Page 1

名称/料号

说明书8458-4334094-001

2016-10-26

A5(148.5x210mm)

PDF

CH171

70g双胶纸

张妹珍

页 数

20 张A4纸

黑白印刷

说明书排版上下不要留太多白,

Page 2

C

O

W

hpr

HAL

W

W

G

n

t

G

h

a

n

n

s

e

o

e

e

w

s

o

c

e

Afte

t

a

b

o

.

a

e

0(M

e

v

T

4

V

o

g

1

800

1

riginal

ARNIN

ese instru

T

oduct, e

m

issing par

LEN

C

Manu

Importa

ctions co

suring it i

s, call th

E

ain

l

t-Please

tain imp

assembl

Custom

Sa

read the

rtant inf

d corre

r Helplin

e instruct

rmation

tly and s

on 0333

r Service S

ions fully

hat will h

fely. If y

300 1614

6

upport

elp you g

u need h

efore st

88617

odel: Y

rting ass

et the be

lp or ha

334-01)

mbly.

st from y

e dama

ur

ed or

0 Oct 20

6

Page 3

2

CONTENTS

GENERAL POWER TOOLS SAFETY WARNINGS……………………………………………....….3

SPECIAL SAFETY INSTRUCTIONS FOR CHAIN SAW…………………………………………..…5

SYMBOLS…………………………………………………………………………………………...…..8

DIAGRAM……………………………………………………………………………………….....….10

PARTS LIST……………………………………………………………………………………………..10

INTENDED USE………………………………………………………………………………….….…11

ASSEMBLY……………………………………………………………………………………………..12

OPERATION……………………………………………………………………………....….……….16

CLEANING AND MANTENIANCE ……………………………………………………….….….…26

TECHNICAL DATA……………………………………………………………………………………34

TROUBLESHOOTING ……….……………………………………………………………................35

GUARANTEE …………………………………...……………………………..…………………….. 36

RECYCLING AND DISPOSAL……………………………………………………………….….…..36

PLUG REPLACEMENT………………………………………………………………………………..37

Page 4

G

E

W

o

a)

b)

liq

u

c)

to

El

e

a)

pl

u

ris

k

b)

ref

r

c)

th

e

d)

Ke

e

in

c

e)

ou

t

f) I

pr

o

P

e

a)

us

e

m

o

b)

du

c

o

c)

so

u

on

d)

at

t

NERAL

P

WARNI

N

instru

c

Save

a

warni

n

(cordl

e

rk Area

Keep work

Do not op

ids, gase

s

Keep chil

d

lose contr

ctrical

S

Power tool

gs with ea

of electri

Avoid bod

r

igerators.

T

Do not ex

p

risk of el

e

Do not ab

u

p cord a

w

rease the

When ope

r

door use.

U

f operatin

g

tected su

p

rsonal S

a

Stay alert,

w

a power

ment of i

n

Use perso

n

st mask,

n

nditions

w

Prevent un

rce and/o

r

the switc

h

Remove a

n

ached to

OWER

G! Read

a

tions may

ll warning

gs refers

ss) powe

r

Safety

area clea

n

erate pow

e

or dust. P

o

ren and b

y

ol.

afety

plugs mus

t

rthed (gro

u

c shock.

y contact

w

T

here is a

n

ose power

ctric sho

c

u

se the co

r

ay from

h

risk of ele

c

ating a po

w

se of a c

o

a power t

o

ply. Use o

f

fet

y

atch wha

t

tool while

attention

al protecti

v

on-skid s

a

ill reduce

intentional

battery p

a

or energ

y adjustin

g

a rotatin

g

TOOLS

S

ll safety w

a

result in e

l

s and ins

t

to your

m

tool.

and well

l

r tools in

wer tools

standers a

match the

nded) po

w

ith earth

e

increase

d

tools to rai

k.

d. Never

u

eat, oil, s

h

tric shoc

k

er tool ou

t

rd suitabl

ol in a da

an RCD r

e

you are d

o

you are ti

r

while op

e

e equipm

e

fety sho

e

personal i

n

starting. E

n

ck, pickin

g

izing pow

e

key or w

r

part of t

h

AFETY

W

rnings an

d

ectric sh

o

ructions f

o

ains-ope

r

it. Clutter

e

explosive

a

create sp

a

way while

o

outlet. Ne

v

er tools. U

n

d or grou

n

risk of el

e

n or wet c

o

se the cor

d

arp edge

s

.

t

doors, use

e for outd

mp locatio

e

duces th

ing and u

s

ed or und

rating po

w

nt. Always

s, hard

h

juries.

sure the s

w

up or car

r

r tools th

a

ench befo

r

e power t

o

3

ARNIN

G

all instru

c

ck, fire an

r future r

e

ated (co

r

d or dark

tmospher

e

a

rks whic

h

o

perating

a

er modify t

h

modified

ded surfa

c

ctric sho

c

nditions.

W

d

for carry

or movin

an extensi

oor use re

n is unavoi

d

e risk of el

e

e common

er the infl

u

er tools

m

wear eye

p

at, or he

itch is in t

h

ying the t

o

t have th

e

e turning t

ol may r

e

S

tions. Fail

u

d/or serio

u

ference.

T

ded) po

w

areas invi

t

s, such a

s

may igni

t

power to

o

e plug in

a

plugs an

d

es, such

a

k if your

b

ater ente

r

ing, pullin

g

g parts. D

a

on cord su

i

duces the

d

able, use

e

ctric sho

c

sense whe

ence of d

ay result

rotection.

aring pro

t

h

e off-posi

t

ol. Carryin

switch o

n

he power t

sult in pe

r

re to follo

w

s injury.

he term

"

er tool

o

e accide

n

in the pr

e

e the dus

t

l. Distrac

t

ny way. D

o

matchin

g

s pipes, r

a

ody is ea

r

ing a po

w

or unplu

g

a

maged

o

table for

risk of ele

c

a residual

k.

n operatin

g

rugs, alco

h

in serious

p

Protectiv

e

ection us

e

ion before

g power t

o

invites a

c

ool on. A

w

sonal inju

r

w

the war

n

power to

o

r battery-

ts.

sence of

f

or fumes.

ions can

c

not use a

n

outlets

w

diators, r

a

thed or g

r

er tool wil

ging the

p

r entang

c

tric shoc

k

current de

v

a power t

o

ol or me

d

ersonal i

n

equipme

n

d for a

p

connectin

g

ols with

y

c

cidents.

rench or

y.

ings and

l" in the

operated

lammable

ause you

y adapter

ill reduce

nges and

ounded.

l increase

ower tool.

led cords

.

v

ice (RCD)

ol. Do not

ication. A

jury.

t such as

propriate

to power

our finger

a key left

Page 5

G

E

P

e

e)

th

e

f)

D

fro

m

g)

th

e

ha

P

o

a)

to

o

b)

b

e

c)

m

a

m

e

d)

un

f

Po

e)

an

yrep

f)

K

e

d

g)

int

o

o

p

S

e

a)

pa

NERAL

P

rsonal S

a

Do not ov

e

power t

o

ress prop

e

m

moving

p

If devices

se are c

o

zards.

wer Tool

Do not for

c

l will do t

h

Do not us

e

controlle

d

Disconnec

t

king any

a

asures re

d

Store idle

p

amiliar wit

wer tools

a

Maintain p

other co

n

aired bef

o

eep cutti

n

ges are le

Use the p

o

account

erations

d

rvice

Have your

rts. This wil

WARNI

N

may u

reduc

e

to co

n

machi

OWER

fety (co

rreach. Ke

e

ol in unex

rly. Do not

arts. Loos

e

are provi

d

nnected

a

Use an

d

e the pow

e

e job be

t

the power

with the

t

the plug

f

djustment

s

uce the r

ower tool

s

h the pow

e

re dang

e

ower tools.

dition tha

t

re use. M

a

g tools s

h

ss likely to

wer tool,

a

the workin

ifferent fr

o

power to

o

l ensure t

h

G! This m

a

nder som

e

the risk

o

sult their

p

ne.

TOOLS

S

ntinued)

p proper

f

pected si

t

wear loos

e

clothes,

ed for the

nd prope

r

Care

r tool. Use

ter and s

a

tool if the

s

switch is

d

rom the p

o

, changin

g

isk of start

i

out of the

r tool or th

e

rous in th

e

Check for

may affe

c

ny accid

e

arp and

c

bind and

ccessorie

s

g conditio

n

m those i

n

l serviced

at the saf

e

chine pr

o

circums

t

f serious

o

hysician

a

AFETY

W

ooting an

d

uations.

clothing

o

jewellery

o

connectio

ly used.

U

the corre

c

fer at the

s

witch doe

s

angerous

wer sourc

e

accesso

r

ng the p

o

reach of c

h

se instruc

t

hands of

misalignm

e

t the pow

e

nts are c

a

lean. Pro

p

are easie

r

and tool

b

s and th

e

tended

c

by a qual

i

ty of the

duces an

ances int

e

r fatal inju

nd the m

e

4

ARNIN

G

balance

a

r jewellery

r long ha

n of dust

e

se of du

s

t power to

o

rate for w

h

s

not turn i

t

and must

and/or th

ies, or sto

r

wer tool

a

ildren an

d

ions to op

e

untraine

d

nt or bind

i

r tool’s o

p

used by

p

erly main

t

to contr

o

its etc. in

a

work to

b

ould resul

t

fied repai

r

power to

o

electrom

a

rfere wit

h

ry, we rec

o

dical imp

l

S

t all times.

. Keep you

r

ir can be

c

xtraction

a

t collecti

o

l for your

a

ich it wa

s

on and of

f

be repair

e

e battery

p

ing power

ccidental

do not all

o

rate the p

o

users.

ng of movi

eration. If

oorly mai

n

ained cu

t

l.

ccordan

c

e perform

e

in a haz

a

person u

s

l is maint

a

gnetic fi

e

active o

r

mmend

p

ant manu

This enab

hair, clot

h

aught in

m

nd collec

t

o

n can r

e

pplication

designe

d

. Any po

w

d.

ack from t

tools. Suc

h

ly.

w persons

wer tool.

ng parts, b

damaged,

tained p

o

ting tools

e with the

s

d. Use of

rdous situ

a

ing only i

d

ined.

ld during

passive

m

ersons wi

t

facturer b

les better

ing and gl

o

oving p

a

ion faciliti

e

duce du

. The corr

e

.

er tool th

a

he power t

prevent

i

reakage o

f

have the

p

wer tools

.

with sha

r

e instructi

o

the pow

e

tion.

entical re

p

operation

edicalim

p

h medic

a

efore ope

control of

ves away

rts.

s, ensure

st-related

ct power

t cannot

ool before

ve safety

parts and

ower tool

p cutting

ns, taking

r tool for

lacement

. This field

lants. To

l implants

rating this

Page 6

5

SPECIAL SAFETY INSTRUCTIONS FOR CHAIN SAW

zKeep all parts of the body away from the saw chain when the chain saw is operating. Before you

start the chain saw, make sure the saw chain is not contacting anything. A moment of

inattention while operating chain saws may cause entanglement of your clothing or

body with the saw chain.

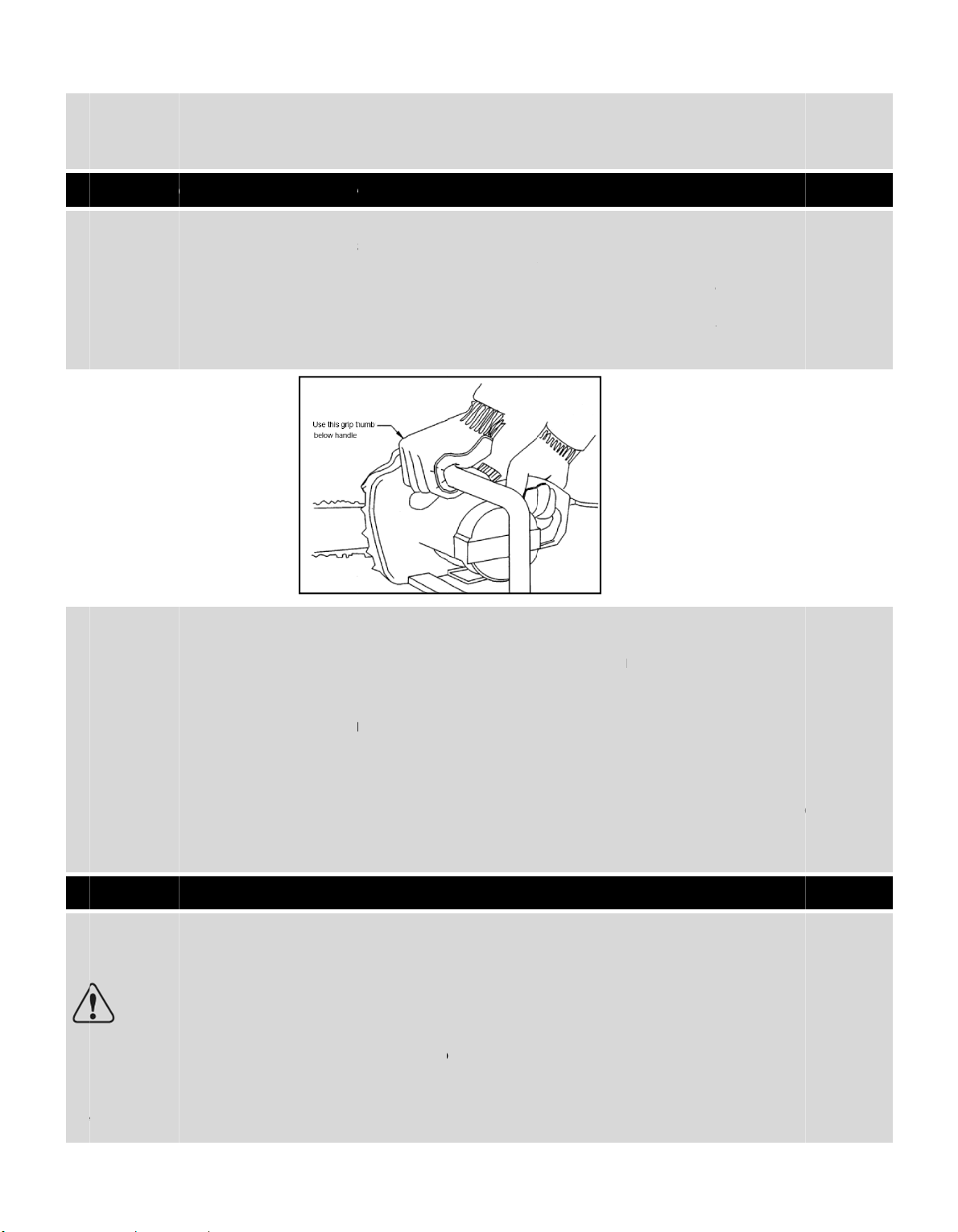

zAlways hold the chain saw with your right hand on the rear handle and your left hand on the front

handle. Holding the chain saw with a reversed hand configuration increases the risk of

personal injury and should never be done.

zWear safety glasses and hearing protection. Further protective equipment for head, hands, legs

and feet is recommended. Adequate protective clothing will reduce personal injury by

flying debris or accidental contact with the saw chain.

zDo not operate a chain saw in a tree. Operation of a chain saw while up in a tree may result

in personal injury.

zAlways keep proper footing and operate the chain saw only when standing on fixed, secure and

level surface. Slippery or unstable surfaces such as ladders may cause a loss of balance or

control of the chain saw.

zWhen cutting a limb that is under tension be alert for spring back. When the tension in the

wood fibres is released the spring loaded limb may strike the operator and/or throw the

chain saw out of control.

zUse extreme caution when cutting brush and saplings. The slender material may catch the

saw chain and be whipped toward you or pull you off balance.

Carry the chain saw by the front handle with the chain saw switched off and away from your body.

When transporting or storing the chain saw please always fit the guide bar cover. Proper handling

of the chain saw will reduce the likelihood of accidental contact with the moving saw chain

.

zFollow instructions for lubricating, chain tensioning and changing accessories. Improperly

tensioned or lubricated chain may either break or increase the chance for kickback.

zKeep handles dry, clean, and free from oil and grease. Greasy, oily handles are slippery

causing loss of control.

zCut wood only. Do not use chain saw for purposes not intended. For example: do not use chain

saw for cutting plastic, masonry or non-wood building materials. Use of the chain saw for

operations different than intended could result in a hazardous situation.

Causes and Operator Prevention of Kickback

Kickback may occur when the nose or tip of the guide bar touches an object, or when the

wood closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a sudden reverse reaction, kicking the guide bar up

and back towards the operator.

Pinching the saw chain along the top of the guide bar may push the guide bar rapidly back

towards the operator.

Either of these reactions may cause you to lose control of the saw which could result in

serious personal injury. Do not rely exclusively upon the safety devices built into your saw. As

a chain saw user, you should take several steps to keep your cutting jobs free from accident

Page 7

S

P

C

a

or

Ki

cca

z

z

z

Fol

th

e

Re

c

x

x

x

Lu

x

x

x

x

If t

cl

e

c

e

ECIAL

S

uses an

d

injury.

kback is t

h

n be avoi

d

Maintain

a

on the sa

w

forces c

a

of the c

h

Do not ov

e

contact

a

Only use

r

bars and

low the m

a

depth g

a

ommend

e

Use a resi

During th

e

cord fro

m

The first-ti

bricatio

n

The chai

n

Use only

n

WARNI

N

pump

;

Check oil

he lubrica

an and fr

e

ntre.

AFETY I

N

d

Opera

t

e result o

f

ed by ta

k

firm grip,

and posi

t

n be con

t

ain saw.

rreach an

nd enab

l

eplaceme

n

chains m

a

nufacturer

’

uge heig

h

d:

dual curr

e

cutting

o

snagged

me user s

h

System

is autom

a

ew chain

G! Never

the bar a

level bef

o

tion syste

m

e from o

b

STRUC

T

or Prev

e

f

tool misu

s

ing prop

e

with thum

b

ion your b

o

rolled by

t

d do not c

u

es better

c

t bars an

d

y cause

c

s sharpeni

n

t can le

a

nt device

peration,

on branc

h

ould, as

a

tically lu

b

oil specifi

use waste

d

nd the ch

a

re each

w

does no

t

struction

s

IONS F

O

ntion of

K

s

e and/or

r precaut

i

s and fing

e

dy and ar

m

he opera

t

t above s

h

ontrol of

chains sp

e

hain bre

a

g and ma

d to incre

a

with a tri

p

the suppl

y

es and t

h

minimum

ricated.

cally form

u

oil, low

q

in may r

e

ork sessi

o

work pro

. If it is still

6

R CHA

I

ickbac

k

incorrect

o

ons as gi

v

rs encircli

to allow

y

or, if pro

p

oulder hei

g

the chain

cified by

t

kage an

d

intenance

sed kick

b

ping curr

e

cord mu

s

e like.

practice,

lated for

uality oil,

o

sult in seri

n, refill if l

e

perly, che

not worki

n

N SA

W

(contin

u

perating

en below:

ng the cha

ou to resi

s

er preca

u

ht. This h

e

saw in un

e

he manuf

a

/or kickb

a

instruction

s

ack.

nt of 30m

t be secu

cutting lo

chainsaw

s

r insuffici

e

ous perso

n

ss than ¼

f

ck if the o

g, conta

c

ed)

procedur

e

in saw han

d

t kickback

tions are

t

lps preve

n

xpected

cturer. Inc

o

ck.

for the sa

w

A or less

rely positi

o

gs on a s

a

.

nt oil. Thi

s

al injury

ull.

il filter an

d

t an auth

s or cond

d

les, with

b

forces. Ki

c

aken. Do

n

t uninten

d

situations.

rrect rep

l

chain. D

e

ned to pr

e

w-horse o

could da

m

all oil-wa

orised ser

v

itions and

oth hands

kback

ot let go

ed tip

acement

creasing

e

vent the

r cradle.

age the

ys are

ice

Page 8

S

P

S

a

Ki

c

u

p

cu

Th

e

In

t

Thi

di

a

It i

s

Fu

r

D

u

a

c

int

e

us

e

m

u

m

awe

Th

e

c

o

m

a

Th

e

R

e

Ev

e

Ac

c

-

C

-

A

- U

- F

l

- F

l

- I

n

- S

k

- L

o

ECIAL

S

fety Ch

a

kback is

wards to

w

tting with

t

risk of ki

c

x

Ensuri

n

x

Not al

l

x

Not c

u

ended

U

s chain sa

meter ac

only allo

w

thermore

ring the u

s

cording t

o

e

nded us

e

/ mainte

st be fam

nufactur

e

ll as the a

user an

d

mbinatio

n

chine.

chain sa

sidual R

i

n with the

i

ording to

t

ontact wi

t

ccess to t

nforeseen

ung out o

ung out o

halation

o

in conta

c

ss of hea

AFETY I

N

in Brake

a pheno

m

ards the

o

t

he blade

kback ca

g the wo

r

owing th

e

tting with

se/Not i

n

w is only

d

cording t

h

ed to cu

t

a professi

o

e of the

c

the man

u

are also

t

nance. P

e

iliar with t

h

rs original

llowed co

not the

m

of not int

e

w is only i

n

sks

ntended u

s

he type an

t

h expose

d

he rotatin

g

, abrupt

m

f parts fro

m

f parts of

t

f work pe

t with the

ring, if no

r

STRUC

T

enon wh

perator.

I

tip, if the

s

n never b

e

k area is f

r

chain to

g

the dang

e

tended

U

esigned f

o

e guide b

wood. E

v

nal use f

o

hain saw

t

al and al

s

he details

ople/User

e manua

l

or appro

v

mbinatio

n

anufactu

r

nded us

e

tended t

o

e of the a

p

d

construc

t

saw tee

t

saw cha

ovement

the saw

he work

p

ace parti

c

oil,

equired

e

IONS F

O

ereby th

e

t happen

s

aw gets

p

complet

ee of de

b

et pinch

e

r area at

se

r cutting

o

ar length.

ery other

r tree ser

v

he user h

a

o to the

n

in the ma

n

who wor

k

. It is only

ed spare

s of guide

er is liabl

e

or a not

a

use outd

pliance th

e

ion of the

a

h of the s

a

in (cuttin

g

of the gui

d

chain (C

u

iece

les,

ar protec

t

7

R CHA

I

tip of th

e

with littl

e

inched in

ely elimin

a

ris.

d.

the tip of

o

f brushes

use of the

ices is stri

c

s to arra

n

amed pi

c

ual rega

r

with the

c

allowed t

o

parts (gui

d

bar / sa

w

for every

llowed c

h

oor.

re is alwa

y

ppliance t

h

w chain

(

hazards)

e bar (c

u

tting / inj

e

ion used

d

N SA

W

e

saw fli

e

or no w

a

it’s cut, o

r

ted but it

the saw .s

, trunks or

machine

tly forbid

d

ge for pe

r

tograms

o

ding safe

t

hain saw

assembl

e

e bar; sa

w

chain as

n

accident

ange of

t

s a residu

a

e followin

g

cutting h

a

tting haz

a

ction haz

a

uring wo

r

s quickly

rning and

if the sa

w

can be r

e

ee illustra

t

timber be

is a not in

t

en.

sonal pro

t

n the ch

a

y warning

s

or make

m

on the c

h

chain, s

p

amed in

which res

u

he constr

u

l risk, whi

c

potential

zards)

rds)

rds)

k.

and unc

o

can be

c

contact

s

duced b

y

ion belo

w

ams up to

ended us

e

ective eq

in saw. P

a

and refe

r

aintenan

c

ain saw

t

ark plug

e

the manu

a

lts from a

ction on

t

h can not

p

hazards m

i

ntrollably

aused by

debris.

:

.

a

.

uipment

rts of the

ences for

c

es on it

he

e

.g.) as

l.

he

revented.

ght apply:

Page 9

S

Y

IM

P

an

m

a

In

d

W

A

W

e

W

e

Pr

o

S

W

S

W

M

a

MBOLS

ORTANT:

d learn th

e

chine m

o

icates da

RNING –

T

ar ear pr

o

ar gloves

tect the

m

ITCH OFF:

ITCH OFF:

ke sure t

h

Some of t

h

ir meani

n

re effecti

v

nger, war

n

o reduce

tection,

e

and safe

t

achine f

r

Remove

p

Remove

p

e “chain

b

e followi

n

g. Proper

ely and r

e

ing or ca

u

the risk of

ye prote

c

y boots to

om the d

a

lug from

m

lug from

t

rake” is

d

g symbol

s

interpreta

duce the

tion.

injury, us

e

tion and

h

protect a

mp and

n

ains bef

o

he mains

i

isengage

d

8

may be

u

tion of th

e

risk of ac

c

r must re

a

elmet wh

e

gainst ele

c

ever exp

o

re cleani

n

mmediat

e

.

sed on y

o

se symbo

l

ident.

d instructi

o

n using t

h

tric shoc

k

se it to ra

i

g or mai

n

ly if the c

a

ur tool. B

e

s will allo

w

o

n manu

a

e produc

n.

tenance

a

ble is da

m

sure to st

u

you to u

s

l.

t.

aged or

dy them

e the

cut.

Page 10

S

Y

Ke

C

o

Thi

W

E

bu

lo

c

G

u

20

0

MBOLS

ep childr

e

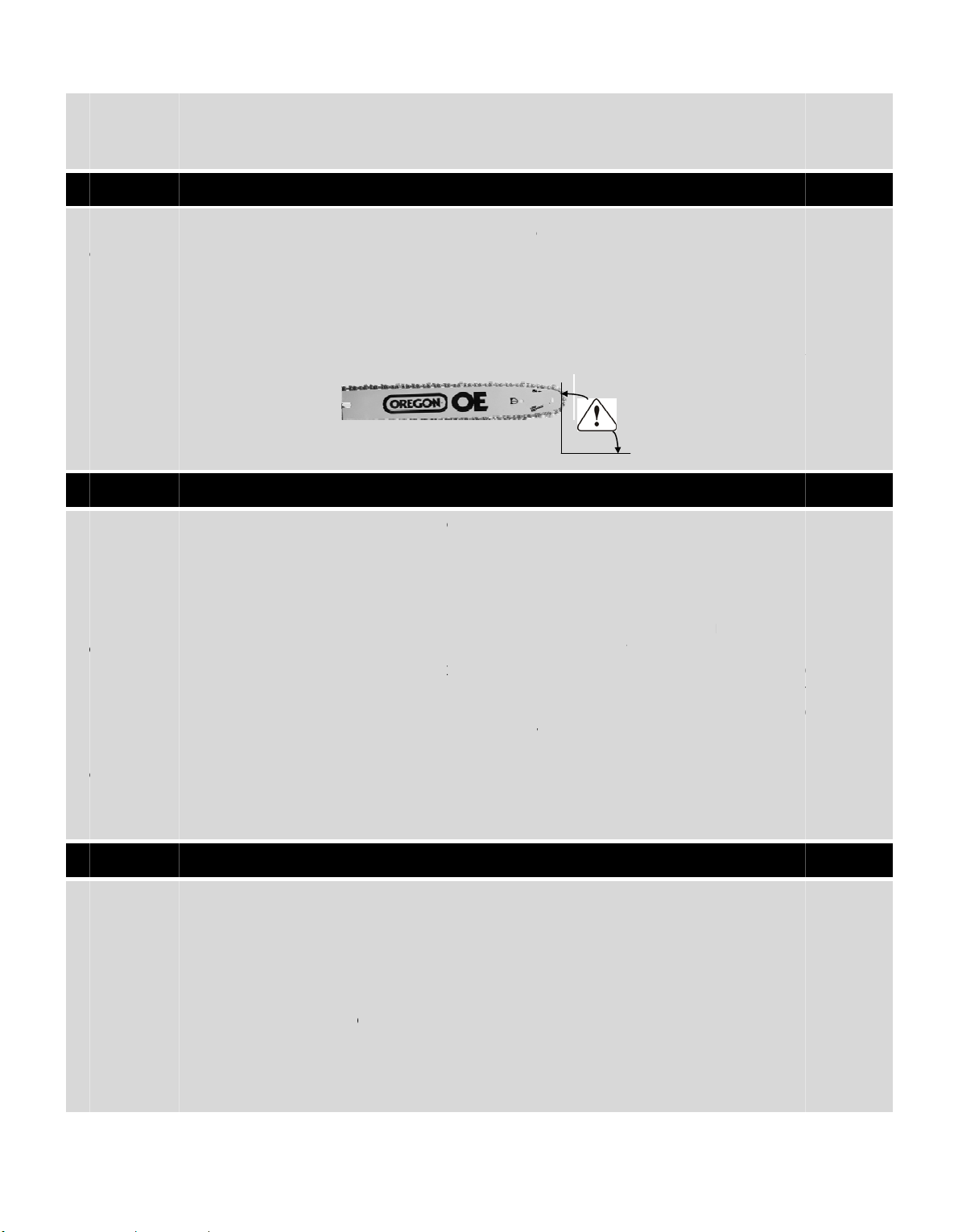

nforms to

s product

EE symbo

l

t in an en

v

al counci

aranteed

5/88/EC)

n at a dis

t

relevant

s

is double

i

. Tools tha

ironment

a

l authority

sound p

o

ance of n

afety stan

nsulated

e

t are no lo

lly friendl

y

for recycl

wer level

(

ot less tha

dards.

lectricall

y

nger usab

l

way. Ple

ing advic

e

(

tested a

c

9

n 10m fro

m

e should

n

ase recyc

l

.

cording t

o

the wor

k

ot be dis

p

e where f

a

Directiv

e

area

osed of w

i

cilities e

x

2000/14/

th househ

ist. Check

EC as am

e

old waste

with your

nded by

Page 11

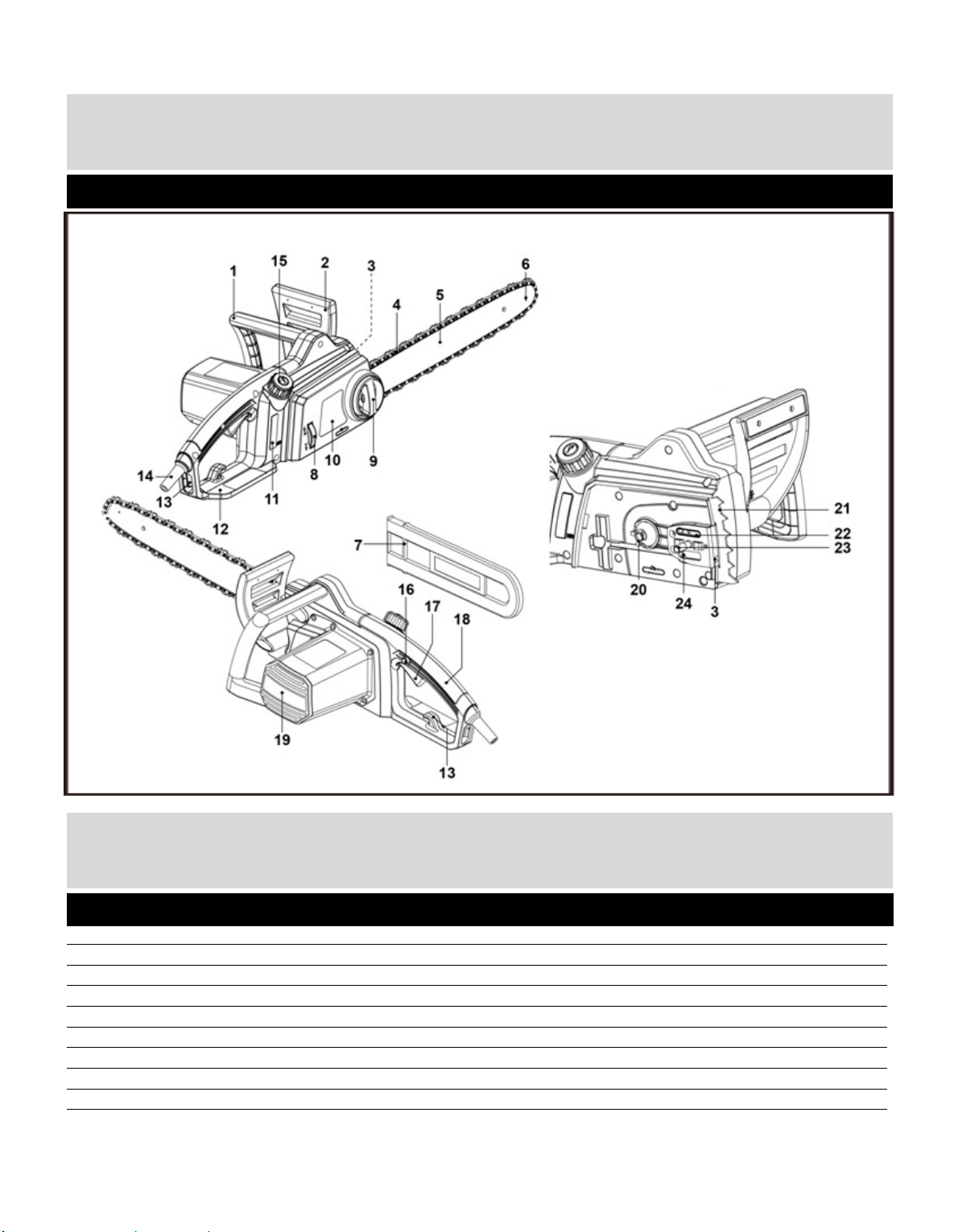

10

DIAGRAM

PARTS LIST

(See Fig. A)

1. Front Handle

2. Front Guard/Chain Brake

3. Anti-skid teeth

4. Saw Chain

5. Guide Bar

6. Sprocket Nose

7. Guide Bar Cover

8. Adjustable knob for Chain Tension

Fig.A

Page 12

11

PARTS LIST

(See Fig. A, continued)

9. Press Knob for Guide Bar Tension

10. End Cover

11. Oil Level Window

12. Rear Guard

13. Cable Strain Relief

14. Power Cord with Plug

15. Oil Tank Cap

16. Lock-off Button

17. On/Off Switch

18. Rear Handle

19. Air Vents

20. Drive Sprocket

21. Spike Bumper

22. Oiling Port

23. Bolt

24. Tension Pin

Remark: Above are all assembled in the standard delivery.

INTENDED USE

This chain saw is designated with a rated input of 1800 Watts. The product is intended for cutting

logs with a thickness of max. 326mm. It must not be used for cutting other materials, such as

plastics, stone, metal or wood that contains foreign objects.

The product may only be used with the guide bar/saw chain combination stated in these

instructions. It is not permitted to use other types or sizes.

Vertical and horizontal cuts can be performed with this product. Longitudinal sections can only

be cut by professionals.

This product should not be used outside of domestic premises e.g. for cutting firewood in forested

areas. The product should not be used on masonry and material that are harmful to health.

This product is intended for private domestic use only, not for any commercial trade use. It must

not be used for any purposes other than those described.

Page 13

AS

U

n

1.

U

2.

R

3.

M

p

a

in

c4.Eals

C

h

N

O

di

sdet

Al

w

ch

ch

Te

n

te

n

cu

su

f

C

h

pr

o

a

p

SEMBL

Y

packing

npack al

emove a

ake sure

rts are mi

s

omplete

o

nsure tha

t

o include

s

ain Ten

s

WARNI

N

tensio

n

when

h

TE: The ch

a

assemble

d

ails.

ays main

ain may j

u

ain! A loo

s

sioning t

h

sion can

tting cha

r

ficient lu

b

eck the

c

duct. Th

e

proximat

e

l parts an

d

ll packing

the deliv

e

sing or sh

o

r damag

e

t

you hav

e

suitable

p

ioning

C

G! Unplu

g

! The cut

t

andling t

in and bar

chain an

d

tain prop

e

mp out o

f

e chain

w

e chain t

o

cause ch

a

acteristic

s

rication a

n

hain tensi

o

correct

ly 2-4mm

f

lay them

materials

ry conte

n

w dama

g

d produ

c

all the a

c

ersonal p

hec

k

the pro

d

ing edge

s

he chain!

have bee

n

bar for re

p

r chain t

e

the guid

e

ill cause r

a

o tightly

w

in deraili

n

and pro

l

d correc

t

n using

o

chain te

n

f

rom the

g

on a flat,

and ship

p

ts are co

m

e do not

u

t represe

n

cessories

a

rotective

e

uct from

t

of the sa

w

already a

s

lacement

,

nsion! A l

o

bar groo

pid wear

ill overlo

a

g, where

a

onged w

o

tensionin

g

ne hand

t

sion is a

c

uide bar

(

12

stable sur

f

ing devic

e

plete an

d

se the pr

o

ts a haza

r

nd tools

n

quipmen

t

he power

chain a

r

sembled

o

please re

a

ose chai

n

ve! This m

a

to the ch

a

d the mo

t

a

s a corr

e

rking life

!

o lift the

s

hieved

w

5) in the

c

ace.

s if appli

c

free of a

duct but

d to peo

p

eeded fo

r

t

.

source b

e

e sharp.

A

n the mac

h

d the mai

n

increase

s

y injure t

h

in, guide

or and c

a

ctly tight

e

! The cha

aw chain

hen the

s

entre (Fig

s

able.

ny dama

g

contact y

le and pr

o

assembl

y

fore adju

s

lways we

a

inewhen

y

tenance

p

s

the risk

o

e operat

o

bar and s

use dam

a

ned chai

n

in life ma

(4) again

s

s

aw chai

n

s

. 9, 10).

e. If you f

i

our store.

perty.

and oper

a

s

ting the

s

r protecti

ou get it o

u

art in this

m

f kickbac

k

r and da

m

procket!

ge, and i

n

provide

s

inly depe

n

t the wei

g

can be

nd that

Using an

a

tion. This

aw chain

ve gloves

t of box. If

anual for

! A loose

age the

sufficient

the best

ds upon

ht of the

lifted by

Page 14

13

ASSEMBLY

Chain Tensioning Check (continued)

If loose chain is found before use, please follow up the instruction below.

(If tight chain is found before use, please do the opposite to the below instruction.)

Firstly slightly tighten the Knob (9) clockwise. (Fig.7)

Do not tighten the locking nut completely and saw chain tensioning is required first.

NOTE: The saw chain (4) has not yet been tensioned. Tension the chain as described under

“Saw chain tensioning”. After operating the product for approximately 1 hour, adjust the

chain tension again.

Saw Chain Tensioning

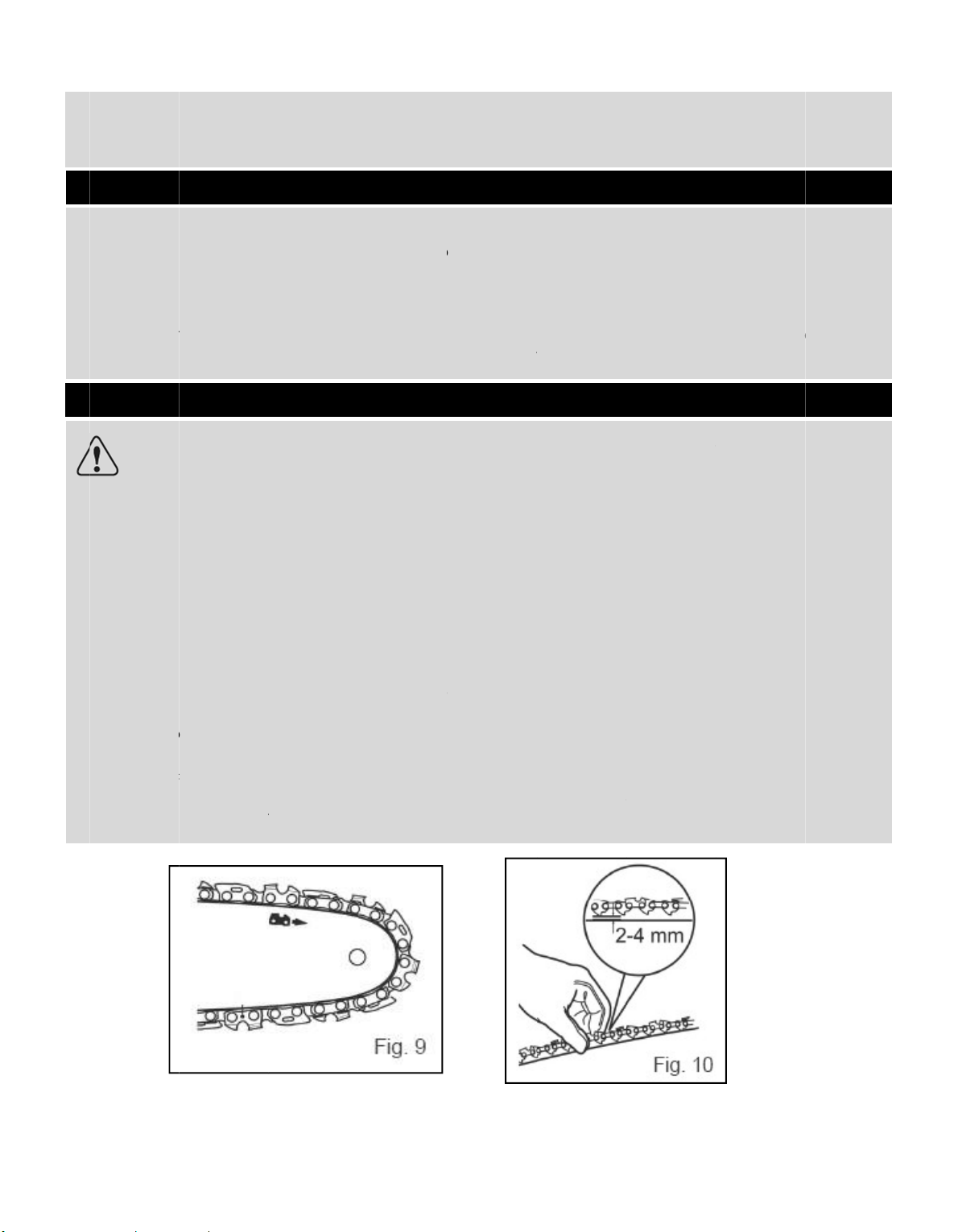

Always check the saw chain tension before use, after first cuts and regularly during use

approximately every five cuts. After initial operation, new chains can lengthen considerably.

This is normal during the break-in period and the interval between future adjustments will

lengthen quickly.

Set the product on a suitable flat surface.

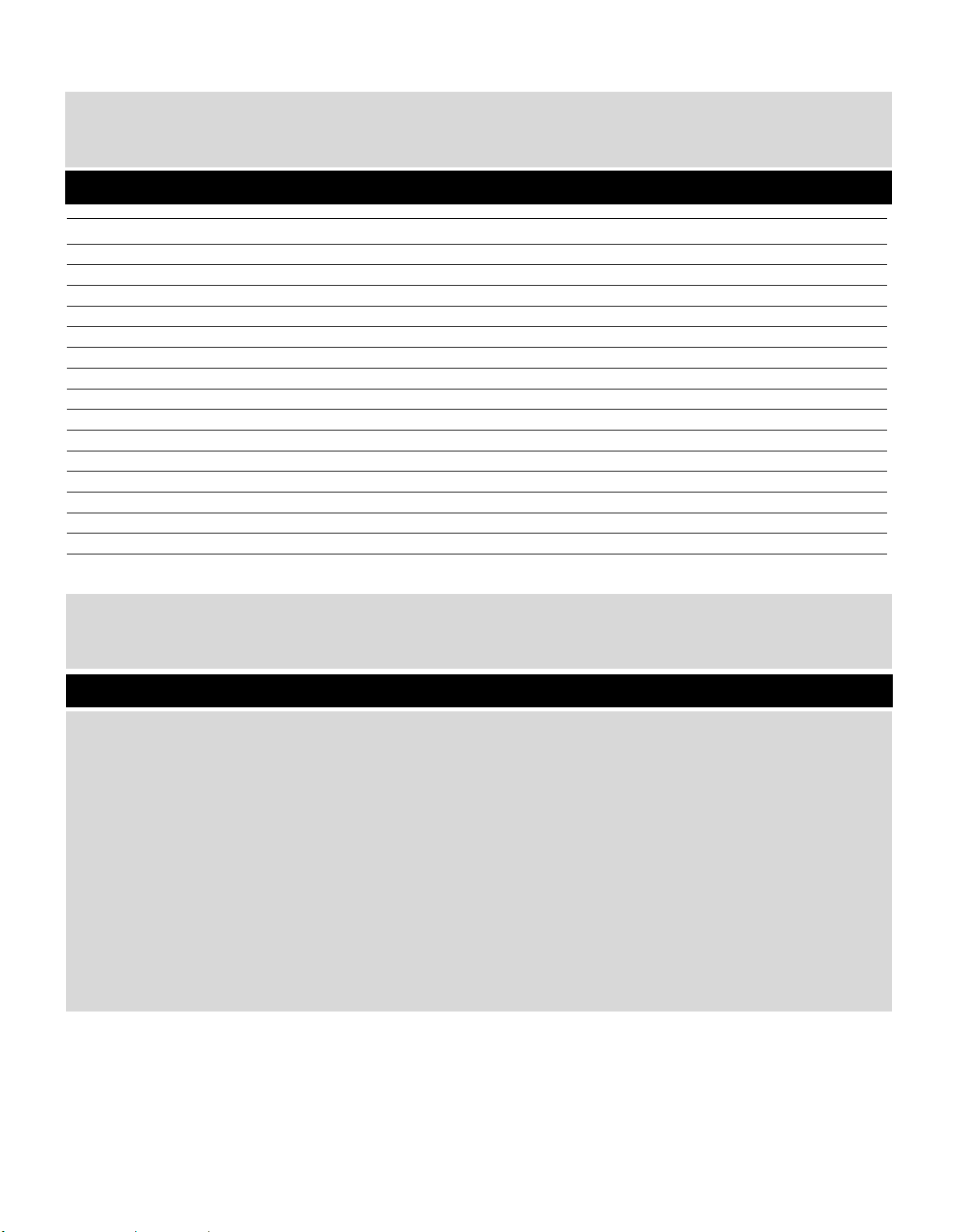

Turn the tension knob (8)clockwise until the chain “tie straps” are adjust touching the bottom

edge of the guide bar(5) Fig.(8).

Page 15

AS

C

h

Tu

r

Lu

N

e

O

p

pr

o

oil

cu

e

q

pr

oSet

Un

fu

n

le

a

(Fi

gCh

th

e

Wi

p

N

O

a

c

SEMBL

Y

ain Ten

s

n the kno

b

bricatio

n

WARNIN

G

using it!

result in

ver opera

erating t

h

duct life

s

is eviden

t

tting ope

r

uipment

w

per amo

u

the prod

u

screw an

d

nel with

a

ve appro

.12).

eck the oi

oil level i

e up spill

TE: Alwa

y

cordanc

e

ioning

C

(9) cloc

k

! The pro

d

Never op

e

extensive

te the ba

r

e produc

t

pan and

by smok

e

ations is

ith an a

u

nt of oil t

o

ct on an

y

remove

t

filter to

p

ximately

5

l level win

d

s lower th

a

ed lubric

a

s dispose

with loca

heck (c

o

wise to ti

g

uct is no

t

rate the

p

damage

t

and chai

n

s dry or

w

cause ra

p

or bar d

i

essential

tomatic

o

the bar

a

suitable

s

he tank

c

revent d

e

mm of sp

ow (11)

p

n “MIN”

m

nt with a

s

of lubri

c

l regulatio

ntinued)

hten the

c

filled wit

h

roduct wi

t

t

o the pro

d

without

l

ith too litt

l

id wear t

o

scoloratio

to minimi

z

iling syst

e

nd chain

!

urface wi

t

ap(15), t

h

bris enteri

ace to th

e

rior to sta

r

arking (F

i

oft cloth

a

ant, use

d

ns.

14

over (10)

oil. It is e

s

t

hout cha

i

d

uct!

ubricatio

n

e oil will

d

the chai

n

n! Adequ

a

e friction

m! The

o

t

h the tan

k

en add t

h

ng the ta

n

lower e

d

t-up and r

e

g. 13).

nd refit t

h

oil and

complet

e

sential to

n oil or wit

oil!

ecrease

c

and bar

te lubric

a

with the

iling syste

cap(15)

e lubrica

n

k and to

a

ge to all

o

gularly d

u

e tank c

a

objects

c

ly (Fig.11)

.

fill the pro

h an emp

t

utting eff

i

from over

h

tion of th

guide b

a

m autom

a

facing up

w

t into the

void spill

i

w the lu

b

ring oper

p (15).

c

ontamin

a

duct with

y oil tank,

ciency, s

h

eating! I

n

e saw ch

a

r. Your

p

tically d

e

ards.

tank. Use

ng and o

v

rication t

o

ation. Refi

ted with

oil before

as this will

orten the

sufficient

in during

roduct is

livers the

a proper

erfill and

expand

ll oil when

them in

Page 16

AS

Lu

C

o

Th

ewit

pr

o

M

a

D

o

str

a

(Fi

g

C

o

Yo

SEMBL

Y

bricatio

n

nnectio

n

WARNIN

G

conne

c

with so

c

proper

s

extensio

n

hout an

tected s

u

ke sure t

h

uble the

e

in relief

(

.14,15).

nnect th

e

ur produc

t

WARNI

N

rating

(contin

u

to the

P

! For you

r

ted to an

kets prot

e

ize and t

y

cable m

extension

pply!

e on/off s

w

xtension

c

13). Gent

l

extensio

n

is now re

G! Chec

k

label

ʽ

ed)

ower Su

p

safety, it

extension

cted ag

a

pe for yo

u

ust alway

s

cable c

itch (17)

able, ab

o

y pull on

t

cable to

ady to be

the volt

a

pl

y

is require

d

cable! Th

e

inst wat

e

r product

be used

w

onnected

is in its off

ut a foot

t

he cord

t

a suitable

used.

ge! The

v

15

that the

extensio

n

r splashin

g

(>/= 1.5

m

ith the c

a

. Always

position.

from the

o ensure

t

socket.

oltage m

u

plug atta

c

cable m

u

! Ensure

t

m2)!

ble strain

use a re

s

end and

h

t

hat it is f

i

st compl

y

hed to th

st be suit

a

he exten

s

relief! Do

n

s

idual cu

r

ook the l

o

rmly atta

c

with the

is produc

t

ble for o

u

ion cabl

e

ot use th

e

rent sup

p

op over

t

hed at t

h

informati

o

is always

tdoor use

is of the

product

ly (RCD)

he cable

e handle

n on the

Page 17

O

P

C

h

¾

¾

¾

¾

¾

¾

¾

¾

¾

C

h

Th

e

o

c

Th

e

16

)

Th

ebra

Ch

Th

e

ch

M

a

ERATI

O

eck that

y

Before st

a

Working

w

fit to co

m

Ensure th

Make su

r

Ensure th

enter th

e

Ensure th

Make su

r

Double

c

Underta

k

about its

WARNI

N

safety

– Safe

t

ain Bra

k

chain b

r

curs the c

chain br

a

.

chain br

a

ke is acti

v

ain Brake

T

followin

g

ain brake

ke sure t

h

N

ou have

n

rting you

ith this p

r

plete the

at you ha

v

e that yo

u

at no una

working

a

at the pr

o

e that saf

e

heck that

e periodi

c

suitability

G! For yo

u

instructio

n

y Warnin

g

e

ake is a

s

hain stop

s

ke (2) in

t

a

ke (2) in

ated (Fig

est

function

a

test is to r

e

e chain b

oted all t

h

must hav

e

oduct is d

e

job safet

y

e all the

a

wear suit

uthorized

p

rea.

duct is fre

ty devic

e

all assem

b

structura

l

for its inte

r own an

s in follow

s.”

afety me

c

immedia

t

he engag

the enga

g

. 17).

l check

s

duce th

e

rake (2) is

e followi

n

fully rea

d

manding

.

ccessori

e

able pers

o

eople, e

s

e from da

m

s and ac

c

ly tools h

a

checks o

f

nded pur

p

d the saf

e

ing sectio

n

hanism

a

ely.

ed diseng

ed positi

o

hould be

possibilit

y

disengag

e

16

g instruct

i

and und

’ therefor

e

s and too

nal prote

c

pecially

c

age an

d

essories a

ve been

this prod

u

ose.

ty of oth

e

“In more

ctivated

b

aged posi

n, the sa

w

carried o

u

of injury

d

d. Disen

g

ons:

erstood t

h

ensure y

o

ls needed

tive equi

p

hildren, a

n

that it is

n

re correct

removed

f

cts; do n

o

r people

y

detail – T

e

y the fro

tion, the

p

chain is

s

t before

e

ue to kic

k

age the

c

e entire i

n

u are phy

s

for assem

ment.

d pets ar

e

ot worn.

ly fixed.

f

rom the

p

t use it if y

o

ou must

r

chnical a

n

nt guard

(

roduct c

a

topped

a

ach use.

back.

hain brak

e

struction

m

s

ically an

d

bly and o

p

nearby

o

roduct b

e

u have a

n

ead and

f

d legal in

f

2). When

n be oper

s soon as

t

The purp

o

(2) by p

u

anual.

mentally

eration.

r could

fore use.

y doubts

ollow the

ormation

kickback

ated (Fig.

t

he chain

se of the

lling it

Page 18

O

P

C

h

b

a

Pl

a

th

e

Gr

a

ha

Pr

e

sw

W

hag

no

O

n

M

a

Gr

i

ch

Pr

e

Sq

u

Re

ERATI

O

ain Bra

k

ck towar

d

ce the pr

o

surface

o

sp the fr

o

ndle (18)

w

ss the lo

itch (17)

w

ile the m

o

ainst the

c

NOTE: T

WARNI

N

take t

h

produ

c

The c

h

rmal oper

a

/Off Swi

t

ke sure t

h

p the pro

d

ain brake

)

ss the loc

eeze in t

h

lease the

o

N

e (conti

n

s the fron

t

duct on

a

r other o

b

nt handl

e

ith your ri

ck-off bu

t

ith your i

n

tor is run

n

hain bra

k

he motor

w

G! If the

s

e produ

c

t if the c

h

ain brak

e

tion!

ch

e safety

c

uct with

b

and your

k-off butt

o

e on/off

s

n/off swi

t

ued)

handle(1

ny suita

b

jects and

(1) with

y

ght hand.

ton (16)

dex finge

r

ing, acti

v

e(2). The

s

ill not st

a

aw chai

n

t to the n

ain brake

should n

hain brak

e

oth hand

right han

d

n (16) an

d

witch (17

)

ch (17) to

) (Fig.16).

le flat sur

f

connect

i

our left

h

Your thu

m

with your

and hold

ate the c

aw chain

rt if the c

h

and mot

o

earest au

t

is not wo

r

ot be us

e

(2) is dis

e

s, your lef

t

holding

t

hold it in

to switch

switch th

e

17

ace, mak

e

t to the p

o

and. Your

b and fin

g

right thu

it in positi

o

hain brak

e

(4) and

m

ain brake

r fail to s

t

horized d

e

king prop

e

d for sta

r

ngaged

(

hand hol

d

he rear h

a

position.

the prod

u

product

sure the

wer supp

thumb a

n

ers shoul

d

mb, then

o

n.

(2) by

m

otor shoul

d

is in the e

t

op when

aler or s

e

rly!

ting and

s

see abov

e

ing the fr

o

ndle(18).

ct on (Fig

off.

saw chai

n

ly as desc

r

d fingers

encircle

t

fully squ

e

oving yo

u

d

stop im

m

ngaged

p

the chai

n

rvice ce

n

s

topping

t

Fig. 16).

nt handl

e

.19).

(4) is not

ibed.

should en

he handl

e

eze in t

h

r left han

d

ediately.

osition.

brake is

e

tre! Do n

o

he produ

(1) do no

t

touching

circle the

(Fig. 18).

e on/off

forward

ngaged,

t use the

ct during

t

hold the

Page 19

18

OPERATION

General Operation

Check the product, its power cord and plug as well as accessories for damage before each

use. Do not use the product if it is damaged or shows wear.

Double check that accessories and the guide bar/saw chain are properly fixed.

Always hold the product by its handle. Keep the handle dry to ensure safe support.

Ensure that the air vents are always unobstructed and clear. Clean them if necessary with a

soft brush. Blocked air vents may lead to overhearing and damage the product.

Switch the product off immediately if you are disturbed while working by other people

entering the working area. Always let the product come to complete stop before putting it

down.

Do not overwork yourself. Take regular breaks to ensure you can concentrate on the work

and have full control over the product.

Basic Operating/Cutting Procedure

To become proficient attend a recognized chain saw training course to learn how to

operate chain saws safely and effectively. Familiarize yourself with all the controls and

switches. Practice all movements with the product switched off.

Always hold the products firmly with both hands. Hold the front grip with your left hand and

the rear grip with your right hand. Fully grip both handles at all times during operation. Never

operate the product using only one hand.

Ensure the power cord is located to the rear, away from the chain and the wood and is

positioned so that it cannot be caught on branches or similar objects during cutting.

Only use the product with a secure stance. Hold the product to the right-hand side of your

body (Fig. 20).

The Saw chain (4) must be running at full speed before it makes contact with the wood. Use

the spike bumper (21) to secure the product onto the wood before starting to cut and use it

as a leverage point while cutting (Fig. 21).

Reset the spike bumper at a low point when cutting thicker logs by pulling the product slightly

backwards until the gripping teeth release, and then reposition at lower level to continue

Page 20

19

OPERATION

Basic Operating/Cutting Procedure (continued)

sawing. Do not remove the product completely from the wood.

Do not force the saw chain while cutting. Let the chain do the work using the gripping teeth

to apply minimal leverage pressure.

Do not operate the product with your arms fully extended or attempt to saw areas which are

difficult to reach, or while on a ladder. Never use the product above shoulder height (Fig.

22).

Optimum sawing is achieved if the chain speed remains constant during cutting.

Be careful when reaching the end of the cut. The weight of the product may change

unexpectedly as it cuts free from the wood. This can cause accidents to the legs and feet.

Always remove the product from a wood cut while the product is running.

Kickback

WARNING! Beware of kickback! Kickback can lead to dangerous loss of control of the

product and result in serious or fatal injury to the operator or anyone standing close by!

Always be alert because rotational kickback and pinch kickback are major product

operational dangerous and the leading cause of most accidents!

Kickback may occur if the nose or the tip of the guide bar touches an object, or if wood

pinches the saw chain in the cut.

In some cases, contact with the tip of the guide bar(5) may cause a lightning-fast reverse

reaction, kicking the guide bar up and back toward the operator (Figs. 23, 24, 25).

Page 21

20

OPERATION

Kickback (continued)

Pinching of the saw chain (4) along the bottom of the guide bar (5) may pull the product

forward away from the operator (Fig. 26)

Pinching of the saw chain (4) along the top of the guide bar (5) may push the guide bar

rapidly back toward the operator (Fig.27).

Any of these reactions may cause a loss of control over the product, which could result in

serious personal injury or even death.

With a basic understanding of “kickback”, the element of surprise can be reduced or

eliminated. Sudden surprise contributes to the majority of accidents.

Keep a good firm grip on the product with both hands, your right hand on the rear handle (18)

and your left hand on the front handle (1), when the motor is running. Maintain a firm grip

with your thumbs and fingers encircling the handles. A firm grip will help you reduce

“kickback” and maintain control of the product.

You should read all the safety warnings and user instructions carefully before attempting to

operate this product.

To Avoid Kickback:

Saw with the guide bar at a flat angle.

Never work with a loose, widely stretched or heavily worn chain.

Page 22

21

OPERATION

Kickback (continued)

Ensure the chain is sharpened correctly.

Never saw above shoulder height.

Never work with the tip of the guide bar.

Always hold the product firmly with both hands.

Always use a low kickback chain.

Apply the metal gripping teeth for leverage.

Ensure correct chain tension.

Felling a Tree

When bucking and felling operations are being performed by two or more persons at the

same time, the felling operations should be separated from the bucking operation by a

distance of at least twice the height of the tree being felled. Trees should not be felled in a

manner that would endanger any person, strike any utility line or cause any property

damage. If the tree does make contact with any utility line, the company should be notified

immediately.

The product operator should keep on the uphill side of the terrain as the tree is likely to roll or

slide downhill after it is felled.

An escape path should be planned and cleared as necessary before cuts are started. The

escape path should extend back and diagonally to the rear of the expected line of fall (Fig.

28).

Before felling is started, consider the natural lean of the tree, the location of larger branches

and the wind direction to judge which way the tree will fall.

Remove dirt, stones, loose bark, nails, staples and wire from the tree.

Page 23

22

OPERATION

Felling a Tree (continued)

Notching Undercut

Make the notch (Fig. 19 B) 1/3 the diameter of the tree, perpendicular to the direction of falls

(Fig. 29). Make the lower horizontal notching cut first. This will help to avoid pinching either

the saw chain or the guide bar when the second notch is being made.

Felling Back Cut

Make the felling back cut(Fig. 29 A) at least 50mm higher than the horizontal notching cut.

Keep the felling back cut parallel to the horizontal notching cut. Make the felling back cut so

enough wood is left to act as a hinge. The hinge (Fig. 29 C) wood keeps the tree from twisting

and falling in the wrong direction. Do not cut through the hinge.

As the felling gets close to the hinge, the tree should begin to fall. If there is any chance that

the tree may not fall in desired direction or it may rock back and bind the saw chain, stop

cutting before the felling back cut is complete and use wedges of wood, plastic or

aluminium to open the cut and drop the tree along the desired line of fall.

Limbing and Pruning

When the tree begins to fall remove the product from the cut, stop the motor, put the

product down, then use the retreat path planned. Be alert for overhead limbs falling and

watch your footing.

Limbing is removing the branches from a fallen tree. When limbing leave larger lower limbs to

support the log off the ground. Remove the small limbs in one cut (Fig. 30). Branches under

tension should be cut from the bottom up to avoid binding the product.

Page 24

O

P

Li

m

C

u

A

s

ot

h

O

n

du

W

a

B

u

Bu

c

w

e

su

p

Fo

l

(Fi

gWh

(u

n

ERATI

O

bing a

n

WARNI

N

logs,

o

When

until y

o

the b

a

WARNI

N

perfor

m

tting Sp

r

pring pol

e

er wood

s

a fallen t

r

ring the b

u

tch out f

o

cking a

L

king is c

u

ight is e

v

ported b

y

low the si

m

. 31), it is

en the lo

derbuck)

N

d Prunin

G! Never

r in any p

o

pruning tr

e

u have c

u

rk from th

e

G! If the

the pru

n

ing Pol

e

is any l

o

o that it s

p

ee, a root

cking cu

t

r spring p

o

og

tting a lo

n

enly distri

b

the use

o

ple direc

cut from

t

g is supp

o

. Then ma

k

g (conti

n

climb into

sition whi

c

es, it is i

m

t off the l

main m

e

limbs to

b

ing!

s

g, branc

h

rings ba

c

ed stump

h

to separ

a

les, they

g into len

g

uted on

f limbs, lo

tions for e

a

he top (o

v

rted on t

h

e the fini

s

ued)

a tree to

l

h may c

a

portant n

o

imb furth

e

mber!

e prune

d

, rooted

s

k if the w

o

as a high

te the lo

g

are dang

e

ths. It is i

m

both fee

t

gs and ch

sy cuttin

g

erbuck).

e end (F

i

hed cut

b

23

imb or pr

u

use you t

o

t to mak

e

r out to re

are abo

v

tump, or

s

od holdi

n

potential

from the

rous.

portant t

o

. When

p

ocks.

. When th

g. 32), c

u

y overbu

c

ne! Do n

o

lose the

b

the flush

duce the

w

e chest

h

s

apling w

h

g it is cut

o

of springi

n

stump.

make su

r

ossible, t

h

e log is su

p

t 1/3 the

king to m

e

t stand o

n

alance o

r

cut next t

o

eight! Th

eight, hir

ich is be

n

r remov

e

g back to

e your fo

o

e log sh

o

ported al

diameter

et the fir

s

ladders,

p

control o

main lim

is prevent

s

e a profe

t under t

e

d.

the uprig

h

ting is fir

m

uld be r

a

ong its en

t

from the

u

t cut.

latforms,

f the saw!

p or trunk

stripping

ssional to

nsion by

t position

and your

ised and

ire length

nderside

Page 25

24

OPERATION

Bucking a Log (continued)

When the log is supported on both ends (Fig. 33), cut 1/3 the diameter from the top

(overbuck). Then make the finished cut by underbucking the lower 2/3 to meet the first out.

When bucking on a slope always stand on the uphill side of the log (Fig. 34). When “cutting

through”, to maintain complete control release the cutting pressure near the end of the cut

without relaxing your grip on the product handles. Don’t let the chain contact the ground.

After completing the cut, wait for the saw chain to stop before you move the product.

Always stop the motor before moving from the tree to tree.

Support small logs on a sawing stand or another log while bucking (Fig. 35).

If the diameter is large enough for you to insert a soft bucking wedge without touching the

chain, you should use the wedge to hold the cut open to prevent pinching (Fig. 36).

Page 26

25

OPERATION

Bucking a Log (continued)

After Use

Switch the product off, disconnect it from the power supply and let it cool down.

Check, clean and store the product as described below.

Page 27

C

L

Th

Ke

Re

Ins

fin

d

G

e

Cl

e

In

p

Re

N

O

to

C

h

au

Sp

r

N

O

Lu

bCle

Usi

an

M

a

th

e

EANIN

G

e Golde

n

WARNI

N

produ

c

ep the pr

o

gular and

pect the

p

broken

a

WARNI

N

All furt

neral C

l

an the p

r

articular

move stu

b

TE: Do no

t

clean this

eck for

w

thorized s

e

ocket Nos

e

TE: It is n

o

rication

c

an the s

p

ng a disp

o

d inject g

r

ke sure t

h

lubricati

o

AND

M

Rules f

o

G! Alway

s

t cool d

o

duct cle

a

proper cl

e

roduct b

e

nd worn

p

G! Only p

her works

eaning

oduct wit

h

clear the

a

born dirt

w

use che

m

product

a

orn or

d

rvice ce

n

o

t necess

a

an be do

rocket no

s

sable lub

e

ease until

at the ch

a

n proced

AINTEN

A

r Care

switch t

h

wn befor

e

n. Remov

e

aning wil

l

fore eac

h

arts.

erform re

p

must be p

a dry cl

o

ir vents(1

ith high

p

ical, alka

l

s they mi

g

amaged

tre for re

p

ry to re

m

ne on the

e(6).

gun, ins

e

it appear

s

in brake(

2

ure until t

h

NCE

e produc

t

performi

n

debris fr

o

help ens

u

use for

w

airs and

m

erformed

b

th. Use a

b

9) after e

v

ressure ai

ine, abras

ht be har

m

parts. Re

p

air befor

e

ove the

s

job.

rt the nos

e

on the o

u

) is deac

t

e sprock

e

26

off, disc

o

g inspect

m it afte

r

re safe us

orn and

d

aintenan

c

y a quali

f

rush for

a

ery use w

r (max. 3

b

ive or oth

e

ful to its

lace wo

using the

aw chai

n

of the n

e

tside ed

g

ivated. R

o

t(6) has b

nnect it f

r

ion, maint

e

each use

e and pro

amaged

p

e work a

c

f

ied speci

a

reas that

a

ith a cloth

ar).

r aggressi

surfaces.

rn parts

a

product

a

(4) to lu

b

edle into

t

e of the s

p

tate the s

een grea

s

om powe

r

nance a

n

and befo

long the li

f

arts. Do

n

cording t

list!

re hard t

o

and brus

h

ve deterg

e

s necess

a

gain.

ricate th

e

he lubric

a

rocket(6

)

aw chain

(

ed.

supply a

n

d cleani

n

re storag

e

e of the

p

ot opera

t

o these in

s

reach.

.

nts or disi

ry or c

o

sprocke

t

tion hole

(

(Fig. 37).

4) by han

d

d let the

g work!

.

roduct.

e it if you

tructions!

nfectants

ntact an

nose(6).

Fig. 37 A)

. Repeat

Page 28

27

CLEANING AND MAINTENANCE

Guide Bar and Saw Chain Maintenance

Most guide bar problems can be prevented merely by keeping the product well maintained.

Incorrect filling and non-standard cutter and depth gauges settings are the causes of most

guide bar problems, primarily resulting in uneven bar wear. As the bar wears unevenly, the

rails widen, which may cause the chain to clatter and make it difficult to complete straight

cuts. If the guide bar is insufficiently lubricated and the product is operated with a saw chain

which is too tight, this will contribute to rapid bar wear. To help minimize bar wear,

maintenance of the guide bar as well as the saw chain is recommended.

Disassemble the guide bar and saw chain in reversed order from assembly.

Check the oiling port (22) for clogging and clean if necessary to ensure proper lubrication of

the guide bar and saw chain during operation. Use a soft wire small enough to insert into the

oil discharge hole.

NOTE: The condition of the oil passages can be easily checked. If the passages are clear, the

chain will automatically give off a spray of oil within seconds of the product starting. Your

product is equipped with an automatic oiling system.

Check the drive sprocket (20). If it is worm or damaged due to strain, have it replaced by an

authorized service agent.

Clear residue from the rails on the guide bar (5) using a screwdriver, putty knife, wire brush or

other similar tool. This will keep the oil passages open to provide proper lubrication to the bar

(5) and chain(4) (Fig. 38).

Check the guide bar “rail” for wear: Hold a ruler (straight edge” against the side of the guide

bar and “cutter side plates”. If there is a gap between the ruler and guide bar the guide bar

“rail” is normal. If there is no gap (ruler flush against the side of the guide bar) the guide bar

“rail) is worn and needs to be replaced with a new one of the same type (Fig. 39).

Turn the guide bar 180eto allow even wear, thereby extending the life span of the guide

bar(5).

Check the saw chain for possible wear and damages. Replace it with a new one if required.

Experienced users can sharpen a dull saw chain (see section “Saw chain sharpening”

below).

Refit the saw chain (4) and the guide bar (5) as described under “Assembly”.

Page 29

C

L

S

a

N

O

int

oHa

ch

su

pThe

th

e

¾

¾

¾

¾

¾

To

¾

¾

¾

Us

e

fil

e

A

f

th

e

EANIN

G

w Chain

TE: Never

o

the tree

ve your c

ain yours

e

plied wit

h

WARNI

N

Use pr

o

height

d

saw cha

i

File angl

e

Cutting

a

File posit

i

Diamete

r

File dept

h

sharpen t

h

Use prot

e

Ensure th

Engage

t

a round

diamete

r

ile guide

i

file at th

e

AND

M

Sharpe

n

saw with

and the

c

hain (4) s

h

lf using

a

the shar

p

G! Only s

h

per tools

ifference

n (4) you

h

ngle

on

of round

e chain,

p

ctive glo

v

e chain is

he chain

b

file, whos

e

is above

t

s availabl

e

correct

p

AINTEN

A

ing

a blunt c

h

hips are v

arpened

proper

ening kit.

arpen th

e

to sharpe

between

t

ave to c

o

file

roceed

a

es.

correctly

t

rake to l

o

diamete

he cutter

’

from m

o

osition.

NCE

ain. The s

a

ery small.

professio

n

sharpeni

n

saw chai

n the saw

he tooth

a

nsider th

e

s follows:

ensioned

.

ck the ch

r is 1.1 tim

s top plat

st reputa

b

28

w chain

i

ally at a

u

g kit. Als

o

n yourself

i

chain!

nd ridge

followin

g

ain on th

e

es the cu

t

e.

le tool m

e

s blunt if

y

thorized s

observ

e

f you are

t

is the cut

t

points (Fi

g

bar.

ting tooth

rchants

a

ou have

t

ervice ce

n

the sha

r

rained an

t

ing dept

h

. 40).

depth. M

a

nd is the

e

o push th

e

tre or sh

a

pening i

n

d have ex

p

. When s

h

ke sure

2

e

asiest w

a

product

rpen the

structions

erience!

arpening

0% of the

y to hold

Page 30

29

CLEANING AND MAINTENANCE

Saw Chain Sharpening (continued)

File at an angle perpendicular to the bar, and at an angle of 25eto the direction of

travel(Fig.41).

File the each tooth from the inside towards outside only. File one side of the chain first than

turn the saw around and repeat the process.

Sharpen each tooth equally by using the same number of strokes.

Keep all cutter lengths equal. Check the safety depth gauge height every 5 sharpenings. If

the depth gauges are also trimmed it is essential that the original profile is restored.

Use a dept gauge measuring instrument to check the height of the depth gauge. Depth

gauge measuring jigs are available from most reputable tool merchants (Fig. 42).

Chain and Bar Replacement

Assemble the guide bar and saw chain before operation. Follow the operating instructions

step-by-step and use the pictures provided as a visual guide to easily assemble the product.

Warning! Read all the instructions carefully! Do not connect the product to the power supply

until it is completely assembled! Always wear gloves during assembly!

Use only the guide bar (5) and saw chain (4) according to the technical data of the product.

Place the product on a suitable flat surface with the cover (10) facing upwards.

Remove the cap (9), loosen the retaining nut (9) anticlockwise with Knob (8) and remove the

cover (10) (Fig.1)

Spread the saw chain (4) out with the cutting edges of the chain pointing in the rotational

direction and side the chain into the groove around the guide bar. (Fig.2)

Page 31

C

L

C

h

Ali

gLay

b

o

EANIN

G

ain and

WAR

N

mee

t

have

prof

e

elimi

n

com

p

conj

u

n the gui

the saw

c

lt. (Fig. 5,

6

AND

M

Bar Rep

l

ING! Alwa

y

s the low-

k

the kick

b

ssional o

p

ated kic

k

lete prot

e

nction wi

t

de bar (5)

hain aro

u

)

AINTEN

A

acemen

y

s use a s

a

ickback r

e

ack redu

c

erator! N

e

back! A l

o

ction ag

a

h other ki

c

and saw

c

nd the dr

i

F

NCE

t (contin

u

w chain

d

quireme

n

ing guar

d

vertheles

s

w-kickba

c

inst injury!

kback pr

o

hain (4)

a

ve sprock

e