Chamberlain PD752KEV User Manual

3/4 hp Chain Drive

Garage Door Opener

Models

PD752KEV and

PD762EV

FOR RESIDENTIAL USE ONLY

■ Please read this manual and the enclosed safety materials carefully!

■ Fasten the manual near the garage door after installation.

■ The door WILL NOT CLOSE unless the Protector System

properly aligned.

■ Periodic checks of the garage door opener are required to ensure safe operation.

■ The model number label is located on the left side panel of your garage

door opener.

■ This garage door opener is compatible with MyQ

■ DO NOT install on a one-piece door if using devices or features providing unattended

close. Unattended devices and features are to be used ONLY with sectional doors.

Write down the following information

for future reference:

.

.

Serial Number:

®

®

is connected and

and Security✚ 2.0™ accessories.

CONTENTS

Preparation .............................. 1-4

Assembly ................................. 5-9

Installation ............................ 10-19

Install the Door Control .............20-21

Install the Protector System® ...... 22-25

Power .................................. 26-27

Adjustments .......................... 28-30

Operation.................................. 31

Features ................................... 32

Door Control ..........................33-34

Remote Control ...................... 34-35

To Erase the Memory .................... 35

To Open the Door Manually ............36

Maintenance .............................. 37

Troubleshooting ...................... 38-39

Accessories ............................... 40

Warranty .................................. 41

Repair Parts .......................... 42-43

Date of Purchase:

www.chamberlain.com

The Chamberlain Group, Inc.

845 Larch Avenue

Elmhurst, Illinois 60126-1196

Torsion

Spring

Extension

Spring

OR

Preparation

Safety Symbol and Signal Word Review

Thisgarage door opener has been designed and tested to offer safe service provided it is installed,

operated, maintained and tested in strictaccordance with the instructions and warnings contained in this

manual.

When you see these SafetySymbols and Signal Words on the following pages, they will alert you to the

possibilityof serious injuryor death if you do not complywith the warnings thataccompany them. The

hazard may come from something mechanical or from electric shock.Read the warnings carefully.

Mechanical

Electrical

When you see thisSignal Word on the following pages, it will alert you to the possibilityof damage to

your garage door and/or the garage door opener ifyou do not complywith the cautionary statementsthat

accompanyit.Read them carefully.

Unattended Operation

The Timer-to-Close (TTC)feature, the MyQ®Smartphone Control app, and MyQ®Garage Door and

Gate Monitor are examples of unattended close and are to be used ONLY with sectional doors . Any

device or feature thatallows the door to close withoutbeing inthe line of sight of the door is considered

unattended close.The Timer-to-Close (TTC) feature,the MyQ®Smartphone Control, and any other

MyQ®devicesare to be used ONLY with sectional doors.

Check the Door

To prevent possible SERIOUSINJURY or DEATH:

l ALWAYS call a trained door systemstechnician if garage door binds,sticks,or is out of balance.

An unbalanced garage door may NOT reverse when required.

l NEVER tryto loosen, move or adjustgarage door, door springs, cables, pulleys,bracketsor their

hardware, ALL of which are under EXTREME tension.

l Disable ALL locksand remove ALL ropes connected to garage door BEFORE installation and

operating garage door opener to avoid entanglement.

l DO NOTinstall on a one-piece door ifusing devicesor features providing unattended close.

Unattended devices and features are to be used ONLY with sectional doors.

To prevent damage to garage door and opener:

l ALWAYS disable locksBEFORE installing and operating the opener.

l ONLY operate garage door opener at120 V, 60 Hz to avoid malfunction and damage.

Before you begin:

1. Disable locks and remove any ropes connected to the garage door.

2. Liftthe door halfway up. Release the door. Ifbalanced, it should stay

in place, supported entirely by itssprings.

3. Raiseand lower the door to checkfor binding or sticking. Ifyour door

binds, sticks,or is outof balance,call a trained door systems

technician.

4. Checkthe seal on the bottomof the door. Any gap between the floor

and the bottom of the door mustnot exceed 1/4 inch (6 mm).

Otherwise,the safetyreversal systemmay not work properly.

5. The opener should be installed above the center of the door. Ifthere

is a torsion spring or center bearing plate in the way of the header

bracket,it may be installed within 4feet(1.2 m) to the leftor right of

the door center. See page11.

1

3/16

7/16

1/2

5/32

5/16

5/8

9/16

1/4

7/16

Preparation

Additional Items You May Need:

Survey your garage area to see if you will need any of the following items:

n (2) 2X4 PIECES OF WOOD

Maybe used to fasten the header bracketto the structural supports.Also used to position the

garage door opener during installation and for testing the safetyreversing sensors.

n SUPPORT BRACKET AND FASTENING HARDWARE

Mustbe used if you have a finished ceiling in your garage.

n EXTENSION BRACKETS (MODEL 041A5281-1) ORWOOD BLOCKS

Depending upon garage construction, extensionbracketsor wood blocksmay be needed to

install the safetyreversing sensor.

n FASTENING HARDWARE

Alternate floor mounting of the safetyreversing sensor will require hardware not provided.

n OUTSIDE QUICK RELEASE (MODEL 7702CB)

Required for a garage with NO access door.

n DOOR REINFORCEMENT

Required if you have a lightweightsteel,aluminum, fiberglass or glass panel door.

n RAILEXTENSION KIT

Required if your garage door is more than 7 feet (2.13 m) high.

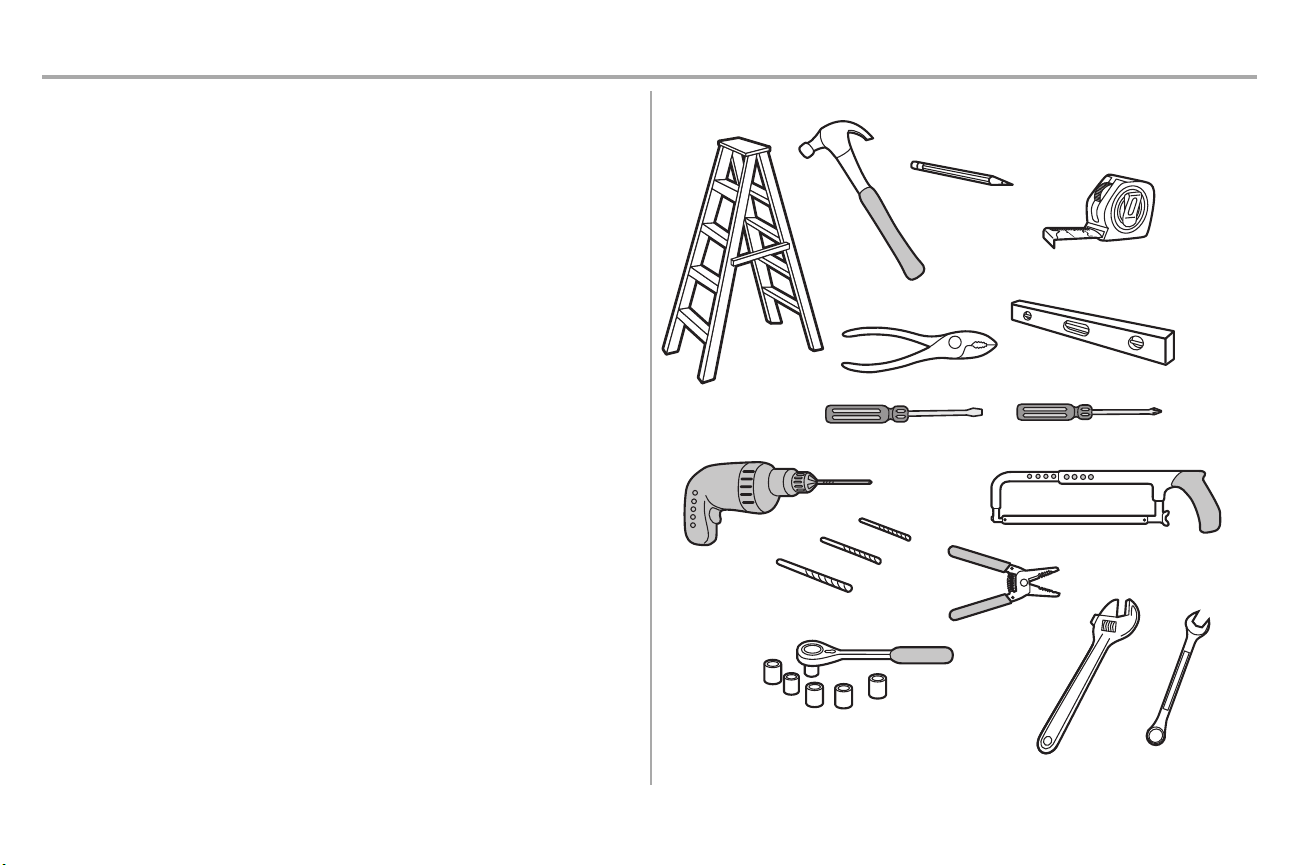

Tools Needed

2

N

A

B

C

H

K

J

O

I

D

E

F

G

L

M

P

Preparation

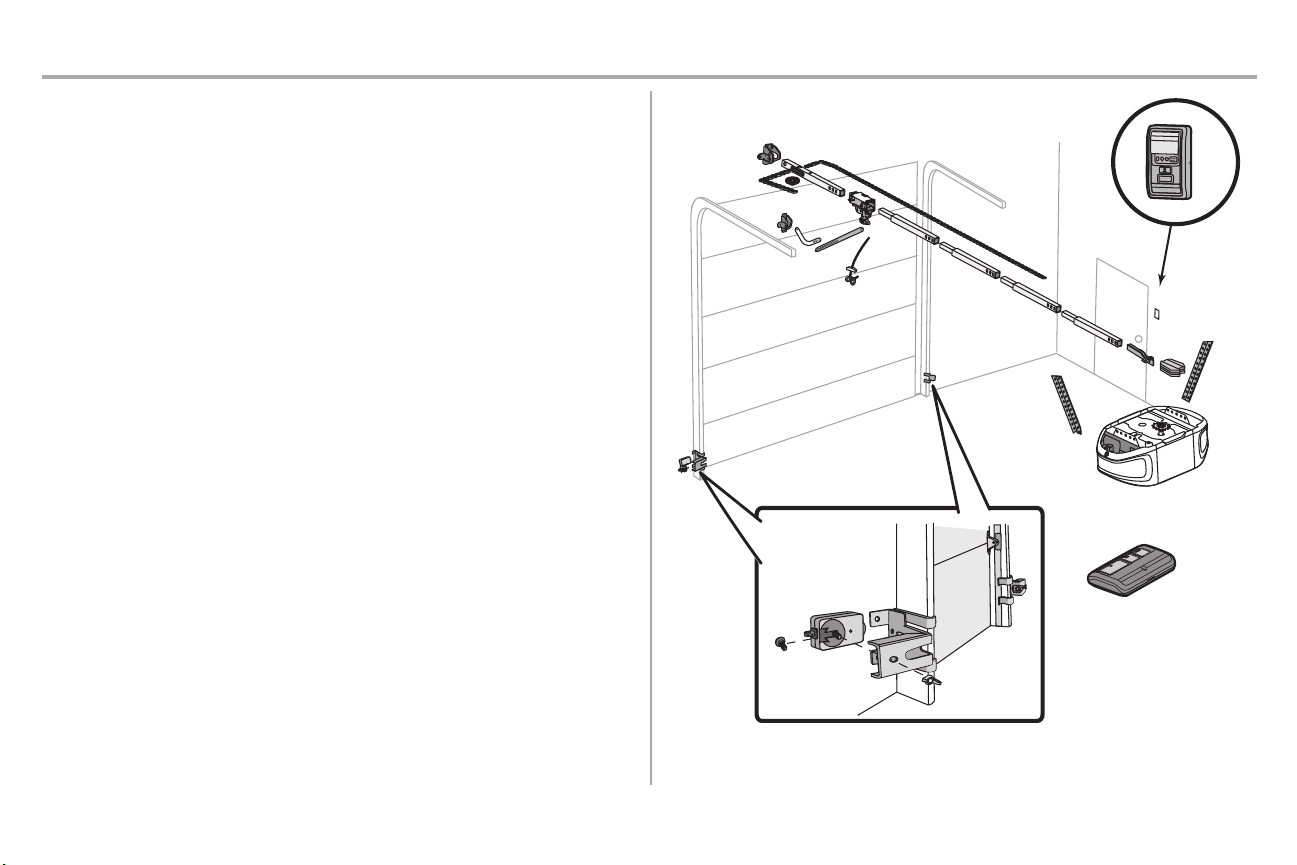

Carton Inventory

Your garage door opener is packaged in one carton which contains the motor unit and all parts

illustrated below.Accessoriesvary depending on the garage door opener model purchased.Depending

on your model, other accessories may be included with your garage door opener. Instructions for these

accessories will be attached to the accessoryand are notincluded in this manual. Save the carton and

packing material until the installation and adjustmentis complete.The images throughout this manual

are for reference only and your productmaylook different.

A. Header bracket

B. Pulley

C. Door bracket

D. Curved door arm

E. Straight door arm (Packaged inside front rail section)

F. Trolley

G. Emergencyrelease rope and handle

H. Rail (1 front and 4 center sections)

K. Chain spreader with screws

L. “U” bracket

M. Chain and cable

N. Door control

O. Remote control

P. The Protector System

NOT SHOWN

NOTE: Be sure to assemble the trolley before sliding onto rail.

I. Hanging brackets (2) (Packaged inside the front rail section)

J. Garage door opener (motor unit)

Safetyreversing sensors with 2 conductor white and white/blackwire attached:Sending Sensor

®

(1), Receiving Sensor (1), and Safety Sensor Brackets(2)

White and red/white wire

Owner's manual

Hardware

3

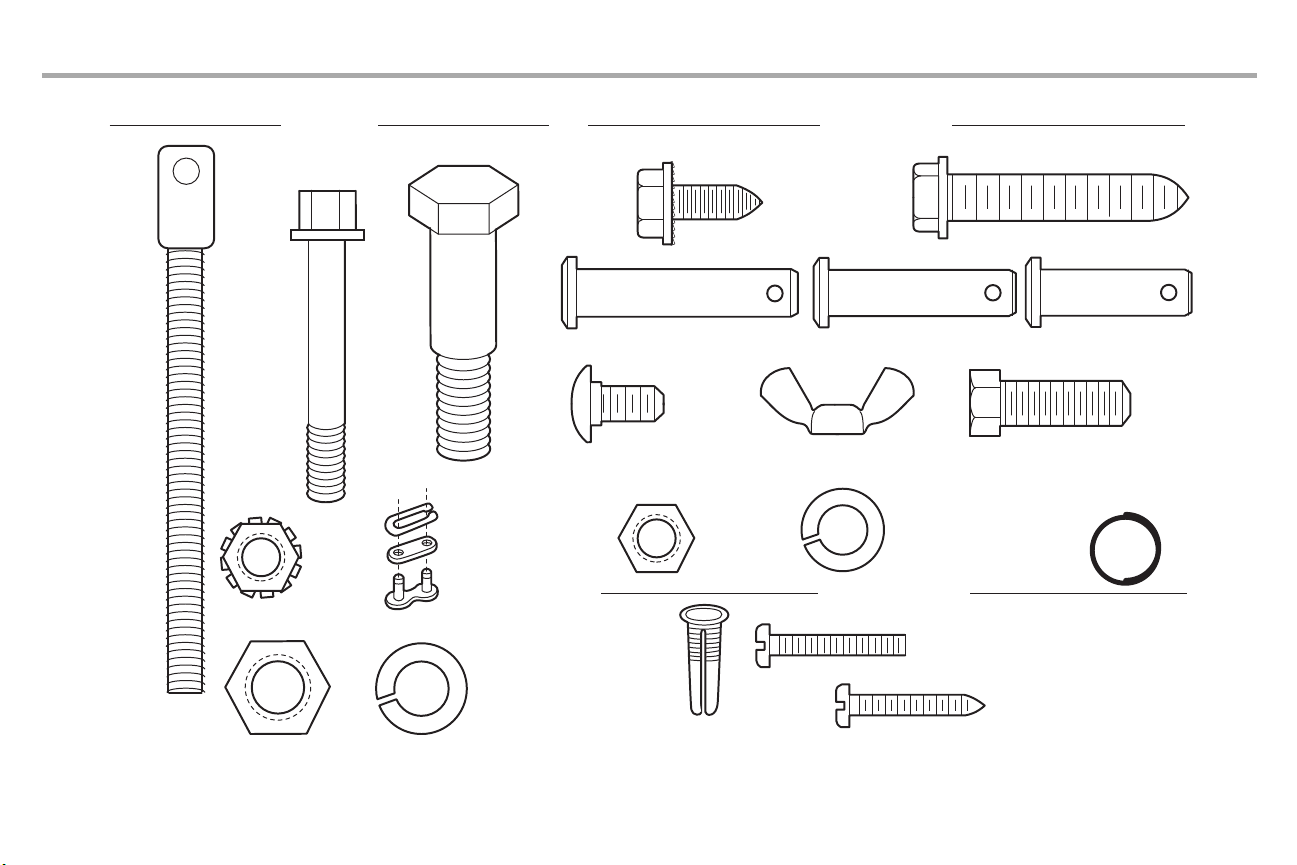

Bolt

1/4"-20x1-3/4"

Lock Nut

1/4"-20

Bolt

Nut 3/8" Lock Washer 3/8"

Master Link

Clevis Pin 5/16"x1-1/2"

Ring Fastener (3)

Hex Bolt 5/16"-18x7/8" (4)

Lock Washer

5/16"-18 (5)

Nut

5/16"-18 (6)

Self-Threading Screw

1/4"-14x5/8" (2)

Clevis Pin 5/16"x1"

Clevis Pin 5/16"x1-1/4"

Carriage Bolt

1/4"-20x1/2" (2)

Wing Nut 1/4"-20 (2)

ASSEMBLY INSTALLATION

Screw 6ABx1" (2)

Drywall Anchors (2)

Screw 6-32x1" (2)

DOOR CONTROL

Insulated

Staples

(Not Shown)

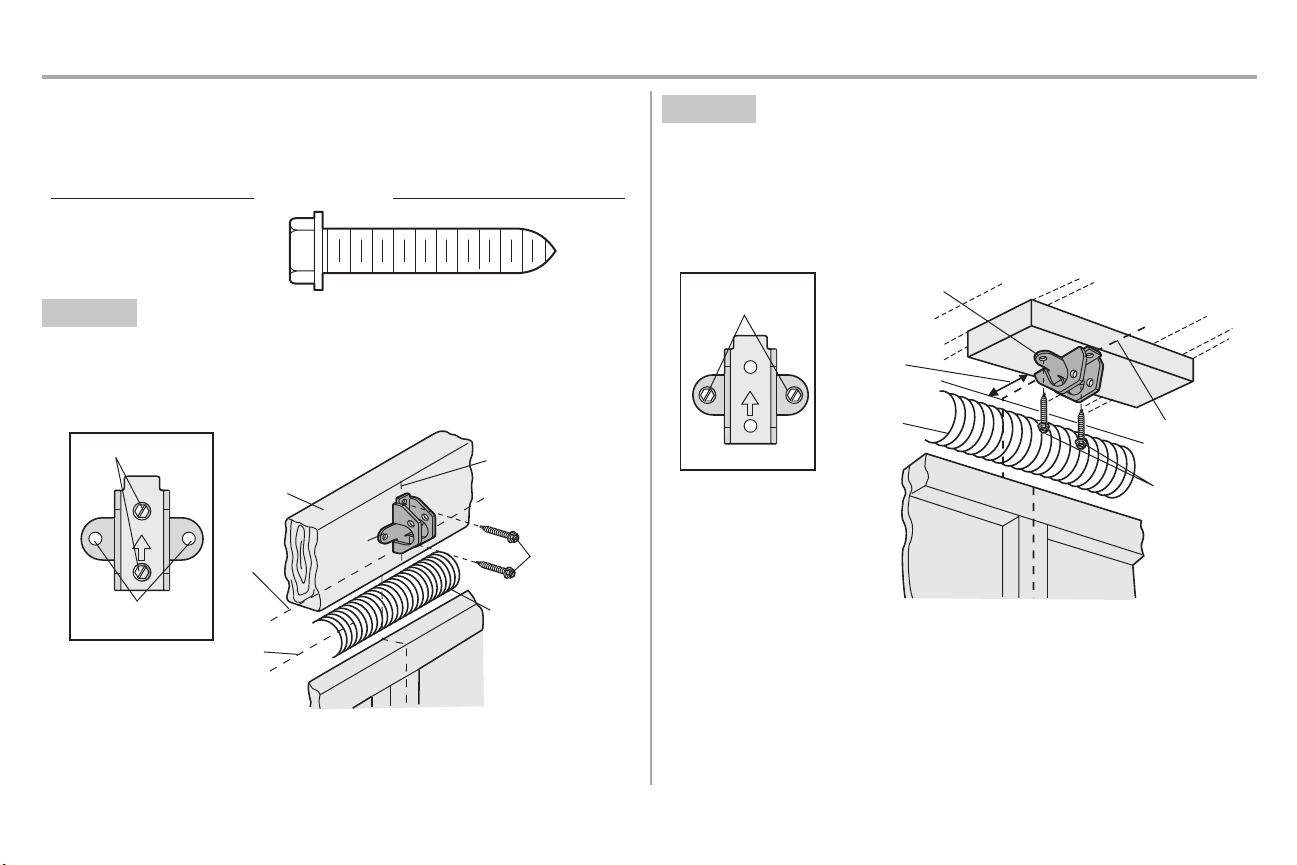

Lag Screw 5/16"-9x1-5/8" (4)

Threaded

Shaft

Preparation

Hardware

4

Assembly

To garage

door opener

(TO MOTOR UNIT)

Front Rail

Section

(TO DOOR)

“U” Bracket

Outer Trolley

Inner Trolley

Wear Pads

SLIDE TO STOPS

ON TOP AND

SIDES OF

“U” BRACKET

Trolley

Rail Tab

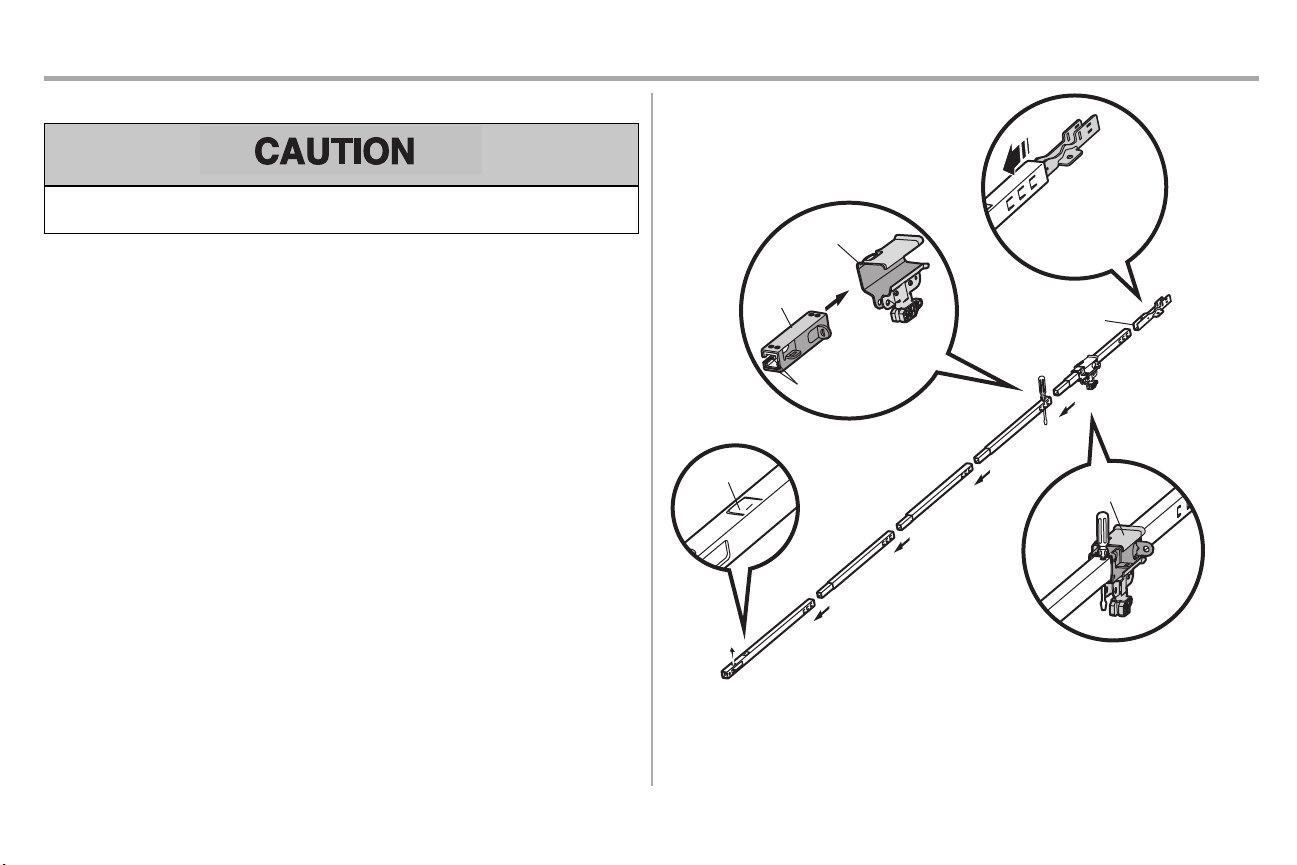

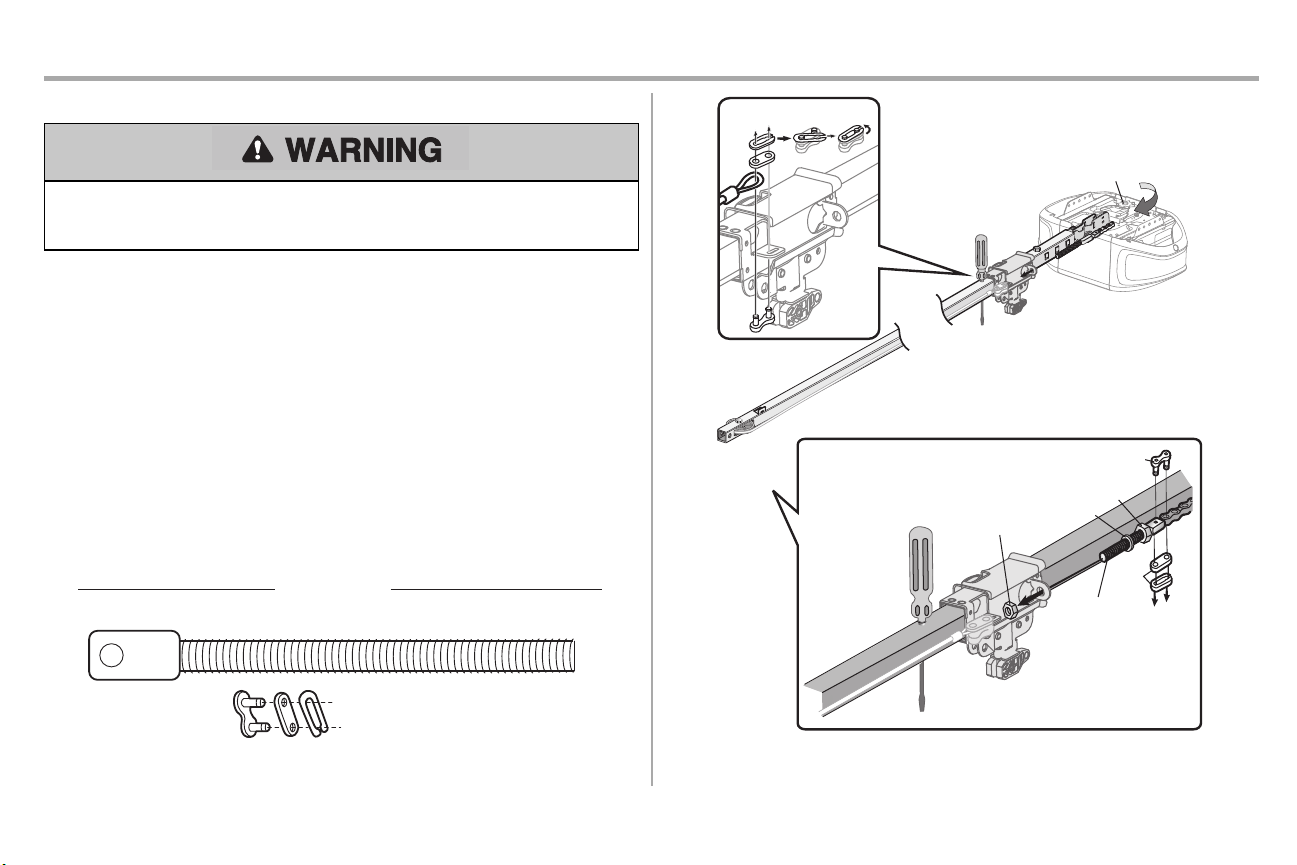

STEP 1 Assemble the rail and install the trolley

To prevent INJURY from pinching, keep hands and fingers away from the jointswhile assembling the

rail.

To avoid installation difficulties, do not run the garage dooropeneruntilinstructed to do so.

The front rail hasa cut out “window” at the door end. The rail tab MUST be on top of the rail when

assembled.

1. Remove the straightdoor arm and hanging bracketpackaged inside the front rail and set aside

for Installation Step 5 and 9. NOTE: To prevent INJURY while unpacking the rail carefully remove

the straight door armstored within the rail section.

2. Align the rail sections on aflat surface as shown and slide the tapered ends into the larger ones.

Tabs along the side will lock into place.

3. Place the motor unit on packing material to protect the cover, and rest the backend of the rail on

4. Asa temporary stop,insert a screwdriver into the hole in the second rail section fromthe motor

5. Checkto be sure there are 4plastic wear pads inside the inner trolley. Ifthey became loose

6. Slide the trolley assemblytoward the screwdriver as shown.

7. Slide the rail onto the “U” bracket, until it reaches all the stops on the top and sides of the “U”

top.For convenience, put a support under the front end of the rail.

unit,as shown.

during shipping, check all packing material. Snap them back into position as shown.

bracket.

5

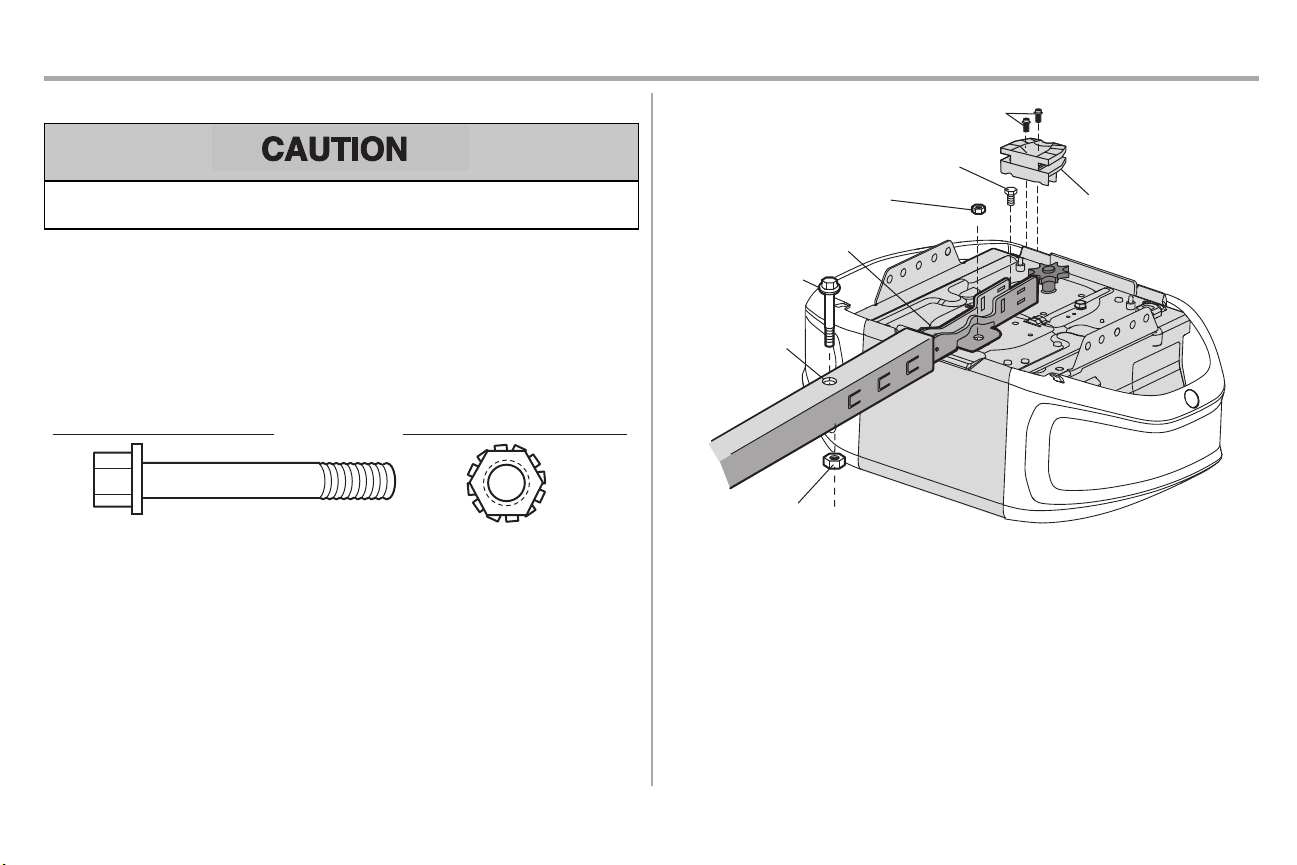

Assembly

HARDWARE

Bolt 1/4"-20x1-3/4"

Lock Nut 1/4"-20

“U” Bracket

Bolt (Mounted in the

garage door opener)

Chain

Spreader

Lock Nut (Mounted in the

garage door opener)

Hex Screws 8-32x7/16

Cover

Protection

Bolt Hole

Bolt 1/4"-20x1-3/4"

Lock Nut 1/4"-20

STEP 2 Fasten the rail to the motor unit

To avoid SERIOUS damage to garage door opener, use ONLY those bolts/fasteners mounted in the

top of the opener.

1. Insert a 1/4"-20x1-3/4" bolt into the cover protection bolt hole on the back end of the rail as

shown.Tighten securely with a 1/4"-20 lock nut.DO NOT overtighten.

2. Remove the bolt and lock nut fromthe top of the motor unit.

3. Use the carton to support the front end of the rail.

4. Place the “U” bracket, flat side down onto the motor unit and align the bracket holes with the bolt

holes.

5. Fasten the “U” bracketwith the previouslyremoved bolt and locknut; DO NOT use any power

tools.The use of power tools may permanently damage the garage door opener.

6. Attach chain spreader to the motor unit withtwo screws.

6

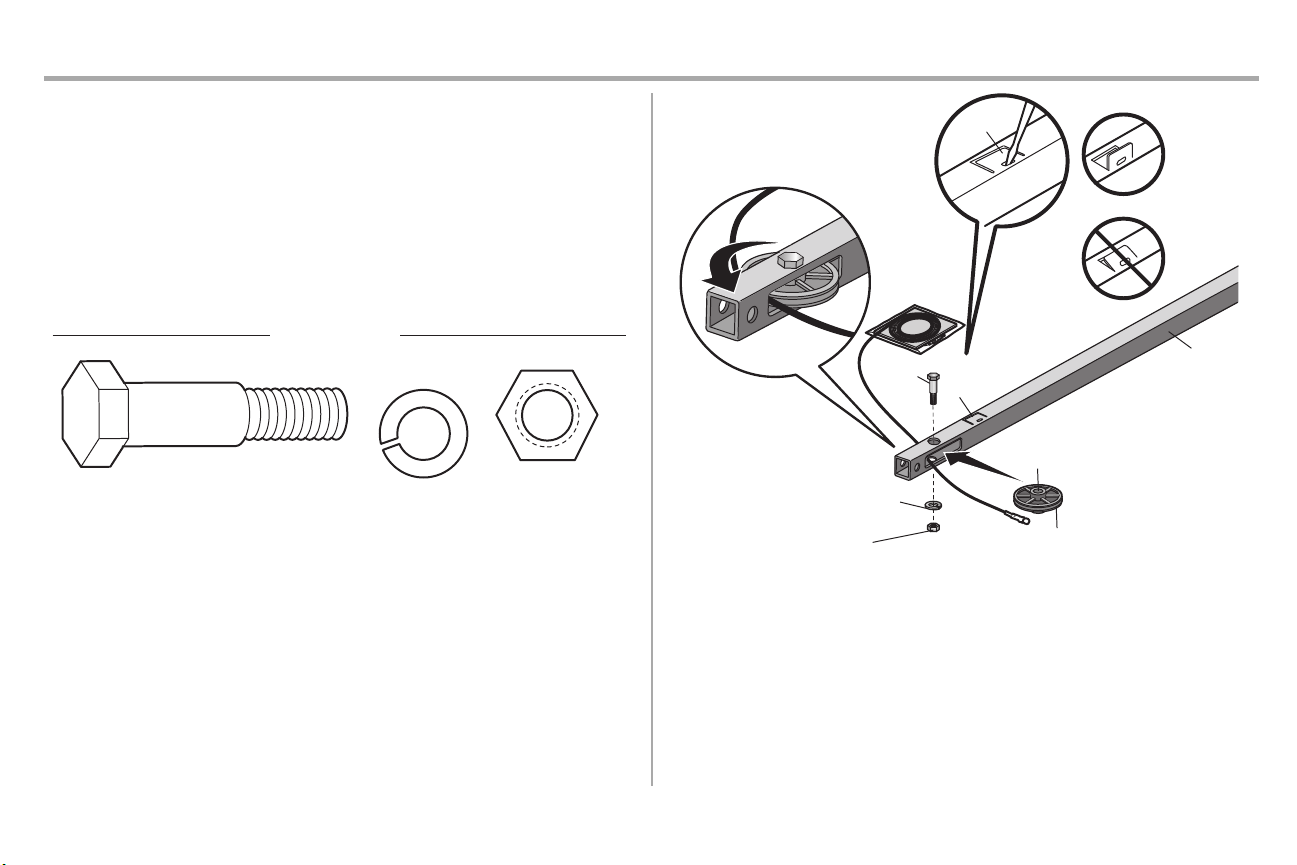

Assembly

HARDWARE

Bolt

Nut 3/8"

Lock Washer 3/8"

Rail

Idler Pulley

Grease Inside Pulley

Bolt

Lock Washer 3/8"

Nut 3/8"

Rail

Tab

CORRECT

INCORRECT

Rail Tab

STEP 3 Install the idler pulley

1. Lay the chain/cable beside the rail, as shown. Grasp the end of the cable and pass

approximately 12" (30 cm) ofcable through the window.Allow it to hang until AssemblyStep 4.

2. Remove the tape from the idler pulley. The inside center should be pre-greased. Ifdry, regrease

to ensure proper operation.

3. Place the idler pulley into the window as shown.

4. Insert the idler bolt from the top through the rail and pulley.Tighten witha 3/8" lock washer and

nut underneath the rail until the lockwasher is compressed.

5. Rotate the pulley to be sure it spins freely.

6. Locatethe rail tab. The rail tab is near the idler pulley on the front rail section. Use a flathead

screwdriver and liftthe rail tab until the tab is vertical (90º).

7

Assembly

HARDWARE

Master

Link

Threaded Shaft

Figure 2

Sprocket

Figure 3

Threaded

Shaft

Outer

Nut

Inner

Nut

Lock

Washer

Master Link

Master

Link

Figure 1

a.

b.

c.

STEP 4 Install the chain

To avoid possible SERIOUS INJURY to finger from moving garage door opener:

l ALWAYS keep hand clear of sprocketwhile operating opener.

l Securely attach chain spreader BEFORE operating.

1. Pull the cable around the idler pulley and toward the trolley.

2. Connectthe cable to the retaining slot on the trolley,as shown. (Figure 1)

a. Push pins of master link bar through cable linkand trolley slot.

b. Push master link cap over pins and past pin notches.

c. Slide the closed end ofthe clip-on spring over one ofthe pins.Push the open end of the

clip-on spring onto the other pin.

3. With the trolley against the screwdriver, dispense the remainder of the cable/chain along the rail

toward the motor unit around the sprocketand continuing to the trolley assembly.The sprocket

teeth must engage the chain. (Figure 2)

4. Checkto make sure the chain is not twisted, then connect it to the threaded shaftwith the

remaining master link.

5. Thread the inner nut and lock washer onto the trolley threaded shaft.

6. Insert the trolley threaded shaftthrough the hole in the trolley.Be sure the chain is not twisted.

(Figure 3)

7. Loosely thread the outer nut onto the trolley threaded shaft.

8. Remove the screwdriver.

8

Assembly

Outer

Nut

Lock

Washer

Trolley

Threaded

Shaft

Inner Nut

To Tighten

Inner Nut

To Tighten Outer Nut

Base of Rail

Mid length of Rail

Chain

1/4" (6 mm)

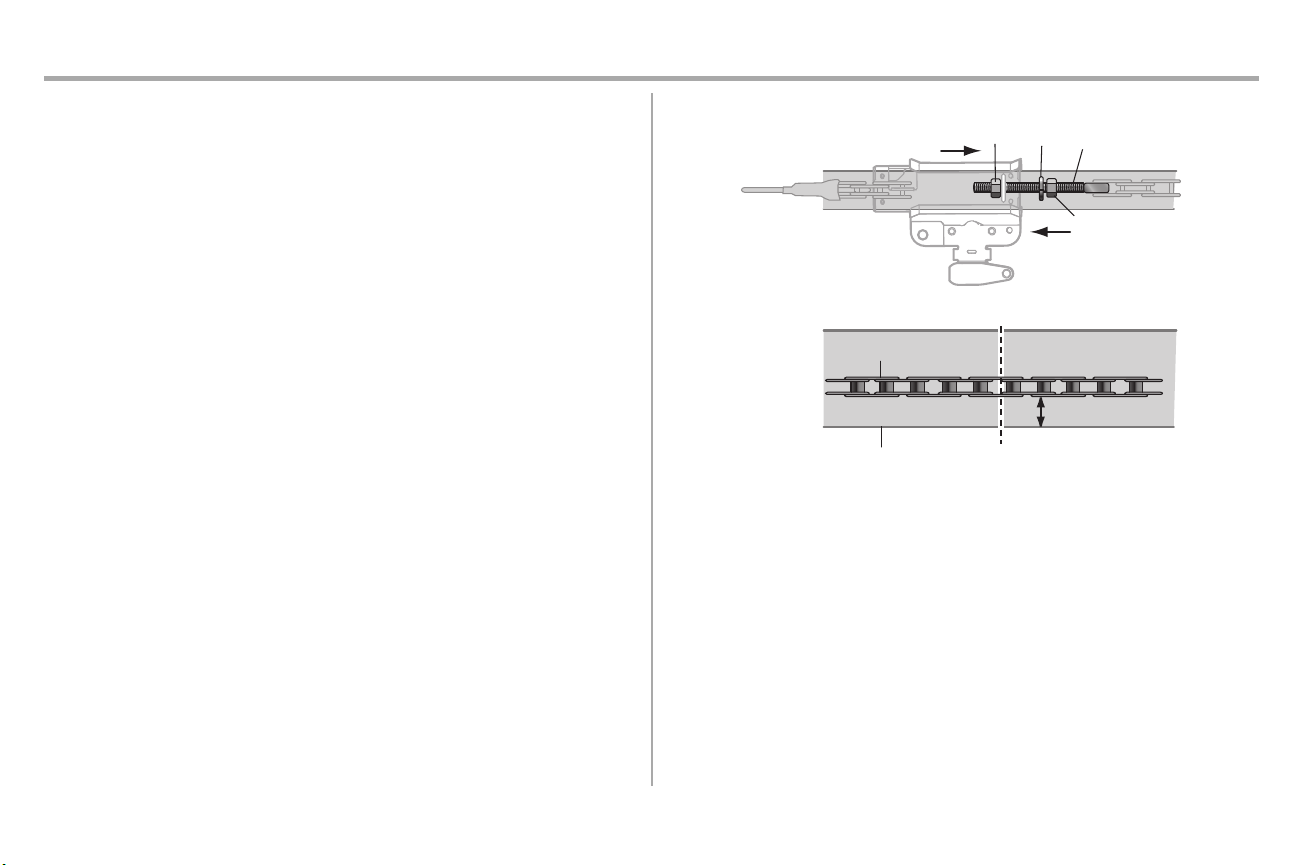

STEP 5 Tighten the chain

1. Spin the inner nut and lock washer down the trolley threaded shaft,awayfrom the trolley.

2. Totighten the chain, turn the outer nut in the direction shown.

3. When the chain isapproximately1/4" (6 mm) above the base of the rail at it's midpoint,retighten

the inner nut to secure the adjustment.

Sprocketnoise can result if the chain is too loose.When installation is complete,you may notice some

chain droop with the door closed. This is normal. Ifthe chain returns to the position shown when the door

is open, do not re-adjustthe chain.

NOTE: During future maintenance, ALWAYS pull the emergency release handle to disconnect the

trolley before adjusting the chain.

You have now finished assemblingyourgarage dooropener.Please read the followingwarnings

beforeproceeding to the installationsection.

9

Installation

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READAND FOLLOW ALL INSTALLATIONWARNINGS AND INSTRUCTIONS.

2. Install garage door opener ONLY on properly balanced and lubricated garage door. An

improperly balanced door may NOTreverse when required and could result in SEVERE

INJURYor DEATH.

3. ALL repairs to cables, spring assembliesand other hardware MUST be made by a trained door

systemstechnician BEFORE installing opener.

4. Disable ALL locksand remove ALL ropes connected to garage door BEFORE installing opener

to avoid entanglement.

5. Install garage door opener 7 feet (2.13 m) or more above floor.

6. Mountthe emergency release within reach, but at least6 feet (1.83 m) above the floor and

avoiding contactwith vehicles to avoid accidental release.

7. NEVER connect garage door opener to power source until instructed to do so.

8. NEVER wear watches,rings or loose clothing while installing or servicing opener. They could be

caught in garage door or opener mechanisms.

9. Install wall-mounted garage door control:

l within sight of the garage door.

l out of reach of children at minimumheight of5 feet (1.5m).

l away from ALL moving partsof the door.

10. Placeentrapment warning label on wall next to garage door control.

11. Placemanual release/safetyreverse testlabel inplain view on inside of garage door.

12. Upon completion of installation,testsafetyreversal system.Door MUST reverse on contactwith a

1-1/2" (3.8 cm)high object(or a 2x4 laid flat) on the floor.

13. To avoid SERIOUS PERSONAL INJURY or DEATH from electrocution,disconnectALL electric

power BEFORE performing ANY service or maintenance.

14. DO NOT installon a one-piece door if using devices or featuresproviding unattended close.

Unattended devices and features are to be used ONLY with sectional doors.

10

Installation

Header Wall

Vertical Centerline of Garage Door

2x4

Structural

Supports

Level

(Optional)

Unfinished

Ceiling

2x4

OPTIONAL CEILING MOUNT

FOR HEADER BRACKET

Sectional door with curved track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door with horizontal track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door without track:

jamb hardware

Header Wall

8" (20 cm)

Highest

Point of

Travel

Door

Jamb

Hardware

One-piece door without track:

pivot hardware

Header Wall

8" (20 cm)

Highest

Point of

Travel

Door

Pivot

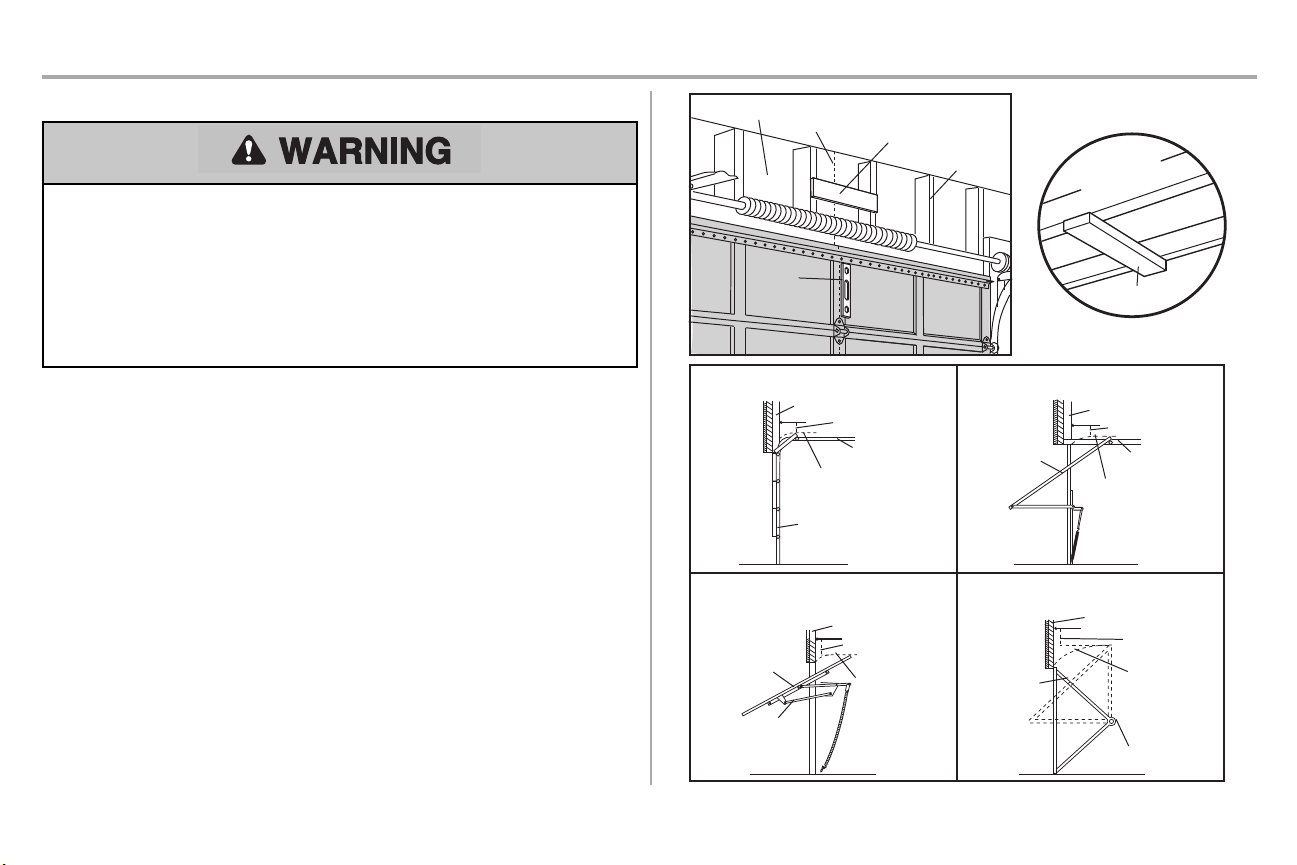

STEP 1 Determine the header bracket location

To prevent possible SERIOUSINJURY or DEATH:

l Header bracket MUST be RIGIDLY fastened to structural support on header wall or ceiling,

otherwise garage door might NOT reverse when required. DO NOTinstall header bracket over

drywall.

l Concreteanchors MUST be used if mounting header bracketor 2x4 into masonry.

l NEVER tryto loosen, move or adjustgarage door, springs, cables,pulleys,brackets,or their

hardware, ALL of which are under EXTREME tension.

l ALWAYS call a trained door systemstechnician if garage door binds,sticks,or is out of balance.

An unbalanced garage door might NOT reverse when required.

Installation procedures vary according to garage door types.Follow the instructions which apply to your

door.

1. Closethe door and mark the inside verticalcenterline of the garage door.

2. Extend the line onto the header wall above the door.You can fasten the header bracketwithin 4

feet(1.22 m) of the leftor right of the door center only if a torsion spring or center bearing plate is

in the way;or you can attach it to the ceiling (see page 12)when clearance is minimal. (Itmay be

mounted on the wall upside down if necessary,to gain approximately1/2" (1 cm).Ifyou need to

install the header bracket on a 2x4 (on wall or ceiling), use lag screws(not provided) to securely

fasten the 2x4 to structural supports as shown here and on page 12.

3. Open your door to the highest point of travel as shown.Draw an intersecting horizontal line on

the header wall 2" (5 cm) above the high point :

l 2" (5 cm) above the high point for sectional door and one-piece door with track.

l 8" (20 cm) above the high point for one-piece door without track.

Thisheight will provide travel clearance for the top edge of the door. NOTE: If the total number of inches

exceeds the height available in your garage, use the maximum height possible, or refer to page 12 for

ceiling installation.

11

Installation

HARDWARE

Lag Screw 5/16"-9x1-5/8"

UP

Wall Mount

Optional Mounting

Holes

Vertical

Centerline of

Garage Door

(Header Wall)

Header

Bracket

2x4 Structural

Support

Door Spring

(Garage Door)

Highest Point

of Garage

Door Travel

Horizontal

Line

Lag Screw

5/16"-9x1-5/8"

UP

(Header Wall)

Ceiling Mounting

Holes

(Finished Ceiling)

Vertical

Centerline of

Garage Door

Header

Bracket

6" (15 cm)

Maximum

Door Spring

(Garage Door)

Lag Screw

5/16"-9x1-5/8"

STEP 2 Install the header bracket

You can attach the header bracket either to the wall above the garage door, or to the ceiling. Follow the

instructions which will work best for your particular requirements.Do not install the header bracketover

drywall.If installing into masonry, use concrete anchors (not provided).

OPTION A WALL INSTALLATION

1. Centerthe bracket on the verticalcenterline with the bottomedge of the bracketon the horizontal

line as shown (with the arrow pointing toward the ceiling).

2. Markthe verticalset of bracketholes. Drill 3/16" pilot holes and fasten the bracketsecurely to a

structural support withthe hardware provided.

OPTION B CEILING INSTALLATION

1. Extend the vertical centerline onto the ceiling as shown.

2. Centerthe bracket on the verticalmark,no more than 6" (15cm) fromthe wall. Make sure the

arrow is pointing away fromthe wall. The bracketcan be mounted flush against the ceiling when

clearance is minimal.

3. Markthe side holes. Drill 3/16" pilot holes and fasten bracketsecurely to a structural support with

the hardware provided.

12

Installation

HARDWARE

Clevis Pin 5/16"x1-1/2"

Ring Fastener

Clevis Pin

5/16"x1-1/2"

Ring Fastener

One-piece

door without

tracks

All other door types

Connected Disconnected

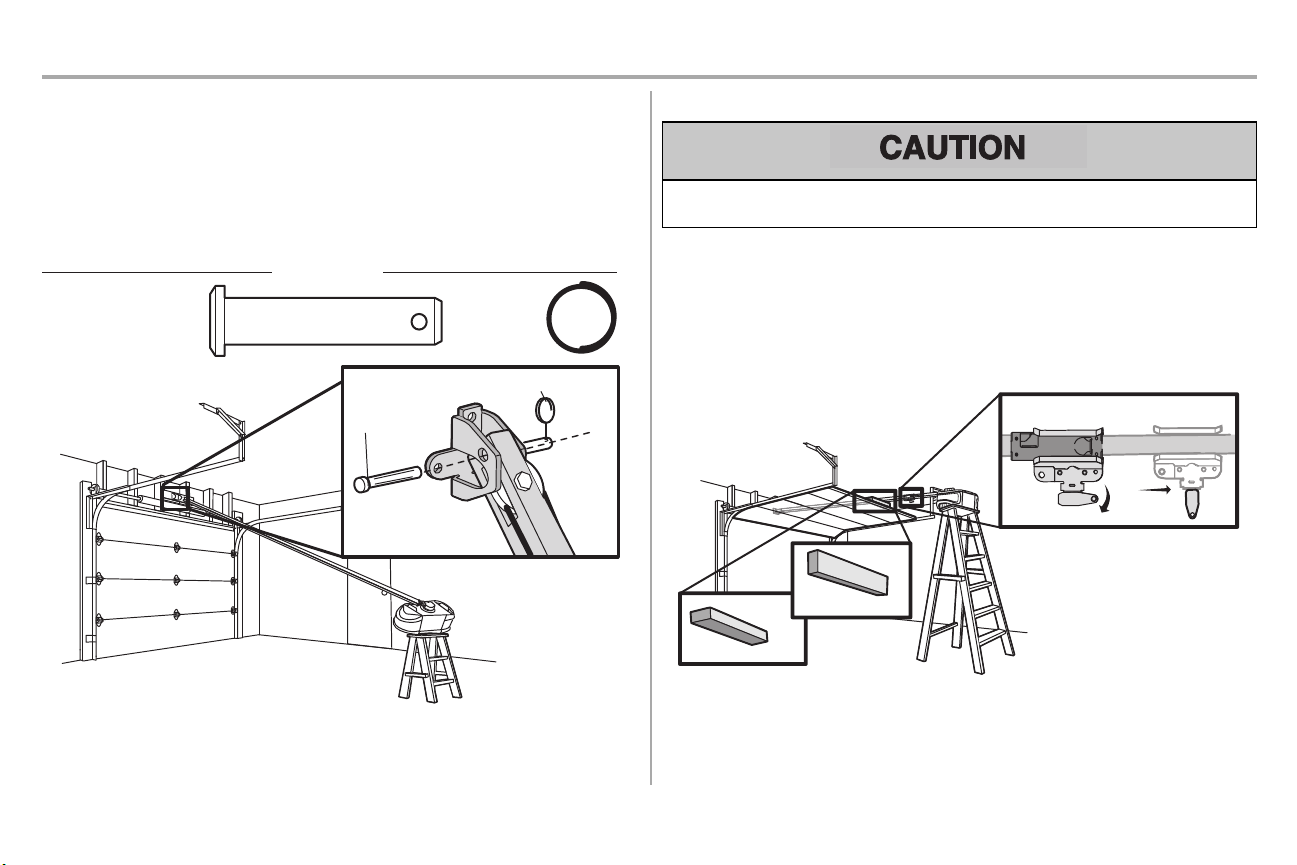

STEP 3 Attach the rail to the header bracket

1. Position the opener on the garage floor below the header bracket. Use packing material as a

protective base.

NOTE: If the door spring is in the way, you will need help. Have someone hold the opener

securely on a temporary support to allow the rail to clear the spring.

2. Position the rail bracket againstthe header bracket.

3. Align the bracket holes and join with a clevis pin asshown.

4. Insert a ring fastener to secure.

STEP 4 Position the garage door opener

To prevent damage to garage door, restgarage door opener rail on 2x4 placed on top section of

door.

1. Remove the packing material and lift the garage door opener onto a ladder.

2. Fullyopen the door and place a 2x4 (laid flat) under the rail. For one-piece doors withouttracks,

lay the 2x4 on it's side.

NOTE: A 2x4 is ideal for setting the distance between the rail and the door. Ifthe ladder is not tall

enough you will need help atthis point. Ifthe door hitsthe trolley when itis raised, pull the trolley release

arm down to disconnectthe inner and outer trolley. Slide the outer trolley toward the garage door

opener. The trolley can remain disconnected until instructed.

13

Loading...

Loading...