Chamberlain LA412-S, LA412 User Manual

12 VOLT DC SINGLE

■

■

■

■

■

SOLAR RESIDENTIAL GATE OPERATOR

Models LA412 and LA412-S

For Residential Use Only

The Chamberlain Group, Inc.

845 Larch Avenue

Elmhurst, Illinois 60126-1196

www.liftmaster.com

Owner’s Manual

Please read this manual and the enclosed safety materials carefully!

Periodic checks of the operator by a qualified technician are required to ensure

safe operation.

The model number label is located inside the control box of your operator.

■ Serial #

■ Installation Date

TABLE OF CONTENTS

WARNINGWARNING

WARNING

WARNING

CAUTIONCAUTION

WARNING

WARNING

WARNINGWARNING

2-7 INTRODUCTION

2 Safety Symbol and Signal Word Review

3 Operator Specifi cations

4-5 Safety Installation Information

6 Carton Inventory

6 Hardware Inventory

7 Additional Items for Purchase

7 Tools Needed

8-12 PREPARATION AND OVERVIEW

8 Single Gate Overview

9 Dual Gate Overview

10 Check Your Gate

11 Mounting Options

12-21 INSTALLATION

12-18 Attach the Operator to the Gate

19-20 Mount the Control Box

21-22 WIRING

21-23 Connect Gate Operator (Gate 1) to Control Box

24-26 Connect Gate Operator (Gate 2) to Control Box

(Model LA412-S Only)

27-32 SOLAR PANEL INSTALLATION

27 Select Site for Solar Panel(s)

28 Overview of Solar Panel Installation

29 Position Solar Panel (s)

30 Position Solar Bracket

30 Insert Mounting Bolts

30 Secure Solar Panel(s) to Solar Bracket

30 Mount Solar Panel(s) Assembly

31 Connect Solar Panel(s) to Operator Control Box

32 Connect Batteries

33-36 PROGRAMMING

33-34 Program Limits

35 Force and Timer To Close

36 To Add or Reprogram a Remote Control

36 To Add a Wireless Keyless Entry

36 To Erase All Codes

37-43 OPERATION AND MAINTENANCE

37 Important Safety Information

37 Using Your Gate Operator

37 Manual Release

37 Maintenance

39 Wiring Diagram

40 Diagnostic Chart

41-43 Troubleshooting

44-45 REPAIR PARTS

46 ACCESSORIES

47 WARRANTY

47 REPAIR PARTS AND SERVICE

INTRODUCTION

BACK TEMPLATE FOR POST BRACKET MOUNTING

Safety Symbol and Signal Word Review

This gate operator has been designed and tested to offer safe service provided it is installed, operated, maintained and

tested in strict accordance with the instructions and warnings contained in this manual.

When you see these Safety Symbols and Signal Words

on the following pages, they will alert you to the possibility

of serious injury or death if you do not comply with the

Mechanical

Electrical

warnings that accompany them. The hazard may come

from something mechanical or from electric shock. Read

the warnings carefully.

When you see this Signal Word on the following pages,

it will alert you to the possibility of damage to your gate

and/or the gate operator if you do not comply with the

cautionary statements that accompany it. Read them

carefully.

IMPORTANT NOTE

• BEFORE attempting to install, operate or maintain the

operator, you must read and fully understand this manual

and follow all safety instructions.

• DO NOT attempt repair or service of your commercial

Introduction 2

door and gate operator unless you are an Authorized

Service Technician.

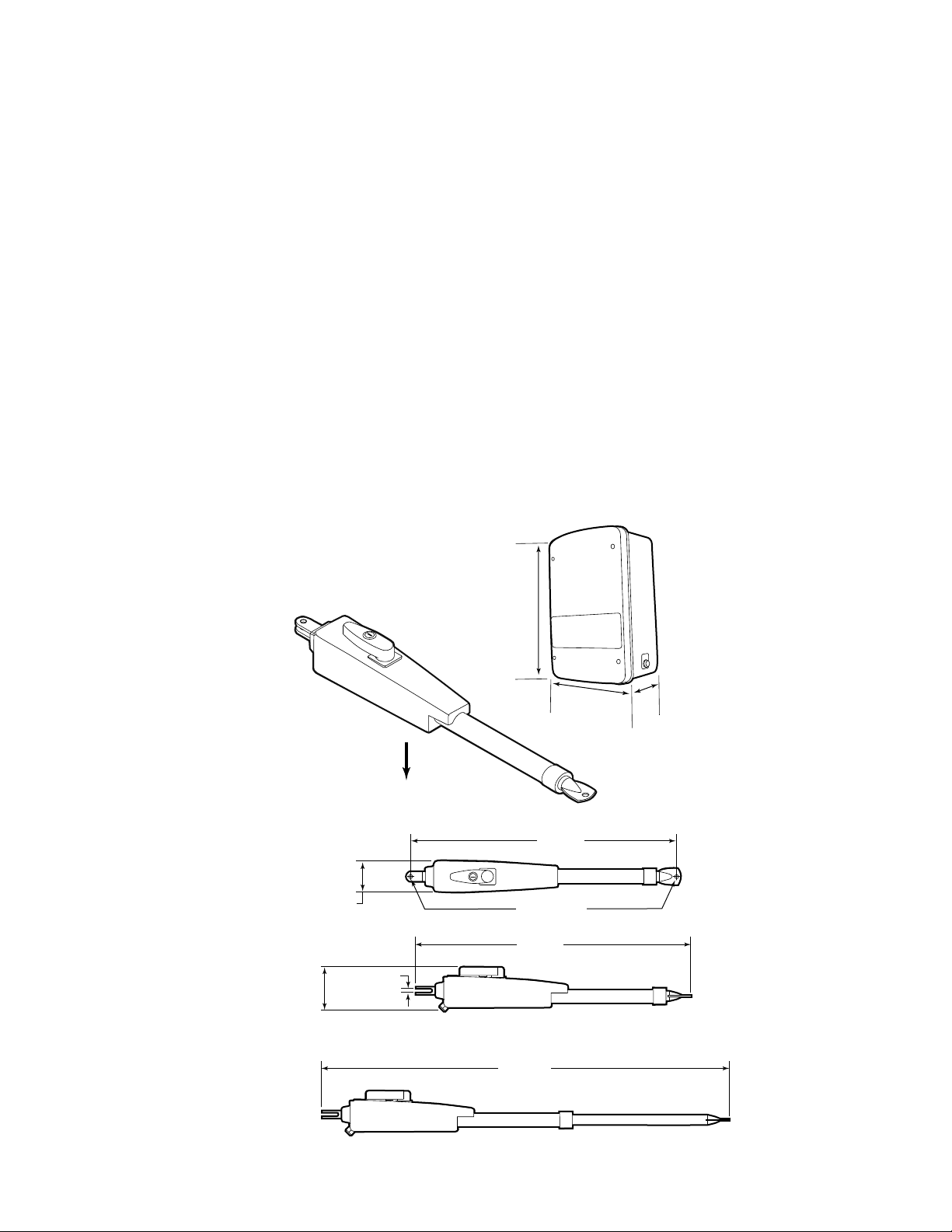

Operator Dimensions and Specifications

Main Supply 12VDC Battery run. Operational between 11.5VDC and 14.5VDC.

Accessory Power 12V nominal Class II battery voltage source is limited to:

• Solar or AC Cable up to 50' - 500 mA

• AC Cable 50' up to 250' - 250mA

• AC Cable 250' up to 1000' - 100mA

NOTE: Increased accessory power drawn from the operator will shorten the

battery life.

Battery Charger Supply (Optional) 14.5Vac nominal, 30 VA max.

Maximum Gate Length and Weight 16 ft. at 550 lbs.

Temperature -20°C to +50°C (-4°F to 122°F)

Protection Fuse Battery 1 ATC 20A

Protection Fuse Battery 2 ATC 20A

4.50"

(11.2 cm)

4.00"

(10.2 cm)

Weight: 47 lbs. (21 kg)

.250"

(0.635 cm)

14"

(35.6 cm)

(95.0 cm)

10"

(25.4 cm)

36.3"

(92.1 cm)

.475" DIA.

(1.2 cm DIA.)

37.4"

6"

(15.2 cm)

53.5"

(136.0 cm)

3 Introduction

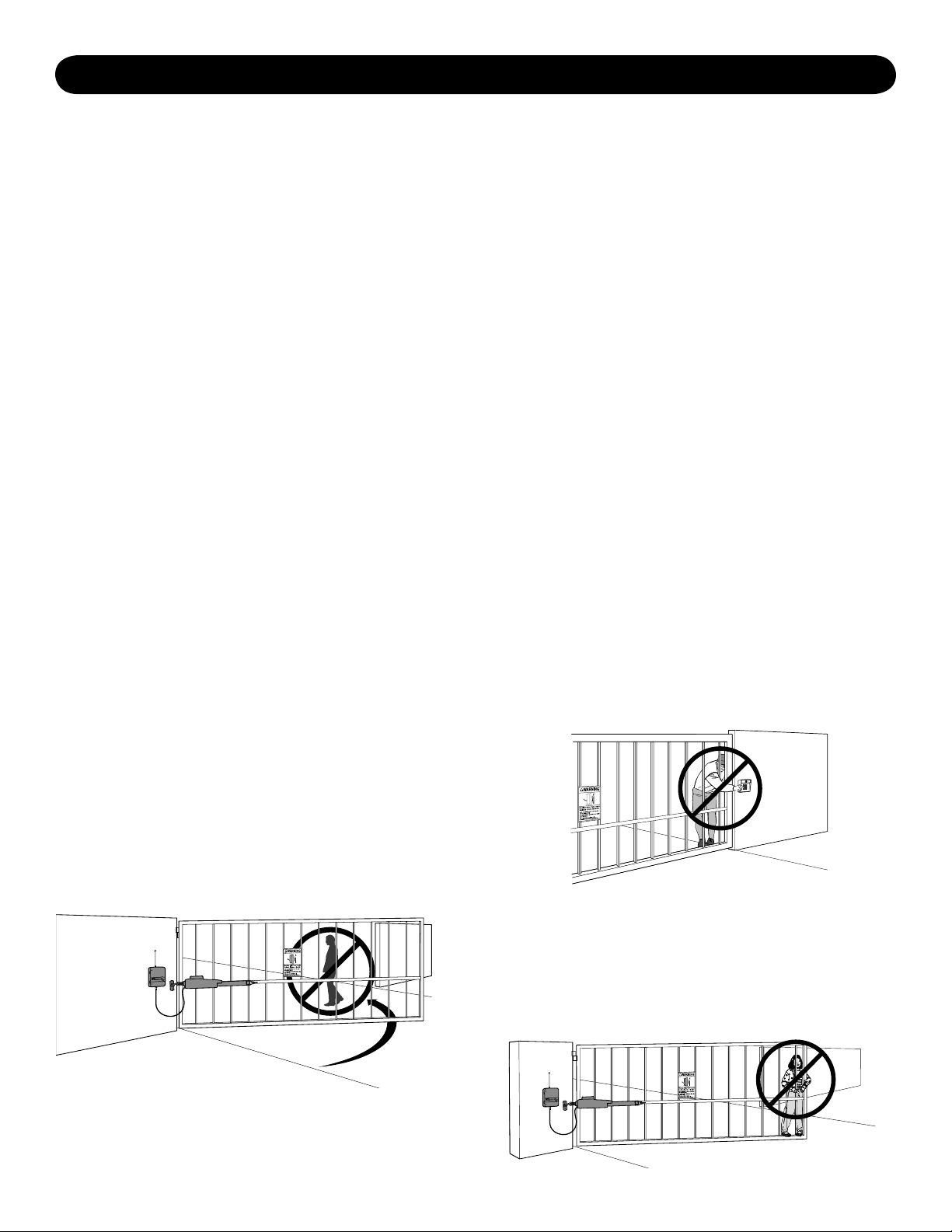

SAFETY INSTALLATION INFORMATION

1. READ and FOLLOW all instructions.

2. The gate operator is intended for use with Class I

vehicular swing gates.

Class I denotes a vehicular gate operator (or system)

intended for use in a home of one to four single

family dwellings, or a garage or parking area associated

therewith.

Install the gate operator only when the operator is

appropriate for the construction and the usage class of

the gate.

3. Gate operating system designers, installers and users

must take into account the possible hazards associated

with each individual application. Improperly designed,

installed or maintained systems can create risks

for the user as well as the bystander. Gate system

design and installation must reduce public exposure to

potential hazards. Install the gate operator only when

the operator is appropriate for the construction of the

gate and the usage class of the gate. All exposed pinch

points must be eliminated or guarded.

4. A gate operator can create high levels of force during

normal operation. Therefore, safety features must be

incorporated into every installation. Specifi c safety

features include safety sensors.

5. The gate must be properly installed and work freely in

both directions prior to the installation of the gate operator.

6. The gate must be installed in a location so that enough

clearance is provided between the gate and adjacent

structures when opening and closing to reduce the risk

of entrapment. Swinging gates shall not open into public

access areas.

7. The operator is intended for use only on gates used for

vehicles. Pedestrians must be supplied with a separate

access opening. The pedestrian access opening

shall be designed to promote pedestrian usage. The

pedestrian access shall be located such that persons

will not come in contact with the moving vehicular gate.

8. Pedestrians should never cross the pathway of a

moving gate. The gate operator is not acceptable for

use on any pedestrian gate. Pedestrians must be

supplied with a separate pedestrian access.

9. For an installation utilizing non-contact sensors (safety

sensors), see product manual on the placement of

non-contact sensors (safety sensors) for each type of

application.

a. Care shall be exercised to reduce the risk of

nuisance tripping, such as when a vehicle trips the

safety sensor while the gate is still moving.

b. One or more non-contact sensors (safety sensors)

shall be located where the risk of entrapment or

obstruction exists, such as the perimeter reachable

by a moving gate or barrier.

10. For a gate operator utilizing a contact sensor such as

an edge sensor:

a. A hard wired contact sensor shall be located and

its wiring arranged so the communication between

the sensor and the gate operator is not subject to

mechanical damage.

b. One or more contact sensors shall be located on

the inside and outside leading edge of a swing gate.

Additionally, if the bottom edge of a swing gate is

greater than 6" (152 mm) above the ground at any

point in its arc of travel, one or more contact sensors

shall be located on the bottom edge.

11. Never mount any device that operates the gate

operator where the user can reach over, under, around

or through the gate to operate the controls. Controls

are to be placed at least 6' (1.8 m) from any part of the

moving gate:

• A hard wired control device shall be located and its

wiring arranged so that communication between the

control device and the gate operator is not subject to

mechanical damage.

Introduction 4

12. Controls intended to be used to reset an operator after

2 sequential activations of the entrapment protection

device or devices must be located in the line of sight

of the gate, or easily accessible controls shall have a

security feature to prevent unauthorized use. Never

allow anyone to hang on or ride the gate during the

entire travel of the gate.

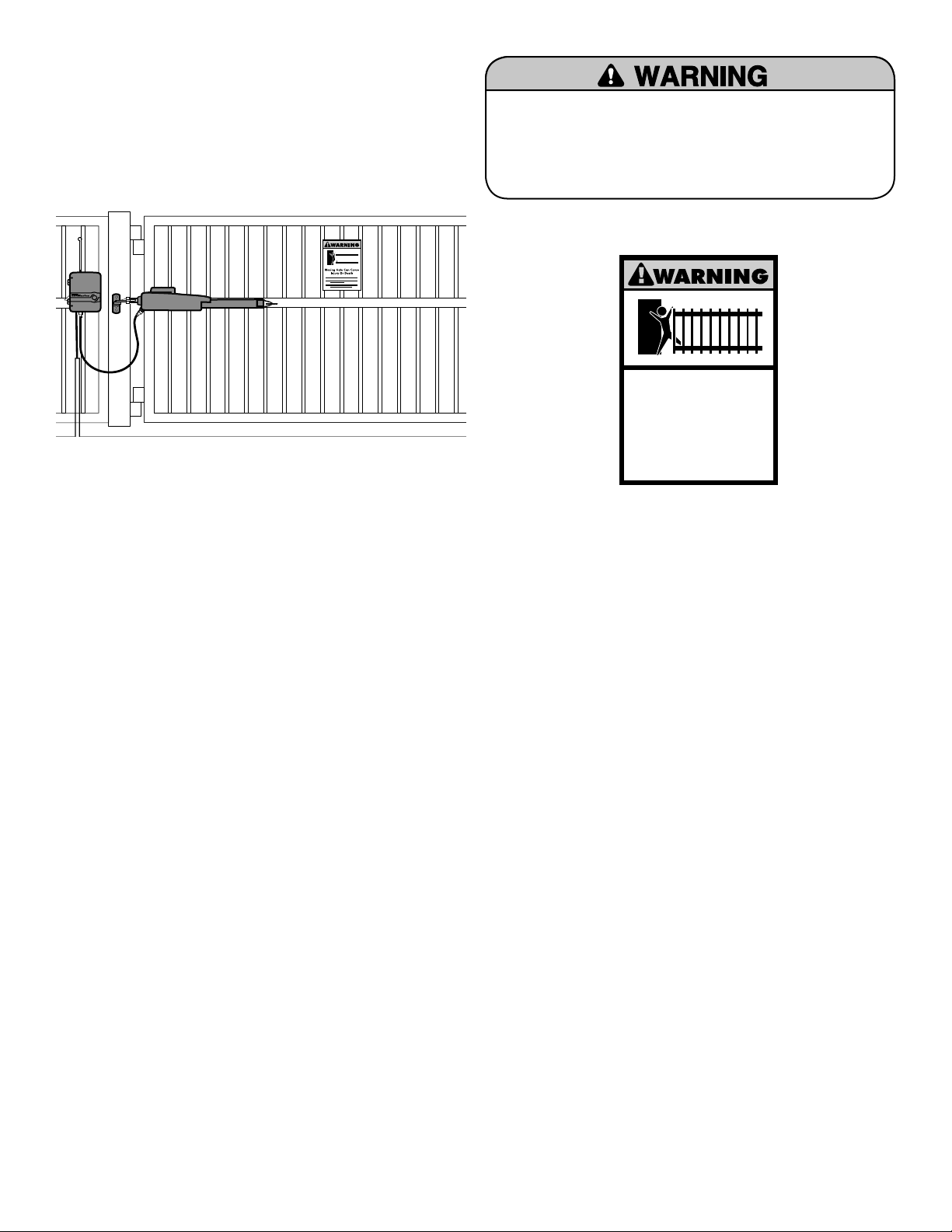

13. Each gate operator is provided with two safety warning

placards. The placards are to be installed on the front

and back of the gate where they are plainly visible. The

placards may be mounted using cable ties through the

four holes provided on each placard.

All warning signs and placards must be installed

where visible in the area of the gate.

14. To AVOID damaging gas, power, or other underground

utility lines, contact underground utility locating

companies BEFORE digging.

15. SAVE THE INSTRUCTIONS.

To prevent SERIOUS INJURY or DEATH from a moving gate:

• Install warning signs on the front and back of the gate in

PLAIN VIEW.

• Permanently secure each warning sign in a suitable manner

using fastening holes.

Moving Gate Can Cause

Injury or Death

KEEP CLEAR! Gate may move at any

time without prior warning.

Do not let children operate the gate or

play in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance

5 Introduction

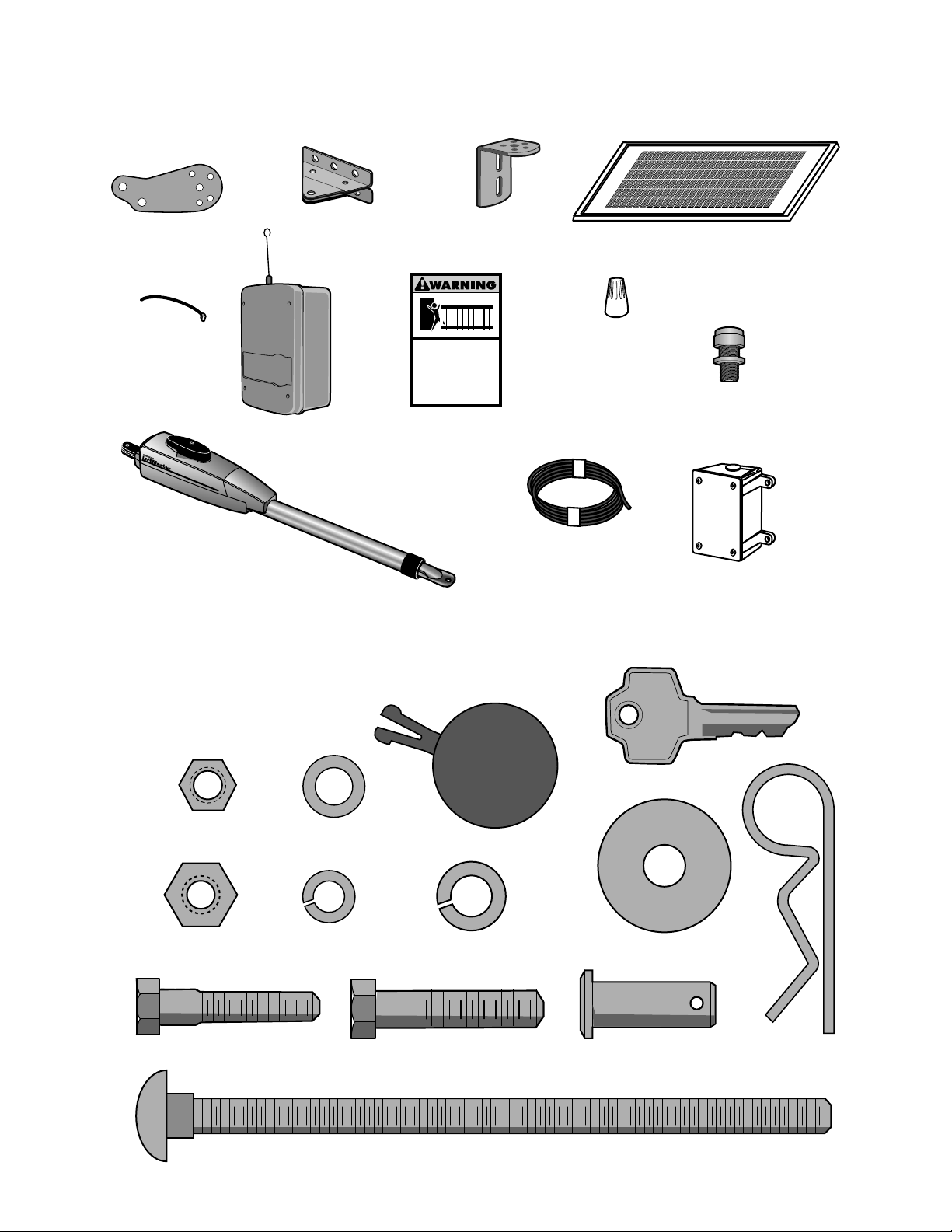

Carton Inventory

This operator comes with the hardware to install on a gate that pulls-to-open. If your application requires the gate to be

pushed open, accessory kit 50-19503 is required.

Extension Bracket

Model LA412 (1)

Model LA412-S (2)

Cable Ties (4)

Gate Operator

Model LA412 (1)

Model LA412-S (2)

Gate Bracket

Model LA412 (1)

Model LA412-S (2)

Control Box (1) with

2 Batteries

Post Bracket

Model LA412 (1)

Model LA412-S (2)

Moving Gate Can Cause

Injury or Death

KEEP CLEAR! Gate may move at any

time without prior warning.

Do not let children operate the gate or

play in the gate area.

This entrance is for vehicles only

Pedestrians must use separate entrance

Warning Signs (2)

Wire Nuts (6)

Model LA412 ONLY

Extension Cable

Model LA412-S ONLY

Hardware Inventory

NOTE: Hardware quantities shown below are for LA412. Quantities are doubled for LA412-S.

12V 10W Solar Panel

Model SOLPNL10W12V (1)

Watertight Connector

Model LA412-S ONLY (2)

Junction Box

Model LA412-S ONLY

Key (2)

Hex Nut 5/16"-18 (1)

Hex Nut 3/8"-16 (3)

Hex Bolt 5/16"-18 x 1-1/2 (1)

Flat Washer 5/16" (1)

Lock Washer 5/16" (1)

Lock Washer 3/8" (3)

Hex Bolt

3/8"-16 x 1-1/2" (1)

Cap

Flat Washer 3/8" (3)

Pin (2)

Hairpin Clip (2)

Carriage Bolt 3/8" x 5-15/16" (2)

Introduction 6

Additional Items For Purchase

The following items are REQUIRED to complete

the installation:

ALL MODELS: LA412-S ONLY:

SAFETY SENSORS

The Model 50-220 safety sensors are intended for

installation with the operators covered in this manual.

To order call 1-800-528-2806 or visit www.liftmaster.com.

HARDWARE

• 5/16" mounting hardware for gate bracket.

• The following hardware is needed to mount the control

box depending on the mounting surface:

Wood: Four #8 1-1/4" zinc plated wood screws.

Metal: Four #10-32x6" zinc plated machine screws with

nut and lock washers.

Concrete, Brick, etc.: Four 1/4" x 1-3/4" masonry

screws.

CONDUIT

UL Listed outdoor electrical conduit with 3/4" diameter to

hold the extension cable between the junction box and the

control box.

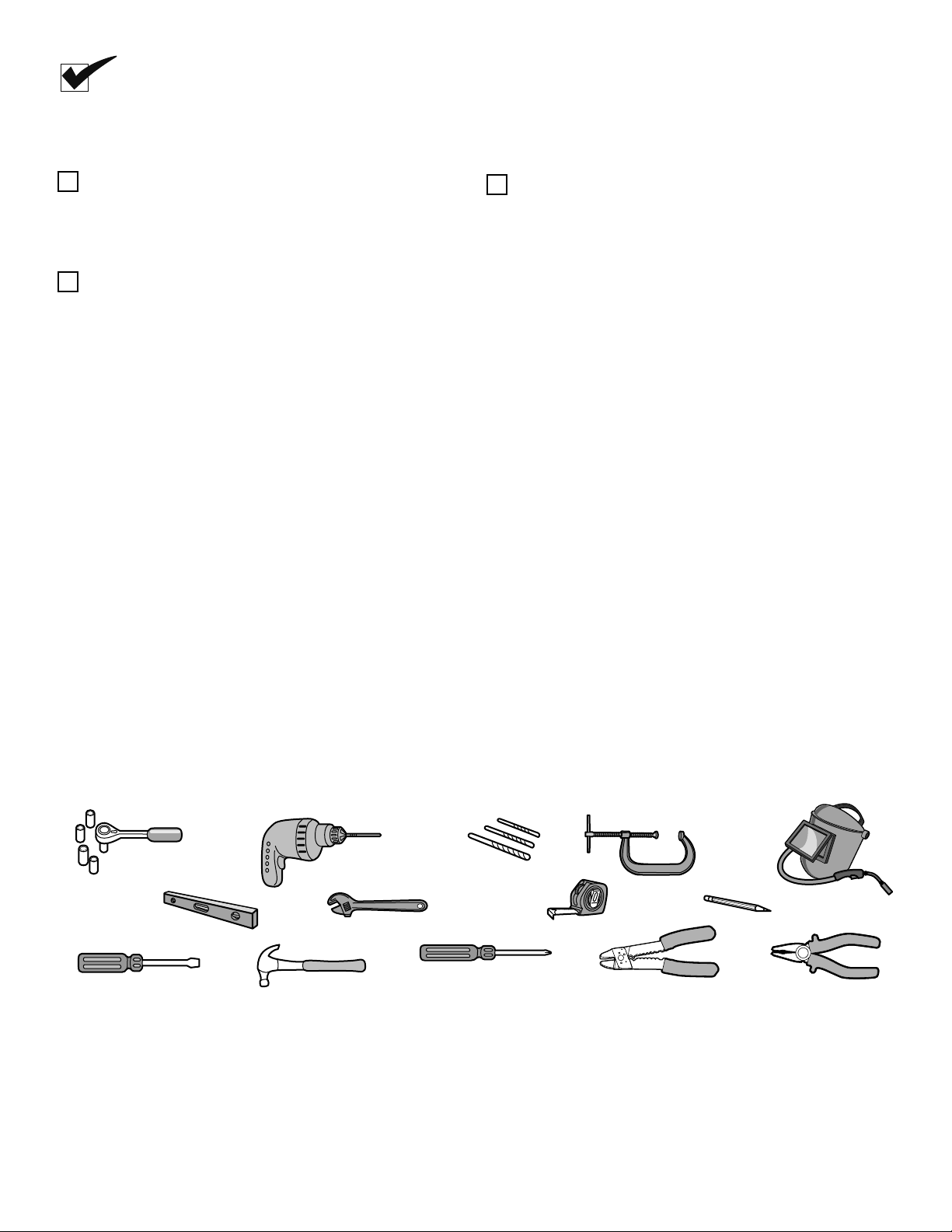

Tools Needed

During assembly, installation and adjustment of the operator, instructions will call for tools as illustrated below.

Deep Well Sockets

and Wrench

1/2", 5/8", 7/16", 9/16"

and 1/4"

Carpenter's Level

Screwdriver

Drill

Adjustable End Wrench

Hammer

Drill Bits

1/2", 3/16", 5/16"

and 5/32"

Phillips Head Screwdriver

2

1

Tape Measure

Clamps

Welder (Optional)

Pencil

Wire Cutters (Optional) Wire Strippers (Optional)

7 Introduction

Mov

i

ng Gate Can Cause

Injury or Death

KEEP CL

EAR!

Gate ma

y move at any

time wi

thou

t p

rior

warn

in

g.

Do no

t let ch

ildren opera

te the gate o

r

play i

n

th

e gate

area.

This ent

r

ance is for vehi

cles

on

ly

Pedestr

ians mu

st use sep

ar

ate

entr

an

ce

12

gauge

wire

8 ft.

(2.4 m)

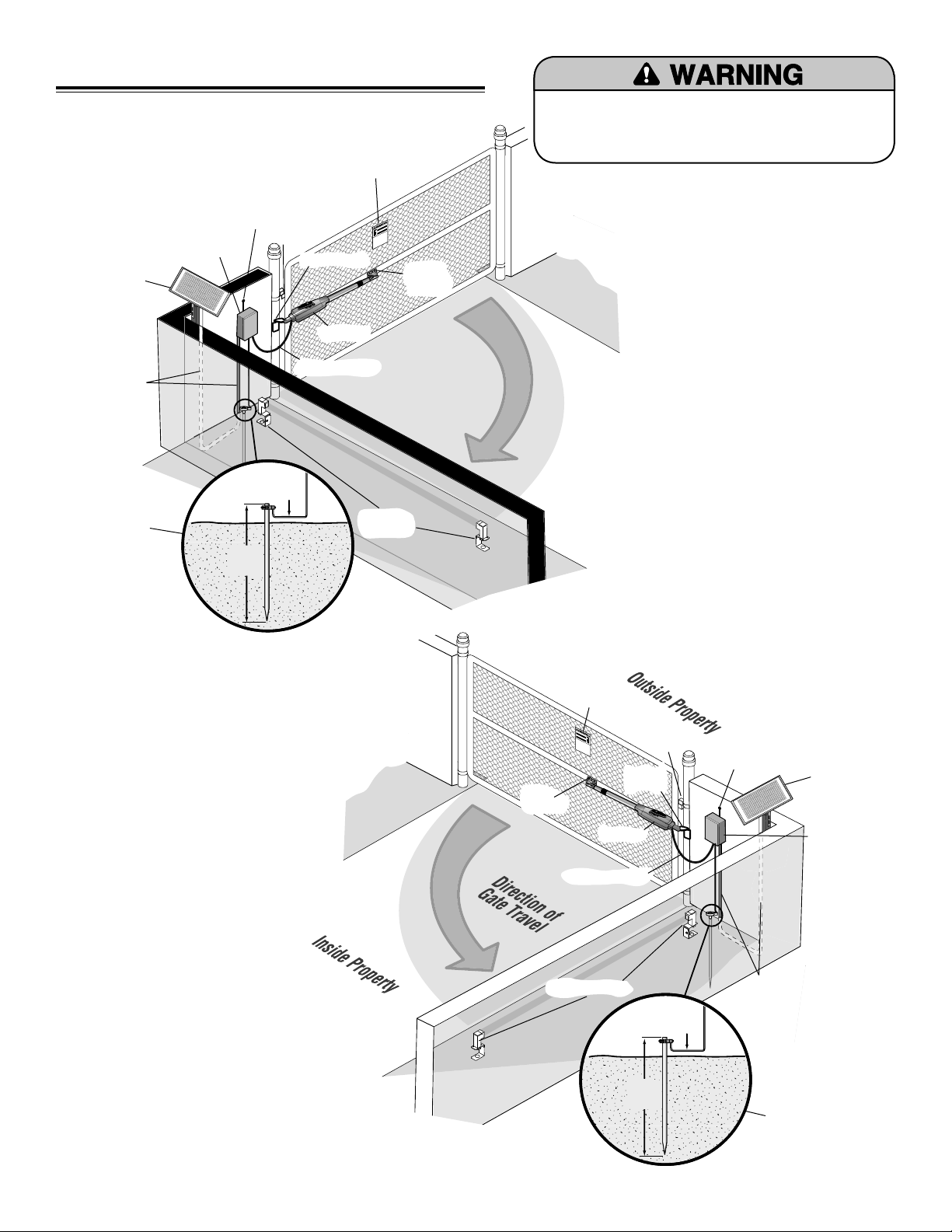

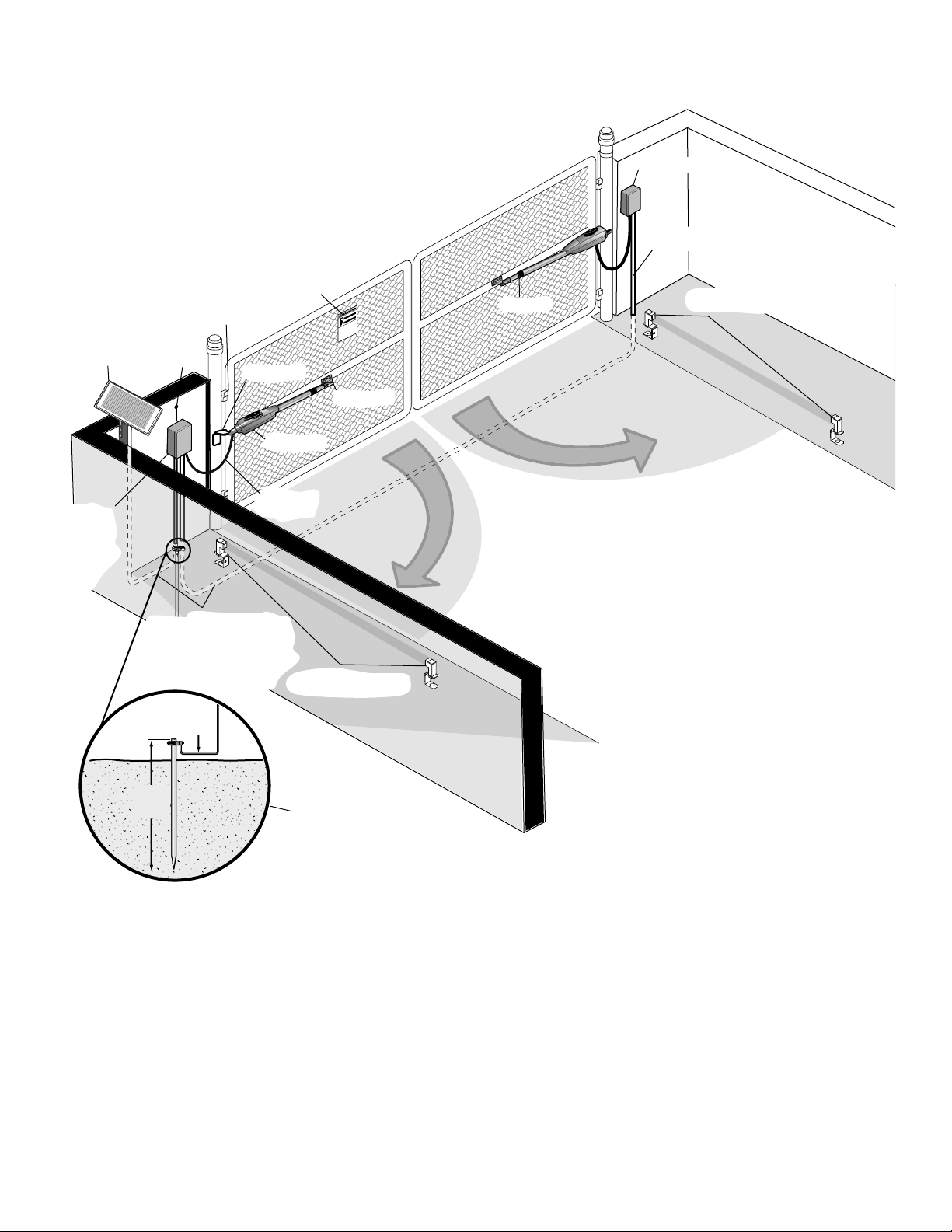

OVERVIEW OF TYPICAL INSTALLATION

Outside Property

Inside Property

Direction of

Gate ravel

Moving Gate Can Cause

Injury or Death

KEE

P CLEAR! Gate

ma

y move at any

ti

me wi

thou

t prior warn

in

g.

Do

not l

et children

op

erate th

e gate or

p

lay

in th

e gate ar

e

a.

T

h

is entr

a

nce

is

f

or vehicles onl

y

Pedestri

a

ns must

u

se s

eparate en

trance

T

12

gauge

wire

8 ft.

(2.4 m)

LEFT-HAND GATE

Warning Sign

To prevent SERIOUS INJURY or DEATH; one or more

non-contact sensors shall be located where the risk of

entrapment or obstruction exists.

Solar Panel

(facing South)

PVC Conduit (not

provided) to

protect the power

cable for solar and

low voltage wire

from lawn mowers

and string

trimmers.

Earth Ground

Installation

(Optional)

Control Box

with Batteries

Antenna

Hinge

Post Bracket

Operator Cable

Operator

Safety

Sensors

Gate

Bracket

NOTE: One or more non-contact sensors shall

be located where the risk of entrapment or

obstruction exists at either the opening or

closing direction. Care shall be exercised to

reduce the risk of nuisance tripping, such as

when a vehicle, trips the sensor while the gate

is still moving.

Preparation and Overview 8

Gate

Bracket

Safety Sensors

Warning

Sign

Post

Bracket

Operator

Operator Cable

Hinge

Antenna

Solar Panel

(facing South)

Control Box

with Batteries

PVC Conduit (not provided)

to protect the power cable

for solar and low voltage wire

from lawn mowers and string

trimmers.

Earth Ground

Installation

(Optional)

Dual Gate Typical Installation

Outside Property

Warning Sign

Hinge

Solar Panel

(facing South)

Control

Box with

Batteries

Antenna

Post Bracket

Gate 1

Operator

Cable

Cause

at any

move

ay

Moving Gate Can

Injury or Death

Gate m

!

AR

ate the gate or

e

KEEP CLE

time without prior warning.

rate entranc

Do not let children oper

y in the gate area.

use sepa

t

ance is for vehicles only

pla

r

ans mus

This ent

Pedestri

Gate Bracket

Direction of

T

Gate 1 ravel

Gate 2

Inside Property

Junction Box

Extension Cable

Direction of

T

Gate 2 ravel

Safety Sensors

PVC Conduit (not provided) to

protect the power cable for

solar and low voltage wire

from lawn mowers and string

trimmers.

12

gauge

wire

8 ft.

(2.4 m)

Safety Sensors

Earth Ground

Installation

(Optional)

NOTE: One or more non-contact sensors shall

be located where the risk of entrapment or

obstruction exists at either the opening or

closing direction. Care shall be exercised to

reduce the risk of nuisance tripping, such as

when a vehicle, trips the sensor while the gate

is still moving.

9 Preparation and Overview

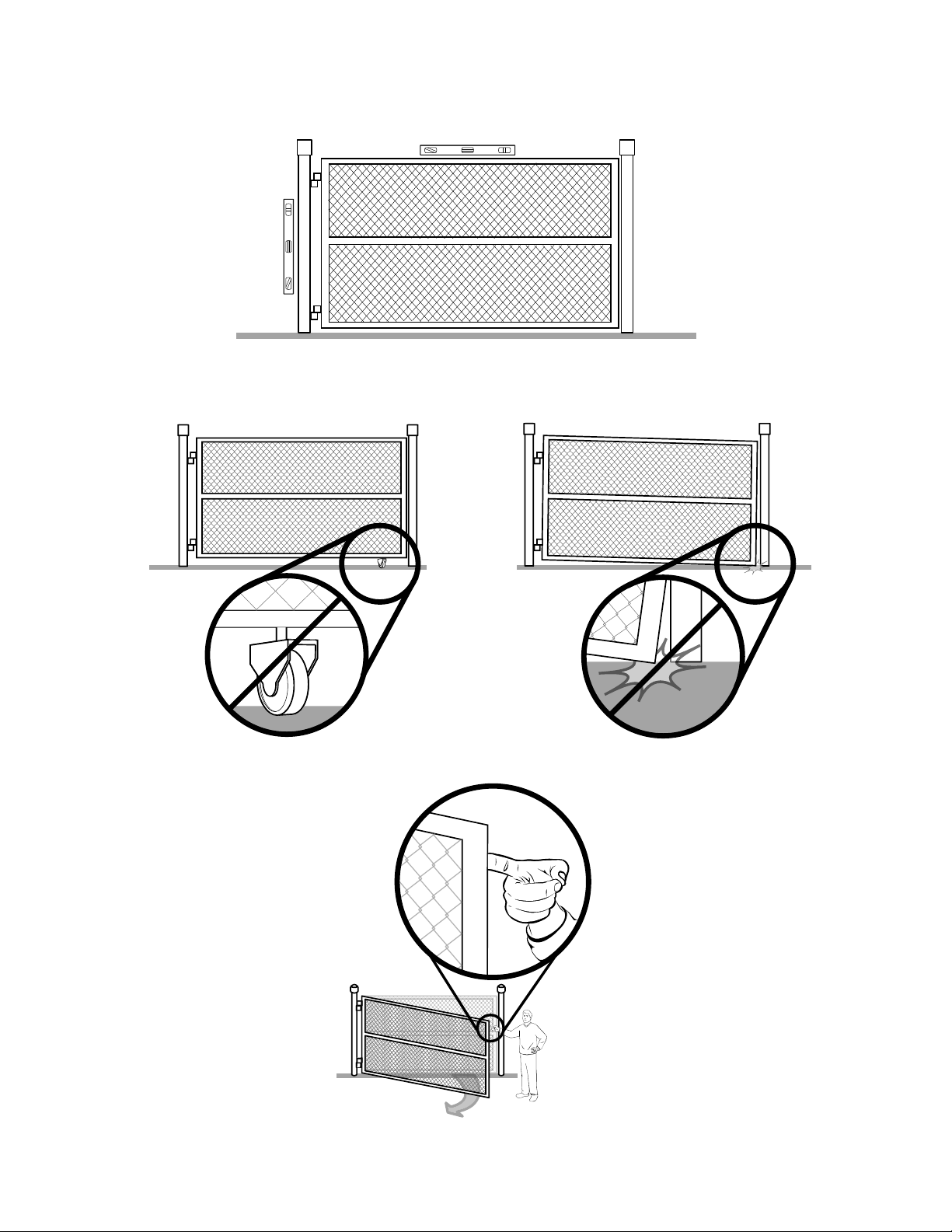

Check Your Gate

Gate MUST be level.

be plumb.

Gate and gate post MUST

Remove ANY/ALL wheels from the bottom of gate.

Gate MUST NOT hit or drag across ground.

Gate MUST swing freely and be supported entirely by its hinges.

Preparation and Overview 10

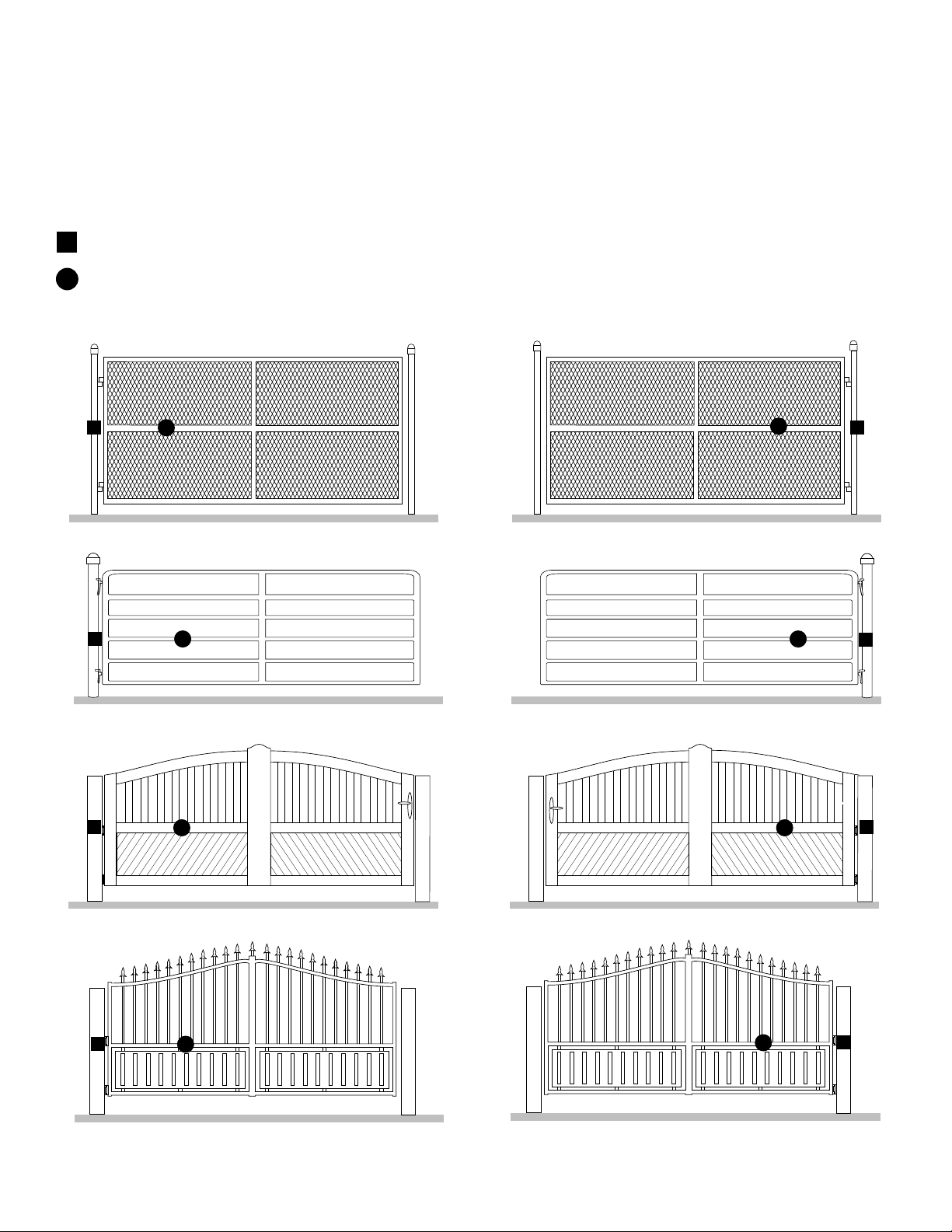

Mounting Options

Mounting locations vary depending on the type and style of your gate.

NOTES:

• The top of the operator must be mounted at least 10 inches above the ground. Environmental conditions should be considered at this

time.

• The operator is not recommended for plastic or vinyl gates. Contact the gate’s manufacturer for recommendations and options.

Recommended:

= Gate post bracket mounting locations

= Gate bracket mount locations

LEFT-HAND HINGE MOUNTED

Typical Chain-Link Gate

Typical Farm/Ranch Gate

RIGHT-HAND HINGE MOUNTED

Typical Chain-Link Gate

Typical Farm/Ranch Gate

Typical Wood Gate Typical Wood Gate

Typical Tubular Metal Gate Typical Tubular Metal Gate

11 Preparation and Overview

INSTALLATION

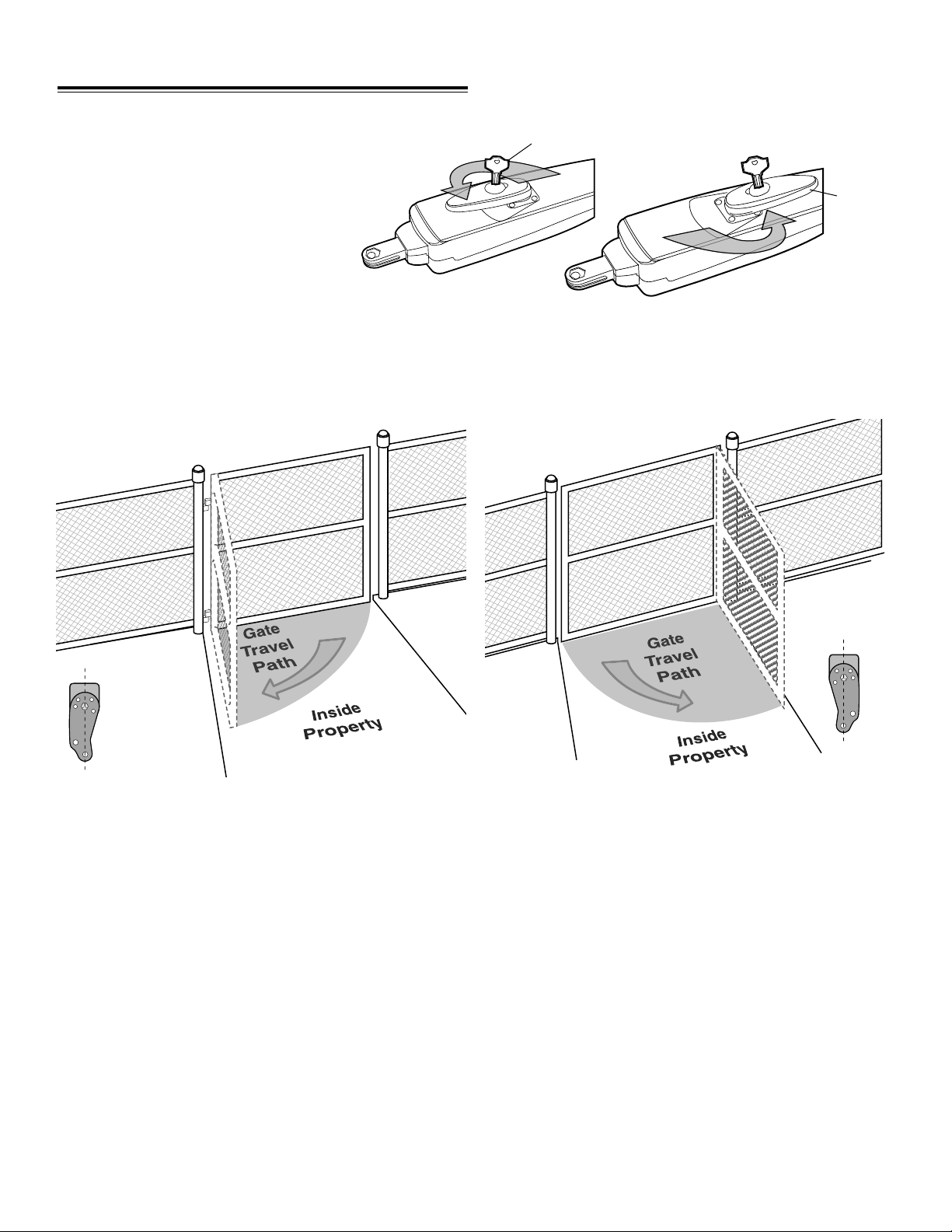

MANUAL RELEASE

Insert the key into the lock and turn it 180°

1

counterclockwise. Turn the release lever

180° counterclockwise. The operator is

now in manual mode.

DETERMINE THE POSITION OF THE EXTENSION BRACKET

The extension bracket can be assembled to work on a Left-Hand or a Right-Hand gate. Review the gate types

2

below and select the type of installation required.

NOTE: If the extension bracket is not assembled correctly damage to the operator may result.

Left-Hand Gate Right-Hand Gate

Key

Release

Lever

Left-Hand Gate

IMPORTANT NOTE: For Push to Open installation purchase kit 50-19503, see accessories.

Installation 12

Right-Hand

Gate

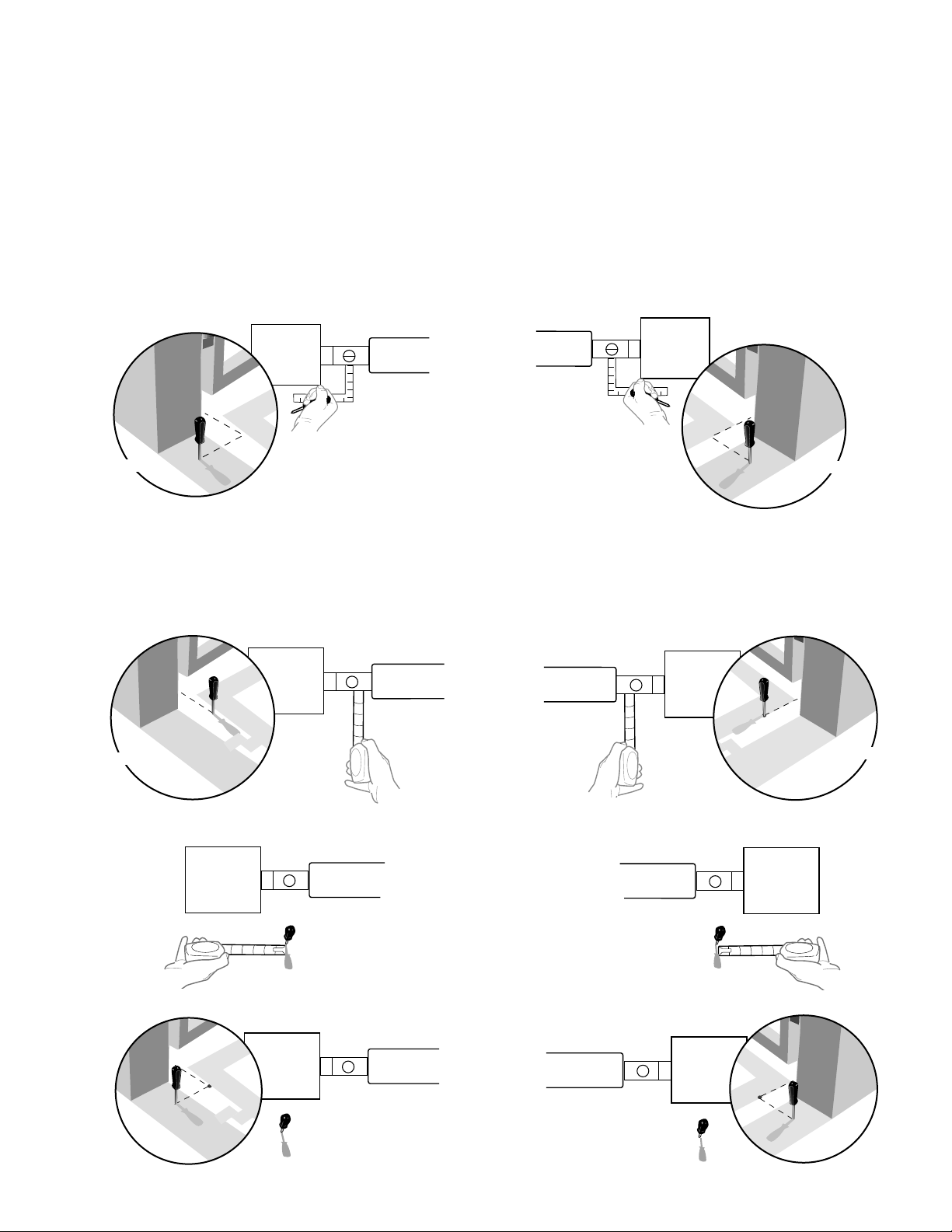

MEASURING AND MARKING FOR THE GATE BRACKET

Before proceeding, begin with the gate in the fully closed position. There are two methods for determining the

3

proper location of the post brackets:

• Paper template (located on the back page of this manual. Must be cut out.)

• Tape measure.

Either method will work depending on preference.

NOTE: Be sure gate is in the closed position before proceeding.

Template Method

Place the template (provided on the back page) under the gate hinge point. Use a screwdriver or dowel rod to

temporarily mark the location in front of the gate post.

LEFT SIDE BRACKET MOUNTING

Gate Post

Gate Hinge Point

TOP VIEW

Gate Post

Use a screwdriver or dowel rod to

temporarily mark measurement.

RIGHT SIDE BRACKET MOUNTING

Gate Hinge Point

TOP VIEW

Gate Post

Use a screwdriver or dowel rod to

temporarily mark measurement.

Tape Measure Method

Place the measuring tape under the gate hinge point and measure 7". Use a screwdriver or dowel rod to

temporarily mark the location of the fi rst measurement.

LEFT SIDE BRACKET MOUNTING

Gate Post

Gate Hinge Point

RIGHT SIDE BRACKET MOUNTING

Gate Post

Gate Hinge Point

Gate Post

7"

X

Gate Post

7"

X

Gate Post

Measure 7" from the previous mark.

Gate Post

X

Gate Hinge Point

7"

Gate Hinge Point

Gate Post

7"

X

Use the screwdriver or dowel rod to mark the location of the second measurement.

Gate Post

Gate Hinge Point

First Marking

X

Gate Hinge Point

First Marking

Gate Post

X

13 Installation

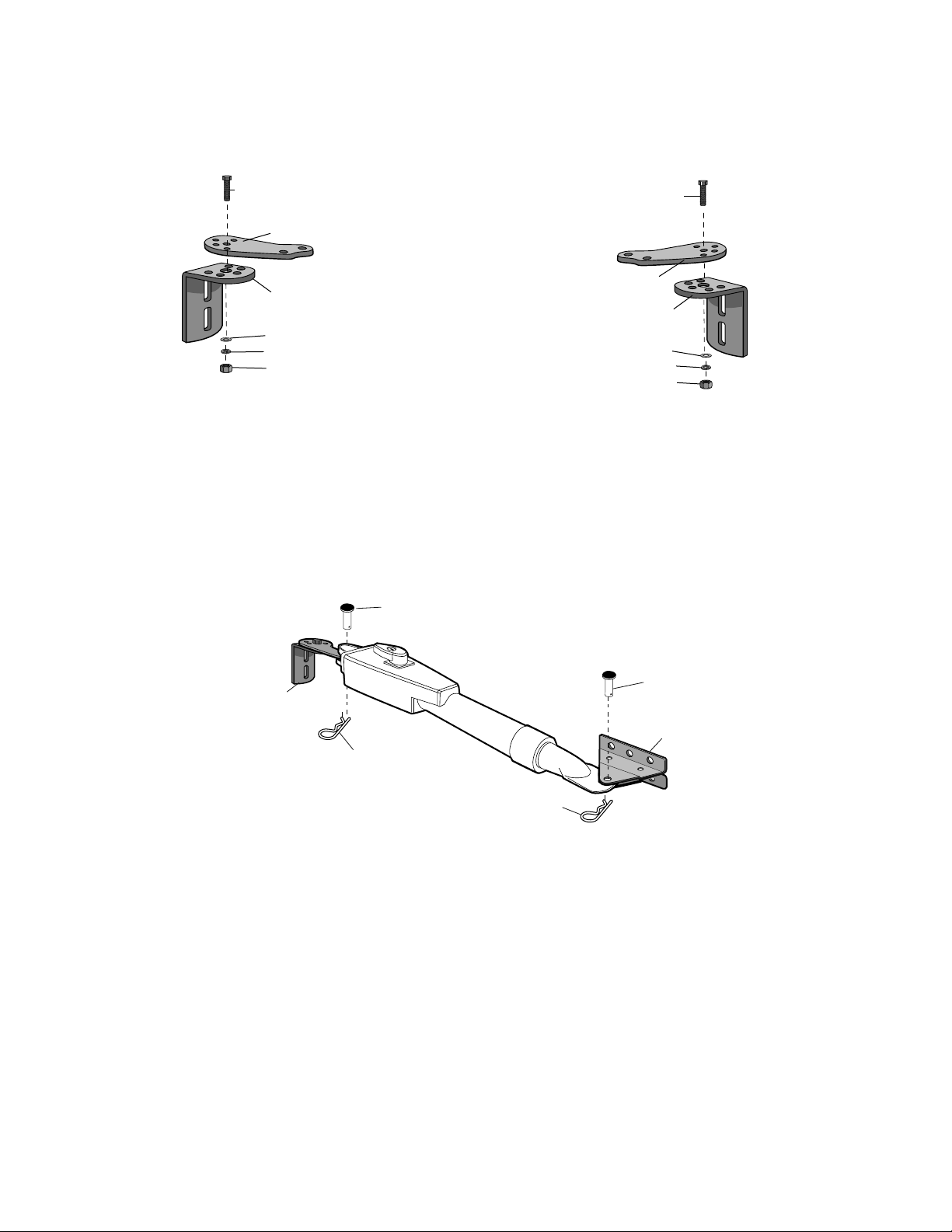

POSITION THE EXTENSION BRACKET TO POST BRACKET

Assemble the post bracket by placing the extension bracket on top of post bracket. Insert the bolt through

4

the brackets and fasten them using the washer, lock washer and nut. DO NOT TIGHTEN AT THIS TIME.

LEFT-HAND GATE

Hex Bolt 3/8"

Extension

Bracket

Post Bracket

Washer

Lock Washer

Nut

RIGHT-HAND GATE

Extension

Bracket

Post Bracket

Lock Washer

NOTE: All the illustrations on the following pages display a typical Left-Hand Gate installation.

ATTACH BRACKETS TO GATE OPERATOR

Attach post bracket and gate bracket to operator using pins and hairpin clips.

5

Hex Bolt 3/8"

Washer

Nut

Post Bracket

Pin

Pin

Gate

Bracket

Hairpin

Clip

Hairpin

Clip

Installation 14

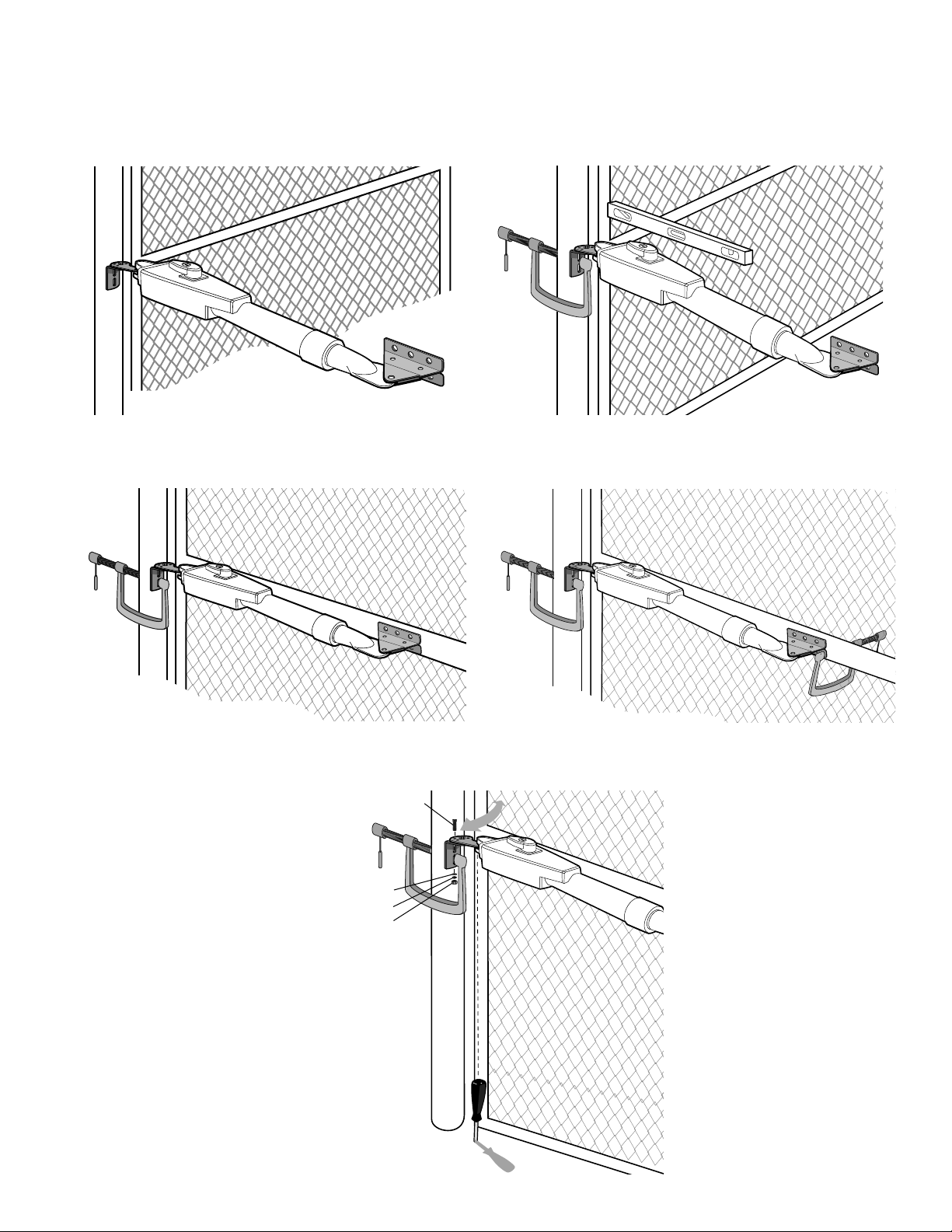

POSITION GATE OPERATOR ON GATE

The post bracket assembly can be mounted several places on the gate post. Refer to page 11 for mounting options.

6

Place the operator arm against gate post at the desired vertical position and temporarily secure post bracket with a

clamp. The gate operator (arm) must be level.

Open the gate to desired open position (no greater than 100°) and hold operator against gate. Mark mounting holes on

gate for reference. Temporarily secure the gate bracket using a clamp.

For push to open installations refer to instructions with push to open kit 50-19503.

Hold the post bracket in the

desired position. Align the

7

extension bracket to a position

as CLOSE AS POSSIBLE

above the marker. Insert hex

bolt through extension bracket

and post bracket and secure

with washer, lock washer and

nut.

15 Installation

Hex Bolt 3/8"

Washer

Lock Washer

Nut

Loading...

Loading...