Page 1

The Chamberlain Group, Inc.

845 Larch Avenue

Elmhurst, Illinois 60126-1196

www.liftmaster.com

GARAGE DOOR OPENER

Model 3885C 3/4HP

For Residential Use Only

Owner’s Manual

■ Please read this manual and the enclosed safety materials carefully!

■ Fasten the manual near the garage door after installation.

■ The door WILL NOT CLOSE unless the Protector System

®

is connected and properly

aligned.

■ Periodic checks of the opener are required to ensure safe operation.

■ The model number label is located under the light lens on the left side panel of your

opener.

®

Page 2

Introduction 2-5

Safety symbol and signal word review........................2

Preparing your garage door ........................................3

Tools needed...............................................................3

Planning .....................................................................4

Carton inventory ..........................................................5

Hardware inventory .....................................................5

Assembly 6-7

Attach the rail to the motor unit...................................6

Set the belt tension .....................................................6

Attach the belt cap retainer .........................................7

Installation 7-22

Installation safety instructions .....................................7

Determine the header bracket location .......................8

Install the header bracket............................................9

Attach the rail to the header bracket.........................10

Position the opener ...................................................11

Hang the opener .......................................................12

Install the control console..........................................13

Install the light ...........................................................14

Attach the emergency release rope and handle .......14

Electrical requirements..............................................15

Install the Protector System®................................16-18

Fasten the door bracket .......................................19-20

Connect the door arm to the trolley .....................21-22

Adjustment 23-25

Adjust the travel limits ...............................................23

Adjust the force .........................................................24

Test the safety reversal system.................................25

Test the Protector System®........................................25

Operation 26-31

Operation safety instructions.....................................26

Using your garage door opener ................................26

Using the wall-mounted control console ...................27

To open the door manually........................................28

Care of your opener ..................................................29

Having a problem? ....................................................30

Diagnostic chart.........................................................31

Programming 32-33

To add or reprogram a hand-held remote control .....32

To erase all codes from motor unit memory..............32

3-Button remotes.......................................................32

To add, reprogram or change

a Keyless Entry PIN ..................................................33

Repair Parts 34-35

Rail assembly parts...................................................34

Installation parts ........................................................34

Motor unit assembly parts .........................................35

Accessories 36

Notes 37-39

Repair Parts and Service 40

Warranty 40

TABLE OF CONTENTS

When you see these Safety Symbols and Signal

Words on the following pages, they will alert you to

the possibility of serious injury or death if you do

not comply with the warnings that accompany them.

The hazard may come from something mechanical

or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following

pages, it will alert you to the possibility of damage to

your garage door and/or the garage door opener if

you do not comply with the cautionary statements

that accompany it. Read them carefully.

INTRODUCTION

Safety Symbol and Signal Word

Review

This garage door opener has been designed and tested to offer safe service provided it is installed, operated,

maintained and tested in strict accordance with the instructions and warnings contained in this manual.

Mechanical

Electrical

WARNING

WARNING

WARNING

WARNING

2

WARNING

WARNING

CAUTION

Page 3

3

To prevent damage to garage door and opener:

• ALWAYS disable locks BEFORE installing and operating

the opener.

• ONLY operate garage door opener at 120V, 60 Hz to

avoid malfunction and damage.

To prevent possible SERIOUS INJURY or DEATH:

• ALWAYS call a trained door systems technician if

garage door binds, sticks or is out of balance. An

unbalanced garage door may not reverse when

required.

• NEVER try to loosen, move or adjust garage door, door

springs, cables, pulleys, brackets or their hardware,

ALL of which are under EXTREME tension.

• Disable ALL locks and remove ALL ropes connected to

garage door BEFORE installing and operating garage

door opener to avoid entanglement.

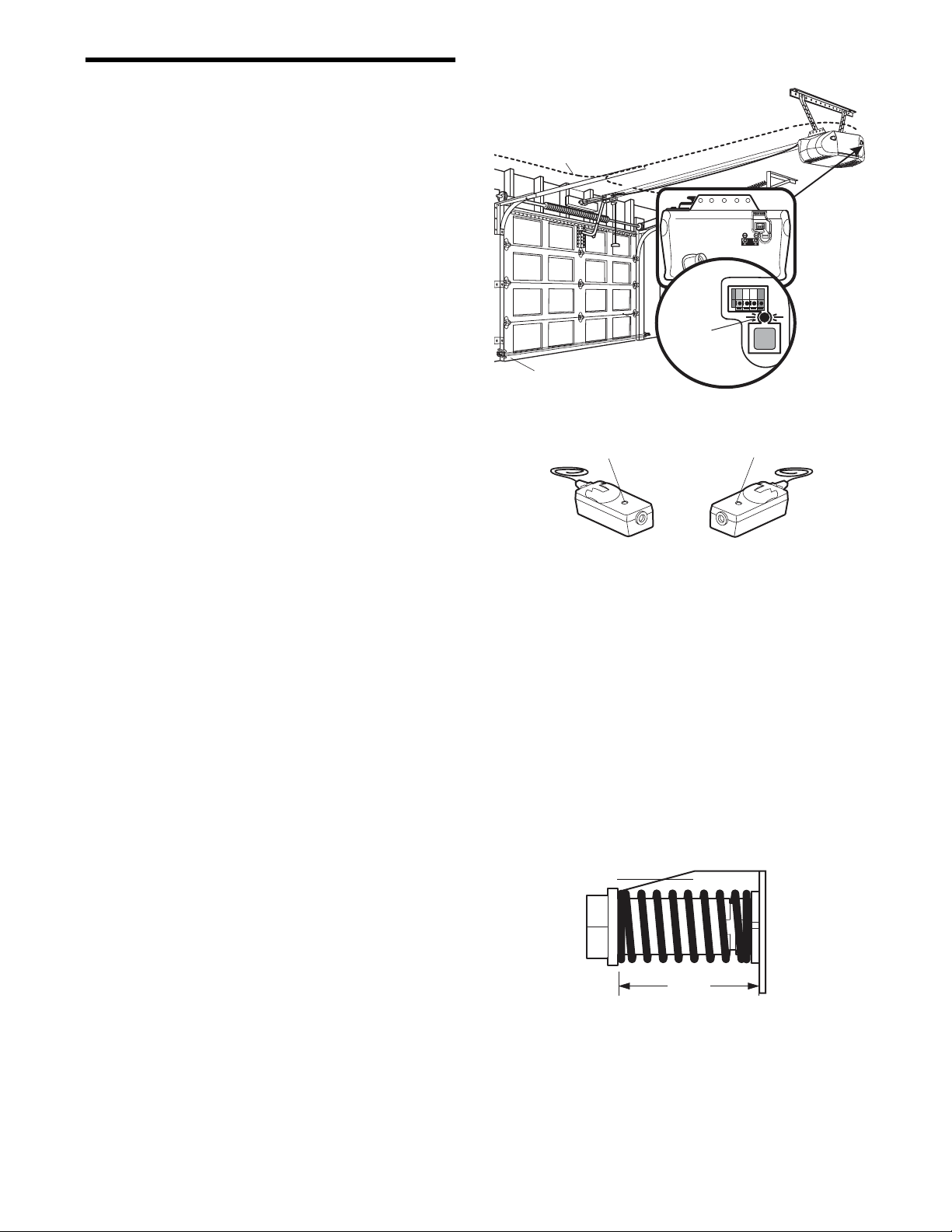

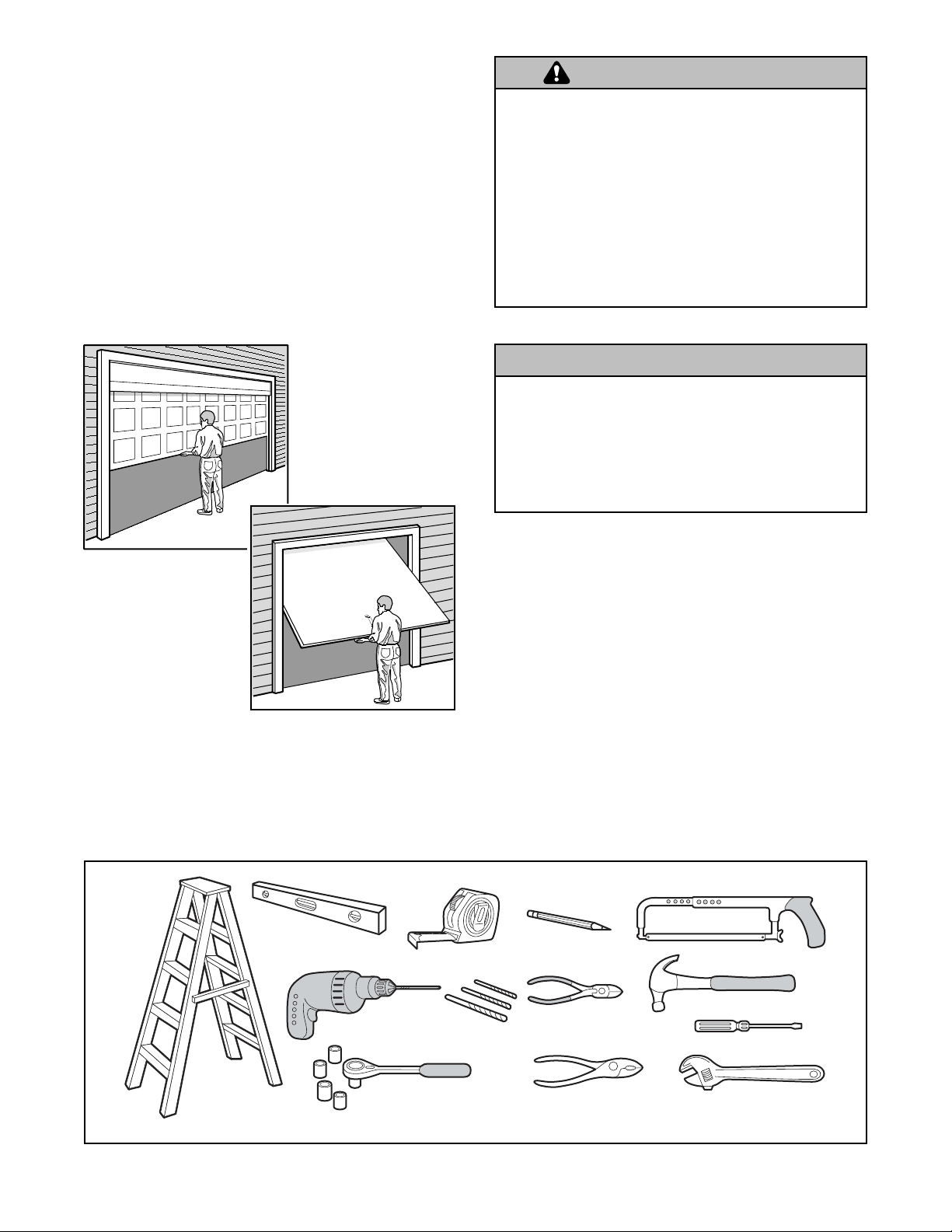

Preparing your garage door

Before you begin:

• Disable locks.

• Remove any ropes connected to garage door.

• Complete the following test to make sure your

garage door is balanced and is not sticking or

binding:

1. Lift the door about halfway as shown. Release

the door. If balanced, it should stay in place,

supported entirely by its springs.

2. Raise and lower the door to see if there is any

binding or sticking.

If your door binds, sticks, or is out of balance, call a

trained door systems technician.

Tools needed

During assembly, installation and adjustment of the

opener, instructions will call for hand tools as

illustrated below.

WARNING

WARNING

WARNING

WARNING

Sectional Door

One-Piece Door

WARNING

CAUTION

Carpenter's

Level (optional)

Drill

2

1

Tape Measure

Drill Bits

3/16", 5/16"

and 5/32"

Pencil

Hack Saw

Claw Hammer

Wire Cutters

Screwdriver

Stepladder

Sockets and Wrench

1/2", 5/8", 7/16", 9/16"

and 1/4"

Pliers

Adjustable End Wrench

Page 4

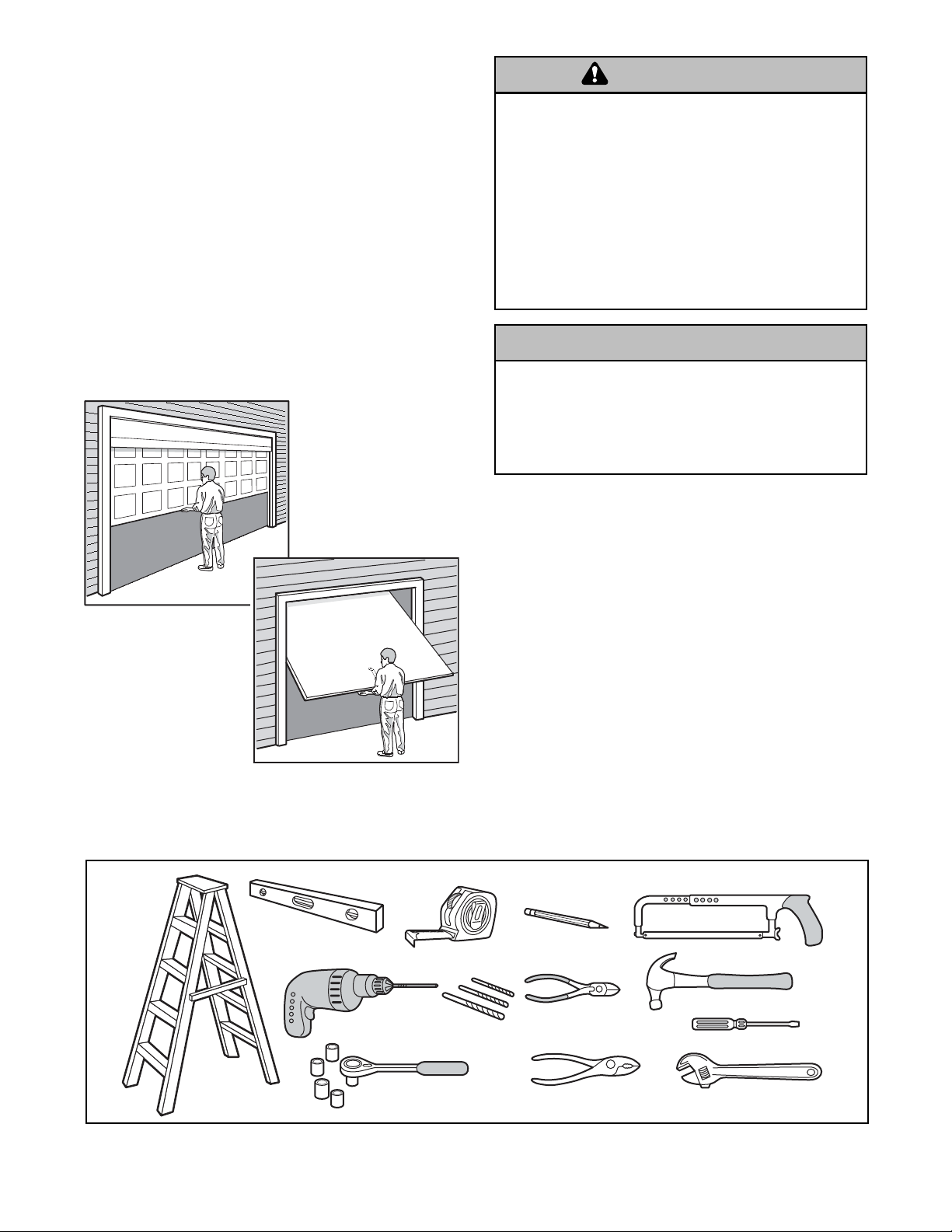

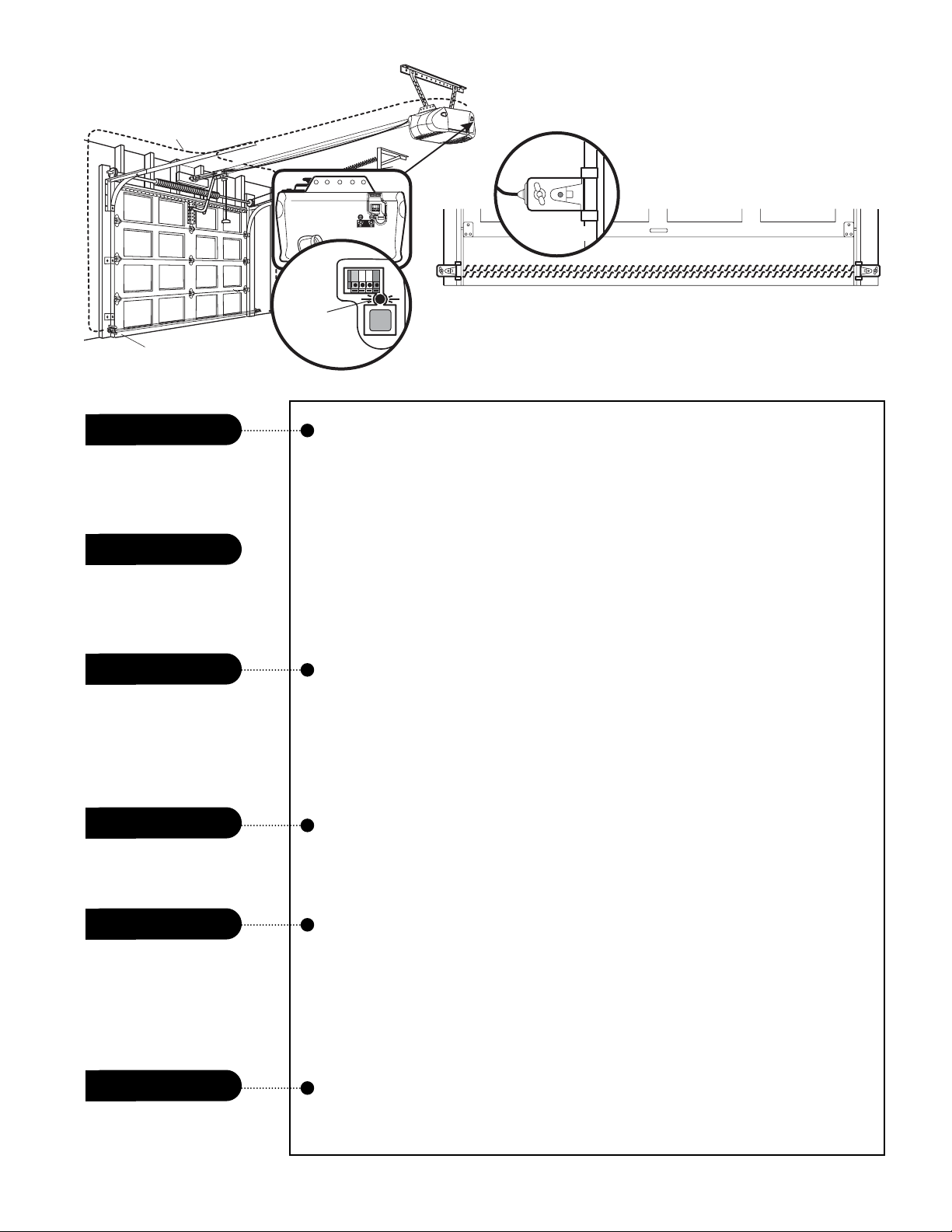

ONE-PIECE DOOR WITHOUT TRACK

4

Planning

Identify the type and height of your garage door. Survey your garage area to see if any of the conditions below

apply to your installation. Additional materials may be required. You may find it helpful to refer back to this page

and the accompanying illustrations as you proceed with the installation of your opener.

ONE-PIECE DOOR WITH TRACK

SECTIONAL DOOR INSTALLATION

Horizontal and vertical reinforcement

is needed for lightweight garage doors

(fiberglass, steel, aluminum, door with

glass panels, etc.). See page 19 for details.

Header Wall

— — — — — — — —

Vertical

Centerline of

Garage Door

Gap between floor and

bottom of door must not

Safety Reversing Sensor

exceed 1/4" (6 mm)

Extension

Torsion

Spring

Safety

Reversing

Sensor

Spring

OR

One-Piece Door-Extension Spring

Door

FINISHED CEILING

Support bracket &

fastening hardware

is required.

See page 12.

OR

Header Wall

Track

Access

Door

Motor Unit

Wallmounted

Door

Control

Header

Wall

Gap between floor and bottom of

Safety

Reversing Sensor

door must not exceed 1/4" (6 mm)

Wallmounted

Door

Control

Safety

Reversing Sensor

Access

Door

FINISHED CEILI

Support

bracket

& fastening

hard

ware is re

See page 12.

NG

quired.

Motor Unit

Gap between floor

Safety

Reversing Sensor

and bottom of door

must not exceed 1/4" (6 mm).

Access

Door

Safety

Reversing

Sensor

Page 5

5

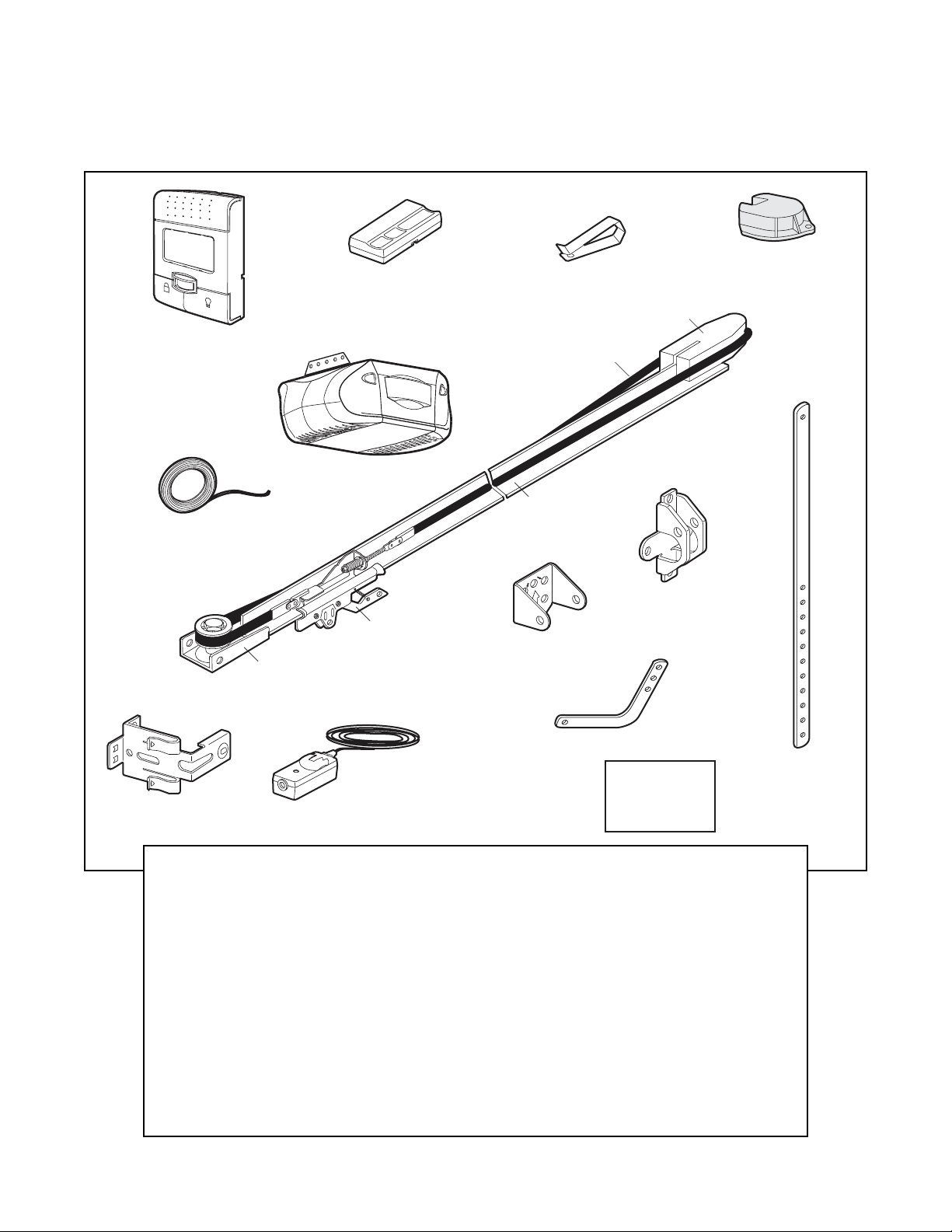

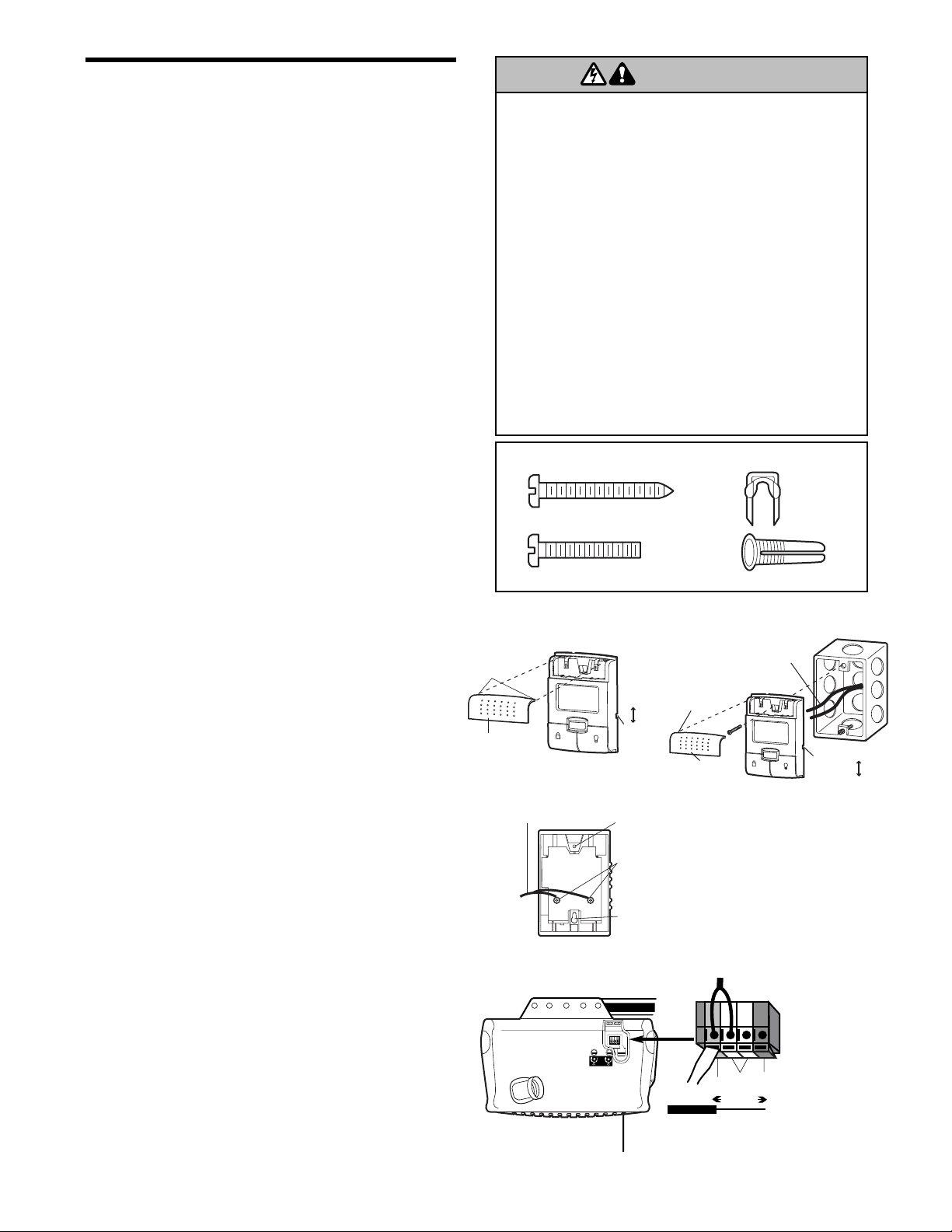

Your garage door opener is packaged in two cartons

which contain the motor unit and all parts illustrated

below. Accessories will depend on the model

purchased. If anything is missing, carefully check the

packing material. Parts may be stuck in the foam.

Hardware for installation is also listed below.

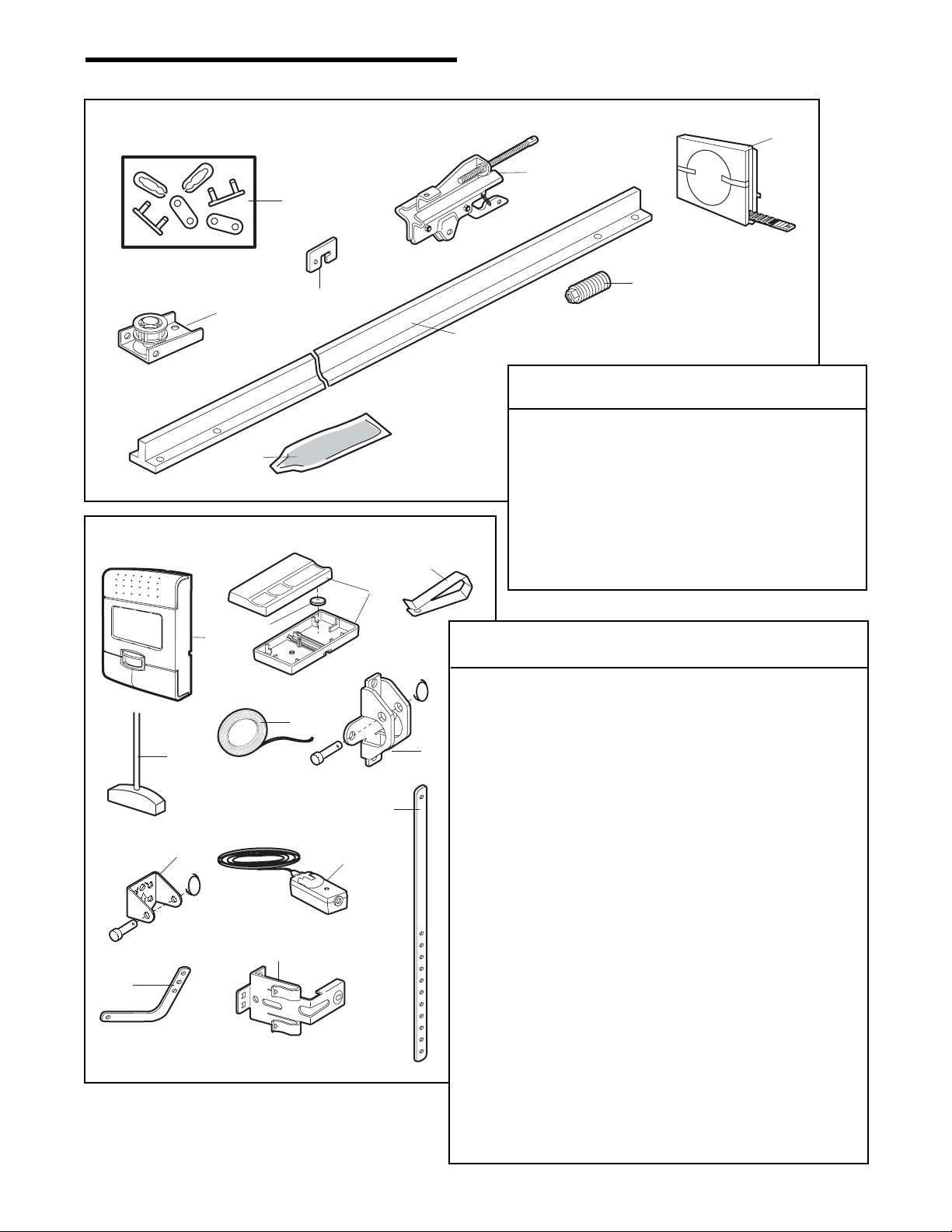

Carton Inventory

INSTALLATION HARDWARE

Hex Bolt 5/16"-18x7/8" (4)

Hex Screw #8 x 3/8" (2)

Lag Screw 5/16"-9x1-5/8" (2)

Lag Screw 5/16"-18x1-7/8" (2)

Clevis Pin 5/16"x2-3/4" (1)

Clevis Pin 5/16"x1-1/4" (1)

Clevis Pin 5/16"x1" (1)

Nut 5/16"-18 (4)

Lock Washer 5/16" (4)

Screw 6ABx1-1/4" (2)

Self-Threading Screw 1/4"-14x5/8" (2)

Screw 6-32x1" (2)

Insulated Staples (30)

Ring Fastener (3)

Drywall Anchors (2)

Rope

Handle

Rail Grease

Carriage Bolt 1/4"-20x1/2" (2)

Wing Nut 1/4”-20 (2)

LOCK

LIGHT

Motion Detecting

Door Control Console (LCD)

2-Conductor Bell Wire

White & White/Red

Belt

Pulley Bracket

SECURITY✚

3-Button Remote Control

Motor Unit w/Light Lenses

®

Trolley

Belt Cap Retainer

Remote Control

Transmitter Visor Clip

Styrofoam

Belt

One-Piece

Rail

Y

L

N

T O

N

U

O

M

G

IN

IL

E

C

P

U

Header Bracket

Door Bracket

Curved Door

Arm Section

Safety Sensor

Bracket (2)

The Protector System

(2) Safety Reversing Sensors

(1 Sending Eye and 1 Receiving Eye)

with 2-Conductor White & White/Black

Bell Wire attached

®

Safety Labels

and

Literature

Straight Door

Arm Section

Page 6

6

To avoid SERIOUS damage to opener, ONLY use

bolts/fasteners mounted in top of motor unit.

WARNING

WARNING

WARNING

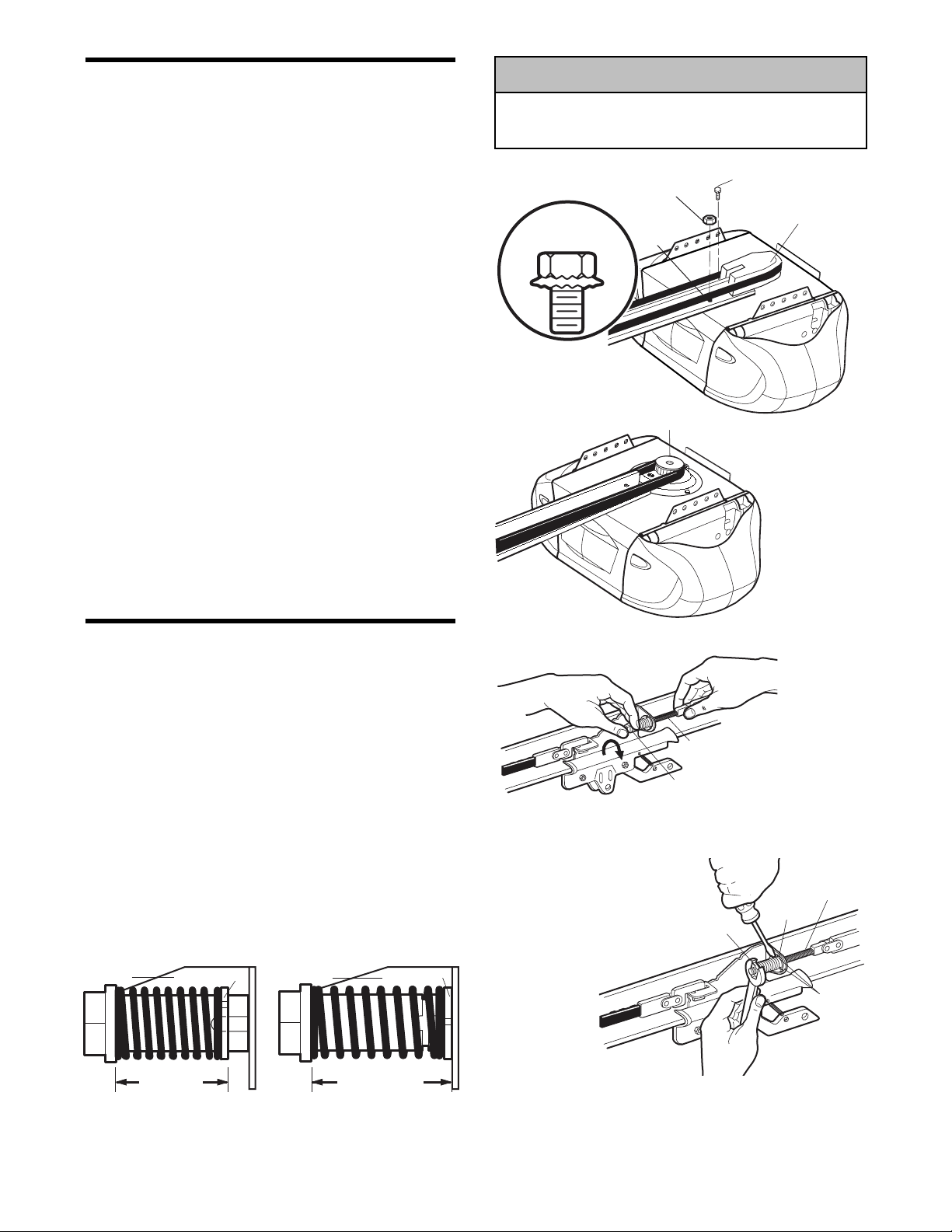

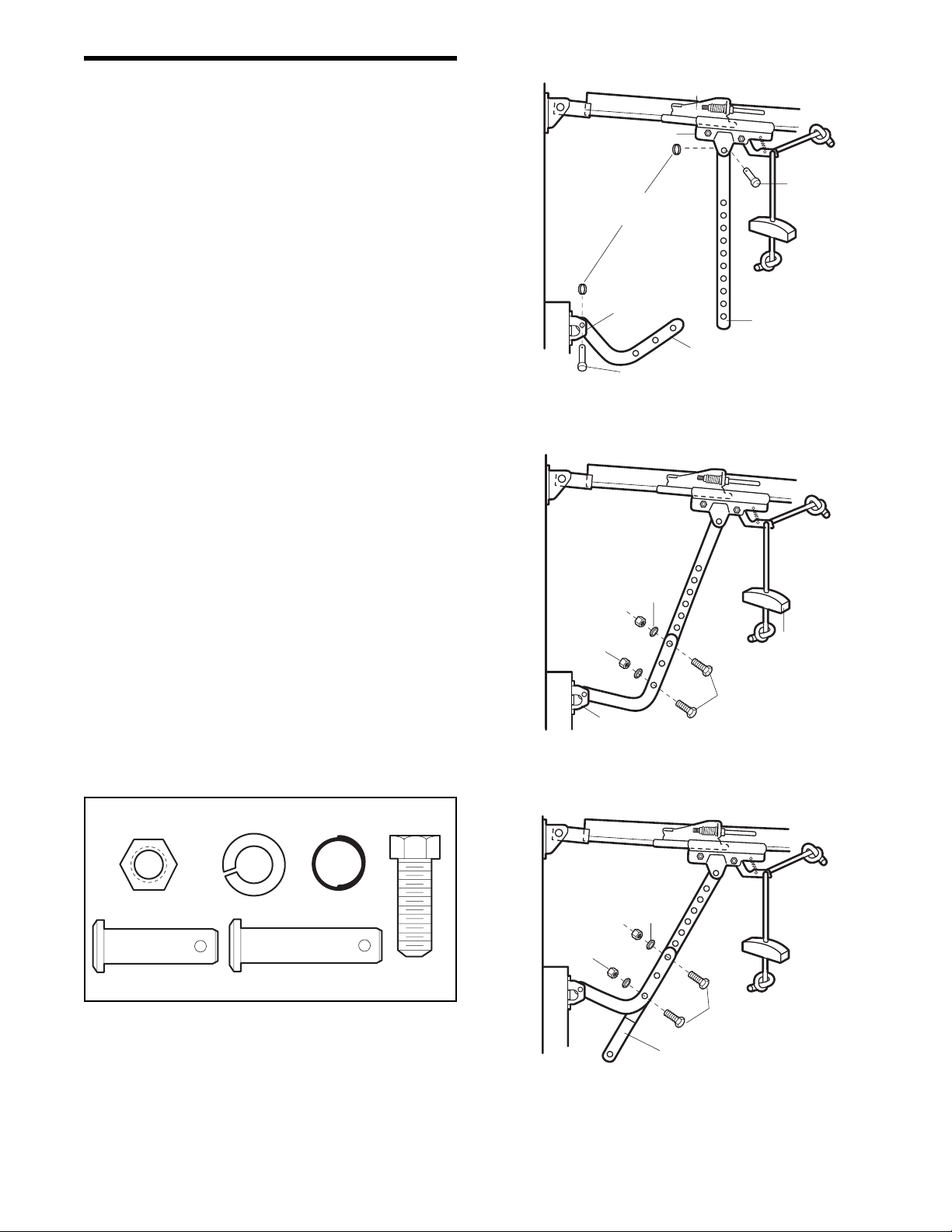

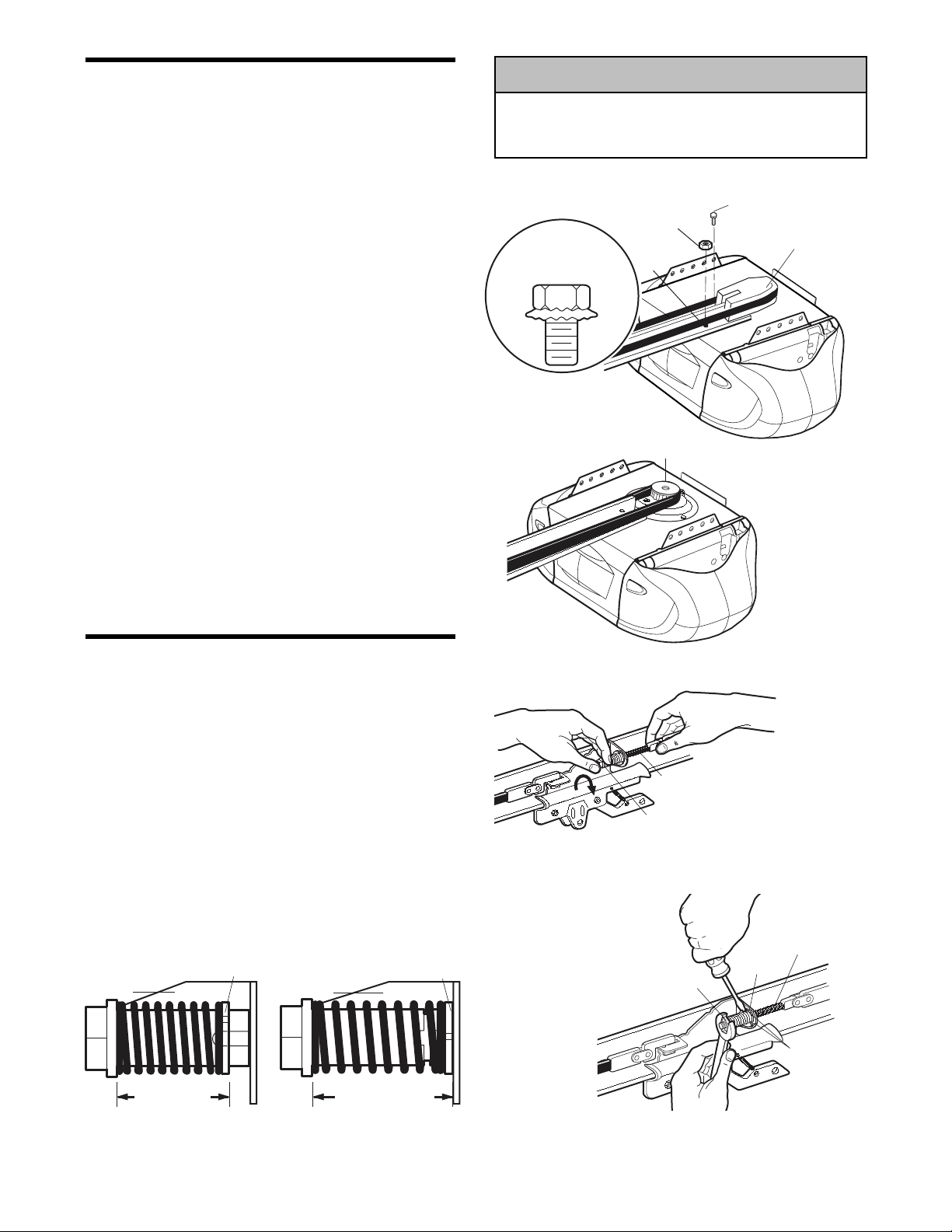

ASSEMBLY STEP 2

Set the Belt Tension

• By hand, thread the spring trolley nut on the

threaded shaft until it is finger tight against the

trolley (Figure 1). Do not use any tools.

• Insert a screwdriver tip into one of the nut ring

slots and brace it firmly against the trolley

(Figure 2).

• Place a 7/16" open end wrench on the square

end. Rotate about 1/4 turn until the spring releases

and snaps the nut ring against the trolley

(Figure 3).

This extends the spring for optimum belt tension.

Figure 1

Figure 2

Figure 3

ASSEMBLY STEP 1

Attach the Rail to the Motor Unit

To avoid installation difficulties, do not run the

garage door opener until instructed to do so.

• Remove the bolt and lock nut from the top of the

motor unit.

• Place rail onto the bolt mounted on the motor unit

and align the back hole with the hole in the top of

the unit.

• Fasten rail with the washered bolt and lock nut

previously removed. Tighten securely. Remember

to use only these bolts/fasteners! Any other

bolts/fasteners will cause serious damage to

the opener.

• Cut tape from rail, belt and styrofoam.

• REMOVE STYROFOAM.

• Position belt over the motor unit sprocket.

USE ONLY THIS

TYPE AND SIZE

BOLT

CAUTION

Washered Bolt

Lock Nut

Rail

Hole

Motor unit

Sprocket

5/16"-18x1/2"

Styrofoam

Trolley

Nut Ring Trolley

BEFORE AFTER RELEASE

1" (2.5 cm) 1-1/4" (3.18 cm)

Nut Ring

Spring/Trolley Nut

Trolley

Threaded

Shaft

Square

End

Nut

Ring

Trolley

Threaded

Shaft

Nut Ring

Slots

Page 7

7

INSTALLATION

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

WARNING

WARNING

1. READ AND FOLLOW ALL INSTALLATION WARNINGS

AND INSTRUCTIONS.

2. Install garage door opener ONLY on properly balanced

and lubricated garage door. An improperly balanced

door may not reverse when required and could result in

SEVERE INJURY or DEATH.

3. ALL repairs to cables, spring assemblies and other

hardware MUST be made by a trained door systems

technician BEFORE installing opener.

4. Disable ALL locks and remove ALL ropes connected to

garage door BEFORE installing opener to avoid

entanglement.

5. Install garage door opener 7 feet (2.13 m) or more

above floor.

6. Mount emergency release handle 6 feet (1.83 m) above

floor.

7. NEVER connect garage door opener to power source

until instructed to do so.

8. NEVER wear watches, rings or loose clothing while

installing or servicing opener. They could be caught in

garage door or opener mechanisms.

9. Install wall-mounted garage door control:

• within sight of the garage door.

• out of reach of children at minimum height of 5 feet

(1.5 m).

• away from ALL moving parts of the door.

10. Place entrapment warning label on wall next to garage

door control.

11. Place manual release/safety reverse test label in plain

view on inside of garage door.

12. Upon completion of installation, test safety reversal

system. Door MUST reverse on contact with a

1-1/2" (3.8 cm) high object (or a 2x4 laid flat) on the

floor.

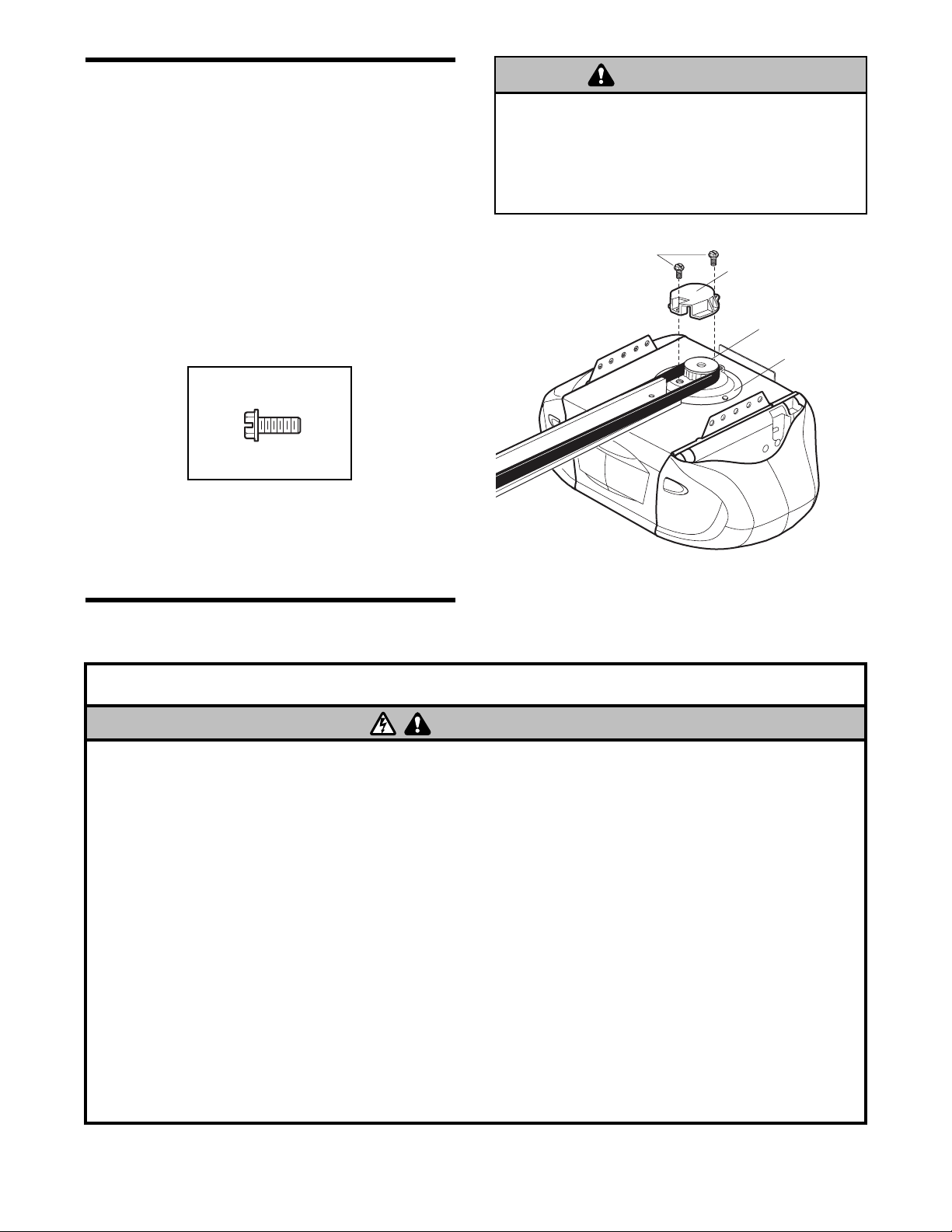

ASSEMBLY STEP 3

Attach the Belt Cap Retainer

• Position the belt cap retainer over the motor unit

sprocket so the two holes in cap align with the two

holes in mounting plate. Attach with 8x3/8" hex

screws provided.

You have now finished assembling your garage

door opener. Please read the following warnings

before proceeding to the installation section.

To avoid possible SERIOUS INJURY to fingers from

moving garage door opener:

• ALWAYS keep hand clear of sprocket while operating

opener.

• Securely attach sprocket cover BEFORE operating.

WARNING

HARDWARE SHOWN

ACTUAL SIZE

Hex Screw

#8x3/8"

WARNING

Hex Screws

8x3/8"

Belt Cap

Retainer

Motor Unit

Sprocket

Mounting Plate

WARNING

Page 8

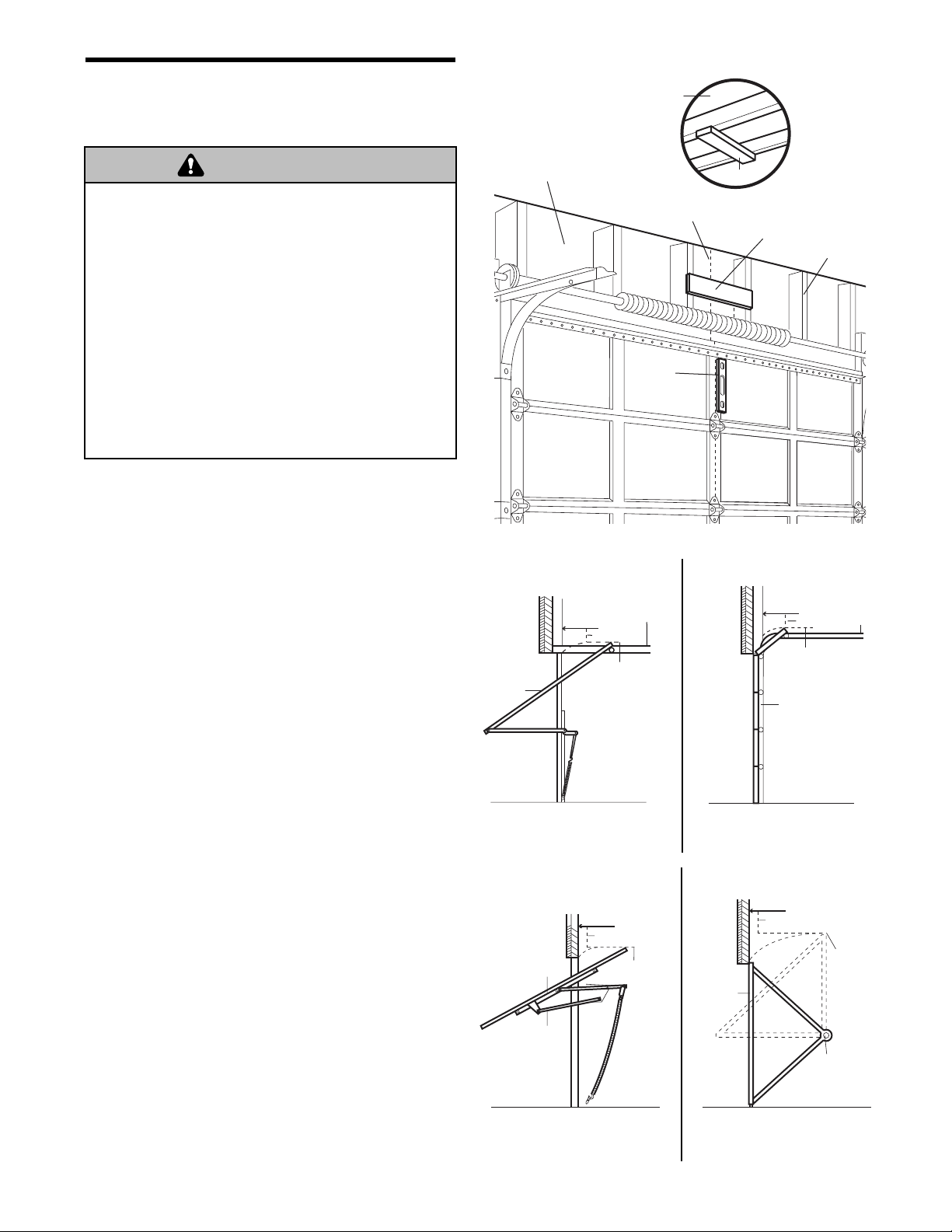

8

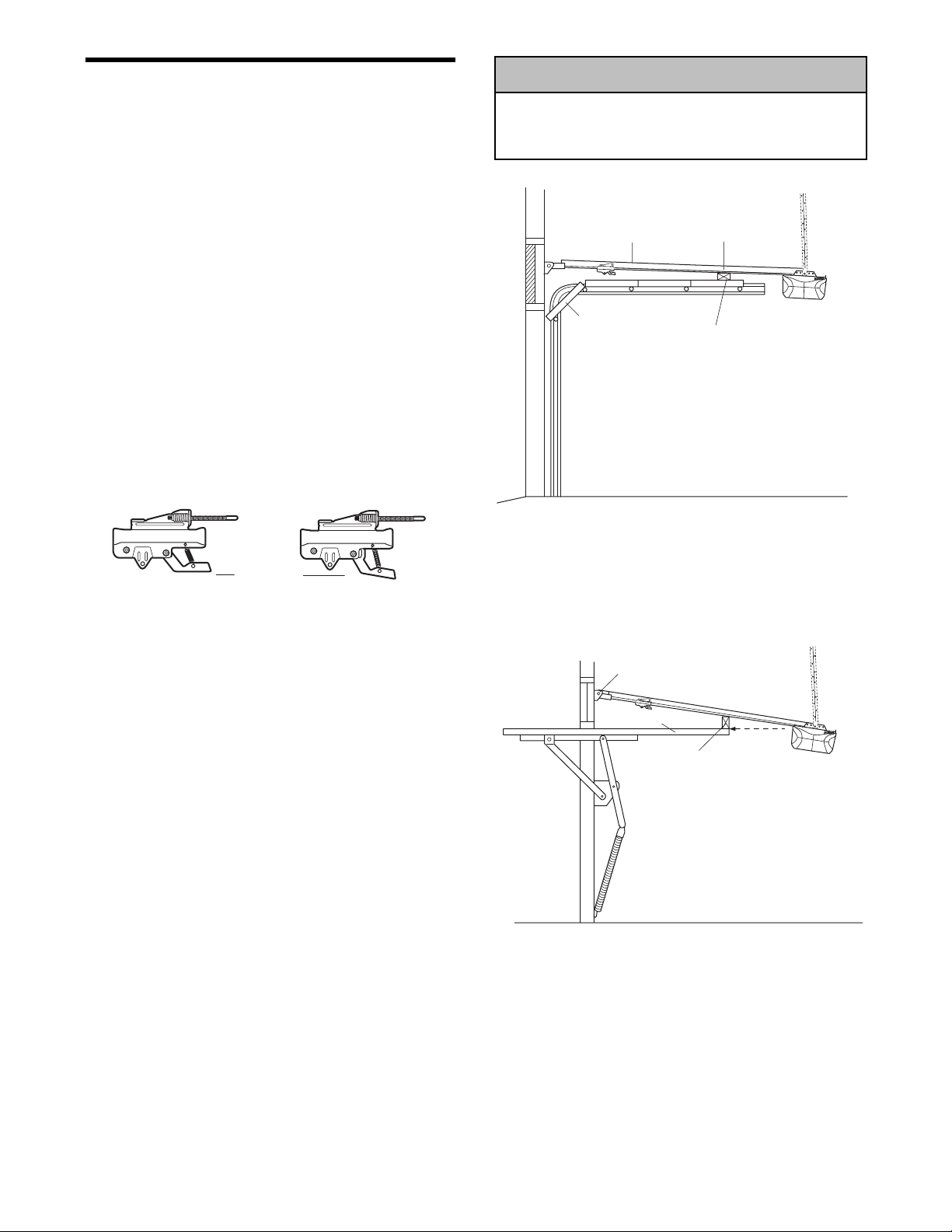

INSTALLATION STEP 1

Determine the Header Bracket

Location

Installation procedures vary according to garage door

types. Follow the instructions which apply to your

door.

1. Close the door and mark the inside vertical

centerline of the garage door.

2. Extend the line onto the header wall above the

door.

You can fasten the header bracket within 4 feet

(1.22 m) of the left or right of the door center

only if a torsion spring or center bearing plate

is in the way; or you can attach it to the ceiling

(see page 9) when clearance is minimal. (It may

be mounted on the wall upside down if

necessary, to gain approximately 1/2" (1 cm).

If you need to install the header bracket on a 2x4

(on wall or ceiling), use lag screws (not provided)

to securely fasten the 2x4 to structural supports as

shown here and on page 9.

3. Open your door to the highest point of travel as

shown. Draw an intersecting horizontal line on the

header wall above the high point:

• 2" (5 cm) above the high point for sectional door

and one-piece door with track.

• 8" (20 cm) above the high point for one-piece

door without track.

This height will provide travel clearance for the top

edge of the door.

NOTE: If the total number of inches exceeds the

height available in your garage, use the maximum

height possible, or refer to page 9 for ceiling

installation.

To prevent possible SERIOUS INJURY or DEATH:

• Header bracket MUST be RIGIDLY fastened to

structural support on header wall or ceiling, otherwise

garage door might not reverse when required. DO NOT

install header bracket over drywall.

• Concrete anchors MUST be used if mounting header

bracket or 2x4 into masonry.

• NEVER try to loosen, move or adjust garage door,

springs, cables, pulleys, brackets or their hardware,

ALL of which are under EXTREME tension.

• ALWAYS call a trained door systems technician if

garage door binds, sticks or is out of balance. An

unbalanced garage door might not reverse when

required.

WARNING

WARNING

Unfinished

Ceiling

Header Wall

Vertical Centerline

of Garage Door

Level

(optional)

Header Wall

2" (5 cm)

Door

One-piece door with horizontal track

Header Wall

8" (20 cm)

Door

Jamb

Hardware

Track

Highest Point

of Travel

Highest

Point

of Travel

OPTIONAL

CEILING

MOUNT

FOR

HEADER

2x4

Sectional door with curved track

Door

BRACKET

2x4

Header Wall

2" (5 cm)

Highest Point

of Travel

Door

Header Wall

8" (20 cm)

Structural

Supports

Highest

Point

of Travel

Pivot

Track

One-piece door without track:

jamb hardware

One-piece door without track:

pivot hardware

Page 9

9

INSTALLATION STEP 2

Install the Header Bracket

You can attach the header bracket either to the wall

above the garage door, or to the ceiling. Follow the

instructions which will work best for your particular

requirements. Do not install the header bracket

over drywall. If installing into masonry, use

concrete anchors (not provided).

WALL HEADER BRACKET INSTALLATION

• Center the bracket on the vertical centerline with

the bottom edge of the bracket on the horizontal

line as shown (with the arrow pointing toward the

ceiling).

• Mark the vertical set of bracket holes (do not use

the holes designated for ceiling mount). Drill 3/16"

pilot holes and fasten the bracket securely to a

structural support with the hardware provided.

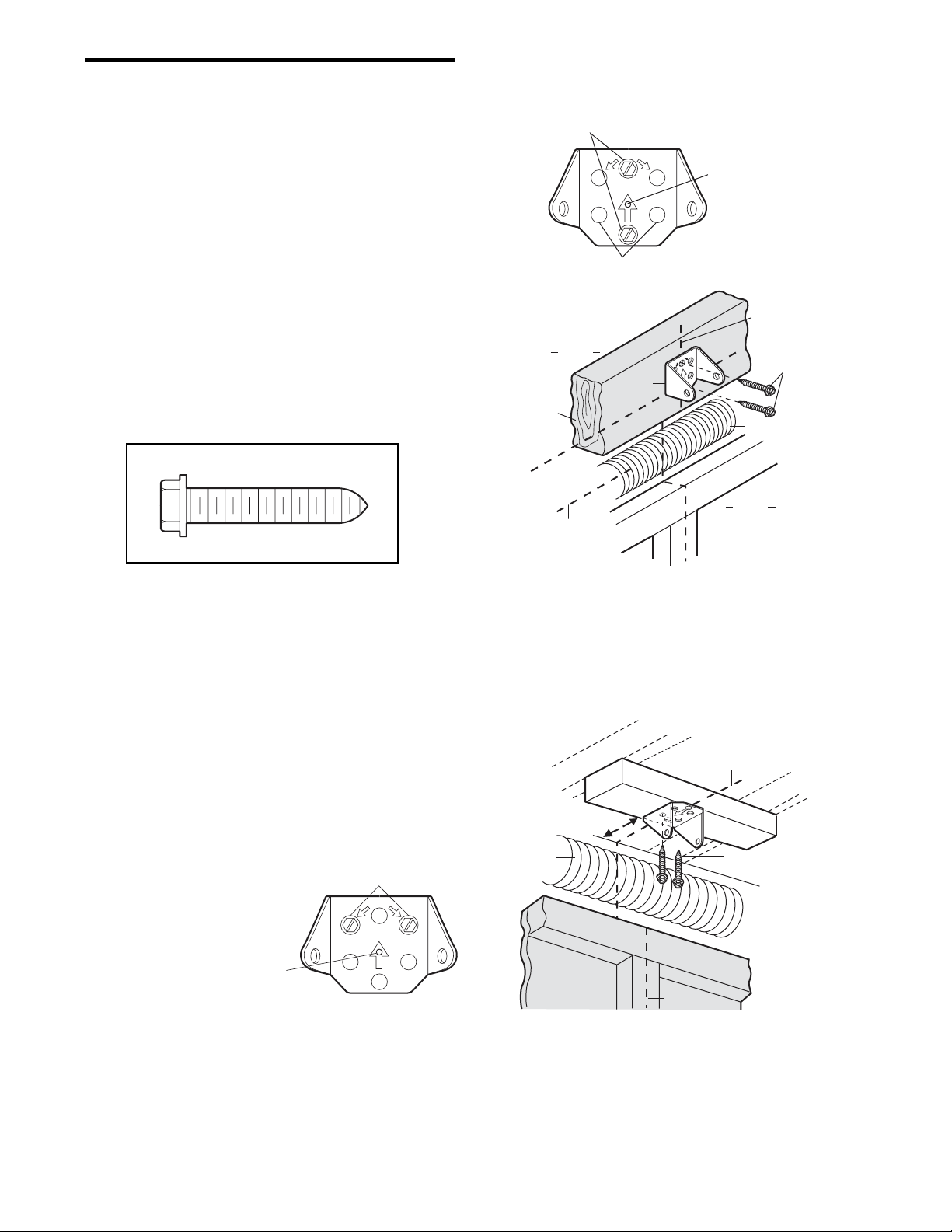

HARDWARE SHOWN ACTUAL SIZE

UP

CEILING MOUNT ONLY

Ceiling Mounting Holes

The nail hole is for

positioning only.

You must use lag screws

to mount the header bracket.

U

P

Lag Screws

5/16"-9x1-5/8"

Garage Door

Vertical

Centerline

of Garage Door

Header Wall

– Finished Ceiling –

Header

Bracket

6" (15 cm)

Maximum

Vertical

Centerline

of Garage Door

Door

Spring

CEILING HEADER BRACKET INSTALLATION

• Extend the vertical centerline onto the ceiling as

shown.

• Center the bracket on the vertical mark, no more

than 6" (15 cm) from the wall. Make sure the arrow

is pointing toward the wall. The bracket can be

mounted flush against the ceiling when clearance

is minimal.

• Mark the side holes. Drill 3/16" pilot holes and

fasten bracket securely to a structural support with

the hardware provided.

Wall Mounting Holes

CEILING MOUNT ONLY

UP

The nail hole is for

positioning only.

You must use lag screws

to mount the header bracket.

Lag Screw

5/16"-9x1-5/8"

Optional

Wall Mounting Holes

Header

Wall

2x4

Structural

Support

Horizontal

Line

Highest Point of

Garage Door Travel

Header

Bracket

IN

L

I

E

C

NL

T O

N

U

O

M

G

UP

Y

Vertical

Centerline of

Garage Door

Vertical

Centerline of

Garage Door

Lag Screws

5/16"-9x1-5/8"

Door Spring

Garage

Door

Page 10

Header Wall

10

INSTALLATION STEP 3

Attach the Rail to the Header

Bracket

• Position the opener on the garage floor below the

header bracket. Use packing material as a

protective base. NOTE: If the door spring is in the

way you’ll need help. Have someone hold the

opener securely on a temporary support to allow

the rail to clear the spring.

• Position the rail bracket against the header

bracket.

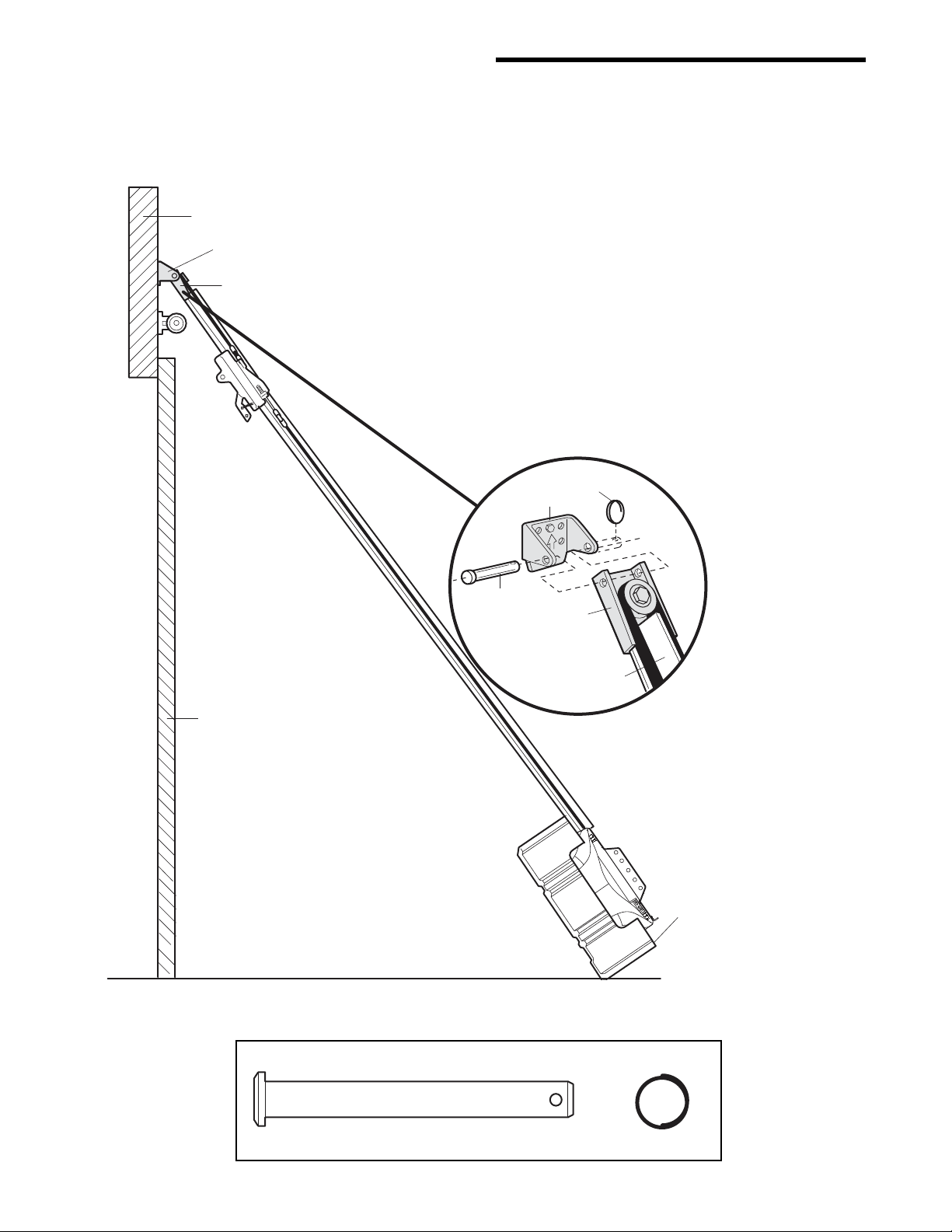

• Align the bracket holes and join with a clevis pin

as shown.

• Insert a ring fastener to secure.

HARDWARE SHOWN ACTUAL SIZE

Header

Bracket

Belt Pulley

Bracket

Ring

Header

Bracket

Fastener

Garage

Door

Clevis Pin

5/16"x2-3/4"

Belt Pulley

Bracket

Rail

Temporary

Support

Clevis Pin

5/16"x2-3/4"

Ring Fastener

Page 11

11

ONE-PIECE DOOR WITHOUT TRACK

A 2x4 on its side is convenient for setting an ideal

door-to-rail distance.

• Remove foam packaging.

• Raise the opener onto a stepladder. You will need

help at this point if the ladder is not tall enough.

• Open the door all the way and place a 2x4 on its

side on the top section of the door beneath the rail.

• The top of the door should be level with the top of

the motor unit. Do not position the opener more

than 4" (10 cm) above this point.

INSTALLATION STEP 4

Position the Opener

Follow instructions which apply to your door type as

illustrated.

SECTIONAL DOOR OR ONE-PIECE DOOR WITH

TRACK

A 2x4 laid flat is convenient for setting an ideal

door-to-rail distance.

• Remove foam packaging.

• Raise the opener onto a stepladder. You will need

help at this point if the ladder is not tall enough.

• Open the door all the way and place a 2x4 laid flat

on the top section beneath the rail.

• If the top section or panel hits the trolley when you

raise the door, pull down on the trolley release arm

to disconnect inner and outer sections. Slide the

outer trolley toward the motor unit. The trolley can

remain disconnected until Installation Step 12

is completed.

To prevent damage to garage door, rest garage door

opener rail on 2x4 placed on top section of door.

WARNING

WARNING

WARNING

CAUTION

Rail

Door

2x4 is used to determine

the correct mounting height

from ceiling.

Trolley

Release Arm

ENGAGED

RELEASED

Header

Bracket

Top of Door

Top of Motor Unit

2x4 is used to determine

the correct mounting height

from ceiling.

Page 12

12

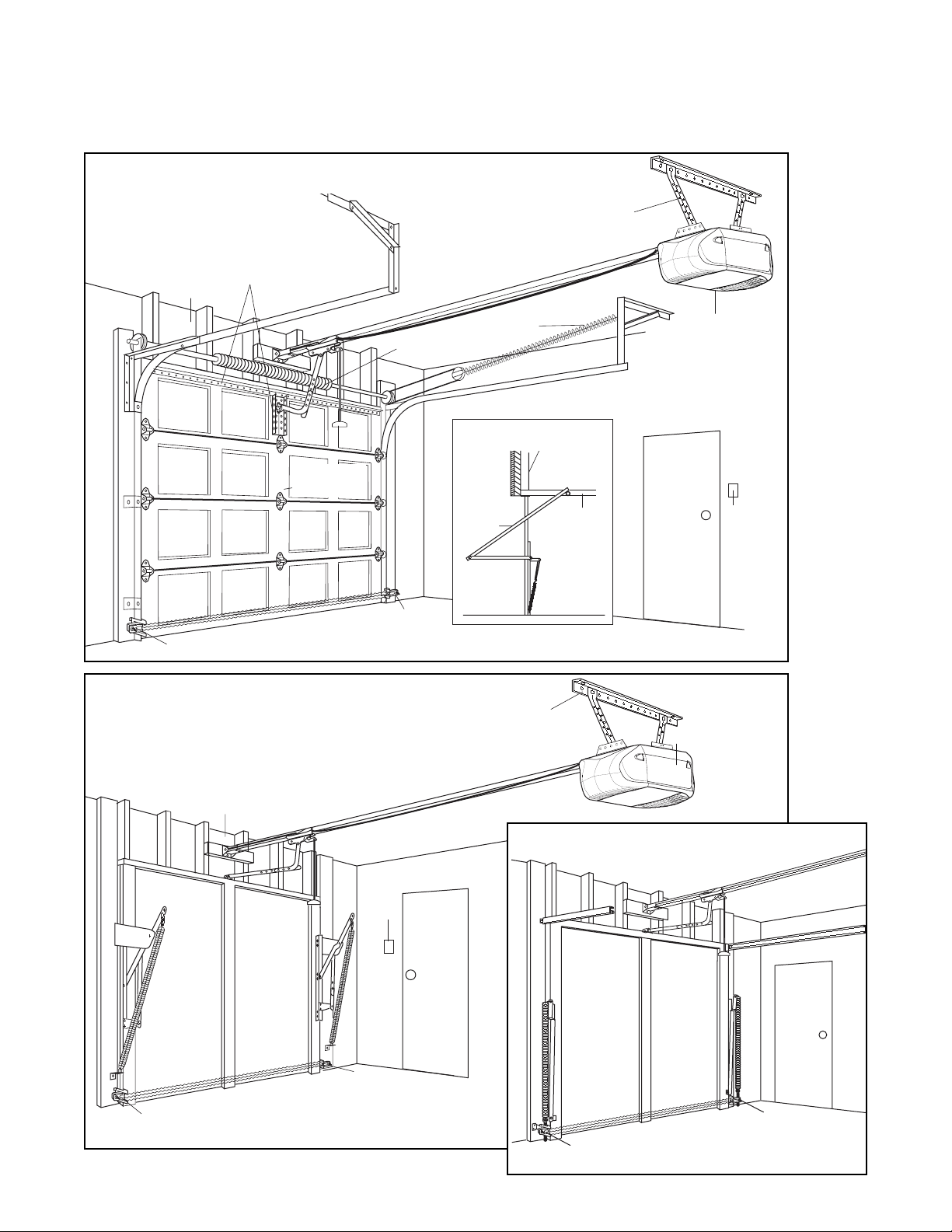

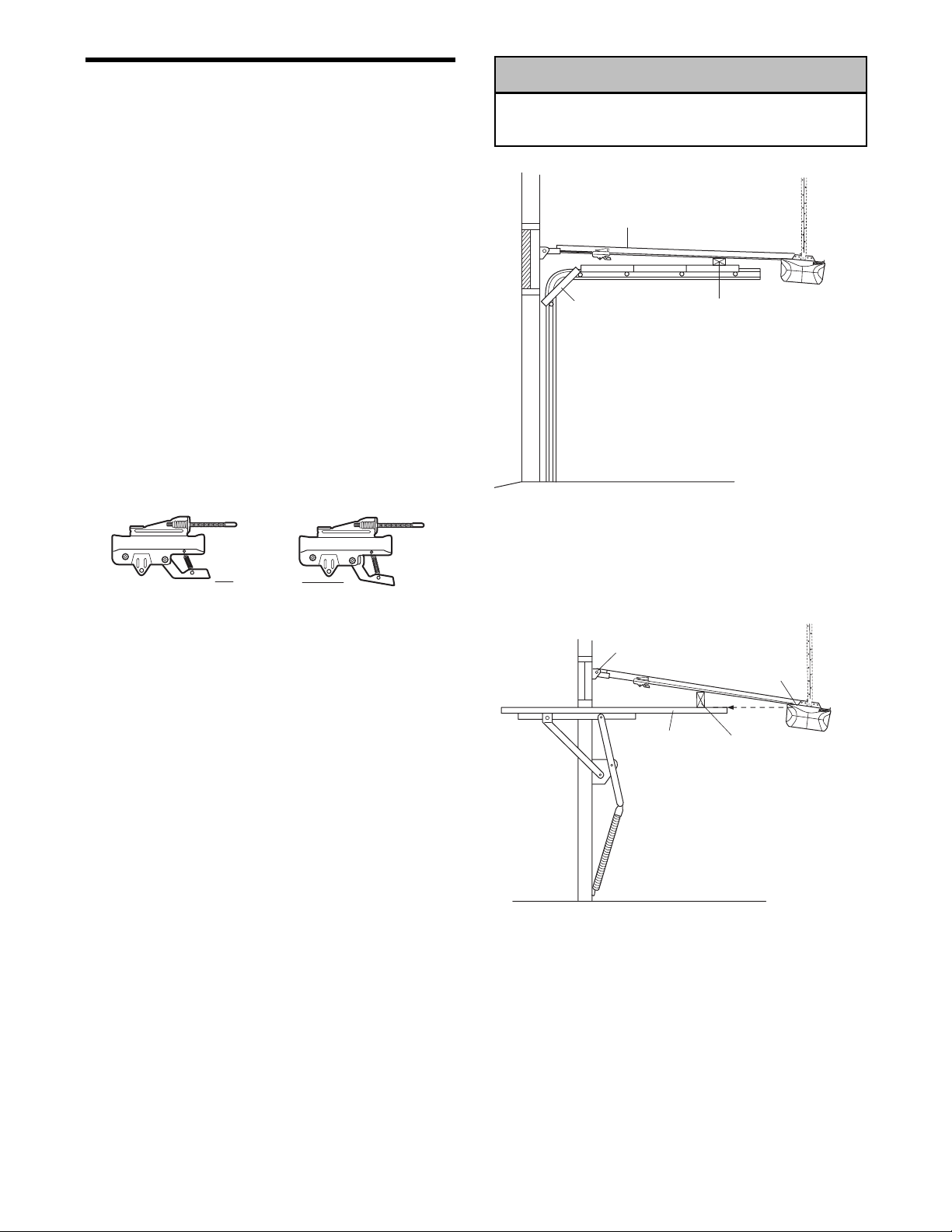

INSTALLATION STEP 5

Hang the Opener

Three representative installations are shown. Yours

may be different. Hanging brackets should be angled

(Figure 1) to provide rigid support. On finished

ceilings (Figure 2 and Figure 3), attach a sturdy

metal bracket to structural supports before installing

the opener. This bracket and fastening hardware are

not provided.

1. Measure the distance from each side of the motor

unit to the structural support.

2. Cut both pieces of the hanging bracket to required

lengths.

3. Drill 3/16" pilot holes in the structural supports.

4. Attach one end of each bracket to a support with

5/16"-18x1-7/8" lag screws.

5. Fasten the opener to the hanging brackets with

5/16"-18x7/8" hex bolts, lock washers and nuts.

6. Check to make sure the rail is centered over the

door (or in line with the header bracket if the

bracket is not centered above the door).

7. Remove the 2x4. Operate the door manually. If the

door hits the rail, raise the header bracket.

8. Grease the top and underside of the rail surface

where the trolley slides with rail grease.

NOTE: DO NOT connect power to opener at this

time.

To avoid possible SERIOUS INJURY from a falling

garage door opener, fasten it SECURELY to structural

supports of the garage. Concrete anchors MUST be used

if installing any brackets into masonry.

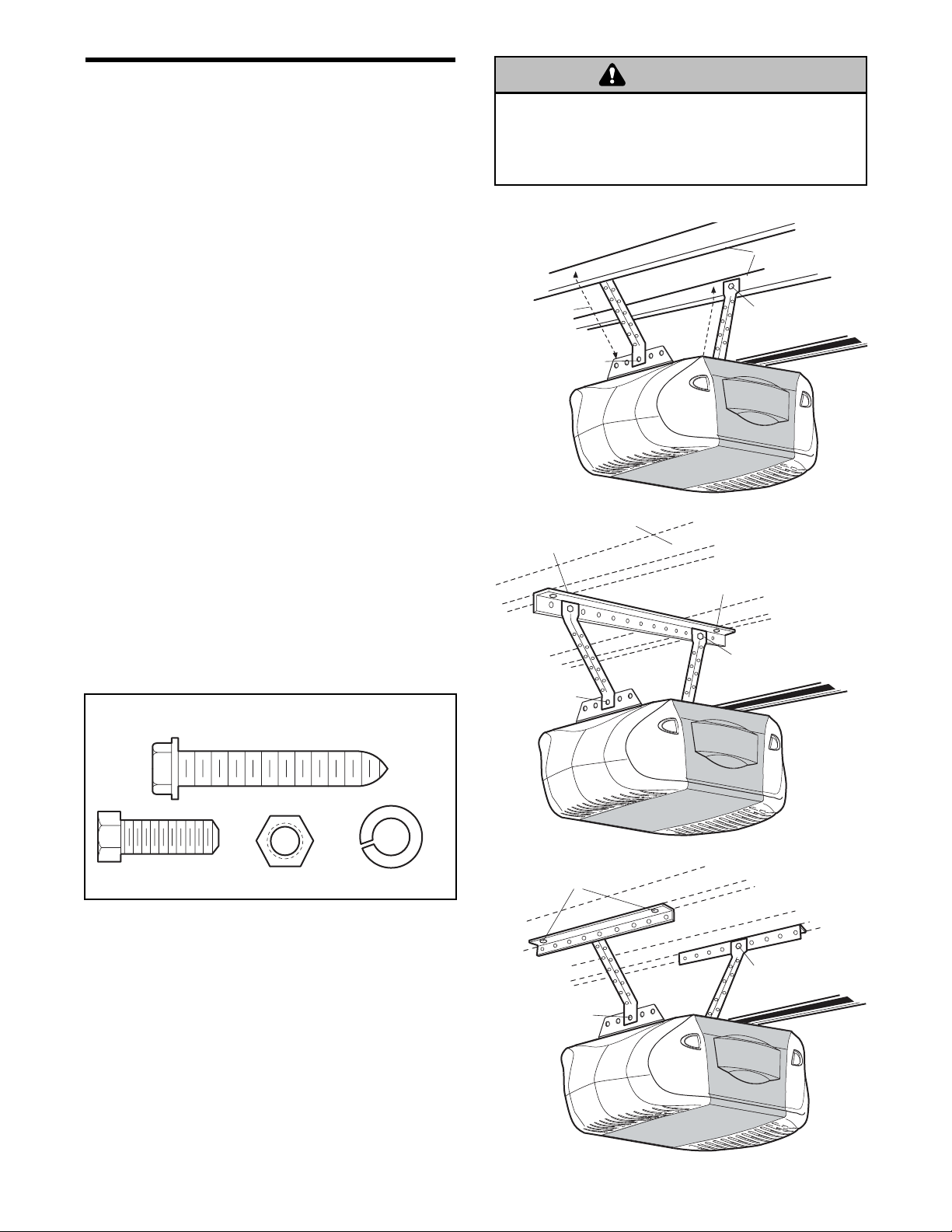

HARDWARE SHOWN ACTUAL SIZE

Figure 1

Figure 2

WARNING

Figure 3

WARNING

Structural

Supports

Measure

Distance

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Bracket

(Not Provided)

Hidden

Support

Lag Screws

5/16"-18x1-7/8"

FINISHED CEILING

Lag Screws

5/16"-18x1-7/8"

Lag Screw 5/16"-18x1-7/8"

Hex Bolt

5/16"-18x7/8"

Nut 5/16"-18

Lock Washer 5/16"

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Lag Screws

5/16"-18x1-7/8"

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

(Not Provided)

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

FINISHED CEILING

(Not Provided)

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Page 13

13

INSTALLATION STEP 6

Install the Control Console

Locate control console within sight of door, at a

minimum height of 5' (1.5 m) where small children

cannot reach, away from moving parts of door and

door hardware. If installing into drywall, drill 5/32"

holes and use the anchors provided. For pre-wired

installations (as in new home construction), it may be

mounted to a single gang box (Figure 1).

CAUTION: Continuous exposure of the control

console to temperatures below -22° F (-30° C) may

damage the LCD screen.

NOTE: The functional temperature range of the

control console is between -20° C (-4° F) and 50° C

(122° F). Scroll speed of display is slower at lower

temperatures although the control console remains

fully functional.

SPECIAL NOTE: Only one 398LM can be connected

to each garage door opener. If additional wall

controls are desired to operate the same garage door

opener, it is recommended to use model 378LM

wireless wall control as the secondary control

console.

1. Strip 7/16" (11 mm) of insulation from one end of

bell wire and connect to the two screw terminals

on back of control console by color: white wire to

the white (2) and white/red wire to the red (1)

(Figure 2).

2. Remove push bar cover by gently prying at the

lower/middle portion of the cover with a small

flat-head screwdriver. Fasten with 6AB x 1-1/4"

self-tapping screws (drywall installation) or

6-32 x 1" machine screws (into gang box) as

follows:

• Install bottom screw, allowing 1/8" (3 mm) to

protrude above wall surface.

• Position bottom of control console on screw head

and slide down to secure. Adjust screw for snug

fit.

• Drill and install top screw with care to avoid

cracking plastic housing. Do NOT overtighten.

• Replace cover by inserting top tabs first and then

snap cover in place.

3. (For standard installations ONLY) Run bell wire

up wall and across ceiling to motor unit. Use

insulated staples to secure wire in several places.

Do NOT pierce wire with a staple, creating a short

or open circuit.

4. Strip 7/16" (11 mm) of insulation from end of bell

wire. Connect bell wire to the quick-connect

terminals on the motor unit: white to white and

white/red to red (Figure 3).

NOTE: If you have any trouble with the operation of

the buttons, loosen the top mounting screw.

NOTE: DO NOT connect the power and operate the

opener at this time. The trolley will travel to the full

open position but will not return to the close position

until the sensor beam is connected and properly

aligned. See Safety Reversing Sensor Instructions

beginning on page 16.

HARDWARE SHOWN ACTUAL SIZE

To prevent possible SERIOUS INJURY or DEATH from

electrocution:

• Be sure power is not connected BEFORE installing door

control.

• Connect ONLY to 24 VOLT low voltage wires.

To prevent possible SERIOUS INJURY or DEATH from a

closing garage door:

• Install door control within sight of garage door, out of

reach of children at a minimum height of 5 feet (1.5 m)

and away from ALL moving parts of door.

• NEVER permit children to operate or play with door

control push buttons or remote control transmitters.

• Activate door ONLY when it can be seen clearly, is

properly adjusted and there are no obstructions to door

travel.

• ALWAYS keep garage door in sight until completely

closed. NEVER permit anyone to cross path of closing

garage door.

WARNING

Figure 1

Figure 3

Figure 2

WARNING

Screw 6ABx1-1/4"

(std installation)

Screw 6-32x1"

(pre-wired)

STANDARD WALL MOUNT

To Replace

Insert Top

Ta bs First

Push Bar Cover

LOCK

2-Conductor

Bell Wire

R

1

(BACK VIEW)

L

I

GHT

W

2

9

7

5

1

9

3

7

5

ON

OFF

Detector

Switch

Top

Mounting

Hole

Door

Control

Terminal

Screws

Bottom

Mounting

Hole

1

3

To Replace

Insert Top

Ta bs First

Push Bar

Cover

Door Control

Connections

Strip wire 7/16" (11 mm)

Drywall Anchors

PRE-WIRED INSTALLATION

24 Volt Bell Wire

L

O

C

K

To release wire, push in tab

with screwdriver tip

White

Red

Grey

7/16" (11 mm)

Insulated

Staples

L

I

GH

T

Detector

Switch

ON

OFF

Page 14

14

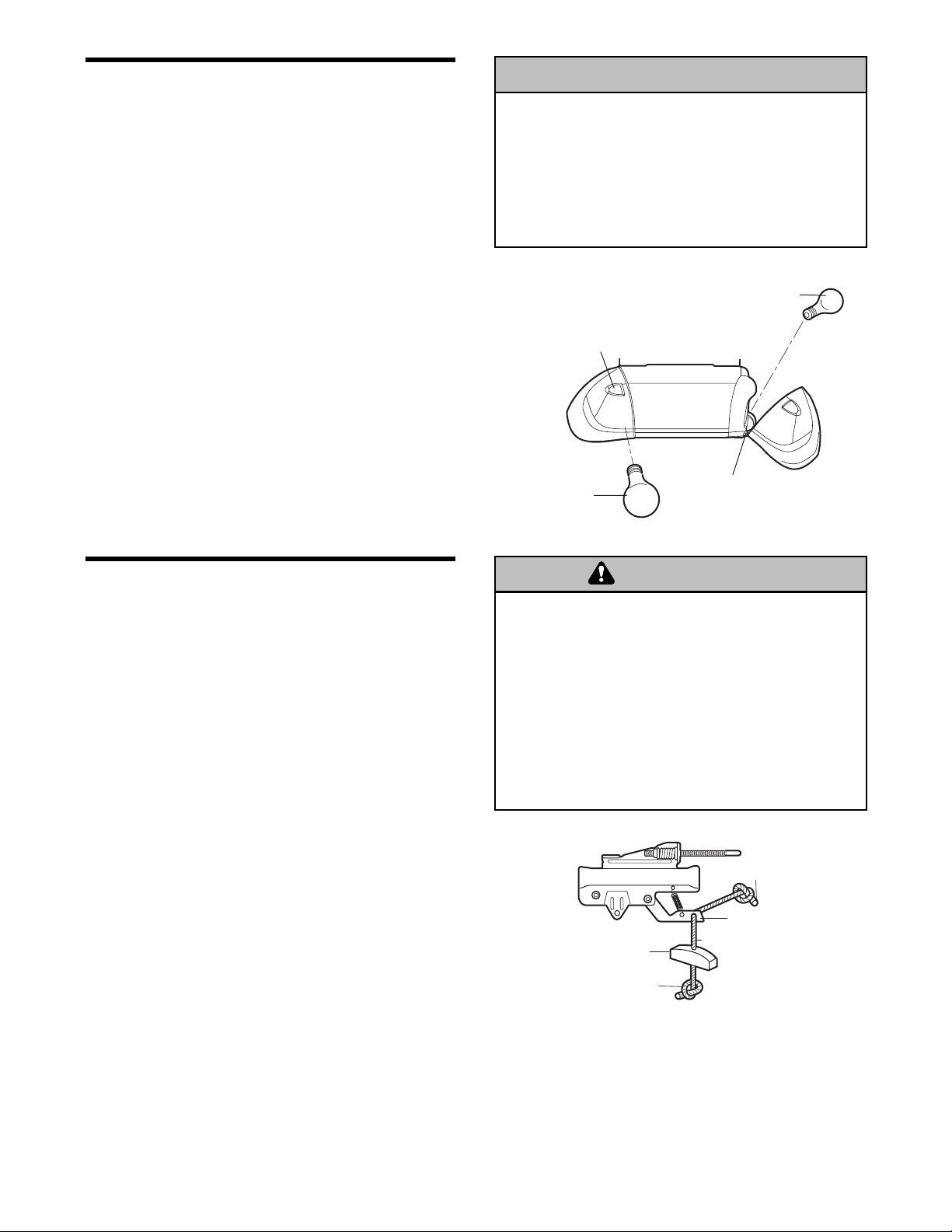

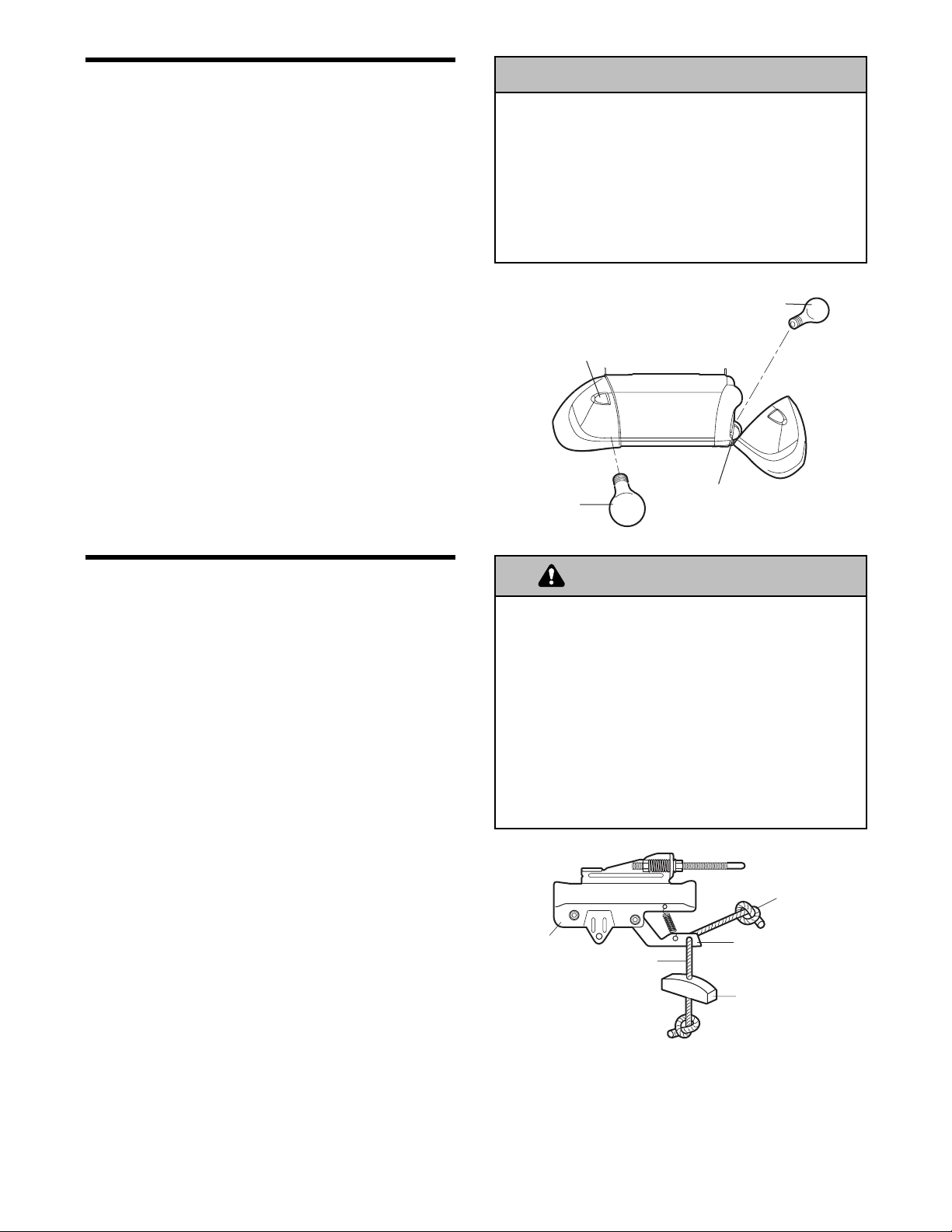

INSTALLATION STEP 7

Install the Light

• Press the release tabs on both sides of lens.

Gently rotate lens back and downward until the

lens hinge is in the fully open position. Do not

remove the lens.

• Install a 100 watt maximum light bulb in each

socket. Light bulb size should be A19, standard

neck only. The lights will turn ON and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the lights will turn OFF.

• Reverse the procedure to close the lens.

• Use A19, standard neck garage door opener bulbs

for replacement.

NOTE: Use only standard light bulbs. The use of

short neck or speciality light bulbs may overheat the

endpanel or light socket.

INSTALLATION STEP 8

Attach the Emergency Release

Rope and Handle

• Thread one end of the rope through the hole in the

top of the red handle so “NOTICE” reads right side

up as shown. Secure with an overhand knot at

least 1" (2.5 cm) from the end of the rope to

prevent slipping.

• Thread the other end of the rope through the hole

in the release arm of the outer trolley.

• Adjust rope length so the handle is 6 feet (1.83 m)

above the floor. Ensure that the rope and handle

clear the tops of all vehicles to avoid

entanglement. Secure with an overhand knot.

NOTE: If it is necessary to cut the rope, heat seal

the cut end with a match or lighter to prevent

unraveling.

To prevent possible OVERHEATING of the endpanel or

light socket:

• DO NOT use short neck or specialty light bulbs.

• DO NOT use halogen bulbs. Use ONLY incandescent.

To prevent damage to the opener:

• DO NOT use bulbs larger than 100W.

• ONLY use A19 size bulbs.

WARNING

WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH from a

falling garage door:

• If possible, use emergency release handle to disengage

trolley ONLY when garage door is CLOSED. Weak or

broken springs or unbalanced door could result in an

open door falling rapidly and/or unexpectedly.

• NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

• NEVER use handle to pull door open or closed. If rope

knot becomes untied, you could fall.

WARNING

CAUTION

100 Watt (Max)

Standard Light Bulb

Release Tab

Lens

100 Watt (Max)

Standard Light Bulb

Hinge

WARNING

Overhand

Knot

Trolley

Emergency

Release Handle

Overhand

Knot

NOTICE

Rope

Release Arm

Page 15

15

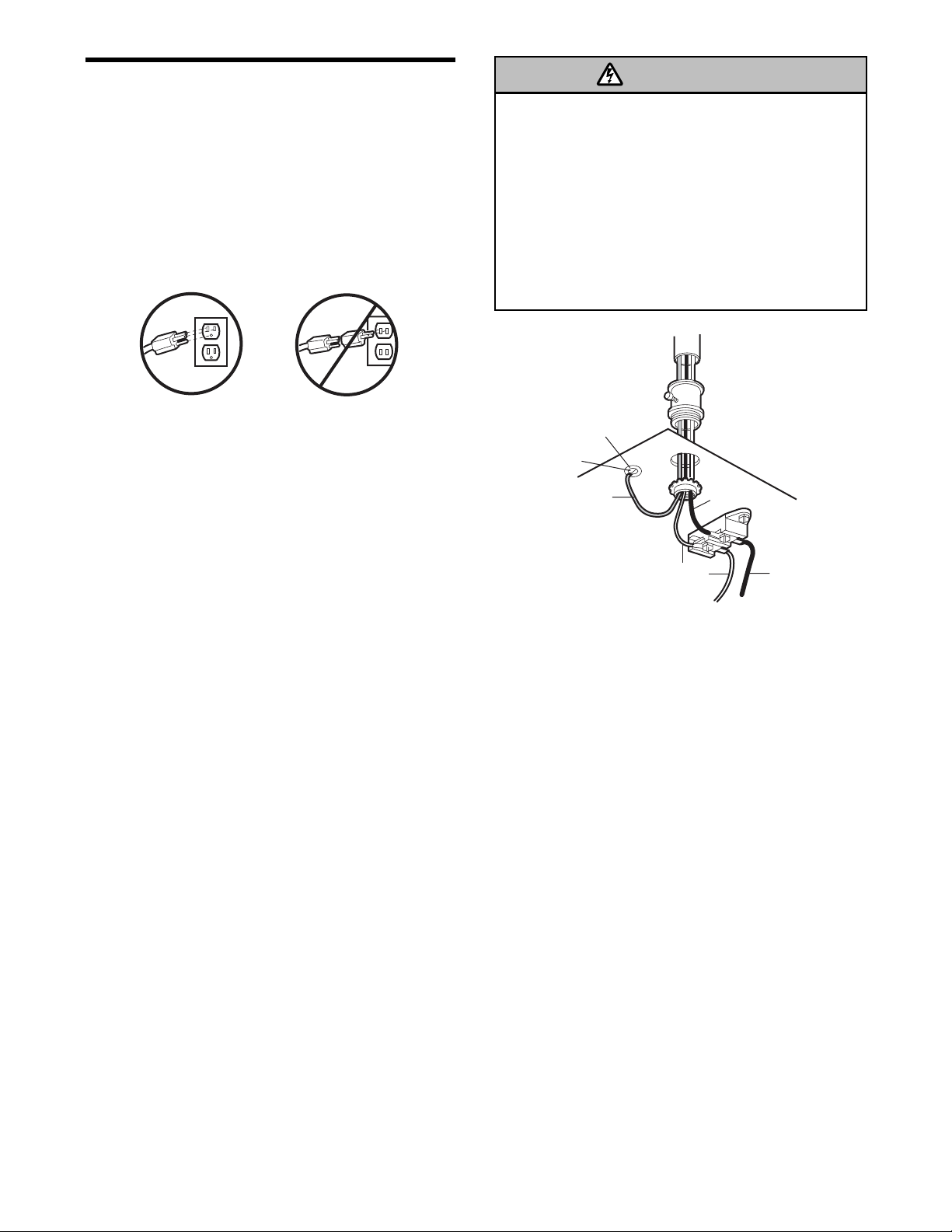

INSTALLATION STEP 9

Electrical Requirements

To avoid installation difficulties, do not run the

opener at this time.

To reduce the risk of electric shock, your garage door

opener has a grounding type plug with a third

grounding pin. This plug will only fit into a grounding

type outlet. If the plug doesn’t fit into the outlet you

have, contact a qualified electrician to install the

proper outlet.

If permanent wiring is required by your local

code, refer to the following procedure.

To make a permanent connection through the 7/8"

hole in the top of the motor unit:

• Remove the motor unit cover screws and set the

cover aside.

• Remove the attached 3-prong cord.

• Connect the black (line) wire to the screw on the

brass terminal; the white (neutral) wire to the

screw on the silver terminal; and the ground wire

to the green ground screw. The opener must be

grounded.

• Reinstall the cover.

To avoid installation difficulties, do not run the

opener at this time.

To prevent possible SERIOUS INJURY or DEATH from

electrocution or fire:

• Be sure power is not connected to the opener and

disconnect power to circuit BEFORE removing cover to

establish permanent wiring connection.

• Garage door installation and wiring MUST be in

compliance with ALL local electrical and building

codes.

• NEVER use an extension cord, 2-wire adapter or

change plug in ANY way to make it fit outlet. Be sure

the opener is grounded.

RIGHT

WRONG

WARNING

PERMANENT WIRING

CONNECTION

Green

Ground Screw

Ground Wire

Ground Tab

White Wire

Black

Wire

Black Wire

Page 16

16

Facing the door from inside the garage

INSTALLATION STEP 10

Install The Protector System

®

The safety reversing sensor must be connected

and aligned correctly before the garage door

opener will move in the down direction.

IMPORTANT INFORMATION ABOUT THE SAFETY

REVERSING SENSOR

When properly connected and aligned, the sensor

will detect an obstacle in the path of its electronic

beam. The sending eye (with an amber indicator

light) transmits an invisible light beam to the

receiving eye (with a green indicator light). If an

obstruction breaks the light beam while the door is

closing, the door will stop and reverse to full open

position, and the opener lights will flash 10 times.

The units must be installed inside the garage so that

the sending and receiving eyes face each other

across the door, no more than 6" (15 cm) above the

floor. Either can be installed on the left or right of the

door as long as the sun never shines directly into the

receiving eye lens.

The mounting brackets are designed to clip onto the

track of sectional garage doors without additional

hardware.

If it is necessary to mount the units on the wall, the

brackets must be securely fastened to a solid surface

such as the wall framing. Extension brackets (see

accessories) are available if needed. If installing in

masonry construction, add a piece of wood at each

location to avoid drilling extra holes in masonry if

repositioning is necessary.

The invisible light beam path must be unobstructed.

No part of the garage door (or door tracks, springs,

hinges, rollers or other hardware) may interrupt the

beam while the door is closing.

Be sure power is not connected to the garage door

opener BEFORE installing the safety reversing sensor.

To prevent SERIOUS INJURY or DEATH from a closing

garage door:

• Correctly connect and align the safety reversing sensor.

This required safety device MUST NOT be disabled.

• Install the safety reversing sensor so beam is NO

HIGHER than 6" (15 cm) above garage floor.

WARNING

WARNING

Safety Reversing Sensor

6" (15 cm) max. above floor

Invisible Light Beam

Protection Area

Safety Reversing Sensor

6" (15 cm) max. above floor

Page 17

17

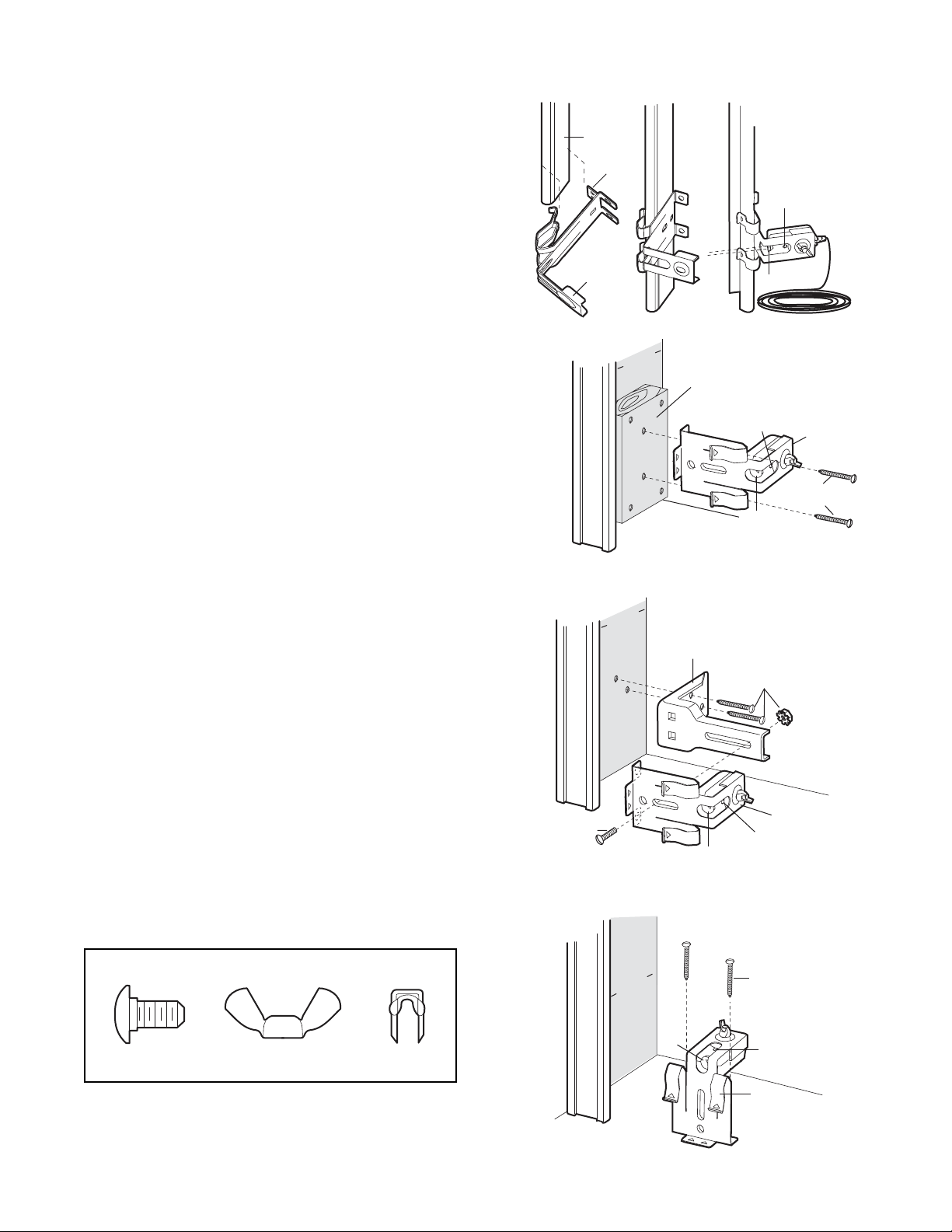

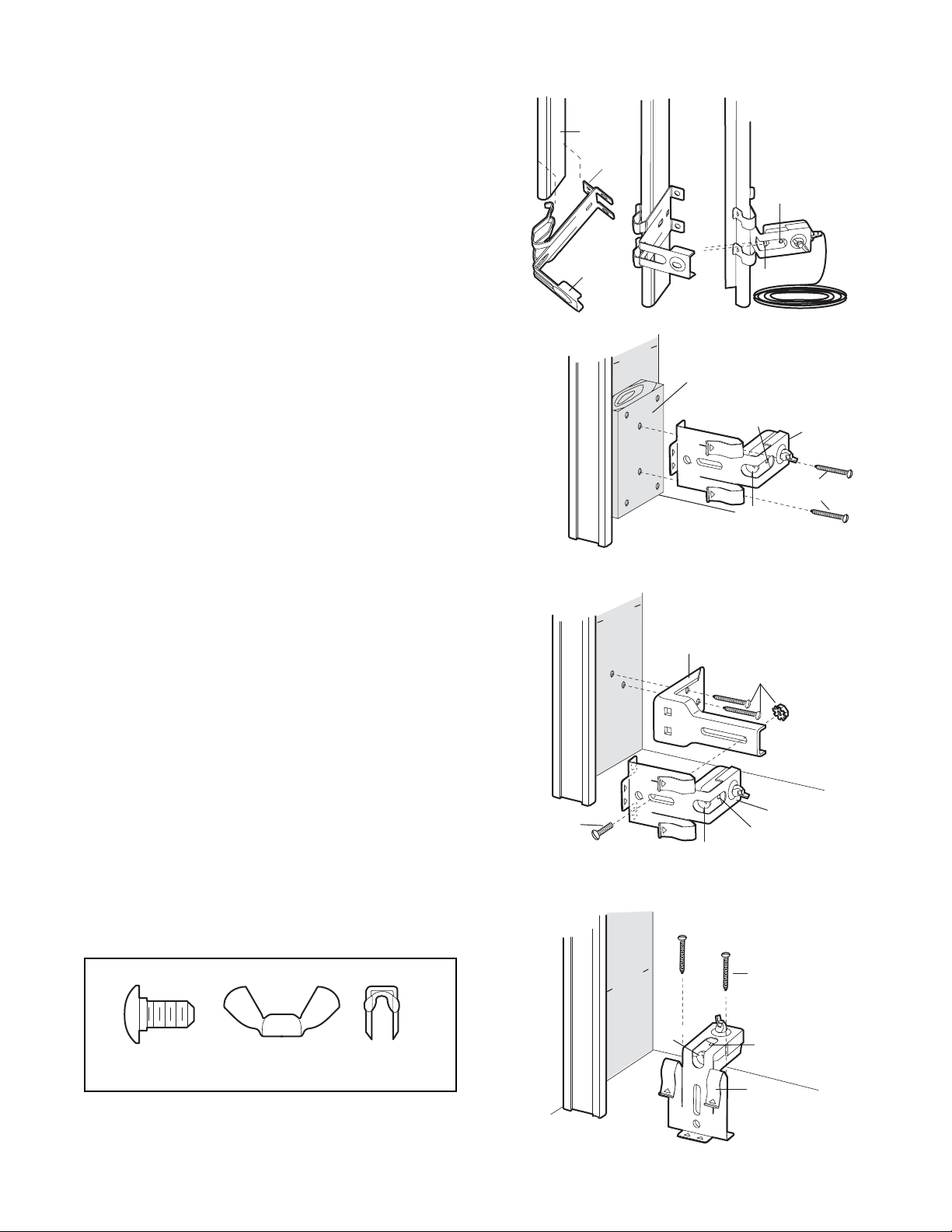

INSTALLING THE BRACKETS

Be sure power to the opener is disconnected.

Install and align the brackets so the sensors will face

each other across the garage door, with the beam no

higher than 6" (15 cm) above the floor. They may be

installed in one of three ways, as follows.

Garage door track installation (preferred):

• Slip the curved arms over the rounded edge of

each door track, with the curved arms facing the

door. Snap into place against the side of the track.

It should lie flush, with the lip hugging the back

edge of the track, as shown in Figure 1.

If your door track will not support the bracket

securely, wall installation is recommended.

Wall installation (Figure 2 & 3):

• Place the bracket against the wall with curved

arms facing the door. Be sure there is enough

clearance for the sensor beam to be unobstructed.

• If additional depth is needed, an extension bracket

(see accessories) or wood blocks can be used.

• Use bracket mounting holes as a template to

locate and drill (2) 3/16" diameter pilot holes on the

wall at each side of the door, no higher than 6"

(15 cm) above the floor.

• Attach brackets to wall with lag screws

(Not provided).

• If using extension brackets or wood blocks, adjust

right and left assemblies to the same distance out

from the mounting surface. Make sure all door

hardware obstructions are cleared.

Floor installation (Figure 4):

• Use wood blocks or extension brackets (see

Accessories) to elevate sensor brackets so the

lenses will be no higher than 6" (15 cm) above the

floor.

• Carefully measure and place right and left

assemblies at the same distance out from the wall.

Be sure all door hardware obstructions are

cleared.

• Fasten to the floor with concrete anchors as

shown.

HARDWARE SHOWN ACTUAL SIZE

Figure 1

Figure 2

Figure 3

(Provided with

Extension

Bracket)

DOOR TRACK MOUNT (RIGHT SIDE)

Door

Track

Lip

Sensor

Bracket

WALL MOUNT (RIGHT SIDE)

l

Fasten Wood Block to Wall with

Lag Screws (Not Provided)

WALL MOUNT (RIGHT SIDE)

Extension

Bracket

(See Accessories)

Lens

Inside

arage

G

al

W

Inside

arage

G

al

W

l

Indicator

Light

Lens

Indicator

Light

Lens

(Provided with

Extension Bracket)

Indicator

Light

Sensor

Bracket

Lag Screws

(Not Provided)

Sensor

Bracket

Carriage Bolt

1/4"-20x1/2"

Wing Nut

1/4"-20

Staples

Figure 4

Inside

arage

G

l

al

W

FLOOR MOUNT (RIGHT SIDE)

Attach with

Concrete Anchors

(Not Provided)

Lens

Indicator

Light

Sensor

Bracket

Page 18

18

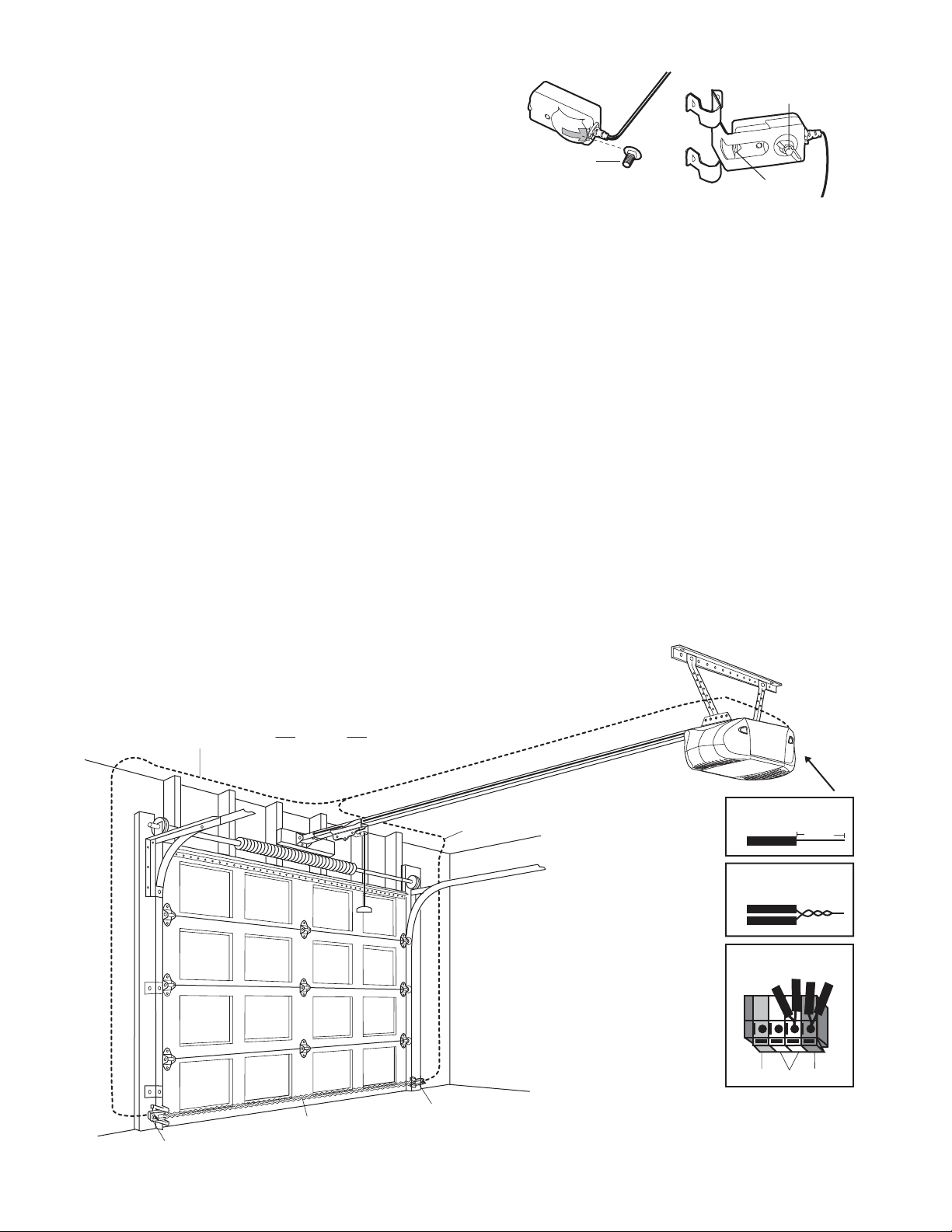

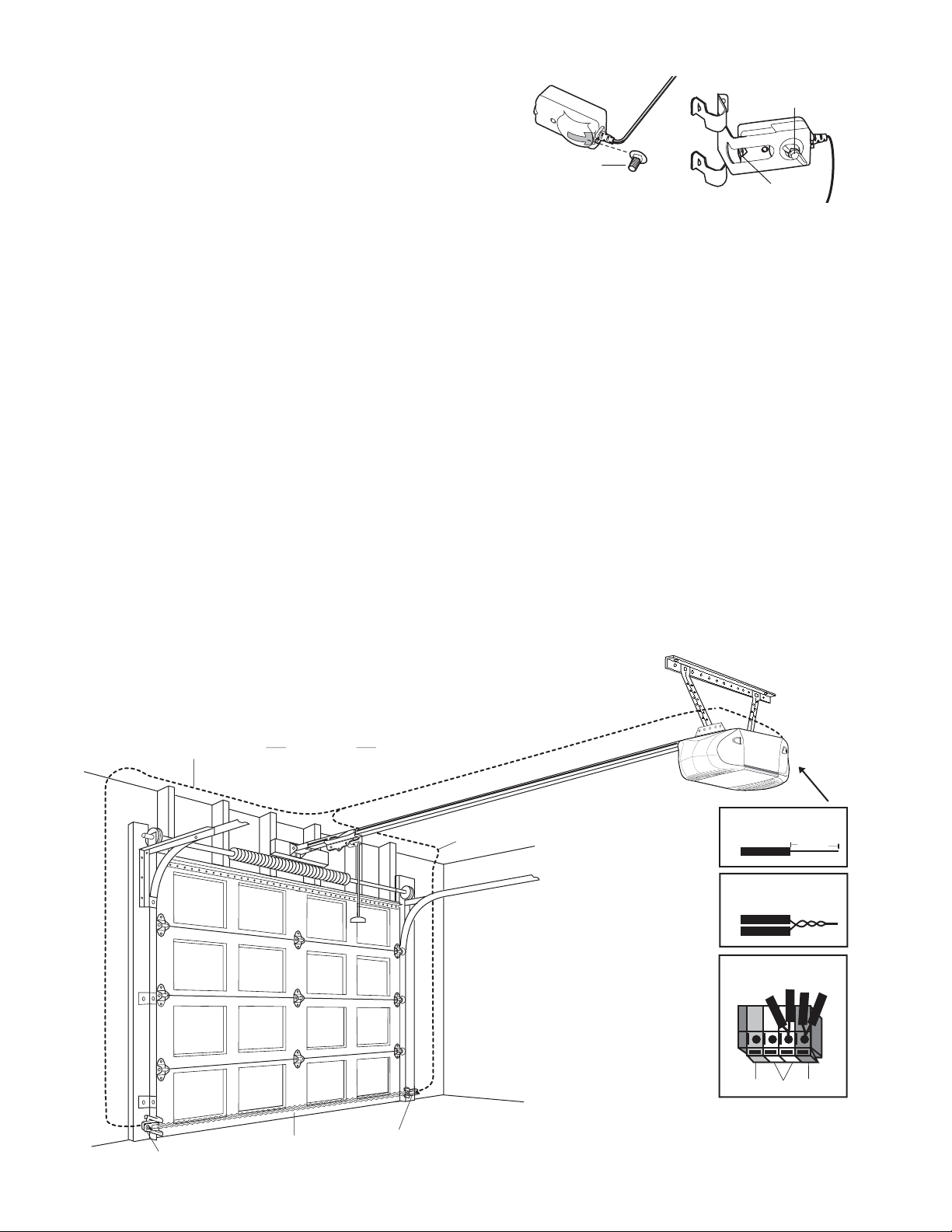

Figure 5MOUNTING AND WIRING THE SAFETY

REVERSING SENSORS

• Slide a 1/4"-20x1/2" carriage bolt head into the slot

on each sensor. Use wing nuts to fasten sensors

to brackets, with lenses pointing toward each other

across the door. Be sure the lens is not obstructed

by a bracket extension (Figure 5).

• Finger tighten the wing nuts.

• Run the wires from both sensors to the opener.

Use insulated staples to secure wire to wall and

ceiling.

• Strip 7/16" (11 mm) of insulation from each set of

wires. Separate white and white/black wires

sufficiently to connect to the opener quick-connect

terminals. Twist like colored wires together. Insert

wires into quick-connect holes: white to white and

white/black to grey (Figure 6).

ALIGNING THE SAFETY REVERSING SENSORS

• Plug in the opener. The indicator lights in both the

sending and receiving eyes will glow steadily if

wiring connections and alignment are correct.

The sending eye amber indicator light will glow

regardless of alignment or obstruction. If the green

indicator light in the receiving eye is off, dim, or

flickering (and the invisible light beam path is not

obstructed), alignment is required.

• Loosen the sending eye wing nut and readjust,

aiming directly at the receiving eye. Lock in place.

• Loosen the receiving eye wing nut and adjust

sensor until it receives the sender’s beam. When

the green indicator light glows steadily, tighten the

wing nut.

TROUBLESHOOTING THE SAFETY REVERSING

SENSORS

1. If the sending eye indicator light does not glow

steadily after installation, check for:

• Electric power to the opener.

• A short in the white or white/black wires. These

can occur at staples, or at opener connections.

• Incorrect wiring between sensors and opener.

• A broken wire.

2. If the sending eye indicator light glows steadily but

the receiving eye indicator light doesn’t:

• Check alignment.

• Check for an open wire to the receiving eye.

3. If the receiving eye indicator light is dim, realign

either sensor.

NOTE: When the invisible beam path is obstructed

or misaligned while the door is closing, the door will

reverse. If the door is already open, it will not close.

The opener lights will blink 10 times. See page 16.

Figure 6

Wing Nut

1/4"-20

Carriage Bolt

1/4"-20x1/2"

Lens

Connect Wire to

Opener Quick-Connect Terminals

Bell Wire

Safety Reversing Sensor

Finished

Ceiling

Invisible Light Beam

Protection Area

Bell Wire

Safety Reversing Sensor

1. Strip wire 7/16"

(11 mm)

2. Twist like colored

wires together

3. Insert into

appropriate terminals

Red

Quick-Connect Terminals

White

7/16"

(11 mm)

Grey

Page 19

19

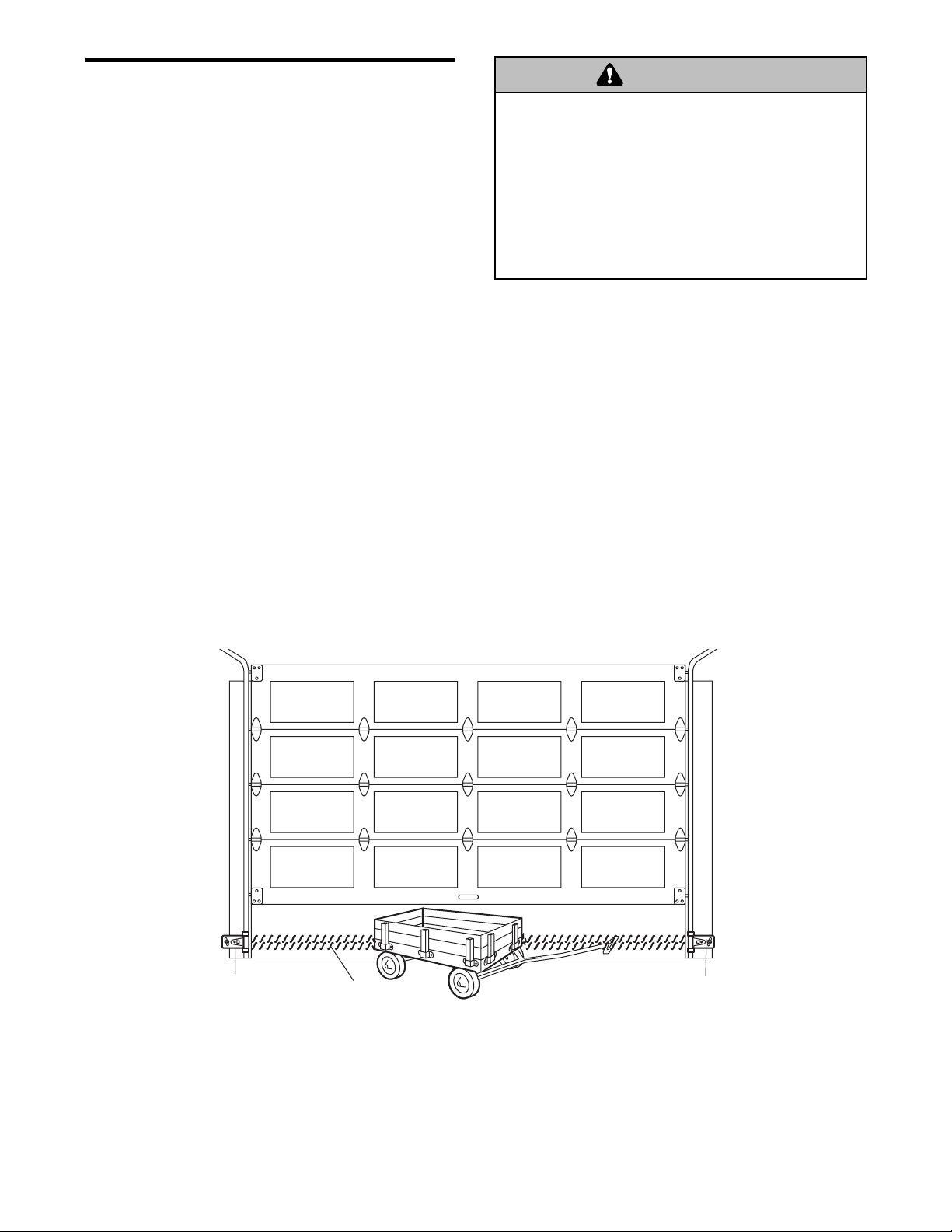

Fiberglass, aluminum or lightweight steel garage doors

will require reinforcement BEFORE installation of door

bracket. Contact your door manufacturer for

reinforcement kit.

WARNING

WARNING

WARNING

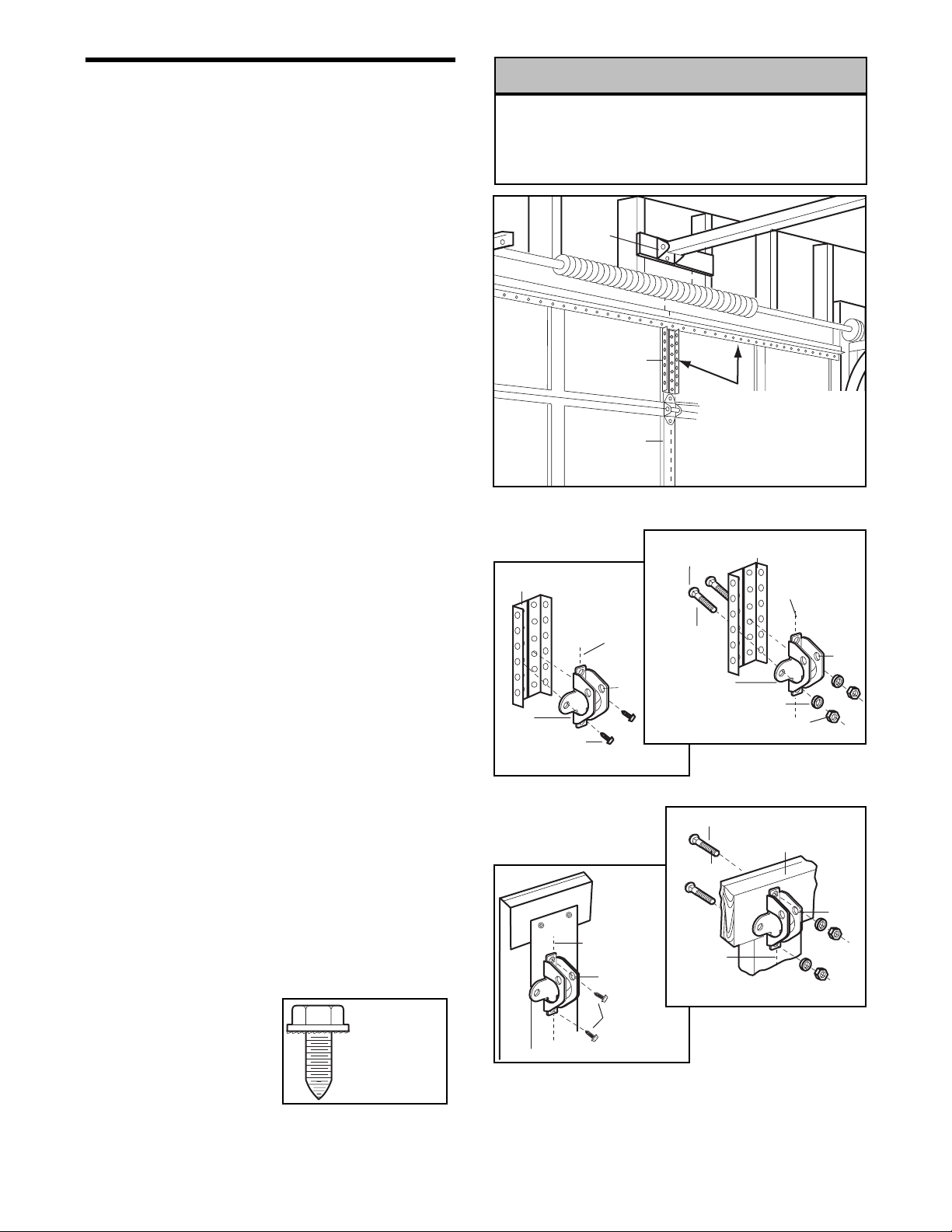

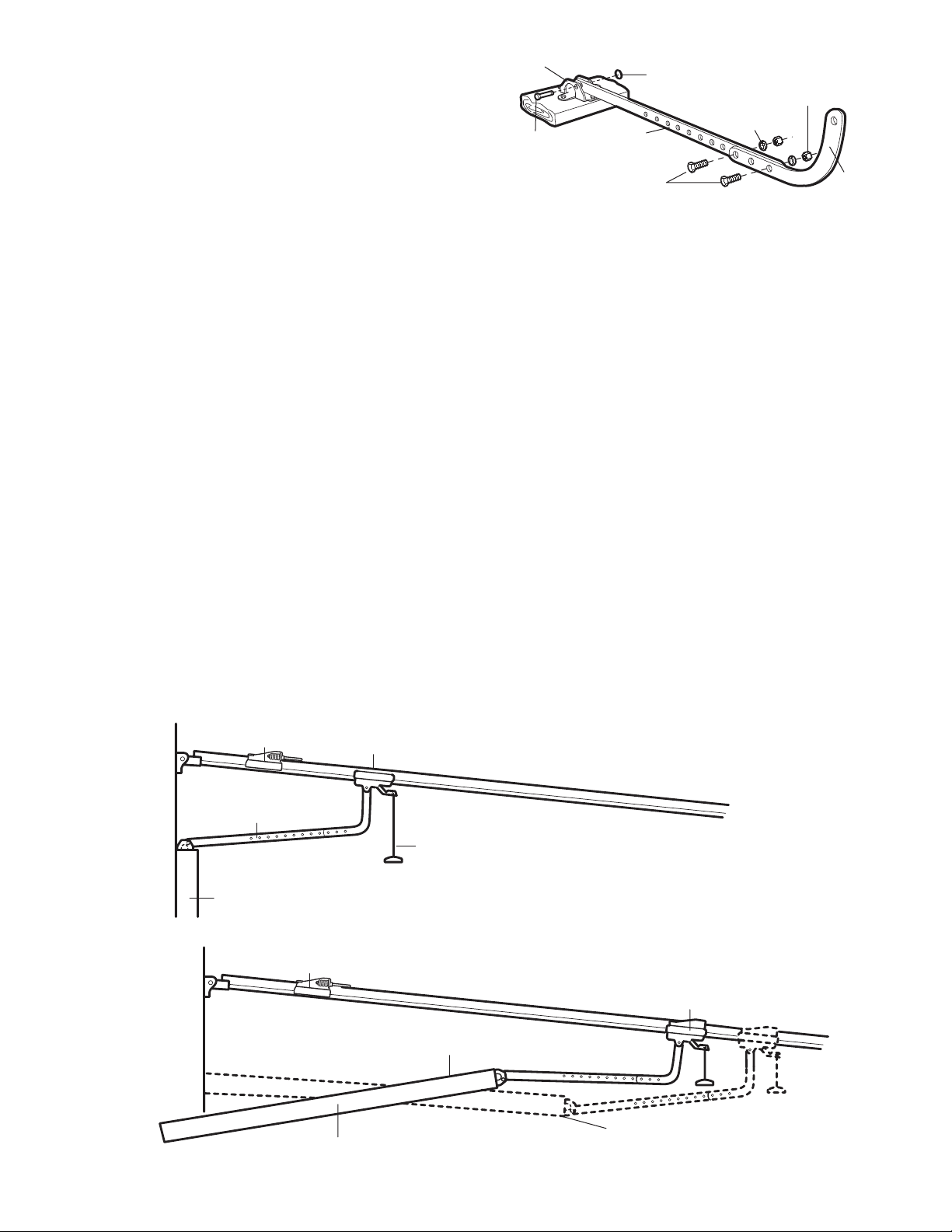

INSTALLATION STEP 11

Fasten the Door Bracket

Follow instructions which apply to your door type as

illustrated below or on the following page.

A horizontal reinforcement brace should be long

enough to be secured to two or three vertical

supports. A vertical reinforcement brace should

cover the height of the top panel.

Figure 1 shows one piece of angle iron as the

horizontal brace. For the vertical brace, 2 pieces of

angle iron are used to create a U-shaped support.

The best solution is to check with your garage door

manufacturer for an opener installation door

reinforcement kit.

NOTE: Many door reinforcement kits provide for

direct attachment of the clevis pin and door arm. In

this case you will not need the door bracket; proceed

to Step 12.

SECTIONAL DOORS

1. Center the door bracket on the previously marked

vertical centerline used for the header bracket

installation. Note correct UP placement, as

stamped inside the bracket.

2. Position the top edge of the bracket 2"-4"

(5-10 cm) below the top edge of the door, OR

directly below any structural support across the top

of the door.

3. Mark, drill holes and install as follows, depending

on your door’s construction:

Metal or light weight doors using a vertical angle

iron brace between the door panel support and

the door bracket:

• Drill 3/16" fastening holes. Secure the door bracket

using the two 1/4"-14x5/8" self-threading screws

(Figure 2A).

• Alternately, use two 5/16" bolts, lock washers and

nuts (not provided) (Figure 2B).

Metal, insulated or light weight factory reinforced

doors:

• Drill 3/16" fastening holes. Secure the door bracket

using the self-threading screws (Figure 3).

Wood Doors:

• Use top and bottom or side to side door bracket

holes. Drill 5/16" holes through the door and

secure bracket with 5/16"x2" carriage bolts, lock

washers and nuts (not provided) (Figure 4).

NOTE: The 1/4"-14x5/8"

self-threading screws are

not intended for use on

wood doors.

Figure 1

Figure 2A

Figure 3

Figure 4

Figure 2B

HARDWARE

SHOWN

ACTUAL SIZE

Self-Threading

Screw

1/4"-14x5/8"

CAUTION

Header

Bracket

Door

Bracket

Location

HORIZONTAL AND VERTICAL

REINFORCEMENT IS NEEDED

FOR LIGHTWEIGHT GARAGE

DOORS (FIBERGLASS,

ALUMINUM, STEEL, DOORS

WITH GLASS PANEL, ETC.).

(NOT PROVIDED)

Vertical

Reinforcement

Vertical

Centerline

of Garage Door

Bolt

5/16"-18x2"

Door

Bracket

Lock Washer

5/16"

(Not Provided)

Bolt

5/16"x2"

Vertical

Centerline

of Garage

Door

Nut

5/16"-18

Inside Edge

of Door or

Reinforcement Board

Vertical

Reinforcement

Vertical

Centerline

of Garage Door

Door

Bracket

Self-Threading

Screw

1/4"-14x5/8"

Vertical

Centerline

of Garage

Door

(Not Provided)

UP

Vertical

Centerline

of Garage Door

UP

Self-Threading

Screw

1/4"-14x5/8"

UP

UP

Page 20

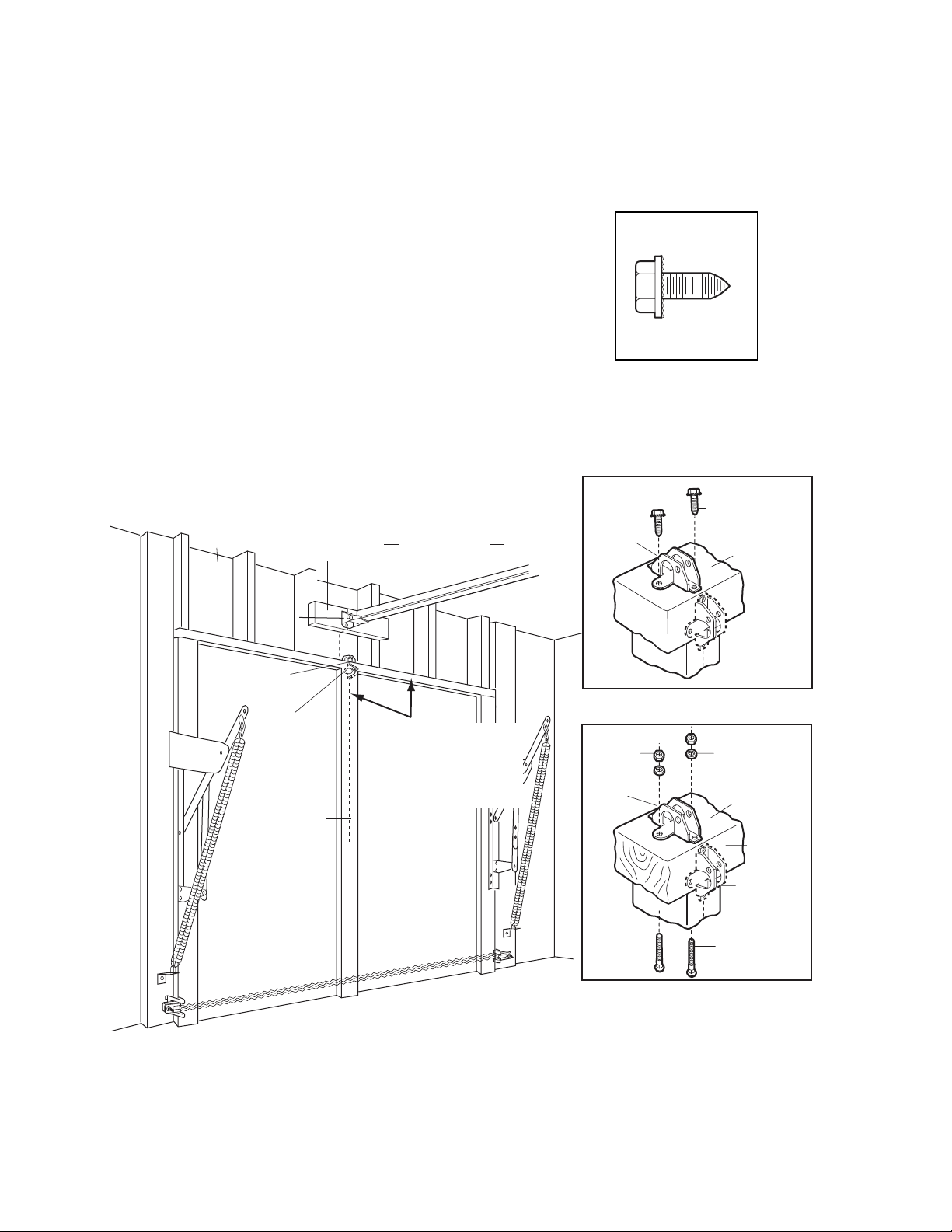

20

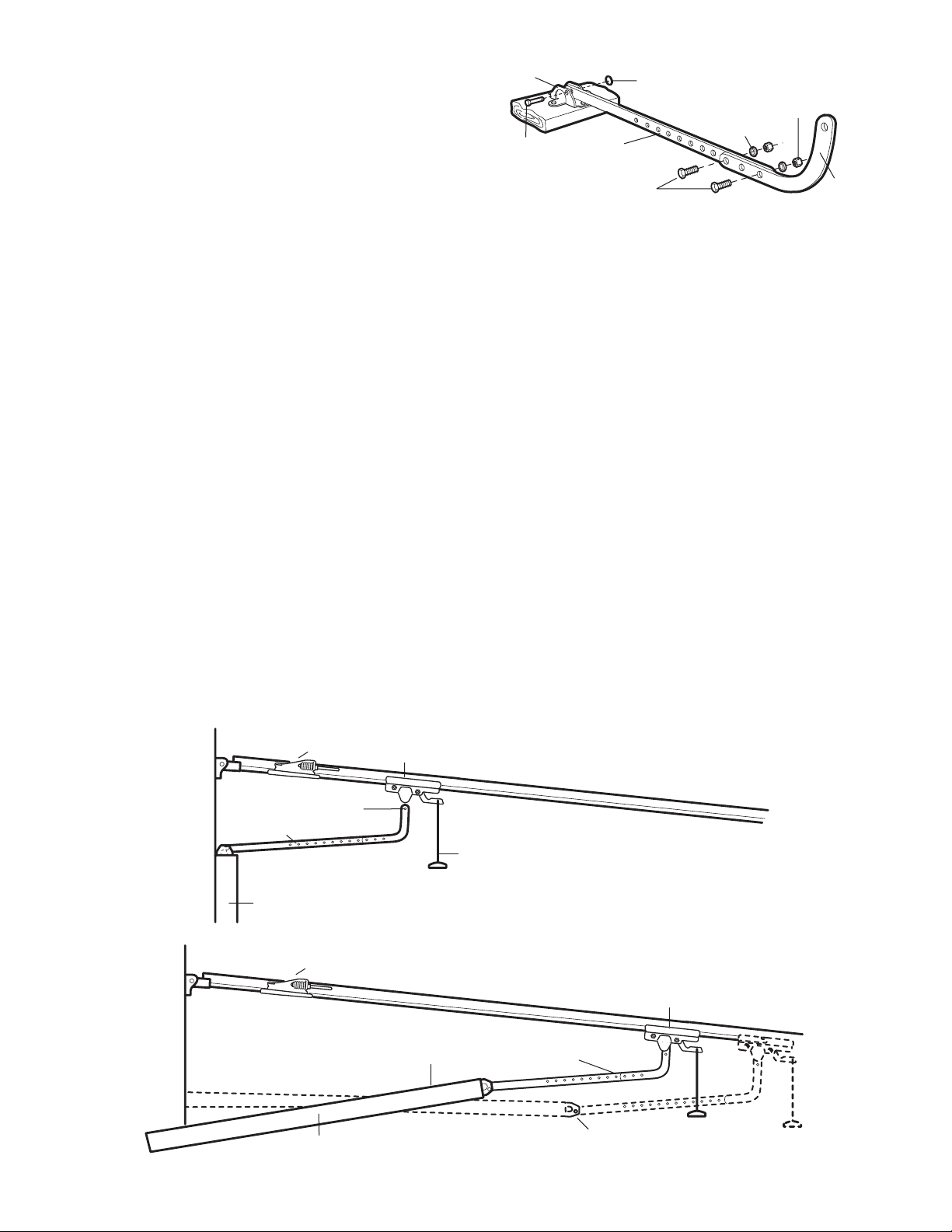

ONE-PIECE DOORS

Please read and comply with the warnings and

reinforcement instructions on the previous page.

They apply to one-piece doors also.

• Center the door bracket on the top of the door, in

line with the header bracket as shown. Mark either

the left and right, or the top and bottom holes.

• Metal Doors: Drill 3/16" pilot holes and fasten the

bracket with the 1/4"-14x5/8" self-threading screws

provided.

• Wood Doors: Drill 5/16" holes and use 5/16"x2"

carriage bolts, lock washers and nuts (not

provided) or 5/16"x1-1/2" lag screws (not provided)

depending on your installation needs.

NOTE: The door bracket may be installed on the top

edge of the door if required for your installation.

(Refer to the dotted line optional placement drawing.)

HARDWARE SHOWN

ACTUAL SIZE

Header Wall

2x4 Support

Header

Bracket

Door

Bracket

Optional

Placement

of Door

Bracket

Vertical

Centerline of

Garage Door

Finished Ceiling

HORIZONTAL AND VERTICAL

REINFORCEMENT IS NEEDED

FOR LIGHTWEIGHT GARAGE

DOORS (FIBERGLASS,

ALUMINUM, STEEL, DOORS

WITH GLASS PANEL, ETC.).

(NOT PROVIDED)

Self-Threading Screw

1/4"-14x5/8"

Door

Bracket

Nut

5/16"-18

Door

Bracket

Self-Threading

Screw

1/4"-14x5/8"

Top of Door

(Inside

Garage)

Top Edge

of Door

Optional

Placement

METAL DOOR

Lock

Washer

5/16"

Top of Door

(Inside

Garage)

Top Edge

of Door

For a door with no exposed framing,

or for the optional installation, use

lag screws 5/16"x1-1/2" (Not Provided)

to fasten door bracket.

Optional

Placement

Carriage Bolt

5/16"x2"

(Not Provided)

WOOD DOOR

Page 21

21

INSTALLATION STEP 12

Connect the Door Arm to the Trolley

Follow instructions which apply to your door type as

illustrated below and on the following page.

SECTIONAL DOORS ONLY

• Make sure garage door is fully closed. Pull the

emergency release handle to disconnect the outer

trolley from the inner trolley. Slide the outer trolley

back (away from the door) about 2" (5 cm) as

shown in Figures 1, 2 and 3.

• Figure 1:

– Fasten straight door arm section to outer trolley

with the 5/16"x1" clevis pin. Secure the

connection with a ring fastener.

– Fasten curved section to the door bracket in the

same way, using the 5/16"x1-1/4" clevis pin.

• Figure 2:

– Bring arm sections together. Find two pairs of

holes that line up and join sections. Select holes

as far apart as possible to increase door arm

rigidity.

• Figure 3, Hole alignment alternative:

– If holes in curved arm are above holes in straight

arm, disconnect straight arm. Cut about 6"

(15 cm) from the solid end. Reconnect to trolley

with cut end down as shown.

– Bring arm sections together.

– Find two pairs of holes that line up and join with

bolts, lock washers and nuts.

• Pull the emergency release handle toward the

opener at a 45° angle so that the trolley release

arm is horizontal. Proceed to Adjustment Step 1,

page 23. Trolley will re-engage automatically when

opener is operated.

Figure 1

Figure 2

Figure 3

HARDWARE SHOWN ACTUAL SIZE

Inner Trolley

Nuts

5/16"-18

Door Bracket

Outer Trolley

Ring

Fastener

Door

Bracket

Clevis Pin

5/16"x1-1/4"

Lock

Washers

5/16"

Clevis Pin

5/16"x1"

Straight

Door Arm

Curved

Door Arm

Emergency

Release

Handle

Bolts

5/16"-18x7/8"

Nut 5/16"-18

Clevis Pin

5/16"x1" (Trolley)

Lock Washer 5/16"

Clevis Pin

5/16"x1-1/4" (Door Bracket)

Ring Fastener

Hex Bolt

5/16"-18x7/8"

Lock

Washers

5/16"

Nuts

5/16"-18

Bolts

5/16"-18x7/8"

Cut This End

Page 22

22

ALL ONE-PIECE DOORS

1. Assemble the door arm, Figure 4:

• Fasten the straight and curved door arm sections

together to the longest possible length (with a 2

or 3 hole overlap).

• With the door closed, connect the straight door

arm section to the door bracket with the

5/16"x1-1/4" clevis pin.

• Secure with a ring fastener.

2. Adjustment procedures, Figure 5:

• On one-piece doors, before connecting the door

arm to the trolley, the travel limits must be

adjusted. Limit adjustment screws are located on

the left side panel as shown on page 23. Follow

adjustment procedures below.

• Open door adjustment: decrease UP travel

limit

- Turn the UP limit adjustment screw

counter-clockwise 4 turns.

- Press the Door Control push button. The trolley

will travel to the fully open position.

- Manually raise the door to the open position

(parallel to the floor), and lift the door arm to the

trolley. The arm should touch the trolley just in

back of the door arm connector hole. Refer to

the fully open trolley/door arm positions in the

illustration. If the arm does not extend far

enough, adjust the limit further. One full turn

equals 3" (7.5 cm) of trolley travel.

• Closed door adjustment: decrease DOWN

travel limit

- Turn the DOWN limit adjustment screw

clockwise 4 complete turns.

- Press the Door Control push button. The trolley

will travel to the fully closed position.

- Manually close the door and lift the door arm to

the trolley. The arm should touch the trolley just

ahead of the door arm connector hole. Refer to

the fully closed trolley/door arm positions in the

illustration. If the arm is behind the connector

hole, adjust the limit further. One full turn equals

3" (7.5 cm) of trolley travel.

3. Connect the door arm to the trolley:

• Close the door and join the curved arm to the

connector hole in the trolley with the remaining

clevis pin. It may be necessary to lift the door

slightly to make the connection.

• Secure with a ring fastener.

• Run the opener through a complete travel cycle. If

the door has a slight “backward” slant in full open

position as shown in the illustration, decrease the

UP limit until the door is parallel to the floor.

NOTE: When setting the up limit on the following

page, the door should not have a “backward” slant

when fully open as illustrated below. A slight

backward slant will cause unnecessary bucking

and/or jerking operation as the door is being opened

or closed from the fully open position.

Figure 4

Figure 5

Door

Bracket

Clevis Pin

5/16"x1-1/4"

Straight

Arm

Bolts

5/16"-18x7/8

Ring

Fastener

Lock

Washers

5/16"

Nuts

5/16"-18

Curved

Door Arm

Door Arm

Closed

Door

Inner Trolley

Door Arm

Connector Hole

Inner Trolley

Open Door

Outer Trolley

Correct Angle

Emergency Release Handle

Outer Trolley

Door Arm

Door with

Backward Slant (Incorrect)

Page 23

23

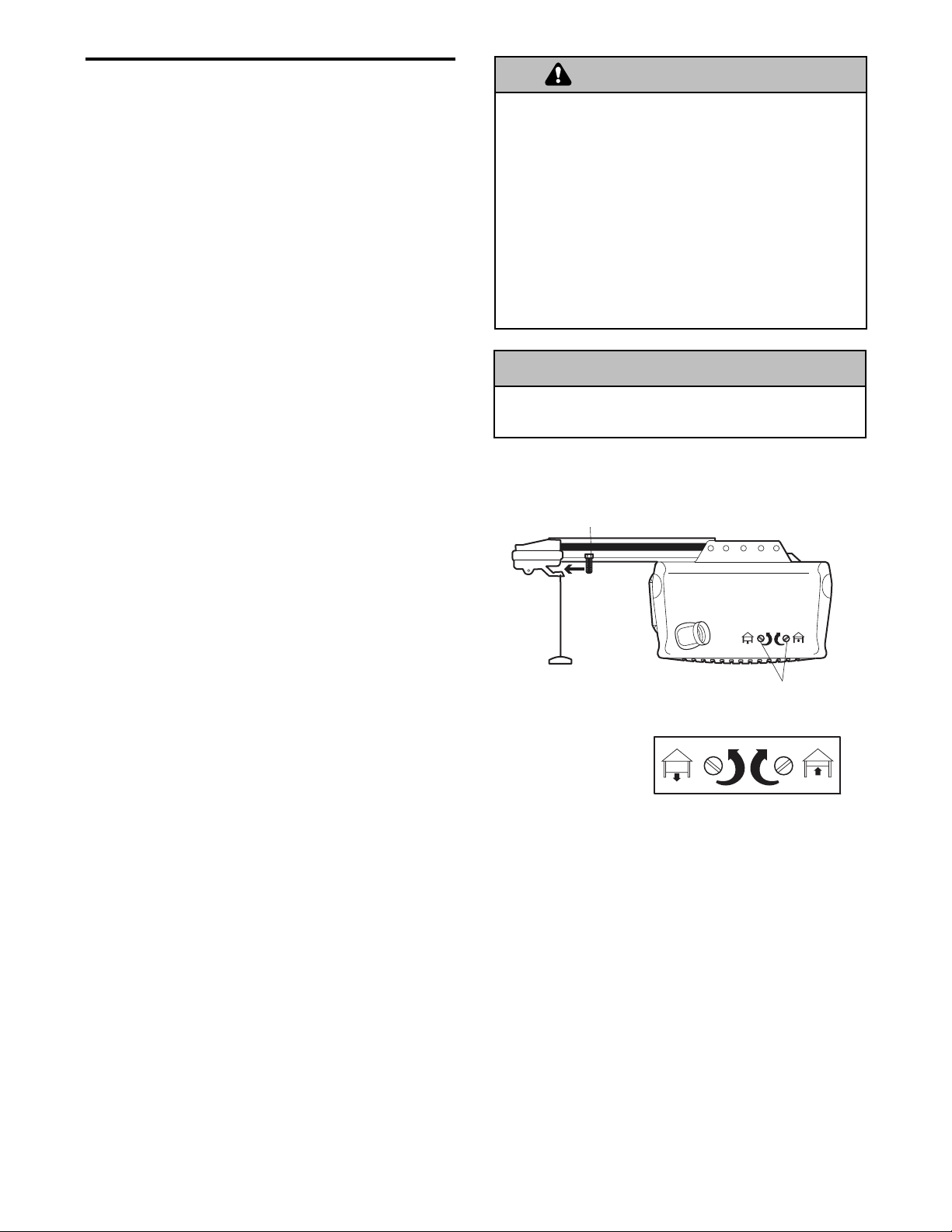

ADJUSTMENT STEP 1

Adjust the Travel Limits

Limit adjustment settings regulate the points at which

the door will stop when moving up or down.

To operate the opener, press the Door Control push

bar. Run the opener through a complete travel cycle.

• Does the door open and close completely?

• Does the door stay closed and not reverse

unintentionally when fully closed?

If your door passes both of these tests, no limit

adjustments are necessary unless the reversing test

fails (Adjustment Step 3, page 25).

Adjustment procedures are outlined below. Read the

procedures carefully before proceeding to

Adjustment Step 2. Use a screwdriver to make limit

adjustments. Run the opener through a complete

travel cycle after each adjustment.

NOTE: Repeated operation of the opener during

adjustment procedures may cause the motor to

overheat and shut off. Simply wait 15 minutes and

try again.

NOTE: If anything interferes with the door’s upward

travel, it will stop. If anything interferes with the

door’s downward travel (including binding or

unbalanced doors), it will reverse.

HOW AND WHEN TO ADJUST THE LIMITS

• If the door does not open completely but opens

at least 5 feet (1.5 m):

Increase up travel. Turn the UP limit adjustment

screw clockwise. One turn equals 3" (7.5 cm) of

travel.

NOTE: To prevent the trolley from hitting the cover

protection bolt, keep a minimum distance of 2-4"

(5 cm - 10 cm) between the trolley and the bolt.

• If door does not open at least 5 feet (1.5 m):

Adjust the UP (open) force as explained in

Adjustment Step 2.

• If the door does not close completely:

Increase down travel. Turn the down limit

adjustment screw counterclockwise. One turn

equals 3" (7.5 cm) of travel.

If door still won't close completely and the trolley

bumps into the pulley bracket (page 4), try

lengthening the door arm (page 21) and

decreasing the down limit.

• If the opener reverses in fully closed position:

Decrease down travel. Turn the down limit

adjustment screw clockwise. One turn equals 3"

(7.5 cm) of travel.

Without a properly installed safety reversal system,

persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage

door.

• Incorrect adjustment of garage door travel limits will

interfere with proper operation of safety reversal

system.

• If one control (force or travel limits) is adjusted, the

other control may also need adjustment.

• After ANY adjustments are made, the safety reversal

system MUST be tested. Door MUST reverse on

contact with 1-1/2" high (3.8 cm) object (or 2x4 laid

flat) on floor.

• If the door reverses when closing and there is

no visible interference to travel cycle:

If the opener lights are flashing, the Safety

Reversing Sensors are either not installed,

misaligned, or obstructed. See Troubleshooting,

page 18.

Test the door for binding: Pull the emergency

release handle. Manually open and close the door.

If the door is binding or unbalanced, call for a

trained door systems technician. If the door is

balanced and not binding, adjust the DOWN

(close) force. See Adjustment Step 2.

WARNING

To prevent damage to vehicles, be sure fully open door

provides adequate clearance.

WARNING

WARNING

WARNING

WARNING

CAUTION

Cover

Protection Bolt

2-4"

(5-10 cm)

Left Side Panel

Limit Adjustment Screws

ADJUSTMENT LABEL

Page 24

24

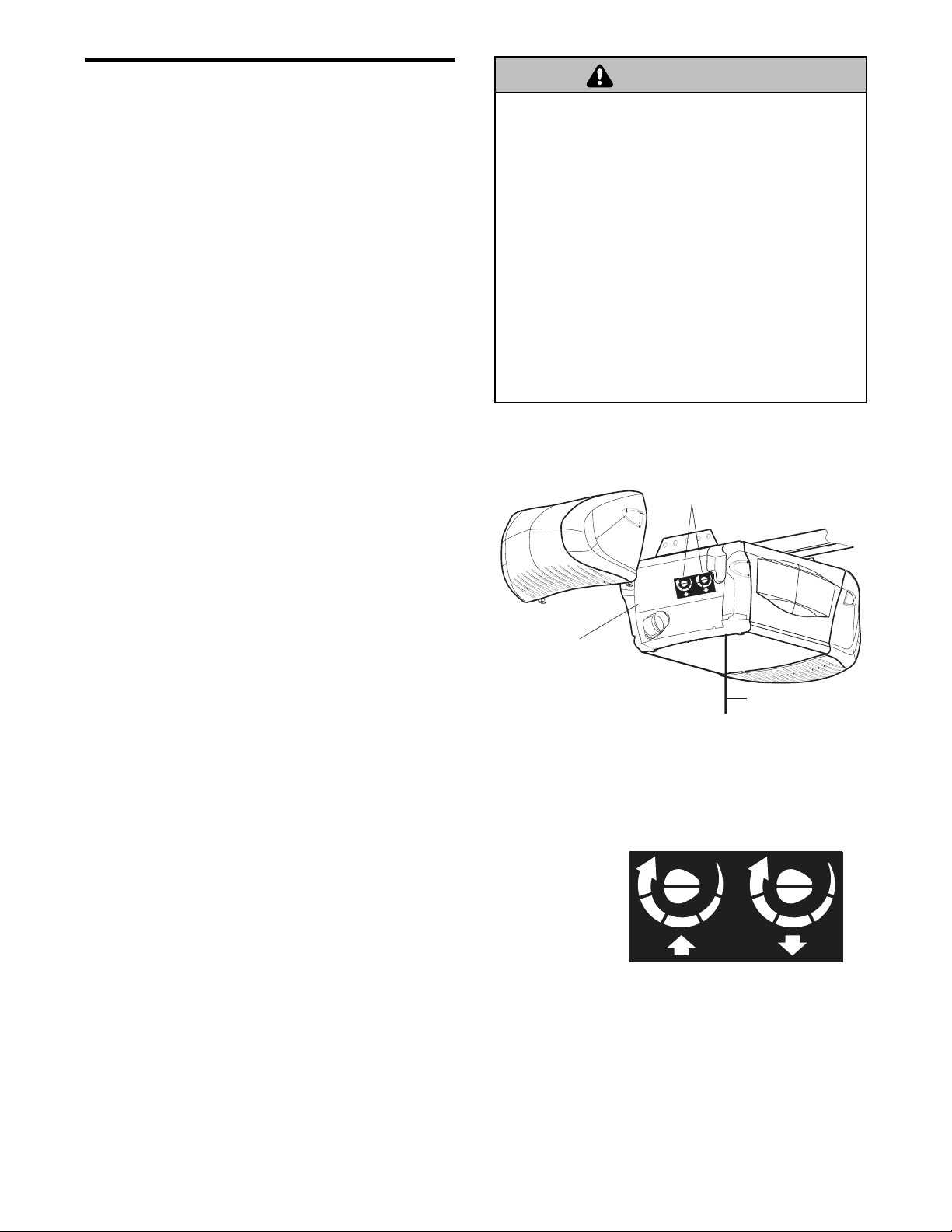

ADJUSTMENT STEP 2

Adjust the Force

Force adjustment controls are located on the back

panel of the motor unit. Force adjustment settings

regulate the amount of power required to open and

close the door.

If the forces are set too light, door travel may be

interrupted by nuisance reversals in the down

direction and stops in the up direction. Weather

conditions can affect the door movement, so

occasional adjustment may be needed.

The maximum force adjustment range is about

3/4 of a complete turn. Do not force controls

beyond that point. Turn force adjustment controls

with a screwdriver.

NOTE: If anything interferes with the door’s upward

travel, it will stop. If anything interferes with the

door’s downward travel (including binding or

unbalanced doors), it will reverse.

HOW AND WHEN TO ADJUST THE FORCES

1. Test the DOWN (close) force

• Grasp the door bottom when the door is about

halfway through DOWN (close) travel. The door

should reverse. Reversal halfway through down

travel does not guarantee reversal on a 1-1/2"

(3.8 cm) obstruction. See Adjustment Step 3,

page 25. If the door is hard to hold or doesn’t

reverse, DECREASE the DOWN (close) force by

turning the control counterclockwise. Make small

adjustments until the door reverses normally. After

each adjustment, run the opener through a

complete cycle.

• If the door reverses during the down (close)

cycle and the opener lights aren’t flashing,

INCREASE DOWN (close) force by turning the

control clockwise. Make small adjustments until the

door completes a close cycle. After each

adjustment, run the opener through a complete

travel cycle. Do not increase the force beyond the

minimum amount required to close the door.

2. Test the UP (open) force

• Grasp the door bottom when the door is about

halfway through UP (open) travel. The door should

stop. If the door is hard to hold or doesn’t stop,

DECREASE UP (open) force by turning the control

counterclockwise. Make small adjustments until the

door stops easily and opens fully. After each

adjustment, run the opener through a complete

travel cycle.

• If the door doesn’t open at least 5 feet (1.5 m),

INCREASE UP (open) force by turning the control

clockwise. Make small adjustments until door

opens completely. Readjust the UP limit if

necessary. After each adjustment, run the opener

through a complete travel cycle.

Without a properly installed safety reversal system,

persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage

door.

• Too much force on garage door will interfere with

proper operation of safety reversal system.

• NEVER increase force beyond minimum amount

required to close garage door.

• NEVER use force adjustments to compensate for a

binding or sticking garage door.

• If one control (force or travel limits) is adjusted, the

other control may also need adjustment.

• After ANY adjustments are made, the safety reversal

system MUST be tested. Door MUST reverse on

contact with 1-1/2" high (3.8 cm) object (or 2x4 laid

flat) on floor.

WARNING

WARNING

Right Panel

Force Adjustment Controls

1

9

1

3

9

7

5

3

7

5

G

K

G

K

Antenna

FORCE ADJUSTMENT LABEL

9

7

5

KG

Open Force

9

1

3

7

Close Force

1

3

5

KG

Page 25

25

Without a properly installed safety reversal system,

persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage

door.

• Safety reversal system MUST be tested every month.

• If one control (force or travel limits) is adjusted, the

other control may also need adjustment.

• After ANY adjustments are made, the safety reversal

system MUST be tested. Door MUST reverse on

contact with 1-1/2" high (3.8 cm) object (or 2x4 laid

flat) on the floor.

ADJUSTMENT STEP 3

Test the Safety Reversal System

TEST

• With the door fully open, place a 1-1/2" (3.8 cm)

board (or a 2x4 laid flat) on the floor, centered

under the garage door.

• Operate the door in the down direction. The door

must reverse on striking the obstruction.

ADJUST

• If the door stops on the obstruction, it is not

traveling far enough in the down direction.

Increase the DOWN limit by turning the DOWN

limit adjustment screw counterclockwise 1/4 turn.

NOTE: On a sectional door, make sure limit

adjustments do not force the door arm beyond a

straight up and down position. See the illustration

on page 21.

• Repeat the test.

• When the door reverses on the 1-1/2" (3.8 cm)

board, remove the obstruction and run the opener

through 3 or 4 complete travel cycles to test

adjustment.

• If the unit continues to fail the Safety Reverse Test,

call for a trained door systems technician.

IMPORTANT SAFETY CHECK:

Test the Safety Reverse System after:

• Each adjustment of door arm length, limits, or

force controls.

• Any repair to or adjustment of the garage door

(including springs and hardware).

• Any repair to or buckling of the garage floor.

• Any repair to or adjustment of the opener.

ADJUSTMENT STEP 4

Test The Protector System

®

• Press the remote control push button to open the

door.

• Place the opener carton in the path of the door.

• Press the remote control push button to close the

door. The door will not move more than an inch

(2.5 cm), and the opener lights will flash.

The garage door opener will not close from a remote

if the indicator light in either sensor is off (alerting

you to the fact that the sensor is misaligned or

obstructed).

If the opener closes the door when the safety

reversing sensor is obstructed (and the sensors

are no more than 6" (15 cm) above the floor), call

for a trained door systems technician.

Without a properly installed safety reversing sensor,

persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage

door.

WARNING

WARNING

WARNING

1-1/2" (3.8 cm) board

(or a 2x4 laid flat)

WARNING

Safety Reversing Sensor

Safety Reversing Sensor

Page 26

26

OPERATION

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

Using Your Garage Door Opener

Your Security✚®opener and hand-held remote

control have been factory-set to a matching code

which changes with each use, randomly accessing

over 100 billion new codes. Your opener will operate

with up to eight Security✚®remote controls and one

Security✚®Keyless Entry System. If you purchase a

new remote, or if you wish to deactivate any remote,

follow the instructions in the Programming section.

Activate your opener with any of the following:

• The hand-held Remote Control: Hold the large

push button down until the door starts to move.

• The wall-mounted Door Control: Hold the push

button or bar down until the door starts to move.

• The Keyless Entry (See Accessories): If provided

with your garage door opener, it must be

programmed before use. See Programming.

When the opener is activated (with the safety

reversing sensor correctly installed and aligned)

1. If open, the door will close. If closed, it will open.

2. If closing, the door will reverse.

3. If opening, the door will stop.

4. If the door has been stopped in a partially open

position, it will close.

5. If obstructed while closing, the door will reverse. If

the obstruction interrupts the sensor beam, the

opener lights will blink for five seconds.

6. If obstructed while opening, the door will stop.

7. If fully open, the door will not close when the beam

is broken. The sensor has no effect in the opening

cycle.

If the sensor is not installed, or is misaligned, the

door won’t close from a hand-held remote. However,

you can close the door with the Door Control, the

Outside Keylock, or Keyless Entry, if you activate

them until down travel is complete. If you release

them too soon, the door will reverse.

The opener lights will turn on under the following

conditions: when the opener is initially plugged in;

when power is restored after interruption; when the

opener is activated.

They will turn off automatically after 4-1/2 minutes or

provide constant light when the Light feature on the

Motion Detecting Control Console is activated. Bulb

size is A19. Bulb power is 100 watts maximum.

Security

✚

®

light feature: Lights will also turn on

when someone walks through the open garage door.

With a Motion Detecting Control Console, this feature

may be turned off as follows: With the opener lights

off, press and hold the light button for 10 seconds,

until the light goes on, then off again. To restore this

feature, start with the opener lights on, then press

and hold the light button for 10 seconds until the light

goes off, then on again.

WARNING

WARNING

1. READ AND FOLLOW ALL WARNINGS AND

INSTRUCTIONS.

2. ALWAYS keep remote controls out of reach of children.

NEVER permit children to operate or play with garage

door control push buttons or remote controls.

3. ONLY activate garage door when it can be seen clearly, it

is properly adjusted and there are no obstructions to

door travel.

4. ALWAYS keep garage door in sight until completely

closed. NO ONE SHOULD CROSS THE PATH OF THE

MOVING DOOR.

5. NO ONE SHOULD GO UNDER A STOPPED, PARTIALLY

OPEN DOOR.

6. If possible, use emergency release handle to disengage

trolley ONLY when garage door is closed. Weak or

broken springs or unbalanced door could result in an

open door falling rapidly and/or unexpectedly.

7. NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

8. NEVER use handle to pull garage door open or closed. If

rope knot becomes untied, you could fall.

9. If one control (force or travel limits) is adjusted, the

other control may also need adjustment.

10. After ANY adjustments are made, the safety reversal

system MUST be tested.

11. Safety reversal system MUST be tested every month.

Garage door MUST reverse on contact with 1-1/2" high

(3.8 cm) high object (or a 2x4 laid flat) on the floor.

12. ALWAYS keep garage door properly balanced (see

page 3). An improperly balanced door may not reverse

when required and could result in SEVERE INJURY or

DEATH.

13. ALL repairs to cables, spring assemblies and other

hardware, ALL of which are under extreme tension,

MUST be made by a trained door systems technician.

14. ALWAYS disconnect electric power to garage door

opener BEFORE making ANY repairs or removing

covers.

15.

SAVE THESE INSTRUCTIONS.

WARNING

Page 27

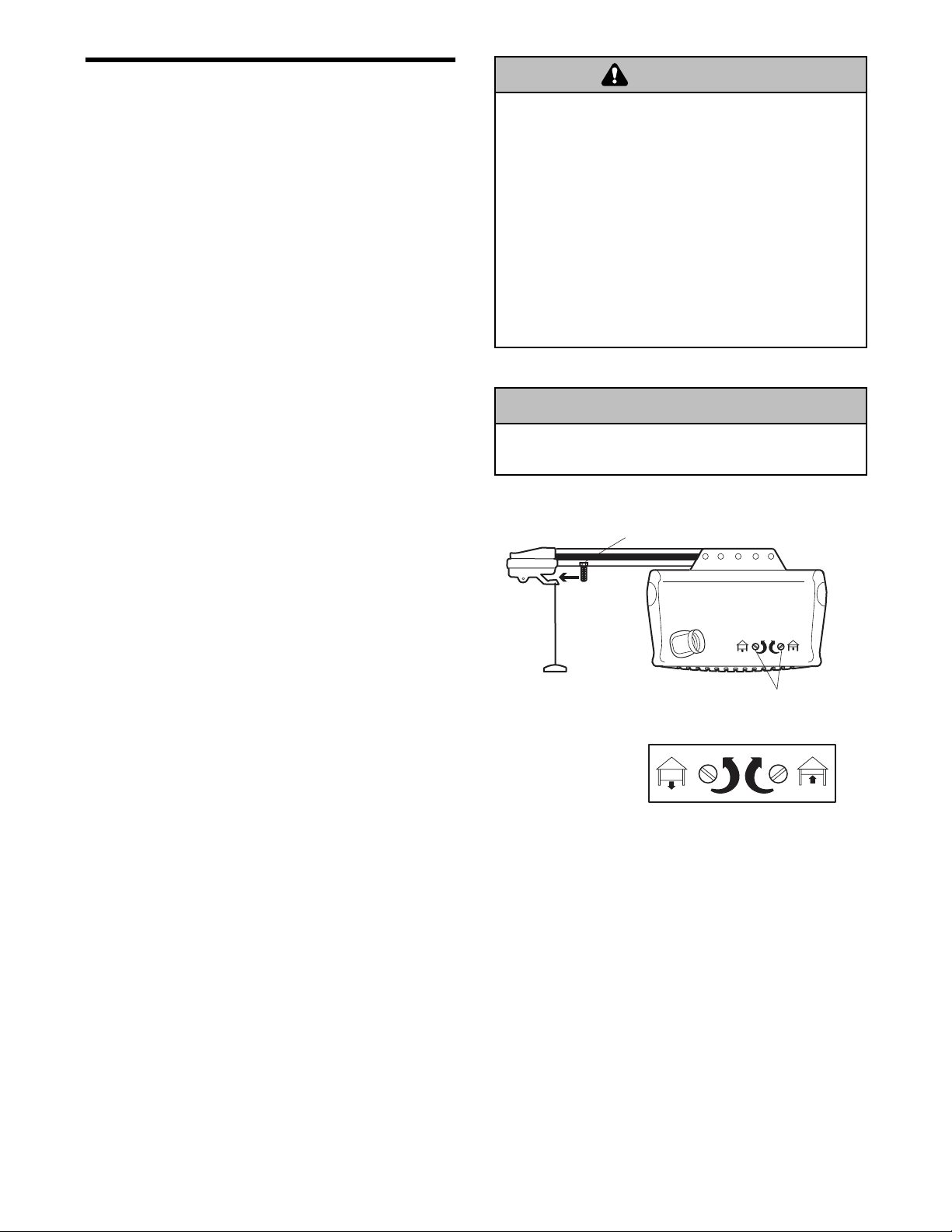

Using the Wall-Mounted Control Console

THE LCD MOTION DETECTING CONTROL

CONSOLE

Press the push bar

to open or close the

door. Press again to

reverse the door

during the closing

cycle or to stop the

door while it's

opening.

This door control contains a motion sensing detector

that will automatically turn on the light when it detects

a person entering the garage.

Light feature

Press the Light button to turn the opener light on or off.

It will not control the opener lights when the door is in

motion. If you turn it on and then activate the opener,

the light will remain on for 4-1/2 minutes. Press again

to turn it off sooner. The 4-1/2 minute interval can be

changed to 1-1/2, 2-1/2, or 3-1/2 minutes as follows:

Press and hold the Lock button until the light blinks

(about 10 seconds). A single blink indicates that the

timer is reset to 1-1/2 minutes. Repeat the procedure

and the light will blink twice, resetting the timer to 2-1/2

minutes. Repeat again for a 3-1/2 minute interval, etc.,

up to a maximum of four blinks and 4-1/2 minutes.

When using the opener lights as working lights, we

recommend that you first disable the motion sensor.

See Automatic Light Feature, below.

Lock feature

Designed to prevent operation of the door from

hand-held remote controls. However, the door will

open and close from the Door Control, the Outdoor

Key Switch and the Keyless Entry Accessories.

To activate, press and hold the Lock button for 2

seconds.

To turn off, press and hold the Lock button again for

2 seconds. The Lock feature will also turn off whenever

the “learn” button on the motor unit panel is activated.

Motion Sensing (Automatic Light Feature): The

opener light will turn on automatically when a person

enters the garage. When a person walks in front of the

door control, the light will come on for five minutes,

then shut off. This feature works by detecting body

heat.

To disable this feature, push the motion

sensing button on the side of the door control.

We recommend that you disable the motion

sensor when using the opener lights as working lights.

Otherwise, they will turn off automatically if you are

working beyond the sensors range.

(PROG) Learn Feature

The control console is equipped with a Prog

<LEARN> button to assist in learning remote controls

to the unit. Press the Prog <LEARN> button once to

initiate LEARN mode and the display will show

‘Learn Remote Control - Press Learn Button Again to

Confirm’. Press the Prog <LEARN> button a second

time and the display will show ‘Learn Mode - Press

Remote Control Button to Learn Remote.’ Press the

button of the remote control to be learned and the

worklight will blink to confirm the remote control has

been learned.

Hour & Minute Feature

Press or hold either of these side buttons to

increment the hour or minute displayed on the LCD

display.

(LANG) Language Feature

Press this side button to toggle between the three

languages - English, French and Spanish.

Degrees F/C Feature

Press this side button to toggle the temperature units

between Fahrenheit and Celsius.

Display Contrast Adjustment

Press and hold the light button then push the hour

button to increase the contrast or the minute button

to decrease the contrast.

Additional feature when used with the 3-Button

hand-held remote

To control the opener lights:

In addition to operating the door, you

may program the remote to operate

the lights.

1. With the door closed, press and hold a small

remote button that you want to control the light.

2. Press and hold the Light button on the door

control.

3. While holding the Light button, press and hold the

Lock button on the door control.

4. After the opener lights flash, release all buttons.

27

LIGHT

Automatic Light

On/Off

Prog <Learn>

Hour

Minute

Language

Degrees (F/C)

IGHT

L

K

C

O

L

Lock Button

Push Bar

Light Button

H M

LOCK

Page 28

28

To Open the Door Manually

The door should be fully

closed if possible. Pull down

on the emergency release

handle and lift the door

manually. To reconnect the

door to the opener, press the

door control push bar.

The lockout feature prevents

the trolley from reconnecting

automatically. Pull the

emergency release handle

down and back (toward the

opener). The door can then

be raised and lowered

manually as often as

necessary. To disengage the

lockout feature, pull the

handle straight down. The

trolley will reconnect on the

next UP or DOWN operation,

either manually or by using

the door control or remote.

To prevent possible SERIOUS INJURY or DEATH from a

falling garage door:

• If possible, use emergency release handle to disengage

trolley ONLY when garage door is CLOSED. Weak or

broken springs or unbalanced door could result in an

open door falling rapidly and/or unexpectedly.

• NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

• NEVER use handle to pull door open or closed. If rope

knot becomes untied, you could fall.

WARNING

LOCKOUT POSITION

MANUAL DISCONNECT

POSITION

WARNING

Emergency

Release

Handle

(Pull Down)

Emergency

Release

Handle

(Down and Back)

N

O

T

IC

E

Trolley

Release

Arm

Trolley

Release

Arm

O

N

E

IC

T

Page 29

29

CARE OF YOUR OPENER

LIMIT AND FORCE ADJUSTMENTS:

Weather conditions may

cause some minor changes

in door operation requiring

some re-adjustments,

particularly during the first

year of operation.

Pages 23 and 24 refer to the

limit and force adjustments.

Only a screwdriver is

required. Follow the

instructions carefully.

Repeat the safety reverse test (Adjustment

Step 3, page 25) after any adjustment of limits or

force.

NOTICE: To comply with FCC and or Industry Canada (IC) rules, adjustment or

modifications of this receiver and/or transmitter are prohibited, except for changing the

code setting or replacing the battery. THERE ARE NO OTHER USER SERVICEABLE PARTS.