Page 1

Portable DWDM OTDR

OPERATING MANUAL

ChallengerOptics

CO-OTDR-DWDM

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

1.0 Using This Manual .........................................3

2.0 Safety ....................................................4

3.0 Quick Start Guide .........................................6

4.0 Inspection and Identication...............................8

4.1 Inspection

4.2 Identication and Conguration

5.0 OTDR Description .........................................9

5.1 OTDR Physical Description

5.2 Home Screen Display

5.3 Power Requirements

5.4 Battery Replacement

6.0 OTDR Operations.........................................12

6.1 Key Pad

6.2 Entering OTDR Function

6.3 Icon Denitions

6.4 Main OTDR screen

6.5 OTDR Parameter Settings Screen

6.6 Auto Test

6.7 Manual Exper t Mode

6.8 Trace Analysis

6.9 Loss Measurements

6.10 Loss Measurement Settings

6.11 Event Analysis

7.0 Project Management .....................................28

7.1 Project Management Description

7.2 Project Management Operation

8.0 File Management.........................................32

8.1 File Management Description

8.2 File Management Operation

9.0 Tunable Laser Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

9.1 Laser Safety

9.2 TLS Quick Star t Guide

9.3 Operation

10.0 Fault Locate..............................................41

10.1 Fault Locater Description

10.2 LTS Fault Locater Operation

11.0 Video Scope..............................................45

11.1 Entering Video Scope Function

11.2 Video Scope Display

11.3 Video Scope File/Help Icon Menu

11.4 Video Scope Operations Icon Menu

11.5 Video Scope Operation

11.6 Pass/Fail Criteria Tables

12.0 Visual Fault Locater.......................................50

12.1 VFL Safety

12.2 VFL Description

12.3 VFL Operation

13.0 Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

14.0 Repair/Warranty/ Version Control .........................53

14.1 Repair Information

14.2 Warranty Information

14.3 Version Control

CONTENTS

090817

Page 2

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 1.0 - Using this Manual / 03

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

This manual contains operation information for the Challenger Cable Sales CO-OTDR Optical Time

Domain Reectometer. This OTDR may be operated by using the touch scree or the on board key

pad. The touch screen is a resistive style screen and only proper stylus devices should be used

when operating the OTDR using the touch screen capability.

This guide is written to instruct operation via the on board keypad. There will be tips throughout

the manual to assist with touch screen operation.

PRECAUTIONS

Optical time domain reectometer are optical instruments that do emit laser radiation

and though this level of radiation is not considered a danger, there are safety

considerations and certain practices that should be followed.

Please read and follow all warning and caution information noted in this manual.

There are warnings, cautions and notes posted throughout this manual.

WARNING

A warning alerts to situations that could cause personal injury.

CAUTION

A caution alerts to situations that may cause damage to the equipment or produce poor

testing conditions resulting in inaccurate test results.

Information contained in this manual is believed to be accurate and reliable. However, no

responsibility is assumed by Challenger Cable Sales for its use nor for any infringements

of patents or other rights of third parties that may result from its use. No license is

granted by implication or otherwise under any patent rights of Challenger Cable Sales.

The information contained in the publications is subject to change without notice.

Chapter 2.0 - Safety / 04

Chapter 3 of this manual is a quick start guide. Prior to using the quick start guide or operating

the equipment in any way, it is highly suggested the user reads all safety information.

The information in this chapter pertains to safety consideration of OTDRs in general.

This product has been designed and tested in accordance with the manufacturer’s safety

standards, and has been supplied in a safe condition.

This document contains information that must be followed by the user to ensure safe operation

and to maintain the product in a safe condition. Failure to follow these safety warnings and

cautions can result in harm to the user or damage to the instrument.

WARNING

Personnel should always be aware when working with ber optic test equipment that

active bers may be present, therefore infrared optical energy may be present.

Never look directly into the end of a connected ber optic cable or ber optic interface

of optical test equipment, to do so could expose the user to laser radiation and could

result in personal injury.

To Prevent Fire or Shock Hazard:

- Do not install battery types other than those specied by the manufacturer

- Do not use the charger without the batteries installed

- Do not expose the battery charger to rain or excessive moisture

- Do not use the AC adapter when there are signs of damage to the enclosure or cord

- Ensure the correct charger is being used for the local line voltage

-Do not use any other charger than the one provided with this instrument.

Page 3

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 2.0 - Safety / 05

CAUTION

Fiber-optic connectors are easily contaminated or damaged. The connection to the

OTDR is physical contact type of connections and dirty or damaged connectors may

impair the instruments capabilities at minimum and at worst result in the need to return

the OTDR to the factory for expensive repairs. Prior to making any connection to the

unit, ensure that all proper cleaning procedures have been followed. Use UPC Finish

Connectors Only -- DO NOT insert APC connectors into the optical ports.

The OTDR is equipped with a protection circuit to avoid damage from live ber

connections The instrument will not operate properly with active bers. Even with this

protection, high power output from EDFA’s or other equipment can damage detectors

and should never be connected to the OTDR.

If a live ber is connected to the OTDR and a scan is attempted, a warning dialog will

be displayed as in g. 2.1. Immediately remove the live ber from the OTDR and press

select to continue testing.

Failure to follow these cautions statements may void the warranty of, or cause

damage to this equipment.

Chapter 3.0 - Quick Start Guide / 06

Press to turn on the OTDR.

This quick start guide demonstrates use by way of the touch screen unless the keypad is required.

Touch the OTDR icon located in the center of the Home screen.

Connect the ber to the appropriate OTDR Optical Port.

Touch the (wavelength (Lambda) icon) on the left side of the parameter area of the display

to bring up the wavelength selection pages. Touch the desired wavelength for testing or select

the next page.

If approximate ber length is unknown:

Press to have the OTDR start a test using the selected wavelength with the OTDR

determining the most appropriate range and pulse width.

If approximate ber length is known:

Set the Wavelength as above.

Touch the (Average icon) to cycle through the available averaging times of Real-Time, 15

seconds, 1, 4, 16 or 40 minutes.

Touch the (Pulse Width icon) to cycle through the available pulse widths of 5ns, 10ns,

30ns, 100ns, 300ns, 1us, 3us, 10us or 20us. (Not all pulse widths will be available, only pulse

widths appropriate for the selected range will be presented)

AutoTest

Page 4

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 3.0 - Quick Start Guide / 07

Touch the (Range icon) to cycle through the available ranges of 500m, 1km, 4km, 16km,

64km, 128km or 256km.

Touch scan or press the Scan button to start a trace. A second touch or press will stop a trace.

To operate the cursors, touch the A ➞ B area of the screen or press the A/B button to toggle

between A and B as the active cursor. To move the cursors, with the desired cursor as the active

cursor (solid vertical cursor line) touch the screen and the cursor will snap to that location, leave

the cursor in contact with the display and drag the cursor to the desired location. The left and

right buttons on the display may also be used.

To view the event table with the trace, touch the Event tab in the center of the display.

To view the schematic with the trace, touch the Schematic tab in the center/right of the display

To save a trace, touch the button and use the left or right buttons to highlight the Quick

Save icon.

Touch it or press . The le will be saved to the active folder (project).

Menu

Select

Chapter 4.0 - Inspection / Identication / 08

4.1 Inspection

Before shipment, this instrument was inspected and found to be in perfect working order and

free of defects.

The shipping carton contains the following:

1. OTDR with Protective boot

2. Universal AC/DC charger with interchangeable mains

3. USB cable

4. Manual and CertSoft software on CD.

5.Set of interchangeable adapters, SC, and FC.

4.2 Identication and Conguration

The instrument’s Model/Part Number, Serial Number and Date of Manufacture are indicated on a

label located on the back of the unit. The instrument’s history is led at the factory by model/part

number and serial number. The unit's serial number is also located on the top plate just above

the USB Port.

Page 5

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

5.1 OTDR Physical Description

Instrument Enclosure

The CO-OTDR is packaged in a rugged housing which is further protected with a rubberized

boot. Although the front panel is weather resistant, care must be taken to avoid liquids and

contaminants around the fragile optical and electrical connectors, and the glass display. Use a

mild cleaning agent and soft damp cloth to clean up the panels and the outside case. See the

maintenance section to clean the optical connector. NEVER open the instrument for cleaning.

Return to the factory for servicing if necessary.

Front Panel

Top panel

Chapter 5.0 - OTDR Description / 09

Power Button

Key Pad

Color Touch Screen

Protective Rubber Boot

Visual Fault Locater

Power Jack

OTDR Port

Video Probe Port

USB Port

Unit Serial Number

Battery Charge Indicator

Chapter 5.0 - OTDR Description / 10

5.2 Home Screen Display

This unit is equipped with a 4” color TFT resistive touch display. All keyboard functions are also

executable on the touch screen.

5.3 Power Requirements

The CO-OTDR-DWDM is equipped with a 100-240V-0.4A input universal battery charger with 15V,

1.2A, (center positive output). The charger is supplied with interchangeable mains plugs for North

America, Great Britain, Europe and Australia. The units internal power supply is an 11.1V 2600

mAh Li-ion battery. Typically, fully discharged batteries require 2 hours of recharging.

WARNING

To Prevent Fire or Shock Hazard: Do not install other battery types. Do not use the

charger without the batteries installed. Do not expose the battery charger to rain or

excessive moisture. Do not use the AC adapter when there are signs of damage to

the enclosure or cord. Do not use any charger other than the one provided with this

instrument. Any other condition will void the warranty.

Visual Fault Locater

If unit is equipment with a VFL,

selecting this icon with will cycle

through the CW, Modulate and O.

Loss Test Set

If CW source is available,

Select this icon to access the

CW mode of the light source.

Video Scope Icon

Select this icon to open the

video scope function.

Optical Time Domain Icon

Select this icon to open the

OTDR function

Firmware Version

Fault Finder

Select this icon to open the

basic fault nder mode

Page 6

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 5.0 - OTDR Description / 11

5.4 Battery Replacement

Batteries are factory installed. The unit should be returned to the factory for a new battery if

required. It is suggested batteries receive a charge at least one a month.

WARNING

To Prevent Fire or Shock Hazard:

- Do not install battery types other than those specied by the manufacturer

- Do not use the charger without the batteries installed

- Do not expose the battery charger to rain or excessive moisture

- Do not use the AC adapter when there are signs of damage to the enclosure or cord

- Ensure the correct charger is being used for the local line voltage

- Do not use any other charger than the one provided with this instrument.

Failure to follow these caution statements could cause unsafe conditions for

the operator and equipment and may void the warranty.

Chapter 6.0 - OTDR Operations / 12

6.1 Key Pad

Power button, turns the unit On and O.

(Hold for 1 second)

Scan button starts a scan or stops scan.

AutoTest button operates range nder trace

mode. The Range Finder mode momentarily

checks test conditions and starts a scan at the

wavelength selected by the user but allows the OTDR to determine the pulse width

and range parameters.

The Menu button displays and hides the icon menu at the top of the display. It will

also back out of most menu selected screens. In the project folder and le manager it

opens the le/edit menu bar. When the menu is displayed at the top of the screen, the

focus of the LRUD buttons and the select buttons are on the icon menu and no longer

on the trace cursors.

Toggles between A and B as the active cursors.

Selects the Zoom level, each press increments through the levels of 1x, 2x, 4x, 8x, 16x

and 32x.

In the menu mode, the select button actuates highlighted item.

While in the trace mode the directional buttons are used to move the cursors. In the Menu mode,

the Left and right buttons move between the icons. The up button hides the menu bar or moves

cursor up in drop-down menus and the down button opens drop-down menus or move cursor

down while in a drop-down menu.

Select

A / B

AutoTest

Menu

Scan

Select

Zoom

Zoom

Select

Scan

Menu

AutoTest

A / B

Page 7

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 6.0 - OTDR Operations / 13

6.2 Entering OTDR Function

Press the power button the to turn on the OTDR.

Use the LRUD buttons to highlight the OTDR icon and press the select button to enter

the OTDR function.

6.3 Icon Denitions

Home Brings the user back to the home page

Quick Save Saves the current trace to the current folder

Quick Load Recalls the next le, chronologically in the current folder

Tool Box Set screen brightness and calibrate touch screen

Project Folder Opens project management

File Manager Opens le management

Schematic View Opens the Fib-R-Map and event analysis view

Settings Opens the parameters setting page

Splice Zone Setting Turns on LSA/Splice markers

Help Opens the context sensitive help menu

Lambda (Wavelength) Cycles through available wavelengths

Averaging Cycles through averaging times

Pulse Width Cycles through available pulse widths

Range Cycles through available test ranges

Index of Refraction Opens the Index of Refraction entry screen

IOR

6.4 Main OTDR Screen

There are three tabs on the main OTDR screen. OTDR, Events and Schematic. Use the OTDR

tab to view the trace with the loss and distance measurements. Use the Events tab to view an

interactive event table with the trace and numbered events or the Schematic tab to view an

interactive schematic view of the events with the trace and numbered events. Selecting an event

in the event table or the schematic view will snap the active cursor to that event.

"B" Cursor with Position Data

"A" Cursor with Position Data

Main Trace Screen

Distance Increment

Indicators

Screen Tabs - Touching OTDR,

Events and Schematic tabs

change the bottom portion of

the display from parameters

and measurement data for the

OTDR, the event table for Events

and the schematic view for

Schematic (See below)

Zoom Control

Displays the zoom level, and the

values in distance and dB per

grid division. Touch anywhere

in the area to cycle through the

zoom levels.

Scan Button

Displays scan state / status and

the charge level of the batteries.

Touch anywhere in the area to

start or stop a scan.

Loss Method

Displays splice loss, LSA splice loss,

dB per Km and ORL. Touch anywhere

in this area to cycle through the loss

methods.

Test Parameters

Displays test parameters of

wavelength, averaging time,

pulse width, range and ORL.

Touch the symbol or value to

cycle through the available

settings.

"A-B" Cursor Status / Select

Displays the 2pt loss and

distance between the "A" and

"B" cursors. Touching anywhere

in this area will toggle between

active cursors.

Chapter 6.0 - OTDR Operations / 14

Trace Screen

w/ Measurement Data

Trace Screen

w/ Schematic view

Trace Screen w/ Event Table

g 6.2

g 6.3

Page 8

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

6.5 OTDR Parameter Settings Screen

To access the parameter settings screen press the menu button, use the LRUD buttons to

highlight the setting icon and press the select button. An alternate manner to open this screen is

to long touch the screen in the test parameter section of the main OTDR screen.

Trace Parameter Settings

Event Table/Fib-R-Map

Sensitivity Settings

Pass/Fail Thresholds

Settings

End of Fiber Pass/Fail Threshold

Setting

Date and Time

Chapter 6.0 - OTDR Operations / 15

g 6.4

Trace Parameter Settings

The cursor is the yellow highlighted area. (If the yellow cursor is on a value that is selected, that

block will be highlighted green) The blue values are the currently selected values. To move

through this section, use the Up/Down buttons to move between parameters and the Left/Right

buttons to change parameter values.

There are two additional setting in this area that are not available on the main OTDR screen,

distance unit and pulse width unit.

Event Table/Fib-R-Map Sensitivity Settings

The cursor is the yellow highlighted area. (If the yellow cursor is on a value that is selected, that

block will be highlighted green) The blue values are the currently selected values. There are

three levels of sensitivity for the event table and Fib-R-Map. The lowest setting possible should

be used to help lter out any events, that may be caused by short pulse widths, but are not true

perturbations in the optical signal

Pass/Fail Threshold Settings

There are ve pass/fail thresholds that may be set. Use the LRUD buttons to move between

threshold categories, once a categories is highlighted, press select to change the focus of the

LRUD buttons. Use the up/down button to make changes to the highlighted digit and the left/

right buttons to move the another digit. Once the desired value is entered, press selected again.

Continue until all thresholds settings have been completed.

Date/Time Settings

Use the LRUD buttons to highlight the calendar month and press select. Use the left and right

buttons to change the month and press select. Use the LRUD buttons, highlight the date and

press select.

Use the LRUD to buttons to highlight the clock and press select. Use the up/down buttons to

make changes to the highlighted digit and the left/right buttons to move the another digit.

Once the desired time is entered, press selected.

Exit Parameter Setting Screen

Press the menu button or touch Return to exit the parameter page.

Chapter 6.0 - OTDR Operations / 16

Page 9

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

WARNING

Before connecting a patch cord or ber under test, be certain the ber has no active

optical sources or instruments connected to the other end. Skin or eye damage could

result from other high power sources e.g. EDFAs, or instrument damage could occur

voiding the warranty.

Clean connector thoroughly prior to connection to the appropriate port of the OTDR.

Failure to ensure the connectors used with the OTDR are properly cleaned can result in

poor launch conditions at the minimum or damage to the optical interface that requires

the unit be returned to the factory for repair.

6.6 Auto Test

Auto Test is a useful feature when the approximate length of the ber to be tested is unknown.

To use the AutoTest, only the IOR and Wavelength need to be set by the user.

Set IOR

It is necessary to have the Index of Refraction set as close as possible to the actual IOR of the

ber. If this is unknown it is best to use the default setting on the OTDR. To view the current IOR

for a wavelength, open the menu use the left/right button to highlight the IOR Icon. Press select

and the IOR for the wavelength that is the active will be displayed. To change the IOR, use the

on screen QWERTY keyboard to enter the new value and touch save. Each wavelength stores an

independent IOR.

Set Wavelength

To select the wavelength, press the menu button to display the menu at the top of the display.

Use the LRUD buttons to highlight the Lambda (Wavelength) icon, press select to open the page

with available wavelengths displayed. Use the touch screen to select a wavelength or move to

the next page of available wavelengths.

Start Auto Test

Press the AutoTest button and the unit will set the average time to short, the appropriate pulse

width and range parameters for the ber under test.

Chapter 6.0 - OTDR Operations / 17

WARNING

Before connecting a patch cord or ber under test, be certain the ber has no active

optical sources or instruments connected to the other end. Skin or eye damage could

result from other high power sources e.g. EDFAs, or instrument damage could occur

voiding the warranty.

Clean connector thoroughly prior to connection to the appropriate port of the OTDR.

Failure to ensure the connectors used with the OTDR are properly cleaned can result in

poor launch conditions at the minimum or damage to the optical interface that requires

the unit be returned to the factory for repair.

6.7 Manual / Expert Mode

Set IOR

It is necessary to have the Index of Refraction set as close as possible to the actual IOR of the

ber. If this is unknown it is best to use the default setting on the OTDR. To view the current IOR

for a wavelength, open the menu use the left/right button to highlight the IOR Icon. Press select

and the IOR for the wavelength that is the active will be displayed. To change the IOR, use the

on screen QWERTY keyboard to enter the new value and touch save. Each wavelength stores an

independent IOR.

Set Wavelength

To select the wavelength, press the menu button to display the menu at the top of the display.

Use the LRUD buttons to highlight the Lambda (Wavelength) icon, press select to open the page

with available wavelengths displayed. Use the touch screen to select a wavelength or move to

the next page of available wavelengths.

Chapter 6.0 - OTDR Operations / 18

Page 10

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Pulse Width

5ns 10ns 30ns 100ns 300ns 1µ 3µ 10µ 20µ

500m ü ü ü ü ü

1km ü ü ü ü ü

4km ü ü ü ü ü

16km ü ü ü ü ü

64km ü ü ü ü ü

128km ü ü ü ü ü

256km ü ü ü ü ü

Set Range

To set the range, press the menu button and use the LRUD buttons to highlight the range icon.

Use the select button to cycle to the desired range.

Set Pulse Width

To set the pulse width press the menu button and use the LRUD buttons to highlight the pulse

width icon. Use the select button to cycle to the desired pulse width

Set Averaging Time

To set the averaging time press the menu button and use the LRUD buttons to highlight the

averaging icon. Use the select button to cycle through the averaging times of RT (Real Time), 15,

or 60 seconds, 2 or 4, 8 or 20 minutes.

Scan

Once all the proper settings have been entered, press the Scan button to take the trace. To stop

the trace press the scan button again.

Range

Chapter 6.0 - OTDR Operations / 19

6.8 Trace Analysis

Unit of Measure

The distance unit of measure may be either displayed in Kilometer (Km), Kilo feet (Kf) or Miles

(Mi). To set the unit of measure, press the menu button, use the LRUD buttons to highlight the

settings icon and press select to open the parameter screen. Use the down button to move the

cursor to the D.Unit line in the parameter menu, and use the left or right button to highlight

the desired unit of measure and press select. Press the menu button or touch Return to exit the

parameter settings page.

Zoom

There are six zoom levels, 1x, 2x, 4x, 8x,16x and 32X. To change the zoom level, press the zoom

button on the keypad. This will cycle through the six levels. When viewing the trace at a zoom

level other than 1x, the active cursor is centered on the trace display and when the cursors are

moved, the trace moves and the cursor will remain centered.

Cursor Movement

The active cursor is displayed as a solid line and the non-active cursor as a dashed line. Pressing

the A/B button on the keypad toggles between the two cursors as the active cursor. The cursors

are moved using the left and right buttons.

6.9 Loss Measurements

2 Point loss

2 Point loss measurements take into account the dierence in vertical height between where

the A and B cursors cross the ber trace to determine loss. This information is located on the

main OTDR screen in the A-B section of the trace information as shown in Fig. 6.2. This is a quick

method of checking the loss between any two points on a ber optic link.

dB/km

The dB/Km (dB/Kft or dB/Mi) loss method takes the 2 Point loss in dB and divides by the distance

between the cursors in Km (Kilometers), Kf (Kilo feet) or Mi (Miles). For accurate dB/.... loss

measurements, the two cursors must be on level back scatter points at least 100m apart (NA will

show for distances that are too short).

Chapter 6.0 - OTDR Operations / 20

Page 11

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Optical Return Loss

This Optical Return Loss (ORL) is separate from the event ORL (Reectance) that is displayed in

the event analysis under the TYPE header for an individual event. The measurement displayed

in the loss measurement area of the main OTDR screen and in the E (End of Fiber) row in the

TYPE column is an optical return loss based on the entire link. It is the total accumulated light

reected back to the source along the telecommunication link.

Basic Splice Loss

Splice Loss method is meant to be used in noisy environments when it is dicult to attain an LSA

area that lays at on the back scatter before and after the cursor. This method takes an average

of the selected points before and after the active cursor and uses this average to make a good

estimation of the event loss. This is an estimation but this method may be more accurate than

LSA Splice Loss method in noisy environments.

When using the splice loss It is necessary to set these areas in clear back scatter (areas that do not

consist of other events) to acquire the most accurate measurements. For accurate measurements,

these areas can not include other events such as reective or splice events. Set a cursor at the

beginning of an event and set splice loss measurement areas as directed below and as shown

in Fig. 6.6 for accurate splice loss measurements. Splice loss measurement areas will follow the

undulations of the back scatter line unlike LSA areas.

Least Squares Approximation (LSA)

Least Squares Approximation (LSA) Splice loss method gives the user a visual aid in setting splice

loss areas. This method can be more accurate by aording the ability to see the slope of the splice

loss areas, however: it can also supply a reading with greater error if not used properly. The splice

loss lines must be set to overlay the back scatter of a trace without over lapping any other events.

Unlike basic splice lose, LSA measurement areas are drawn as straight lines without regard to the

undulations of the back scatter

6.10 Loss Measurement Settings

Setting Splice Loss Measurement Areas. To set the basic splice loss measurement/ LSA ares,

the OTDR must be in Splice AVG or Splice LSA mode. To adjust the splice loss areas around the

cursors, press the menu button, highlight the LSA icon and press select. The splice lose position

indicator will be displayed at splice loss position number 1 as indicated in Fig. 6.6 Use the left

and right buttons to adjust the loss measurement area. Press the select button to move the

splice lose position indicator to the position number 2, set the area and continue with positions

3 and 4 in the same manner. Press select when done with position number 4 to hide the splice

lose position indicator and reset the focus of the keyboard back to the cursors. Press the menu

button at any time to escape the splice lose settings sequence.

Chapter 6.0 - OTDR Operations / 21 Chapter 6.0 - OTDR Operations / 22

Splice Loss Adjustment Areas

Splice Loss Adjustment Positions

LSA Splice Loss

Measurement Areas

LSA Splice Loss

Measurements

Basic Splice Loss

Measurements

Basic Splice Loss

Measurement Areas

Active Splice

Zone Cursor

Active Splice

Zone Cursor

Splice Loss Position

#1

Splice Loss Position

#4

Splice Loss Position

#3

Splice Loss Position

#2

g 6.6

g 6.5

Page 12

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 6.0 - OTDR Operations / 23

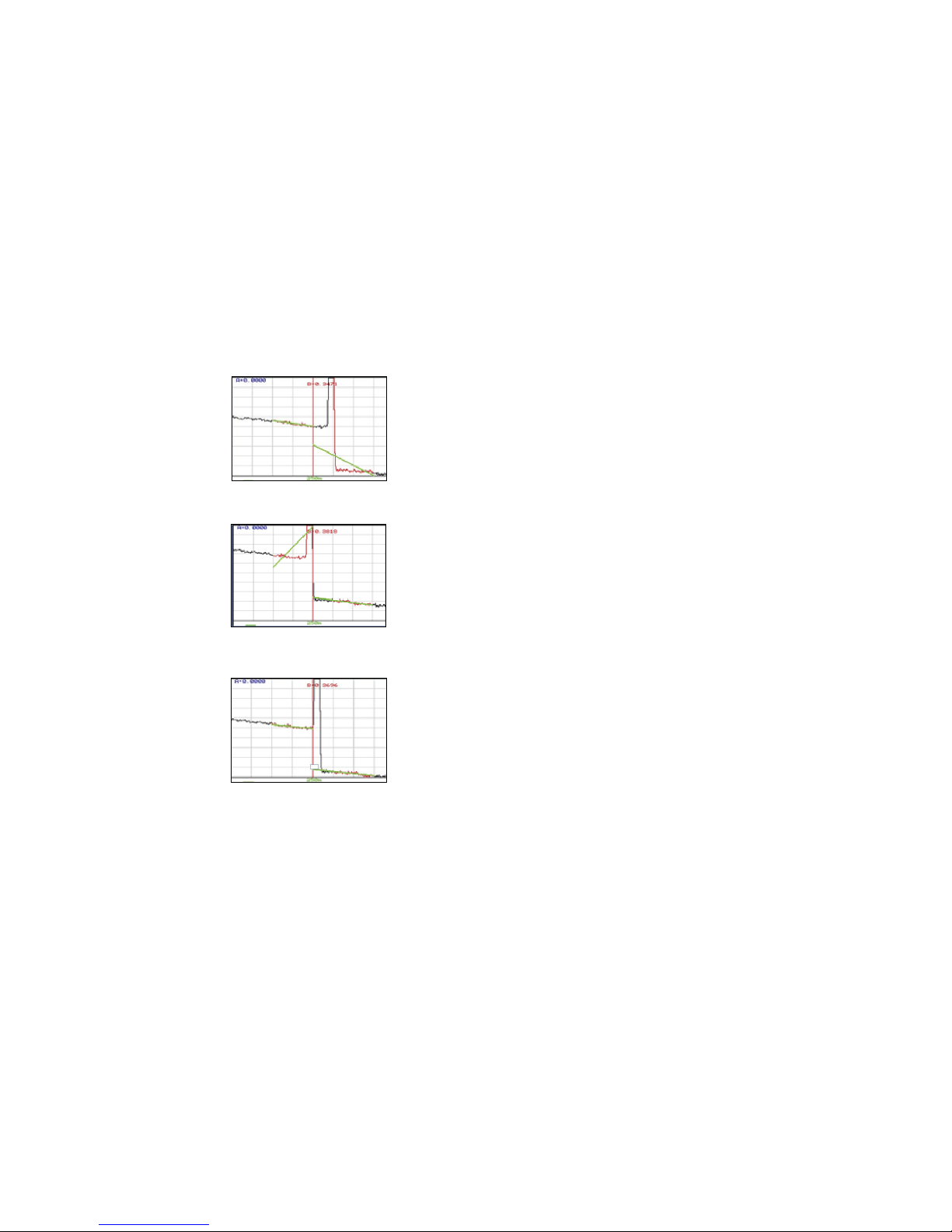

LSA Examples

LSA Set Too Early:

The LSA area and cursor are set too early.

The right most green LSA indicator line

is not over laying the back scatter of the

trace properly

LSA Set Too Late:

The LSA area and cursor are set too late.

The left most green LSA indicator line is

not over laying the back scatter of the

trace

Proper LSA Setting:

The LSA area and cursor are set properly.

The green LSA indicator line is over

laying the back scatter of the trace

properly.

g 6.7

g 6.8

g 6.9

6.11 Event Analysis

Enter Event Analysis

To enter event analysis, press the menu button and use the left / right buttons to highlight the

Schematic View analysis icon and press select.

Threshold Settings

There are four threshold settings, EOF, Loss, ORL and Link. (See Fig 6.4) The EOF is not a Pass/Fail

threshold, it is used to set a loss value to determine the end of ber. IF the EOF threshold is set for

3dB, then the rst event that has a loss of 3dB or greater will be deemed the EOF.

To change the threshold settings, press the Menu button, use the left/right buttons to highlight

the settings icon and press select. The cursor is the yellow highlighted area. (If the yellow

cursor is on a value that is the current selection, that block will be highlighted green.) The

setting highlighted in blue is the current setting. Use the LRUD buttons to highlight the desired

threshold category and press the select button. Use the up/down buttons to set the digit,

and use the left/right buttons to move to the next or previous digit. Once the desired setting

is entered, press the select button. Use the LRUD buttons to move to the next setting until all

thresholds have been set as desired. To exit the parameter screen, press the menu button.

Splice, ORL and Link are all thresholds for Pass/Fail purposes.

Examples of these settings are as follows:

Splice: If a 1.00dB splice loss is acceptable, set the threshold to 1.00. If a splice loss of

1.00 is the fail point, set the threshold to 0.99

ORL: If a -50dB reectance is acceptable, set the threshold to 50. If -50dB is the fail

point, set the threshold to 50.5.

Link: If a 20dB, link loss is acceptable, set the threshold to 20. If 20db link loss is the

fail point, set the threshold to 19.5.

Sensitivity Settings

There are three levels of sensitivity for the event table and Fib-R-Map. (See Fig 6.4) To change the

event sensitivity, press the Menu button, use the left/right buttons to highlight the settings icon

and press select. The cursor is the yellow highlighted area. (If the yellow cursor is on a value that

is the current selection, that block will be highlighted green.) The setting highlighted in blue is

the current setting. Use the LRUD buttons to highlight the desired setting and press select. To

exit the parameter screen, press the menu button.

Chapter 6.0 - OTDR Operations / 24

Page 13

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

The lowest setting possible should be used to help lter out any false events that may be caused

by short pulse widths, but are not true perturbations in the optical signal. High sensitivity

presents events with loss down to approximately 0.1dB, Medium (Md) with events down to

approximately 0.2dB and Low (Lo) for event down to about 0.5dB. Longer pulse widths, and

averaging help to lower the number of false events. Highest sensitivity settings should only be

used for traces with high signal level, low noise, long pulse width and long average.

Event Analysis Screen

Chapter 06 - OTDR Operations / 25

Fib-R-Map

(Schematic View)

Event Table

Event Map with

adjustable splice zones

Trace Parameters

g 6.10

Fib-R-Map

Event Table

Failing Event is Red

Event Number

Range of the Trace

Red Ares is Currently

Being Displayed

Reective Events

Event Location

Fiber Link Length

Passing event

is green

Event Number

Pass/Fail

Event Location Event Loss in dB

Loss Between

Events

dB Per/Km

Between Events

Event Type or

Reectance Value

EOF Location Link Loss

EOF Data

System ORL

Link Data Line

Link

dB Per/Km

Chapter 06 - OTDR Operations / 26

Non-Reective Event

g 6.11

g 6.11

Page 14

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Table Denitions

# Event Number: Indicates the event in sequence, where the higher the number the further

distance from the OTDR the event occurs. “E” (End) is the event determined to be the End of Fiber

(EOF). "L" is the link row and contains information about the entire link tested.

Pass/Fail: if any one of the thresholds are not met for and event, the P/F column will display a

red F. The parameter that failed will also be displayed in red. If all the parameters are met, this

column will display P. The Pass/Fail threshold for the event labeled "L" is the loss displayed in the

2POINT column, the link loss threshold.

Km or KF or MI: Event Location, Km for Kilometer or KF if unit of measure is Kilo-feet MI for mile.

This is the distance/location that the event occurs along the ber link.

Splice: Event Loss, is the splice loss (event loss) of the numbered event. (A positive number is

the amount of loss and a negative number indicates a gain normally due to mismatched index of

refraction.) This is a settable threshold for the Pass/Fail feature. The "E" event will display N/A as

this is not an event that would have meaning. The "L" line of the table is the link and as such does

not have an event (Splice) loss.

2POINT: 2 Point Loss is the loss measured from the end of the dead zone of the previous event

to the beginning of current event. The value in the "L" line of the table for this column is the link

loss. The loss from the beginning of the trace to the event determined to be the EOF. This is the

value used to determine if the ber link passes or fails it's loss threshold.

dB/Km: dB per Kilometer if in KM and DB/KF if in Kilo-Feet and DB/MI if in mile unit of measure.

This is the calculated loss per Km, Kf or Mi from the end of the dead zone of the previous event to

the beginning of the current event. The value in the "L" line of the table for this column is the dB

Per/KM, Kf or Mi for the total link.

TYPE: Event Type is the type of event or the ORL measurement. If the event has no reection,

“splc” will be displayed and if the event contains a reection, the event reectance value will

be displayed. For the last event which is labeled "L" in the # column, the value displayed is the

system ORL.

Chapter 6.0 - OTDR Operations / 27 Chapter 7.0 - Project Management / 28

7.1 Project Management Description

Project Management allows the user to save a set of parameters to be recalled for use at a later

time. It also incorporates the le management system to save traces to the active project folder.

When the OTDR is turned on, the default project is [NONE]. If an existing project is not open or a

new one not set, all traces will be saved to the [NONE] folder.

Project Management Screen

Project Management Menu

The menu for project management may be operated with the touch screen, however, this manual

describes the manner of operation with the keypad. To open the menu press the menu button.

There are four tabs available, File, Edit, View and Help. Use the left or right buttons to move to a

desired tab and use the select or the down button to open the drop-down menus. Pressing the

menu button again or the up button will hide the operations menu.

Project Folder

List

Project

Details/Properties

g 7.1

g 7.2

Page 15

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 7.0 - Project Management / 29

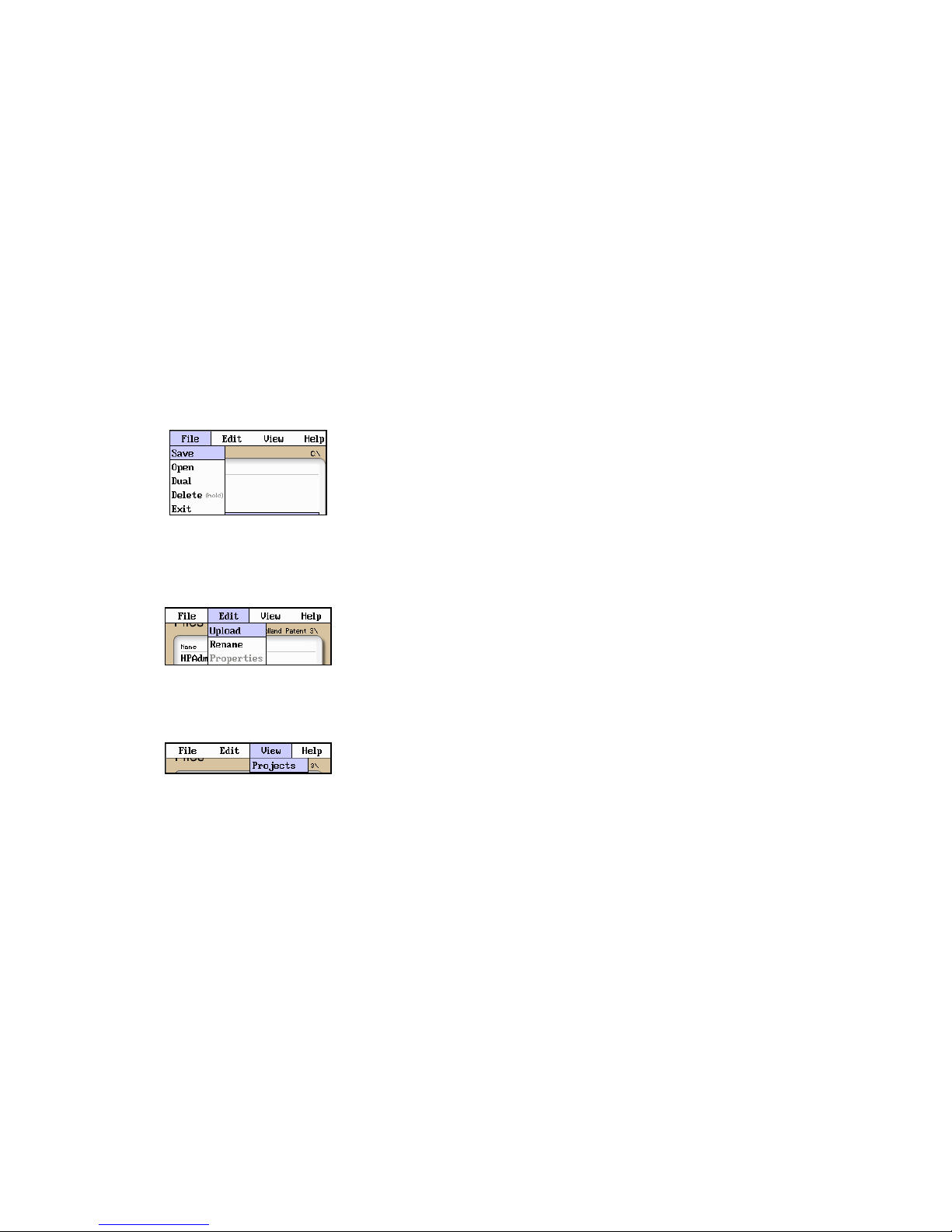

Project Management File Tab

To open the drop down menu under le, with le tab highlighted, press select or the down

button. Use the down or up buttons to move through the drop down menu and select to

choose and operation. Selecting new will open a new project folder using the current parameter

settings. Open will open the highlighted project, dual is not operational in the project

management and therefore grayed out, delete permanently removes the highlighted project.

(The delete button must be held for at least one second to remove projects.) Once delete is

selected, the project and all les associated with that project are deleted. Use exit to leave the

project manager and return to the trace screen.

Project Management Edit Tab

To open the drop-down the menu under edit, with the edit tab highlighted, press select or the

down button. Use the down or up buttons to move through the drop down menu and press

select to choose an operation. Upload is used to transfer les to the CertSoft software. Rename

allows the highlighted folder name to be modied while maintaining all settings and associated

les. Properties allows the user to edit the properties displayed at the bottom of the project

window.

Project Management View and Help Tabs

View oers the user the opportunity to move to the le manager from the projects page. With

view highlighted, press select or the down button to open the drop-down menu, with the les

tab highlighted, press select to move to the le management page. For on board help pages,

highlight the help tab and press select.

g 7.3

g 7.4

g 7.5

7.2 Project Management Operation

Create a New Project

The parameters that are stored for a project are; range, pulse width, average, wavelength,

distance units, pulse width units, event sensitivity and the thresholds. To create a new project,

press menu, select the settings icon, set the parameters as required, when all setting are

established, use the arrow button to highlight the return button or touch return at any time while

in the settings screen. Press the menu button, highlight the project folder icon and press select.

With the le tab highlighted, press select or the down button to open the drop down menu. Use

the down or up buttons to highlight new and press select again. Use the on screen QWERTY

keyboard to name the folder and touch save. The folder names are limited to 16 characters.

To enter details about the project, use the up and down buttons to highlight the project that was

just created and press the menu button. Use the left or right button to highlight the edit tab, use

the down button to highlight properties and press select. Use the up and down buttons to select

the desired eld to be entered or modied and press select. Use the QWERTY keyboard to enter

the information and touch save when complete. Up to 24 characters may be entered for these

elds. To exit the project screen, press menu, press select, use the down button to highlight exit

and press select again.

Open an Existing Project

To open a project, press the menu button, highlight the project folder and press select. Use the

up or down buttons to highlight the desires project folder and press select. This will open the le

management screen listing all the les previously stored in this project. All saved traces will now

be stored to this project ,until a new project is created or another project is opened.

Delete a Project

To delete a project, with the project to be deleted highlighted, open the le drop down menu,

highlight delete and press and hold select. Ensure the proper project is selected as once deleted,

the folder and les cannot be recalled.

Upload a Folder to CertSoft

To upload a folder and all it's associated les from the OTDR to the computer, open the CertSoft

software and ensure the OTDR is connected to the computer with the USB cable.

Highlight the project to be uploaded, press menu to open le manager menu, use the right

button to highlight edit tab, press select or the down button to open the drop down menu and

with upload highlighted, press select. The folder with all les will be uploaded to the target folder

selected on the computer.

Chapter 7.0 - Project Management / 30

Page 16

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Rename a Project

To rename a project, have the project to be renamed highlighted, press menu, to open the

project management menu. Use the left and right buttons to highlight edit tab and press select

or the down button to open the drop-down menu. Use the down button to highlight rename

and press select. The project name will be displayed with the on board QWERTY keyboard. Use

the keyboard to rename the project and touch save.

Modify Properties

To modify the properties, have the project to modied highlighted. Press menu, highlight edit/

properties and press select. The project properties will be displayed, use the up/down buttons to

highlight the eld to be changed, use the on board QWERTY keyboard to make the change and

touch save. Continue with the changes needed, when compete highlight close and press select.

Use the left and right buttons to highlight edit tab and press select or the down button to

open the drop-down menu. Use the down button to highlight properties and press select.

The properties list will be display, use the up or down buttons to highlight the property to

be modied and press select. The QWERTY keyboard will be displayed with the property

information. Press save when done with the change. Continue with the changes needed, when

compete highlight close and press select.

Temporary Modication of Parameters

Test parameters may be temporarily changed by selecting new settings, such as wavelength,

average time, pulse width, and range directly on the main OTDR screen with the touch screen

capabilities or open the parameter settings screen, set the new parameter and save. All

subsequent test will use the new settings until the original settings are returned or the folder is

reopened resetting the project parameters. To make temporary changes to event sensitivity or

thresholds, open the parameters settings page.

Exit Project Management

To exit the project management, press menu, use the left or right buttons to highlight the le tab,

press select or the down button to open the drop down menu. Use the down button to highlight

Exit and press select.

Chapter 7.0 - Project Management / 31 Chapter 8.0 - File Management / 32

8.1 File management Description

File Management is use to save and recall traces. It operates in conjunction with the projects

manager in that if a project folder is open, the les saved to and listed in the le manager are

associated with the open project. When the OTDR is turned on, the default folder is [NONE],

therefore, any les save without opening a project will be save to the [NONE] folder. Any les

saved in the scope function will also be associated with the open folder.

File Management Screen

File Management File Menu

The menu for le management may be operated with the touch screen, however, this manual

describes the manner of operation with the keypad. To open the le management menu press

the menu button.

OTDR Traces Files List

Trace Details/Properties

Project Folder Being Viewed

g 8.1

g 8.2

Page 17

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 8.0 - File Management / 33

File Management File Tab

To open the drop down menu under le, with le highlighted, press select or press the down

button. Use the down or up arrow to move through the drop down menu and press select to

open the highlighted operation. The operations are Save, Open, Dual, Delete and Exit. Save stores

the current trace, Open displays the trace that is currently highlighted, Dual opens a secondary

trace, Delete permanently removes a le and Exit closes the le management screen.

File Management Edit Tab

To open the drop down menu under edit, with edit highlighted, press select or press the down

button. Use the down or up arrow to move through the drop down menu and press select to

choose a highlighted operation. Upload is used to transfer the highlighted le to the CertSoft

software. Rename allows the highlighted le name to be modied. Properties is grayed out and not

accessible from this location.

File Management View/Help Tab

View oers the user the opportunity to move to the projects management page from the le

management page. With view highlighted, press select or the down arrow to drop down the view tab

and press select to move to the le management page. For on board help pages, highlight the help

tab and press select.

8.2 File management Operation

Save a Trace File

To save a trace, press menu, highlight the le manager icon and press select. Press select or the

down button to open the drop down menu and with save highlighted, press select again. The le

naming window will open and the on board QWERTY key board will be available. Use the touch

keyboard to name the le and touch save. The le names are limited to 16 characters. This method

should be used to set the base le name for a group of traces. These le names are save exactly as

entered. To save les with a chronologically numbered sux, use the quick save. Quick Save uses

the last enter base le name.

g 8.3

g 8.4

g 8.5

Chapter 8.0 - File Management / 34

Open/View a Trace

To open a trace, press the menu button, highlight the le folder and press select. Use the up or

down buttons to highlight the trace to be viewed and press select.

Dual Trace Mode

Dual trace mode may be used to view and compare two traces. Both traces must be of the same

range setting. To utilize dual trace feature, rst open the primary trace as you would a normally,

by highlighting the trace in le management, pressing menu to open the le management menu,

with le highlighted, open the drop-down menu use the down button to highlight dual and

press select. The trace opened using the dual feature is the secondary trace and all information

displayed is that of the primary trace. To exit the dual trace mode, start a scan with the scan

button.

Delete a File

To delete a le, with the le to be deleted highlighted, press menu or the down button to open

the le drop down menu, use the down or up buttons highlight delete and press select for at

least one second. Ensure the proper le is selected as once deleted, the le cannot be recalled.

Upload a Trace to CertSoft

To upload a trace from the OTDR to the computer, Open the CertSoft software and ensure the

OTDR is connected to the computer with the USB cable.

Highlight the le to be uploaded, press menu to open le manager menu, use the right button

to highlight the edit tab, press select or the down button to open the drop down menu and with

upload highlighted, press select. The le will be uploaded to the target folder on the computer .

Rename a Trace File

To rename a trace le, have the le to be renamed highlighted. Press menu, use the left or right

button to highlight edit, press select, or the down button to open the drop-down menu, press

the down button to highlight rename and press select. The le name will be displayed with the

on board QWERTY keyboard. Use the keyboard to rename the project and touch save.

Exit File Management

To exit the le management, press menu, use the left or right buttons to highlight the le tab,

press select or the down button to open the drop down menu. Use the down button to highlight

Exit and press select.

Page 18

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 9.0 - Tunable Laser Source / 35

9.1 Laser Safety

The Tunable Laser Source has been congured to provide laser radiation in the C Band of

operation. (1530-1565nm) L Band may be available upon request with a range of (1565-1625nm).

Please see the warning label in gure 9.1.

This is displayed on the left hand side of the

body of the TLS. The unit has been designed

to comply with 21 CFR (Code of Federal

Regulations) 1040.10 and 1040.11, for Class

1M emission limits. Although Class 1 levels are

not considered to be hazardous, we suggest limiting exposure by never looking directly into the

optical aperture. Also, do not under any circumstance view or inspect the laser output bers,

connectors or the ber under test through collimating or focusing optics unless the unit is turned

o, batteries are removed and the power adapter is disconnected.

CAUTION

Personnel should always be aware when working with ber optic test equipment that

active bers may be present, therefore infrared optical energy may be present.

Fiber-optic connectors are easily contaminated or damaged. The connection to this

tunable light source is a physical contact type of connection and dirty or damaged

connectors will impair the instrument’s capabilities at the minimum and at worst result

in the need to return the equipment to the factory for expensive repairs.

Never look directly into the end of a connected ber optic cable or ber optic interface

of optical test equipment, to do so could expose the user to laser radiation and could

result in personal injury.

g 9.1

9.2 TLS Quick Start Guide

Prior to any operation please read the laser safety section of this chapter.

To operate the TLS at a specic wavelength/frequency/channel in CW mode follow this

quick start guide:

Touch the TLS icon on the Home screen.

The Laser Output is displayed in the center of the screen. Touch this value to cycle

through units of, Wavelength (nm), Frequency (THz) and Channel (Ch). 0.4nm

(0.05THz), 0.8nm (0.10THz) or 1.6nm (0.20THz).

Touch and hold the blue wavelength/frequency/channel selector on the scale. Drag

the selector to the desired output value.

Touch the step size indicator to cycle through step sizes until set at 0.40nm for

wavelength, 50 GHz for frequency or 0.5 Ch for channel is displayed.

Touch the power value and a numeric keypad will be displayed. Enter the desired

power value within the ranges set at the top of the display and touch OK.

Touch the Laser icon to energize the laser in a CW mode. Touch the Laser icon a second

time to turn o the laser.

Chapter 9.0 - Tunable Laser Source / 36

Page 19

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

9.3 Operation

From the home screen, touch the TLS icon to enter the tunable laser source feature.

TLS Screen Description

Home Icon Help Icon

Laser Start/Stop/Activity Indicator

Power

Step Size Dwell Time

Output Value

Low End Slide

Output Unit

Active Output Slide

High End Slide

Channel Scale

Snap to Lowest Laser

Output

Laser Output Down

Laser or Sweep Start/

Pause

Laser Output

UP

Snap to Highest Laser

Output

Chapter 9.0 - Tunable Laser Source / 37

g 9.2

Touch Screen Operation

Laser Start/Stop/Activity Indicator Flashing indicates active laser Starts and stops laser/sweep

Home Icon Brings the user back to the home page

Help Icon Opens the context sensitive help menu

Step Size Cycles through available step sized in nm, Freq, and Ch

Power Opens numeric keypad to enter power level

Dwell Time Opens numeric keypad to enter dwell time or CW mode

Output Value Laser output value in nm, Freq or Ch

Output Unit Indicates displayed output unit

Active Output Slide Used to select/indicate output laser

Channel Scale Full scale of available laser output

Low end Slide Used to select lowest laser output of sweep

High End Slide Used to select highest laser output of sweep

Snap to Lowest laser Output Moves the active slide to the lowest laser output set by the Low End Slide

Snap to highest laser Output Moves the active slide to the highest laser output set by the High End Slide

Laser Output Down Moves the low end slide down the scale

Laser or Sweep Start/Pause Start and stops the laser/sweep

Laser Output Up Moves the high end slide up the scale

Chapter 9.0 - Tunable Laser Source / 38

Page 20

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Setting Parameters

Set Output Units

The output may be displayed in wavelength or frequency or channel. To set the units, touch the

output value in the center of the screen to cycle through the available units.

Set Step Size

There are three available step sizes when selecting output or for sweep purposes. While in

wavelength mode, the steps are 0.4nm, 0.8nm or 1.6nm. In Frequency mode they are 0.05THz,

0.10THz or 0.20THz, and in channel mode they are .5, 1 or 2 channel steps. The step size changes

to the appropriate unit when the output units are changed. To set the step size, touch the step

size indicator to cycle through the available choices.

Power Level

The power level of the signal is adjustable from approximately +2 dBm to +11 dBm in increments

of 0.01 dBm. To set the power level, touch the power level indicator and an numeric keypad will

be displayed. At the top of the keypad will be the available power level range. Enter the desired

power to 0.01dBm. Once entered touch OK or to back out without change, touch cancel.

Dwell Time

To set the dwell time when operating in sweep mode, touch the dwell time indicator. A numeric

key pad will be displayed. The dwell time may be set from 2.00 to 60.00 seconds for sweep mode

operation. Enter the desired dwell time and touch OK or to exit without change touch cancel.

A dwell time of 0.00 is used for manual operation. This will set the laser to a CW mode at the

output value displayed. The output may be changed with either the active output slide or the up

or down channel select buttons.

Set Low and High End Laser Output

To set the low end laser output, touch the Low end slide and release. The output indicator and

the Up and down arrows will change to green. The focus of the up down movement arrows and

snap to end arrows changes to the low end slide. Use these arrows, or the slide to set the low end

laser output.

Touch the red high end slide to change the output indicator and focus of the arrows to the high

end slide to set the high end laser output.

Chapter 9.0 - Tunable Laser Source / 39

Manual/CW Operation

To re the laser in a CW mode, Set the output to the desired unit, set the step size if required and

set the power lever to dBm level required. Set the dwell time to 0.00. When the laser is red with

the Laser Start/Stop /Activity Indicator or the Laser or Sweep Start/Pause, it will be in CW mode.

To change the output laser, use the arrows at the bottom of the display to move or snap the laser

to a value or use the Active Output Slide to set the desired wavelength, frequency or channel.

Touch the Laser Start/Stop /Activity Indicator or the Laser or Sweep Start/Pause again to turn o

the laser.

Sweep Operation

To run a sweep of the laser, set the output to the desired unit, set the step size, power level and

dwell Time as described above. Use the low end and high end sliders to set the low and high end

laser levels to be red. Touch the Laser Start/Stop /Activity Indicator or the Laser or Sweep Start/

Pause

Exit Tunable Laser Feature

Touch the Home icon to return to the home screen.

WARNING

Even if the indicator shows the laser to be o never looking into the end of a ber

connected to the TLS or directly into the connector port. Do not under any circumstance

view or inspect the laser output bers, connectors or the ber under test through

collimating or focusing optics unless the unit is turned o, batteries are removed and

the power adapter is disconnected.

Chapter 9.0 - Tunable Laser Source / 40

Page 21

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 10.0 - Fault Locate / 41

10.1 Fault Locater Description

The Fault Locater is a simple auto test feature which displays the test results in event table with

the Fib-R-Map schematic view. The fault locater will take a scan of the ber in auto test mode.

The user sets the wavelength to be tested and the OTDR will set the pulse width and range to

best suite the ber under test at the selected wavelength.

If Pass/Fail information is desired, rst enter the OTDR mode and set the Pass/Fail threshold to

meet requirements.

To enter the Fault Locater mode, touch the Fault icon on the home screen. The screen below will

be displayed. The rst time the mode is entered it will be void if data, it may be populated with

data from a previous session.

Fault Locater Screen

The fault locater screen includes the event table, Fib-R-Map (Schematic View) and event map view

of highlighted event.

Fib-R-Map

(Schematic View)

Event Table

Event Map with

adjustable splice zones

Trace Parameters

g 10.1

Chapter 10.0 - Fault Locate / 42

Fib-R-Map

Event Table

Failing Event is Red

Event Number

Range of the Trace

Red Ares is Currently

Being Displayed

Reective Events

Event Location

Fiber Link Length

Passing event

is green

Event Number

Pass/Fail

Event Location Event Loss in dB

Loss Between Previous

and Current Events

dB Per/Km, Kf or Mi

Between Events

Event Type or

Reectance Value

EOF Location Link Loss

EOF Event

Information

System ORL

Link Information

Link dB Per/Km, Kf or Mi

Non-Reective Event

g 10.2

g 10.3

Page 22

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Event Table Denitions

# Event Number:

Indicates the event in sequence, where the higher the number the further distance from the

OTDR the event occurs. “E” (End) is the event determined to be the End of Fiber (EOF). "L" is the

link row and contains information about the entire link tested.

P:

Pass/Fail, if any one of the thresholds are not met for and event, the P/F column will display an F.

The parameter that failed will be displayed in red. If all the parameters are met, this column will

display a P. There is no Pass/Fail threshold for the last event labeled "E" (End) and the Pass/Fail for

the "L" (Link) row includes the 2POINT column, which for the link is the total link loss and the TYPE

column which for the link row is the system ORL.

Km or KF or MI:

Event Location, Km for Kilometer or KF if unit of measure is Kilo-feet MI for mile. This is the

distance/location that the event occurs along the ber link.

Splice:

Event Loss, is the splice loss (event loss) of the numbered event. (A positive number is the

amount of loss and a negative number indicates a gain normally due to mismatched index of

refraction.) This is a settable threshold for the Pass/Fail feature. The "E" event will display N/A as

this is not an event that would have meaning. The "L" line of the table is the link and as such does

not have an event (Splice) loss.

2POINT:

2 Point Loss is the loss measured from the end of the dead zone of the previous event to the

beginning of current event. The value in the "L" line of the table for this column is the link loss.

The loss from the beginning of the trace to the event determined to be the EOF. This is the value

used to determine if the ber link passes or fails it's loss threshold.

dB/Km:

dB per Kilometer if in KM and DB/KF if in Kilo-Feet and DB/MI if in mile unit of measure. This is

the calculated loss per Km, Kf or Mi from the end of the dead zone of the previous event to the

beginning of the current event. The value in the "L" line of the table for this column is the dB Per/

KM, Kf or Mi for the total link.

TYPE:

Event Type is the type of event or the ORL measurement. If the event has no reection, “splc” will

be displayed and if the event contains a reection, the event reectance value will be displayed.

For the last event which is labeled "L" in the # column, the value displayed is the system ORL.

Chapter 10.0 - Fault Locate / 43

10.2 Fault Locater Operation

Set Wavelength

To set the wavelength rst enter the OTDR mode and touch the Lambda icon or wavelength to

open the wavelength selection pages. Use the touch screen to select a wavelength or move to

the next pages of available wavelengths.

Start Scan

To start a scan, touch in the bottom right corner of the display. A "Please Wait, Scanning"

message will be displayed. The scan will take about 15 seconds.

View Test in OTDR Screen

To View a test in the full OTDR mode, touch an event in the table and the scan will be displayed in

trace mode with the active cursor at the selected even.

Exit Fault Locater

To exit the fault locater mode touch the Home icon.

Chapter 10.0 - Fault Locate / 44

Page 23

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Chapter 11.0 - Video Scope / 45

11.1 Entering Video Scope Function

To operate the video scope, from the home screen, highlight the Scope icon and press the select

button. If a probe is not connected already, connect the VIS300 video probe to the video probe

port on the top of the OTDR.

11.2 Video Scope Display

11.3 Video Scope File/help Icon Menu

The Icons at the top of the display are Home, le save, project management, le management

and Help.

Home

Press the menu button, use the left and right buttons to highlight the home icon and press select

to return to the home Screen.

File Manager

Pass/Fail Label Icon

Brightness Adjustment Icon

Quick Save

Help Icon

Pass/Fail Marker

25um Ring

130um Ring

(Green)

Live View/Pause View

Indicator

250um Ring

120um Ring

(Yellow)

Home Icon

Pass/Fail Grading Ring

Overlay Icon

Contaminant Scale

Project Folder

g 11.1

Quick Save

Press the menu button, use the left or right buttons to highlight the quick save icon and press the

select button to store a le image of the scope screen in the le folder within an active project.

Scope les will be preceded by a target icon.

Project Management

To open project management, press the menu button, use the left or right buttons to highlight

the project management folder icon and press select. Use the project management folder

to open the project that the scope images are to be stored. When entering the video scope

function, the active folder will be the one last used in the OTDR or LTS. For more information

about the project management system, please refer to Chapter 7 of this guide.

File Management

To open le management, press the menu button, use the left or right buttons to highlight the

le management icon and press select. Use File management to view a list of saved les or to

open a stored image. File types are identied by the preceding icon. Trace les are indicated by a

trace icon, LTS le by an LTS icon and scope les are preceded by scope (target) icon

Help

Press the menu button, use the left and right buttons to highlight the help icon and press select

to view the help information.

11.4 Video Scope Operation Icon Menu

The following functions are only available for use when the video scope is in live scan mode.

Grading Rings

Used to turn on and o the rings that indicate the IEC61300-3-35 grading zones.

Enter the menu mode with the menu button, use the LRUD buttons to highlight the pass/fail

grading rings overlay icon and press the select button. Exit the menu mode and use the LRUD

buttons to center the image in the rings. Use the Pass/Fail Criteria Tables from page 45 to grade

the connector end face. 2, 3, 5 and 10 micron contaminant examples are displayed just below the

connector image on the video scope display.

Pass/Fail Label

Used to cycle through P/F (Pass/Fail) O, P/F Man (In Red "Fail"), P/F Man (In Green "Pass") and

P/F auto. To set the pass/fail indicator, press the menu button, use the left or right buttons to

highlight the pass/fail icon and press select to cycle through the pass/fail states.

Chapter 11.0 - Video Scope / 46

Page 24

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

Brightness

Press the menu button, use the left and right buttons to highlight the brightness icon, use the

Select button to cycle through the adjustments for the brightness level.

11.5 Video Scope Operation

Video Probe Tips

There are a number of video probe tips available. To remove a tip from the Probe, grasp the

probe tip and unscrew the tip retention nut from the tip. Pull the tip straight up from the probe.

To place a tip on the probe, ensure the lens is clean, slide the tip on to the end of the probe and

tighten the tip retention nut. Do not over tighten the retention nut.

Viewing/Focusing a Connector

With the video scope turned on and the video probe plugged into the OTDR, insert a connector

in to universal tip or insert the panel adapter tip into the appropriate port. The scope must be

in the live scanning mode to make focus adjustments. Use the focus ring to get the connector

image as sharp as possible. When using panel adapters it is possible to turn the body of the probe

to while the adapter is inserted into the panel to make focus adjustments.

Tip Retention Nut

Focusing Ring

Adapter Tip

Chapter 11.0 - Video Scope / 47

g 11.2

Centering a Connector Image

Once the image is stable and focused, use the stylus to touch the approximate center of the

connector to snap the image near the center of the display and the center of the grading rings.

Use the LRUD buttons to ne tune the image to the center of the display.

Pausing Image Scan

To freeze an image in position and focus level for inspection, press the scan button. This will

pause the image at the current position and focus level. Simply press the scan button again to set

the operational mode back to live mode for focus and position adjustments

Grading Rings

Turn on or o the grading rings by pressing menu and using the left or right buttons to highlight

the grading ring icon and press select. The unit must be in live scan mode to turn the rings o or

on.

Manual Pass/Fail

Use the pass/fail criteria tables on the next page to determine if the connector passes the

IEC61300-3-35 standard. There is a guide to contamination size located at the bottom of the

image. To mark a connector as Pass or Fail, enter the menu mode, highlight the Pass/Fail Label

icon and press select to cycle through pass, fail, or no grading. This must be done in the Live Scan

mode. Once the pass fail status has be entered, the scan may be paused with the scan button

and the points of contamination that caused a failure may be marked on the image.

Manually Marking Points of Contamination

To mark the points of contamination the unit must be in paused mode. Pick up the

contamination marker by using the stylus and touching the contamination sample size that is

required. Touch the image to place the marker. The marker may be ne tuned with the stylus

to cover the contamination point on the image to be marked. Once the marker is positioned

properly, touch the area just below the image that states, "Place marker, touch here to apply" to

lock the marker in place. Repeat this as necessary to mark all the points that need to be indicated

for the pass/fail status. At this point the image should be save with the Quick Save icon

Auto Pass/Fail

Once the image has been centered in the grading rings, set the P/F icon to Auto and press

the scan button. The video scope will evaluate the image and grade it with Pass or Fail.

Contamination will be displayed on the image.

Exiting Video Scope Operation

Enter the menu mode, use the left or right buttons to highlight the Home icon and press select.

Chapter 11.0 - Video Scope / 48

Page 25

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

ChallengerOptics.com

Wavelength Specic Optical Testing and Measurement Equipment

11.6 Pass/Fail Criteria Tables

Fiber End Face Criteria Table for Angled PC Polished Connectors

Zone Description Diameter Allowable Scratches (W) Allowable Defects (D)

A Critical Zone 0µm to 25µm ≤ 4µm None

B Cladding Zone 25µm to 120µm No limit No Limit < 2µm

5 from 2µm to 5µm

None > 5µm

C Adhesive Zone 120µm to 130µm No limit No limit

D Contact Zone 130µm to 250µm No limit None ≥ 10 µm

Fiber End Face Criteria Table for Ultra PC Polished Connectors

Zone Description Diameter Allowable Scratches (W) Allowable Defects (D)

A Critical Zone 0µm to 25µm None None

B Cladding Zone 25µm to 120µm No limit ≤ 3µm No Limit < 2µm

None > 3µm 5 from 2µm to 5µm

None > 5µm

C Adhesive Zone 120µm to 130µm No limit No limit

D Contact Zone 130µm to 250µm No limit None ≥ 10 µm

Fiber End Face Criteria Table for SM PC Polished Conn. (Single Mode Fiber, RL≥ 26 dB)

Zone Description Diameter Allowable Scratches (W) Allowable Defects (D)

A Critical Zone 0µm to 25µm 2 ≤ 3µm 2 ≤ 3µm

None > 3µm None > 3µm

B Cladding Zone 25µm to 120µm No limit ≤ 3µm No Limit < 2µm

None > 3µm 5 from 2µm to 5µm

None > 5µm

C Adhesive Zone 120µm to 130µm No limit No limit

D Contact Zone 130µm to 250µm No limit None ≥ 10 µm

Chapter 11.0 - Video Scope / 49 Chapter 12.0 - Visual Fault Locater / 50

12.1 VFL Safety

CAUTION

This Visual Fault Locater is classied as a Class II laser system and must be used with

all commensurate safe ty precautions . Never view the light emanating from the ber

directly. Place a white pie ce of paper at th e end of the ber and look for the presence

of a red spot on the pap er.

12.2 VFL Description