Page 1

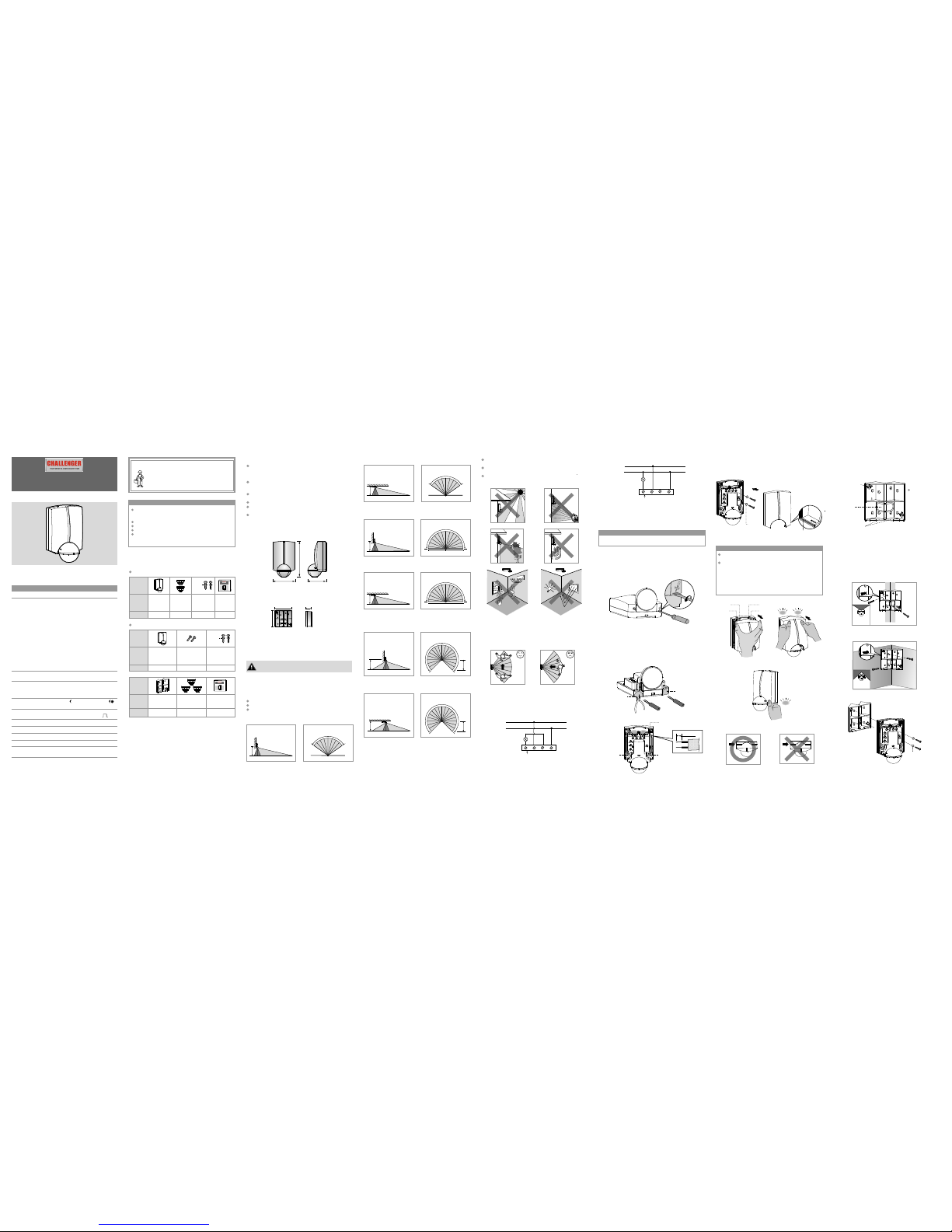

FIG.9- B

Click

22

22

FIG.1- B

2 PROD UCT D ESC RIPTION

FIG.4

3.2.1 Typ e 1:

Please d isconn ect powe r comple tely and r ead the

entire i nstruc tion man ual care fully be fore ins tallat ion.

Item

Item

Item

Quanti ty

Quanti ty

Quanti ty

Patter n

Patter n

Patter n

SL01, SL 01B / SL02 , SL02B

SL03, SL 03B

Manual

1

1

1

INSTRUCTION MA NUAL

Lens

shield s

Detect or

Detect or

Wood screws

x

Φ4 25.4MM

+ Rubber

washers

Wood screws

x

Φ4 25.4MM

+ Rubber

washers

3

Manual

1

Lens

shield s

3.1.1

the

inner co verage i s a circul ar with ra dius of 0. 5M.

O

SL01, SL 01B dete ction an gle: 110 (See FIG.2 -A).

O

SL02, SL 02B dete ction an gle: 180 (See FIG. 2-B).

O

SL03, SL 03B dete ction an gle: 270 (See FIG. 2-C).

It is reco mmende d to insta ll the det ector at t he heigh t

of 2 - 3M. The d etecti on range c an reach u p to 10M,

3.3.1 Wa ll mount

3.3.1. 1 Unscre w the fron t cover by s crewdr iver.

3.3.1. 2 To insert th e "-" head s crewdr iver bla de into th e gap

betwee n front co ver and bo ttom cas e, then ro tate

anti-c lockwi se 90° to det ach the fr ont cove r

(See FIG .6).

3.3 In stall ation p roce dure

SL01, SL 02, SL03 c an be inst alled on t he wall di rectly,

recess / c orner wi th wall br acket, ( SL03, SL 03B only ) or on

the ceil ing dire ctly.

NOTE

NOTE

SL01 /SL 01B/ SL02 /

SL02 B/S L03/ SL03 B

230V~5 0Hz

N

L

Load

L N N L

FIG.5

3.2.2 Typ e 2:

230V~5 0Hz

N

L

Load

L N N L

Φ3.5 x 10MM

Screws

Rubber

washer

FIG.11- A

FIG.11- B

Rubber

washer

x x

Detect or : 129 80 63MM ( See FIG. 1-A)

2.2 Di mensi on

1 PACKAGE CONTENTS

3 INSTALLATION A ND WI RING

3.1 Se lect a pr oper l ocati on

3.2 Wi ring ( See FIG .5)

Motion d etecto r is facto ry defau lt for

wall mou nt.

SL01, SL 02, SL03 ,

FIG.1- A

129

80

63

DO NOT rem ove the ru bber str ip and mak e sure it li nes

up with th e front co ver perf ectly (S ee FIG.8 ).

There sh ould be a cl ick soun d, this id entifi es that th e

upper ho ok has bee n fasten ed into th e slot (Se e FIG.9- A),

and a seco nd click s ound sho ws the low er hook ha s been

fasten ed into th e slot ( See F IG.9-B ). Pleas e ensure f ront

cover is l ocked we ll on bott om case (S ee FIG.9 -C),

IMPORTA NT NOTE - If no t (See FIG .9-D), w ater wil l

enter in to the ins ide of pro duct and w ill caus e damage t o

the unit a nd there i s potent ial of ele ctrica l shock.

FIG.6

3.3.2. 2 Break sc rew knoc k-outs ( See FIG. 10), the n fix the

wall bra cket ont o recess / c orner wi th wood sc rews

(See FIG .11-A & FIG. 11-B), ma ke sure "U P"mark

upward s. refer t o 3.3.1. 1 - 3.3.1. 3 to conne ct power

cables , and fix th e bottom c ase on wal l bracke t

(See FIG .12), th en assem bly fron t cover.

FIG.10

FIG.3

W

3.3.1. 3 Cut the ca ble entr y knock- out by a pli ers or cut ters

(See FIG .7-A), a nd feed ca bles thr ough cab le entry

knock- out and ru bber gas ket, the n refer to w iring

diagra m (See FIG .5) to con nect pow er cable s, and

please b e noted to s trip off 6 - 8 MM of cabl e

sheath ing (See F IG.7-B ).

FIG.9- A

FIG.8

Rubber

washer

Rubber s trip

Front co ver

inside v iew

Click

Click

Slot

Slot

Hook

Hook

Wall mou nt

Top view

o

110

10M 10M

R0.5M0

Side vie w

FIG.7- A

Rated Vol tage 230 V~50Hz

Load SL01 , SL01B / S L02, SL 02B:

Max. 5A (co sφ=1)

Incand escent L amp: Max . 1000W

HV Halog en Lamp: M ax. 500W

LED Lamp : Max. 120 W

Energy S aving: 2 00VA(in clude

CFL and PL La mp)

SL03, S L03B:

Max. 8A (co sφ=1)

Incand escent L amp: Max . 1840W

HV Halog en Lamp: M ax. 1000 W

LV Haloge n Lamp: Ma x. 300VA

Fluore scent La mp: Max. 4 00VA

(Uncom pensat ed)

LED Lamp : Max. 150 W

Energy S aving: 2 00VA(in clude

CFL and PL La mp)

Detect ion angl e

O

SL01, S L01B: u p to 110

O

SL02, S L02B: u p to 180

O

SL03, S L03B: u p to 270

LUX

Adjust ment

Auto OFF

Time Del ay

from " - " (ap prox.6 sec) to

" + "

" Test ",

(appro x.10mi n) and" "

LED Mode O FF / Warni ng / Watch

Meter Max. 10MAdjust ment

Power Co nsumpt ion Appr ox. 1W

Instal lation h eight

2.0 - 3.0M , recomm ended

instal lation h eight is a pprox. 2 .5M

o o

Operat ing Temper ature -2 0 C to +45 C

Enviro nmenta l IP44

Protec tion

1S.

TECH NICAL S PECI FICATI ONS

From" " (a pprox. 5 LUX) to " "

( )

∞

SL01, SL 01B, SL0 2, SL02B , SL03, SL 03B are pa ssive in fra

red sens ors to swi tch vari ous type s of load up on detec tion

of movem ent. Sui table fo r indoor o r outdoo r use and us ed

in resid ential o r commer cial env ironme nts.

0.5M 0 0.5M 10M

2.5M

FIG.2- A (SL01, SL 01B)

Ceili ng mount

Top view

o

110

10M 10M

R0.5M0

Side vie w

0.5M 0 0.5M 10M

2.5M

As the det ector re sponds t o temper ature ch ange, pl ease

avoid th e follow ing cond itions ( see FIG. 3):

3.1.2 He lpful ti ps for ins tallat ion.

Avoid di rectin g the tow ard the ob jects wh ose

surfac es are hig hly refl ective , such as mi rror, mon itor, etc .

detect or

Avoid mo unting t he detec tor near h eat sour ces, suc h as

heatin g vents, a ir condi tioner s, vents , l ights, e tc.

Avoid ai ming the d etecto r toward s object s which ma y

move in th e wind, su ch as curt ains, ta ll plant s, trees e tc.

o

180

10M 10M

0 R0.5M

FIG.2- C ( )SL03, S L03B

Wall mou nt

Ceili ng mount

Top view

FIG.2- B (SL02, S L02B)

Wall mou nt

Top view

10M 10M

O

270

R0.5M

7M

Top view

10M 10M

O

270

R0.5M

7M

Side vie w

Ceili ng mount

Side vie w

o

180

10M 10M

0 R0.5M

Top view

Side vie w

Side vie w

0.5M 0 0.5M 10M

2.5M

0.5M 0 0.5M 10M

2.5M

7M 0.5M 0 0.5M 10M

2.5M

7M 0.5M 0 0.5M 10M

2.5M

3.3.2 Co rner / rec ess moun t with wal l bracke t.

wall bra cket is de signed f or vario us

applic ation ( Se e FIG.10 ), break t he knock -out to

feed the w ires thr ough the c orresp onding h ole.

3.3.2. 1 8-knoc k-out

FIG.9- DFIG.9- C

Cable en try

knock- out

Cable en try

knock- out

Verify ca refull y and make s ure the wi res are co nnecte d

correc tly.

3.1.3 Pa y attent ion when t esting , the dete ction ar ea is more

sensit ive cros s the dete ctor up to 1 0 , and t owards t he

detect or acros s up to 1m (Se e FIG.4) .

m

Less sens itive to mov ement

directl y towards de tector

More sens itive to mov ement

across th e pattern

CAUTI ON!

A circuit b reaker ( 250VAC, 1 0A) type C a ccordi ng to

EN6089 8-1 of loa dⅠshall be i nstall ed in the fi xed wiri ng

for prot ection .

Do not mou nt on cond uctive s urface .

Do not ope n the encl osure fr equent ly.

Turn off po wer when r eplaci ng lamps .

High in- rush cur rent wou ld occur w hen lamp s of certa in

brands u sed whic h may dama ge the uni t perman ently.

Various t ypes of li ghting l oad can be c onnect ed to suit

most app licati ons.

Lens shi eld equi pped for e asy deta chment a nd fixin g

enable s a precis e adjust ing of the d etecti on zone.

MOTI ON DET ECTO R LIGH T CONT ROL

SL01/SL01B/SL02/

SL02B/SL03/SL03B

MOTION DETECTOR LIGHT CONTROL

SL01/SL01B/SL02/

SL02B/SL03/SL03B

MOTION DETECTOR LIGHT CONTROL

1

Corner

mounti ng

bracke t

Wall corner mounting bracket (Optional purchase):80 74.528mm

(See FIG.1-B)

x x

74.5mm

80mm

28mm

Screw su pport

Cable en try

knock- out

Cable en try

knock- out

1

2

3

5

4

6

7

8

1-8 hole s are

screw

knock- outs

Corner installation

Recess installation

U

P

U

P

UP

UP

3.3.1. 4 Put wood s crews in to the rub ber wash er,and fi x

the bott om case on t he wall or c eiling ,

up the fro nt cover a nd tight en it with s crews.

(See FIG .8).

then cov er

FIG.7- B

L'

L

N

N

6-8MM

Earth te rminal

Rubber

gasket

Rubber

gasket

METER

TIME

Test

1S.

LUX

LED Mode

Warning

OFFWatch

2.1 Fea ture s

4 Progra mmable d isplay L ED's sho w the dete ctor sta te.

Choose d iffere nt confi gurati ons to sho w detect or is in

standb y or test mo de. They c an also be t urned of f if not

requir ed.

Can be wal l or ceili ng mount ed. SL03 & S L03B can a lso

be corne r (inter nal & exte rnal) mo unted wi th the sup plied

corner b racket .

Unique d esign fo r multi- direct ion sens ing incl uding up /

down / for ward / sid eways ad justme nt.

3 versio ns avail able wit h differ ent dete ction an gles.

Instal lation m ust be car ried out b y qualif ied

electr icians o r skille d/comp etent pe rson who i s

famili ar with th e approp riate st andard s and

techni cal requ iremen ts of the ap plianc e and its

proper i nstall ation.

Contac t a qualif ied elec tricia n in the eve nt of

fault or b reak dow n.

FIG.12

Rubber

washer

Page 2

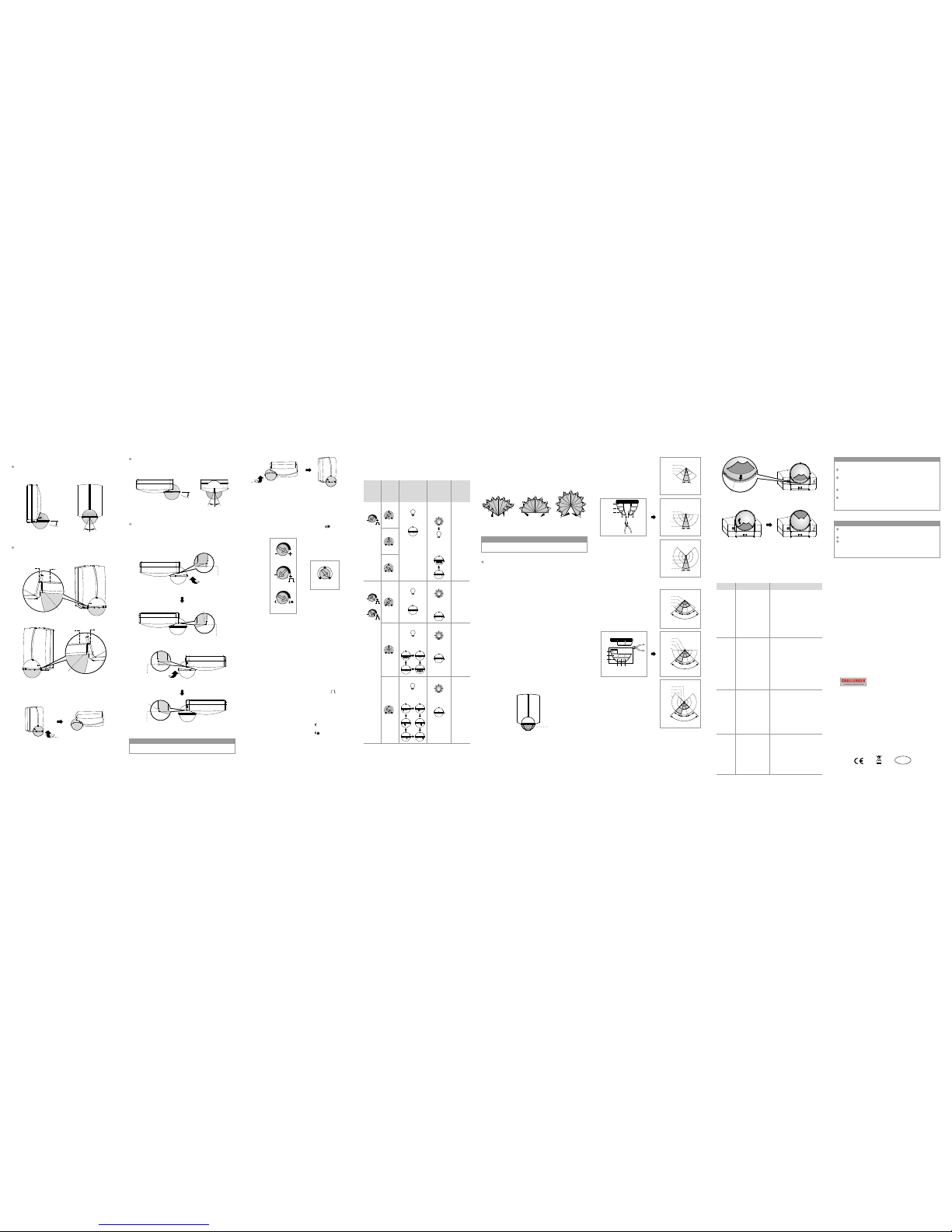

4.1 Ad juste r sett ings

4.2 Wal k test

FIG.17

4.1.1 ME TER sett ings

4.1.1. 1

4.1.1. 2

4.1.1. 3

Set METE R knob val ue at the po sition o f " - " for the

" smalle st field o f view ".

Set METE R knob val ue at the po sition o f " + " for the

" larges t field of v iew ".

Set METE R knob val ue at the po sition b etween " - "

and " + " for " de sired fi eld of vie w ".

4.1.4 LE D mode set ting

LED mode c an be swit ched to "w atch", " warnin g" or "off " in

normal u se. Plea se note LE D's act di fferen tly in "Test " mode.

See belo w for LED op tions.

FIG.18

3.28. 02184 018101 01

Load OFF.

LEDs OFF.

Load ON

2sec, th en

OFF.

LEDs ON

2sec, th en

OFF.

Test

mode

TIME

settin g

LED

mode

settin g

Standb y,

Load and

LED stat us

Impuls e,

Load and

LED stat us

Whethe r

Impuls e

is controlle d

by LUX

NO

LED Mode

Warning

OFF Watch

Warning

OFF

Watch

Warning

OFF

Watch

Warning

OFF

Watch

METER

LUX

TIME

Test

1S.

Test

1S.

4.3.2 Cu t the exce ss lens sh ield by a sc issors o r cutter s.

4.3.3 Fi x lens shi eld: Pus h the lens s hield in to the slo t path

( See FIG. 22), the n along th e slot pat h to turn ri ght or

left ( See F IG.23) .

Walk Test

SL01, SL 01B

SL02, SL 02B SL03, SL 03B

Start

Finish

Start

Finish

Start

Finish

4.1.3 LU X settin gs

4.1.3. 1 When set ting the L UX knob to " ", the det ector wi ll

operat e the ligh ting onl y in the dar kness.

4.1.3. 2 When set ting the L UX knob to " ", the det ector wi ll

operat e the ligh ting at an y light le vel.

4.1.3. 3 To adjust th e LUX knob a ccordi ng to user 's neede d.

W

W

W

All LEDs f lash

simult aneously.

LED flas hes

in turn.

LEDs all

OFF.

Load ON.

No test

mode

YES

YES

YES

Warning

OFF

Watch

Warning

OFF

Watch

Warning

OFF

Watch

Test

1S.

Test

1S.

LEDs all

OFF.

LEDs all O FF.

LEDs all

OFF.

Load OFF.

W

Load OFF.

W

Load OFF.

W

W

Load ON.

W

Load ON.

W

2sec

2sec

FIG.15 -D

FIG.15 -C

Detect or base ed ge

Detect or

base

edge

Grove in d etecto r head

Groove i n

detect or head

4 OPERATION AND FUNCTION

4.1.2 TI ME setti ngs

4.1.2. 1 Set TIME k nob valu e at the pos ition of " Tes t ", start

to walk te st , the loa d and LED tu rn on 2sec t hen turn

off whil e detect or is trig gered.

4.1.2. 2 Set TIME k nob valu e at the pos ition of " - " , the

minimu m delay ti me will be 6 sec.

4.1.2. 3 Set TIME k nob valu e at the pos ition of " + " , the

maximu m delay ti me will be 1 0min.

4.1.2. 4 Set TIME k nob valu e at the pos ition of " " ,

for "sho rt impul se" mode . Used if de tector c onnect ed

to a seper ate time s witch. T he time sw itch wil l receiv e

1sec sig nal once S L01, SL0 2, SL03 is t rigger ed, then

the ligh t ON 1sec, O FF 9sec.

4.1.2. 5 To adjust th e TIME kno b in betwe en" - " &" + "

accord ing to use r's desi re.

5 TROUBLE S HOOTING

If the det ector is n ot funct ioning c orrect ly, pleas e check th e

follow ing tabl e for assi stance :

Problem

Lighti ng

device

does

not turn

on

Nuisan ce

trigge ring

Lighti ng

device

does not

turn off

LED

does not

turn on

Possib le cause

1. Exceed ing the

detect ion

range.

2. No power

suppli ed.

3.TIME k nob is

not loca ted to

TEST pos ition.

4. Wired

incorr ectly.

1. time

se tting .

2.D is

nuisa nce

trigg ered.

3. Wired

incorr ectly.

Incor rect

etecto r

There ar e heat

source s, highl y

reflec tive obj ects

or any obj ects

which ma y be

swayed i n the

wind wit hin the

detect ion

covera ge.

1. Power d oes

not turn o n.

2. Wired

incorr ectly.

3. LUX Kno b

adjust ed

incorr ectly.

4. Malfu nction ed

load.

Sugges ted solu tion

1. Walk in t he effect ive

detect ion rang e

2. Switc h on the pow er.

3. TIME kn ob must be

locate d to TEST po sition .

4. Refer t o wiring d iagram s.

1. To test the d elay tim e

specif ied on TIM E knob

and chec k is

nuisan ce trigg ered if li ght ing devi ce does no t turn

off as the d elay tim e is up.

2. Keep aw ay from de tectio n

covera ge to avoi d activa t ing wh ile doin g

the test .

3. Make su re load an d wires

are conn ected co rrectl y.

detect or

detect or

Avoid ai ming the

toward a ny heat so urces,

such as ai r condit ioners ,

electr ic fans, h eaters o r any

highly r eflect ive surf aces.

Make sur e there ar e no

swayin g object s within t he

detect ion cove rage.

detect or

1. Switc h on the pow er.

2. Refer t o wiring d iagram s

( FIG.5) a nd check i f the

load is ma lfunct ioned.

3. Check i f LUX knob a re set

to the cor rect pos ition.

4. Repla ce the dis abled lo ad

with a new o ne.

T

adjust er

he purpo se of the wa lk test is t o select a p roper in stalla tion

place an d gain the d esired d etecti on cover age. Turn M ETER

to " + ", TIME k nob to " Test ", t hen cond ucting a w alk

test ref erring t o step 4.1 ( See FIG. 18).

NOTE

The foll owing co nditio ns may cau se lower s enseti vity:

In very fo ggy cond itions , the sens itivi ty may be re duced

due to moi sure col lating o n the lens .

In very ho t condit ions, th e sensit ivity ma y be reduc es as

high amb ient tem peratu re could b e close to b ody

temper ature.

In cold co nditio ns when he avy clot hing is us ed, very l ittle

heat is em itted fr om the bod y (espec ially if f ace is cov ered)

Cleani ng: Wipe w ith dry cl oth only. S oap or rou gh cloth

may dama ge the det ector le ns.

NOTE

It takes a pprox. 6 0sec to wa rm up afte r power is s upplie d.

NOTE

adjust er

adjust er

Be aware o f the walk d irecti on (See FI G.4).

4.2.1 Sw itch pow er on.

4.2.2 Us er must be w ithin th e detect ion cove rage.

4.2.3 Aft er the war ming up pe riod, wa lk from ou tside

across t o the dete ction pa ttern un til LED tu rns on for

approx . 2sec .

4.2.4 Ro tate sen sor head t o change t he detec tion dir ection

(See FIG .13-A, FIG.13 -B & FIG.1 5-A,FI G.15-B ).

4.2.5 Adj ust METE R to chan ge detec tion ran ge.

4.2.6 Adj ust TIME t o change t he delay t ime for li ght.

4.2.7 Re fer to sec tion " 4.3 " t o use the le ns mask fo r

reduci ng the det ection z one.

4.2.8 Re peat ste p 4.2.5 - 4. 2.6 unti l meets us er's dem ands

4.2.9

4.3 Us age of l ens sh ield

The defa ult sett ing of eac h knob bef ore ex-f actory i s as

follow ing: MET ER: " + ", TIM E: " Test " , LUX: , L ED mode:

" Watch " (S ee FIG.1 7).

1S.

4.3.1S L01, SL0 2 has two pi eces of le ns shiel ds, and SL 03

has thre e pieces o f lens shi eld. Len s shield c onsist s of

three la yers , eac h layer is d ivided i nto 3 smal l units,

O

and the un it can mas k an angle o f approx . 30 , wh en

mounti ng the det ector at t he heigh t of 2.5M, t he outer

covera ge is:

Layer C el iminat ed: mask t he zone wi th a secto r

about fr om 0.5M to 4 .5M. Lay er B elimi nated: m ask the

zone wit h a sector a bout fro m 0.5M to 7M . Layer A

elimin ated: ma sk the zon e with a sec tor abou t from

0.5M to1 0M.

The inne r covera ge is a circ ular wit h radius o f 0.5M

Separ ate lens s hield ca n be elimi nated

to fit use r's desi red dete ction ar ea (See FI G.19 &

FIG.20 & F IG.21) .

(See FIG .21),

To rotate an ti- cloc kwise 18 0 of det ector he ad for wal l

mount ( Se e FIG.16 ).

O

FIG.16

FIG.15 -A

25O25

O

28

O

FIG.15 -B

FIG.15 -E

Groove i n

detect or head

For opti mum dete ction ra nge, ens ure that t he end of th e

groove s on the det ector he ad (see FI G 15-C & FIG 1 5-E)

match up w ith the de tector b ase edge ( see FIG 15 -D &

FIG 15-F ).

Groove i n detect or head

FIG.15 -F

O

Detect or head ca n be adjus ted down ward max . 28

vertic ally (Se e FIG.15 -A) to sho rten the d etecti on range ,

O

or turne d leftwa rd and rig htward m ax. 25 h orizon tally

(See FIG .15-B) .

The sele cted par t

to be elim inated

FIG.21

A

B

C

a b c

Take examp le: cut th e lens

shield w ith plie r.

FIG.22

FIG.23

Slot pat h

b(30

o

)

a(

3

0

o

)

c

(

3

0

o

)

R10 m

R7 m

R0.5 m

R4.5 m

90

o

Detect ion patte rn

FIG.13 -C

3.3.2. 3 Desire d detect ion angl e can be rea ched by de tector

head adj ustmen ts after w all moun t finish ed.

O

Detect or head ca n be adjus ted down ward max .15

vertic ally (Se e FIG.13 -A) to sho rten the d etecti on range ,

O

or turne d leftwa rd and rig htward m ax. 25 h orizon tally

(See FIG .13-B) .

FIG.13 -B

FIG.13 -D

Line A

Bulge

Line C

In order t o obtain o ptimum d etecti on range , it must be

carefu l to ensur e that lef tward Li ne B (See FI G.13-C ) and

rightw ard Line C ( See FIG. 13-D) al ign bulg e respec tively

to keep de tector h ead hori zontal ly.

3.3.3C eiling m ount

3.3.3. 2 Fix it ont o the ceil ing refe r to step 3. 3.1.1 - 3. 3.1.4.

3.3.3. 3 Desire d detect ion angl e can be rea ched by de tector

head adj ustmen ts after c eiling m ount fin ished.

FIG.14

3.3.3. 1To rotate c lockwi se 180 o f detect or head fo r ceilin g

mount (S ee FIG.1 4).

O

FIG.13 -A

25O25

O

15

O

Line A

Line B

Bulge

FIG.19

SL01, SL 01B

Detect ion patte rn

A

ABB

C

C

a

A

B

C

b

c

Take examp le: cut a le ns

shield w ith plie r.

30

o

R0.5 m

R4.5 m

R10 m

R7 m

R0.5 m

R7 m

R4.5 m

Detect ion patte rn

30

o

R10 m

SL02, SL 02B

30

o

A

A

B

B

C

R10 m

R7 m

R0.5 m

R4.5 m

b(30

o

)

90

o

a

(30

o

)

c

(

30

o

)

Detect ion patte rn

A

B

C

b(30

o

)

a(3

0

o

)

c(3

0

o

)

R10 m

R7 m

R0.5 m

R4.5 m

90

o

Detect ion patte rn

AB

C

C

R10 m

R0.5 m

R7 m

R4.5 m

SL03, SL 03B

Detect ion patte rn

FIG.20

Test proc edure

O

180

O

180

Rotate sl ightly

Rotate sl ightly

CHALLE NGER SEC URITY PR ODUCTS

SANDER SONS WAY

MARTON

BLACKP OOL

FY4 4NB

Tel No: 0125 3 792898

Websit e: www.ch alleng er.co.u k

Email: e nquiri es.cha llenge r@adiv ision. co.uk

RoHS

Conform

CAUTI ON!

Due to our p olicy of c ontinu ous impr ovemen t we reser ve

the righ t to chang e specif icatio n withou t prior no tice.

Errors a nd omiss ions exc epted.

These in struct ions hav e been car efully c hecked p rior to

public ation. H owever, n o respon sibili ty can be ac cepted

by Chall enger fo r any misi nterpr etatio n of these

instru ctions .

SL01, SL 01B

SL02, SL 02B

SL03, SL 03B

Loading...

Loading...