Page 1

OPERATING MANUAL

INDUSTRIAL DOOR DRIVES

2 YEAR WARRANTY

Serial nummer:

(see motor gearbox)

Installed on:

Switchgear standart:

DK/DKA-SERIES

Page 2

TABLE OF CONTENTS PAGE 2

IMPORTANT SAFETY ADVICE 3 - 4

GENERAL INFORMATION 4

PREPARATORY TASKS 5

INSTALLATION ADVICE

MOUNTING ARRANGEMENT 6

INSTALLATION ADVICE

ELECTRICAL CONNECTION 7

NEC LIMIT SWITCH WITH 8

ILLUSTRATION

CAM LIMIT SWITCH WITH 9

CONNECTING TERMINAL BOARD

CIRCUIT DIAGRAMS STS1 / 10

NEC/MOTOR

CIRCUIT DIAGRAM STS1 11

CAM LIMIT SWITCH WITH

CONNECTING TERMINAL STRIP

+ TST2 CONTROLS 12

CIRCUIT DIAGRAM

EWS2T/TST1 13

TECHNICAL DATA PAGE 14

DK / DKS DRIVES

DIMENSIONAL DRAWINGS

DK / DKS DRIVES

TECHNICAL DATA 15

DKA DRIVES 16

DIMENSIONAL DRAWINGS

DKA DRIVES 1.1

DIMENSIONAL DRAWINGS 17

DKA DRIVES 1.2

CORNER BRACKETS 18

UNIVERSAL BRACKETS

DIMENSIONAL DRAWINGS

WELDED AXES / 19

SET COLLARS/CLAMPING BEARINGS

CALCULATION OF LIFTING SPEED

MAINTENANCE PLAN 20

WARRENTY 21

SPAREPARTS 22

NOTES 23

2

TABLE OF CONTENTS

Page 3

The door should be counterbalanced.

If this is not done then additional

measures must be taken, such as

unwinding protection, to guarantee

proper operation. In the case of DKA

drives unwinding protection is

standard! Non-movable or stuck

doors must be repaired. Doors, door

springs, cables, pulleys, retainers and

rails are under extreme tension in

such situations and this can lead to

serious injuries.

Do not attempt to loosen, move or

realign the door yourself.

Contact your maintenance service.

Suitable protective clothing should be

worn during maintenance or installation

of the door opener. This includes safety

glasses, back supporting belt, and

protective gloves. When installing or

maintaining a door opener no jewellery,

watches or loose clothing may be worn.

When working from ladders or on

extended platforms the corresponding

safety procedures must be followed.

To avoid serious injuries resulting from

getting tangled or caught in the

mechanisms, all ropes and chains,

which are connected to the door,

must be removed before installing the

door opener.

During installation and connection of the

electrical supply the local building and

electrical regulations must be followed.

Power cables may only be connected to

a properly earthed network.

This system must not be installed in

damp or wet rooms.

Work on the door opener may only be carried

out by one (1) person working on his own.

When working on the door opener all

the local safety regulations must be

observed. Installation of this device

must be done according to EN12453.

The force on the closing door edge

must not exceed 150 N(15kg). If the

closing force is set to more than 150N

then the corresponding additional

safety accessories must be installed

(see "Installation of safety applications"). The force must never be

set to move a stuck door.

Too high a force leads to faults in the

proper operation of the reversing system

or to damage to the door.

To remind all operators of the safety

procedures the corresponding warning

sign should be attached beside the

operating control unit.

To avoid damage to the door all the

blocking devices should be deactivated.

If however the blocking devices must

remain in operation an unlatching switch

can be installed.

The three-switch block, main disconnecting switch and all other

control devices must be installed

within view of the door and out of

reach of children. Children should not

be allowed to operate switches or the

remote controller. Misuse of the door

opener can lead to serious injuries.

The door opener may only be

operated if the operator can see the

whole door area, if it is free from

obstacles and the door opener is

properly adjusted. No one may pass

through the door while it is moving

and children must not be allowed to

play in the vicinity of the door.

Before carrying out repairs or removing the covers on the door

opener, it is essential to ensure that

no one can inadvertently start the

drive by installing a lockout device or

disconnecting the cables.

This symbol means "Caution" and stands in front of safety advice intended to avoid

personal injury or material damage. Please read such advice carefully. The door drive is of

course designed and tested for safe operation. It is however only possible to guarantee this

if the following safety instructions are accurately followed during installation and operation.

This symbol is intended to advise that if the respective instruction is not followed serious

personal injury or material damage can occur.

IMPORTANT SAFETY INFORMATION

3

Before installation, operation or maintenance of this door drive,

this operating manual must be read through carefully

and all the safety advice must be followed.

Page 4

In doing so you should also follow:

· The instructions in this manual

· All other project planning documents for the drive

· The start-up instructions and circuit diagrams

· The currently-valid national regulations (safety and accident prevention)

Guarantee, storage

It is essential to follow these instructions and advice since they are the basis for trouble-free operation as well as for any

guarantee claims. Check the delivery immediately after receipt for any transport damage. Report any damage immediately

to the transport company as well as to the supplier. If you do not install the geared motor straight away you should store it in

a dry, dust-free, low-vibration room at temperatures between 0 and +40°C.

Zustand bei Auslieferung

Delivered condition

Every geared motor is manufactured according to the valid technical documentation and subjected to a test run at

Chamberlain. We retain the right to make changes to technical data and design, which are in the interests of progress.

Dispatch takes place in the appropriate packaging.

4

IMPORTANT SAFETY INFORMATION

Live and moving parts of electrical

machines can cause serious or fatal

injuries. The installation, connection

and starting up, as well as maintenance and repair work may only be

carried out by qualified specialist

personnel.

To avoid damage to the door or the

drive, all the locking devices must be

put out of operation. Set locking

device(s) to the "Open" position. If a

lock is to remain in operation an

unlatching switch must be installed.

Please find the technical data for the geared motor

from the type plate or from the attached documents.

We thank you for purchasing our product.

If you still have questions on the installation then please contact:

Chamberlain GmbH, Alfred-Nobel-Str. 4,

66793 Saarwellingen Germany

Tel: (0049)(0)6838-907222

Fax: (0049)(0)6838-907179

e-mail: info@garog-service.de

Internet: www.garog-service.de

GENERAL INFORMATION

Page 5

5

The drive may only be installed:

If the details on the rating plate on the drive correspond with the mains voltage.

If the drive is undamaged

If the ambient temperature is between 0 and 40°C

If the installation height is not more than 1000m above sea level

If the type of protection has been appropriately selected.

Output shafts and mounting surfaces are to be thoroughly cleaned to remove the corrosion protection agent (use standard

commercial solvent). To avoid material damage the solvent must not get onto the sealing edges of the rotary shaft seals.

Abrasive agents must not be used.

To avoid shaft breakages and hence serious or fatal injuries it is essential to note the following during mounting:

The precondition for suitable dimensioning of the shaft with respect to its fatigue strength is stress-free installation and an

immovable bearing device for the gearbox support as well as any additional or essential supporting bearings in each

direction as supplied by the user.

The machine frame and force introduction points are to be designed with respect to construction and strength according to

the bearing forces which arise. The gearbox housing with two bearings and all the other bearing points are located on a

common, stable framework on which the bearing surfaces have been machined in one operation. Thereby the installer

must ensure that any deformation of the frame under load will not have any negative influences on the shaft load. The

screws may only be fully tightened once the gearbox has been accurately aligned. Installation in damp rooms or in the open

air is only permitted following agreement with the manufacturer. If the drives are stored for a lengthy period of time it is also

necessary to discuss this with the manufacturer.

PREPARATORY MEASURES

Before starting the installation work make sure that all the

necessary safety measures have been implemented.

1. Installation

Place machine down on smooth mounting plate or aligned slide rails and tighten fixing

screws uniformly.

Make sure beforehand that:

The drive is not damaged or sticking

The drive has been reprepared after a lengthy storage period

The supply line is switched off and safeguarded against being switched on again

(VDE regs.) (VDE = German assoc. of electronic engineers)

The connections have been made properly

The turning direction of the geared motor is correct

All motor protection devices are active

No other danger sources exist

INSTALLATION ADVICE

Page 6

6

INSTALLATION ADVICE

Commissioning:

During commissioning check whether:

The drive does not get excessively hot

In the event of unusual running noises the drive must be stopped immediately and Customer Services should be

informed. If oil is lost Customer Services should be called, the oil level should be checked by means of the dipstick on the

vent screw and the drive must also be switched off if the level falls below the minimum filling quantity.

T o ensure efficient support in the event of a fault we require the following information:

The data from the type plate on your drive unit

The type and extent of the fault

When and under what accompanying conditions the fault occurred.

Whether the drive was subject to speed variations or other distinctive happenings

Electrical connection

The connections according to the circuit diagram and the maintenance of the electrical drive may only be

carried out by electrical specialist personnel.

The corresponding accident prevention regulations must be followed.

For switching the motor and the brake connections, switching contacts of

utilization category AC-3 acc. to IEC 158 must be used.

The types of line and their cross-sections must be selected according to the

relevant regulations. The nominal flows and the type of connection are given

on the motor type plate. The drive details must agree with the connected

values.

If operated with electronic control devices it is essential to take account of

the corresponding start-up instructions and circuit diagrams.

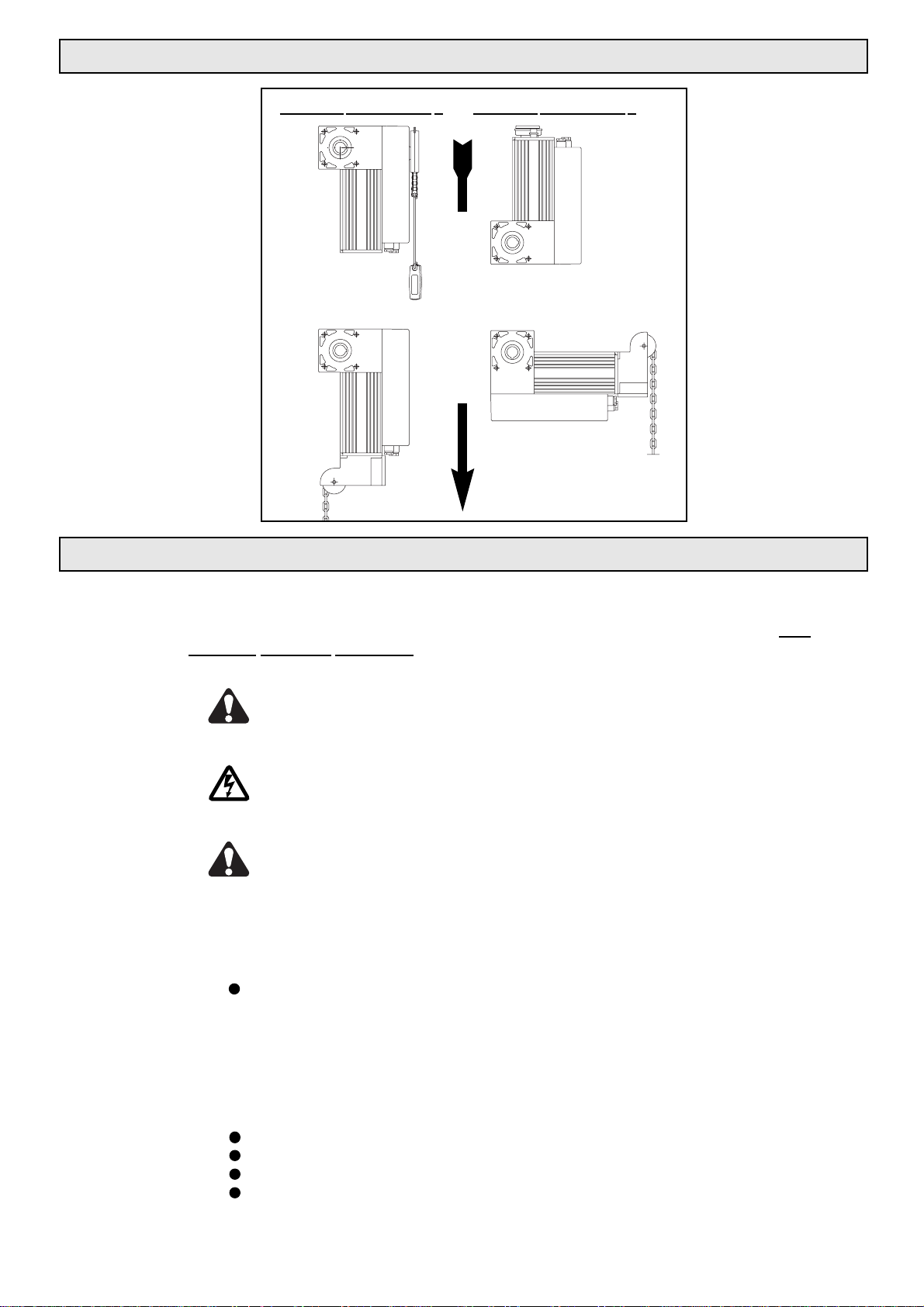

MOUNTING ARRANGEMENT

Closing direction

Mounting arrangement 1

Mounting

arrangement 2

1a 2a

1b

2b

Page 7

7

ELECTRICAL CONNECTION

Before the installation of power cables and control devices it is essential to take note of all the

following specifications and warnings. If they are not heeded serious injuries or damage to the

drive can occur.

The control housing of the door drive may only be opened by trained"Chamberlain" specialist

personnel. If necessary please contact your local Chamberlain dealer.

Before electrical installation or the starting up of the drive please study the circuit diagram

carefully. The valid local regulations must be followed for all the electrical wiring work.

Before carrying out any maintenance work on the door drive it is first necessary to disconnect

the power supply / power transmission at the main switch.

After completion of the maintenance work the danger zone must be cleared and secured again

before restarting.

If you require additional accessories or spare parts

please contact your local Chamberlain dealer.

CHAMBERLAIN - GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

ORDERING FAX NO: (0049)(0)6838-907179

TECHNICAL HOTLINE: (0049)(0)6838-907222

l A: Pushbutton for control by holding down continuously

l B: Keyswitch, or suchlike for controlling by means of continuous actuation

l C: Limitation of driving force by force limiting (clutch) and protection devices

(safety edge padding).

l D: Device to detect people or obstacles which are on the ground on one side (inside) of the door

leaf (infrared light barrier)

l E: Device to detect people or obstacles which are on the ground on both sides

(inside and outside) of the door leaf (infrared light barrier).

ADVICE: For more detailed information see EN12453.

MATRIX FOR THE USE OF SAFETY EQUIPMENT

Control by continuous switch

operation

Pulse actuation within visual

range of door

Automatic control

Trained

people(inaccessible

to the public)

Group 1

A

C

C and D

(General public area)

Group 3

No info.

C and E

C and E

Public area

Group 2

B

C and D

C and E

TYPE OF CONTROL DOOR WILL BE USED BY

Page 8

8

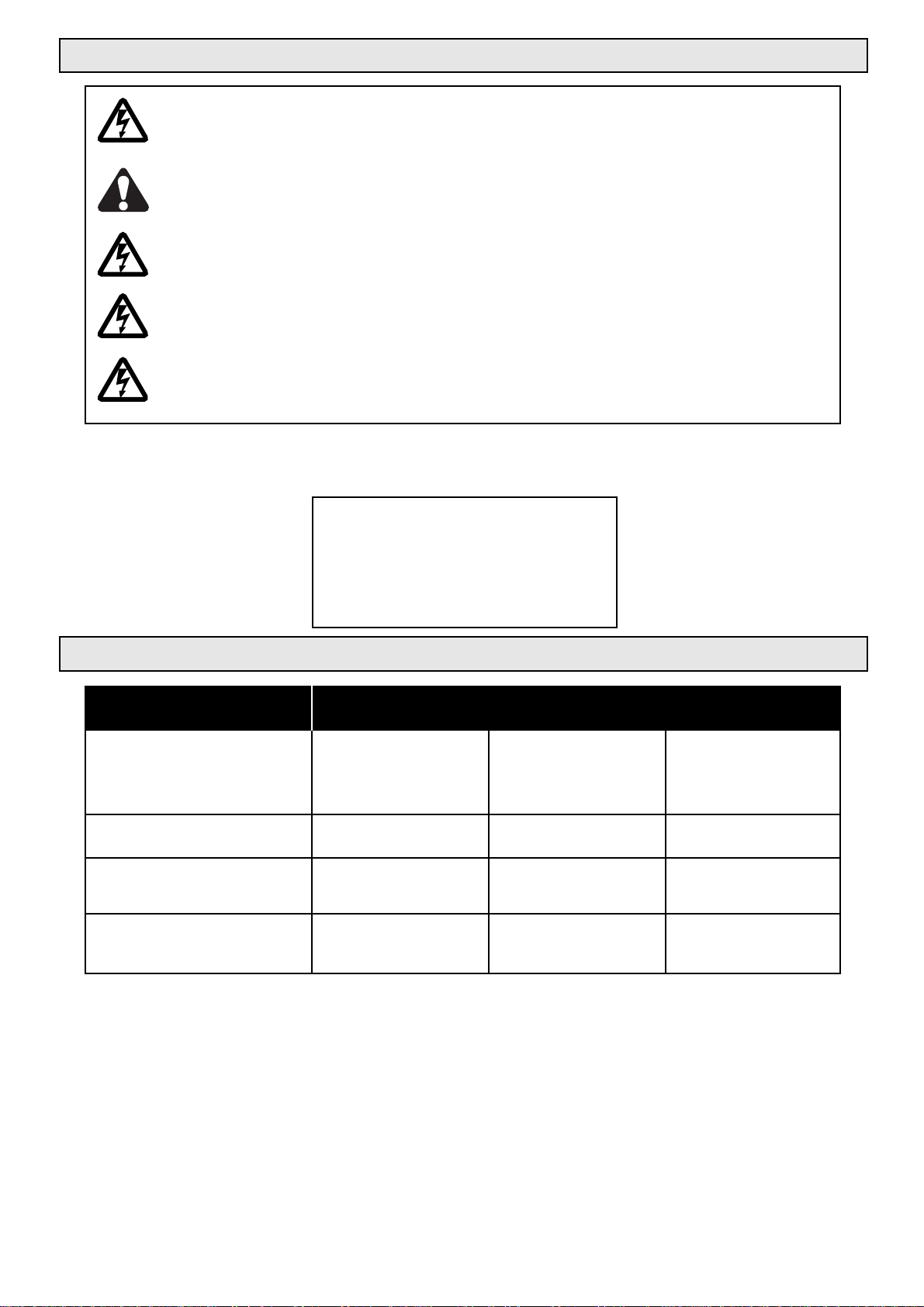

NEC LIMIT SWITCH WITH ILLUSTRATION

Limit switch setting:

The limit switch is delivered in a non-adjusted state. It has two all-purpose cams which each consist of an operating

limit switch and a safety limit switch (black and yellow cams) and potential-free contacts (grey, white and blue

cams). The design of the new cams significantly simplifies the setting of the end positions, since both the end

position as well as the respective safety limit switch can be set in one movement.

The limit switch configuration is explained in the illustration above. Move the door in "dead-man" state to the

end position to be set and place the adjusting screwdriver into the stud screw for coarse setting as shown in

the right-hand picture. Set the all-purpose cams for the corresponding end positions (BLACK for UP and

YELLOW for DOWN) so that the microswitch is almost actuated.

Note: Take note of the approach direction of the cam to the microswitch. Tighten the screw thus

safeguarding the cam from turning.

Now turn the fine setting screw on the operating limit switch until the limit switch is actuated. Check the end

position in travel operation. For re-adjustment purposes the door should always be travelled about 0.5 m

away from the respective end position.

In the normal situation it is not necessary to separately set the safety limit switch since delayed switching of

the safety limit switch is guaranteed due to the special shape of the actuating noses on the all-purpose

cams. This means it is unimportant from which side the microswitch is actuated. However in the normal

case the safety limit switch should be actuated about 10 cm after the normal end position has been

reached. It is possible to alter this switching point at any time by means of the "Safety limit switch - fine

setting" (see picture at top right).

Repeat the procedure for the other end position. If the safety limit switch is actuated an error is displayed

optically in the case of GAROG processor controllers. Don't forget that after finishing the setting work the

coarse setting screws must be tightened up so that the limit switch cannot move during door operation. The

cams in the supplementary contacts, which can be overrun, can only be adjusted with the coarse setting

screw.

Two freely-adjustable changeover contacts

(grey and blue cams) are fitted to plug-in terminals.

A third switch is set as a pre-limit switch (white cam).

"UP"

limit switch,

black

"DOWN"

limit switch,

yellow

Operating

limit switch -

fine setting

Coarse

setting

Safety limit

switch - fine

setting

Switching nose for

safety limit switch

Switching nose for

operating limit switch.

Page 9

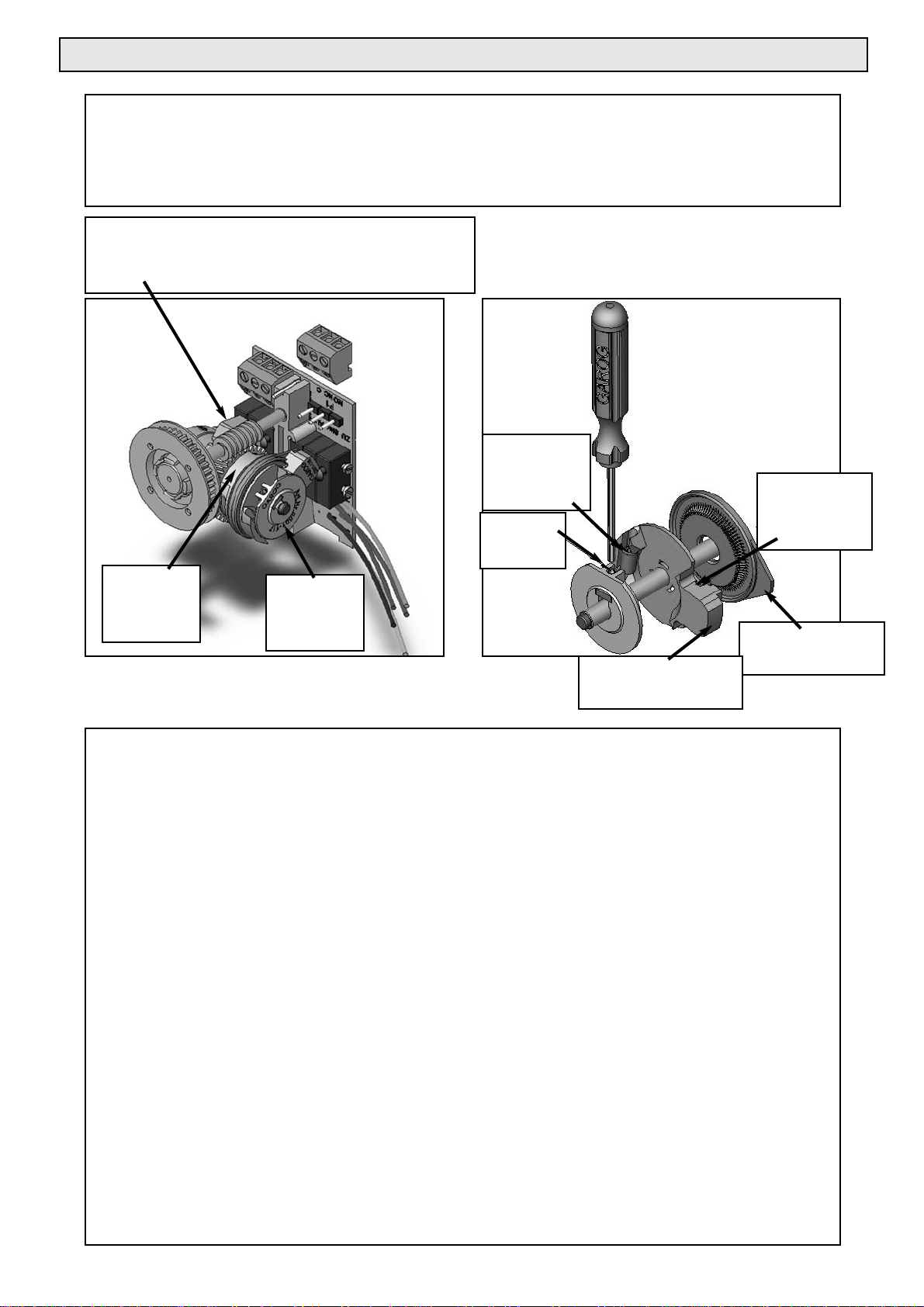

CAM LIMIT SWITCH WITH CONNECTING TERMINAL STRIP

9

Redundant safety devices are self-monitoring, i.e. they can detect an error within the

circuit and in the device connections. This type of circuit requires the use of selfmonitoring sensing equipment.

Safety contact for

emergency

chain / crank

Supplementary

limit switch,

grey

Operating

limit switch,

DOWN,

yellow

Operating limit

switch, UP,

black

Safety limit

switch

Controller fuse, 1.6A

Supplementary

limit

switch,

white

Supplementary

limit switch,

blue

Page 10

CIRCUIT DIAGRAM STS1 / NEC / MOTOR

10

Limit switch UP

Limit switch DOWN

Safety limit switch

RELAY

STS1

NEC

INCORRECT

VOLTAGE

DESTROYS

THE TRANS-

FORMER

INCORRECT

VOLTAGE

DESTROYS

THE TRANS-

FORMER

Caution: Earth should be connected to motor housing

Caution: Earth should be connected to motor housing

CONTACTOR

TRANSFORMER

COM

ES UP

VE

SHK

ES DOWN

COM

400V

VOLTAGE

SELECTION SWITCH

VOLTAGE

SELECTION SWITCH

230V

400V

230V

Black

Light blue

Brown

Yellow

Green

Red

24V

LED

STOP

STOP

UP

UP

VE

SKS

DOWN

DOWN

Crank

switch

Thermostat

Limit switch UP

Limit switch DOWN

Safety limit switch

RELAY

CONTACTOR

TRANSFORMER

400V, 3 phase feed

230V, 3 phase feed

COM

ES UP

VE

SHK

ES DOWN

COM

Black

Light blue

Brown

Yellow

Green

Red

24V

LED

STOP

STOP

UP

UP

VE

SKS

DOWN

DOWN

Crank

switch

Thermostat

Page 11

CIRCUIT DIAGRAM - STS1

11

Jumper J1 bridged over =

Self-latching upward travel

Redundant safety devices are self-monitoring, i.e. they can detect an error within the

circuit and in the device connections.

This type of circuit requires the use of self-monitoring sensing equipment.

INCORRECT

VOLTAGE

DESTROYS

THE TRANSFORMER

VOLTAGE

SELECTION SWITCH

400V

230V

Feed cable / CEE plug

"Stabantenne" = Rod aerial

Garog DK series door drive

with STS1 controller

Before switching over

read operating manual

Triple button with LED

Ch. A B C

CFU3 - 3 Channel wireless control

Switching strip with NC contact

Door contact or slack rope switch

Connection example 4: Self-latching

STS1 with triple button, door contact and 3-channel remote controller

Caution: Earth should be connected to motor housing

Caution: Switching over to 230V may only be

carried out in the case of 3 x 230V applications.

UP

STOP

UP DOWN

STOP

UP

DOWN

DOWN

Page 12

CAM LIMIT SWITCH WITH CONNECTING TERMINAL STRIP + TST2 CONTROLS

12

AA

AATTTTTTTTEEEE

NN

NNTTTTIIII

OO

OO

NN

NN!!!!!!!!!!!!

CC

CCIIII

RR

RR

CC

CC

UU

UUIIIITTTT

DD

DDIIII

AA

AA

GG

GG

RR

RR

AA

AA

MM

MM

MM

MM

HH

HH

AA

AASSSS

BB

BBEEEEEEEE

NN

NN

CC

CC

HH

HH

AA

AA

NN

NN

GG

GGEEEE

DD

DD!!!!!!!!

Page 13

CIRCUIT DIAGRAM EWS2T/TST1

13

Page 14

TECHNICAL DATA - DK / DKS DRIVES

14

Chamberlain Garog base set drives include the ready wired door drive with a potential-free cam limit switch

(NE) or a 24V contactor controller (STS) with cam limit switch (NEC). Various types of emergency actuators

are available: The short emergency crank handle (NHK), the automatic emergency chain (NKU) as well as

the quick-action clutch (DKS).

MODEL

TYPE

RPMLIMIT SWITCH EMERGENCY ACTUATION

NHK-Emergency crank handle

NHK-Emergency crank handle

NKU-Emergency crank handle

NKU-Emergency crank handle

NKU-Emergency crank handle

NKU-Emergency crank handle

NKU-Emergency crank handle

NKU-Emergency crank handle

DKS - Quick-action clutch

DKS - Quick-action clutch

Article

Description

Torque bracket E719 - zinc-plated flat steel with fixing screws

for sectional doors DK(S) 70-90

Chain hoist extension (HK4) - 4m chain length, 4 mm,

with two connecting elements.

Articulated crank (E1111) with universal joint, useful in restricted installation

conditions (drive mounted on wall)

Mounting set for indirect drive - DK series - for sectional doors, complete

with assembly brackets (E - 1104), 1" plug-in shaft, setting rings, chain

wheel transmission ratio 1:1, 1.5 m chain, 2 pinions - ½ * 3/16"

Technical data

Type:

Motor power

Torque

Speed

Duty factor

Type of motor protection

[rpm]

DF

Operating voltage

Nominal current

Hollow shaft

Weight:

Accessories for sectional door drives

Page 15

DIMENSIONAL DRAWINGS DK / DKS DRIVES

15

4xM10, depth 20,

362

98

293

270

209

both sides

50

50

74

74

100

49

ª

DK...NKU

293

270

27

98

96,5

49

74

209

50

50

100

74

ª

4xM10, depth 20,

both sides

DK...NHK

M

O

T

O

R

H

A

N

D

293

270

98

96,5

231.5

49

74

209

100

50

74

50

ª

4xM10, depth 20,

both sides

DKS

Fig. 1

Page 16

16

CIRCUIT DIAGRAM: SEK

DIMENSIONAL DRAWINGS DKA DRIVES 1.1

Technical Data

Chamberlain Garog base set drives include the ready wired door drive with a potential-free cam limit switch

(NE) or a 24V contactor controller (STS) with cam limit switch (NEC). Various types of emergency actuators

are available: The short emergency crank handle (NHK), the automatic emergency chain (NKU) as well as

the quick-action clutch (DKS).

K

25

kurze Kurbel

(Serie NHK)

122

108

96.2 72.5

Emergency manual

chain gearbox

NKW (from DKA250)

Emergency manual

chain gearbox

NKU (from DKA200)

94

MODEL

TYPE

RPM

LIMIT SWITCH

EMERGENCY ACTUATION

NHK-Emergency crank handle

NHK-Emergency crank handle

NKU-Emergency crank handle

NKU-Emergency crank handle

NHK-Emergency crank handle

NHK-Emergency crank handle

NHW-Emergency crank handle

A2B-Emergency crank handle

A2B-Emergency crank handle

A2B-Emergency crank handle

A2B-Emergency crank handle

A2B-Emergency crank handle

Type:

Motor power

Torque

Speed

Duty factor

Type of motor protection

n2 [rpm]

DK NHK

DF

DK(S)

Operating voltage

Nominal current

Hollow shaft

Weight:

Arresting torque

ABE no.

Fig. 2

Page 17

a

D

b

=

25

=

25

L1L2

B3

A2

L5

108.5

B4 ... B5

s

9.5

B6

B2

20

Bracket type

OKD5-8

Torque angle

DW1 to DW3

B1

I

0

L3

A1 A2 A3

Space requirement

to lift cover

ª

Articulated food - article G-GF

do not use for DKA120

a

D

b

17

DIMENSIONAL DRAWINGS DKA DRIVES 1.2

Section 2

Fig. 3

Fig. 4

Drive type:

Drive dimensions (in mm)

Page 18

18

DIMENSIONAL DRAWINGS - ANGLE BRACKETS / UNIVERSAL BRACKETS

Fig. 5

L3

6

150

70

45,5

B3

B6

B4...........B5

Fig. 6

WK angle brackets

OKD universal brackets with bearings

Angle brackets: WK3L or 3R /

WK4L or 4R / WK5L or 5R

Bracket

type:

Bracket

type:

Material

thickness

Door

weight

Article no.

for DKA 120

Material

thickness

Door

weight

Article no.

OKD

Page 19

19

DIMENSIONAL DRAWINGS - WELDED AXES / SET COLLARS

CALCULATION OF LIFTING SPEED

L

5

L2

Ød

b x h

M100

Fig. 7

Formula for roller door speed calculation:

Vm = Average lifting speed in cm/sec

D = Largest bale diameter in cm

d = Smallest bale diameter in cm

n = Nominal speed of drive in rpm

3,14 = Circle constant

π

Vm=

(D+d x 3,14 x n)

2 x 60

[cm/sec]

Welded axes / set collars

Axis

Dia. d

w x h

Use

Article no.

Welded axes and set collars

Bearing side

Drive side

Drive side

Both sides

Both sides

Set collar 30

Set collar 40

h9 fit

none

none Bearing side

Table for determination of the lifting speed & lifting force for roller doors

* = Theoretical values, direct on the winding shaft, 20% deduction for friction has already been calculated.

With special door dimensions a load arm increase must be separately considered due to the profile thickness

Roller/bale diameter

V with n2 = 14 rpm

V with n2 = 16 rpm

Lifting force with M = 120 Nm

Vm (sm/sec)

Page 20

20

If for whatever reason your drive does not operate as desired or not as is described in the operating

manual, please first check whether you have read and correctly followed all the instructions. If faults are

still occurring please make contact with your local Chamberlain

dealer who will be happy to support

you in rectifying the fault.

Before carrying out any maintenance work on the door drive it is first necessary to disconnect the

power supply / power transmission at the main/ emergency switch. All maintenance work may only be

carried out by trained "Chamberlain"

specialist

personnel. If necessary please contact your local

Chamberlain

dealer.

MAINTENANCE PLAN

Maintenance

All gearboxes are filled with lubricant in the factory. This lubricant is suitable for at least 1000 operating

hours. After this time or at the very latest every 6 years it is advisable to renew the special oil. For this

purpose only SHELL OMALA 460 should be used in the following filling quantities. The oil quantities for

the different types of drive are as follows:

In the case of low running times and favourable temperature conditions the lubricant may still be fit for use even

after 6 years. In this case however we still recommend that about 1/3 of the given amount of lubricant is added.

If losses of lubricant take place it is necessary to top up with the special oil given above at the correct

time.

Before starting up, a check should be made on whether all the internal and external conditions have been met so

as to ensure perfect functioning.

Drive Filling quantity Filling quantityDrive

Page 21

21

GUARANTEE AND STORAGE

Definition of qualified personnel

Within the meaning of the operating manual and the warning information concerning the product itself, these are people

who are familiar with the setting out, installation, commissioning and operation of the product and have suitable

qualifications for their work, such as:

a. Training or instruction in, and authorization to connect up, switch on and off, earth and mark power circuits and

devices according to the engineering safety standards.

b. Training or instruction according to engineering safety standards in the care and use of the appropriate safety

equipment.

c. Training in first aid.

The fitting of drive elements

The fitting of drive elements such as rope pulleys, wheels etc is best done after previous warming of the respective part.

The preheating temperature should be 100°C.

A precoating of a copper paste eases mounting and provides long-term protection from frictional corrosion.

To avoid damage to bearings, housings and shafts the drive elements must never be mounted on the end of the

shaft by hammer blows.

The fitting of drive elements by means of pressure requires a force introduction surface (seating on output shaft).

Fitted transmission elements must be counterbalanced and must not cause any non-permitted radial or axial forces.

The corresponding tolerances must be observed during the fitting work (see dimension drawing).

Page 22

22

The spare parts kits obtainable for your drive are given in the following parts lists. If your drive

already has optional modifications and/or accessories, certain parts can be added or removed from

the list. Possibly individual parts of a kit are not obtainable - please contact a member of staff

responsible for spare parts and maintenance. He will be happy to inform you about the availability of

individual parts in the kits listed below.

You will find general information on ordering on page 24.

SPARE PARTS

Art. no: GA-DK70/30

Art. no: GA-DK90/22

Art. no: GA-DK120/16

Art. no: GA-DK200/14

NEC cam limit switch system for DK70 - DKA120

NEC cam limit switch system for DK200 - DKA300

NEC cam limit switch system for DK300 - DKA500

NE cam limit switch system for DK70 - DKA120

NE cam limit switch system for DKA200 - DKA300

NE cam limit switch system for DKA400 - DKA500

Art. No.: 041G-NHK-GH1 Emergency hand crank for GH1/DK series

Art. No.: 041G-NHK-GH2 Emergency hand crank for GH2/DK series

Art. No.: 041G-NHK-GH3 Emergency hand crank for GH3/DK series

Art. no: GA-DK250/14

Art. no: GA-DK300/14

Art. no: GA-DK400/14

Art. no: GA-DK500/14

MOTOR / GEARBOX

LIMIT SWITCHES

MECHANICAL SPARE PARTS

Page 23

NOTES

23

Page 24

Anl.-Nr. 709413

This is how to order:

When ordering spare parts or accessories we need

the following information from you:

Part number, description, model number

IN EUROPE

ADDRESS FOR ORDERS:

Chamberlain

-GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

TEL. NO. FOR ORDERS:

+(49) 6838-907222

FAX NO. FOR ORDERS:

+(49) 6838-907179

TECHNICAL HOTLINE:

+(49) 6838-907222

ONLINE-SERVICE:

www.garog-service.de

IN NORTH AMERICA

ADDRESS FOR ORDERS:

The Chamberlain Group Inc.

Electronic Parts and Service Department

2301 N. Forbes Blvd., Suite 104

Tucson, Arizona 85745 USA

TEL. NO. FOR ORDERS:

1-520-792-0511

FAX NO. FOR ORDERS:

1-520-884-0966

TECHNICAL HOTLINE:

1-800-528-2806

Declaration of Conformity

The industrial door drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

corresponds to the applicable sections and standards . . . . . . . . . . . . .

in accordance with the regulations and amendments

of EU Guidelines……………………………………………………………73/23EEC & 89/336/EEC

Manufacturer's Declaration

Provided that the industrial door drive, Series DK type is installed and maintained in accordance with all the

manufacturer's instructions in conjunction with an industrial door, which is also installed and maintained in accordance

with all the manufacturer's instructions, it meets the regulations of EU Guideline 89/239/EEC in its amended form.

Chamberlain-GmbH

66793 Saarwellingen

August 2004

Loading...

Loading...