Page 1

For more information, please visit www.devancocanada.com or call toll free at 855-931-3334

Page 2

SAFETY INFORMATION

Mechanical

Electrical

IMPORTANT NOTES:

• BEFORE attempting to install, operate or maintain the

commercial door operator, you must read and fully understand

this manual and follow all safety instructions.

• DO NOT attempt repair or service of a commercial door

operator unless you are an Authorized Service Technician.

• A commercial door operator should only be installed on a

properly balanced door only. Ensure door is properly balanced

prior to installation.

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will

alert you to the possibility of damage to your door and/or the

door operator if you do not comply with the cautionary

statements that accompany it. Read them carefully.

IMPORTANT INSTALLATION INSTRUCTIONS

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH:

1. READ AND FOLLOW ALL INSTALLATION WARNINGS AND

INSTRUCTIONS.

2. Install door operator ONLY on a properly balanced and

lubricated door. An improperly balanced door may NOT

reverse when required and could result in SEVERE INJURY

or DEATH.

3. ALL repairs to cables, spring assemblies and other hardware

MUST be made by a trained door systems technician BEFORE

installing an operator.

4. Disable ALL locks and remove ALL ropes connected to a

door BEFORE installing an operator to avoid entanglement.

5. Install an operator, a minimum of 8 feet (2.44 m) from the

floor.

6. NEVER connect a door operator to a power source until

instructed to do so.

7. NEVER wear watches, rings or loose clothing while installing

or servicing an operator. They could be caught in the door or

operator mechanisms.

ENTRAPMENT PROTECTION DEVICES:

LiftMaster Monitored Entrapment Protection (LMEP)

Monitored photoelectric sensors and/or door edge sensors are

required for any momentary contact to close modes of operation.

Refer to operator manual for additional information. Refer to the

‘Commercial Door Entrapment Protection Systems’, and

accessories page 64, for available options.

8. Install a control station:

• within sight of the door

• out of reach of small children and at a minimum height of

5 feet (1.5 m) above floors, landings, steps, or any other

adjacent walking surface.

• away from ALL moving parts of the door

9. Install the control station far enough from the door to

prevent the user from coming in contact with the door while

operating the controls.

10. Install the entrapment warning placard on the wall next to

the control station in a prominent location, visible from the

door.

11. Place the manual release/safety reverse test label in plain

view on the inside of door.

12. Upon completion of installation, test the entrapment

protection device(s).

13. SAVE THESE INSTRUCTIONS.

Page 3

General Information

This guide is intended to help with Commercial Door Operator maintenance and troubleshooting. The guide offers several

different troubleshooting scenarios and provides answers to frequently asked questions. The comprehensive, yet user-friendly

guide will hopefully be used as a tool to solve all of the Commercial Door Operator maintenance problems you may encounter.

SECTION A

Basic Troubleshooting 4-6

SECTION B

Logic Operators

Industrial Duty Logic Operators 8-26

Medium Duty Logic Operators 27-31

SECTION C

Mechanical Operators 34-36

SECTION D

Basic Electrical Information 38-45

SECTION E

General Information 46-52

SECTION F

Wiring Diagrams 54-62

Commercial Door Entrapment Protection Systems 64

Page 4

Table of Contents

SECTION A

Page

Basic Troubleshooting 5

4

Page 5

Basic Troubleshooting

Always Follow Local Electrical Codes

WARNING! If you are not trained in electrical safety, contact a professional electrical safety trainer. It is in your best

interest to have electrical safety training. Do not attempt to work on a powered (turned on) operator if you have

not received electrical safety training. Remember, it is dangerous to deal with high-voltage electricity. Many people

incurred serious injuries, including fatalities, as a result of electrical accidents. You must be very careful when

checking line voltages.

The high-voltage wiring to the operator, low-voltage wiring to the control station(s), and safety devices may require a

licensed electrician for installation.

Make Sure The Door Is Working Properly

Close the door and disconnect the door from the operator. Manually operate the door. The lifting force needed by most

doors should be manageable by one person and the door should move smoothly. Check all hardware for wear, binding

and tightness. Replace any marginal parts. The door should be in good working order. An unbalanced or jerking door

will put excess wear on the operator and cause premature failure. When checking a door with a hoist operator, be sure

the door is disconnected from the operator and lifted by hand and not by the hoist/hand chain. It is very diffi cult to

determine if the door is balanced when using the operator chain hoist. Repair any door problems before reattaching

the operator.

A

Remove All Accessories And Control Devices

In many cases an operator may be malfunctioning due to accessories or control devices attached to the operator’s

control circuit. The fi rst step in troubleshooting is to use a process of elimination. Disconnect all wired accessories

and control devices. Many times in complicated installations, there will be extra devices installed by an electrician

or other subcontractor that may not be functioning properly with the operator. If the door functions properly after

disconnecting additional devices, start reconnecting each device one at a time. Determine if any of the control

device(s) are causing the problem. Advise the customer of your fi ndings and their options for repairs/replacements.

NOTE: When monitored entrapment protection devices are removed from operators that require a monitored

entrapment protection device such as photo eyes; they will no longer function unless they are under constant

pressure.

5

Page 6

Basic Troubleshooting

Check Incoming Voltage

Check the incoming power voltage to ensure readings are within 10% of the rated voltage. For example, a 115VACrated power line should read between 103.5 to 126.5VAC. Continue to monitor voltage as the operator is activated

through one cycle. Voltage drops occur, but should not drop more than 5% under load from the non-functioning

position, +/- 10% at startup and +/- 5% while the operator is running. Low voltages can cause damage to components

and cause functionality issues.

NOTE: The installation of a dedicated circuit is required for achieving optimal voltage.

Check The Overload

Look at the overload button (when present) on the outside or inside of the electrical box. To confi rm if the overload has

been tripped, press the overload button. If the overload has been tripped, look for a short or bad wire in the operator.

Resetting the overload will only fi x the problem temporarily. LiftMaster recommends the cause of the overload be

identifi ed and resolved. Logic operators are equipped with a thermal overload and will automatically reset themselves.

After the operator cools it must be run a full cycle.

Check Any Interlock Switches

Check any interlock and/or disconnect switches for full activation. Manually activate any interlock switches to verify

proper motion of the switch and use a multimeter across the switch leads to verify proper electrical output. The output

should show a closed circuit (low resistance) when the door is ready to be activated.

A

All of the above testing is generic for Logic 3.0, Logic 4.0, Logic 5.0, Medium Duty Logic and Mechanical operators.

Mechanical operators are also known as Contactor or Electro-Mechanical operators. Effi ciency in troubleshooting

operators differs from this point. Logic operators have many LEDs and special controls to speed up diagnosis. For a

Mechanical operator, refer to Section C. For Logic 3.0, 4.0, 5.0 operators, continue on to Section B.

6

Page 7

Page 8

Table of Contents

SECTION B

Logic Operators

Industrial Duty Logic Operators

Page

Logic Board Overview 9

Troubleshooting 13

Selected Features 21

Diagnostic Chart 22

Symptoms And Solutions 23

Error Codes 25

Remote Controls 27

Medium Duty Logic Operators

Page

Troubleshooting 28

Symptoms And Solutions 29

Error Codes 30

Programming 31

Page 9

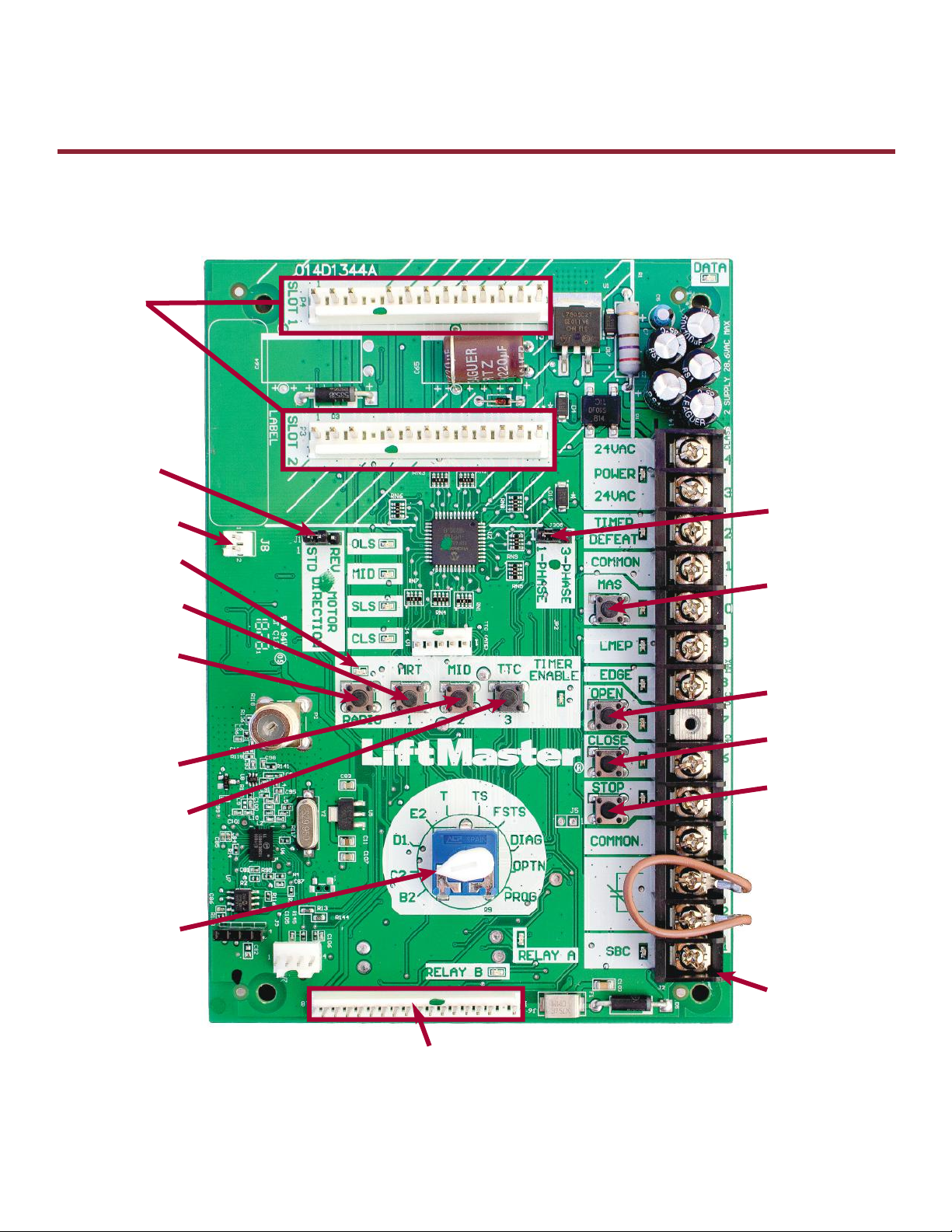

Logic Board Overview

LOGIC 5.0 - SERVICE KIT# K001D8395

Optional Auxiliary

Card Receptacles

Motor

Direction

Jumper

Current Sense

B

Industrial Duty Logic Operators

Single Phase

& Three Phase

Jumper

Receiver LED

Maximum Run

Timer Button

Radio

Learn Button

Mid Stop

Learn Button

Timer-To-Close

Learn Button

Selector Dial

(used for

programming

and selecting

wiring type)

Maintenance

Alert System

Button for

Programming

Open Button

Close Button

Stop Button

Control Wiring

Terminal Block

Main Motor Control Harness Connection

9

Page 10

Logic Board Overview

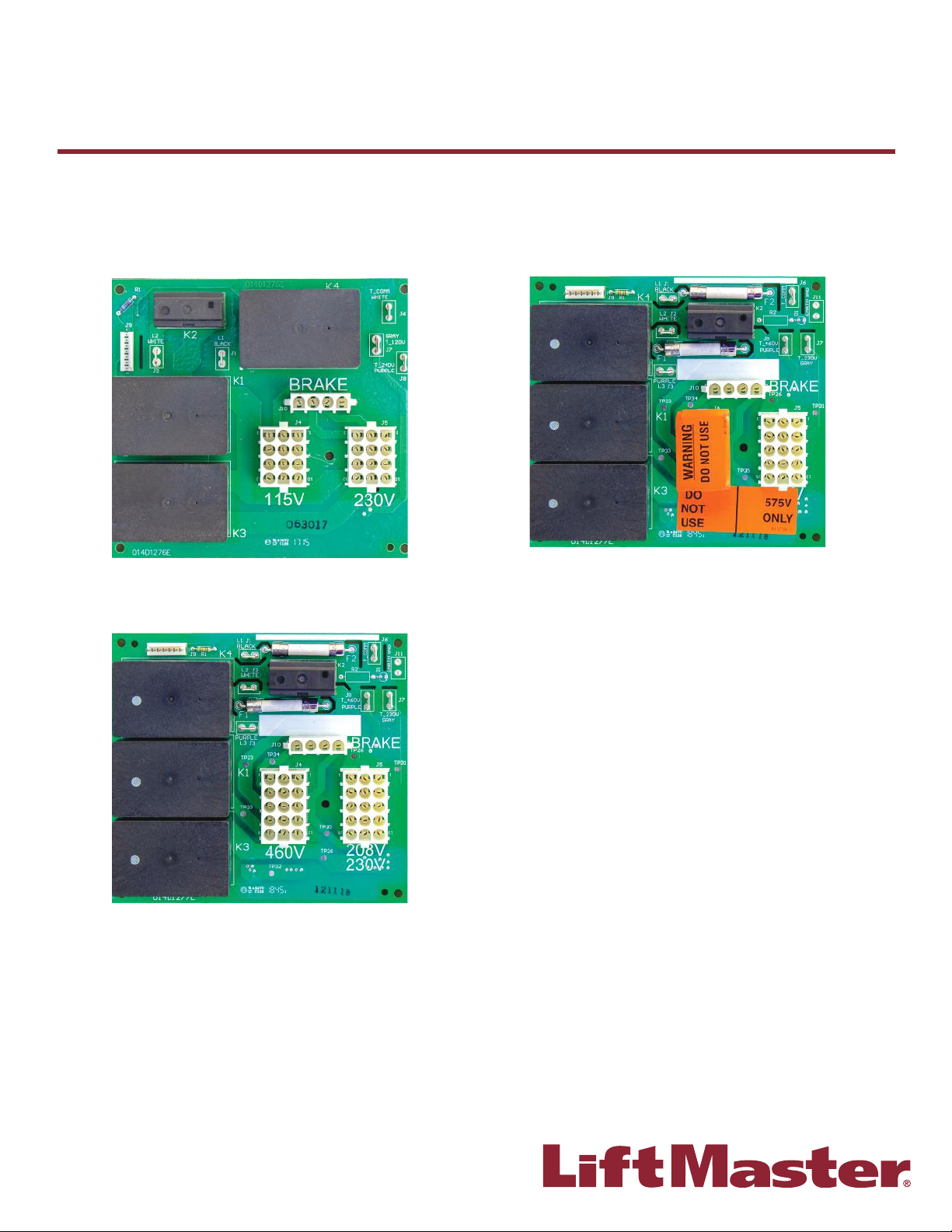

Logic 5.0 Power Board - Dual Voltage Connections

• Reduces stocking a wide variety of operators due to range of potentially required voltages.

• Minimizes lost time if operator does not meet predetermined job site voltage requirements.

B

Industrial Duty Logic Operators

1 Phase Power Board 115/230V

Service Kit# ...................................... K001D8396-1

3 Phase 208/230/460V

Service Kit# ..........................................K001D8397

N4 & N4X Electrical Box Board Requirements

The N4 & N4X Electrical Boxes require specifi c power boards.

When installing power boards for the N4 or N4X Electrical boxes, choose one of the compatible power boards outlined

below that fi t your specifi c voltage requirements.

3 Phase Power Board 575V

Service Kit# ...................................... K001D8397-1

1 Phase Power board - 115/230V, N4/N4X

Service Kit#

3 Phase Power board - 230/460/575V, N4/N4X

Service Kit#

.............................................................................................................................................................................K001D8398

.........................................................................................................................................................................K001D8116-1

10

Page 11

Logic Board Overview

LOGIC 4.0 K001A6837

Optional Auxiliary

Optional Auxiliary

Card Receptacles

Card Receptacles

Motor

Motor

Direction

Direction

Jumper

Jumper

Receiver LED

Receiver LED

Maximum Run

Maximum Run

Timer Button

Timer Button

Radio

Radio

Learn Button

Learn Button

B

Industrial Duty Logic Operators

Single Phase

Single Phase

& Three Phase

& Three Phase

Jumper

Jumper

Maintenance

Maintenance

Alert System

Alert System

Button for

Button for

Programming

Programming

Mid Stop

Mid Stop

Learn Button

Learn Button

Timer-To-Close

Timer-To-Close

Learn Button

Learn Button

Selector Dial

Selector Dial

(used for

(used for

programming

programming

and selecting

and selecting

wiring type)

wiring type)

Main Motor Control Harness Connection

Main Motor Control Harness Connection

5

Open Button

Close Button

Stop Button

5

Control Wiring

Terminal Block

Open Button

Close Button

Stop Button

Control Wiring

Terminal Block

11

Page 12

Logic Board Overview

LOGIC 3.0 K001A5729

Optional Auxiliary

Card Receptacles

B

Industrial Duty Logic Operators

Single Phase and

Three Phase

Jumper

Motor

Direction

Jumper

Open Limit

Switch LED

Mid-Stop LED

Safety Limit

Switch LED

Close Limit

Switch LED

Receiver LED

Radio Learn

Button

Maximum

Run Timer

Learn Button

Mid-Stop

Learn Button

Timer to

Close Learn

Button

Power LED

Timer Defeat

LED

MAS

Learn Button

and LED

Entrapment

Protection LED

Edge LED

Open Button

LED

Close Button

LED

Stop Button

LED

Relay LEDs

Selector Dial

Failsafe/Non-Failsafe

Selector Switch

Control Wiring

Terminal Block

Timer

Enable LED

On-Board

3-Button

Control Station

Single Button

Control LED

12

Page 13

Troubleshooting

Look For Green “POWER” LED

The Industrial Duty Logic Operator has many features reducing time required to identify and make repairs, as well

as time spent training service technicians. Please note when working on an operator, always follow proper electrical

safety guidelines and local codes.

The transformer should produce 24VAC (±10 %) on the secondary side. If the green power LED, which is located near

terminal 13, is illuminated then 24VAC is present on the logic board. Verifying with a multimeter is still recommended.

To check the secondary side of the transformer, set the meter to volts AC and check across the yellow and blue wires

on the transformer or terminals 13 and 14 on the logic board. If working properly, they should each show 24VAC +/10%.

The logic board and all the controls are run on 5VDC. The 5VDC control signal allows 1000 ft. control runs with

18AWG wire. Be sure any incoming signal to the board is from a dry contact and not a voltage source. A dry contact,

such as a standard switch, is a device connecting two wire leads to make a closed circuit. Some examples are the open

or close buttons on LiftMaster’s standard 3-button control station, limit switches and standard relay outputs.

If the green “POWER” LED does not turn on, the transformer may not be working correctly. Verify primary voltage

feeding the transformer by checking: Logic 3.0 and Logic 4.0 - White and Brown wires. Logic 5.0 - Common and

appropriate wire. See the chart for high voltage wires.

B

Industrial Duty Logic Operators

Transformer - High Voltage Color Code

LOGIC 3.0 AND LOGIC 4.0 LOGIC 5.0

115V Brown and White White and Gray

208/230V Single Phase Brown and White White and Purple

208/230V Three Phase Brown and White White and Gray

460V Brown and White White and Purple

575V Brown and White White and Gray

Check Control Station

Verify the control stations are wired to the terminal strip correctly. This is easily checked by using the “OPEN,”

“CLOSE”, and “STOP” LED diagnostic LEDs. The operator should have the “OPEN” and “CLOSE” LEDs off and the

green “STOP” LED on.

Turn the selector dial to DIAG to put the operator in diagnostic mode. Confi rm the wiring is correct on the

board by pressing the “OPEN” and “CLOSE” button on the board separately. When each button is pressed, the

corresponding LED should turn on. When working properly, the STOP LED should be illuminated. Pressing the STOP

button should make this LED turn off. If the LED’s respond accordingly to the on-board OPEN/CLOSE/STOP buttons,

test the 3-button control station or the wiring to the 3-button control station.

To test the 3-button control station, open the control station and use a multimeter to verify continuity. When working

properly, an idle 3-button control station with no depressed buttons should read infi nite resistance (open circuit)

across the “OPEN” and “CLOSE” buttons and 0 Ohms (closed circuit) across the “STOP” button. The meter should

read 0 Ohms (closed circuit) when the “OPEN” and “CLOSE” buttons are pressed, and infi nite resistance (open circuit)

when the “STOP” button is pressed. If the continuity test on the 3-button control station yields different results than

listed, the control station will have to be replaced.

NOTE: Don’t run control wiring and power wiring in the same conduit, these wirings should be separated by 18”.

13

Page 14

Troubleshooting

Check Control Station (Continued)

Terminals 2 and 3 are also a normally closed circuit used when an external interlock is present. If the external interlock

is activated the “STOP” LED will not be lit.

If the LEDs do not respond, disconnect the wall control station(s), put a jumper between the “STOP” and “COMMON”

terminals, and try activating the LEDs by pressing the on-board 3-button control station next to the terminal strip. If

the LEDs do not respond, there is a problem with the logic board and will require replacement.

If the lights do respond, but the operator still does not run, reset the operator to factory defaults.

B

Industrial Duty Logic Operators

Resetting Factory Defaults - Clearing Memory

To reset most of the user installed settings back to factory defaults:

1) Turn the selector dial to DIAGNOSTIC.

2) Press and hold the STOP button for 5 seconds. The MAS LED will fl ash

momentarily when the factory defaults have been restored.

3) Return the selector dial to the desired wiring type.

Factory Defaults:

a) Timer-To-Close is set to 0 seconds.

b) The Mid Stop is deactivated.

c) The Maintenance Alert System is deactivated.

d) The Maximum Run Timer is set to 90 seconds.

e) Car Dealer Mode is deactivated.

f ) The remote controls and myQ® devices will still be learned.

g) Remote control programming via the 3-button control station.

h) The LiftMaster Monitored Entrapment Protection (LMEP) device(s) will

be unprogrammed.

NOTE: Life of Operator feature (Odometer/Cycle Counter) and programmed

remote controls and myQ devices are not cleared.

SELECTOR DIAL

Operation will

vary depending

on wiring type

14

Page 15

Troubleshooting

Advanced Troubleshooting: Testing Single Phase Logic 3.0 And 4.0 Relays

The following tests should be performed by a qualifi ed technician. A multimeter is required.

B

Industrial Duty Logic Operators

(YE)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(YE)

(YE)

(OR)

(GY)

(PU)

(OR)

01

A

4

2

(PU)

(BL) (GY)

See Motor

Connections

8

6

SLOT 1

hot

neutral

ground

(YE)

SLOT 2

MOV

MOV

L3 L2 L1

(WH)

COM

+24 VAC -24 VAC

(BK)

120

VAC

OLS

REV

STD

120 / 240

VAC

MID

SLS

MOTOR

DIRECTION

(BR)

(WH)

CLS

See Motor

Connections

NO

COM

COIL

RADIO

(WH)

C

(GY)

(WH)

01

B

4

8

6

2

Testing C Relay

Check Coil Wires. 0VDC at idle, 24VDC when given a command either direction. Check NO Contact. Metering L1 to

either white wire on C relay should read line voltage when given a command.

Testing B Relay

Check Coil Wires. 0VDC at idle, 24VDC when given an OPEN command. *Special applications might show voltage in

the opposite direction.

Check NO Contact. Metering L2 to 6 on B relay should read line voltage when given an OPEN command. *Special

applications might show voltage in the opposite direction.

Testing A Relay

Check Coil Wires. 0VDC at idle, 24VDC when given a CLOSE command. *Special applications might show voltage in

the opposite direction.

Check NO Contact. Metering L2 to 2 on A relay should read line voltage when given a CLOSE command. *Special

applications might show voltage in the opposite direction.

Testing K3 Relay (Start Winding Relay On Board With White And Yellow Wires)

K3 is a NO relay that closes for 1.25 seconds during start up. To test, remove White and Yellow wires and test for

continuity across the contacts on the relay. Reading should be OPEN when operator is idle and should close for 1.25

seconds when operator is given a command.

NOTE: 1) This test will put the operator into a restricted close mode. Simply cycle power to reset.

2) If the K3 relay is stuck CLOSED, the motor will 'GROWL' loudly and trip the circuit breaker.

3) If the K3 relay is stuck OPEN, motor will only hum.

15

Page 16

Troubleshooting

R

R

Advanced Troubleshooting: Testing Three Phase Logic 3.0 And 4.0 Relays

The following tests should be performed by a qualifi ed technician. A multimeter will be required.

B

Industrial Duty Logic Operators

SLOT 1

208/230/460

VOLT 3PH.

POWER IN

(YE)

SLOT 2

L3 L2 L1

(WH)

COM 120

+24 VAC

MOV

MOV

(WH)

(BK)

VAC

240 / 460 /

575 VAC

-24 VAC

OLS

REV

STD

MID

SLS

MOTOR

DIRECTION

CLS

MRT

NO

COM

COIL

(WH)

D

1

RADIO

(WH)

(WH)

(PU)

(BR)

(BR)

E2

D1

See Motor

Connections

(WH)

NO

COM

C

COIL

C2

B2

01

B

(WH)

(GY)

(GY)

(YE)

(RD)

(WH)

(PU)

(YE)

(OR)

(GY)

(PU)

(OR)

(WH)

(WH)

(WH)

84

(WH)

62

(WH)

01

A

8

4

62

(YE)

(GY)

See Motor

Connections

Testing C And D Relays

Check Coil Wires. Both are 0VDC at idle. Metering across either coil should read 12VDC when given a command.

Check NO Contact. Metering L1 to either white wire on C or D relay should read line voltage when given a command.

Testing B Relay

Check Coil Wires. 0VDC at idle, 24VDC when given an OPEN command. *Special applications might show voltage in

the opposite direction.

Check NO Contact. Metering L2 to 6 on B relay should read line voltage when given an OPEN command. *Special

applications might show voltage in the opposite direction.

Testing A Relay

Check Coil Wires. 0VDC at idle, 24VDC when given a CLOSE command. *Special applications might show voltage in

the opposite direction.

Check NO Contact. Metering L2 to 2 on A relay should read line voltage when given a CLOSE command. *Special

applications might show voltage in the opposite direction.

16

Page 17

Troubleshooting

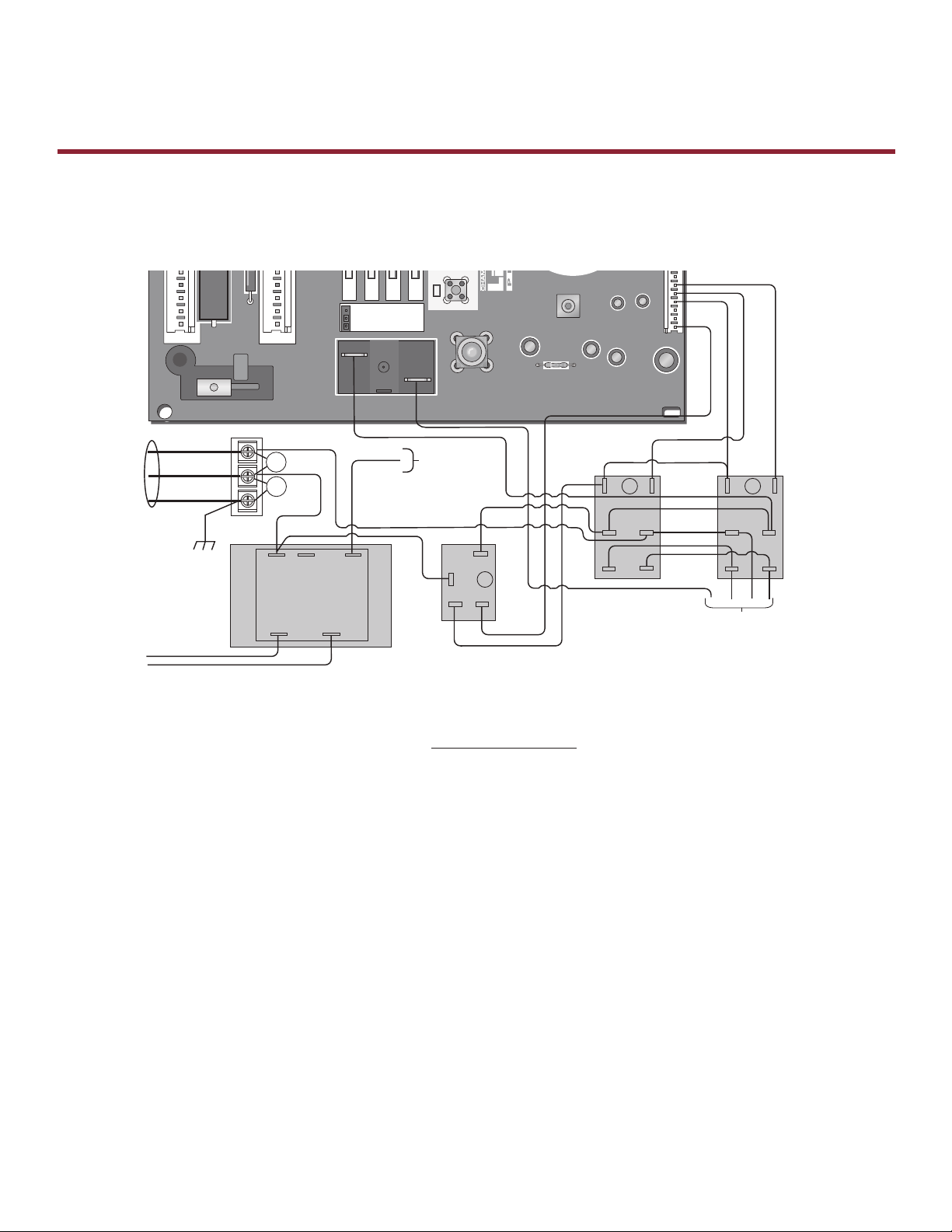

Advanced Troubleshooting: Checking Logic 5.0 Single Phase Motor

The following tests should be performed by a qualifi ed technician. A multimeter will be required.

B

Industrial Duty Logic Operators

123

456

789

10 11 12

1) Turn power off to the operator.

2) Locate the motor plug on the POWER BOARD and unplug.

3) Set the multimeter to continuity/ohms. Ω *Certain meters have a setting that beeps when a closed circuit is

detected. This setting is preferred for the test.

4) Using the guide below, check for continuity across the following pins on the motor harness:

a. Place probe between Thermal Protector, Pins 4 and 10. Continuity should be present.

b. Place probe between Run Winding 1, Pins 12 and 8. Continuity should be present.

c. Place probe between Run Winding 2, Pins 11 and 9. Continuity should be present.

d. Place probe between Start Winding, Pins 1 and 7. Continuity should NOT be present.

5) If the readings are different than the results expected above, the motor will have to be replaced.

17

Page 18

Troubleshooting

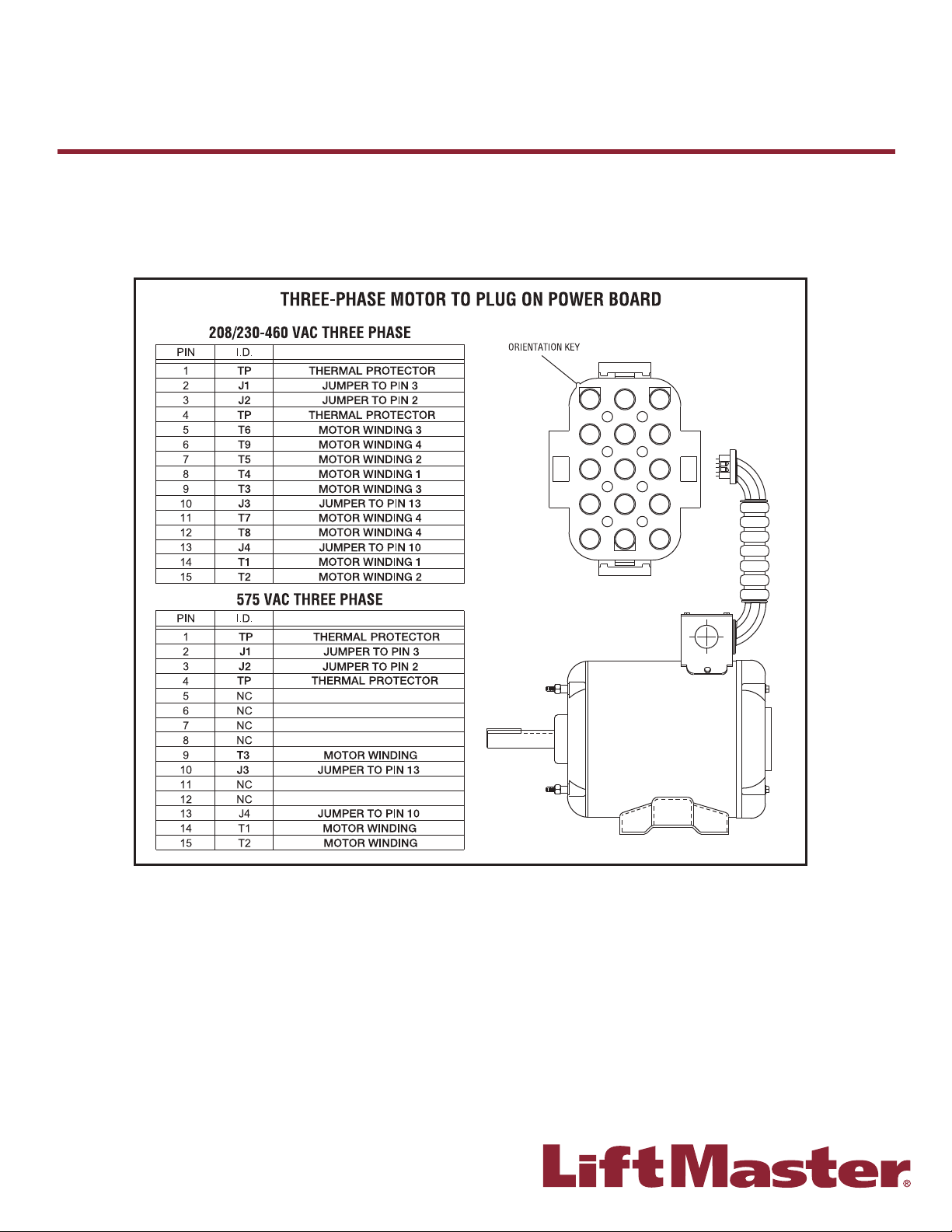

Advanced Troubleshooting: Checking Logic 5.0 Three Phase Motor

The following tests should be performed by a qualifi ed technician. A multimeter will be required.

B

Industrial Duty Logic Operators

123

456

789

10 11 12

13 14 15

1) Turn power off to the operator.

2) Locate the motor plug on the POWER BOARD and unplug.

3) Set the multimeter to continuity/ohms. Ω *Certain meters have a setting that beeps when a closed circuit is

detected. This setting is preferred for the test.

4) Using the guide below, check for continuity across the following pins on the motor harness:

a. Place probe between Thermal Protector, Pins 1 and 4. Continuity should be present.

b. Place probe between Motor Winding 1, Pins 14 and 8. Continuity should be present.

c. Place probe between Motor Winding 2, Pins 15 and 7. Continuity should be present.

d. Place probe between Motor Winding 3, Pins 9 and 5. Continuity should be present.

e. Place probe between Motor Winding 4, Pins 6, 11 and 12. Continuity should be present. *Any combination

between Pins 6, 11 and 12, continuity should be present.

5) If the readings are different than the results expected above, the motor will have to be replaced.

18

Page 19

Troubleshooting

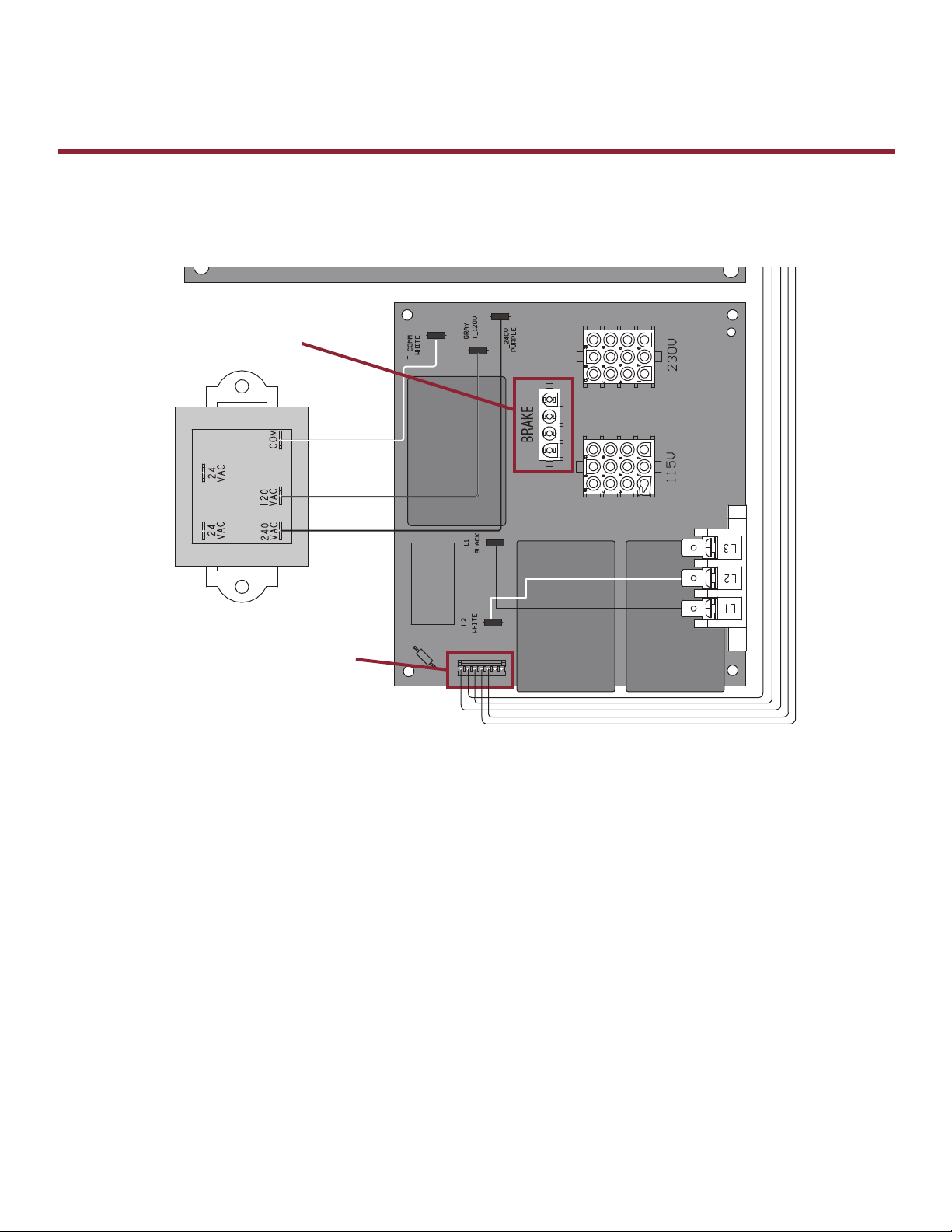

Advanced Troubleshooting: Checking Logic 5.0 Single Phase Brake And Power Board

The following tests should be performed by a qualifi ed technician. A multimeter is required.

To Check Brake

(when present)

B

Industrial Duty Logic Operators

To Check Power Board

To Check Brake (When Present)

1) Turn power off to the operator.

2) Locate the brake plug on the POWER BOARD and unplug.

3) Set the multimeter to continuity/ohms. Ω *Certain meters have a setting that beeps when a closed circuit is

detected. This setting is preferred for the test.

4) Using the guide below, check for continuity across the following pins on the brake harness:

a. On 115v operators, place probe between the White and Yellow wires on the brake

harness. Continuity should be present.

b. On 208/230v operators, place probe between the Blue and Black on the brake

harness. Continuity should be present.

5) If the readings are different than the results expected above, the brake solenoid will have to be replaced.

To Check Power Board

This measurement is done with power removed from the operator and the low voltage harness plugged in to the

Power Board. Set meter to ohms(Ω) and check :

Orange to Gray should read 335 ohms

Orange to Purple should read 648 ohms

Orange to Black should read 335 ohms

Orange to Yellow should read 648 ohms

* Readings are to allow +/- 10% deviation If the readings are different than the results expected above, the Power

Board will have to be replaced.

19

Page 20

Troubleshooting

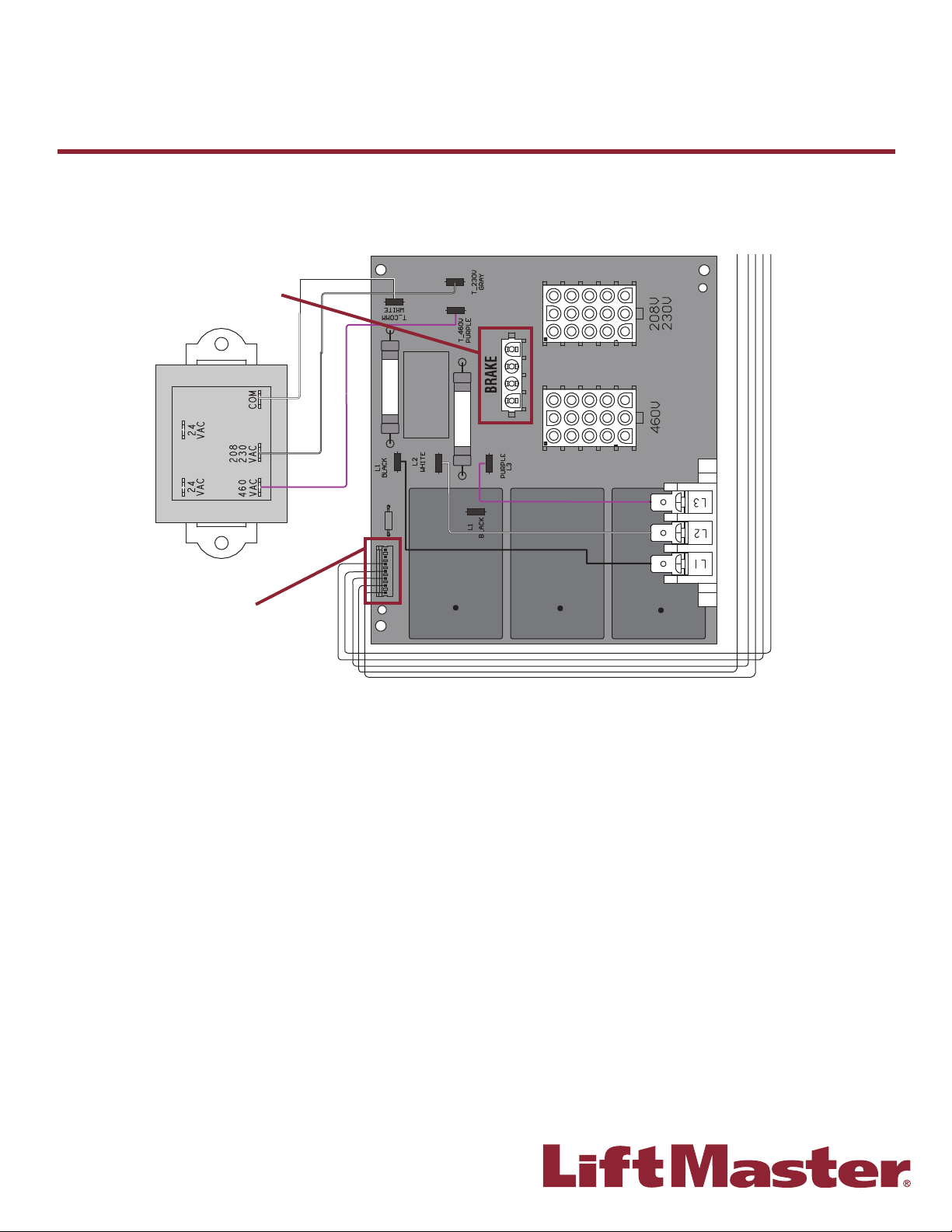

Advanced Troubleshooting: Checking Logic 5.0 Three Phase Brake And Power Board

The following tests should be performed by a qualifi ed technician. A multimeter will be required.

To Check Brake

(when present)

B

Industrial Duty Logic Operators

To Check Power Board

To Check Brake (When Present)

1) Turn power off to the operator.

2) Locate the brake plug on the POWER BOARD and unplug.

3) Set the multimeter to continuity/ohms. Ω *Certain meters have a setting that beeps when a closed circuit is

detected. This setting is preferred for the test.

4) Using the guide below, check for continuity across the following pins on the brake harness:

a. Place probe between Pins 1 and 4 on the brake harness. Continuity should be present.

5) If the readings are different than the results expected above, the brake solenoid will have to be replaced.

To Check Power Board

This measurement is done with power removed from the operator and the low voltage harness plugged in to the

Power Board. Set meter to ohms(Ω) and check :

Orange to Gray should read 350 ohms

Orange to Purple should read 640 ohms

Orange to Black should read 350 ohms

Orange to Yellow should read 350 ohms

*Readings are to allow +/- 10% deviation If the readings are different than the results expected above, the Power

Board will have to be replaced.

NOTE: Fusing on the 3-Phase Power Board is not fi eld-replaceable. An Open Fuse indicates that the 3-Phase Power Board

is damaged and must be replaced. Failure to replace the complete 3-Phase Power Board may result in additional damage

to the Operator.

20

Page 21

Selected Features

Car Dealer Mode

Feature: The car dealer mode uses the SBC (Single Button Control input)

to bring the door from a closed position to the programmed Open Mid-Stop

position and keep it at that location even with multiple inputs.

Benefi t: Provides energy cost savings by limiting the door opening height.

Requirements: This feature works in conjunction with the programmable

Timer-To-Close feature. To enable this feature you must fi rst connect a treadle,

photoelectric sensor or loop detector accessory to the SBC input and must

have at least one LiftMaster Monitored Entrapment Protection (LMEP)

device installed (refer to the installation manual). Wiring type must be

set to TS or T.

TO PROGRAM:

1) Start with the door in the closed position.

2) Turn the SELECTOR DIAL to PROG.

3) Push the TTC button and release (Green Timer LED will

be lit).

4) Push the MID button and release. This turns on the Car Dealer Mode.

(The Green Timer LED will fl ash 6 times indicating the Car Dealer Mode

is turned on.)

5) Push the TTC button and release.

6) Turn the SELECTOR DIAL to the desired wiring type (TS or T).

NOTE: To disable the Dealer Mode follow steps 2 and 3, then press the MRT button and release. (The Green Timer LED

will fl ash 3 times indicating that the Car Dealer Mode is off.)

B

Industrial Duty Logic Operators

SELECTOR DIAL

Operation will

vary depending

on wiring type

Life Of Operator (Odometer/Cycle Counter)

The operator is equipped with an odometer to show how many months and cycles the operator has performed from

the time it was installed. This feature can help determine how long the operator has been in service.

1) Start with the door in the closed position.

2) Turn the SELECTOR DIAL to DIAG (diagnostic mode).

3) Press and release the MAS button on the logic board.

4) Press and release the MRT button on the logic board.

5) The open and close lights will fl ash. OPEN for every 5,000 cycles and CLOSE for every 3 months.

6) Return the SELECTOR DIAL to the desired wiring type.

NOTE: If operator has not reached 5,000 cycles or 3 months, there will be no indications.

Thermal Overload

The Logic operators have been equipped with a thermal motor overload. The thermal overload has replaced the need

for a manual overload on the operator electrical box. The thermal overload works by shutting down the operator until

the operator can cool off and reset automatically. After the overload resets, the operator must be cycled with constant

pressure. The operator must be opened and closed fully to reset the operator to normal operation. This feature saves

the installer from having to physically reset the operator manually.

Motor Direction Jumper

This feature is designed to save the installer from having to rewire the limit switches and motor when unique

applications require reversing the open and close limits. This would typically be seen on an auxiliary trolley

modifi cation, through-wall application, or when mounting the operator upside down. By removing the jumper from the

motor direction pins, the door can be set to either a standard or reversed direction. The factory default is the standard

direction. The logic board automatically changes the motor direction and reverses the Open Limit Switch (OLS) and

the Close Limit Switch (CLS). The only limit switch requiring movement is the Sensing Limit Switch (SLS) to the close

side of the operator. This feature is provided for ease of install.

NOTE: Not for use when a 3PH operator is reverse phased, for 3PH two of the incoming legs of power should be reversed.

21

Page 22

Diagnostic Chart

The industrial duty logic boards (5.0, 4.0, 3.0) have several LEDs to assist in the installation and troubleshooting of the

operator. The following chart should assist in verifying the operator is functioning properly. Turn the selector dial to

DIAGNOSTIC to keep the door from moving while troubleshooting.

LED COLOR DEFINITION

Power Green Indicates power is being generated for the logic board.

Stop Green Indicates a closed circuit between Common terminal 4 and Stop terminal 5.

Open Yellow Indicates a closed circuit between Common terminal 4 and Open terminal 7.

Close Yellow Indicates a closed circuit between Common terminal 4 and Close terminal 6.

LMEP

(Photoelectric

sensors) (CPS-U,

CPS-UN4)

Timer Defeat Yellow Solid on indicates a closed circuit between common and terminal 12.

OLS Yellow Pressing the Open Limit Switch should turn ON this LED.

CLS Yellow Pressing the Close Limit Switch should turn ON this LED.

SLS Yellow Pressing the Sensing Limit Switch should turn ON this LED.

Edge Yellow Indicates a closed circuit between common and terminal 8. Pressing the edge

Mid-Stop Yellow Solid on indicates door is stopped on mid-stop.

Timer Enabled Green Solid on indicates TIMER is programmed and will activate from open or mid

SBC Yellow Indicates a closed circuit between common and terminal 1. Pressing the

MAS Yellow Indicates the Maintenance Alert System has been activated or an error code

Green Solid on indicates LMEP learned. Flashing indicates sensors need to be

B

Industrial Duty Logic Operators

Pressing stop should turn off this LED.

Pressing the open button should turn ON this LED.

Pressing the close button should turn ON this LED.

re-connected or activated, or unlearned if removed**. Solid off indicates no

sensors learned.

Timer-To-Close will not close.

should turn ON this LED.

stop position. Flashing indicates TIMER is counting down and door will close

after preset time. Each fl ash represents 1 second of programmed time.

single button control station should turn ON this LED.

has been triggered. See inside cover of the operator.

NOTE: After a power cycle, the board will fl ash a series of lights, and then

fl ash the fi rmware Rev. on the MAS light. The fi rmware revision will always

be fl ashed as X.Y.; e.g. current version is 8.12 which would fl ash as; 8 blinks,

pause, one blink, pause, 12 blinks. The fi rmware version is printed on the

label of each L5 board. These blinks should not be confused with an error code

which would continue to fl ash repeatedly.

Relay A Yellow Indicates open or close command has been given to the motor. LED turns on

when OPEN/CLOSE button is pressed.

Relay B Yellow Indicates open or close command has been given to the motor. LED turns on

when OPEN/CLOSE button is pressed.

DATA* Green Indicates communication between the Logic 5.0 board and optional

TLS1CARD.

* Logic 5.0 ONLY

** To unlearn, turn the selector dial to DIAG. Press and hold the STOP button until the MAS LED fl ashes (5 fl ashes).

Return the selector dial to the desired wiring type.

22

Page 23

Symptoms and Solutions

SYMPTOM: The Operator Will Not Respond To Any Commands

POSSIBLE CAUSE: SOLUTION:

No power supply Verify primary line voltage from power source. Green

Operator 3-button control station is miswired Use the OPEN, CLOSE and STOP LEDs to help check

Interlock switch is activated Check interlock(s). If more than one external interlock is

Dial still in programming or diagnostic mode Set dial to desired wiring type.

Motor is malfunctioning Verify proper voltage getting to the motor.

Motor thermal overload tripped Check for obstructions and verify the door moves freely.

Failsafe switch is activated requiring photoelectric

sensors (Logic 3.0 only)

B

Industrial Duty Logic Operators

POWER LED must be on.

correct wiring. Verify the logic board is accepting

commands by using the on-board 3-button control

station. Green light next to the STOP button must be on.

present they must be wired in series.

Cycle operator in constant pressure one full cycle open

and close to reset fault. Check to see if motor is hot.

Allow motor to cool before attempting to move door.

Move switch to non-failsafe or connect a failsafe sensing

device.

LiftMaster Monitored Entrapment Protection (LMEP) not

installed (Logic 4.0 and 5.0)

A relay or the power board (Logic 5.0 ONLY) may need

to be replaced

Possible accessory malfunction Disconnect all devices; reattach them one at a time

Possible logic board failure Replace logic board.

SYMPTOM: Power LED Is Not On

POSSIBLE CAUSE: SOLUTION:

Loose secondary wiring connections or a faulty control

transformer

Logic board failure Replace logic board.

Interlock switch Check interlock(s).

SYMPTOM: Stop Button LED Is Not On

POSSIBLE CAUSE: SOLUTION:

Control station miswired or not connected Check wiring to control station.

Interlock switch Check interlock switch(es) for continuity.

Move selector dial to C2 for constant pressure to close

or add a LiftMaster Monitored Entrapment Protection

(LMEP).

When the OPEN or CLOSE button is pressed, Relay A or

B LED should turn on and the door should move in the

corresponding direction. If Relay A or B lights and the

door does not move, the relay or Power Board (Logic 5.0

ONLY) may need to be replaced.

testing for a failure after each one is replaced.

Repair or replace connections or control transformer.

23

Page 24

Symptoms and Solutions

SYMPTOM: The Door Will Move About A Foot, Then Stop. After Stopping, Only Constant Pressure

Commands Will Move The Door

POSSIBLE CAUSE: SOLUTION:

RPM sensor is not connected properly or may need to

be replaced

SYMPTOM: The Door Will Move Most Of The Way Towards A Limit, Then Stop. An Extra Open Or Close

Command Is Able To Get Door To Complete Cycle

POSSIBLE CAUSE: SOLUTION:

The Maximum Run Timer is not set correctly Manually reprogram the Maximum Run Timer OR reset

SYMPTOM: The Door Will Open Partway And Stop. A Second Open Command Is Needed To Open The

Door Completely.

POSSIBLE CAUSE: SOLUTION:

There may be a Mid-Stop set Check to see if the Mid-Stop LED is on. Clear the Mid-

SYMPTOM: The Door Will Open But Will Only Close After A Five Second Delay With Constant Pressure

On The Close Button

POSSIBLE CAUSE: SOLUTION:

The photoelectric sensor, sensing edge or other

entrapment protection device is obstructed or activated

The logic board thinks the photoelectric sensors are

attached and blocked

Failsafe switch set (L3 only) Slide switch to Non-Failsafe mode.

SYMPTOM: The Operator Will Not Respond To Any Commands

POSSIBLE CAUSE: SOLUTION:

Possible accessory malfunction Disconnect all devices; reattach one at a time testing for a

Possible logic board failure Replace logic board.

B

Industrial Duty Logic Operators

a) Check the RPM assembly for loose connections. Check

the Interrupter Cup to ensure it turning when the

operator is running. Check for foreign matter blocking

the optical lens.

b) Replace RPM sensor.

to factory defaults.

Stop by turning the selector dial to program. Press and

hold the Mid-Stop button for 5 seconds. Return dial to

desired wiring type.

If the on-board EYES LED is fl ashing, the photo-eyes are

misaligned or not connected. Remove any obstructions;

check the safety device wires for continuity or a short.

Erase the LMEP device; turn the selector dial to DIAG,

push and hold the stop button until the MAS LED fl ashes.

If a LiftMaster entrapment protection device is not

connected the only modes of operation are C2, D1 or E2.

failure after each one is replaced.

24

Page 25

Error Codes

LiftMaster Logic 3.0, 4.0, and 5.0 Operators incorporate a self-diagnostic feature built into the MAS LED. In

addition to indicating when routine maintenance is due, the MAS LED can be used to troubleshoot problems with

the operator.

If the MAS LED on the logic board or 3-button control station is fl ashing on and off rapidly, the Maintenance Alert

System has been triggered and service is due on the operator. If the MAS LED fl ashes 2 or more times in a row

followed by a pause, an operator error has occurred. To view the errors, turn the selector dial to DIAGNOSTIC

and press the OPEN button. To view the individual error codes (if more than one exists) press CLOSE. It is

possible to have more than one error at a time. Use the chart below to determine the error.

B

Industrial Duty Logic Operators

ERROR

CODE

1 blink MAS triggered (cycles or

2 blinks No RPM input during opening

3 blinks (MRT) Maximum Run Time

4 blinks Obstruction sensed on closing Operator will reverse to

5 blinks A button is stuck (longer than

6 blinks Invalid option card plugged

7 blinks LiftMaster Monitored

8 blinks Brownout detected Operator will run as

9 blinks Motor movement at invalid

10 blinks Operator was not in programming

12 blinks

(3 Phase

Only)

DESCRIPTION SYMPTOM SOLUTION

Normal operation Reset MAS.

months)

The door only responds

or closing

has timed out

2 minutes)

into option card receptacles

Entrapment Protection (LMEP)

device faulted or removed for

greater than 2 minutes

time

mode when the motor phase

jumper was changed.

Current sense fault. Motor moves for limited

to constant pressure

commands.

OR

No operator movement for

3-Phase Operator.

The door stops before

reaching the desired time

OPEN position

The control station will not

respond

Option card will not

function properly

Normal operation (5

second constant pressure

override required to close)

long as enough power is

present

Operator will continue

to function normally for

5 operations and then

default to a constant

pressure mode

The phase will not change Enter programming mode and move phase jumper to

cycles, then motor no

longer moves.

Clutch is slipping; adjust clutch, or verify RPM sensor

connection or replace RPM sensor.

NOTE: To relearn the RPM sensor, move the door with

a constant pressure command. The door will stop

once relearned and normal operation will resume.

OR

Replace 3-Phase Power Board.

Check the operator for any faults (e.g., bad limit switch),

program the Max Run Timer OR reset to factory defaults.

Remove obstructions or realign photoelectric sensor.

The control station must be fi xed or replaced before

it will be recognized as an input.

Refer to accessories (page 63) for list of supported

option card(s).

Cleared when entrapment protection device is

cleared or connected.

1. Check AC line for voltage.

2. Check transformer secondary for low voltage. Too many

accessories may be connected to the transformer.

Check relays and the drive circuitry to insure that

they are turning off. Operator must run correctly for

two starts for the error to be cleared.

change phase.

1. Check current sense wiring connection.

2. Cycle operator power after wiring has been corrected.

OR

Replace 3-Power Power Board

NOTE: 12 flash for current sense 3ph only. Error codes take priority over normal MAS LED operation. Error codes will repeat on the MAS every

1.5 seconds until cleared. There may be more than one error present, but only the highest priority will flash. If the highest error is cleared, the

next highest will flash. All errors self-correct when corrective action is taken and a reset is not needed.

NOTE: After a power cycle, the board will flash a series of lights, and then flash the firmware Rev. on the MAS light. The firmware revision will

always be flashed as X.Y.; e.g. current version is 8.12 which would flash as; 8 blinks, pause, one blink, pause, 12 blinks. The firmware version is

printed on the label of each L5 board. These blinks should not be confused with an error code which would continue to flash repeatedly.

25

Page 26

Remote Controls

Error Codes

Error codes will be displayed by the radio receiver LED on the logic board.

NOTE: The logic 3.0 and Logic 4.0 radio receivers are compatible with Security+

switch remote controls. The Logic 5.0 radio receiver is compatible with Security+ 2.0™ remotes and keyless entry

devices.

B

Industrial Duty Logic Operators

®

315MHz remote controls and DIP

ERROR

CODE

R1 No response from

R2 No response from

R3 The remote cannot

R4 The remote cannot

R5 The remote cannot

R6 Cannot close via

SYMPTOM DISPLAY POSSIBLE CAUSE SOLUTION

the remote

the remote

be programmed

be programmed

be programmed

constant pressure

in C2, D1 or E2

modes

Quick Flash Unlearned remote – A user tries

to use a remote, but the RADIO

LED only fl ashes briefl y and

there is no response from the

operator.

No LED activity Cannot recognize remote –

A weak signal caused by a

discharged battery or outside

interference with the radio

OR is not compatible with the

operator.

Radio LED

turns off after

30 seconds

2 blinks Receiver memory full – A user

3 blinks Duplicate remote – A user

LMEP LED

fl ashes

Cannot recognize remote –

A weak signal caused by a

discharged battery or outside

interference with the radio

OR is not compatible with the

operator.

enters RADIO programming

mode but there is no space

available to add another

remote.

enters RADIO programming

mode and selects the function

to be programmed. When

the remote button is pressed

for programming, a search

reveals that remote is already

programmed.

No entrapment protection

device present – An entrapment

protection device is required to

close via remote.

Try relearning the remote.

Replace battery OR eliminate

interference OR obtain a

compatible remote.

Replace battery OR eliminate

interference OR obtain a

compatible remote.

Erase all learned remotes

and relearn the desired

remote(s).

This remote already has a

function associated with it.

To change the function, erase

all programmed remotes and

reprogram the desired

remote(s).

Must connect a LiftMaster

Monitored Entrapment

Protection (LMEP) device.

26

Page 27

Remote Controls

Compatibility Chart - 315 & 390MHz And Security+ 2.0™

MODEL DESCRIPTION

Remote Controls

893MAX 3-Button Remote Control

w/ Security+ 2.0 and MAX Technology

895MAX* *No Longer available. USE 893MAX as

replacement.

811LM 1-Button Remote Control w/ DIP and

Security+ 2.0 Technology

813LM 3-Button Remote Control w/ DIP and

Security+ 2.0 Technology

891LM 1-Button Remote Control

w/ Security+ 2.0 Technology

893LM 3-Button Remote Control

w/ Security+ 2.0 Technology

371LM 1-Button Remote Control 315MHz

w/ Security+ Technology

372LM 2-Button Remote Control 315MHz

w/ Security+ Technology

373LM 3-Button Remote Control 315MHz

w/ Security+ Technology

374LM 4-Button Remote Control 315MHz

w/ Security+ Technology

333LM 3-Button Remote Control 315MHz Red/

Yellow/Green w/ Security+ Technology

971LM 1-Button Remote Control 390MHz

w/ Security+ Technology

973LM No longer available. Use 893MAX as its

replacement

Wireless Keypads

877MAX Wireless Keypad with Security+ 2.0 and

MAX Technology

877LM Wireless Keypad with Security+ 2.0

Technology

377LM Wireless Keypad 315MHz w/ Security+

Technology

387LM Wireless Keypad - Universal X X X X X

Industrial Duty Logic Operators

Compatible with these CDO Models that have

On-Board Radio Receivers

ATS

LOGIC

5.0

LOGIC 4.0

315MHZ

XX X X X

XX X X X

X

X

X

X

XXX

XXX

XXX

XXX

XXX

XX X X X

X

XXX

LOGIC 4.0

390MHZ

X

X

(PURPLE

LEARN

BUTTON)

MEDIUM-

DUTY

LOGIC

B

27

Page 28

Troubleshooting

MEDIUM DUTY LOGIC BOARD

B

Medium Duty Logic Operators

4 3 2

5

6

7

ITEM DESCRIPTION FUNCTION

1 Open Button Open Door

2 Close Button Close Door

3 Stop Button Stop Door

4 Learn Button Programs the remote controls and

5 Timer-to-Close Button Programs the Timer-to-Close.

6 Purple Wire Antenna Primary Antenna.

7 Auxiliary Antenna

Connection

8 LED Used during programming and

9 Field Wiring Terminal Field wiring connections.

10 Factory Wiring Connector Factory wiring harness connection.

1

1098

performs additional programming.

For use with external antenna kit -EXTANT. Not provided.

diagnosing error codes.

NOTE: SBC feature available with the 71MLSBC kit.

28

Page 29

Symptoms and Solutions

SYMPTOM: Operator Will Not Respond To Any Commands

POSSIBLE CAUSE: SOLUTION:

No power Verify primary line voltage (120 Vac, 60 Hz) is present at terminals L1 & L2. The LED will

Stop circuit not complete Verify Stop Button input (terminals 3 & 5) is properly wired and stop button is not stuck.

Stuck button on 3-button control

station

Interlock input activated a) Verify jumper is located at terminals 3 & 4 if interlock is not present.

Motor overload tripped Overload is internal within motor. Allow to cool and retry.

Accessory failure a) Attempt to close by holding the CLOSE button for more than 5 seconds. If door closes,

Possible component failure Call Technical Support for assistance.

SYMPTOM: Operator Makes Noise But Door Does Not Move

POSSIBLE CAUSE: SOLUTION:

Clutch slipping Adjust clutch, see owner’s manual.

Brake not releasing (if present) Verify brake assembly operation and wiring.

Door operation problem Check door for proper operation.

SYMPTOM: Operator Moves In The Wrong Direction

POSSIBLE CAUSE: SOLUTION:

OPEN and CLOSE button wiring

connection reversed

SYMPTOM: Door Drifts After Operator Stops

POSSIBLE CAUSE: SOLUTION:

Door not balanced properly Check door for proper operation.

Clutch slipping Adjust clutch, see owner’s manual.

Brake not functioning properly (if

present)

SYMPTOM: Door Opens/Closes Too Far

POSSIBLE CAUSE: SOLUTION:

Limits not adjusted properly Adjust limits. See owner’s manual.

SYMPTOM: Door Reverses Unexpectedly

POSSIBLE CAUSE: SOLUTION:

Intermittent Entrapment Protection

Device activation

SYMPTOM: TTC Not Functioning

POSSIBLE CAUSE: SOLUTION:

LiftMaster Monitored Entrapment

Protection Devices

TTC temporarily disabled Close and Open the door. TTC will be re-enabled.

TTC not programmed properly Reprogram TTC. See see owner’s manual.

Radio Functionality NOTE: Built in radio receiver compatible with all LiftMaster 315 MHz remote control devices.

SYMPTOM: No Response

POSSIBLE CAUSE: SOLUTION:

Remote control is not programmed See owner’s manual for programming instructions.

Remote control not compatible Obtain compatible LiftMaster remote control.

Low battery Replace battery.

SYMPTOM: Remote Cannot Be Learned

POSSIBLE CAUSE: SOLUTION:

Low battery Replace battery.

Remote control not compatible Obtain compatible LiftMaster remote control.

SYMPTOM: Poor Radio Range

POSSIBLE CAUSE: SOLUTION:

Low battery in remote Replace battery.

Antenna not confi gured See owner’s manual.

Ambient radio interference or

building structural issue

fl ash when power is present.

Verify that all buttons are actuating freely and releasing properly.

b) Verify interlock is properly wired and not activated when present.

check LiftMaster Monitored Entrapment Protection (LMEP) for proper wiring, polarity,

connections or damage.

b) Remove obstructions or realign photoelectric sensor.

Check 3-button control wiring.

Check brake mechanism to ensure brake lever is free and brake pads are engaging the

brake disc.

Check all connections. Remove obstructions or realign photoelectric sensor.

Check all connections. Verify photoelectric sensors are not blocked and the sensing edge

(if installed) is not activated.

Use EXTERNAL ANTENNA kit, (part: EXT-ANT, see owner’s manual).

B

Medium Duty Logic Operators

29

Page 30

Error Codes

The status of a Medium Duty Logic Operator can be determined by counting the number of fl ashes of the LED on the

logic board.

DIAGNOSTIC LED TABLE

# OF LED FLASHES STATUS SOLUTION

1 System OK. Operating in

2 System OK. Operating in

3 Stuck CLOSE button Check for stuck close button or shorted close wire

4 LiftMaster Monitored

5 Incorrect motor direction Reverse the yellow and red motor wires on the capacitor.

6 Maximum run timer has

7 Logic board Failure REPLACE logic board. NOTE: It is normal for the logic board LED

C2 mode

B2 mode

Entrapment Protection

Device failure

timed out (Maximum run

time = 90 seconds)

B

Medium Duty Logic Operators

None

None

Check for: 1) Misaligned or blocked Photoelectric Sensors.

2) Issue with Monitored Sensing Edge and/or wiring.

Check clutch adjustment. Door height or speed may exceed

the range the operator can travel. Call Technical Support for

assistance.

to fl ash 4 times when power is applied or cycled to the operator.

(Not a logic board failure.)

RESTRICTED CLOSE

This method will allow the door to be closed when LMEP device(s) are no longer working. Press and hold the CLOSE

button until the door reaches the closed limit. If the CLOSE button is released before the door reaches the closed limit

the operator will stop and the procedure will need to be repeated to fully close the door.

30

Page 31

Programming

Requires LiftMaster Monitored Entrapment Protection (LMEP) device. See installation manual for selection and

installation of LiftMaster Monitored Entrapment Protection (LMEP) devices.

REMOTE CONTROLS

Built in 315 MHz radio receiver permits as many as 20 Security+® remote controls or dip switch remote controls in any

combination.

Single Button Remote Control

1) Press and release the LEARN button (LED will light).

2) Press and hold the button on the remote control until the LED fl ashes rapidly, then release to complete

programming (LED will go out).

Repeat steps 1 and 2 for additional remote controls.

3-Button Remote Control To Operate As A Wireless 3-Button Control Station

NOTE: The feature will use 3 of the 20 memory channels in the operator.

1) Press and release the LEARN button (LED will light).

2) Press and release the desired button on the logic board (OPEN, CLOSE or STOP).

3) Press and hold the desired button of the remote control until the LED fl ashes rapidly, then release to complete

programming (LED will go out).

B

Medium Duty Logic Operators

Repeat steps 1 through 3 to program additional buttons.

To Erase All Remote Controls

1) Press and hold the LEARN button (over 5 seconds) until the LED goes out. All programmed remote controls will be

erased.

STOP Button

LEARN Button

R27

LEARN

TTC

1

LMEP1 LMEP2

STOP CLOSE OPEN

D14

LED

234567

COM INTRLK STOP

^^^^

AUX ANT

AUXANT

AUXANT

LEARN

STOPCLOSE OPEN

TTC

D14

LED

1

234567

LMEP1LMEP2

COMINTRLKSTOP

OPENCLOSE

Press and hold button to program Press and hold button to program

CLOSE Button

OPEN Button

OPENCLOSE

Single Button Remote Control 3-Button Remote Control

31

Page 32

Programming

TIMER-TO-CLOSE

Timer-to-Close feature enables the Medium Duty Logic Operator to close from the open limit after a preset time,

adjustable from 5 to 60 seconds in 5 second increments.

To Program

Begin with the door in a fully closed position.

1) Press and release the LEARN button to enter program mode (LED will light).

2) Press and release the TTC button.

3) Every press and release of the STOP button will add 5 seconds to the Timer-to-Close.

Example: 30 second TTC = 6 presses of the STOP button.

4) Press and release the TTC button to exit the programming mode. The LED will fl ash once per 5 seconds of timer

setting.

The TTC will become active after completion of the next open cycle.

NOTE: The LED does not indicate the timer is running.

To Verify The Timer-To-Close (TCC) Setting

1) Press and hold the LEARN button (LED will light).

2) Press and release the TCC button.

3) Press and release the TTC button a second time. The LED will fl ash once per 5 seconds of timer setting.

B

Medium Duty Logic Operators

Clear The Timer-To-Close (TCC)

1) Press and release the LEARN button (LED will light).

2) Press and hold the TCC button for 6 seconds.

3) Release the TTC button (LED will go out). The TTC will no longer be active.

Timer Defeat

The TTC can be temporarily disabled by pressing a STOP button. TTC will become enabled after the next open

command.

LEARN Button

TTC Button

STOP Button

R27

TTC

D14

LED

1

234567

COM INTRLK STOP

LMEP1 LMEP2

^^^^

AUX ANT

AUXANT

AUXANT

TTC

1

LMEP1LMEP2

LEARN

STOP CLOSE OPEN

LEARN

STOPCLOSE OPEN

D14

LED

234567

COMINTRLKSTOP

OPENCLOSE

CLOSE Button

OPEN Button

OPENCLOSE

32

Page 33

33

Page 34

Table of Contents

SECTION C

Mechanical Operators

Page

Symptoms And Solutions 35

Page 35

Symptoms And Solutions

SYMPTOM: The Motor Hums And The Motor Output Shaft Will Not Rotate

POSSIBLE CAUSE: SOLUTION:

Brake did not release (if present) Check the solenoid and check brake adjustment settings.

Door locked or jammed Check door.

Dead phase Check the power supply.

Brake may not be disengaging when starting

relays energize (if present)

SYMPTOM: Door Will Not Move In Either Direction

POSSIBLE CAUSE: SOLUTION:

Clutch is loose Adjust the clutch.

The pulley V-belt is loose Adjust belt by adjusting motor position.

The drive chain has broken Replace drive chain.

Manual disconnect may be engaged Disengage the disconnect.

SYMPTOM: Door Travels In One Direction Only

POSSIBLE CAUSE: SOLUTION:

Bad or miswired limit switch Test continuity of switches and replace as needed. Verify wiring with

Bad or miswired 3-button control station Rewire or replace control station.

Open or close relay miswired or defective Rewire or replace relay.

SYMPTOM: Motor Hums And Starts When It Is Spun

POSSIBLE CAUSE: SOLUTION:

Faulty centrifugal start switch (no start switch

on 1/3 and 1/2 HP motors using Logic 2.0)

Faulty capacitor Replace capacitor.

SYMPTOM: Motor Does Not Hum Or Run In Either Direction

POSSIBLE CAUSE: SOLUTION:

Motor thermal overload tripped Let the motor cool down so internal overload can reset itself, or press

Power is not connected properly Check terminals, circuit breaker, fuses and electrical service panel.

Open and close limit switches are activated Check limit switches.

Control station wired wrong, or has a stuck

button, or auxiliary device is not functioning

properly

Bad start switch in motor (single phase only) Check across black wires on coil of IR relay. Should read same as line

SYMPTOM: Jackshaft Or Hoist Operator Makes Clicking Noise

POSSIBLE CAUSE: SOLUTION:

External interlocks Interlocks must be “normally closed”. Check switch and wiring.

Miswired motor Verify the motor is wired correctly

The operator is mounted wrong; the drive

sprockets are not in line with the driven

sprockets and the chain is clicking

Manually disengage and test again. Repair if needed.

schematic provided.

Tap the motor; if it runs now, the centrifugal switch may be faulty –

replace the motor.

the reset depending on model.

Check continuity from common to NC prongs. Readjust or replace

switches. Remove control stations and auxiliary devices. Test the

operator by jumping T4 and T3, then cross T3 and T1 to open T3 and

T2 to close. Reattach items one at a time and test operation between

each component installation using the component of lowvoltage control wires. Replace, repair, or rewire non-working devices.

voltage.

Reposition the operator.

C

Mechanical Operators

35

Page 36

Symptoms And Solutions

SYMPTOM: Door Drifts After The Operator Is Shut Off

POSSIBLE CAUSE: SOLUTION:

Brake needs adjusting (if present) Check and adjust brake.

Door poorly balanced Check and adjust door/springs.

SYMPTOM: Door Travels Down And Then Stops And Reverses

POSSIBLE CAUSE: SOLUTION:

A sensing device is being activated Check wiring of the sensing device.

Radio receiver may be sending a long signal

to the operator; this can cause the operator

to travel down off the open limit, then reverse

again

SYMPTOM: Door Opens And Then Stops Short Of The Full Open Position

POSSIBLE CAUSE: SOLUTION:

Limit nut not set correctly Adjust limit nut.

An obstruction may be preventing the proper

operation of the door

The clutch may need adjustment Check the sensitivity of the clutch.

Defective limit switch activating prematurely Check limit switch; replace if necessary.

SYMPTOM: Operator Does Not Open Or Close In Response To Command From 3-Button Control Station

POSSIBLE CAUSE: SOLUTION:

Bad wire to 3-button control station Recheck wiring.

Circuit breaker has tripped Reset circuit breaker.

Damaged transformer Check transformer and circuit for 24V.

If equipped with electric interlock, there may

be a poor contact to the interlock switch

Blown fuse Replace fuse.

SYMPTOM: The Door Will Not Close Completely

POSSIBLE CAUSE: SOLUTION:

The limit assembly depression plate is not

properly engaged with nylon limit nut

The door is binding or meeting an obstruction Look for obstruction.

Loose drive or limit chain can cause the chain

to “jump” the sprocket teeth

SYMPTOM: Motor Runs In Wrong Direction

POSSIBLE CAUSE: SOLUTION:

Operator is upside down For MJ, install operator with motor toward the ceiling. For MT,

Motor is wired incorrectly Check and correct wiring.

Three-phase wires are in the wrong order Rearrange any two incoming three-phase power legs on the

Try disconnecting the receiver. If the problem disappears, use a

LiftMaster Brand Receiver

Check door for obstruction.

Verify all interlock switches are working correctly and wiring is

making good contact.

Check and adjust if necessary.

Check the chain as necessary. The limit chain can be adjusted/

tensioned at the electrical box assembly via two mounting screws.

the electrical box and motor should be toward the floor. Correct if

necessary.

terminal strip.

C

Mechanical Operators

36

Page 37

Symptoms And Solutions

SYMPTOM: Motor Is Running But The Door Will Not Move

POSSIBLE CAUSE: SOLUTION:

The door is obstructed or locked Check the door

The clutch may need adjustment Adjust the clutch.

SYMPTOM: Operator Continues To Run At End Of Door Travel

POSSIBLE CAUSE: SOLUTION:

Limits are not set correctly Adjust limits.

Limit switch is faulty Test the switch and check the switch wiring.

SYMPTOM: Motor Operates In Only One Direction When Operated From Radio

POSSIBLE CAUSE: SOLUTION:

Auxiliary device limit switch is not being

activated properly

SYMPTOM: Timer To Close Function Is Inoperable

POSSIBLE CAUSE: SOLUTION:

Timer to close control station is defective Test continuity through wire, then repair or replace.

Timer impulse or timer latch relays are

defective

Timer defeat switch may be activated or

miswired

Defective timer If timer latch and timer impulse relays activate and timer does not

SYMPTOM: Auxiliary Device(s) Will Not Cause Operator To Function Properly

(Radio Control, Sensing Edge, Interlocks, Etc.)

POSSIBLE CAUSE: SOLUTION:

Incorrect control function settings Check positions of control wiring for desired wiring type and reset

Incorrect electrical wiring connections Check wiring with diagram; rewire if necessary.

Auxiliary device uses too many watts If the device is suspect of using too much power, add an additional

Auxiliary device limit switch or sensing limit

switch is not responding or may be overrunning sensing limit switch

Verify the Auxiliary and Sensing Limit Switches (SLS) are activated

in full open and close positions (respectively). Reposition, rewire or

replace.

Repair or replace.

Verify it is “normally closed” and wired correctly; replace if needed.

time out, replace timer.

if necessary.

transformer to power this device.

Test switches and the timing of the switches.

C

Mechanical Operators

37

Page 38

Table of Contents

SECTION D

Basic Electrical Information

Page

Basic Electrical Circuit 39

Limit Switches 40

Multimeter 41

Relays 42

Transformers 44

38

Page 39

Basic Electrical Circuit

A basic electrical circuit is made up of one continuous electrically conductive loop. As an example, see the wiring

diagram of a typical fl ashlight to the right.

Electricity fl ows from positive (+) to negative (-). The

switch stops the electricity from fl owing.

When the switch is closed, electricity will fl ow in a

continuous loop and make the bulb light up. The

electricity will fl ow from the positive side of the battery

past the closed switch through the light bulb (providing

the electricity to light the bulb) and return to the negative

side of the battery.

When the switch is open, the electricity cannot pass

through and electrical fl ow is stopped.

There are many types of switches and components

available within an electrical circuit. Examples include:

motors, contactors, relays, interlocks, capacitors and

limit switches of various types. For commercial operators

to function, each component must be working correctly

for the electrical fl ow to pass through and form a

continuous electrical circuit or loop.

D

Basic Electrical Information

Light Bulb

Switch

Battery

39

Page 40

Limit Switches

D

Basic Electrical Information

Activation Arm

Press this lever down

to activate the switch

Three prongs are present on a limit switch. They are labeled Common or “Com”; Normally Open, abbreviated NO; and

Normally Closed, abbreviated NC. Below is a wire diagram of a limit switch.

When no pressure is applied to the limit switch activation arm, electricity will fl ow from the Common prong to the

Normally Closed prong.

Normally Open

Common

Normally Closed

Activation arm IS NOT being pushed

Normally Closed

Normally Open

Common

When the activation arm is pressed, electricity will fl ow from the Common Prong to the Normally Open Prong.

Electricity will never travel from the NO prong to the NC prong.

Normally Open

Common

Normally Closed

Activation arm IS being pushed

The word “NORMALLY” generally refers to the action of the switch when nothing is activating it. “Normally Closed”

is a continuous fl ow of electricity when the switch is not activated, establishing a closed circuit. “Normally Open” is a

non-continuous fl ow (no fl ow) of electricity when the switch is not activated, establishing an open circuit.

40

Page 41

Multimeter

When shopping for a meter, look for a meter able to fi t in a shirt pocket or clip on a belt. A meter with an audio signal

(buzzer) for continuity checks is recommended.

Checking Ohms/Continuity

When checking the operation of a switch, select the ohm mode on multimeter. (The ohm symbol is Ω). Make sure the

test leads are plugged into the correct sockets for reading ohms. If there is more than one setting in the ohm section

of the meter, select the one with the audio signal.

D

Basic Electrical Information

To test a limit switch, connect one test lead to the Common prong and the other to the Normally Closed prong. The

meter should read 0 resistance or very low resistance. The electricity is fl owing from the Common prong to the

Normally Closed prong. This demonstrates continuity. Activate the switch, the meter will read infi nite resistance or no

continuity. The wires inside the switch are no longer touching between the Common prong and the Normally Closed

prong.

Move the test lead from Normally Closed to Normally Open. While the activation arm is not pressed, the meter should

read open circuit, demonstrating no continuity. Activating the arm should read 0 resistance, demonstrating continuity.

The procedure is called a “Continuity Check” and is used to check for a continuous fl ow of electricity.

Checking Voltage

A multimeter may have several settings for checking voltages. The number associated with each setting is the

maximum voltage able to be read. A meter may be damaged if connected to a higher voltage than selected. Either AC

or DC must be selected prior to testing any circuit. AC stands for alternating current and DC stands for direct current.

AC is usually the incoming line voltage, i.e. 115VAC, 460VAC and so on. 24VAC is also found in the control circuit of a

commercial operator. DC is usually a power source from a battery or the control voltage in a logic board.

AC

Set the meter to VOLTS AC at the lowest setting which is still higher than the expected voltage. If 115VAC is expected

and the meter has 10VAC, 50VAC, 250VAC and 1000VAC, turn the dial to 250VAC. Some meters have only one VAC

choice and the meter can automatically adjust for the voltage received (auto scaling).

DC

41

Page 42

Relays

Relays

In commercial operators, relays are often used to either control

certain operator functions or activate/deactivate ancillary devices

such as heaters or lights.

When electricity is applied to a relay coil, it energizes a magnet and

will close a Normally Open switch or open a Normally Closed switch.

A relay typically has prongs labeled Comm, NO, NC, and two prongs

to power the relay coil. See the light circuit example below containing

a relay.

The diagram below shows two different batteries supplying different voltages. The relay separates the electricity so the

different components are able to work together. Commercial door operators work in a similar fashion. Relays make it

possible for high voltage to work with low voltage.

D

Basic Electrical Information

An “Ice Cube” relay

Light Bulb

NO Switch

Relay

Battery

12V 24V

When the NO switch is pressed closed, electricity will travel through the relay coil and activate the relay. The relay

switch will allow electricity to fl ow through the circuit and turn on the light.

Comm NO NC

42

Page 43

Relays

Relays are available with different coil voltages and contact options. LiftMaster’s line of commercial operators primarily

use Double Pole/Double Throw Relays. A pole is another name for a switch. Double Pole is two separate switches

being turned on or off by the same activation coil (two separate Comms, NCs and NOs). Double Throw means there are

two positions for the output (NO and NC). When shopping for relays, Triple Pole/Single Throw and Single Pole/Double

Throw and many other options are available. Relays are rated with specifi c amp and voltage ratings. Always replace a

relay with the same ratings.

When looking at a wiring schematic, relays will be drawn with several components and the name of the relay will be

noted.

D

Basic Electrical Information

The Coil The NC ContactsThe NO Contacts

R1

Here is the same relay light switch shown as a wiring schematic.

NO

Switch

R1

Battery

R1

R1

Light Bulb

R1

AC Power Source

43

Page 44

Transformers

Transformers

Transformers are used to change incoming voltage to a different outgoing voltage. A transformer has a primary side

(incoming voltage) and a secondary side (outgoing voltage). The primary side connects to wires from the main power

source and the secondary side outputs the new voltage created. In commercial door operators, the secondary side is

generally 24VAC. Read the markings on the transformer to determine the primary and secondary voltages.

Transformers are rated in VOLT Amps (VA). A transformer can only pass the rated amount of electricity from the main

power to the secondary side. Be careful not to overload the transformer. Verify the amperage rating on all devices

connected to the 24VAC side of the transformer including devices attached to the logic board. Multiply the Amperage

rating for each device by the voltage needed to run the device.

▲

COMM 120V▲ 240V

D

Basic Electrical Information

▲

44

Page 45

Transformers

Example for calculating amperage draw:

Below is an example of text for a label that could be placed on accessory devices:

Output Rating…5 AMPS 28VAC or DC Max

Power…24VAC @ 30ma

The “Power” rating is required. The transformer’s secondary side is 24VAC and the transformer is rated for 20VA. The

example accessory above uses 30 milli-amps, which is .03 Amps. Multiply the volts being used (24V) and the amps

(.03A) to get the VOLT Amps (VA) used by the accessory (24Vx0.03A=0.72VA). That leaves (20-0.72=) 19.28VA left

for other accessories (photo-eyes, loop detectors, etc). Once the total VA exceeds 20VA, the operator may experience