Page 1

The Challenge Machinery Company provides owner's manuals on its

products s olely as a court esy to i ts cust omers. Se e the inf ormati on belo w

before using this manual.

These manuals are for reference only. These manuals include products which are noncurrent,

unsupported or no longer pr oduced by The Chal l enge M achi nery Com pany , and are pr ov ided sol el y as

an accommodat i on to our c ustom ers. By prov i ding these m anuals, T he Ch al lenge M achi nery Com pany

makes no representation or warranty as to the products, their current condition, or their suitability or

fitness for use in any particular application, which are the sole and i ndependent responsibility of the

product owner and user.

Older produ cts may not co mply with curren t safety pro cedures, guidel ines or regu lat ions, and i t

is the product owner's and user's responsibility to evaluate the suitability and fitness of the

products in their current use and application. The Challenge Machinery Company makes no

representation, warranty or recommendation regarding any modifications which may be

required on non -current o r u nsuppo rted prod ucts. T he Ch allenge Mach inery Co mpan y assumes

no liability for any modification or alteration to any Challenge product, and any such

modification or alteration to any Challenge product is not authorized by The Challenge

Machinery Comp any. The av ailabilit y of t hese manuals is sol el y for t he purpose of provi ding ref erence

information for the products.

This manual may not be complete in all aspects of product maintenance and repair. All products

should be used only by qualified and properly trained personnel, following proper safety

procedures. Al l product s should be regular l y i nspected and m aintai ned, and their condition, appli cation

and use should be periodically evaluated by qualified personnel. Only qualified and properly trained

technicians should perform maintenance, repair and replacement procedures. Attempting these

procedures without pr oper training may cause machine dam age or operat or injury!

Products may be unsup por ted by The Chall enge M ac hinery Company due to age or the unavailability of

parts from their ori ginal m anufactur er. No parts or produc t support will be available to repair or maintain

unsupported prod uc ts. Older products may not be UL listed (if the product does not have a UL l abel it i s

not a listed product), and may not comply with applicable installation or other regulations or

requirement s if rel ocated to a new f acilit y. Many munici palities requi re a product t o be UL l isted bef ore

an electrician will connect power to them. Often the cost of updating an older pro duct to compl y with

current saf ety r egulations is greater than the v alue of t he product .

The Challeng e Machin ery Comp any

6125 Norton Center Drive

Norton Shores, MI 49441-6081 USA

ChallengeMachinery.com

F.265XT-EO

TITAN 265 XT

Operator’s Manual

Serial Numbers 071755 & Up

Sold and Serviced by

January 2014

Page 2

1.0 Introduction

1.0 Introductio n

THIS MANUAL is designed to help you get the most from your Challenge equi pment. Keep this

manual in a safe, conv enient place for quick reference by operators and service personnel.

SAFETY ALERT! This symbol means CAUTION: P erson al saf et y

instructions! Pay special attention to the instructions in bol d ty pe. Personal injury may result if the

precautions are not r ead and followed.

READ THIS MANUAL BEFORE OPERATING! Follow precautions and instr uc tions given and you

should have years of trouble-free operation. If after reading the manual questions sti ll remain, contact

your Authorized Challenge Dealer.

FOR PARTS AND SERVICE contact the Authorized Challenge Deal er fr om whom you pur c hased

your machine. Use the illustrations and parts lists at the bac k of this manual to identify the correct

parts needed. Always give the SERIAL NUMBER and MODEL of your machine to insure t he correct

parts are sent as soon as possible.

Take a few minutes right now to RECO RD YOUR MACHINE S E RIAL NUMBER in the space

provided on the front cover of this manual. Also be sure to fill out the warranty card accompanying

your machine and r eturn it DIRE CTLY TO CHALLENG E.

If you bought a used machine, it is important to have the following information on record at Chall enge.

Copy this page, fill in the information and send it care of The Challenge Serv ice Department, Norton

Center Drive • Norton S hor es • MI 49441-6081.

CHALLENGE MODEL SERIAL NUMBER

ATTN COMPANY

ADDRESS

CITY STATE/PROVINCE ZIP

PHONE DATE INSTALLED

DEALER NAME & CITY

* WARRANTY INFORMATION *

It is very important that y ou r ead and under st and the conditions outli ned in the Warr anty Information

Sheet att ached to the outside of the shipping cont ainer of your machine.

The Warr anty Inf or m ation Sheet must be filled out completely and returned to THE CHALLENGE

MACHINERY COMPANY in order for the warranty to be issued for this machine.

Challenge® is a registered trademark of The Challenge Machinery Company• 6125 Norton Center Drive • Norton Shores, MI

49441-6081

Copyright© 2007-2013 by The Challenge Machinery Company. All rights reserved. Printed in the U.S.A

2

Page 3

1.0 Introduction

TABLE OF CONTENTS

1.0 Introduc tion................................................................................................................................. 2

2.0 Safety .........................................................................................................................................5

2.1 Precautions............................................................................................................................. 5

2.2 Power Lockout Proc edur e .......................................................................................................5

2.3 Warning Label Definitions........................................................................................................6

3.0 Packing List.................................................................................................................................8

Optional Items .............................................................................................................................. 8

4.0 Specifications.............................................................................................................................. 9

5.0 Installation & Setup ...................................................................................................................10

5.1 Inspecting Shipment.............................................................................................................. 10

5.2 Uncrating.............................................................................................................................. 10

5.3 Cleaning ............................................................................................................................... 11

5.4 Fitti ng Through Nar r ow Door .................................................................................................11

5.4.1 Removing the Extension Tables ..................................................................................... 11

5.4.2 Removing the Table....................................................................................................... 12

5.4.3 Removing the Electric Eyes............................................................................................14

5.4.4 Removing the Footswitch............................................................................................... 14

5.4.5 Atta ching the Ta b le........................................................................................................14

5.4.6 Attaching the Extension Tables...................................................................................... 14

5.4.7 Attaching the Electric Eyes............................................................................................. 15

5.4.8 Atta ching the Fo o tswitch................................................................................................ 15

5.5 Hydraulic System Check....................................................................................................... 15

5.6 Optional Fal se Cl am p Pl ate................................................................................................... 16

5.7 Power Hook-Up (208/230 50/ 60Hz )......................................................................................17

5.7.1 Single Phase Hook-Up................................................................................................... 18

5.7.2 Three Phase Hook-Up ................................................................................................... 18

5.8 Power Hook-Up (380/400/ 415V 50Hz ) – also appl ies for (460V 60Hz).................................. 19

5.8.1 Three Phase Hook-Up ................................................................................................... 20

5.9 Line Light .............................................................................................................................. 21

6.0 Operation .................................................................................................................................. 23

6.1 Main Power and Start Up ...................................................................................................... 23

6.2 Making a Cut.........................................................................................................................23

6.3 Air Tab le Option....................................................................................................................24

6.4 Jogging Aid........................................................................................................................... 24

6.5 Adjusting the Clamp Pressure...............................................................................................24

6.6 Pre-Clamping........................................................................................................................24

6.7 Electric Eyes......................................................................................................................... 25

6.8 False Clamp Plate.................................................................................................................25

6.9 Sleep Mode........................................................................................................................... 25

6.10 Display Panel......................................................................................................................25

6.11 Definition of Keys................................................................................................................25

6.11.1 Touch Screen .............................................................................................................. 25

6.11.2 Backgauge Glide Control ............................................................................................. 26

6.11.3 IN/MM Key...................................................................................................................26

6.11.4 A ir Ta b le ON / OFF Key................................................................................................. 26

6.11.5 CANCEL Key...............................................................................................................26

6.11.6 SEND Key................................................................................................................... 26

6.11.7 Push-Out Key .............................................................................................................. 26

6.11.8 CLEAR Key..................................................................................................................27

6.11.9 ENTER Key ................................................................................................................. 27

6.11.10 Priority Add (X/Y) Key................................................................................................ 27

6.11.11 Arrow Keys................................................................................................................ 27

6.11.12 PAGE Keys................................................................................................................ 27

3

Page 4

1.0 Introduction

6.12 Interface..............................................................................................................................28

6.12.1 Icons.............................................................................................................................28

6.12.2 Main Window................................................................................................................29

6.12.3 Job Statistics................................................................................................................30

6.13 Jobs.....................................................................................................................................31

6.13.1 Programming a Job.......................................................................................................31

6.13.2 Openi ng a Prev iousl y S av ed J ob ..................................................................................33

6.13.3 Editing an O pen Job.....................................................................................................33

6.13.4 Savi ng an Open J ob .....................................................................................................34

6.13.5 Delete a Previously Saved Job......................................................................................34

6.13.6 Copy a Job To/From a USB Storage Dev ic e..................................................................34

6.13.7 Locking/Unlocking a Job...............................................................................................34

6.14 Safety Systems....................................................................................................................34

6.14.1 False Clamp Plate........................................................................................................34

6.14.2 Safety Eyes..................................................................................................................34

6.15 Maintenance........................................................................................................................35

6.15.1 Maintenanc e.................................................................................................................35

6.16 Upgrade...............................................................................................................................38

6.16.1 Calculator.....................................................................................................................39

6.17 Diagnostic............................................................................................................................39

6.17.1 Sensor Data..................................................................................................................39

6.17.2 Last Error Code............................................................................................................40

7.0 Knife Installation/Changing.........................................................................................................41

7.1 Knife Removal.......................................................................................................................41

7.2 Knife Installation....................................................................................................................43

7.3 Knife Care Tips......................................................................................................................44

7.3.1 Knife Blade Life ..............................................................................................................44

7.3.2 Cutting Stick...................................................................................................................45

7.3.3 Bevel Angle....................................................................................................................45

7.3.4 Helpf ul Suggestions........................................................................................................45

7.3.5 Knife Care......................................................................................................................45

8.0 Oil and Grease ...........................................................................................................................48

9.0 Safety Systems Test..................................................................................................................50

4

Page 5

2.0 Safety

2.0 Safety

2.1 Precautions

• This machine i s designed f or one- per son operation. Never operate the machine with more than

one person.

• Safe use of this machi ne is the r esponsibility of the operator . Use good judgment and common

sense when working with and around this machine.

• Read and understand all instructions thoroughl y before using the machine. If questions remain,

contact the deal er from whic h y ou purchased this machine. Failure to under stand the operating

instructions may result in personal injury.

• Only trained and aut hor iz ed people should operate this machine.

• Do not alter saf ety guar ds or devic es. They are for your protection. Severe personal injury may

result.

• Disconnect power bef or e cl eaning or performing mai ntenance. See S ection 2.2 Power Lockout

Procedure.

• Observe all cauti on labels on this machine.

• Be sure the cutter i s properly grounded.

• Be sure there is sufficient power to operate the cutter properly.

• Observe all cauti on plates mounted on this cutter.

• Keep foreign objec ts off table and away from cutter blade.

• BE EXTREMELY CAREFUL when handling and changing the cutter knife. Severe lacerations or

dismemberm ent could result from careless handling pr oc edur es.

• Keep the floor around the cutter free of trim, debris, oil and grease.

• When replacing hy dr aulic parts, loosen the connections slowly to release pressure. Never loosen

connections with the machine running.

• If the cutter sounds or operates unusually, turn i t off and consult the troubleshooting section of

this manual. If the problem cannot be corrected, have it chec k ed by a qualif ied service person.

• CRUSH HAZARD, keep hand and fingers from under the clamp when clamping paper . Use

Jogging Aid to load paper , and use the backgauge to push paper out before unloading. DO NOT

REACH UNDER THE KNIFE AND CLAMP AREA!

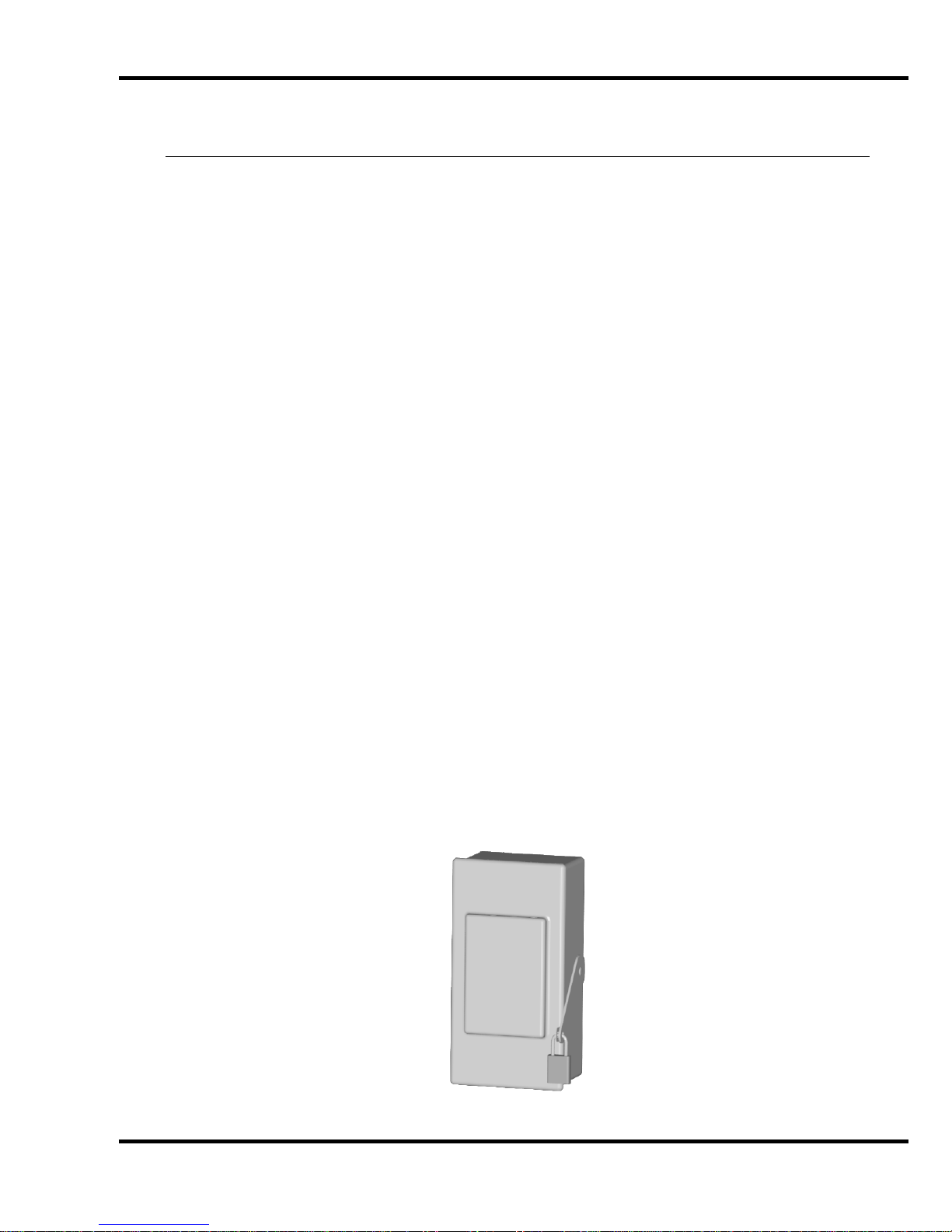

2.2 Power Lockout Procedure

For maximum safety when m aki ng adjustments or repairs to your machine, be sure to lock out the

main power control switch to which the machine is connected. The switch should be moved to the

OFF position and a padlock placed in the loop. The key should be held by the person serv icing the

machine.

Figure 1

5

Page 6

2.0 Safety

2.3 Warning Label Definitions

The following warni ng labels are found at various loc ations on your machine. Read and understand

the meaning of each symbol. If a label is lost from the machine, it should be replaced.

HAZARDOUS AREA

Disconnect power bef or e cl eaning, servicing, or m aki ng adjustm ents not requiring

power. Do not alter saf ety guar ds or devices; they are for your prot ection. Replace

all guards. Do not operate with any guards removed.

SHOCK HAZARD

Disconnect power bef or e r em ov ing cover. Replace cover before operation.

SHOCK HAZARD

Disconnect power bef or e r em ov ing cover. Replace cover before operation.

SINGLE OPERATOR

Do not operate with m or e than one person.

6

Page 7

2.0 Safety

!OJO!

This Este simbolo de alerta de seguridad significa ¡ OJO ! INSTRUCCIONES DE SEGURIDADPERSONAL. Lea las i nstrucciones po rque se refieren a su

seguridad personal. Fall de obedecer las instrucciones que siguen podria resultar en lesiones

corporales.

• Esta maquina, junto con sus mecanismos de seguridad, esta disenada para ser manejada por

• UNA SOLA PERSONA a la vez. Jamas debe ser manejada por mas de una persona al mismo

• tiempo.

• La seguridad es la responsabilidad del operario que usa esta maquina.

• LEA DETENIDAMENTE el manual de instrucciones y las PRECAUCIONES DE SEGURIDAD

antes de poner a funcionar la c or tadora. Pidale a su supervisor una copia.

• El manejo de la guill otina debe estar exclusivamente a cargo de per sonal entrenado y autoriz ado

para ello.

• NO MODIFIQUE LOS MECANISMOS DE SEGURI DAD, estan ahi para su proteccion no deben

ni modificar se ni quitarse.

• DESCONECTE LA CORRIENTE ELECTRICA antes de proceder a hacerle servicio de limpieza,

engrasar, o de hacer adjustes que no requieren corrient e. Trabe el interruptor en la posicion

OFF (apagado); vea “Procedimiento para cortar la corriente elect ri c a” al pi e de esta pagi na.

• Eche llave a la guillotina y quite la llave cuando la maquina no esta en operacion; vea “Corriente

electrica”.

• Asegurese de que la guillotina este debidament e a tierra. V ea “Conexion de la fuerza electrica”.

• Verifique el v oltaje y asegurese de que este sea suficient e par a el debido funcionamiento de la

guillotina.

• Preste atenci on a todas las pl ac as con advertencias instaladas en esta guillotina.

• No permita que objetos estranos esten en la mesa o cerca de la cuchilla cort ador a.

• TENGA SUMO CUIDADO al tocar y cambiar la cuchilla. Heridas severas y hasta

desmembrami ento pueden resultar del manejo sin cui dado o negligente.

• El suelo alrededor de la guillotina debe mantenerse despejado y libre de recortes, desperdi c ios,

aceite y grasa.

• Al haber la necesidad de r eem plazar partes hidraulic as, afloje todas las conexiones poco a poco

para dejar escapar l a pr esi on. Jamas debe aflojarse conexiones mientras la maquina este

• andando.

• Si la guillotina empezara a sonar o trabajar difer entemente a lo acostumbrado, desconectela y

consulte la seccion “Troubleshooting” ( Reparador) de este manual. Si no es posible corregir el

problema, llam e a su servi ci o autorizado para que le examinen la maquina.

• PELIGRO DE MACHUQUE - Mantenga manos y dedos f uer a de la agar r ader a mi entras sujeta el

papel. Use el calibr ador trasero y su rueda de mano para empujar el papel cortado. NO PONGA

SUS MANOS BAJOLA CUCHILLA O AREA DE LA AGARRADERA.

• NO OPERE SIN LAS GUARDAS PROTECTORAS!

¡ OJO ! PRECAUCION - Como proceder para desco nect ar

la corriente electrica.

Para maxima seguridad durante ajustes y reparaciones de su maquina, verifique bien que el interruptor principal

de control de corriente al cual la maquina esta conectada, este desconectado. El interruptor deba ser puesto en

la posicion “OFF” (desconectado) y se debe poner un candado en la anilla. La llave del candado debe ser

guardada por la persona que estara efectuando los trabajos de servicio o de reparacion en la guillotina.

Desconecte la corriente electrica antes de proceder a hacer cualquier ajuste o reparacion o de efectuar el

engrase en cualquier maquina.

7

Page 8

3.0 Packing List

3.0 Packing List

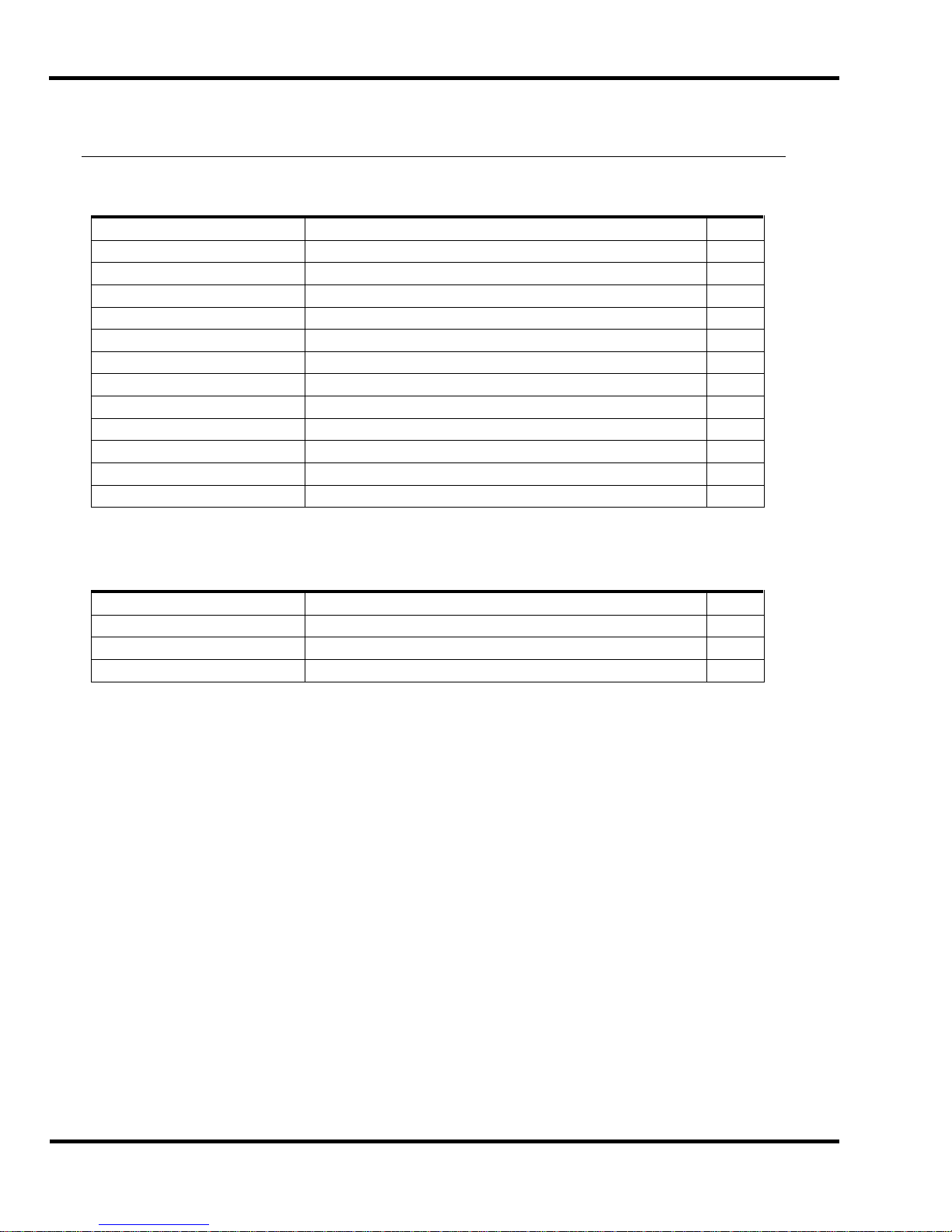

Part No. Description Qty.

2263-2 Knife 2

4165 Cutting Stick (in addition to one installed in machine) 3

F.265XT-EO Operator’s Manual 1

A-12608-4 Jogging Aid 1

20-2150-4 Tool Kit 1

H-6918-608 Knife Bolts, 3/8 – 16 x 1” 6

8815 Knife Washers, Special 6

5064 Cutting Stick Puller 1

44183 Knife Lifter Assembly 1

W-141 1/8” Allen Wrench 1

W-137 5/32” Allen Wrench 1

W-164 5/16” Hex ‘T’ Wrench 1

W-158 3/8 x 5/16” Wrench 1

Optional Items

Part No. Description Qty.

44027 False Clamp Plate

4165 Cutting Stick

2263-3 High Speed Steel Knife

41058 Waste Wagon

8

Page 9

4.0 Specification s

4.0 Specificati ons

Description Inch Units Metric Units

Cutting Width 26 ½” 67.3 cm

Minimum Cut* 5/8” 16 mm

Clamp Opening 4” 10.2 cm

Table Space

Front:

Back:

Dimensions

Table Height 36” 91 cm

Overall Height 59” 150 cm

Overall Length** 69 ½” 176.5 cm

Overall Width 54” 137.2 cm

Approx. Net Weight 1780 lbs 807 kg

Approx. Shipping Weight 2020 lbs 916 kg

Floor Loading 22 PSI 14.9 kPa

Electrical

208/230 Volts, 25 Amps, 3 Phase, 60 Hz, AC. Service size 30 Amps

Optional:

208/230 Volts, 30 Amps, 1 Phase, 60 Hz, AC. Service size 40 Amps

208/230 Volts, 30 Amps, 1 Phase, 50 Hz, AC. Service size 40 Amps

380/415 Volts, 15 Amps, 3 Phase, 50 Hz, AC. Service size 20 Amps

Sound Emission

A-weighted sound pressure level measured in an enclosed room at operator level

(6 feet/183 cm):

Machine in idle state: 60 dB

Machine cycling without cutting paper: 70 dB

*With false cl am p plate attached, minimum cut is 1-7/8” (48 mm).

**With table, elec tric eyes, and footswitch remov ed, can be fit through a 32” (81.3 cm) door

opening.

Challenge reserves the right to make changes to any product or specif ication without notic e and

without inc ur ri ng r esponsibility to existing units.

24 ¼”

28”

62 cm

71 cm

9

Page 10

5.0 Installati on & Setup

5.0 Installation & Setup

5.1 Inspecting Shipm ent

This machine has been carefully packed to prevent damage during shipment. However, claim s f or

damage or loss are the responsibility of the recipient. Inspect all shipment s as soon as they are

received. If there is any noticeable damage, note it on the fr eight bill. Visual and/or hidden damage

must be report ed to the claims department of the carrier within 15 days. Contact your dealer if you

need any assistance. Check the contents of the box against the packing list on page 8. Make sure

there are no missing items.

5.2 Uncrating

The Titan 265 weighs approximately 1780 lbs (807kg). DO NOT risk personal injury or damage by

attempting to move machinery with makeshift equipment or inadequate manpower. Thi s mac hine is

shipped on a wooden skid and enclosed in a protective, corrugated top. The machine is secured in

place with (4) l ag screws. All ac c essories are pac k ed in a separat e box.

Remove the cart on by remov ing the nails or staples holding it to t he skid and lift it straight up over the

cutter. If you don’t have the ceiling clearance to do this, c ar efully slit the carton down the side and

then unwrap it fr om around t he c utt er . Remov e the accessory box. Remove the lag screws that

secure the machine to the skid. Cut shipping straps on the hydraulic reservoir and remove wood

spacer from under r eservoir.

The machine may then be remov ed from the ski d. A fork-lift may be used if the forks will extend to

the back of the machine base. Raise the m ac hine enough to create a small clearance bet ween the

skid and machine. Make sure the f or k s engage t he fork pockets found beneath the base. Remov e

the skid.

DO NOT place hands under machine at any time during skid removal.

Place the machine on t he gr ound and r eadjust placement of the forks for saf e transport to its

destination.

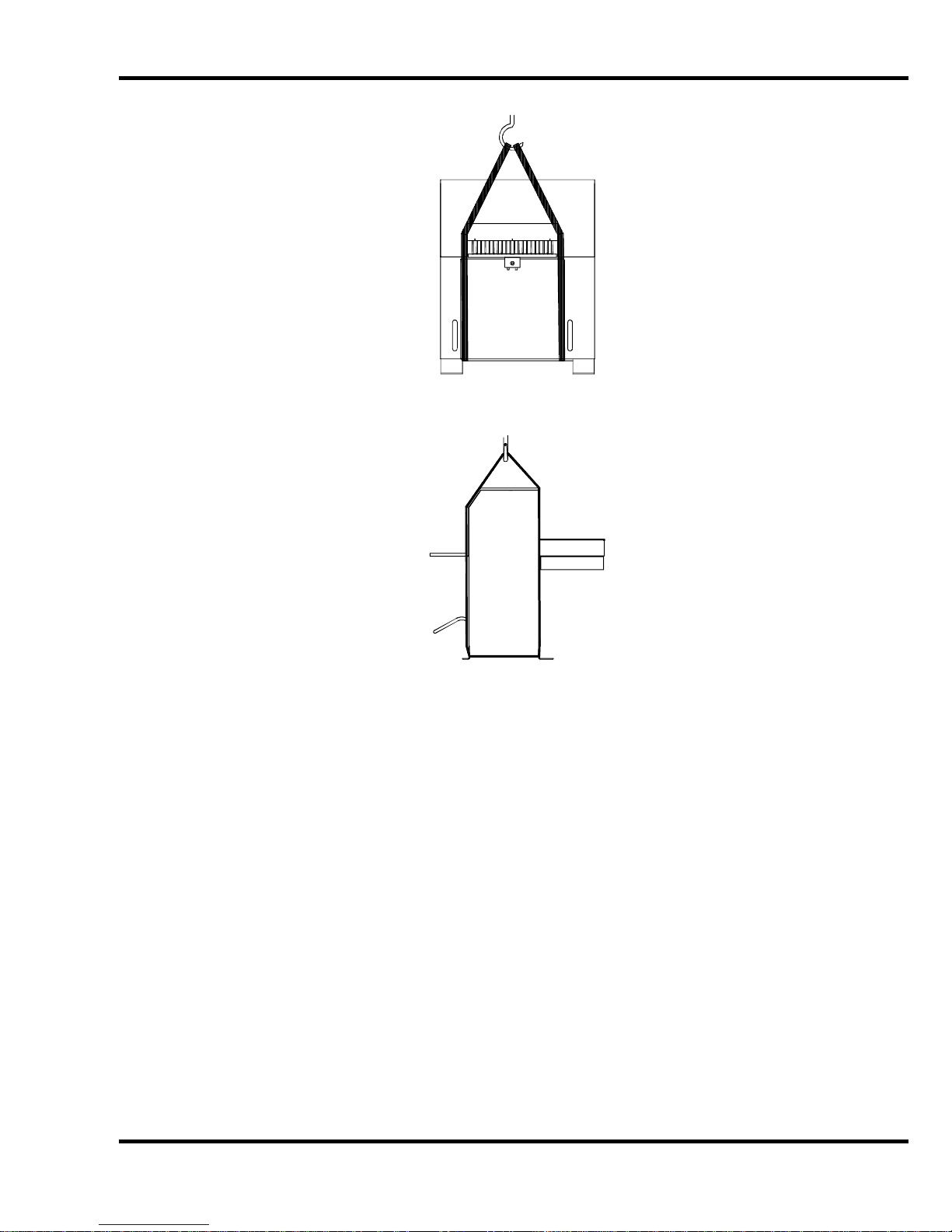

Alternately, the following method may be used to lif t t he machine from the skid. Remove the table

extensions (page 11) and the lower front cover. Using lifting straps rated at 2000 lbs. or more, wrap

the straps around the m ac hine base from front to back on each side of the tabl e as shown in Fi gure 2

& Figure 3. Hoist the machine and r em ov e its skid.

IMPORTANT! Do not lift the machine by any portion of the table. The aluminum table may pull

from the base and strip it s moun ting threads. Injury may result.

10

Page 11

5.0 Installati on & Setup

Figure 2

Figure 3

5.3 Cleaning

After unpacki ng, wipe down all machine panels and clean the table surface. The touch screen and

control console should be c leaned using a mild water-based soap solution. DO NOT use petroleum

or oil based solvents as they wi ll damage the touch screen and control console.

5.4 Fitting Throu gh N ar ro w Door

As shipped, the Tit an 265 c utt er will not fit through an opening less than 57” (137 cm). With the

extension tables removed, it will fit through a 46-1/2” (118 cm) opening. With the table and electric

eyes removed, it will fit through a 32” (81.3 cm) opening.

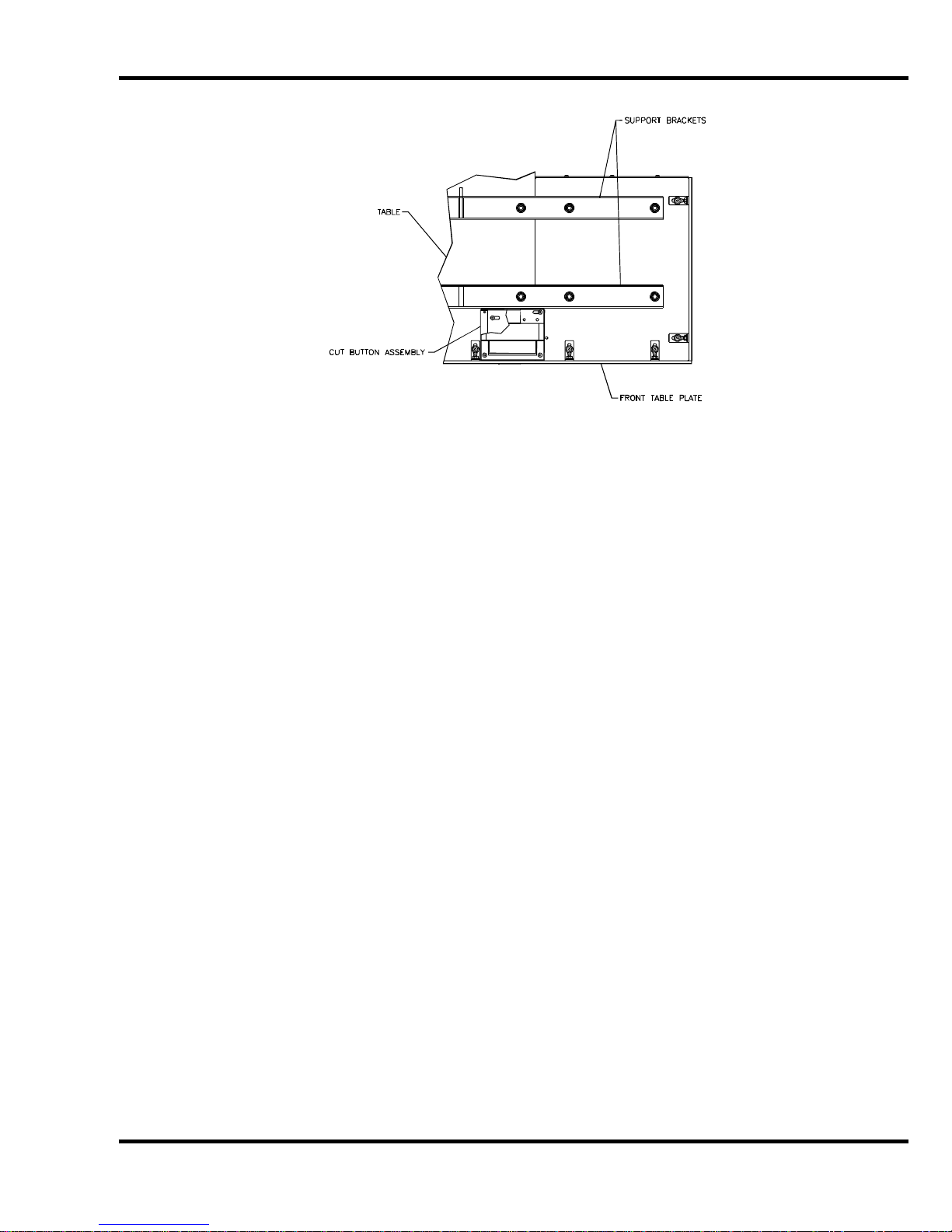

5.4.1 Removing the Extension Tables

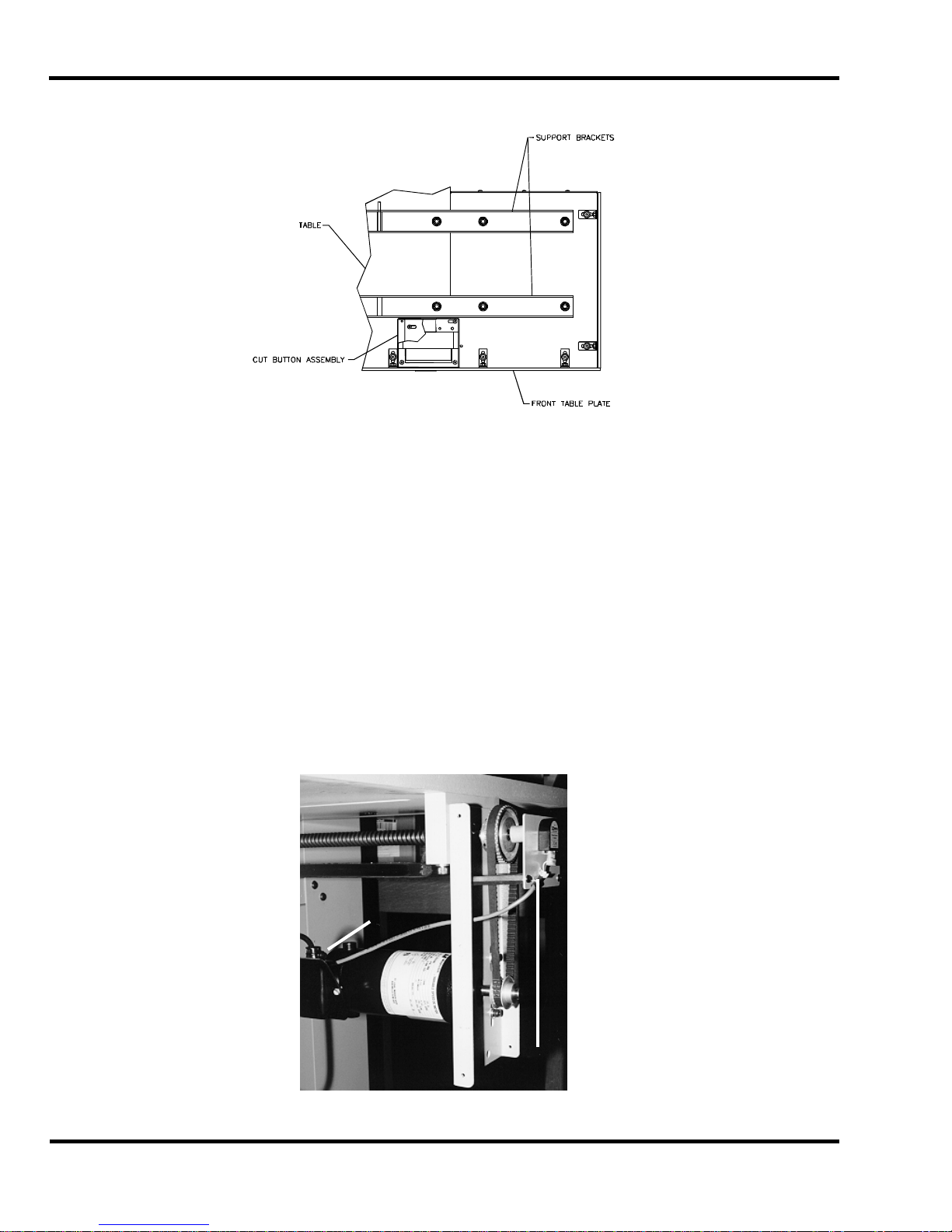

Make sure power is disconnect ed from the machine. Remove the f r ont t able plate (Figure 4) by

removing the hex nut s. Rem ov e the extension table hardware and remov e extensi on tables.

NOTE: There may be shims locat ed between the extension tables and the ext ensi on table brackets.

These are used for l ev eling the extension tables at the factor y . Take not e as to where they are

located so they c an be plac ed in the proper posi tion when reattaching the extension tables later.

11

Page 12

5.0 Installati on & Setup

g

Now remove the two extensi on table support brackets (Figure 4).

View from underneat h table

Figure 4

5.4.2 Removing the Table

Make sure the knife has been removed from the machine and that the knif e and clamp ar e in the “up”

position. If they are not , read the Power Hookup Section (page 17) to connec t power to the machine.

Turn on the power using the red and y ellow main power switch, and press the CLEAR butt on. This

will preset the back gauge and send the k nife and clamp up.

Turn off the machi ne and disconnect the power.

Make sure the extension tables have been removed (page 11). Remov e the 2-hand button controls.

Remove the sheet metal c ov er s fr om the r ear of the t able. Remove the backgauge motor cover, the

lower back panel, and the lower front cover of the machine.

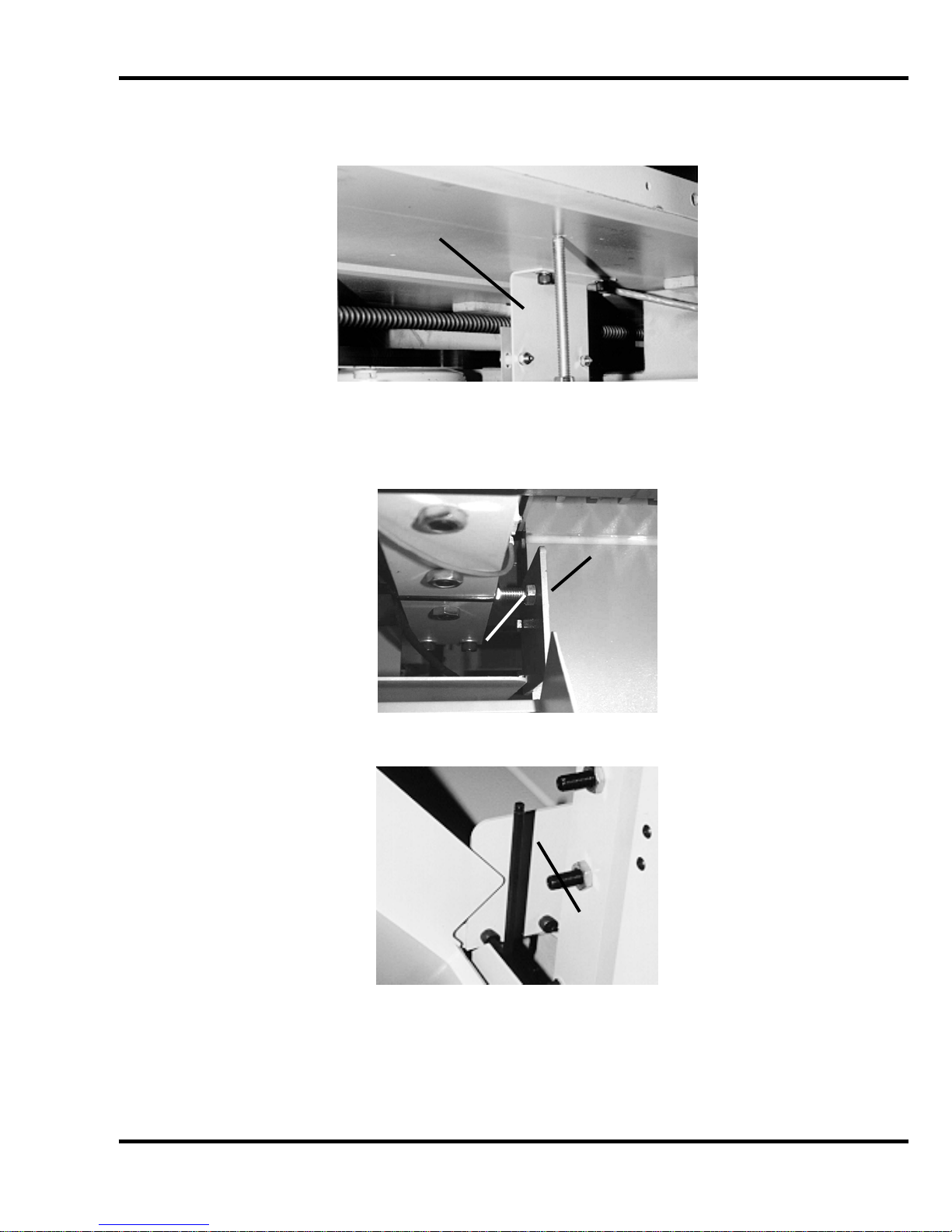

Unplug the cabl e to the encoder at t he bac k of the machine (Figure 5). Remove the motor juncti on

box cover and disconnect the wires to the motor (Figure 5). Rem ov e the leadscrew cover and the

nylon tyraps that ar e att ac hed to the bottom of the table. The motor wires and encoder wires shoul d

now be free from the tabl e.

12

Motor

Junction

Box

Figure 5

Encoder

Plu

Page 13

5.0 Installati on & Setup

Remove the preset board assembly from the bottom of table (Figur e 6) .

Preset Board

Assembly

Figure 6

Open the top hood and loosen the jam nut on left hand side guide support screw and turn it in a few

turns for clearance, then remove the left and right si de guides as shown in Figure 7 & Figure 8.

Left Side

Guide

Side Guide

Support Screw

Figure 7

Right Side

Guide

Figure 8

Remove the two taper pins from the bottom side of the table by tightening the jam nut on the taper

pin. Then remove the f our screws that mount the table to the base. CAUTION: the table assembl y

is very heavy and requi res at least four people to remove. Pull the table out towards the back of

the machine.

13

Page 14

5.0 Installati on & Setup

5.4.3 Removing the Electric Eyes

Make sure power is disconnect ed from the machine. Open top cov er. Remove the four hex -head

screws for each el ectri c ey e assem bly from the inside of the machine. By slidi ng some of the sl ac k in

the cable through t he si de of t he m ac hine, t he ey e assem blies can be set on the machine. If it is

necessary to completely remove the eyes from the machine, the wires must be disconnected from t he

power panel.

5.4.4 Removing the Footswitch

Make sure power is disconnect ed from the machine. Remove lower fr ont cover. Remove the two

screws that mount the f ootswitch bracket (Figure 9). Lay footswitch assembly inside t he m ac hine.

Mounting

Screws

Figure 9

5.4.5 Attaching the Table

Set the table in posi tion, and start its front two mounting screws. Then start the rear two mounti ng

screws. Replace the t wo taper pins (must be snug to seat the table), and then tighten all four screws.

Attach the right and left si de guides then re-adjust the left hand side guide support screw until it

contacts the side guide and tighten the jam nut. (Figure 7 & Figure 8 on page 13), the preset board

assembly (Figur e 6 on page 13) , t he m otor and enc oder wir e ( Figure 5 on page 12) and all guards

and panels.

Once the table is instal led, the backgauge squareness and accur ac y m ust be r eadjusted. See the

Titan 265 Technic al S ervice and Parts manual for information on how to do this.

5.4.6 Attaching the Extension Tables

Attach the ext ensi on table support brackets to the under side of the main table as shown in Figure 10,

but do not tight en screws completely. Route each cut button wire thr ough the slots in the brackets

while attachi ng them. Next, place any shims that were instal led at the factory in the positi on they

were in when the extension tables were removed. Lay the table extensions in place and insert the

screws. Align the front edges of the tables and tighten screws. Attach the front table plate.

14

Page 15

5.0 Installati on & Setup

Figure 10

5.4.7 Attaching the Electric Eyes

Make sure power is disconnect ed from the machine. If necessary, connect the wires to the power

panel. Attac h electri c ey e assemblies with provided hardware, m aki ng sure that the bottom of the

electric ey e housings are paral lel to the table. Once power is hooked up, the electric eyes should be

checked for alignment. See the Titan 265 Technical Servic e and P arts manual for information on how

to do this.

5.4.8 Attaching the Footswitch

Make sure power is disconnect ed from the machine. Attach the foot switc h br acket using the

mounting hardware (F igure 9, page 14).

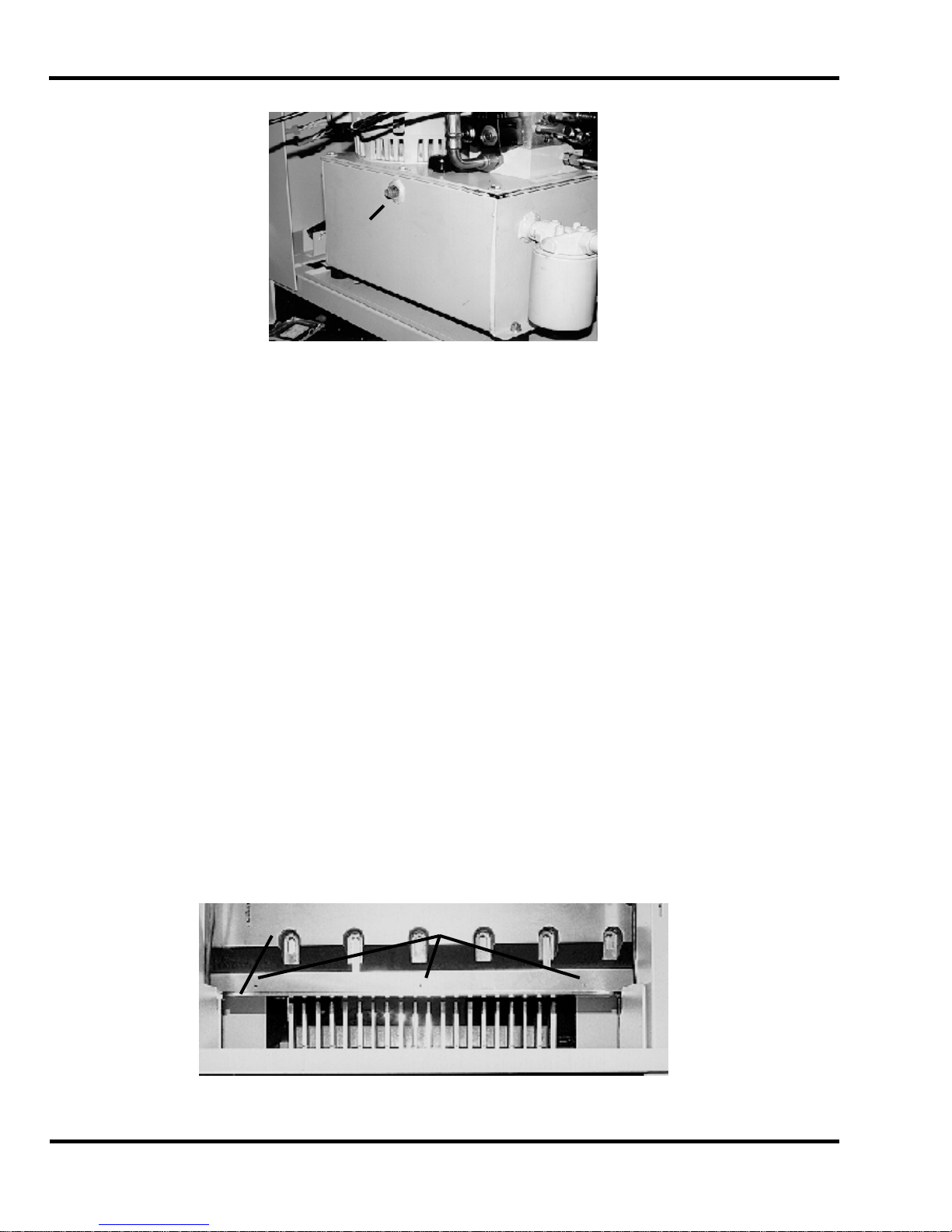

5.5 Hydraulic System Check

The Titan 265 is powered by a hydraul ic system consisting of an electric m otor c oupled directly to a

hydraulic pump.

The hydraulic r eservoir holds 5 gallons of hydraulic fluid. It is filled with Tellus #46 hydraul ic fluid at

the factor y but shoul d be c hec k ed before operation. Remove the lower rear panel c ov er. Check the

sight gauge on the rear si de of t he hy dr aulic tank. Fluid should just be vi si ble in the si ght gauge

(Figure 11, next page). Add fluid if necessary, but avoid overfilling. For more inform ation about

checking and changing the hydraulic fluid, including a cross-referenc e c har t of appr ov ed fluids, See

the Titan 265 Technical Service and Parts manual. When finished, replace the panel.

15

Page 16

5.0 Installati on & Setup

Sight

Gauge

Figure 11

The hydraulic fluid should be checked weekly and changed AT LEAST ONCE-PER-YEAR or after

every 1,000 hours of operation.

5.6 Optional Fals e Cl am p Plat e

To prevent marking on pressure sensitive jobs, a false clamp plate is availabl e as an optional item for

your machine. Thi s pl ate attac hes to the bottom of the clamp. It is secured with (3) setscrews

located in holes on the lower front face of the clamp.

To insta ll :

1. Make sure t he k nife and clamp are in the up position. If they are not , t ur n on the power using

the red and yellow mai n power swit c h. Press the CLEAR button. This will preset the

backgauge and send the knife and clamp up.

2. REMO V E KNIF E. See Section 7.1 Knife Removal, page 41.

3. Turn the power off and disconnect the power cord.

4. Sli de the false clamp plate under the cl am p and slide the plate up into position.

5. Hold the plate in position and secure with the (3) setscrews located in the lower f r ont f ace of

the clamp, Figure 12.

6. A sensor det ec ts that the false clamp is installed and the computer setting will automatically

be set to ON.

NOTE: The minimum cut with the false clamp plate attached is 1-7/8”.

False Clamp Plate Set Screws

16

Figure 12

Page 17

5.0 Installati on & Setup

5.7 Power Hook-Up (208/230 50/60Hz)

For satisfact ory oper ation, be sure that your cutt er is wired for the correct phase and v ol tage and has

adequate power. The c orrect elect rical specifi cations for your machine are shown on the seri al plate.

Check the machine serial plate before connecting the power. For future reference, transfer this

information to the front cover of this manual.

Watch Setup Voltage- Inadequate power to the cutter can be a major source of problems. Too

many machines on the same circuit will reduce the power to each machi ne. Inadequate v oltage wil l

frequently cause overheating, loss of power, and in extreme cases, failure to operate. Test your

voltage when the shop is at actual working level s. Challenge recommends a dedi cated line wit h a

lockable di sconnect to provide adequate power f or this machine.

CAUTION: SHOCK HAZARD! Always disconnect power at main

power panel befo re working on the cutter. Lock it out to prevent accidental power up. (S ee

Power Loc kout Procedure page 5).

Important: You must have an adequ at e si ze ci rc uit and heavy enough wir ing for this mac hine. T he

circuit size should be a minimum of 20% greater than the amperage rating on the machine

nameplate. If a wire is run over 75 feet ( 23 meters), the next siz e wire should be used. Check local

electric al c odes.

Electrical Sp ecifications for the Titan 265:

Three Ph.: 208/230 V 25 A 30 A #10 AWG

Voltage Amperage Circuit Size Wire Size

Single Ph.: 208/230 V 30 A 40 A #8 AWG

‘XT’ models – ther e are two places that must be set for the proper incoming v oltage. The first is the

terminal bloc ks found in the power panel. Check incoming voltage and position the Termi nal Block

Jumper for the proper v oltage selection location as shown in Fi gur e 13.

Voltage Amperage Circuit Size Wire Size

Figure 13

17

Page 18

5.0 Installati on & Setup

NOTE: The terminal block jum per must be set t o the correct location according to the supply voltage

of the machine. Failure to set the t erminal block jumper will cause damage to the machi ne!

The second place that must be set for the proper incoming voltage is the transformer terminal stri p

behind the control console. Check the incoming voltage and move wire #21 to the proper terminal as

shown in Figure 14

Figure 14

NOTE: The terminal block jum per must be set t o the correct location according to the supply voltage

of the machine. Failure to move wire #21 to the proper terminal will cause damage to th e

machine!

The power source is connect ed to the cutter at in the junction box loc ated at the rear , r ight hand side

of the machine.

5.7.1 Single Phase Hook-Up

1. Disconnec t the power at the main power panel and l ock it out to prevent accidental power-up.

See Power Lock-Out pr oc edur e, page 5.

2. Thread the power cord through the knock - out hole in the junction box located near the fl oor in

the lower left hand c or ner of t he machine rear. Secure it with a conduit connector.

3. Fasten the ground lead to the ground terminal lug found in the junction box.

4. Use wire nuts to join the two power leads to the L1 and L2 leads found in the junction box.

5. Close al l doors and guards, unlock the main power and swit c h it on. The machine should

now have power.

5.7.2 Three Phase Hook-Up

1. Disconnec t the power at the main power panel and l ock it out to prevent accidental power-up.

See Power Lock-Out pr oc edur e, page 5.

2. Thread the power cord through the knock - out hole in the junction box located near the fl oor in

the lower left hand c or ner of t he machine rear. Secure it with a conduit connector.

3. Fasten the ground lead to the ground terminal lug found in the junction box.

18

Page 19

5.0 Installati on & Setup

4. Use wire nuts to join the three power leads to the L1, L2 and L3 leads found in the junction

box.

5. Close al l doors and guards, unlock the main power and swit c h it on. The machine should

now have power.

6. Press both cut buttons simultaneously to activate the motor and check to make sure it is

turning the same dir ec tion as the arrow on the motor casing. If it isn’t, disconnec t the power

and simply exc hange any two leads of the power cord as in Figure 15. The motor will now

turn the corr ect dir ec tion. Double check to make sure.

1

2

31 2

3

Figure 15

5.8 Power Hook-Up (380/400/415V 50Hz) – also applies for (460V

60Hz)

For satisfact ory oper ation, be sure that your cutt er is wired for the correct phase and v ol tage and has

adequate power. The c orrect elect rical specifi cations for your machine are shown on the seri al plate.

Check the machine serial plate before connecting the power. For future reference, transfer this

information to the front cover of this manual.

Watch Setup Voltage- Inadequate power to the cutter can be a major source of problems. Too

many machines on the same circuit will reduce the power to each machi ne. Inadequate v oltage wil l

frequently cause overheating, loss of power, and in extreme cases, failure to operate. Test your

voltage when the shop is at actual working level s. Challenge recommends a dedi cated line wit h a

lockable di sconnect to provide adequate power f or this machine.

power panel befo re working on the cutter. Lock it out to prevent accidental power up. (S ee

Power Loc kout Procedure page 5).

Important: You must have an adequ at e si ze ci rc uit and heavy enough wir ing for this mac hine. T he

circuit size should be a minimum of 20% greater than the amperage rating on the machine

nameplate. If a wire is run over 75 feet ( 23 meters), the next siz e wire should be used. Check local

electric al c odes.

Electrical Sp ecifications for the Titan 265:

Three Ph.: 380/400/415V 50Hz 15 A 30 A #10 AWG

460V 60Hz 11.5A 25 A #10 AWG

Voltage Amperage Circuit Size Wire Size

CAUTION: SHOCK HAZARD! Always disconnect power at main

19

Page 20

5.0 Installati on & Setup

Check the incoming voltage – if it is different from the factory set 415V, the tap on the main

transform er must be changed t o m atch the incoming voltage - see Figure 16 below for the procedure

The following also appl ies for 460V 60Hz Hook-ups – use taps H4 and H1.

Figure 16

The power source is connect ed to the cutter at in the junction box loc ated at the rear , r ight hand side

of the machine. The power i s then r un up to t he m ai n transformer mounted to the side of the machine,

under the top hood.

5.8.1 Three Phase Hook-Up

7. Disconnec t the power at the main power panel and l ock it out to prevent accidental power-up.

See Power Lock-Out pr oc edur e, page 5.

8. Thread the power cord through the knock - out hole in the junction box located near the fl oor in

the lower left hand c or ner of t he machine rear. Secure it with a conduit connector.

9. Fasten the ground lead to the ground terminal lug found in the junction box.

10. Use wir e nuts to join the three power leads to t he L1, L2 and L3 leads found in the junction

box.

20

Page 21

5.0 Installati on & Setup

11. Close all doors and guards, unlock the main power and switch it on. The machine shoul d

now have power.

12. Pr ess both cut buttons simultaneousl y to activate the motor and check to make sure it is

turning the same dir ec tion as the arrow on the motor casing. If it isn’t, disconnec t the power

and simply exc hange any two leads of the power cord as in Figure 17. The motor will now

turn the corr ect dir ec tion. Double check to make sure.

1

2

31 2

3

Figure 17

5.9 Line Light

The Titan 265 is equipped with two lights, which provide a line of li ght on the paper in the

approxim ate loc ation of where the paper will be cut. The lights come on when power to the machine

is turned on. The light from eac h bulb r eac hes t he table after passing between the knife and cl amp.

Each light is foc used with a socket head capscrew see Figur e 18

To Adjust:

1. Pl ac e a wi de sheet of paper on the cut stick to view the line light.

2. Using a 3/16” hex allen wrench, turn one of the cap screws until you see a 1/16-1/8” beam.

NOTE: it is best to start by turning the screw clockwise. If the screw turns all the way in

before a line appears, begin turning the screw counterclockwise.

3. Similarly, turn the adjustment screw of the other bulb, until one c ontinuous beam is seen

across the cut stick.

Line Light

Adj. Screws

Figure 18

21

Page 22

5.0 Installati on & Setup

SHOCK HAZARD! Always disconnect power at main power panel

before working on the cutt er. Lock it out to prevent accidental power up. See Power Lo ckou t

Procedure, page 5.

Bulb repl acement:

1. Make sure power is off (see Power Lockout Proc edur e, page 5).

2. Rem ov e the old bulb by lightly pushing the bulb into the socket and turning it 1/4 turn

countercl oc k wise. CAUTION! If the bulb is still hot, allow a few minutes for it to cool.

3. Insert the new bulb into the socket, push it in and twist it cl ockwise until the bulb locks i nto

place.

4. Reconnect power and t ur n the main power switch on. Readjust the line if necessary.

22

Page 23

6.0 Operation

6.0 Operation

IMPORTANT: DO NOT ATTEMPT TO OPERATE THE CUTTER UNTIL YOU HAVE

THOROUGHLY READ AND UNDERSTAND ALL OF THE FOLLOWING INST RUCTIONS. CALL

YOUR AUTHORIZED CHALLENGE DEALER IF YOU STILL HAVE ANY QUESTIONS.

6.1 Main Power and Start Up

Figure 19 - Main Power Switch

Power is brought to the m ac hine when the main power switch is turned to t he “ON” position (Figure

19). The Lower and upper boards receive power and line lights are turned on at t hi s time. The LCD

screen does not light up for approximately one minute. The program st ar ts and waits for the ‘Clear’

button to be pressed. The upper boar d then queries the lower board f or the settings and checks them

against it s settings. If they both agree, the startup continues. T he bac k gauge moves to the preset

location and wait s for user input. If they do not agree, once the backgauge reac hes the pr eset, a

window will show asking f or user input to choose which board is correct. After the values are set the

cutter is ready t o use.

If the knife and clamp are not in the “up” position, the display will prom pt the

operator to raise them by pr essing t he cut buttons prior to presetting the backgauge.

The screen saver will activate and the line lights will shut off after 5 minutes without any activit y. This

shut-off time c an be changed i n the Par am eters screen of the Maintenance Mode. To rest or e power

to the display and line lights, press any button on the keyboard or touch the screen.

6.2 Making a Cut

Place the paper agai nst the backgauge and side guide. Press and release both c ut buttons once to

start the hydraulic motor. Then press and hold both cut buttons to star t the cut cycle. While holding

the cut buttons, t he k nife and clamp will complete the cut cycl e. If the but tons are released at any

time during the cy cl e, t he k nife and clamp will immediately return to the up position.

Both cut buttons must be released before a new cut can be made. Also, the cut

buttons must be pressed wit hin 0.5 seconds of each other in order to initi ate a cut.

CLAMP HAVE STOPPED IN THE UP POSITION! Due to static buildup, fine trim may have a

tendency to stick to the clamp or knife surfaces. Fingertips might be d rawn into the knife by

DO NOT ATTEMPT TO REMOVE TRIM UNTIL THE KNIFE AND

23

Page 24

6.0 Operation

the clamp if this is attempted. Wait until the knife and clamp have BOTH STOPPED MOVING

before removing stock t rim.

The hydraulic m otor c an be shut off at any tim e by pr essing t he ‘S top Motor’ button or pressing and

holding one cut but ton for about five seconds. The hydraulic motor will also shut off when the screen

saver is activ ated. This shut-off time can be changed in the Param eters screen of the Maintenance

Mode. (See Section 6.1.3 – Figure 14)

6.3 Air Table Option

Machines equipped wit h an air table option can have the air table feature turned on or off by pressing

Air Table ON/OFF key or by pressing and holding the left cut but ton for three seconds.

6.4 Jogging Aid

All Titan 265 cutter s i ncl ude a jogging aid as standard equipment. The jogging aid allows the

operator to load and align stock without placing hands or arm s under t he cl am p and k nife area.

Figure 20

Load and align the paper against the side guide (Figure 20), t hen square it to the backgauge for

cutting.

Always remove the jogging aid from the t abl e before maki ng a cut.

Additional j ogging aids can be purchased by contacting your authorized Challenge deal er .

6.5 Adjusting the Clam p Pr ess ur e

Touch the 'Clamp Pressure' num ber or the 'False Clamp' symbol and a set of arrows will appear.

Touch these arrows to vary the pressure. The pressure scale ranges from 0 to 15, 15 being the

maximum. (See Section 6. 12.2 B, C and D)

6.6 Pre-Clam pin g

The Titan 265 is equipped with a low-pressure clamping feat ur e, which allows the operator to cl am p

paper under low pressure bef or e beginning the cut cycle. To use this feature, press down on the foot

24

Page 25

6.0 Operation

switch loc ated at the front of t he m achine until the clamp comes down on the paper. To raise the

clamp, rel ease the foot switch. To make a cut, keep the foot switch pressed and press the c ut

buttons. Release the foot switch once the cut has been complet ed. Avoi d placi ng hands under t he

clamp.

6.7 Electric Eyes

The electric ey es prevent reaching into the cutti ng ar ea while a c ut is being m ade. If the beams are

broken while a cut i s bei ng made, the knife and clamp will return to the up posi tion.

6.8 False Clamp Plate

The false clamp plate is an optional attachment, whic h reduces the cr easi ng of paper caused by the

clamp. The disadv antage of using the false clamp plate is that it limi ts the smallest cut dimension.

The machine has a built-i n sensor that detects when the fal se clamp plate is installed, and the

computer will automatically restrict the backgauge position accordingly.

6.9 Sleep Mode

The Sleep Mode starts after a time of inactivity. This is to save the screen and other par ts of the

cutter from wear. Touch the screen, press a cut button or press a key on the keyboard t o bri ng the

cutter out of Sl eep Mode. To change the Time Out for the Sleep Mode see Section 6.15. 1.3 under

‘Maintenance - Memory’.

6.10 Display Panel

6.11 Definiti on of Ke ys

6.11.1 Touch Screen

The touch screen can be used to mak e m any selections. Use by touching the appropriate area with a

light touc h of your finger . Do not use sharp objects such as a ballpoint pen when using the touch

screen.

Figure 21 - Console Layout

25

Page 26

6.0 Operation

6.11.2 Backgauge Glide Control

The Backgauge Glide Control is used to manually position t he backgauge. The speed of the

backgauge will depend upon where the ac tuator is pressed. Press farther from center for a faster

speed and closer to center for a slower speed. To move the backgauge for ward, pr es s do wn ward.

To move the backgauge backward, pr es s up ward. P r es si ng the center displays true posi tion.

6.11.3 IN/MM Key

This key toggles the display to show the position and programmed send values in inches (e.g. 5.250),

inch fractions to the nearest 1/64” (e.g. 5_1/4) , or millimeters (e.g. 133.3).

6.11.4 Air Table ON/OFF Key

This key turns the ai r pump on and off.

6.11.5 CANCEL Key

The CANCEL key closes the current m ode. Some modes need multiple presses of CANCE L to

return to the Send mode.

6.11.6 SEND Key

The SEND key is used to send the backgauge to any valid position. If an att em pt is made to send the

backgauge to an illegal position, an error message will be displ ay ed. In the Job mode, the SEND key

will move the backgauge t o the location in the Current Cut box (S ee S ection 6.12.3 ).

The job must be open and running to send to t he loc ation in the Current Cut box.

6.11.7 Push-Out Key

The push-out key will move the backgauge forward 5 inches (127 MM) (or to the most forward

position) and then return it to its previous positi on. This allows paper to be removed from the c utt er

without putti ng hands under t he k nife and clamp.

26

Page 27

6.0 Operation

Never place hands in the clamp and knife area. Use the push-out key

or the backgauge gli de c ontrol to move the paper to an area where it can be reached.

6.11.8 CLEAR Key

The CLEAR key is used to clear err or messages or the cur r ent entry line.

6.11.9 ENTER Key

The ENTER keys select options and stores typed data.

6.11.10 Priority Add (X/Y) Key

The Priority Add key is used f or entering fractions when they are c om bined wi th whole numbers. The

symbol display ed when this key is pressed is the underli ne symbol “ _”. An exam ple of a number

entered using the Pri or ity Add key is 1_1/2.

6.11.11 Arrow Keys

The four arrow keys can be used in almost all screens. The arrow keys are prim aril y used for moving

the cursor around on the screen, or to toggle between highlighted selections. In some screens, the

left arrow key act s as a backspace key.

6.11.12 PAGE Keys

The PAGE keys are used with li sts. Pressing a PA GE key when a job is open moves the cut location

eighteen cuts. If the c ut location is beyond the first or last cut, the PAGE k ey s mov e to the fir st c ut

(PAGE Up) or to the last cut (PAG E Down). Pressing a P A GE k ey when a li st of jobs is di splayed will

move ten lines to displ ay m or e of the li st.

27

Page 28

6.0 Operation

6.12 Interfac e

6.12.1 Icons

Load Zone

Clamp Only

Cut and Record

Air

Job Locked

Disk or USB Storage Device

Cutter

Help

28

Page 29

6.0 Operation

6.12.2 Main Window

J

L

B A C E

M

D G

H F

N O

I

K

Figure 22 - Main Window

A. Backgauge location

B. Clamp Pressure (0 – 15)

C. False Clamp Indicator

No False Clamp | False C lamp On

D. Clamp Pressure Change

E. Job Name

F. Clamp Only / Load Zone Indicator

G. Locked Job Indi c ator

H. Curr ent Cut Number

I. Job Timer (Touch t o get mor e information)(See Section 0)

29

Page 30

6.0 Operation

Figure 23 - Job Timer

Additional Information

J. Edit Box

K. Job Statistics (See Section 6.12.3 ,Figure 24)

L. Help Button

M. Air On/Off indicator. Also used for the ‘Air Off’ option in an open job.

N. Job S tatistics Icon Referenc e ( Not F unc tion Keys)

O. Function Key Colum n

6.12.3 Job Statistics

List Pictur es

Previous Cuts

Current Cut

More Cuts

Hours: Minutes

• List Pictures

The List Pictures show graphic ally what inform ation each column contains.

The Clamp Only/Load Zone c olum n shows that when there is a ‘C’ (Clamp Only) or an “L”

(Load Zone) in the cur r ent cut t her e wi ll be no c ut made for that location, but the Backgauge

will advance to the next position in memory.

If there is an "X" in the Push Out Col um n, the backgauge will not perform a push out when

going to that position. When there is a "P" in the cut the backgauge will be for c e d to perform

a push out when going to that position.

An “X” in the current cut of the Air Off column overrides the table air tur ning it off when

moving to that cut. The air turns back on again after the next cut.

30

Figure 24 – Job Statisti cs

Page 31

6.0 Operation

There are four options in the Turn column. The symbol “<” means rotate t he lift left

(clockwise) 90° and r eplace it against the backgauge. The sym bol “<<” m eans rot ate the lift

180° and replace it agai nst the backgauge. The symbol “>” means rotate t he lift ri ght

(counter clock wise) 90° and r eplace it against the backgauge. The symbol “B” means bring

back a previous lift to finish it (automatic programming only).

The Pressure column allows you to set the clamp pressure for the curr ent cut.

• Previous Cuts

The previous cut s rows are the cuts t hat have already been made or passed. See Section

6.11.11 and 6.11.12 for more inf ormation on how to move around in a job.

• Current Cut

The cut contai ned in this row is the current cut of the job.

• More Cuts

The More Cuts rows contain t he nex t nineteen cuts of the job.

6.13 Jobs

6.13.1 Programming a Job

6.13.1.1 Manual E ntry / By Cut

Select 'New Job' from the 'J ob' m enu or 'New Job' f r om the function key column. Select 'Manual

Entry' and fill in the box with the job name.

All cut positions for the job will be entered in the 'Edit Box'. If there is not a number in the 'Edit Box'

the current bac k gauge posi tion will be used when 'Enter' is pressed or a cut is made. Any new

position can be entered from the number keys, the result fr om a math formula or sending to a location

and then pressing 'Enter' . Each successive position wil l appear below the previous positi on in the

programming c olum n.

Options may be entered to the cut position line using the func tion keys. Pressing the yellow up and

down arrows changes clamp pressure number. 'Load Zone' "L" indicates load zone position (no cut

or clamp). 'Turn' "<" indic ates turn lift clockwise. 'T ur n' ">" indic ates turn lift countercloc k wise.

'Turn' "<<" indicates turn lift 180 degrees. ' P ush Out' "P" indicates a push out and "x" indicates no

push out for that cut. 'Ai r ' "x" indicates the air off between cuts.

When one cut positi on is complete, repeat the same procedure f or the nex t position. The blue box

will turn yellow when the value inside is a send value or if the sli de bar for the back gauge is used. To

save this value, pr ess 'Enter ' . Press 'Finish' when the program is compl ete.

In the 'Manual Job' there is a 'Cut Rec or d' option. This allows the operator to make cut s and the

location of the c ut is entered automatically into the new job. The job is incremented and is ready for

the next cut. To start the 'Cut Rec or d' mode press the 'Cut Rec or d On' function button while m aki ng

a 'Manual Job'.

31

Page 32

6.0 Operation

6.13.1.2 Sheet Division

Figure 25

Select 'New Job' from the 'J ob' m enu or 'New Job' f r om the function key column. Select 'Sheet

Division' and fi ll in the box with the job name. The program will ask if you want 'Pre- Trims'. 'PreTrims' are entered just like a 'Manual' job. Press the 'Pre-Trims Done' function button when the 'P r eTrims' have all been entered. Enter the dimensions of the 'Parent Size' and the dimensions of t he

'Finish Product'. Use the up and down arrows to move from one dimension to the next or press

'Enter' when the value is complete. The left arrow key is a backspace. Set t he ' Clamp Pressure'

using the number keys fr om 0 to 15. Select " Ai r off between cut s", "Allow cross grain cuts" and " Cut

columns separately " by touching the box. Choose 'Finish' to move on to the 'Layout' screen.

On the 'Layout' screen, sel ec t the layout that best suits the job. Press 'Next Layout' or touch the text

of the desired layout to view each option. To enter new numbers without star ting over, press the

'Reenter' button. Press the 'Accept Layout' when the desired layout is selected and the c utt er will

calculate the new job. The Layout should be saved to the cutter m emory or to a disk. The 'Save

Job' window will show when the new job i s ready ( see 6.13.4 " S av ing an Open Job" for help in saving

a job).

6.13.1.3 Label Cut

Figure 26

Select 'New Job’ f r om the 'Job' m enu or ' New Job' from the function key column. Selec t 'Label

Cutting' and fill in the box with the job name.

The program will ask for two 'Pre-Trims'. 'Pre-Trim s' are enter ed just like a 'Manual' job. Press the

'Pre-Trim s Done' f unc tion button when the 'Pre-Trim s' have all been entered.

Enter the quanti ty of the finished pieces horizontal and v ert ical, the dimensions of the 'Finish Product'

and the dimensions of the 'Gutters'. Use the up and down arrows to move from one dimension to the

next or press 'Enter' when the value is complete. The left arrow key is a backspace. S et the 'Clamp

Pressure' using the number keys from 0 to 15. Select "Air off between cuts" and "Cut columns

separately" by touching the box. Choose 'Finish' t o m ov e on to the 'Layout' screen.

32

Page 33

6.0 Operation

A

On the 'Layout' screen, sel ec t the layout that best suits the job. Press 'Next Layout' or touch the text

of the desired layout to view each option. To enter new numbers without star ting over, press the

'Reenter' button. Press the 'Accept Layout' when the desired layout is selected and the c utt er will

calculate the new job. The Layout should be saved to the cutter m emory or to a disk. The 'Save

Job' window will show when the new job i s ready ( see 6.13.4 " S av ing an Open Job" for help in saving

a job).

6.13.1.4 Repeat Cut

Press the 'Repeat Cut' opt ion from the function key column. Enter the

length of the lif t in t he 'Back gauge S tart' box and press 'Enter'. Enter

the cut dimension in the 'Step Size' box and press 'Enter' to ac c ept t he

job or 'Exit' to rejec t t he v alues. When the job is accepted the

backgauge will m ov e to the start loc ation and each cut will send the

backgauge to the next 'Step Size' dimension. Press 'Exi t' from the

function key c olum n to close the ' Repeat Cut' job.

Figure 27

6.13.2 Opening a Previously Saved Job

Choose the 'Open Job' option from the 'Job' menu or the 'Open Job' key from the function key

column. Use the arrow keys (on the key boar d) , the arrows on the window, and 'Page Up' and 'Page

Down' keys to scroll t hr ough the job names. If you see the name you want you may also just t ouc h

the name and it will appear as the selec tion. Press the 'Open' functi on butt on or the 'E nter' button to

open the selected job. (SeeFigure 26 for Open Job Window layout. )

6.13.3 Editing an Open Job

Editing an open job is similar to ‘Manual Entry’. Edit the loc ation using the keypad and use the

function button column to change the options. When a job is closed without being saved, the save

window will show. If the changes are unwant ed, press the ‘Exit’ funct ion button to skip saving.

Otherwise, choose either the disk, or the cutter to save it to.

A job written wit h ‘Sheet Div ision’ or ‘Label Cut’ can only have some of its vari ables changed. No

new cuts may be added and no cuts can be remov ed. The options can be changed using the

function key column.

rrows

Selected Job Name

Job Names

Locked Job Indi c ator

Display Options

Disk Space

Open Job, Save Job, Copy Job, Delete Job

Lock/Unlock Job

Buttons (See 5.7)

Figure 28 Job Window

33

Page 34

6.0 Operation

6.13.4 Saving an Open Job

Choose the 'Sav e Job' option from the 'Job' menu or the 'Save Job' key fr om the function key column.

The name of the job can be changed on t he 'Save Job' window. The job can be saved to either the

cutter or a USB Storage Dev ic e. Pr ess the "S av e To: " cutter butt on or "Save To:" disk button (Must

have a USB Storage Devi c e in the driv e before opening the Save Job Window) to save the job. A job

must be open to be saved. (See

Figure 28 for Sav e Job Window lay out.)

6.13.5 Delete a Previously Saved Job

Choose 'Delete J ob' from the 'J ob' m enu. Choose the job t o be deleted from the menu and press the

'Delete' button. The ‘Delete All’ check box allows for erasing all of the jobs on a USB Storage Device

or the cutter. Del eting all files will delete all locked jobs as well. Select the ‘Delete All’ c hec k box and

then delete the jobs on the cutter or the USB Storage Device. (See Figure 10 f or Del ete Job Window

layout.)

Press 'Exit' when finished deleting jobs.

6.13.6 Copy a Job To/From a USB Storage Device

Choose 'Copy Job' option from the 'Job' menu. To copy one job, select the job t o be copi ed and

press the 'Copy' button. To copy all jobs, select the 'Copy All' check box and choose the destination

of the jobs (Cutter or USB Stor age Dev ic e). The 'Copy To:' buttons will copy from the ot her to t he

one selected. (S ee Figure 10 for Copy Job Window layout.)

Press 'Exit' when finished copying jobs.

6.13.7 Locking/Unlocking a Job

Locking a job prevents changes from being saved to the job that i s l oc k ed. A locked job can be

changed and saved wit h a diff er ent name. Jobs can be locked or unlocked from the 'Open Job',

'Save Job', 'D elete Job' and 'Copy Job' windows using the 'Lock (U nlock) Job' button or the 'LockPassword' button. The Lock - P assword button gives an added level to loc ki ng a job si nc e changes

cannot be saved to the job wit hout fi r st unlocking it with the password. When a job is lock ed a

padlock will appear besi de the name on the Job window and next to the open job on the Main

window. (See Figure 22 and Figure 10)

A locked job can be deleted using the 'Delete All' command.

Remember to write down the password for each file for later refer enc e.

6.14 Safety Systems

6.14.1 False Clamp Plate

If a false clamp is in installed, the cutter will detec t it and show the false clamp as “on”.

6.14.2 Safety Eyes

The safety eyes stop the back gauge and pr event a cut. When the backgauge is moving f or ward and

the safety eyes are broken, the backgauge will stop at about 3.5 inches and a message will ask that

34

Page 35

6.0 Operation

the eyes be cleared. The message includes the 'MOVE' button to move the back gauge forward

slowly without clearing the eyes. Pressing the slider will also allow movement.

Safety Beam Broken Message

6.15 Maintenance

There are three options under the ‘Maintenance’ pull-down menu: ‘Maintenance’, ‘Upgr ade’ and

‘Calculator’.

6.15.1 Maintenance

The ‘Maintenance’ window contains six tabs for changing t he variables that affect t he performance of

the cutter: ‘Paramet ers’, ‘Miscellaneous’,’ Memory’, ’ Adjust’, ‘Knife Adjust’ and ‘Language’.

6.15.1.1 Parameters

Settable Variables

Current Values

Figure 29 – Parameters Tab

The ‘Parameter s’ tab has thr ee settable variables; ‘P ush Out On’, ‘Reposition On’, and ‘False Cl am p

On’ (PC version only ). It al so shows the current values of ‘Accuracy Adjust’, ‘K nife Count’, ‘Lube

Count’ and ‘Machine Count ’.

6.15.1.2 Miscellaneous (Misc.)

Figure 30 - Miscellaneous Tab

35

Page 36

6.0 Operation

6.15.1.2.1 Job Timer

Check the ‘Job Tim er ’ check box to turn on the Job Timer. The Job Timer keeps track of the amount

of time a job has been running. Pausing the job will pause the timer as well. Touching the timer

display beside an open job opens a window to more information (See 6.12.2 - I for a picture). The

window shows how many cuts have been made in the open job and how many cuts were made per

minute. If a job is running or paused, t he time cannot be reset. The values may only be reset when

a job is not running. Closing a job r esets the timer.

6.15.1.2.2 Keyboar d Lay out

There are two choic es for the key boar d l ay outs. ‘ABCDEF’ stands for setti ng the keys in alphabetical

order. ‘QWERTY’ stands for setting the keys in the standard keyboar d layout. The keyboards are

used to enter job names, dealer information, etc… (See Figure 31)

6.15.1.3 Memory

Figure 31 – Keyboard Layouts

Clear Knife

Clear Lube

Set Knife

Figure 32 - Memory Tab

The ‘Memory’ tab cont ains buttons to change variabl es in memory. The ‘Clear Saved Errors’ button

removes the stored er r or s fr om the c utter. The ‘Clear Knife’ button clears the Knife Count. The ‘Clear

Lube’ button clear s t he Lube Count. The ‘Knife Reminder’ button allows the user to set the number of

cuts before the ‘Shar pen K nife’ reminder shows on the main window. The ‘Time Out’ box sets the

amount of tim e that will elapse before the cutter goes into sleep mode. ( S ee Secti on 6.9 )

6.15.1.4 Adjust

Clear Saved Errors

Current Values

Time Out

36

Change Button

Figure 33 - Adjust Tab

Page 37

6.0 Operation

To enable the settings on this screen, first press the ‘Change’ button.

Enter code: 1433

Figure 34 - Adjust Tab

Next, in the text box that appear s enter the code: 1433. Then press the ‘Change’ button again. The

screen should now look li k e the one shown in Figure 35 below:

Set Maximum/Minimum Bars

Set Accuracy

Adjust

Send Buttons

Figure 35 - Adjust Tab

6.15.1.4.1 Max / Min Clam p P r essure

Touch the 'Set Maximum' or 'Set Minimum' bar to change the Maxim um /Minimum Clamp Pressure

setting. Press the ‘Send’ button corresponding to the pressure changed to send the new maximum or

minimum pressure settings to the lower board. These buttons al so set the c urrent pressure to 15 or 0

so that the pressure can be tested i n the 'Maintenance' screen by m aki ng a c ut. Repeat t he changes

and cuts until the pressure is set. See the Technical Manual for inst r uc tions on how to adjust clamp

pressure.

6.15.1.4.2 Accuracy Adjust

The Accuracy Adjust window (Figure 36) is used to adjust the accur ac y of t he backgauge. Press the

‘Accuracy’ but ton (Figure 35) to set.

Figure 36

There are three ways to set the A c c ur acy A djust:

Option 1: Measure and Record

After pressing t he ' S et Ac c ur acy Adj ust' button the 'Accuracy Adj ustm ent' window appears. Two

inches (50.8 MM) i s autom atically entered into the 'E dit Box ’. Thi s number c an either be accepted by

pressing 'Send' or a different position entered and pr essing ' S end' . The backgauge will move into

37

Page 38

6.0 Operation

position f or a cut. Place a small stac k of paper onto the table and square it to the middle of the

backgauge. Make a cut and rem ov e the scrap. Tak e the stack and measure it. Enter the length into

the text box and press the 'Ent er ' button. After the cutter has reset, this process may be repeated or

press the 'Fi nish' but ton to return to the 'Maintenance' window. Press 'OK' on the maintenanc e

window to save the new values.

Option 2: Cut and Compare

The second procedure is much like the first. Press the 'Accur ac y ' butt on to start the 'Accuracy

Adjustment' . Two inches (50.8 MM) is automaticall y entered i nto the ‘Edit Box’. This number can

either be acc epted by pr essing 'S end' or a different position enter ed and pr essing 'S end' . The

backgauge will m ov e into position for a cut. Place a small stack of paper great er than 4 inches (102

MM) onto the table and square it to the middle of the backgauge. Make a cut and remove the scrap.

Press Cancel and send the backgauge to half the distance of t he first c ut. Make a second cut . Place

the two halves together . Compare the two stacks to see how closely they match. The stack that was

still against the backgauge is suspect. THE STACK CUT OFF IS THE EXACT LENGTH. Type + or the differenc e between the two stacks based on the stack cut off ( Example +.03 or -.053) and press

'Enter'. After the cutt er has reset, this process may be repeated or pres s t he ' Finish' button to retur n

to the 'Maint enanc e' window. Pr ess 'OK' to save the new values.

Option 3: Send and Record

The third procedur e is for a c oar se sett ing of the Accuracy Adjustment. Press the Acc ur ac y butt on to

start the 'Accurac y A djustm ent'. Two inches (50.8 MM) is automatic ally entered into the ‘Edit Box’.

This number can eit her be accept ed by pr essing ' S end' or a different position entered and pr essing

'Send'. With a ruler, measure the distance from the backgauge t o the cut line on the cut stick. Enter

this distance into the text box and press 'Enter'. After the cutter has reset, this process may be

repeated or press the 'Finish' button to retur n to the 'M aintenance' window. Press 'OK' to save the

new values.

6.15.1.5 Knife Adjust

The ‘Knife Adjust’ (Figure 37) tab provides a way to send the knife up or down (which is necessary to

change or adjust the k nife). To send the knife to the down position, pr ess the ‘Knife Down’ button,

clear the table, and press and hold the cut buttons until the hydr aulic motor stops. To send the knife

to the up position, press the ‘Knife Up’ button and press both cut buttons.

Figure 37 – Knife Adjust T ab

6.15.1.6 Language

In this tab, the user select s the language that will be displayed.

6.16 Upgrad e

38

Upgrade XT Software

Current Help

Update Jobs

Current Language

Page 39

6.0 Operation

• Update Jobs

The ‘Upgrade’ window shows the files that are used with the program and the version number

they are using. The ‘Updat e Cutter’ and ‘Update Disk’ buttons change t he job files previously

saved to the newest ver si on.

• Upgrade XT Program

To install the newest XT upgrade pl ac e the ‘XT Upgrade’ disk (EE-2933- 1- X) supplied by

Challenge into the disk drive. Select the 'Upgrade XT Soft ware' but ton to start the XT Upgrade

program. Press ‘Upgrade’ to start the process. If the disk has an older ver sion of software, the

upgrade program will allow it to be installed. This is useful if t he older software is more desirable

than the new software. W hen upgr ading is complete, shut down the cutter and r estar t it. The

cutter will now run with t he upgr aded software.

Because of changes in the upgrade pr ogr am , the upgrade program ver si ons

previous to 3.01.08.01 do not install all upgrades before the first restart. To rectify this, the XT

software will ask for the upgrade disk to be reinserted when the new XT soft ware is started for the

first time. The final upgrades are then installed and c an be used without restarting the machi ne.

Figure 38 – Upgrade Window

6.16.1 Calculator

The calculator is present for miscellaneous cal c ulating needs. The number calc ulated can be used

as a position if the ‘Send’ key is pressed after the ‘=’ button is pressed. Pr ess the ‘Exit’ button when

finished.

6.17 Diagnostic

6.17.1 Sensor Data

Figure 39 - Sensor Data

39

Page 40

6.0 Operation

The ‘Sensor Data’ area shows the stat us of the inputs and outputs on the cutter. The inputs and

outputs do not update during a cut so the lower board can concentrat e on the safety systems. To

check input sensors that ar e only active during a cut, place a piec e of metal on t he pr ox ' s t o activ ate

them.

DO NOT ATTEMPT TO MAKE A CUT WHILE INSIDE THE CUTTER!

6.17.2 Last Error Code