Page 1

Challenge MS-5 Multi-

Spindle Paper Drill

Instruction Manual

Page 2

Serial Numbers 965600 & Up

INSTRUCTION AND

PARTS MANUAL

The Challenge Machinery Company

1433 Fulton Avenue

Grand Haven, MI 49417-1594 USA

ChallengeMachinery.com

MODEL MS-5

PAPER DRILLING

MACHINE

Sold and Serviced by

F.300-B

JULY 2000

Page 3

INTRODUCTION

WELCOME to the family of Challenge® users. Challenge has been developing and manufacturing Graphics Arts

Equipment for over 100 years and is today one of the world’s leading producers and distributors of Paper Cutters,

Paper Drills and Bindery Equipment.

SAFETY ALERT! This symbol means CAUTION OR WARNING: Personal safety instructions! Pay

special attention to the instructions in bold type. Personal injury may result if the precautions are not

read and followed. See SAFETY PRECAUTIONS, page 4.

• This machine is designed for ONE PERSON OPERATION ONLY!

• Always DISCONNECT THE POWER before working on this machine.

• DO NOT OPERATE WITH ANY GUARDS REMOVED! Replace all guards before operating.

• CRUSH HAZARD - Keep hands, hair, cleaning rags, & loose clothing away from drills.

READ THIS MANUAL BEFORE OPERATING! Follow precautions and instructions given and you should have

years of trouble-free operation. If after reading the manual questions still remain, contact your Authorized Challenge Dealer.

FOR PARTS AND SERVICE contact the Authorized Challenge Dealer from whom you purchased your machine.

Use the illustrations and parts lists at the back of this manual to identify the correct parts needed. Always give

the SERIAL NUMBER and MODEL of your machine to insure that the correct parts are sent as soon as possible.

Take a few minutes right now to RECORD YOUR MACHINE SERIAL NUMBER in the space provided on the

front cover of this manual. Also be sure to fill out the warranty card accompanying this manual and return it

DIRECT TO CHALLENGE.

If you bought a used machine, it is important to have the following information on record at Challenge. Copy this

page, fill in the information and send it care of: The Challenge Service Department, 1433 Fulton Avenue, Grand

Haven, MI 49417-1594.

CHALLENGE MODEL SERIAL NUMBER

ATTN COMPANY

ADDRESS

CITY STATE ZIP

PHONE DATE INSTALLED

DEALER’S NAME AND CITY

WARRANTY INFORMATION

PLEASE REVIEW THE ENCLOSED WARRANTY SHEET!

It is very important that you read and understand the conditions outlined in the Warranty Information Sheet

included with the manual information package.

The Warranty Information Sheet must be filled out completely, returned, and be ON-FILE at THE CHALLENGE

MACHINERY COMPANY in order for the warranty to be issued for this machine.

Challenge® is a registered trademark of The Challenge Machinery Company. 1433 Fulton Street, Grand Haven, MI 49417.

Copyright © 1996 by The Challenge Machinery Company. All rights reserved. Printed in the U.S.A.

2

F.300-B/MS-5 DRILL/JULY 2000

Page 4

TABLE OF CONTENTS

INTRODUCTION........................................................................................... 2

CAUTION: POWER LOCK-OUT PROCEDURE ............................................ 4

SAFETY PRECAUTIONS ............................................................................. 4

PACKING LIST ............................................................................................ 5

SPECIFICATIONS ........................................................................................ 5

WARNING LABEL DEFINITIONS.................................................................. 6

INSTALLATION ............................................................................................ 7

Unpacking ............................................................................................. 7

Power Hookup ....................................................................................... 7

SETUP INSTRUCTIONS............................................................................... 7

Starting the Machine .............................................................................. 7

Safety Interlock System......................................................................... 8

Hydraulic Check .................................................................................... 8

Positioning Drill Heads........................................................................... 8

Drive Belt Adjustment............................................................................. 9

Drill Installation ...................................................................................... 9

Drill Removal ......................................................................................... 9

Stroke Adjustment (Table Height Adjustment).......................................... 9

Adjusting the Stroke Speed .................................................................... 9

Setting Up the Backgage ..................................................................... 10

Using the Side Guide(s) ....................................................................... 10

Drill Blocks.......................................................................................... 10

Emptying the Drill Chips ...................................................................... 10

OPERATION .............................................................................................. 10

DRILLING TIPS ...........................................................................................11

ACCESSORIES FOR CHALLENGE PAPER DRILLING MACHINES ............ 12

TECHNICAL SECTION FOR TRAINED PERSONNEL ONLY

TROUBLESHOOTING ................................................................................ 16

ROUTINE MAINTENANCE ......................................................................... 17

SERVICE CHECKLIST............................................................................... 17

NOTES...................................................................................................... 19

MAIN ASSEMBLY - FRONT VIEW ............................................................. 20

MAIN ASSEMBLY - SIDE VIEW ................................................................. 22

MAIN ASSEMBLY - SIDE VIEW ................................................................. 24

MAIN ASSEMBLY- TOP VIEW ................................................................... 26

MAIN ASSEMBLY- TOP VIEW ................................................................... 27

MAIN ASSEMBLY - DRILL GUARD (50 HZ ONLY) ...................................... 28

MAIN ASSEMBLY - DRILL GUARD (50 HZ ONLY) ...................................... 29

BELT INSTALLATION ................................................................................. 30

HYDRAULIC POWER UNIT ASSEMBLY .................................................... 32

HYDRAULIC SEQUENCE OF OPERATION ................................................ 33

BASIC MACHINE SCHEMATIC .................................................................. 34

ELECTRICAL SEQUENCE OF OPERATION............................................... 35

POWER PANEL ASSEMBLY ..................................................................... 36

POWER PANEL ASSEMBLY ..................................................................... 38

POWER PANEL ASSEMBLY ..................................................................... 40

DRILL HEAD ASSEMBLY .......................................................................... 42

POWER PANEL LABEL ............................................................................ 43

TWO HAND CONTROL OPTION ................................................................ 44

DRILL GUARD KIT ..................................................................................... 46

BELT GUARD SWITCH REPLACEMENT KIT.............................................. 47

DRILL GUARD SWITCH REPLACEMENT KIT............................................. 48

SAFETY SYSTEM TESTS ......................................................................... 49

F.300-B/MS-5 DRILL/JULY 2000

3

Page 5

SAFETY PRECAUTIONS

This safety symbol means CAUTION/WARNING - PERSONAL SAFETY INSTRUCTION. Read

the instructions because it has to do with safety. Failure to comply with the following instructions may result in personal injury.

• This machine is designed and safeguarded for ONE PERSON operation. NEVER operate the machine

with more than one person.

• Safety of this machine is the responsibility of the user and operator. Use good judgement and com-

mon sense when working with and around this machine.

• READ and understand all instructions thoroughly before using the machine. If questions still remain,

call your Authorized Challenge Dealer - Failure to understand operating instructions may result in

personal injury.

• Only trained and authorized persons should operate the machine.

• DO NOT ALTER SAFETY GUARDS OR DEVICES, they are for your protection and should not be al-

tered or removed. Severe lacerations could result.

• DISCONNECT POWER before cleaning, lubricating, servicing, or making adjustments not requiring

power. Lock the disconnect switch in the OFF position, see Power Lockout Procedure below.

• HIGH SPEED DRILL - Keep rags, loose clothing and long hair away form rotating drill. Personal injury

could result from items being caught on drill.

• Have your electrician make sure the machine is properly grounded, see Power Hookup, page 7.

• Have your electrician check for sufficient power to operate the machine properly, see page 7.

• OBSERVE ALL CAUTION PLATES AND LABELS on this machine.

• KEEP FOREIGN OBJECTS off table and away from drill.

• BE EXTREMELY CAREFUL when handling and changing the drills. Severe lacerations or dismember-

ment could result from careless handling procedure.

• KEEP THE FLOOR around the machine free of trim, debris, oil and grease.

• When replacing hydraulic parts, loosen the connections slowly to release pressure. Never loosen

connections with the machine running.

• If the machine sounds or operates abnormally, turn it off and consult the Trouble Shooting section of

this manual. If the problem cannot be corrected, have it checked by a qualified service person or your

Authorized Challenge Dealer.

• CRUSH HAZARD, keep feet off the pedal when handling paper under the clamp. DO NOT REST FOOT

ON PEDAL at any time!

• DO NOT REACH UNDER THE DRILL AND CLAMP AREA!

• DO NOT OPERATE WITH ANY GUARDS REMOVED! Replace all guards after adjusting, lubricating or

servicing the machine.

• SEVERE LACERATIONS - Contact with high speed drill could cause severe injury. Always turn ma-

chine off and wait for drill to stop before removing drill bits. Keep hands away from drill(s) when

operating.

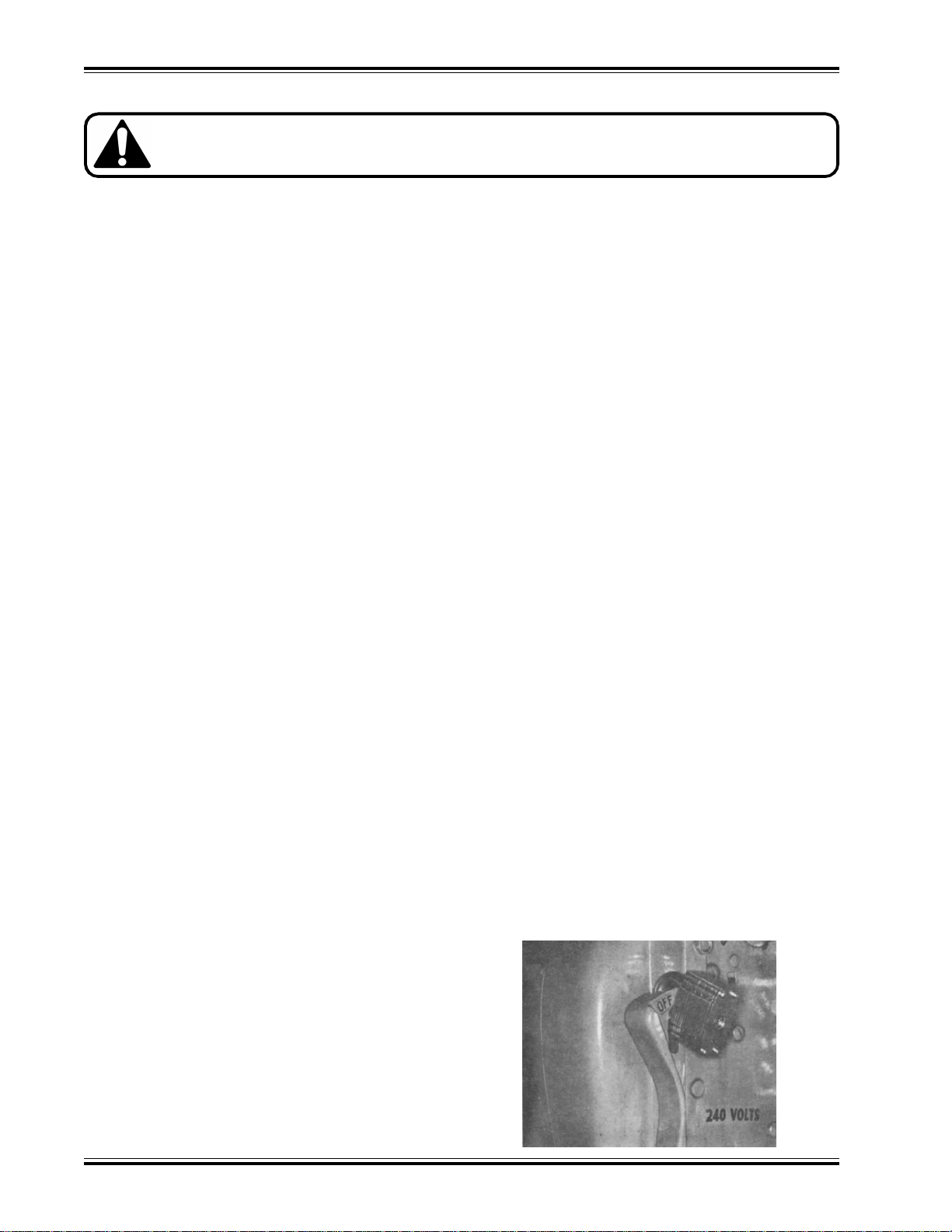

CAUTION: POWER LOCK-OUT PROCEDURE

For maximum safety when making adjustments or

repairs to your machine, be sure to lock out the

main power control switch to which the machine

is connected. The switch should be thrown to the

OFF position and a padlock placed in the loop. The

key should be held by the person servicing the

machine.

4

(fig. 1)

F.300-B/MS-5 DRILL/JULY 2000

Page 6

PACKING LIST

Part No. Description Qty.

Basic Machine ....................................................................1

W-105-1 Allen Wrench, 1/4” ‘T’ Handle ...............................................1

A-6588 Wrench, ‘T’ Handle Drill Drift ...............................................1

4688 Lubrication Stick, Drill Ease.................................................1

A-4950 Drill Sharpener, Hand.......................................................... 1

6564 Drill Block ...........................................................................3

45067 Backgage Filler Block Asm. (magnetic) ...............................2

45163 Spring - Drill Block ..............................................................1

8278-1 Knob...................................................................................2

Drill Head(s)-as orderedIncludes as Standard (per head)

CD-4-21/2

1

/4” (64mm) Hollow Drill .......................................................1

K-85 Drift Hole Cover ..................................................................1

SPECIFICATIONS

Drilling

Number of Drill Heads 2 to 5

Drill Bit Sizes Available

Center To Center Maximum 15” (38 cm)

Minimum Center Distance Between Heads 17/8” (8.7 cm)

Maximum Drilling Capacity (Pile Height) 21/2” (63 mm)

Strokes per Minute (Adjustable) Up to 18

Backgage Adjustment 0 to 5” (0 to 13 cm)

Vertical Adjustment of Individual Heads

Dimensions

Table 173/4” x 34” (45 cm x 86.4 cm)

Table Height 37” (94 cm)

Overall Height 56” (142 cm)

Floor Space Needed 36” x 36” (92 cm x 92 cm)

Net Weight (Approximate) 830 lbs (373.5 kg)

Shipping Weight (Approximate) 1000 lbs (453.6 kg)

Electrical

208/230 Volts (±10%)/18 Amps, 1 Phase, 60 Hz, AC. Service size 30 Amps.

Pump: 1/2 H.P. Spindle: 11/2 H.P.

Optional Motor: 208/230 Volts (±10%)/10 Amps, 3 Phase, AC. Service size 20 Amps.

460 Volts (±10%)/5 Amps, 3 Phase, AC. Service size 15 Amps.

Sound Emission

A-weighted sound pressure level measured in an enclosed room at 6 feet (183 cm)

above floor:

Machine running: Less than 70 dB

Machine drilling paper: 71 dB

1

/8” to 1/2” (3 mm to 13 mm)

1

/4” (6mm)

Challenge reserves the right to make changes to any product or specification without notice and without

incurring responsibility to existing units.

F.300-B/MS-5 DRILL/JULY 2000

5

Page 7

WARNING LABEL DEFINITIONS

SINGLE OPERATOR

SHOCK HAZARD

SHOCK HAZARD

Do not operate with more than one person.

Disconnect power before removing cover. Replace

cover before operation.

Disconnect power before removing cover. Replace

cover before operation.

HAZARDOUS AREA

6

Disconnect power before cleaning, servicing, or making adjustments not requiring power. Do not alter safety

guards or devices, they are for your protection. Replace all guards, do not operate with any guards removed.

F.300-B/MS-5 DRILL/JULY 2000

Page 8

INSTALLATION

Power Panel

NOTE: All guards and instruction plates are installed for your safety and information and must

remain on the machine as shipped from the factory.

Unpacking

Unless otherwise specified, this machine is packaged

completely assembled. The drill head(s) specified on

the order are shipped already installed. The machine

should be unpacked carefully by removing the packaging materials without damaging any of the machine

parts.

Immediately after uncrating, check off parts received

against the packing list. Also, examine for any physical signs of damage incurred during shipment. The

machine is inspected before and after crating at our

plant. The responsibility for filing a claim against the

carrier for damages incurred during shipment rests with

the receiver of the goods (FOB our factory).

The machine is held in place on its shipping skid with

plastic strapping material. The machine weighs approximately 850 lbs. (380 kg.), so be sure you have

sufficient equipment and manpower to handle the machine safely. Contact your Authorized Challenge Dealer

to arrange for installation.

Remove the protective coating of light oil from the

machined surfaces with a cleaning solvent, such as

type wash. Clean all other surfaces with a solvent such

as C.R.C.

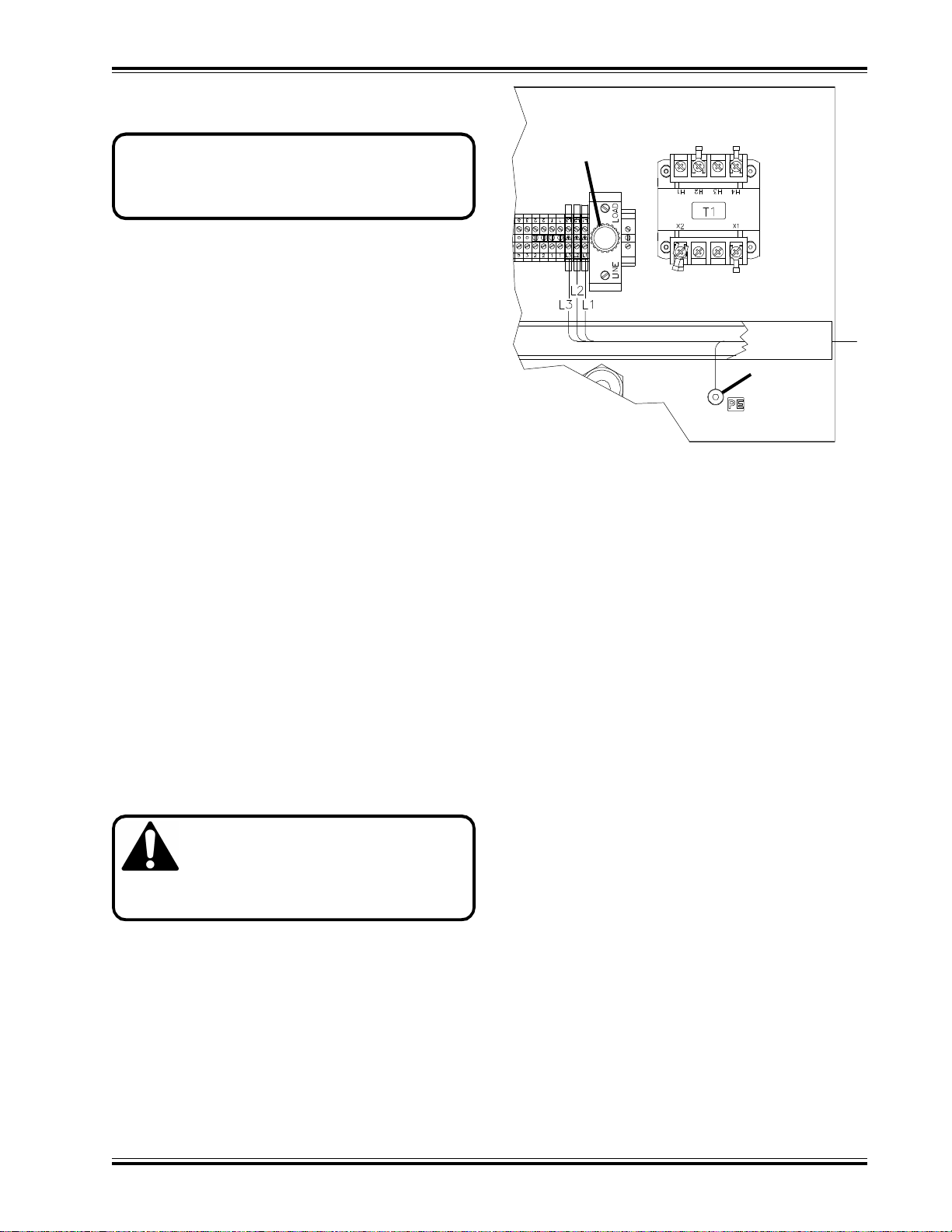

Power Hookup

WARNING: DISCONNECT POWER before cleaning, lubricating, servicing, or

making adjustments not requiring

power. Lock the disconnect switch in the OFF

position (see Power Lockout Procedure, pg. 4).

Fuse

Ground

(fig. 2)

and wired with #10 gauge wire. Optional three phase

motors are available also; 230/208 three phase, 20 amp

circuit, #12 GA. wire; and 460 volt three phase, 15 amp

circuit, with #14 GA. wire.

Remove the lower front cover. Remove the knockout

plug on the right side of the machine. Route the power

cord through the knockout hole and secure using a

conduit connector. Connect wire leads to terminals as

shown in fig 2 (single phase use L1 and L2 only). Connect the ground lead to the power panel as shown.

Replace the front cover.

On three phase machines, check to see that the motor

turns in the proper direction. Briefly turn the machine

on and off then look at the belt. If it turns in the opposite direction of the arrow on top of the motor, disconnect power to the machine and switch the connection

of any one wire with another. Check the rotation of the

motor again to be sure it turns in the proper direction.

SETUP INSTRUCTIONS

The machine is factory wired to the customer’s specification. It is the customer’s responsibility to wire the

motor for the current and voltage specified on the name

plate. It is important that the line voltage specified be

maintained. Failure to do so will result in improper operation of the machine (see trouble shooting section

for specific problems). It may be necessary to provide

a dedicated line for the machine.

The standard motor for this machine is a 208/230 single

phase. This machine should be on a 30 amp circuit

F.300-B/MS-5 DRILL/JULY 2000

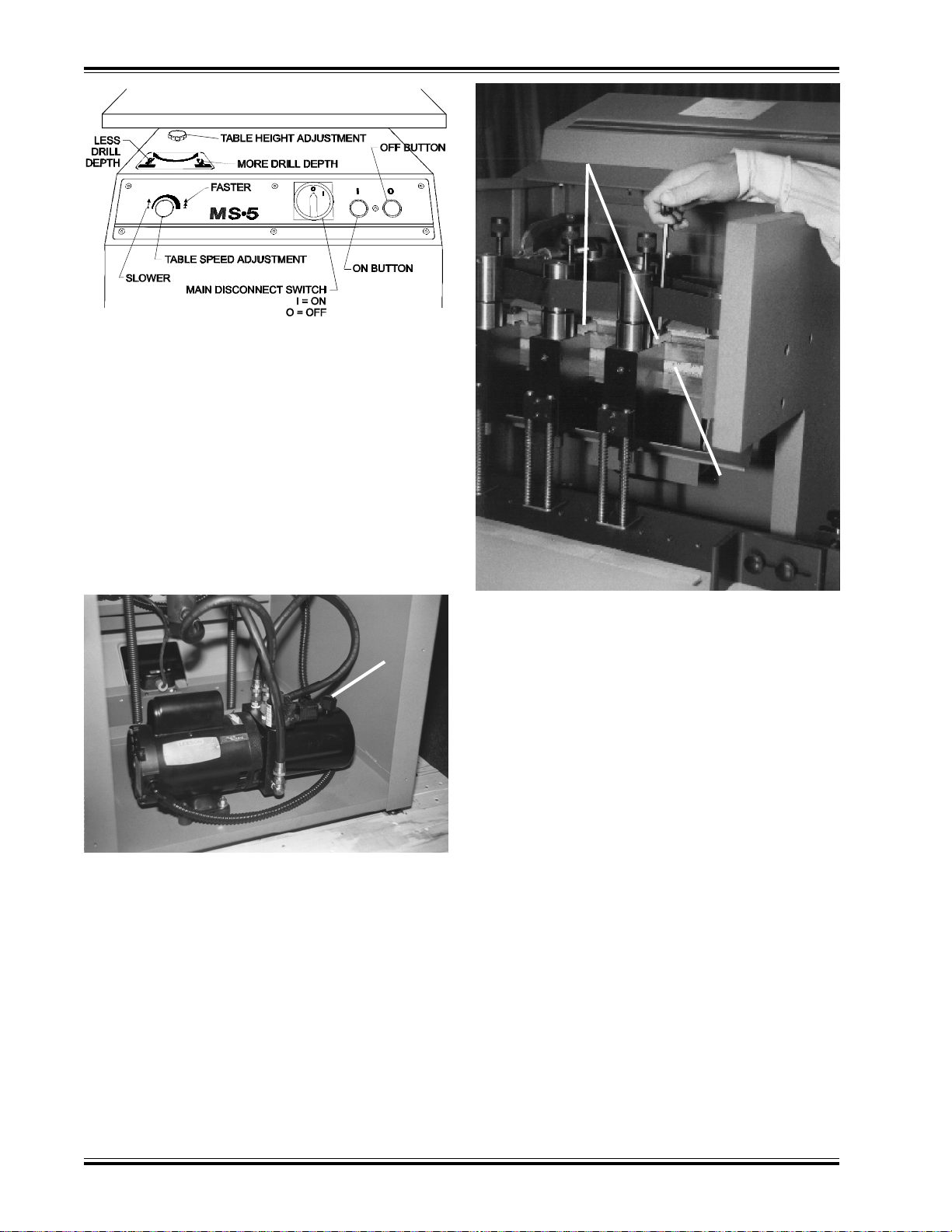

Starting the Machine

The power for this machine is supplied by two motors;

one is for the hydraulic power pack and the other is for

the spindle. The hydraulic motor drives the pump directly while the spindle motor drives the drill heads.

The two motors are started and stopped simultaneously

by “on” and “off” push-buttons located on the control

panel (the main disconnect switch must be in the “on”

position, see fig. 3). The on button has a collar guard

to reduce the possibility of accidental contact. Be sure

both motors are operating before trying to drill paper.

7

Page 9

(fig. 3)

Safety Interlock System

The MS-5 paper drill is equipped with a safety interlock system which prevents the machine from being

started with the front cover open or the optional drill

guard removed. If the cover is opened or the guard

removed when the drill is in operation, the motors will

shut off and must be restarted when the cover and

guard are back in place. This is a safety feature provided to prevent accidental contact with moving parts

and must not be tampered with.

Hydraulic Check

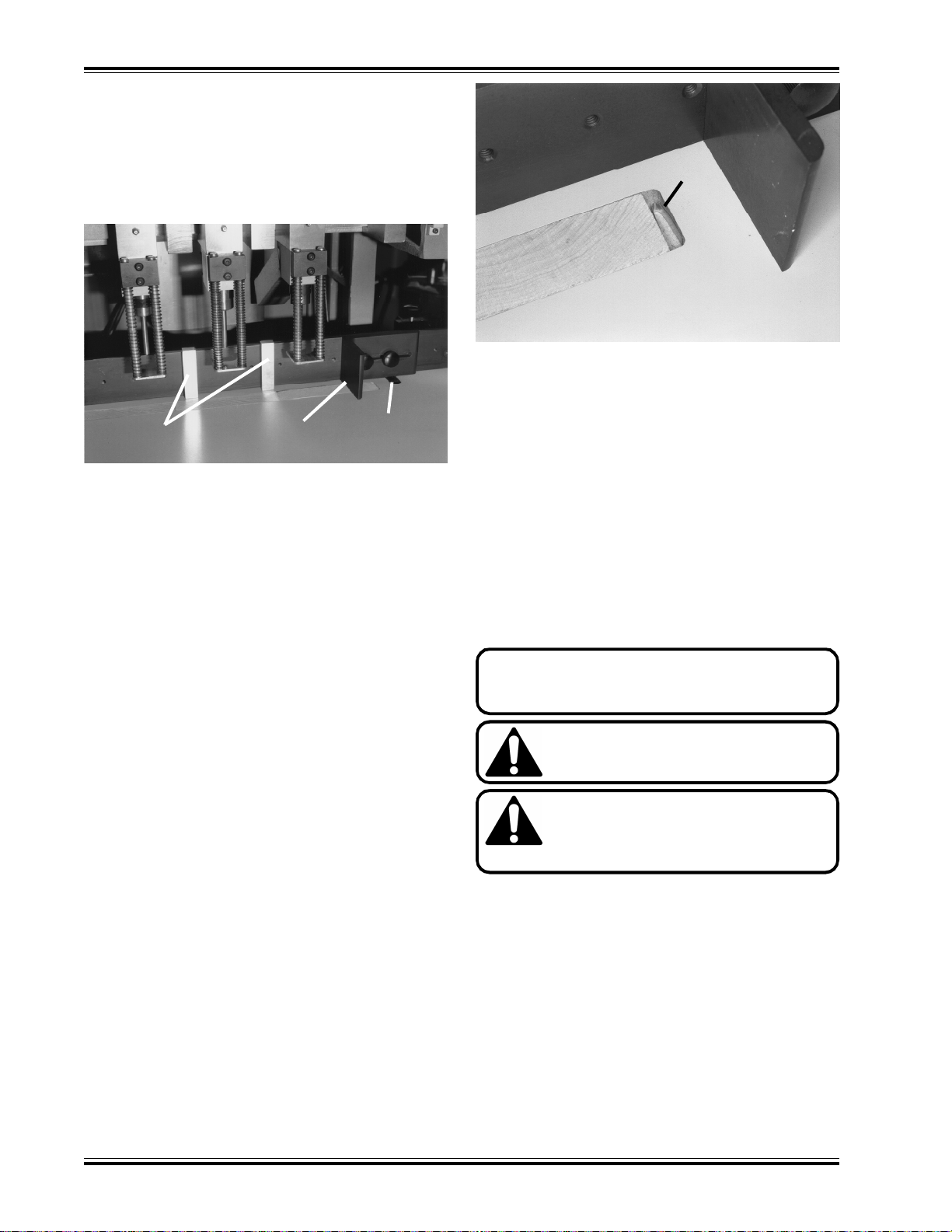

Dovetail

Clamps

Scale

(reads from out-

side edge of head)

Dipstick

Cap

(fig. 4)

Check the hydraulic oil supply for the proper level. This

check is made by removing the rear panel and unscrewing the dip stick located on the hydraulic tank (fig. 4).

The oil level should be no higher than ½” (13 mm) up

from the bottom of the dip stick to allow room for expansion of the oil when running. Recommended oils

and a cross-reference chart are found in the maintenance section of this manual.

Positioning Drill Heads

Drill heads ordered with your machine have been installed at the factory. One ¼” drill is supplied as standard equipment with each head unless otherwise speci-

(fig. 5)

fied. The MS-5 handles two to five drilling heads

mounted on a dovetail. Each head is independently

adjustable allowing a minimum center-to-center distance of 17/8" (47.6 cm) to a maximum center-to-center

distance of 15" (381 mm). NOTE: Any number of

heads (up to five) or combination of drill hole sizes

can be drilled at one time. However, when using

½” (13 mm) drills, it is recommended that no more

than three heads be used at the same time.

Always position heads so that the lift of paper being

drilled is centered on the table. Drill heads are mounted

on a dovetail and positioned by a scale mounted on

the front of the dovetail (fig. 5).

To move heads: raise the front cover and release the

drive belt tension by lifting the belt lever. Loosen the

socket head screws holding the head to the dovetail

and position the heads according to the scale (fig. 5).

The dovetail scale is calibrated from the center of the

table and is setup to give readings to the center of the

holes. The scale is read from the outside edge of the

drill heads. (Heads mounted to the right of center read

the scale from the right side, heads to the left of center

are read to the left of the head.) Once the heads are in

the desired position, tighten the socket head screws in

the dovetail.

8

F.300-B/MS-5 DRILL/JULY 2000

Page 10

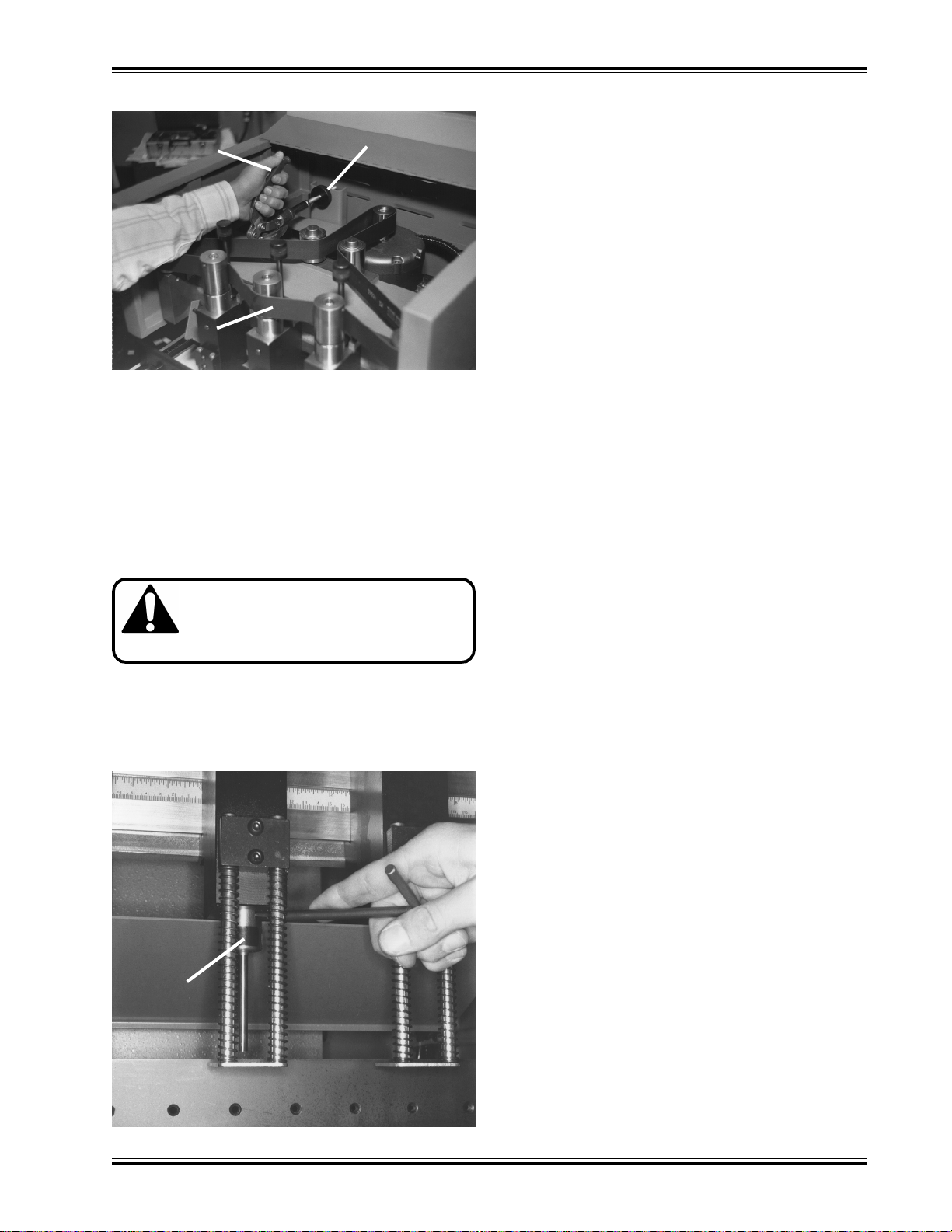

Drive Belt Adjustment

ers (black bands) are in place before operation (fig. 7).

Drive Belt

Adjusting

Lever

Drive Belt

Knurled Nut

(fig. 6)

Whenever changing head configurations or repositioning heads, reset the drill head belt tension. This is

done by backing off the knurled adjusting nut (fig. 6)

with the belt lever in the up position. Lower the lever

and turn the knurled nut out until it is tight. Raise the

lever and turn the knurled nut out an additional 1½ to 2

turns. Lower the lever and close the front cover.

Drill Installation

CAUTION: Always handle drills with

care to avoid severe lacerations. Even

dull drills are sharp enough to cause

lacerations.

Insert the tapered head of the hollow drills into the

spindles. Press the drills firmly into place so they do

not fall out when the motor is first started. To prevent

drill chips from flying out be sure that the drift hole cov-

Make sure the cutting stick blocks are in position before trying to drill paper.

Drill Removal

After use, drills may become seated making it difficult

to remove them. Use the T-handled drill drift tool to

free stuck drills. Uncover the drill drift hole by sliding

the cover down. Insert the drill drift with the flat edge

down and lift up to force the drill out of the head (fig. 7).

Stroke Adjustment (Table Height Adjustment)

Whenever installing new or resharpened drills, the table

stroke and drill height must be adjusted. Turn in (clockwise) the table height adjustment to lower the table

(fig. 3). Next, lift the front cover and back off the drill

head adjustment on each head. Place a single sheet

of paper under the drills and raise the table with the

foot treadle. Gradually raise the table height by turning the table height knob out (counter clockwise) and

pressing the foot treadle to check the table height.

Continue to do this until the first drill cuts through the

paper. Once the table height has been set, adjust the

drill heads individually until all the drills now cut through

the paper. When cutting full lifts, any further stroke

adjustment can now be made with the table height adjustment knob.

Note: The MS-5 uses 2” and 21/2” long drills. Be sure

to adjust the table stroke and/or drill height accordingly

when changing from one drill length to another.

Adjusting the Stroke Speed

Drift Hole

Cover

F.300-B/MS-5 DRILL/JULY 2000

(fig. 7)

The hydraulic unit is equipped with an adjustable valve

for regulating the table stroke speed (up and down

travel). Maximum speed is 18 strokes per minute which

is the speed used on the average run of work. Soft

stocks such as mimeographs, NCR, etc., are apt to

wrinkle at high speeds, and the speed should be regulated to a point where the best results are obtained.

This is found mostly by “trial and error.”

This adjustment is made by turning the adjustable valve

(located on the left side of the control panel) counterclockwise to reduce speed and clockwise to increase

speed.

Never turn the speed control knob more than 2½ turns

counterclockwise (slow speed) as the drill will not bottom and engage the return cycle. Less than one turn

counterclockwise should suffice for all drilling operations. Slow speeds may also cause the drills to “burn”

through the paper. If burning occurs, either increase

9

Page 11

the vertical speed, sharpen the drills or check for proper

belt tension.

Slower vertical speeds are recommended when drilling with the maximum number of heads.

Setting Up the Backgage

Filler Blocks Side Guide

Scales are provided in the table for setting up the backgage. The scales read in inches/mm and will give you

the dimension from the back of the sheet to the

centerline of the holes. Two magnetic filler blocks are

provided if it is necessary to drill within 1" of the edge

of the sheet, fig. 8. The blocks are ½” (13 mm) thick

and when used, ½” (13 mm) must be subtracted from

the scale reading to give the set up dimension. Example: To drill 3/4" (19 mm) from the edge of the sheet,

install the filler blocks and set the backgage to 1¼” (32

mm) on the scale.

Using the Side Guide(s)

The adjustment for the location of the holes to the top

or bottom edge of the sheet is provided by a sturdy

side guide. The backgage has a series of threaded

holes to which the side guide is attached with two

threaded knobs. In addition, the side guide is slotted

to fine adjust the position of the paper. When setting

up drill head positions and side guides, always try to

keep the paper centered on the table as much as possible.

Two side guides are provided as standard equipment

so stock may be drilled to the left or right or for setting

up multiple drilling sequences for more than five holes.

Drill Blocks

Place the drill blocks in the slot in the table. They are

held tightly in place by pinching the drill block spring

and placing it in the slot in the table at the end of the

drill blocks (fig 9).

Table

Scale

(fig. 8)

Spring

Drill Block

(fig. 9)

The drill blocks are removed by simply lifting them from

their groove in the table. They should set flush with

the table and may be shimmed if necessary. For best

use and longest life, turn them end for end, top and

bottom.

Emptying the Drill Chips

A large capacity chip bag attached to the rear of the

machine, can be easily taken off and emptied by slipping it off the two hooks provided.

OPERATION

For EMERGENCY STOP release foot from

treadle and turn main disconnect switch to “off”

position.

CAUTION: NEVER REST YOUR FOOT

ON THE TREADLE WITHOUT INTENDING TO BRING UP THE TABLE.

CAUTION: NEVER PUT HANDS OR

FINGERS NEAR DRILL HEADS WHEN

OPERATION THE MACHINE. SEVERE

LACERATIONS COULD RESULT.

Pressing the foot treadle activates the hydraulic unit

bringing the table and stock up to the drills and returning back again automatically. The pedal must be released and depressed again before the next drill cycle

assuring full control and allowing no repeat stroke.

Releasing the pedal at any time stops the table movement and returns it to its normal down position, thus

preventing costly errors.

The vertical movement of the table is actuated by the

hydraulic unit. Depressing the foot treadle sets the

hydraulic unit into action. Keeping your foot on the

10

F.300-B/MS-5 DRILL/JULY 2000

Page 12

treadle allows the drills to drill through the entire lift of

stock and reach the bottom of their stroke. At this point,

the solenoid is de-energized and the valve released,

relieving the pressure off of the cylinder and allowing

the table to return to the down position.

DRILLING TIPS

Important! To prevent the drill from overheating, always avoid drilling too slowly. The table should be brought

up as rapidly as possible allowing the drills to easily cut through the paper. Also, adjust the vertical table guide to

return the table to the down position as rapidly as possible to avoid spinning the drills in the stock.

Slotted Holes - Instead of punching slotted holes for five and seven hole universal binding work, save time and

cost by drilling a 1/2 inch diameter hole in place of the slot. The slot is only intended to allow the post or ring to be

used in either location, and the large hole permits this.

Plastic Bindings - Drilling holes for plastic bindings, instead of punching them, is practical and saves a great

deal of time, particularly on long run jobs.

Keep Drills Sharp - A dull drill is the major cause of drill breakage and production tie-ups. Usually after three

hours of drilling, depending on the type of paper being processed, the drill should be sharpened. A dull drill

results in poor quality work.

Keep Drills Clean - A dirty and rusty drill will not permit the free upward passage of the drill chips. Pressure built

up by a clogged drill will split or break the drill. To keep it free from dirt or rust, clean the drill of all chips after each

use and apply a light oil to the inside and outside. Drills should be cleaned out immediately after each use. This

is particularly true if a coated or varnished stock has been drilled. On these jobs the coating on the chips

frequently fuse the chips into one solid mass when the drill cools, causing breakage the next time the drill is used.

Lubricate Drills - Lubrication assists in the passage of the chips and helps avoid overheating of the drills. Use

readily available stick lubricants for this purpose. Hold the end of the stick against the side of the rotating drill. Be

sure to touch the cutting edge with the lubricant also. Wipe off excess oil before drilling. CARE MUST ALWAYS

BE TAKEN WHEN HANDLING DRILLS.

Keep Spindle Clean - Clean out the drill spindle frequently. This will prevent any buildup in the spindle of the

drill.

Set the Drills Correctly - Do not cut too deeply into the cutting block. The drill should just touch the block and

cleanly cut through the bottom sheet. During drilling, do not set the drill deeper into the block but change the

position of the block frequently. Drilling deeper into the block dulls the drills quickly. Use a piece of chipboard

underneath your stock. This will make handling the stock easier and will ensure that the last sheet is cut cleanly

through.

Check for Drill Wobble - If spindles are badly worn or bent through misadjustment, have them replaced immediately. A wobbly or loosely held drill will break.

Check Your Drill Sharpener - The cutting edge of the sharpening bit should be inspected frequently to make

certain that it is sharp and free of nicks. Never let a drill drop onto the sharpening bit. It will chip the sharpening

edge. Use gentle pressure when sharpening - let the sharpening bit do the work. Check the sharpness of the drill

after sharpening. The cutting edge should be razor sharp.

Just a little time and effort taken with each use of your paper drilling machine should result in trouble free operation over many years.

F.300-B/MS-5 DRILL/JULY 2000

11

Page 13

ACCESSORIES FOR CHALLENGE PAPER DRILLING MACHINES

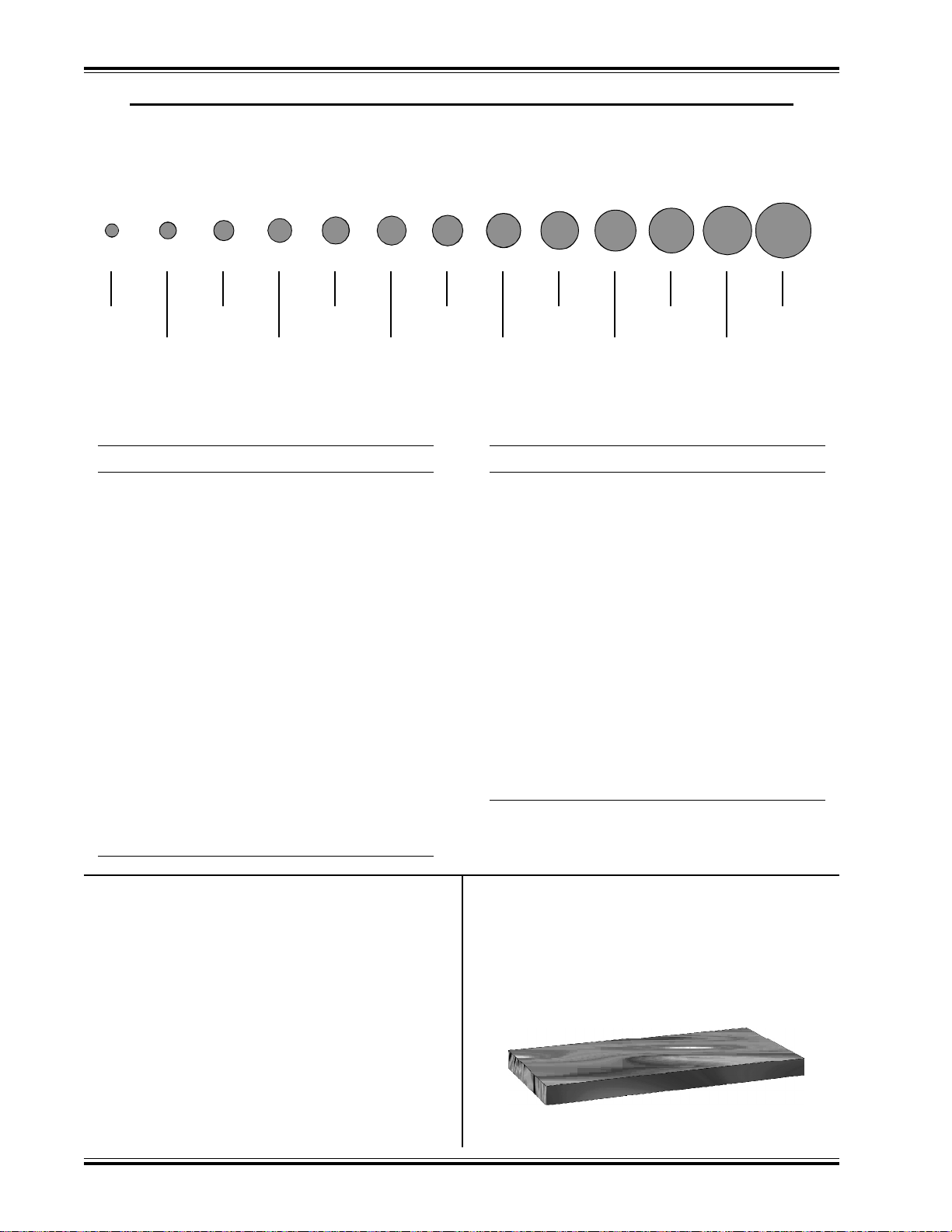

Genuine Challenge Hollow Drills

In 13 Standard Sizes For Every Drilling Need

1/8” 3/16” 1/4” 9/32”

5/32” 7/32”

17

/64” 5/16” 3/8” 7/16”

11

/32”

13

/32” 1/2”

All drills carried in stock by local Challenge dealers (17/32” & 9/16” available by special order).

HOLLOW DRILLS

Diameter x Drill Capacity Cat. No.

1

/8” x 5/8” (3.2 x 16 mm) ................... CD-2-3

5

/32” x 11/8” (4 x 29 mm) ................... CD-52

3

/16” x 15/8“ (4.8 x 41 mm) ................ CD-3

7

/32” x 2” (5.6 x 51 mm) ................... CD-72

1

/4” x 2” (6.3 x 51 mm)..................... CD-4

1

/4” x 21/2” (6.3 x 63.5 mm)............... CD-4-21/2

17

/64” x 2” (6.7 x 51 mm) .................. CD-174

9

/32” x 2” (7.1 x 51 mm) ................... CD-92

5

/16” x 2” (7.9 x 51 mm) ................... CD-5

5

/16” x 21/2” (7.9 x 63.5 mm) ............. CD-5-21/2

11

/32” x 2” (8.7 x 51 mm) .................. CD-112

3

/8” x 2” (9.5 x 51 mm)..................... CD-6

3

/8” x 21/2” (9.5 x 63.5 mm)............... CD-6-21/2

13

/32” x 2” (10.3 x 51 mm) ................ CD-132

7

/16” x 2” (11.1 x 51 mm).................. CD-7

1

/2” x 2” (12.7 x 51 mm)................... CD-8

1

/2” x 21/2” (12.7 x 63.5 mm)............. CD-8-21/2

TEFLON COATED HOLLOW DRILLS

Diameter x Drill Capacity Cat. No.

1

/8” x 5/8” (3.2 x 16 mm) ................... TCD-2-3

5

/32” x 11/8” (4 x 29 mm) ................... TCD-52

3

/16” x 15/8“ (4.8 x 41 mm) ................ TCD-3

7

/32” x 2” (5.6 x 51 mm) ................... TCD-72

1

/4” x 2” (6.3 x 51 mm)..................... TCD-4

1

/4” x 21/2” (6.3 x 63.5 mm)............... TCD-4-21/2

17

/64” x 2” (6.7 x 51 mm) .................. TCD-174

9

/32” x 2” (7.1 x 51 mm) ................... TCD-92

5

/16” x 2” (7.9 x 51 mm) ................... TCD-5

5

/16” x 21/2” (7.9 x 63.5 mm) ............. TCD-5-21/2

11

/32” x 2” (8.7 x 51 mm) .................. TCD-112

3

/8” x 2” (9.5 x 51 mm)..................... TCD-6

3

/8” x 21/2” (9.5 x 63.5 mm)............... TCD-6-21/2

13

/32” x 2” (10.3 x 51 mm) ................ TCD-132

7

/16” x 2” (11.1 x 51 mm).................. TCD-7

1

/2” x 2” (12.7 x 51 mm)................... TCD-8

1

/2” x 21/2” (12.7 x 63.5 mm)............. TCD-8-21/2

Special order drills

17

/32” x 2” (13.5 x 51 mm) ................ CD-172

9

/16” x 2” (14.3 x 51 mm).................. CD-9

Challenge Drill-Ease Lubricant

Stick

Cat. No. 4688

This lubricating stick provides a dry stainless lubricant

which has many uses throughout the printing plant. It

is specially recommended for use on hollow drills for

easier drilling, particularly when drilling clay coated

stock. It eliminates binding and excessive heating of

the drill. Will not discolor the stock.

CARE MUST ALWAYS BE TAKEN WHEN USING

STICK AND HANDLING DRILLS.

12

Challenge Drilling Blocks

Cat. No. A-6626-24

These Challenge 11/4 x 6” End-Wood Drilling Blocks

are for round hole drilling operations. Sold in packages of 24.

F.300-B/MS-5 DRILL/JULY 2000

Page 14

ACCESSORIES FOR CHALLENGE PAPER DRILLING MACHINES

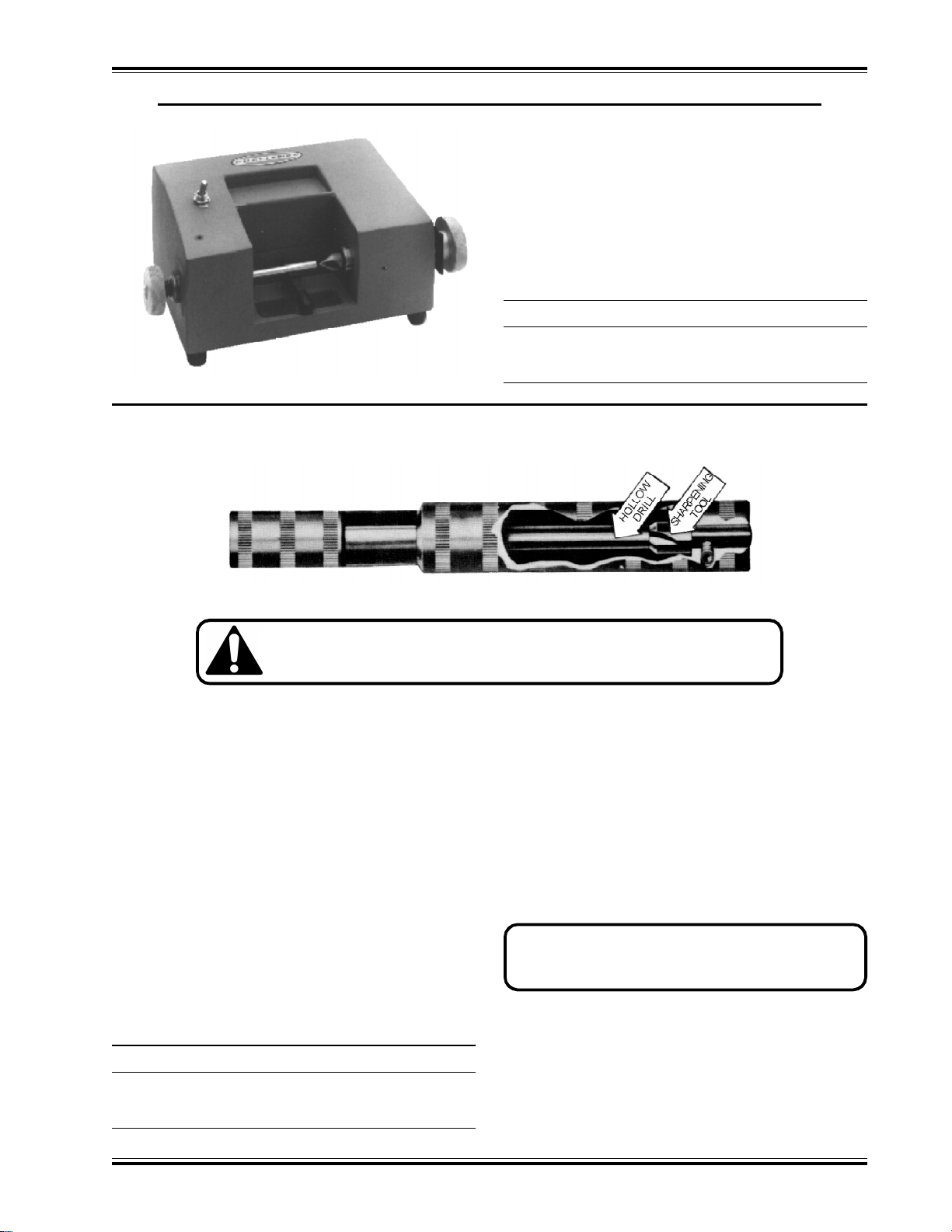

Challenge Power Sharpener

(115 Volt / 60 HZ only)

Cat. No. A-6450

A power drill sharpener. Plugs into any standard 115

volt, 60 cycle, AC outlet. Handles Challenge and other

taper shank drills. Adaptors also available for handling

practically all other makes.

Item Cat. No.

Replacement Cutting Bit 6469

Resharpening Service - Your Old Bit 6469-R

HOLLOW DRILL SHARPENER For fast, easy drill sharpening

CAUTION: Drills are sharp even after use. Be careful to keep edge

away from your body. To prevent personal injury and/or damage to

the drill, ALWAYS keep drills in protected area.

Here’s a unit that really makes drill sharpening easy.

All you do is place the hollow drill in the tapered end of

the drill holder, insert the unit on the cylinder, then turn

two or three times...and you have a perfectly sharpened drill.

This Challenge Hollow Drill Sharpener can pay for itself many times over through longer drill life, easier,

faster drilling, and less sharpening time. All sizes of

drills from 1/8 to 1/2 inch in diameter can be sharpened.

The drill sharpener automatically puts just the right

amount of bevel on the hollow drill for the best drilling

results. It’s self centering, too, so that the center of the

sharpening bit exactly meets the center of the hollow

drill. The drill sharpener also has a replaceable sharpening bit.

Item Cat. No.

Challenge Hollow Drill Sharpener A-4950

Extra Cutting Bit 4952

Instructions:

NOTE: Always handle carefully

1. Be sure to wipe off all grease before using the

sharpener.

2. Remove any paper chips from the hollow drill.

3. Place the hollow drill in the drill holder section.

Insert the sharpening section, being very careful

to bring the drill and cutting tool together without

bumping.

NOTE: The cutting tool is made of a glass hard

material and may be chipped by careless handling.

4. Turn the cutting unit clockwise, maintaining an even

pressure until the hollow drill is sharpened (usually two or three turns). The cutting tool seldom

requires regrinding, but when it does, the bit should

be sent to the factory as regrinding must be done

on a diamond wheel.

F.300-B/MS-5 DRILL/JULY 2000

13

Page 15

ACCESSORIES FOR CHALLENGE PAPER DRILLING MACHINES

Optional Narrow Drill Head Assembly, p/n: 45200

For drilling holes with a center to center distance as low as 1-3/8”/3.5 cm

14

F.300-B/MS-5 DRILL/JULY 2000

Page 16

NOTICE

The instructions on the

following pages are for the

use of trained service

personnel only!

Attempting to perform

repair and replacement

procedures without proper

training may cause machine

damage or operator injury!

PARTS CUSTOMERS: The Challenge Machinery Company provides parts with the express understanding that they are to replace parts found missing or no longer serviceable on equipment designed

and/or manufactured by Challenge. The Challenge Machinery Company assumes no liability for any

modification or alteration to any Challenge products, and any such modification or alteration to any

Challenge products is not authorized by The Challenge Machinery Company. Any modification or

alteration of any Challenge product will void any remaining warranty.

F.300-B/MS-5 DRILL/JULY 2000

15

Page 17

TROUBLESHOOTING

WARNING: DISCONNECT THE POWER AND LOCK IT OUT whenever working on the machine

unless the instructions specifically require the machine to be powered (see Power Lockout

Procedure, page 4). Several of the following tests may require the machine to be operational

for checking and adjusting. Be very careful that tools and other people are clear of moving parts, and

that the drill is not accidentally operated while adjustments are being made.

CAUTION: Whenever repairing hydraulic components, loosen connections slowly to bleed

off any trapped pressure.

Problem Area to Check Solution

1. No power Power to machine Connect Power

Main Disconnect Switch Turn to ON position

Interlocking Guards Replace guards

Fuse blown Replace fuse - see fig. 2 page 7

2. Lack of power Relief valve in pump may be bad Clean or replace relief valve or pump.

or have dirt in it.

Check oil level - may be low. Add oil.

Check voltage at machine - may Remove other machinery on line or

be low. provide a dedicated line.

3. Spindle motor stalls Dull drills. Sharpen drills.

Check for low voltage. (See above).

Check drive pulley and belt for (See SETUP INSTRUCTIONS in main

tightness. section for adjustment).

Check for paper plugging drills Clean out hollow drills - We recom-

mend cleaning and soaking drills in

oil overnight.

4. Table stroke won’t adjust Stroke Adjustment Chain off Remove back panel and replace

sprockets. chain (fig. 10).

16

Table Lift Rod

(fig. 10)

F.300-B/MS-5 DRILL/JULY 2000

Page 18

ROUTINE MAINTENANCE

General

Production losses can be reduced if good maintenance

practices are followed. The following suggestions may

be helpful:

1. Recognize the fact that the user of hydraulic equipment has more control over maintenance than the

manufacturer.

2. Operators should be familiar with use, care, and

limitations of the equipment. ALL OPERATORS

SHOULD READ THIS MANUAL COMPLETELY.

3. Use properly trained maintenance personnel.

4. Establish a program of systematic preventative

care for your equipment or put this machine on an

existing preventative maintenance program.

5. Analyze and isolate trouble before having any part

of the equipment dismantled.

Lock Nut

6. Be aware of how your machine should sound and

perform. If the machine is not operating properly

or if it doesn’t “sound right”, stop running your job

immediately and try to identify the problem.

7. Call the dealer for any problems that cannot be

handled by your own personnel.

Vertical Table Guide

CAUTION: PINCH POINT. This adjustment requires a guard to be removed

for adjustment and testing purposes

only. Be very careful while adjusting. Replace

all guards before operating. Do not operate

machine with any guards removed.

The vertical table guide is located on the right side of

the machine beneath the table and may need periodic

adjustment to keep the table steady yet allow it and

stock to fall away from the drills as rapidly as possible.

The table down stroke is controlled by a return spring.

Remove the guide block cover guard. Tighten the two

guide block lock nuts (fig. 11) and power the table up

by pressing the foot treadle. Gradually back the locknuts off evenly until the table releases freely. Retest

the upstroke and table return, and check the table for

side play. Replace the guard.

CAUTION: PINCH POINT.

Replace guard after adjusting.

(fig. 11)

SERVICE CHECKLIST

Daily

1. Keep drills sharp!

2. Lubricate the hollow drill frequently with the lubricating stick provided.

3. For better hollow drill life, remove the drills when

not in use and soak in light oil. Wipe off excess oil

before drilling.

4. Wipe off excess grease from the drill heads and

idlers.

Weekly (or every 40 hours of operation)

1. Check belt wear/tension.

2. Oil the table lift rod between the table and stand

with light oil (fig. 10).

F.300-B/MS-5 DRILL/JULY 2000

17

Page 19

Monthly

1. Oil the table height adjusting knob shaft with a light

machine oil. Wipe off excess oil.

2. Check the hydraulic oil supply for the proper level.

This check is made by removing the rear panel

and removing the dip stick/plug (pg. 8, fig. 3). The

oil should be visible on the dip stick but no higher

than 1/2“ up from the bottom when cool. This allows for expansion of the oil when hot. Use only

one of the recommended oils or an ISO VG 100

Hydraulic Fluid equivalent. Oils other than the recommended type will cause seals, cups and O-rings

to deteriorate. See Chart & CAUTION.

Yearly

1. Check all adjustments.

2. Tighten all screws.

3. Change hydraulic oil in reservoir. Oil may have to

be changed more often if contamination of any kind

gets in the oil.

Super Hydraulic 100 Conoco

Nuto H-100 Exxon

Harmony 100 AW Gulf

HO 2A Hydraulic Oil Lubriplate

DTE No. 18 Mobil

Pennzoil AW 100 Pennzoil

Magnus A Oil 215 Phillips

Tellus 100 Shell

Energol HLP 100 Sohio

Industron 100 Std. Oil Indiana/Boron

Sunvis 851 WR Sunoco

Rando HD 100 Texaco

Unax AW 100 Union Oil Co.

Hydraulic

Through normal use, hydraulic systems gum up and

seals wear. Signs of wear are hydraulic leaks and erratic operation of the vertical speed. Check with your

Authorized Challenge Dealer for a current repair and/

or replacement policy.

Drill Heads

Through normal use, bearings will wear and need replacing. Signs of wear are excessive noise, heat, or

loose spindles.

CAUTION: NEVER USE Automatic

Transmission oil or brake fluid as a

substitute! Oils other than the recommended type will cause seals, cups and O-rings

to deteriorate. Unsafe operating conditions will

result.

Recommended Oils

Oil Name Distributor

Rykon No. 100 AMOCO

Duro AW Oil 465 Arco

AW Machine Oil 100 Chevron

Pacemaker XD No. 100 Citgo

18

F.300-B/MS-5 DRILL/JULY 2000

Page 20

NOTES

F.300-B/MS-5 DRILL/JULY 2000

19

Page 21

MAIN ASSEMBLY - FRONT VIEW

45000 SHEET 1 REV L

20

F.300-B/MS-5 DRILL/JULY 2000

Page 22

MAIN ASSEMBLY - FRONT VIEW

45000 SHEET 1 REV L

F.300-B/MS-5 DRILL/JULY 2000

21

Page 23

MAIN ASSEMBLY - SIDE VIEW

45000 SHEET 2 REV K (S/N 975272 & BELOW)

22

F.300-B/MS-5 DRILL/JULY 2000

Page 24

MAIN ASSEMBLY - SIDE VIEW

45000 SHEET 2 REV K (S/N 975272 & BELOW)

F.300-B/MS-5 DRILL/JULY 2000

23

Page 25

MAIN ASSEMBLY - SIDE VIEW

45000 SHEET 2 REV L (S/N 975273 & ABOVE)

24

F.300-B/MS-5 DRILL/JULY 2000

Page 26

MAIN ASSEMBLY - SIDE VIEW

45000 SHEET 2 REV L (S/N 975272 & ABOVE)

F.300-B/MS-5 DRILL/JULY 2000

25

Page 27

MAIN ASSEMBLY- TOP VIEW

45000 SHEET 3 REV F (S/N 985049 and Down)

26

F.300-B/MS-5 DRILL/JULY 2000

Page 28

MAIN ASSEMBLY- TOP VIEW

45000 SHEET 3 REV G (S/N 985050 and Up)

F.300-B/MS-5 DRILL/JULY 2000

27

Page 29

(KIT FOR 60 HZ MACHINES: K-45180)

45000 SHEET 4 REV A (S/N: 975272 & BELOW)

MAIN ASSEMBLY - DRILL GUARD (50 HZ ONLY)

28

F.300-B/MS-5 DRILL/JULY 2000

Page 30

45000 SHEET 4 REV C (S/N: 975273 & ABOVE)

(KIT FOR 60 HZ MACHINES: K-45180)

MAIN ASSEMBLY - DRILL GUARD (50 HZ ONLY)

F.300-B/MS-5 DRILL/JULY 2000

29

Page 31

BELT INSTALLATION

30

F.300-B/MS-5 DRILL/JULY 2000

Page 32

NOTES

F.300-B/MS-5 DRILL/JULY 2000

31

Page 33

HYDRAULIC POWER UNIT ASSEMBLY

H-378-1 (50/60 HZ 1 PHASE)

H-407-1 (50/60 HZ 3 PHASE)

32

F.300-B/MS-5 DRILL/JULY 2000

Page 34

HYDRAULIC SEQUENCE OF OPERATION

NOTE: PLEASE SEE SECTION ON THE ELECTRICAL SEQUENCE OF OPERATION FOR MORE

DETAILS

HYDRAULIC SEQUENCE OF OPERATION

A. Pump relay is energized providing power to the

hydraulic motor.

B. Energize the UP solenoid (the table is sent up).

C. De-energize the UP solenoid (the table is sent

down).

HYDRAULIC SCHEMATIC REFERENCES

(Drawing H-378 & H-407)

Once the pump relay (RL1) is energized, the hydraulic

motor runs with the UP solenoid de-energized. This

allows oil to flow through the UP solenoid valve (Item

#6) and back to the tank. The table remains in the

down position.

When the UP solenoid is energized, oil stops flowing

through the UP solenoid valve (Item #6), and flows to

the table up (TU) port of the table speed adjustment

valve (Item #9) and to the table up (TU) port of the

cylinder. Oil exits the table speed adjustment valve

(Item #9) through the table speed (TS) port and then

returns to the tank. The amount of oil that flows through

the valve affects how much oil flows to the cylinder.

This determines the speed of the cylinder piston. As

the piston moves up, excess oil in the cylinder is forced

out the excess (EX) cylinder port and back to the tank.

When the UP solenoid is de-energized, oil from the

pump flows freely through the UP solenoid valve (Item

#6) and back to the tank. This allows oil to flow out of

the cylinder through the table up (TU) cylinder port,

through the UP solenoid valve (Item #6), and back to

the tank. Two springs force the piston down. The pump

relay (RL1) remains energized.

F.300-B/MS-5 DRILL/JULY 2000

33

Page 35

E-2384-1 REV A

BASIC MACHINE SCHEMATIC

34

F.300-B/MS-5 DRILL/JULY 2000

Page 36

ELECTRICAL SEQUENCE OF OPERATION

NOTE: PLEASE SEE SECTION ON THE HYDRAULIC SEQUENCE OF OPERATION FOR MORE

DETAILS

ELECTRICAL SEQUENCE OF OPERATION

A. Close the main disconnect switch (MD).

B. Press the ON button (START).

C. Press the foot switch (FOOTSWITCH).

ELECTRICAL SCHEMATIC REFERENCES

(Drawing E-2384-1)

While the main disconnect switch MD is closed, power

is brought to transformer T1, provided fuse F1 is conductive. Transformer T1 provides power to the hydraulic motor and spindle motor contactors RL1. The

contactors are open and therefore the motors will not

run. Opening the main disconnect switch MD at any

time cuts power to transformer T1.

When the START switch is closed, the hydraulic motor

and spindle motor relay coil RL1 will energize, provided

interlock switches S1 and S2 are closed. Power is

then supplied to the hydraulic and spindle motors. RL1

remains energized until the STOP switch or any interlock switch is opened.

While the FOOTSWITCH switch is closed, power is

brought to the UP solenoid, which raises the table.

When the table reaches the top, the TAKE UP STOP

switch closes, causing relay coil RL2 to energize. While

RL2 is energized, the UP solenoid becomes de-energized, which lowers the table. Opening the

FOOTSWITCH switch de-energizes RL2 and the UP

solenoid.

F.300-B/MS-5 DRILL/JULY 2000

35

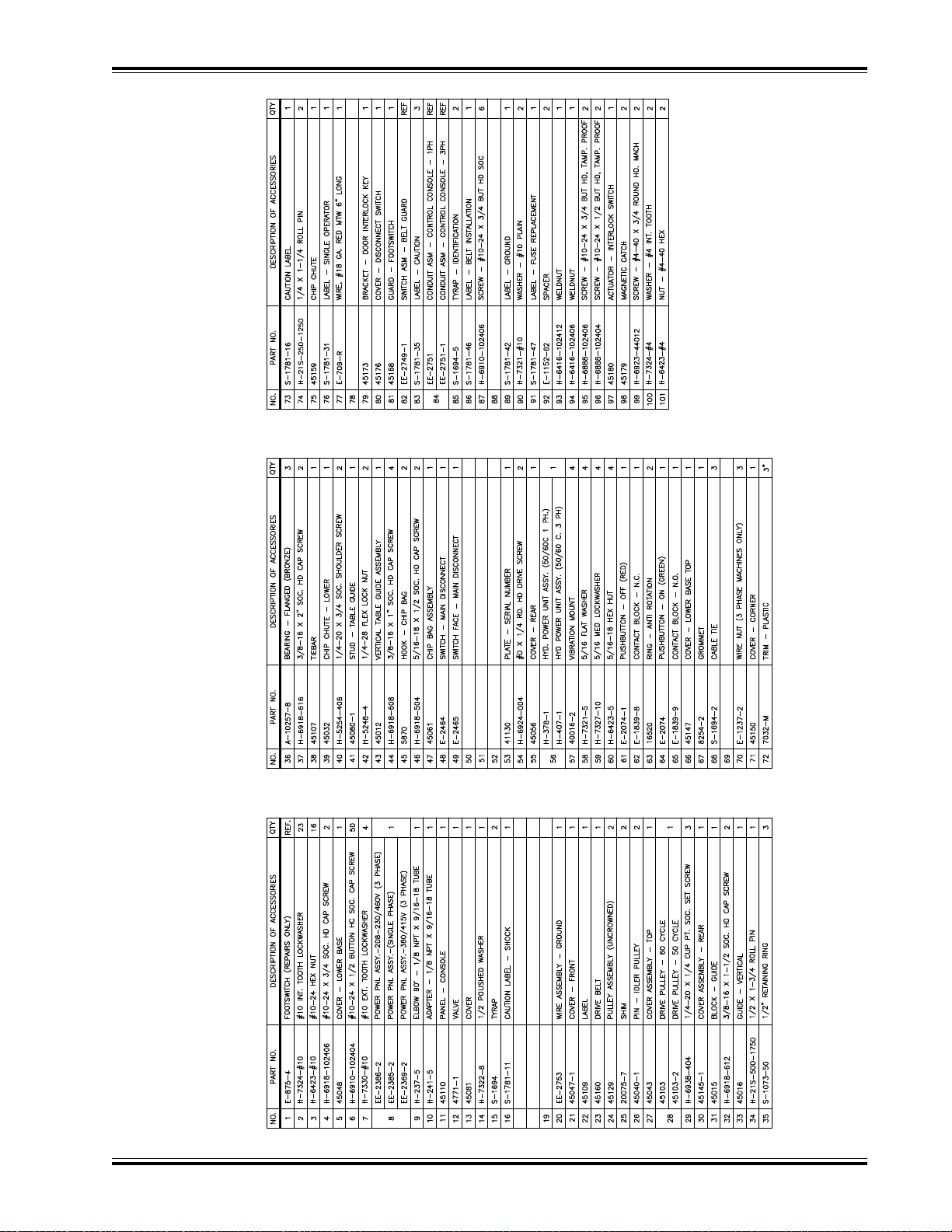

Page 37

EE-2385-2

1PH 208/230 V 50/60 Hz

POWER PANEL ASSEMBLY

36

F.300-B/MS-5 DRILL/JULY 2000

Page 38

EE-2385-2

1PH 208/230 V 50/60 Hz

POWER PANEL ASSEMBLY

F.300-B/MS-5 DRILL/JULY 2000

37

Page 39

EE-2386-2

POWER PANEL ASSEMBLY

3PH 208/230V 50/60Hz/460 V 60 Hz

38

F.300-B/MS-5 DRILL/JULY 2000

Page 40

EE-2386-2

POWER PANEL ASSEMBLY

3PH 208/230V 50/60Hz/460 V 60 Hz

F.300-B/MS-5 DRILL/JULY 2000

39

Page 41

EE-2369-2

3PH 380/415 V 50 Hz

POWER PANEL ASSEMBLY

40

F.300-B/MS-5 DRILL/JULY 2000

Page 42

EE-2369-2

3PH 380/415 V 50 Hz

POWER PANEL ASSEMBLY

F.300-B/MS-5 DRILL/JULY 2000

41

Page 43

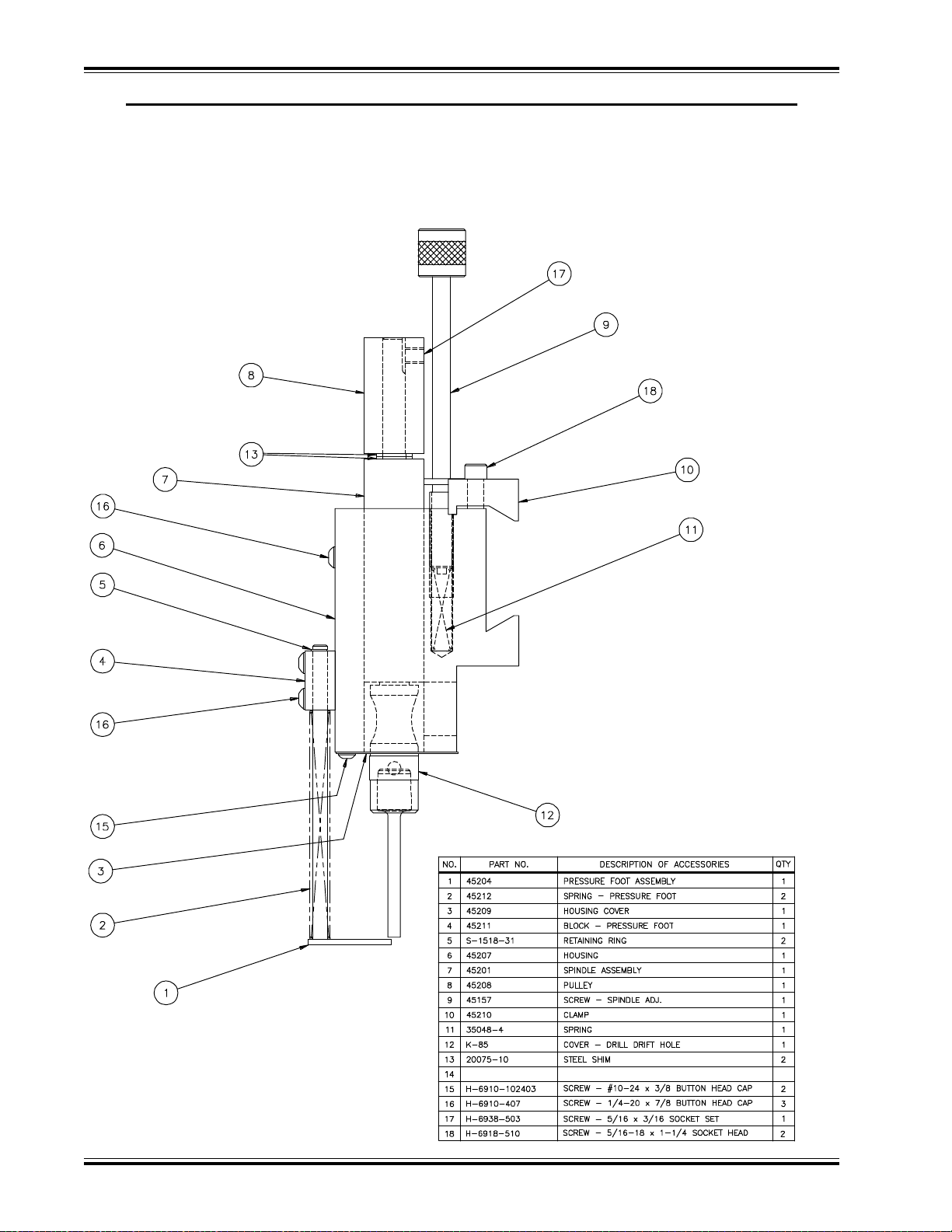

DRILL HEAD ASSEMBLY

45152

42

F.300-B/MS-5 DRILL/JULY 2000

Page 44

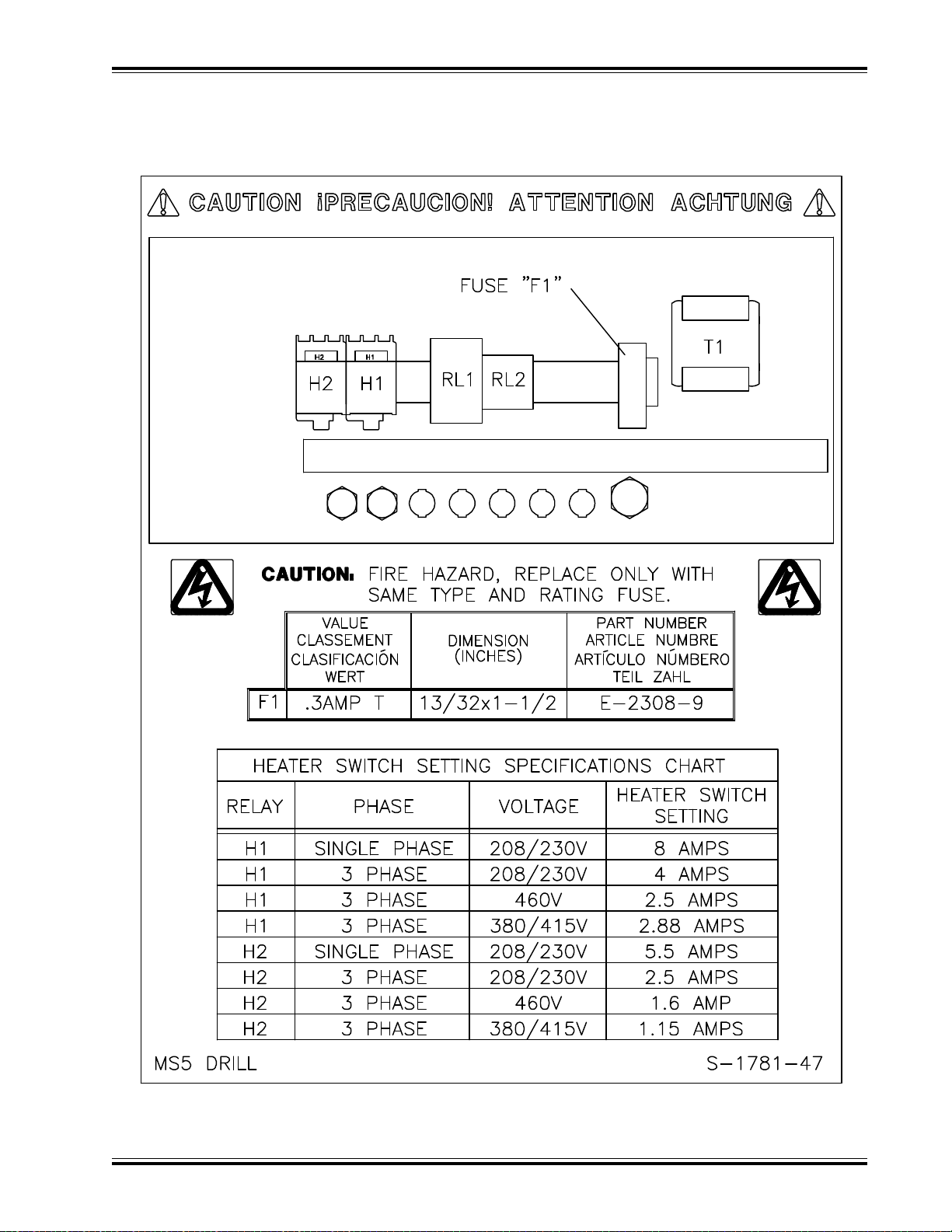

POWER PANEL LABEL

50/60 Hz REV A

F.300-B/MS-5 DRILL/JULY 2000

43

Page 45

A-4851-48

TWO HAND CONTROL OPTION

44

F.300-B/MS-5 DRILL/JULY 2000

Page 46

A-4851-48

TWO HAND CONTROL OPTION

F.300-B/MS-5 DRILL/JULY 2000

45

Page 47

K-45180 REV A

DRILL GUARD KIT

46

F.300-B/MS-5 DRILL/JULY 2000

Page 48

K-45181 (S/N: 975272 & BELOW ONLY)

BELT GUARD SWITCH REPLACEMENT KIT

F.300-B/MS-5 DRILL/JULY 2000

47

Page 49

K-45182 (S/N: 975272 & BELOW ONLY)

DRILL GUARD SWITCH REPLACEMENT KIT

48

F.300-B/MS-5 DRILL/JULY 2000

Page 50

SAFETY SYSTEM TESTS

Machine manufacturer _______________ Model ____________

Serial Number __________________

Frequency of test: THESE TESTS SHOULD BE PERFORMED AT THE BEGINNING OF EACH WORK DAY.

Connect power to the machine, turn the main disconnect switch to the “on” position, and press the “on” button.

Check both motors to see that they are operating.

Test #1:With the machine running, open the upper front cover. This should stop all motion. Close front cover.

Test #2:With the machine running, remove the front guard. This should stop all motion. Replace guard.

If the motors continue to run during either test, readjustment or repair is needed.

Please enter date and initials for both tests.

Date ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______

Test 1 ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______

Test 2 ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______

Date ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______

Test 1 ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______

Test 2 ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______

Date ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______

Test 1 ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______

Test 2 ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______ ______

Initials of

Repairs Repairer Date

_________________________________________ ________ _____________

_________________________________________ ________ _____________

_________________________________________ ________ _____________

_________________________________________ ________ _____________

_________________________________________ ________ _____________

_________________________________________ ________ _____________

_________________________________________ ________ _____________

_________________________________________ ________ _____________

_________________________________________ ________ _____________

F.300-B/MS-5 DRILL/JULY 2000

49

Page 51

F.300-B/MS-5 DRILL/JULY 2000© 1996, 1997 by The Challenge Machinery Company. All rights reserved. Printed in the U.S.A.

Page 52

Loading...

Loading...