Page 1

CHALLENGE

6044644

(Model: YT9305-01)

Petrol Hedge Trimmer

Original Manual

WARNING Important-Please read these instructions fully before starting assembly.

These instructions contain important information that will help you get the best from your

product, ensuring it is assembled correctly and safely. If you need help or have damaged or

missing parts, call the Customer Helpline on 0333 300 1614.

Page 2

CONTENTS

GENERAL SAFETY WARNINGS………………………………….………………….…………....….3

SYMBOLS …………………………………………………………………………………………...…. 6

DIAGRAM……………………………………………………………………………………….....…...8

PARTS LIST……………………………………………………………………………………………….9

INTENDED USE ………………………………………………………………………………….….…..9

PREPARATION ………………………………………………………………………………………..10

OPERATION…………………………………………………………………………….....….……….15

CLEANING AND MANTENIANCE ……………………………………………….……….….….…20

TECHNICAL DATA…………………………………………………………………………………….28

TROUBLESHOOTING ……….……………………………………………………………..............29

DISPOSAL …………………………………………………………….….……………………….....30

GETTING HELP ……………………………………………….………………………………………..30

GUARANTEE …………………………..……………………………………………………………... 31

2

Page 3

GENERAL SAFETY WARNINGS

WARNING! Read all safety warnings and all instructions in this manual carefully.

Failure to follow the warnings and instructions may result in electric shock, fire

and/or serious injury. Save all warnings and instructions for future reference.

WARNING! Long-term exposure to noise can result in permanent hearing impairment.

So always use approved hearing protection.

WARNING! Under no circumstances may the design of the machine be modified

without the permission of the manufacturer. Always use genuine accessories.

Non-authorized modifications and/or accessories can result in serious personal injury

or the death of the operator or others.

IMPORTANT!

Incorrect or careless use of a hedge trimmer can turn it into a dangerous tool that

can cause serious or even fatal injury. It is extremely important that you read and

understand the contents of this operator’s manual.

You must use approved personal protective equipment whenever you use the

machine. Personal protective equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen. Ask your call center for help

in choosing the right equipment.

Become familiar with the owner’s manual before attempting to operate the

equipment.

The machine is only designed for cutting branches and twigs.

Never use a machine that has been modified in any way from its original

specification.

Never use the machine if you are tired, if you have drunk alcohol, or if you are

taking medication that could affect your vision, your judgment or your co-ordination.

Wear personal protective equipment. See instructions under the

heading ”Personal protective equipment”.

Never use the machine in extreme weather conditions such as severe cold, very

hot and/or humid climates.

Never use a machine that is faulty. Carry out the checks, maintenance and

service instructions described in this manual. Some maintenance and service

measures must be carried out by trained and qualified specialists. See instructions

under the heading Maintenance.

All covers and guards must be fitted before starting. Ensure that the spark plug

cap and ignition lead are undamaged to avoid the risk of electric shock.

3

Page 4

GENERAL SAFETY WARNINGS

THIS HEDGE TRIMMER CAN CAUSE SERIOUS INJURIES. Read the instructions carefully

for the correct handling, preparation, maintenance, starting and stopping of the

hedge trimmer. Become familiar with all controls and the proper use of the hedge

trimmer.

Never allow children to use the hedge trimmer.

Beware of overhead power lines.

Avoid operating while people, especially children, are nearby.

Dress properly! Do not wear loose clothing or jewellery, which can be caught in

moving parts. Use of sturdy gloves, non-skid footwear and safety glasses is

recommended.

Use extra care when handling petrol. They are flammable and the vapors are

explosive. The following points should be observed.

-Use only an approved container.

-Never remove the fuel cap or add petrol with the power source running. Allow

engine and exhaust components to cool down before refuelling.

-Do not smoke.

-Never refuel indoors.

-Never store the hedge trimmer or fuel container inside where there is an open flame,

such as near a water heater.

-If petrol is spilled, do not attempt to start the power source, but move the hedge

trimmer away from the spillage before starting.

-Always replace and securely tighten the fuel cap after refuelling.

-If the fuel tank is drained, this should be done outdoors.

Warn of the need for ear protection.

Warn of the need for eye protection.

In an emergency switch the product off by immediately releasing the throttle

control and setting the ignition switch to its off position “STOP”.

Stop the engine before cleaning ,checking, carrying out maintenance or working

on the hedge trimmer,

Ensure that the hedge trimmer is correctly located in a designated working

position before starting the engine.

While operating the hedge trimmer, always ensure that the operating position is

safe and secure, especially when using steps or a ladder.

Do not operate the hedge trimmer with a damaged or excessively worn cutting

device.

To reduce fire hazards, keep the engine and silencer free of debris, leaves and

excessive lubricant.

Always ensure that all handles and guards are fitted when using the hedge

trimmer. Never attempt to use an incomplete hedge trimmer or one fitted with an

unauthorized modification.

4

Page 5

GENERAL SAFETY WARNINGS

Always use two hands to operate a hedge trimmer fitted with two handles.

Always be aware of your surroundings and stay alert for possible hazards of which

you may not be aware due to the noise of the hedge trimmer.

When the hedge trimmer is stopped for servicing, inspection or storage, shut off

the power source, disconnect the spark plug wire from the spark plug and make sure

all moving parts have come to a stop. Allow the hedge trimmer to cool before

making any inspections, adjustments, etc.

Store the hedge trimmer where the petrol vapor will not reach an open flame or

spark. Always allow the hedge trimmer to cool down before storing.

When transporting or storing the hedge trimmer, always fit the cutting device

transport guard.

WARNING! Listen out for warning signals or shouts when you are wearing hearing

protection. Always remove your hearing protection as soon as the engine stops.

WARNING! Running an engine in a confined or badly ventilated area can result in

death due to asphyxiation or carbon monoxide poisoning.

WARNING! Faulty blades can increase the risk of accidents.

5

Page 6

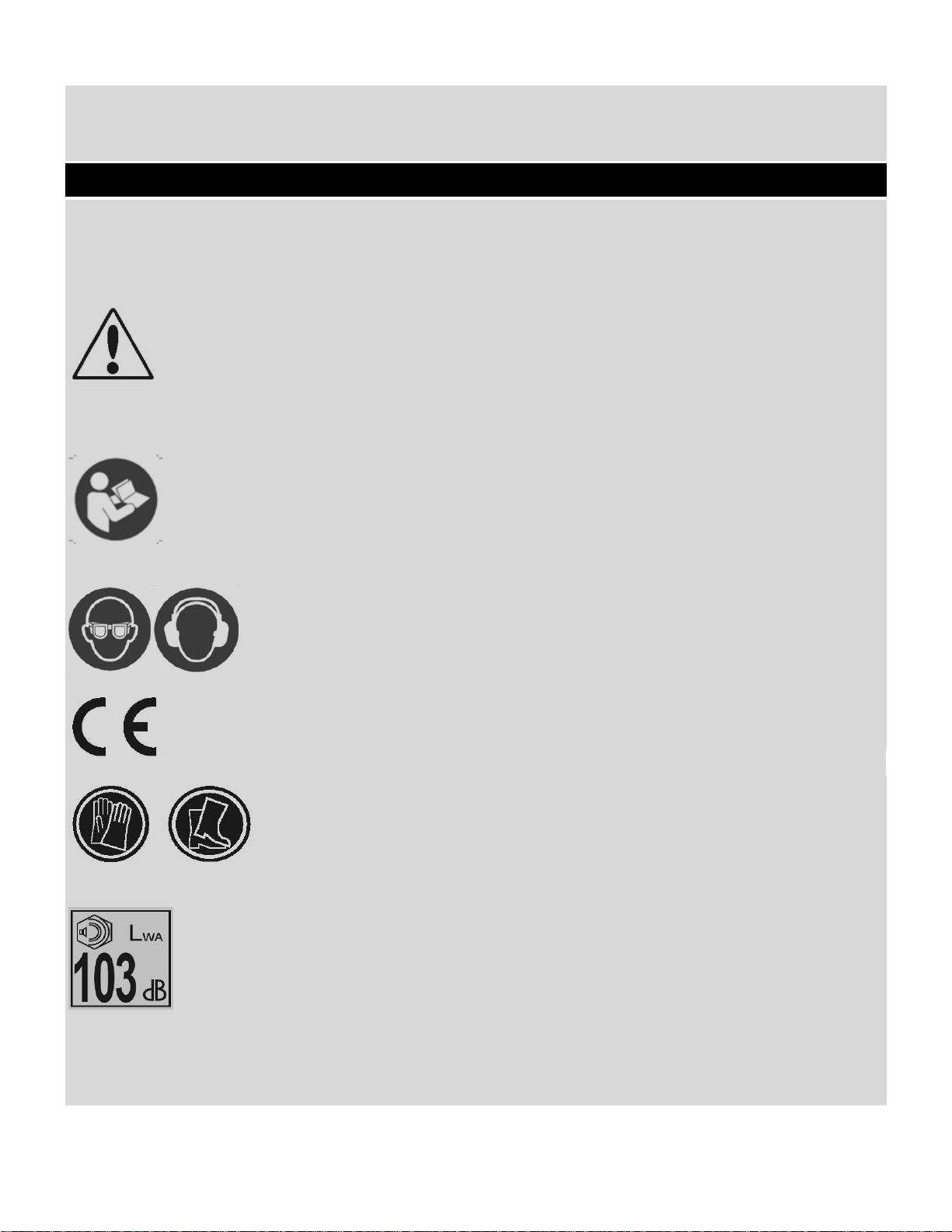

SYMBOLS

IMPORTANT: Some of the following symbols may be used on your tool. Be sure to study

them and learn their meaning. Proper interpretation of these symbols will allow you

to use the machine more effectively and reduce the risk of accident.

WARNING! Incorrect or careless use of a hedge trimmer can turn it into a dangerous

tool that can cause serious or even fatal injury. It is extremely important that you read

and understand the contents of this operator’s manual.

Please read the operator’s manual carefully and make sure you understand the instructions

before using the machine.

Always wear: Approved hearing protection and approved eye protection

This product is in accordance with applicable EC directives.

Always wear approved protective gloves.

Wear sturdy, non-slip boots or shoes.

Noise emission to the environment according to the European Community’s Directive. The

machine’s emission is specified in chapter Technical data and on label. Other

symbols/decals on the machine refer to special certification requirements for certain

markets.

6

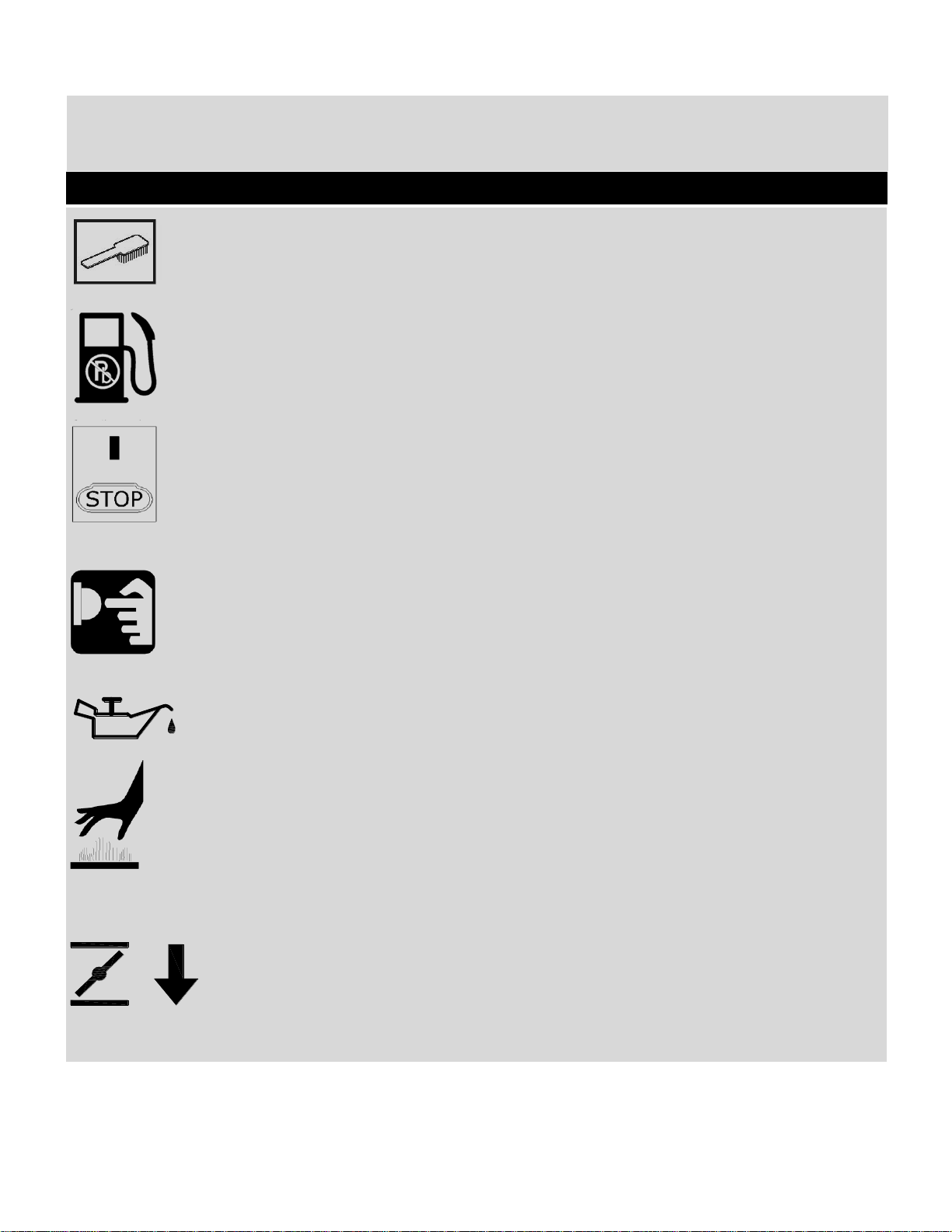

Page 7

SYMBOLS

Regular cleaning is required.

Always use clean, fresh unleaded petrol.

Switch off the engine by moving the stop switch to the STOP position before carrying out any

checks or maintenance.

Push primer bulb, fully and slowly, 8-10 times.

Refer to operator’s manual for the proper type of oil.

WARNING: Do not touch a hot muffler or cylinder.

You may got burned. These parts get extremely hot from operation. When turned off they

remain hot for a short time.

Set the choke button in the choke position.

7

Page 8

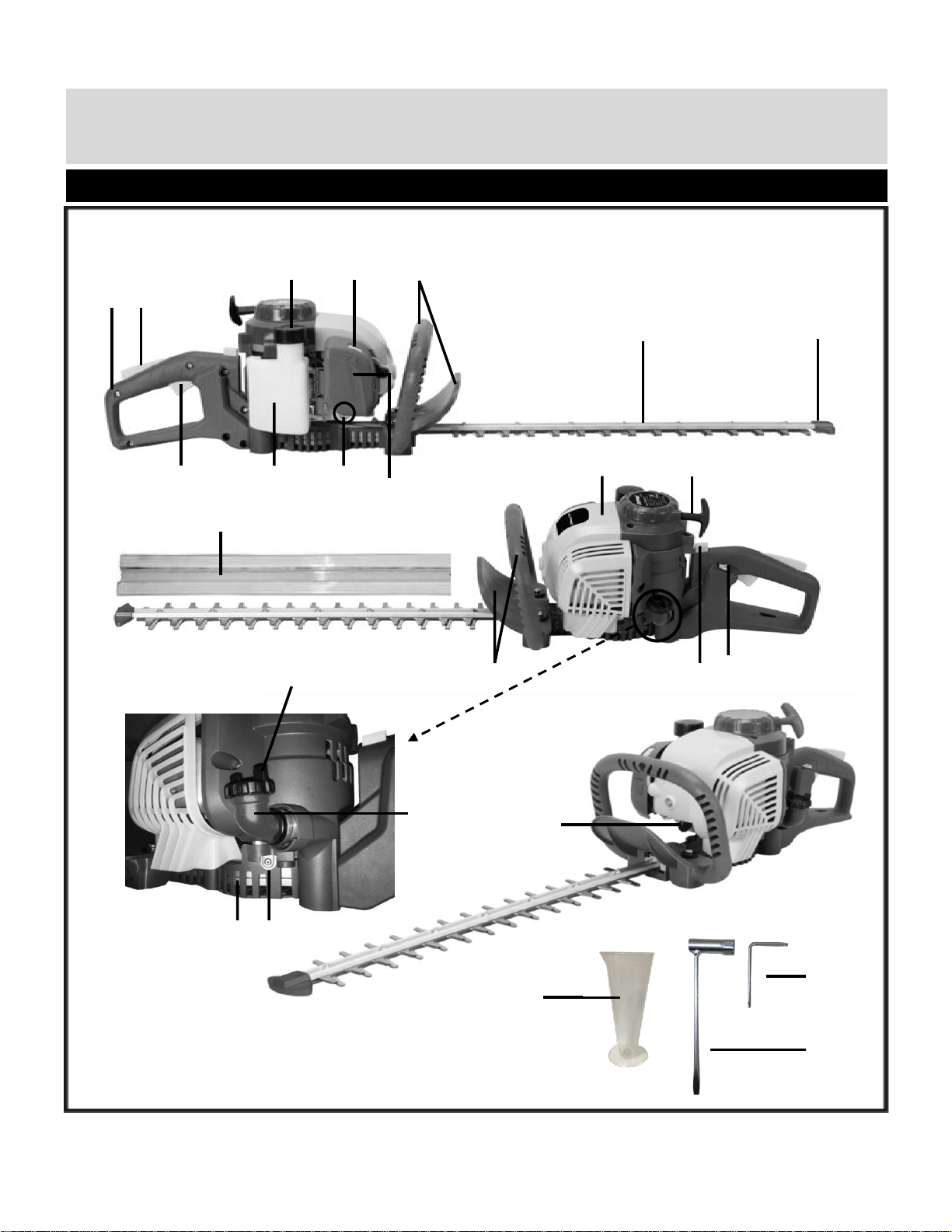

Fig. A

1 2 8 9 10

11

3 4 5

6

7

15

13

14

16

5

12

20

19

17

18

24

23

22

21

DIAGRAM

8

Page 9

1. Rear handle

2. Throttle lockout

3. Fuel tank cap

4. Choke button

5. Front handle/safety guard (integrated)

6. Cutting blade

7. Tip protector

8. Throttle control

9. Fuel tank

10. Primer bulb

11. Air filter cover

12. Spark plug with cap

13. Cylinder housing

14. Recoil Starter

15. Lock button for rotary handle

16. ON/OFF switch

17. lubrication nipple for gearbox

18. Gear box

19. Oil elbow

20. Oil cap

21. Blade cover

22. Oil measuring cup

23. Spanner for spark plug

24. Key for screws on the machine

Remark: Above are all assembled in the standard delivery. 22, 23, 24 are the accessories.

PARTS LIST

(See Fig. A)

INTENDED USE

This petrol hedge trimmer is designated with an engine displacement of 26.5 cc³.

The product is intended for trimming hedges, bushes and shrubs. Observe the technical data

for the maximum cutting capacity. Do not cut branches exceeding the stated maximum

capacity. This product is intended for private use only, not for any commercial applications.

It may not be used for any purposes other than those described.

9

Page 10

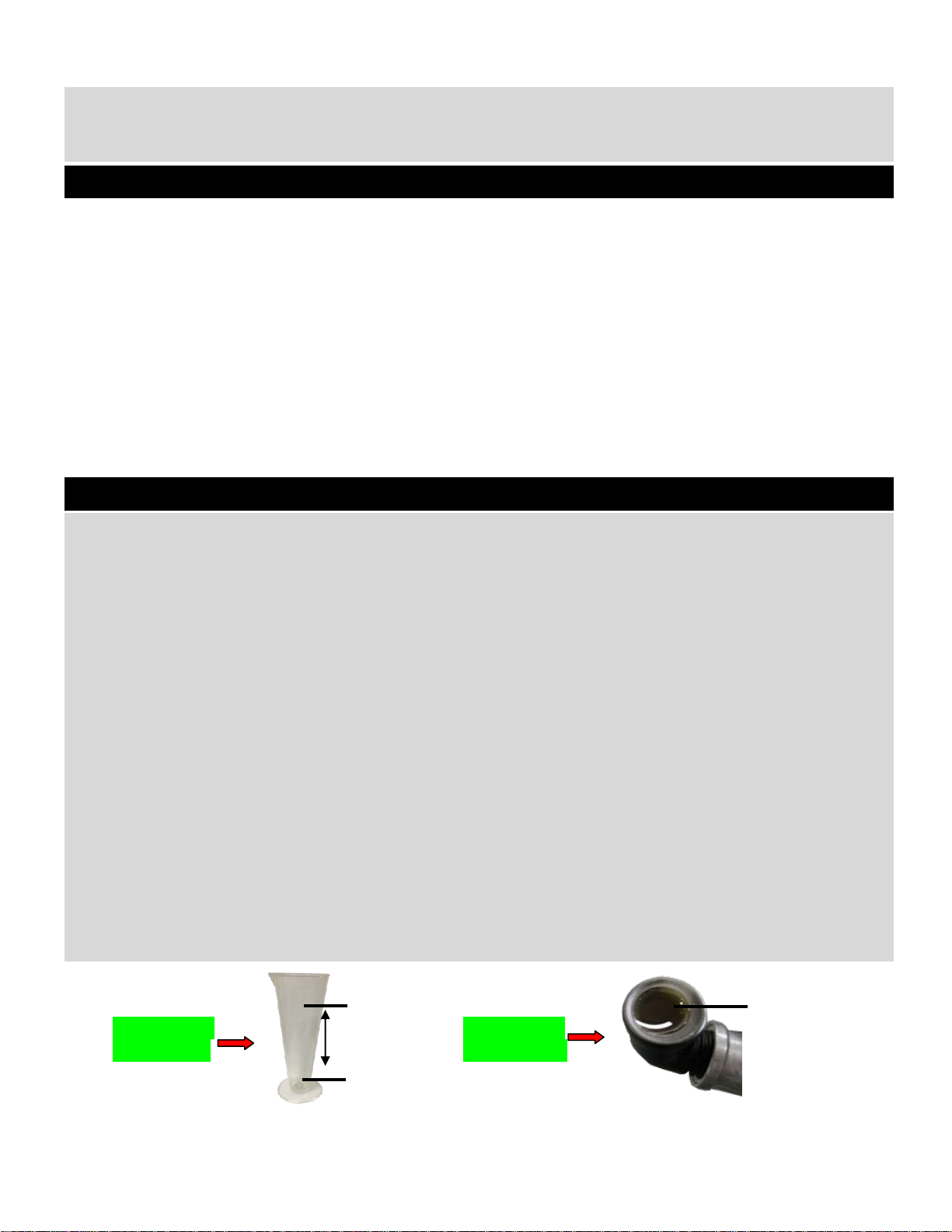

60ml

Fig. B

Fig. C

Add the oil

for first use

Add the oil

for next use

Full level

PREPARATION

Unpack

> Unpack all parts and lay them on a flat, stable surface.

> Remove all packing materials and shipping devices if applicable.

> Make sure the delivery contents are complete and free of any damage. If you find that

parts are missing or show damage do not use the product but contact call center. Using

an incomplete or damaged product represents a hazard to people and property.

> Ensure that you have all the accessories and tools needed for assembly and operation. This

also includes suitable personal protective equipment.

Note: you will need below (items not supplied):

> Fuel (unlead petrol)

> 4-stroke engine oil

> Soft cloth (optional for cleaning)

Using the right engine oil

CAUTION! Lubricant has a major influence on engine performance and service life. The

machine is equipped with a 4-stroke engine and must always been run using 4-stroke engine

lubricant. Use high-quality oil. DO NOT fill the used oil. Failure to use clean oil of the correct

type can cause premature engine wear and failure.

WARNING! Do not change engine lubricant while it is hot. Accidental contact with hot

engine lubricant could result in serious burns.

NOTE: This unit was shipped without oil in the crankcase. Oil must be added before starting

the unit.

Attention: Must use API SF grade or the higher grade SAE 10W-30 lubricating oil (four stroke

lubricating oil for the engine of car);

WARNING: OVERFILLING THE CRANKCASE MAY CAUSE SERIOUS PERSONAL INJURY.

NOTE: Check the oil level before each use.

1. When the machine is filled with oil for the first time, you must use the oil measuring

2. When the machine is used again after the first time, check the oil as always before

cup (22) to fill 60ml, then open the oil cap (20) and fill the oil into the oil tank of

machine. (see Fig. B)

use. Ensure the oil level is always close to the full position visually (see Fig. C). Either

Insufficient oil or overfilled oil both causes the malfunction of machine.

10

Page 11

PREPARATION

Using the right engine oil (continued)

For best performance, engine lubricant should be changed entirely after every 25 hours of

operation. Please pour out all the oil and refill the new lubricating oil instead.

NOTE: Never add oil to the fuel tank. This unit has 4- stroke engine. DO NOT mix oil with

petrol.

Using the right petrol

The use of old petrol is the most common cause of performance problems. Use only fresh,

clean unleaded petrol.

CAUTION! Use low-emission petrol, also known as alkylate petrol, if it is available.

The lowest octane recommended is 90 (RON). If you run the engine on a lower octane grade

than 90 so-called knocking can occur. This gives rise to a high engine temperature, which

can result in serious engine damage.

When working at continuous high revs a higher octane rating is recommended.

NOTE: Do not use E15 or E85 petrol (or petrol containing greater than 10% ethanol) in this product. It

is a violation of federal law and will damage the unit.

Petrol safety

Transport and storage

•Store and transport the machine and petrol so that there is no risk of any leakage or fumes

coming into contact with sparks or naked flames, for example, from electrical machinery,

electric motors, electrical relays/switches or boilers.

•When storing and transporting petrol always use approved containers intended for this

purpose.

•When storing the machine for long periods the fuel tank must be emptied. Contact your

local petrol station to find out where to dispose of excess petrol.

•Ensure the machine is cleaned and that a complete service is carried out before long-term

storage.

•The transport guard must always be fitted to the cutting attachment when the machine is

being transported or in storage.

•Secure the machine during transport.

WARNING! Petrol and petrol fumes are highly inflammable and can cause serious injury when

inhaled or allowed to come in contact with the skin. For this reason observe caution when

handling petrol and make sure there is adequate ventilation.

WARNING! Take care when handling petrol. Bear in mind the risk of fire, explosion and

inhaling fumes.

11

Page 12

PREPARATION

Fuelling

WARNING!

•Always shut off engine before fueling. Never add petrol to a machine with a running or hot

engine.

•Move at least 30 ft. from refueling site before starting engine.

•Do not smoke and stay away from open flames and sparks. Failure to safely handle petrol

could result in serious personal injury.

•Never start the machine if you have spilt petrol on it. Wipe off the spillage and allow

remaining petrol to evaporate.

•If the machine is leaking petrol. Check regularly for leaks from the fuel cap and fuel lines.

•Always use a fuel container with an anti-spill valve.

•Clean the area around the fuel cap. Contamination in the tank can cause operating

problems.

•When refuelling, open the fuel cap slowly so that any excess pressure is released gently.

•Tighten the fuel cap carefully after refuelling.

•Always move the machine away from the refuelling area before starting.

Fuelling the unit according to the following procedure:

1. Position the unit with the fuel cap facing up.

2. Remove the fuel cap.

3. Place the fuel container spout into the fill hole on the fuel tank and fill the tank.

NOTE: Do not overfill the tank.

4. Wipe up any petrol that may have spilled.

5. Reinstall the fuel cap.

6. Move the unit at least 30 ft. (9.1 m) from the fuel container and the fueling site before

starting the engine.

Starting/stopping the machine

Check before starting

•Inspect the working area. Remove any objects that could be thrown out.

•Check the cutting attachment. Remove the blade cover before use and never use blades

that are dull, cracked or damaged.

•Check that the machine is in perfect working order. Check that all nuts and screws are

tight.

12

Page 13

PREPARATION

Starting/stopping the machine (continued)

•Make sure the gear housing is lubricated correctly. See instructions under the heading Gear

housing.

•Check that the cutting attachment always stops when the engine is idling.

•Only use the machine for the purpose it was intended for.

•Make sure that the handle and safety features are in good working order. Never use a

machine that lacks a part or has been modified outside its specifications.

•All covers must be correctly fitted and undamaged before you start the machine.

Starting and stopping

WARNING! The complete clutch cover and gear housing must be fitted before the machine is

started, otherwise the clutch may come loose and cause personal injury.

Always move the machine about 3 metres from the refuelling position before starting. Place

the machine on a firm surface. Remember that the blades may start to move when the

engine is started. Make sure the blades cannot come into contact with any object. Make

sure that no unauthorised persons are in the working area, otherwise there is a risk of serious

personal injury. The safety distance is 15 metres.

Cold engine

- Check the oil level before use.

- Fill the fuel tank.

- Press the on/off switch (16) to the position “I”. (Fig. D)

- Press the choke button (4) in the full choke position. (Fig. E)

- Press the primer bulb (10) repeatedly 8-10 times until petrol begins to fill the bulb. (Fig. F)

- Quickly pull the recoil starter handle (14) 3-5 times. (Fig. G)

Note: Hold the body of the machine on the ground using your left hand. Grip the starter

handle, slowly pull out the cord with your right hand until you feel some resistance, now

quickly and powerfully pull the cord. Never twist the starter cord around your hand.

- Squeeze the throttle trigger (Fig. H) to make the choke button come back to the run

position. Quickly pull the recoil starter handle (14) until the engine runs.

Note: the choke button will automatically come back to the run position while you

squeezing the throttle trigger.

If the engine does not run, please repeat above steps.

- Allow the engine to run for 10 seconds and now you can use the machine.

CAUTION! Do not pull the starter cord all the way out and do not let go of the starter handle

when the cord is fully extended. This can damage the machine.

13

Page 14

Fig. D

Fig. E

Fig. F

Fig. G

Fig. H

PREPARATION

Cold engine (continued)

Warm engine

- Check the oil level before use.

- Make sure there is enough fuel in the fuel tank.

- Press the on/off switch (16) to the position “I”. (Fig. D)

- Quickly pull the recoil starter handle (14) until the engine runs. (Fig. G)

Hold the body of the machine on the ground using your left hand (CAUTION! Not with your

foot!). Grip the starter handle, slowly pull out the cord with your right hand until you feel some

resistance (the starter pawls grip), now quickly and powerfully pull the cord. Never twist the

starter cord around your hand.

Caution! Never press the choke button (4) when you start the warm engine.

14

Page 15

PREPARATION

Starting/stopping the machine (continued)

CAUTION! Do not pull the starter cord all the way out and do not let go of the starter handle

when the cord is fully extended. This can damage the machine.

Stopping

The engine is switched off by moving the stop switch to the stop position.

15

Page 16

OPERATION

WARNING! The machine can cause serious personal injury. Read the safety

instructions carefully. Learn how to use the machine.

WARNING! Do not touch the tool without first switching off the engine.

Safety instructions regarding the surroundings

•Never allow children to use the machine.

•Ensure that no-one comes closer than 15 m while you are working.

•Never allow anyone else to use the machine without first ensuring that they have

understood the contents of the operator’s manual.

•Never work from a ladder, stool or any other raised position that is not fully secured.

•Keep in mind that the operator is responsible for accidents or hazards occuring to

other people or their property.

Safety instructions while working

•Always ensure you have a safe and stable working position.

•Always use both hands to hold the machine. Hold the machine in front of your

body.

•Make sure that your hands and feet do not come near the cutting attachment

when the engine is running.

16

Page 17

OPERATION

•When the engine is switched off, keep your hands and feet away from the cutting

attachment until it has stopped completely.

•Watch out for stumps of branches that can be thrown out during cutting.

•Do not cut too close to the ground. Stones and other objects can be thrown out.

•Check the working area for foreign objects such as electricity cables, insects and

animals, etc, or other objects that could damage the cutting attachment, such as

metal items.

•If any foreign object is hit or if vibrations occur stop the machine immediately.

Disconnect the HT lead from the spark plug. Check that the machine is not damaged.

Repair any damage.

•If anything jams in the blades while you are working, switch off the engine and wait

until it has stopped completely before cleaning the blades. Disconnect the HT lead

from the spark plug.

Safety instructions after completing work

•The transport guard should always be fitted to the cutting attachment when the

machine is not in use.

•Make sure the cutting attachment has stopped before cleaning, carrying out

repairs or an inspection. Disconnect the HT lead from the spark plug.

•Always wear heavy-duty gloves when repairing the cutting attachment. This is

extremely sharp and can easily cause cuts.

•Store the machine out of reach of children.

•Use only original spare parts for repairs.

Basic working techniques

•Work with a swinging action from the bottom upwards when trimming sides.

•Adjust the throttle setting to suit the load.

•When trimming a hedge the engine should always face away from the hedge.

•Hold the machine as close to your body as possible to get the best balance.

•Make sure that the tip does not touch the ground.

•Do not rush the work, but work steadily until all the branches have been cut back

cleanly.

17

Page 18

NOTE: Try to keep the cutting device angled at approximately 15° to the cutting surface.

NOTE: When shaping it is advisable to achieve a trapezoidal shape (Fig. K). This is where the

bottom is wider than the top. A trapezoidal cut corresponds to the natural growth of plants

and results in optimal hedge growing, as it will expose more light to the lower end of the

hedge.

Fig. I

Fig. J

Fig. K

OPERATION

Cutting

> Adjust the handle so that it fits the intended cut and start the product as described.

> Cut and remove branches exceeding the cutting capacity of this product using a proper

pruner before operation.

> Move the cutting device lightly through the cutting surface in a sweeping motion following

the shape of the hedge or shrub. A slight tilt downwards of the cutting device in the

direction of motion is recommended for optimum cutting performance.

> Do not to rush and do not attempt to cut too much with one stroke of the cutting device.

> First cut both sides from the bottom cutting upwards to the top. This will prevent any of the

cuttings falling into the path of the area still to be cut (Fig. I).

> After cutting the sides proceed to the top (Fig. J).

> Cut in a number of stages if the area being cut is particularly long to achieve a better result;

smaller cuttings will allow for easy composting.

18

Page 19

-90 0C

+90 0C

15

OPERATION

Rotary handle

•The hedge trimmer’s rear handle can be set in three positions by press down the button on

the handle (15). See figure below.

When the handle is adjusted the hedge trimmer should be idling or not running.

•While working the handle should always be facing upwards irrespective of how the hedge

trimmer is directed

19

Page 20

2

8

CLEANING AND MAINTENANCE

IMPORTANT! All servicing and repair work on the machine requires special training. This is

especially true of the machine’s safety equipment. If your machine fails any of the checks

described below you must contact the call center by dialing helpline number.

WARNING! Never use a machine with faulty safety equipment. The machine’s safety

equipment must be checked and maintained as described in this section. If your machine

fails any of these checks contact the call center to get it repaired.

Throttle lockout

The throttle lockout is designed to prevent accidental operation of the throttle control. When

you press the lockout (2) (i.e. when you grasp the handle) it releases the throttle control (8).

When you release the handle, the throttle control and the throttle lockout both move back

to their original positions. This movement is controlled by two independent return springs. This

arrangement means that the throttle control is automatically locked at the idle setting.

Make sure the throttle control is locked at the idle setting when the throttle lockout is

released.

Press the throttle lockout and make sure it returns to its original position when you release it.

Check that the throttle control and throttle lockout move freely and that the return springs

work properly.

See instructions under the heading Start. Start the hedge trimmer and apply full throttle.

Release the throttle control and check that the blades stop and remain stationary.

If the blades move when the throttle control is in the idle position then the carburetor idle

setting must be adjusted.

Stop switch

Use the stop switch to switch off the engine.

Start the engine and make sure the engine stops when you move the stop switch to the stop

setting.

20

Page 21

CLEANING AND MAINTENANCE

Muffler

The muffler is designed to keep noise levels to a minimum and to direct exhaust fumes away

from the user.

For mufflers it is very important that you follow the instructions on checking, maintaining and

servicing your machine.

Never use a machine that has a faulty muffler.

WARNING! The exhaust fumes from the engine are hot and may contain sparks which can

start a fire. Never start the machine indoors or near combustible material!

WARNING! The inside of the muffler contain chemicals that may be carcinogenic. Avoid

contact with these elements in the event of a damaged muffler.

CAUTION! The muffler is designed to reduce the noise level and to direct the exhaust gases

away from the operator. The exhaust gases are hot and can contain sparks, which may

cause fire if directed against dry and combustible material.

21

Page 22

mm

CLEANING AND MAINTENANCE

Spark plug

The spark plug condition is influenced by:

•Incorrect carburettor adjustment.

•An incorrect petrol

•A dirty air filter.

These factors cause deposits on the spark plug electrodes, which may result in operating

problems and starting difficulties.

If the machine is low on power, difficult to start or runs poorly at idle speed: always check the

spark plug first before taking any further action. If the spark plug is dirty, clean it and check

that the electrode gap is 0.7 mm. The spark plug should be replaced after about a month in

operation or earlier if necessary.

CAUTION! Always use the recommended spark plug type! Use of the wrong spark plug can

damage the piston/cylinder.

NOTICE: Be careful not to cross-thread the spark plug. Cross-threading will seriously

damage the product.

1. Stop the engine and allow it to cool. Grasp the spark plug boot firmly and pull it from the

spark plug.

2. Clean around the spark plug. Remove the spark plug from the cylinder head with a

5/8-inch socket, turning counterclockwise.

WARNING: Do not sand blast, scrape or clean spark plug electrodes.

Grit in the engine could damage the cylinder.

3. Inspect the spark plug. If the spark plug is cracked, fouled or dirty, replace it with a new

spark plug.

4. Use a feeler gauge to set the air gap at 0.025 in. (0.635 mm).

5. Install the spark plug in the cylinder head. Tighten the spark plug with a 5/8-inch socket,

turning it clockwise until snug.

6. Reattach the spark plug boot.

22

Page 23

CLEANING AND MAINTENANCE

Air filter

The air filter must be regularly cleaned to remove dust and dirt in order to avoid:

•Carburettor malfunctions

•Starting problems

•Loss of engine power

•Unnecessary wear to engine parts.

•Excessive petroll consumption.

Clean the filter every 25 hours, or more regularly if conditions are exceptionally dusty.

Cleaning the air filter

Remove the air filter cover and take out the filter. Wash it clean in warm, soapy water. Ensure

that the filter is dry before refitting it.

An air filter that has been in use for a long time cannot be cleaned completely. The filter must

therefore be replaced with a new one at regular intervals. A damaged air filter must always

be replaced.

If the machine is used in dusty conditions the air filter should be soaked in oil.

The air filter should be cleaned by air or shaking the air filter.

23

Page 24

17

CLEANING AND MAINTENANCE

Gear

There is a grease nipple and a plug for filling lubricant on the gear housing. Use a grease gun

to fill with grease. This should be done after every 25 working hours.

CAUTION! The gear housing must not be filled completely with grease. The grease expands

as the machine heats up during operation. If the gear housing was completely filled with

grease it could damage the seals and lead to leakage of grease.

The grease in the bevel gear does not normally need to be changed except if repairs are

carried out.

NOTE: The gear housing gets hot when the machine has been in use. To avoid burning

yourself do not touch the gear housing.

Cutting Blade

Clean any resin and plant residue from the blades using cleaning agent before and after

using the machine.

Lubricate the blade bars with rust preventive oil before long periods of storage.

To ensure good cutting results it is important that the contact pressure between the blades is

correct. The contact pressure is adjusted by turning the screws on the underside of the bar

clockwise as far as they will go. Lock the screws using the locking nut on the top of the bar.

Check that the screws are loose enough to allow the washers under the screw heads to slide

sideways.

24

Page 25

CLEANING AND MAINTENANCE

Cutting Blade (continued)

When the blades are correctly adjusted the play between the blades should be 0,2–0,4 mm,

measured at the screws.

The edges of the blades are too hard to be filed. Dull blades should be sharpened using a

grinder.

Replace the blades if they are bent or damaged.

Hand guard

The hand guard prevents hands from coming into contact with the moving blades, for

example, if the operator loses grip on the front handle.

Check that the hand guard is fitted correctly.

Check that the hand guard is undamaged

FUEL CAP, TANK

WARNING! Check for petrol leaks. A leaking fuel cap, tank, or lines are a fire hazard and must

be replaced immediately. If you find any leaks, correct the problem before using the

product. Failure to do so could result in a fire that could cause serious personal injury.

The fuel cap contains a non-serviceable filter and a check valve. A clogged fuel filter will

cause poor engine performance. If performance improves when the fuel cap is loosened,

check valve may be faulty or filter clogged. Replace fuel cap if required.

NOTICE: Do not overfill. Overfilling the crankcase may cause excessive smoke, oil loss, and

engine damage.

Reinstall the bottom engine cover. Replace the screws and tighten securely. Replace the

screw in the top engine cover and tighten securely.

NOTE: Used lubricant should be disposed of at an approved disposal site. See your local

retailer for more information.

25

Page 26

Maintenance

Daily

Weekly

Monthly

Clean the outside of the machine.

X

Make sure the throttle control lock and the throttle

function correctly from a safety point of view.

X

Check that the stop switch works correctly.

X

Check that the blades do not move when the engine is

idling or when the choke is in the start throttle position.

X

Check that the blades are undamaged and show no

signs of cracking or other damage. Replace the blades if

necessary.

X

Check that the blade guard is not damaged or distorted.

Replace the blade guard if it is bent or damaged.

X

Clean the air filter. Replace if necessary.

X

Check that the hand guard is not damaged. Replace the

guard if damaged.

X

Check that nuts and screws are tight.

X

Check that there are no petrol leaks from the engine,

tank or petrol lines.

X

Check the starter and starter cord.

X

Check that the vibration damping elements are not

damaged.

X

Clean the outside of the spark plug. Remove it and check

the electrode gap. Adjust the gap to 0.7 mm or replace

the spark plug. Check that the spark plug is fitted with a

suppressor.

X

Clean the machine’s cooling system.

X

Clean or replace the spark arrestor mesh on the muffler

(only applies to mufflers without a catalytic converter).

X

Clean the outside of the carburetor and the space

around it.

X

Fill the gear housing with grease. This should be carried

out approximately every 25 working hours.

X

Check that the screws that hold the blades together are

correctly tightened.

X

Clean the fuel tank.

X

Check the fuel filter from contamination and the fuel

hose from cracks or other defects. Replace if necessary.

X

CLEANING AND MAINTENANCE

Maintenance Schedule

The following is a list of the maintenance that must be performed on the machine. Most of

the items are described in the Maintenance section. The user must only carry out the

maintenance and service work described in this Operator’s Manual. More extensive work

must be carried out by an authorized service workshop.

26

Page 27

Maintenance

Daily

Weekly

Monthly

Check all cables and connections.

X

Check the clutch, clutch springs and the clutch drum for

wear. Replace if necessary by an authorized service

workshop.

X

Replace the spark plug. Check that the spark plug is

fitted with a suppressor.

X

Check and clean the spark arrestor mesh on the muffler

X

To reduce the fire hazard, clean dirt, leaves and surplus

lubricant, etc from the muffler and engine.

X

CLEANING AND MAINTENANCE

Maintenance Schedule (continued)

27

Page 28

Model No.

YT9305-01

Cylinder displacement

26.5 cm3

Cylinder bore

Φ 36 mm

Stroke

26 mm

Recommended max. speed

11000/min

Max. engine output, acc. to ISO 8893

650W/7000rpm

Blade length

550 mm

Cutting length

480 mm

Blade speed

2000 /min

Blade tooth space

35 mm

Max. cutting diameter

28 mm

Fuel tank capacity

280 ml

Weight without petrol

4.9 kg

Spark plug model No.

CMR5H

Sound pressure level LpA

86.8 dB(A) K=3dB(A)

Sound power level, measured LwA

100.2 dB(A) K=3dB(A)

Sound power level, guaranteed LwA

103 dB(A)

Vibration (front handle)

4.14 m/s2, K=1.5m/s2

Vibration (rear handle)

8.33 m/s2, K=1.5m/s2

TECHNICAL DATA

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity

with EC directive 2000/14/EC. Reported sound power level for the machine has been

measured with the original cutting attachment that gives the highest level. The difference

between guaranteed and measured sound power is that the guaranteed sound power also

includes dispersion in the measurement result and the variations between different machines

of the same model according to Directive 2000/14/EC.

Note 2: Reported data for equivalent sound pressure level for the machine has a typical

statistical dispersion (standard deviation) of 1 dB (A).

Note 3: Reported data for equivalent vibration level has a typical statistical dispersion

(standard deviation) of 1 m/s2

28

Page 29

Problem

Possible cause

Fault correction

1. Engine does not start

1.1 Not enough petrol in fuel

tank

1.2 Primer has been not

pressed at cold start

1.3 Primer has been pressed

at warm start

1.4 Spark plug is wet

1.5 Spark plug is damaged

1.6 Spark plug connector lose

1.7 Ignition switch is not

switched on

1.8 Choke button position is

wrong

1.1 Add petrol

1.2 Press the primer and

restart

1.3 Dry spark plug

1.4 Dry spark plug

1.5 Replace spark plug

1.6 Attach properly

1.7 Set ignition switch to “I”

1.8 Set the choke lever

position correctly as the

starting steps

2. Engine stops

2.1 Not enough petrol in the

fuel tank

2.2 Cutting device is blocked

2.3 Cold machine does not

warmup

2.4 Not enough oil or wrong

oil

2.1 Add petrol in to fuel tank

2.2 Remove blockage

2.3 Let the engine warm up at

idle for a while

2.4 Add the 4 stroke engine

oil to the full level of oil tank

3. Unsatisfactory cutting

performance

3.1 Cutting blade is dull/

damaged

3.2 Cutting material exceeds

capacity

3.1 Have a specialist to

sharpen or replace it3.2 Only

cut materials according to

the capacity of the product

4. Excessive vibration / noise

or exhaust

4.1 Cutting device is dull/

damaged

4.2 Bolts/nuts are loosen

4.3 Petrol/oil is incorrect

4.1 Replace with a new one

4.2 Tighten bolts/nuts

4.3 Empty unused petrol/ oil

and refill with the correct

petrol/oil

TROUBLESHOOTING

Suspected malfunctions are often due to causes that the users can fix themselves. Therefore

check the product using this section. In most cases the problem can be solved quickly.

WARNING! Only perform the steps described within these instructions! All further

inspection, maintenance and repair work must be performed by an authorized service

centre or a similarly qualified specialist if you cannot solve the problem yourself!

29

Page 30

DISPOSAL

Instructions

The machine and its accessories are made of various recyclable materials. Dispose of the

the machine in accordance with your local recycling regulations.

GETTING HELP

Our dedicated UK based customer helpline is open 5 days a week to assist you with assembly,

parts queries and technical support.

UK/Ireland helpline 0333 300 1614 Monday to Friday 9am–5pm

30

Page 31

GUARANTEE

Dear Customer,

In the unlikely event that your device develops a fault, please contact our Customer service

helpline (0333 300 1614).

1. These guarantee terms cover additional guarantee rights and do not affect your statutory

warranty rights.

Claims must be accompanied by Proof of Purchase. This must be in the form of a Sales

receipt or Bank statement and must show that the product has been purchased within 1 year

prior to the claim, from the retailer that it was originally sold to.

2. Our guarantee covers problems caused by material or manufacturing defects, and will

result in the repair of these defects or replacement of the device with a like for like or similar

article. Please note that our devices have not been designed for use in commercial, trade or

industrial applications. Consequently, the guarantee is invalidated if the equipment is used in

commercial, trade or industrial applications or for other equivalent activities.

3. The following are also excluded from our guarantee:

A) Faults due to accidents, customer misuse, or unauthorized repairs

B) Consumable Parts such as Blades/ /Spark plugs or Filters

C) Failure due to lack of routine maintenance

D) Failure as a result of not using the equipment in accordance with the manual and safety

instructions

E) The adjustment of cables, drive belts, or recoil starters

4. The guarantee is valid for a period of 1 years starting from the purchase date of the device.

Guarantee claims should be submitted before the end of the guarantee period within two

weeks of the defect being noticed. No guarantee claims will be accepted after the end of

the guarantee period. The original guarantee period remains applicable to the device even

if repairs are carried out or parts are replaced. In such cases, the work performed or parts

fitted will not result in an extension of the guarantee period, and no new guarantee will

become active for the work performed or parts fitted. This also applies when an on-site

Service is used.

5. Please keep your sales receipt in a safe place. If the defect is covered by our guarantee

your device will either be repaired under the terms of guarantee or we will send you a

replacement device. This device may be re-conditioned or Like for like replacement.

31

Loading...

Loading...