommended oil is 10W-30. The engine

2. Add gasoline with a minimum octane rating of 87 and an

3. Move the choke lever to “CHOKE” position.

4. Move the throttle lever, on the handle at the user position,

5. Move the fuel valve to “OPEN” position.

6. Pull the starter cord slowly until resistance is felt and then

7. As engine warms up, move the choke to “RUN”.

can be seriously damaged without oil. Always check the oil

level before using. The machine must be resting firmly on

level ground when checking.

ethanol content of less than 10% by volume.

to the “FAST” position (forward).

pull rapidly.

Stopping the Engine

1. Move the fuel valve to the “CLOSED” position.

2. Press the engine switch to the “OFF” position.

11

200947 - WALK BEHIND BLOWER

CONTROLS AND FEATURES

CONTROLS AND FEATURES

Read this operator’s manual before operating your blower. Familiarize yourself with the location and function of the controls and features.

Save this manual for future reference.

1

2

12

1

3

11

10

10

9

Blower

1. Upper Handle

2. Throttle/Speed Control

4

5

6

7

8

2

3

4

5

6

7

8

9

Engine

1. Muffler

2. Air Filter

9. Engine OFF Switch

10. Fuel Tank

3. Handle Adjust Lever

4. Lower Handle

5. Engine

6. Rear Wheel

7. Forward Air Flow Attachment

8. Vertical Air Flow Adjustment

9. Front Wheel

10. Front Wheel Swivel Lock

3. Oil Fill Cap/Dipstick

4. Recoil Starter

5. Oil Drain Bolt

6. Throttle

7. Choke

8. Fuel Valve

12

11. Fuel Gauge

12. Fuel Tank Cap

200947 - WALK BEHIND BLOWER

Parts Included

CONTROLS AND FEATURES

Part Part Qty.

Front wheel 1

Upper handle 1

Throttle control 1

Forward flow air

attachment

Engine Oil

16.9 fl. oz (500 ml)

Engine Oil Funnel 1 N/A

1 N/A

1 N/A

Hardware

Needed

M8x20

Hexagon bolt

M8 Nylon

flange lock nut

M6x65 carriage

bolt

M6 Nylon

flange lock nut

Hardware Qty. Hardware Reference Tool Needed

4

1

1

1

13mm Wrench

13mm Wrench

10mm Wrench

Parts Not Included

– Metric Wrench or Socket Set

– Phillips Screwdriver

– Pliers

13

200947 - WALK BEHIND BLOWER

ASSEMBLY

Your blower requires some assembly. This unit ships from the

factory without oil. It must be properly serviced with fuel and oil

before operation. For questions regarding the assembly of your

blower, call our help line at 1-877-338-0999. Please have your

serial number and model number available.

Remove the Blower from the Shipping Carton

1. Set the shipping carton on a solid, flat surface.

2. Remove all contents from the carton.

Assemble Front Wheel

1. Align the 4 holes on the front wheel bracket with the 4 holes

on the blower frame near the rear wheel on the left side of

the frame (from the user position).

2. Thread a M8 × 20 hex bolt into each hole and, using a 13mm

wrench, tighten to 15 lbf. ft. - 19 lbf. ft.

(20.3 - 25.8 Nm)

ASSEMBLY

Assemble Throttle Control

1. Align the throttle control to the outside of the upper left

handle (from the user position) with the groove against the

handle and fast speed towards the front.

2. From the outside of the throttle control, place the M6 × 65

carriage bolt through the hole on the throttle and through the

hole on the handle tube.

Assemble Upper Handle

1. Place the upper handle assembly down over the lower handle

assembly, with the upper handle on the outside, and align the

teeth of the upper handle adjuster so they seat into the teeth

on the lower handle adjuster.

2. From the outside of the handle assembly, insert the threaded

end of the handle adjust lever through the hole on the upper

handle assembly and the hole on the lower handle assembly.

3. Thread the M6 nylon lock nut onto the bolt and tighten

securely.

3. Thread a M8 nylon lock nut onto the threaded end of the

handle adjust lever. Holding the handle adjust lever in place,

use a 13mm socket or wrench to tighten the lock nut securely

locking the handle in place. (see operation section for handle

height adjustment).

14

200947 - WALK BEHIND BLOWER

OPERATION

OPERATION

Add Engine Oil

CAUTION

DO NOT attempt to crank or start the engine before it has been

properly filled with the recommended type and amount of oil.

Damage to the engine as a result of failure to follow these

instructions will void your warranty.

NOTICE

The recommended oil type is 10W-30 automotive oil.

If running engine in extreme temperatures, refer to the

following chart for recommended oil type.

Recommended Engine Oil Type

10W-30

10W- 405W-30

5W-30 Full Synthetic

-20 0 20 40 60

°F

-28.9

°C -17. 8 -6.7 4.4 15.6 26.7 37. 8 48.9

1. Place the blower on a flat, level surface.

Ambient temperature

80 100 120

NOTICE

Once oil has been added, a visual check should show oil about

1-2 threads from running out of the fill hole.

If using the dipstick to check oil level, DO NOT screw in the

dipstick while checking.

NOTICE

Check oil often during the break-in period. Refer to the

Maintenance section for recommended service intervals.

CAUTION

The engine is equipped with a low oil shut-off and will stop

when the oil level in the crankcase falls below the threshold

level.

NOTICE

The first 5 hours of run time is the break-in period for the

engine. During the break in period, it is recommended to use

standard automotive, non-synthetic blended oils. After the

break-in period synthetic oil, can be used but is not required.

Adjusting throttle setting will increase/ decrease engine speed

helping to seat piston rings. Avoid bogging or lugging the

engine down and avoid prolonged running at constant RPM.

After the 5 hour break-in period, change the oil.

2. Remove oil fill cap/dipstick to add oil.

3. Using a funnel, add up to 16.9 fl. oz (500 ml) of oil (included)

and replace oil fill cap/dipstick. DO NOT OVERFILL.

4. Check engine oil level before every use and add as needed.

MAX

OIL DIP STICK

NOTICE

Synthetic oil may be used after the 5 hour initial breakin period. Using synthetic oil does not decrease the

recommended oil change interval. Full synthetic 5W-30 oil

will aid in starting the engine in cold ambient < 41º F (5º C)

temperatures.

NOTICE

Weather will affect engine oil and engine performance. Change

the type of engine oil used based on weather conditions to suit

the engine needs.

15

200947 - WALK BEHIND BLOWER

Add Fuel

CAUTION

Use regular unleaded gasoline with a minimum octane rating

of 85 and an ethanol content of less than 10% by volume.

DO NOT light or smoke cigarettes.

DO NOT mix oil and gasoline.

DO NOT overfill the tank. Fill tank to approximately ¼ in.

(6.4 mm) below the top of the tank to allow for gasoline

expansion.

Always turn the blower off and let cool for minimum of two

minutes before removing the gasoline cap.

Afterwards, loosen gasoline cap to relieve pressure from the

gasoline tank.

Only fill or drain gasoline outdoors in a well-ventilated area.

Store fuel in a container approved for gasoline.

DO NOT pump gasoline directly into the blower at the gas

station. Always use an approved fuel container to transfer the

fuel to the gasoline tank.

OPERATION

5. The approximate fuel level is shown on the fuel gauge on top

of the fuel tank.

DO NOT overfill the gasoline tank.

Always keep gasoline away from sparks, open flames, pilot

lights, heat and other sources of ignition.

WARNING

Pouring gasoline too fast through the fuel screen may result in

blow back of gasoline at the operator while filling.

WARNING

Always shut off engine before fueling. Never add fuel to a

machine with a running or hot engine. Wait at least 2 minutes

to allow for cool down before refueling. Move at least 50’

(15 m) from refueling site before starting engine. Do no smoke

and stay away from open flames and sparks. Failure to safely

handle fuel could result in serious personal injury and or

property damage.

1. Use clean, fresh, regular unleaded gasoline with a minimum

octane rating of 87 and an ethanol content of less than 10%

by volume. ybc

2. DO NOT mix oil with gasoline.

3. Remove the gasoline cap.

4. Slowly add gasoline to the tank. DO NOT OVERFILL. Gasoline

can expand after filling. A minimum of ¼ in. (6.4 mm) of

space left in the tank is required for gasoline expansion,

although more than ¼ in. (6.4 mm) is recommended. Gasoline

can be forced out of the tank as a result of expansion if

overfilled, and can affect the stable running condition of the

blower.

6. Screw on the gasoline cap and wipe away any spilled fuel.

NOTICE

Our engines work well with 10% or less ethanol blend

gasoline. When using ethanol-gasoline blends there are some

issues worth noting:

– Ethanol-gasoline blends can absorb more water than

gasoline alone.

– These blends can eventually separate, leaving water or a

watery goo in the tank, fuel valve and carburetor.

– The compromised gasoline can be drawn into the

carburetor and cause damage to the engine and/or create

power performance problems.

– There are only a few suppliers of fuel stabilizer that are

formulated to work with ethanol blend fuels.

– Any damages or hazards caused by using improper fuel,

improperly stored fuel, and/or improperly formulated

stabilizers, are not covered by manufacturer’s warranty.

It is advisable to always shut off the fuel supply (where

applicable - not every unit has a fuel shut off), run the

engine to fuel starvation and drain the tank when the

equipment is not in use for more than a 30-day period.

– See Storage instructions for extended non-use.

16

200947 - WALK BEHIND BLOWER

DANGER

OPERATION

NOTICE

The blower engine exhaust contains carbon monoxide,

a colorless, odorless, poison gas. Breathing carbon monoxide

will cause nausea, dizziness, fainting or death.

If you start to feel dizzy or weak, get to fresh air immediately.

Operate the blower outdoors only in a well ventilated area.

DO NOT operate the blower inside any building, including

garages, basements, crawlspaces and sheds, enclosure or

compartment.

DO NOT allow exhaust fumes to enter a confined area through

windows, doors, vents or other openings.

DANGER

Using an engine indoors CAN KILL YOU IN MINUTES. Engine

exhaust contains carbon monoxide. This is a poison you cannot

see or smell.

NEVER use inside a home or garage, EVEN IF doors and

windows are open.

ONLY use OUTSIDE and far away from windows, doors,

and vents.

In some State and local jurisdictions, operate power equipment

during reasonable hours to comply with local noise ordinances.

For more information, contact your State and local government

for specific requirements.

Starting the Engine

1. Make certain the blower is on a flat, level surface.

2. Move the throttle lever on the handle to the “FAST” position

(forward).

Install battery-operated carbon monoxide alarms or plug-in

carbon monoxide alarms with battery back-up according to the

manufacturer’s instructions.

WARNING

Running engines produce heat. Severe burns can occur on

contact. Combustible material can catch fire on contact.

DO NOT touch hot surfaces.

Avoid contact with hot exhaust gases.

Allow equipment to cool before touching.

Maintain at least 3 ft. (91.4 cm) of clearance on all sides to

ensure adequate cooling.

Maintain at least 5 ft. (1.5 m) of clearance from combustible

materials.

WARNING

Never run the unit without the blower fan cover installed.

Use of an improperly assembled unit could result in serious

personal injury.

3. Move the choke lever to the “CHOKE” position.

4. Move the fuel valve to the “OPEN” position.

FAST SLOW

CHOKE RUN

FUEL OFF FUEL ON

WARNING

Rapid retraction of the recoil cord could pull your hand

and arm towards the engine faster than you can let go.

Unintentional startup can result in entanglement, traumatic

amputation or laceration. Broken bones, fractures, bruises or

sprains could also result.

17

200947 - WALK BEHIND BLOWER

OPERATION

5. Pull the starter cord slowly until resistance is felt and then

pull rapidly.

6. As engine warms up, move the choke lever to the “RUN”

position.

Stopping the Engine

In an emergency, turn the engine switch to the “OFF”

position.

NOTICE

If the engine does not stop when the engine switch is moved

to the “STOP” position, move the throttle to the slow speed

position and slide the choke lever to the cold start (closed)

position.

CHOKE RUN

NOTICE

Keep choke lever in “CHOKE” position for 2 pulls of the recoil

starter. After second pull, move choke lever to the “RUN”

position for up to the next 3 pulls of the recoil starter. Too

much choke leads to spark plug fouling/engine flooding due to

the lack of incoming air. This will cause the engine not to start.

NOTICE

Allow engine to warm at least 30 seconds depending on

ambient temperature. The colder the temperature, the longer

the warm-up required.

Under normal operation:

1. Turn the fuel valve to the “OFF” position.

2. Let the engine run until fuel starvation has stopped the

engine. This usually takes few minutes.

Important: Always ensure that the fuel valve is in the “OFF”

position when the engine is not in use.

NOTICE

If the engine will not be used for a period of two (2) weeks or

longer, please see the Storage section for proper engine and

fuel storage.

18

200947 - WALK BEHIND BLOWER

OPERATION

Blower Operation

WARNING

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes and other possible serious

injuries.

Before Each Use Inspect the Blower

1. Always make sure the spark plug wire has been disconnected

and engine has been grounded.

2. Always visually inspect the blower fan cover for loose fittings,

cracks, or other damage.

3. DO NOT operate the blower if there is any indication of

damage to parts or the unit.

4. DO NOT operate the blower if the discharge chute is clogged.

Remove all debris before operation.

5. Always inspect the engine and make sure the oil level and

fuel level are correct before operating.

2. Move the handle to the desired height for user comfort.

3. Ensure that the adjuster teeth are aligned to seat into each

other then, push the handle adjust lever inward to lock back

into place

6. Always inspect the work area for any distractions or factors

that may prevent operator safety or proper operation.

Adjust the Handle Height

The handle height can be adjusted to a comfortable position for

the user and, also be folded down for storage.

1. Pull the handle adjust lever outward to loosen the teeth

engagement on the adjusters.

19

200947 - WALK BEHIND BLOWER

OPERATION

Vertical Air Flow Adjustment

The blower is equipped with an adjustable vertical air flow louver.

The vertical air flow can be adjusted to 3 positions: Straight

(level), 15 degrees up and 15 degrees down.

1. Stop the engine (see Stopping the Engine section)

2. Pull the index lever out of its existing hole.

3. Rotate the index lever to the desired position.

4. Release the index lever and allow it to insert into the desired

hole.

4. Slide the attachment over the discharge chute. The slot

on the top of the attachment will mate with the bolt of the

attachment knob.

5. Hand-tighten the attachment knob to secure the attachment.

When not in use, the forward air flow attachment can be stored

under the frame at the rear of the blower.

1. Turn the attachment so “This Side Up for Storage” is visible

and the arrows are oriented towards the storage area.

15° DOWN

STRAIGHT/LEVEL

15° UP

5. To direct the air flow down 15 degrees, place the index lever

into the top position. To direct the air flow level/straight,

place the index lever into the middle position. To direct the

air flow up 15 degrees, place the index lever into the bottom

position.

Forward Air Flow Attachment

The blower includes a forward air flow attachment. Assembly of

this attachment to the discharge chute will direct the air flow to

the front of the blower instead of the side.

2. Insert the attachment into frame opening, with the orientation

identified on the label.

3. The edge of the attachment will be supported by a bracket

under the frame.

4. Secure the attachment by forcing it upward and rotating

it so the pin on the frame will insert into the slot on the

attachment.

1. Stop the engine (see Stopping the Engine section).

2. Loosen the attachment knob located on top of the blower

discharge chute.

3. Orient the attachment so “This Side Up for Use” is visible and

the arrows are oriented toward the discharge chute.

20

200947 - WALK BEHIND BLOWER

MAINTENANCE

Front Wheel Swivel

This blower has a multi-function front wheel that can be locked in

the front facing position or unlocked to swivel.

1. Pull up on the swivel lock lever and turn it a quarter turn to

lock into the slot in the up position. This will allow the wheel

to swivel 360 degrees.

2. To put the wheel back into the locked forward-facing position,

pull up on the swivel lock lever and turn it back a quarter of

a turn and let it seat back into the down position with the pin

locking into the hole on the wheel bracket. The wheel is now

locked into the front facing position.

alternative main jet and installation instructions can be obtained

by contacting our Technical Support Team. Installation instructions

are also available in the Technical Bulletin area of the CPE website.

The part number and recommended minimum altitude for the

application of the high-altitude carburetor main jet is listed in the

following table.

In order to select the correct high-altitude main jet, it is necessary

to identify the carburetor model. For this purpose, a code is

stamped on the side of the carburetor.

Select the correct high-altitude jet part number corresponding to

the carburetor code found on your particular carburetor.

Carb. Code

16100-Z2M031000M0

High Alt. Jet Part

Number

16161-Z151710-0000

16161-Z151510-0000

Min. Altitude

3,000~6,000 ft.

(914.4~1,828.8 m)

6,000~8,000 ft.

(914.4~2438.4m)

WARNING

Operation using the alternative main jet at elevations lower

than the recommended minimum altitude can damage the

engine. For operation at lower elevations, the originally

supplied standard main jet must be used. Operating the

engine with the wrong engine configuration at a given altitude

may increase its emissions and decrease fuel efficiency and

performance.

Operation at High Altitude

The density of air at high altitudes is lower than at sea level.

Engine power is reduced as the air mass and air-fuel ratio

decrease. Engine power and output will be reduced approximately

3½% for every 1000 ft. of elevation above sea level. At high

altitudes increased exhaust emissions can also result due to the

increased enrichment of the air fuel ratio. Other high-altitude

issues can include hard starting, increased fuel consumption and

spark plug fouling.

To alleviate high altitude issues other than the natural power

loss, CPE can provide a high-altitude carburetor main jet. The

MAINTENANCE

Make certain that the blower is kept clean and stored properly.

Only operate the unit on a flat, level surface in a clean, dry

operating environment. DO NOT expose the unit to extreme

conditions, excessive dust, dirt, moisture or corrosive vapors.

The owner/operator is responsible for all periodic maintenance.

Complete all scheduled maintenance in a timely manner. Correct

any issue before operating the blower. For service or parts

assistance, contact our help line at 1-877-338-0999.

WARNING

Never operate a damaged or defective blower. Improper

maintenance will void your warranty.

21

200947 - WALK BEHIND BLOWER

MAINTENANCE

WARNING

Before inspecting, cleaning, or servicing the blower, shut off

the engine. Wait for all moving parts to stop, disconnect spark

plug wire and move it away from the spark plug. Failure to

follow these instructions could result in personal injury or

damage to the blower.

NOTICE

For emission control devices and systems, read and

understand your responsibilities for service as stated in the

Emission Control Warranty Statement of this manual.

WARNING

When servicing, use only genuine approved replacement parts.

Use of any other parts could result in poor performance or

damage the blower.

Cleaning the Blower

4. Tighten dipstick securely.

MAX

OIL DIP STICK

B. Changing the Engine Oil

CAUTION

DO NOT attempt to crank or start the engine before it has been

properly filled with the recommended type and amount of oil.

Damage to the blower as a result of failure to follow these

instructions will void your warranty.

NOTICE

The recommended oil type is 10W-30 automotive oil.

CAUTION

DO NOT spray engine with water.

Water can contaminate the fuel system and can enter the

engine through the cooling slots and damage the engine.

1. Use a damp cloth to clean exterior surfaces of the blower.

2. Use a soft bristle brush to remove dirt and oil.

3. Use an air compressor (25 PSI) to clear dirt and debris from

the blower.

4. Inspect all air vents and cooling slots to ensure that they are

clean and unobstructed.

Engine Oil Services

Check the engine oil level before each use and after every five

hours of continuous operation. Running the engine when it is low

on oil will quickly ruin the engine. It is recommended that you

change the engine oil after every 10 hours of operation and even

sooner when operating in extremely dirty or dusty conditions.

A. Check the Engine Oil Level

Change oil when the engine is warm. Refer to the oil specification

to select the proper grade for your operating environment.

1. Place the blower on a flat, level surface.

2. Clean around the oil drain plug to prevent dirt from falling into

the crankcase. Remove oil drain plug with a 10mm socket

(not included)

DRAIN BOLT

1. Park the blower on a level area and shut off the engine.

2. Clean around the oil dipstick to prevent dirt from falling into

the crankcase.

3. Remove the dipstick and wipe it clean. Reinsert the dipstick

(do not tighten) and remove it. Add oil as needed to bring the

level up to the FULL mark. Wipe the dipstick clean each time

the oil level is checked. Do not overfill.

22

200947 - WALK BEHIND BLOWER

3. Allow the oil to drain completely into an appropriate container.

4. Replace the oil drain plug.

5. Remove the oil fill cap/dipstick to add oil.

6. Add oil according to Add Engine Oil in Assembly section.

7. DO NOT OVERFILL. Oil not included for routine maintenance.

MAINTENANCE

4. Make certain the spark plug gap is 0.028-0.031 in.

(0.7-0.8 mm).

SPARK PLUG GAP

5. Refer to the spark plug types in Specifications when replacing

the plug.

6. Firmly re-install the plug.

7. Attach the spark plug cable to the spark plug.

Cleaning the Air Filter

1. Using your finger, pry the outer tab up slightly and lift the air

filter cover above the tab lock position.

2. Remove both air filter cover and air filter element.

8. Dispose of used oil at an approved waste management

facility.

NOTICE

Once oil has been added, a visual check should show oil about

1-2 threads from running out of the fill hole. When using the

dipstick to check oil level, DO NOT screw in the dipstick while

checking.

Cleaning and Adjusting the Spark Plug(s)

1. Remove the spark plug cable from the spark plug.

3. Wash in liquid detergent and water. Squeeze thoroughly dry in

a clean cloth.

4. Saturate in clean engine oil.

5. Squeeze in a clean, absorbent cloth to remove all excess oil.

6. Place the filter in the assembly.

7. Reattach the air filter cover. Attach the side closest to the

gas tank then pivot down to close. Make sure air filter cover

snaps in place.

2. Use a spark plug socket tool (not included), or a 13/16 in.

(21 mm) socket (not included) to remove the plug.

3. Inspect the electrode on the plug. It must be clean and not

worn to produce the spark required for ignition.

Cleaning the Spark Arrestor

1. If so equipped, allow the engine to cool completely before

servicing the spark arrester.

2. Remove the screws holding the cover plate which retains the

end of the spark arrester to the muffler.

3. Remove the spark arrester screen.

23

200947 - WALK BEHIND BLOWER

STORAGE

4. Carefully remove the carbon deposits from the spark arrester

screen with a wire brush.

5. Replace the spark arrester if it is damaged.

6. Position the spark arrestor on the muffler and attach with the

screws removed in step 2.

CAUTION

Failure to clean the spark arrestor will result in degraded

engine performance.

NOTICE

Federal and local laws and administrative requirements

indicate when and where spark arrestors are required. When

ordered, spark arrestors are required for operation of this

blower in National Forest lands. In California, this blower must

not be used on any forest-covered land, brush-covered land, or

grass-covered land unless the engine is equipped with a spark

arrestor.

WARNING

Always check for fuel leaks before use. A leaking fuel cap is

a hazard and must be replaced immediately. If any leaks are

found, correct the problem before using the product. Failure

to do so could result in a fire hazard that could cause serious

personal injury, including equipment and property damage.

Service your blower more frequently when operating in adverse

conditions.

Contact our Technical Support Team at 1-877-338-0999 to locate

the nearest CPE certified service dealer for your blower or engine

maintenance needs.

EVERY 8 HOURS OR DAILY

Check oil level

Clean around air intake and muffler

FIRST 5 HOURS

Change oil

EVERY 50 HOURS OR EVERY SEASON

Clean air filter

Change oil if operating under heavy load or in hot

environments

EVERY 100 HOURS OR EVERY SEASON

Change oil

Clean/adjust spark plug

Check/adjust valve clearance*

Clean spark arrestor

Clean fuel tank and filter*

Adjusting the Governor

NOTICE

Tampering or adjusting the factory set carburetor is a Federal

Violation and will void your warranty coverage.

The air-fuel mixture is not adjustable. Tampering with the governor

can damage your blower and will void your warranty. Contact our

Technical Support Team at 1-877-338-0999 for all other service

and/or adjustment needs.

Maintenance Schedule

Follow the service intervals indicated in the following maintenance

schedule.

EVERY 250 HOURS

Clean combustion chamber*

EVERY 3 YEARS

Replace fuel line*

* To be performed by knowledgeable, experienced owners or Champion Power

Equipment certified dealers.

STORAGE

Refer to the Maintenance section for proper cleaning instructions.

1. Allow the blower to cool completely before storage.

2. Turn off the fuel supply at the fuel valve.

3. Clean the blower according to the instructions in the

Maintenance section.

4. Store the unit in a clean, dry area out of direct sunlight.

Short Term Engine Storage (Up to 30 Days)

1. Allow the engine to cool completely before storage.

2. Clean engine according to the Maintenance section.

24

200947 - WALK BEHIND BLOWER

STORAGE

3. To extend the fuel storage life add a properly formulated fuel

stabilizer to the tank.

4. Ensure the fuel valve is in the “OFF” position.

Long Term Engine Storage (30 Days – 1 Year)

1. Add a properly formulated fuel stabilizer to the tank.

2. Run the engine for a few minutes so the treated fuel cycles

through the fuel system and carburetor.

3. Turn the fuel valve to the “OFF” position.

4. Let the engine run until fuel starvation has stopped the

engine. This usually takes a few minutes.

5. The engine needs to cool completely before cleaning and

storage.

6. Clean the engine according to the Maintenance section.

7. Change the oil according to the Maintenance section.

8. Remove the spark plug and pour about 1/2 oz. (14.9 mL) of oil

into the cylinder. Crank the engine slowly to distribute the oil

and lubricate the cylinder.

9. Reattach the spark plug.

NOTICE

The engine works well with 10% or less ethanol blend fuels.

When using blended fuels, there are some issues worth noting:

– Ethanol-gasoline blends can absorb more water than

gasoline alone.

– These blends can eventually separate, leaving water or a

watery goo in the tank, fuel valve and carburetor.

– The compromised gasoline can be drawn into the

carburetor and cause damage to the engine and/or create

power performance problems.

– There are only a few suppliers of fuel stabilizer that are

formulated to work with ethanol blend fuels.

– Any damages or hazards caused by using improper fuel,

improperly stored fuel, and/or improperly formulated

stabilizers, are not covered by manufacturer’s warranty.

It is advisable to always shut off the fuel supply (where

applicable - not every unit has a fuel shut off), run the

engine to fuel starvation and drain the tank when the

equipment is not in use for more than a 30-day period.

WARNING

Never store the blower indoors or next to appliances where

there is a source of heat, open flame, spark or pilot light as

these conditions can ignite gasoline vapors. DO NOT store the

blower near fertilizer or any corrosive material. Even with an

empty fuel tank, gasoline vapors could ignite. When storing the

blower for short or long periods of time, always be sure that

the engine switch (where applicable) and the fuel valve (where

applicable) are set in the “OFF” position.

NOTICE

To avoid possible damage to the threads, do not try to remove

the plug from a hot aluminum cylinder head.

25

200947 - WALK BEHIND BLOWER

SPECIFICATIONS

SPECIFICATIONS

Blower Specifications

Model ....................................................... 200947

Air Velocity* ...........................Max 160 MPH (257.5 km/h)

...............................................Max 1300 CFM (ft3/min)

Sound Pressure ........................... 85 dB(A) @ 20 ft. (6 m)

Wheel Diameter ..... 12 in. (30.5 cm) Rear / 8 in. (20.3 cm) Front

* Rated per ANSI/OPEI B175.2

Overall Dimensions

Net Weight ........................................... 104 lb. (47 kg)

Length ............................................35.9 in. (91.2 cm)

Width .............................................. 26.8 in. (68 cm)

Height ........................................... 47.4 in. (120.5 cm)

Engine Specifications

Model ........................................................ R224P

Displacement (cc) ...............................................224

Type ................................................... 4-Stroke OHV

Star t Type .................................................... Recoil

Spark Plug Specifications

OEM ....................................................NHSP F6RTC

Replacement ...........................NGK BPR6ES or equivalent

Gap (in/mm) .............................. 0.028 - 0.031 / 0.7 - 0.8

Valve Specifications

Intake Clearance (in/mm) ............ 0.0039 - 0.0059 / 0.1 - 0.15

Exhaust Clearance (in/mm) ..........0.0059 - 0.0079 / 0.15 - 0.2

NOTICE

A technical bulletin regarding valve adjustment procedures is

available at www.championpowerequipment.com.

Oil Specifications

NOTICE

Temperature will affect engine oil and engine performance.

Change the type of engine oil used based on temperature

shown in the “Recommended Engine Oil Type” table.

Recommended Engine Oil Type

10W-30

10W- 405W-30

5W-30 Full Synthetic

-20 0 20 40 60

°F

-28.9

°C -17. 8 -6.7 4.4 15.6 26.7 3 7. 8 48.9

Ambient temperature

Oil Capacity (fl. oz/mL) ...................................16.9 / 500

80 100 120

Fuel Specifications

Use regular unleaded gasoline with a minimum octane rating of 87

and an ethanol content of less than 10% by volume. DO NOT USE

E15 or E85. DO NOT OVERFILL.

Fuel Capacity (gal/L) .......................................0.82/3.1

Important Message About Temperature

NOTICE

An important message about temperature: Your product

is designed and rated for continuous operation at ambient

temperatures up to 104°F (40°C). When needed, it may be

operated at temperatures ranging from 5°F (-15°C) to 122°F

(50°C) for short periods of time. If exposed to temperatures

outside this range during storage, it should be brought back

within this range before operation. In any event, the product

must always be operated outdoors, in a well-ventilated are and

away from doors, windows and vents.

Starting Temperature Range (°F/°C) ........... 5 to 104/-15 to 40

26

200947 - WALK BEHIND BLOWER

Parts Diagram - Figure A

SPECIFICATIONS

)LJXUH$

27

200947 - WALK BEHIND BLOWER

Parts List - Figure A

# Part Number Description Qty.

1 2550011234 Hex Screw 6×12 6

2 2540006536 Fan Guard 1

3 2550011732 Nut GB6171 M16×1.5 1

4 2550000883 Spring Washer Ø8 4

5 2570000821 Impeller Assembly 1

6 2550011344

7 2550011734 Spring Washer Ø16 1

8 2550011239 Flat Washer Ø8 4

9 2540006548 Subplate 1

10 2540006535 Volute Assembly 1

11 255 0 0117 3 3 Flat Washer Ø16 1

12 2560004155

13 2550001556 Nut GB6177.1 M8 6

14 2540006537

15 2540006538 Wind-direction Plate 1

16 2550011247 Bolts M4 x 16 2

17 2550011235 Locknut M4 2

18 2560004099 Compression Spring 1 1

19 2540006558 Locking Lever 1

20 2540006539 Outlet Assembly 1

21 2 5 5 0 0 115 9 9

22 2550 011476 Locknut M8 1

23 2550004645

24 Figure B See Figure B

Bolt 5/16×25-24UNF-

8.8

Gasoline Engine

R224P-B00KY

Wind-direction

Adjusting Bracket

Hexagon Bolt M8 x

40-8.8

Hexagon Bolt M8 x

20-8.8

SPECIFICATIONS

4

1

1

4

2

28

200947 - WALK BEHIND BLOWER

Parts Diagram - Figure B

LJXUH%

SPECIFICATIONS

29

200947 - WALK BEHIND BLOWER

Parts List - Figure B

SPECIFICATIONS

# Part Number Description Qty.

1 2550011243 Locknut M6 2

2 2550002033 Flat Washer Ø6 3

3 2540006550

4 2550011246 Bolts GB12 M6 x 65 1

5 2540006560 Handlebar 1

6 2540006551

7 2550000963 Flat Washer Ø4 8

8 255001138 8

9 2550011244 Large Flat Washer Ø8 8

10 2570000813

11 2540006555

12 2540006549 Lower Handlebar 1

13 2550011236 Locknut M10 1

14 2550011245 Flat Washer Ø10 3

15 2550001551 Nut GB6170 M6 1

16 2540006563 Flange Bushing 2

17 2560004100

18 2540006557

19 2550001554 Locknut M8 2

20 255 0 011417 Starter Rope Bracket 1

21 2 5 5 0 0 112 3 9 Gasket Ø8 1

22 2550 01123 8 Nut GB6183.1 M8 2

23 2550004645

24 2540006559 Handle Grip 1

25 2540006562 Handlebar Bracket 2

26 2540006556 Rubber Bushing 4

27 2550001556 Nut GB6177.1 M8 14

28 2540006545 Base Assembly 1

29 2540006546 Nozzle Bracket 1

30 2540006547 Rubber Sleeve 1

31 2 5 5 0 011242 Hex bolt M8 x 20 2

32 2540006544

33 2550 0116 0 3 Cotter Pin Ø2.5×16 1

34 2540006543

Throttle Control

Assembly

Upper Handlebar

Connecting Base

Cross-head Tapping

Screw

Handle Height Adjust

Lever

Lower Handlebar

Connecting Base

Compression Spring

Ø2

Rear Wheel Assembly,

12in. Yellow

Hexagon Bolt M8 x

20-8.8

Front Wheel Hinge Pin

Assembly

Front Wheel Swivel

Mount

17

# Part Number Description Qty.

35 2540006542

1

2

8

2

2

1

2

1

1

36 2540006541

Front Wheel

Connecting Mount

Front Wheel Assembly,

8in. Yellow

1

1

30

200947 - WALK BEHIND BLOWER

Engine Parts Diagram

85

86

78

99

80

79

SPECIFICATIONS

87

53

92

89

88

77

76

75

90

91

93

95

99

34

35

96

44

43

42

52

50

51

47

46

45

95

95

49

48

1

97

58

81

82

83

95

95

84

39

40

41

31

36

37

38

35

71

72

73

54

94

57

56

55

67

98

65

66

61

60

64

63

62

10 0

74

10 1

59

69

70

68

31

200947 - WALK BEHIND BLOWER

Engine Parts List

SPECIFICATIONS

# Part Number Description Qty.

Hexagon Flange Bolt,

1 90001-0612-0101

2 12410-Z440110-0001

3 12004-Z440110-00A0

4 14314-Z010110-0000 Valve Adjusting Nut 2

5 14311-Z010110-0000 Valve Rocker 2

6 14313-Z010110-0000 Valve Adjusting Bolt 2

7 12003-Z010110-0001

8 12109-Z810110-0000 Valve Lock Clamp 4

9 12103-Z010110-000 0 Valve Spring 2

10 12101-Z810210-000 0 Seal Guide 1

11 30010-Z010110-0000 Spark Plug, F6RTC 1

12 12131-Z950210-0000 Cylinder Head Gasket 1

13 12121-Z810120-0000 Exhaust Valve 1

14 12111-Z810110 - 0 0 00 Inlet Valve 1

15 12110-Z810120-0099 Valve Set 1

16 13200-Z140210-00A9 Piston Ring Assembly 1

17 13122-Z510210-0000 Piston Pin Clip 2

18 13010-Z810210-00A 0

19 90001-0630-0101

20 17004-Z440110-0002

21 14312-Z010110-0000 Valve Lock Nut 2

22 14090-Z010110-0000

23 12112-Z810210-0000 Valve Spring Retainer 2

24 12140-Z810210-00A0

25 9 0 5 0 2-1114 - 0 0 Pin, 11 x 14 2

26 14071-Z440110-0000 Valve Lifter 2

27 14081-Z040110-0000 Valve Tappet 2

28 13111-Z810120- 0 0 A 0 Piston 1

29 13121-Z810110-0000

30 11310-Z810310-0000

M6 x 12, Blue White

Zinc

Cylinder Head Cover

Subassembly, Blue

White Zinc

Cylinder Head Cover

Gasket

Cylinder Head Bolt, M8

x 60, Blue White Zinc

Connecting Rod

Assembly

Hexagon Flange Bolt,

M6 x 30, Blue White

Zinc

Tube, Breather, Ø8 x

Ø12 x 90

Lifter Stopper Plate

Subassembly, Blue

White Zinc

Cylinder Head

Subassembly

Piston Pin, Ø13 x

Ø45.9

Crankcase

Subassembly

# Part Number Description Qty.

8

1

1

4

1

1

1

1

1

1

1

31 90682-Z300110-0001

32 90408-Z010110-0000

33 11007-Z010110-0001

34 16400-Z810210-0000

35 90547-0205-00 Bearing 2

36 13300-Z812310-00A0 Crankshaft Assembly 1

37 14200-Z810310-0000 Camshaft Assembly 1

38 110 0 1-Z440110 - 00 A 0 Crankcase Gasket 1

39 15010-Z290110-L401

40 11411-Z 4 4 0 410 - 0 0 A 0 Crankcase Cover 1

41 90001-0832-0101

42 90684-Z010510-0000 Clip Ø20 x 43 1

43 19340-Z011010-0000 Lower Shield 1

44 37050-Z010210-0001

45 19304-Z010610-0001

46 90684-Z030210-0000 Clip Ø5.7 1

47 28110-Z810410-L400 Shroud 1

48 28200-Z141010-H301

49 90408-0600-03 Washer Ø6, Black Zinc 3

50 90001-0608-03

51 35541-Z010610-0000

52 35555-Z810110-0000

53 35540-Z010610-R901

54 13510-Z440810-00A0 Flywheel Subassembly 1

55 19352-Z440110-0001 Impeller 1

56 28002-Z0L0110-0000

57 13501-Z010110-0000

58 30400-Z2M0110-0000 Ignition Coil 1

Oil Seal, Ø25 x Ø41.25

x 6

Washer, Ø10 x Ø15.8

x 1.5

Drain Plug Bolt, M10

x1.25 x15, Blue White

Zinc

Governor Gear

Assembly

Oil Dipstick

Subassembly

Hexagon Flange Bolt,

M8 x 32, Blue White

Zinc

Oil Protector, Blue

White Zinc

Cylinder Body Shroud,

Blue White Zinc

Recoil Starter

Assembly

Hexagon Flange Bolt,

M6 x 8, Black Zinc

Stop Engine

Connecting Wire

Switch Connector

Grounding Wire

Stop Engine Switch

Subassembly

Starter Pulley, Blue

White Zinc

Flywheel Nut, M14 x

1.5, Blue White Zinc

2

2

2

1

2

6

1

1

1

3

1

1

1

1

1

32

200947 - WALK BEHIND BLOWER

SPECIFICATIONS

# Part Number Description Qty.

59 90204-Z620110-00A0

60 16002-Z010110-0000

61 16003-Z010110-0000

62 16001-Z010110-0000 Carburetor Gasket 1

63 16100-Z2M0310-00M0 Carburetor Assembly 1

64 17001-Z010210-0000 Air Cleaner Gasket 1

65 17100-Z012210-00A1 Air Cleaner Assembly 1

66 90722-Z2R0110-0000 End Plug 1

67 17150-Z2M0110-0000 Air Cleaner Element 1

68 16112-Z010310 Seal Ring, Float 1

16161-Z151910-0000 Main Jet, Standard 1

16161-Z151710-0000

69

16161-Z151510-0000

70 90681-Z010610-0000 Seal Ring 1

71 90203-Z010110-0000

72 18001-Z440110-00A0 Exhaust Gasket 1

73 18100-Z140710-00A0 Muffler Assembly 1

74 18250-Z2M0110 -0000 Spark Arrestor 1

75 16061-Z010110-0000 Governor Arm 1

76 90408-Z010210-0000

77 90501-Z010110-0001 Pin, Blue White Zinc 1

78 16070-Z010110-0001

79 16072-Z010110-0001

80 16063-Z810210-0000 Spring, Governor 1

81 16062-Z010110-0001

82 16012-Z010310-0000

83 16520-Z012610-0100

84 90502-0912-00 Pin, 9 x 12 2

85 16730-Z440810-LK01 Fuel Tank Cap 1

86 16652-Z010810-0001 Fuel Strainer 1

87 37200-Z810210-0001 Fuel Gauge 1

88 16620-Z810310-H200 Fuel Tank, 3.1L 1

Stud, M6 x 115, Black

Zinc

Carburetor Insulator

Gasket

Carburetor Insulator

Plate

Main Jet, Altitude

3000-6000 Feet

Main Jet, Altitude

6000-8000 Feet

Stud, M8 x 34, Black

Zinc

Washer, Ø6.2 x Ø15

x 0.6

Governor Support

Subassembly, Blue

White Zinc

Governor Support Bolt,

M6 x 21, Blue White

Zinc

Governeor Rod, Blue

White Zinc

Throttle Valve

Returning Spring

Throttle Control

Assembly

# Part Number Description Qty.

2

1

1

1

1

2

1

1

1

1

1

1

89 16680-Z010210-0000

90 90740-Z010510-00A1 Clamp 1

91 90686-Z010710-00M1

92 30431-Z010110-0003

93 90685-Z030610-01A1 Clamp, Ø8 x 7 x 0.6 1

94 90007-0630-A1

95 90001-0610-0101

96 90001-0616-01

97 90001-0625-01

98 90305-0600-33

99 90305-0600-3101

100 90303-0800-3101

101 90107-4285-01A0 Screw 3

Fuel Tank Oil Outlet

Subassembly

Fuel Pipe, Ø4.5 x Ø8.5

x 160

Rubber Jacket, Ø9.5 x

Ø11 x 90, Black

Hexagon Flange Bolt,

M6 x 30, Blue White

Zinc

Hexagon Flange Bolt,

M6 x 10, Blue White

Zinc

Hexagon Flange Bolt,

M6 x 16, Blue White

Zinc

Hexagon Flange Bolt,

M6 x 25, Blue White

Zinc

Hexagon Flange Nut,

M6, Black Zinc

Hexagon Flange Nut,

M6, Blue White Zinc

Hexagon Nut, M8, Blue

White Zinc

1

1

1

1

5

1

2

2

3

2

33

200947 - WALK BEHIND BLOWER

TROUBLESHOOTING

Problem Cause Solution

Spark plug wire disconnected. Reconnect wire.

Engine does not start

Engine Runs Poorly

Engine Overheats

Excessive vibration/noise

Engine does not shut off

Air flow is low

Engine Throttle Control Lever incorrectly

set.

Fuel tank empty. Add fuel.

Choke control (if so equipped) in incorrect

position.

Stale gasoline. Drain fuel and add fresh fuel.

Dirty air filter Clean or replace filter

Defective or incorrectly gapped spark plug Inspect spark plug

Carburetor out of adjustment Contact Technical Support Team

Misadjusted throttle control Contact Technical Support Team

Dirt or water in fuel tank Contact Technical Support Team

Defective or incorrectly gapped spark plug Inspect the spark plug

Dirty air filter Clean or replace filter

Carburetor out of adjustment Contact Technical Support Team

Stale gasoline. Replace with fresh gasoline

Dirt or water in fuel tank Contact Technical Support Team

Engine cooling system clogged Clean air-cooling system

Engine cooling system clogged Clean air-cooling system

Carburetor out of adjustment Contact Technical Support Team

Oil level is low Check oil level

Loose parts Check and tighten all fasteners

See engine problems above See engine solutions above

Misadjusted throttle control or ignition

switch

Throttle is in slow position Ensure throttle is in fast position

Air intake is clogged Clean any debris from the air intake

Air discharge is clogged Clear any obstructions from the discharge

Put lever in START position.

Move to CHOKE position.

Contact Technical Support Team

TROUBLESHOOTING

For further technical support:

Technical Support Team

Mon-Fri 8:30 AM-5:00 PM (PST/PDT)

Toll Free 1-877-338-0999

support@championpowerequipment.com

34

WARRANTY*

CHAMPION POWER EQUIPMENT

2 YEAR LIMITED WARRANTY

Warranty Qualifications

To register your product for warranty and FREE lifetime call center

technical support please visit:

https://www.championpowerequipment.com/register

To complete registration you will need to include a copy of the

purchase receipt as proof of original purchase. Proof of purchase

is required for warranty service. Please register within ten (10)

days from date of purchase.

Repair/Replacement Warranty

CPE warrants to the original purchaser that the mechanical and

electrical components will be free of defects in material and

workmanship for a period of two years (parts and labor) from

the original date of purchase and 180 days (parts and labor) for

commercial and industrial use. Transportation charges on product

submitted for repair or replacement under this warranty are the

sole responsibility of the purchaser. This warranty only applies to

the original purchaser and is not transferable.

Do Not Return The Unit To The Place Of

Purchase

Contact CPE’s Technical Service and CPE will troubleshoot any

issue via phone or e-mail. If the problem is not corrected by

this method, CPE will, at its option, authorize evaluation, repair

or replacement of the defective part or component at a CPE

Service Center. CPE will provide you with a case number for

warranty service. Please keep it for future reference. Repairs or

replacements without prior authorization, or at an unauthorized

repair facility, will not be covered by this warranty.

Warranty Exclusions

This warranty does not cover the following:

Normal Wear

Products with mechanical and electrical components need

periodic parts and service to perform well. This warranty does not

cover repair when normal use has exhausted the life of a part or

the equipment as a whole.

Installation, Use and Maintenance

This warranty will not apply to parts and/or labor if the product is

deemed to have been misused, neglected, involved in an accident,

abused, loaded beyond the product’s limits or modified. Normal

maintenance is not covered by this warranty and is not required to

be performed at a facility or by a person authorized by CPE.

Other Exclusions

This warranty excludes:

– Cosmetic defects such as paint, decals, etc.

– Wear items such as starter pulleys, starter ropes, filter

elements, belts, blower fans, impeller blades, blower and/or

vacuum tubes, vacuum bag and straps (where applicable), etc.

– Failures due to acts of God and other force majeure events

beyond the manufacturer’s control.

– Problems caused by parts that are not original Champion

Power Equipment parts.

Limits of Implied Warranty and

Consequential Damage

Champion Power Equipment disclaims any obligation to cover

any loss of time, use of this product, freight, or any incidental

or consequential claim by anyone from using this product.

THIS WARRANTY AND THE ATTACHED U.S. EPA and/or CARB

EMISSION CONTROL SYSTEM WARRANTIES (WHEN APPLICABLE)

ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

A unit provided as an exchange will be subject to the warranty

of the original unit. The length of the warranty governing the

exchanged unit will remain calculated by reference to the purchase

date of the original unit.

This warranty gives you certain legal rights which may change

from state to state or province to province. Your state or province

may also have other rights you may be entitled to that are not

listed within this warranty.

Contact Information

Address

Champion Power Equipment, Inc.

12039 Smith Ave.

Santa Fe Springs, CA 90670 USA

www.championpowerequipment.com

Customer Service

Toll Free: 1-877-338-0999

info@championpowerequipment.com

Fax no.: 1-562-236-9429

Technical Service

Toll Free: 1-877-338-0999

tech@championpowerequipment.com

EMERGENCY 24 HOUR SUPPORT: 1-562-204-118 8

*Except as other wise stipulated in any of the following enclosed Emission C ontrol System Warranties (when applicable) for the Emission C ontrol System: U.S. Environment Protection Agency

(EPA) and/or California A ir Resources Board (CAR B).

CHAMPION POWER EQUIPMENT, INC. (CPE),

THE UNITED STATES ENVIRONMENTAL PROTECTION AGENCY (U.S. EPA)

AND THE CALIFORNIA AIR RESOURCES BOARD (CARB) EMISSION CONTROL SYSTEM WARRANTY

Your Champion Power Equipment (CPE) engine complies with both the U.S. EPA and state of California Air Resources Board

(CARB) emissions regulations.

YOUR WARRANTY RIGHTS AND OBLIGATIONS:

The US EPA, California Air Resources Board, and CPE are pleased to explain the Federal and California Emission Control Systems warranty

on your 2020 small off-road engine (SORE) and equipment. In the United States and California, new small off-road engines (SORE) and new

equipment that use small off-road engines (SORE) must be designed, built and equipped to meet the State’s stringent anti-smog standards.

CPE must warrant the emission control system on your small off-road engine (SORE) and equipment for the period of time listed below,

provided there has been no abuse, neglect or improper maintenance of your small off-road engine (SORE) and equipment leading to the

failure of the emission control system.