Page 1

Serial Numbers 995774 & Up

OPERATION

MANUAL

The Challenge Machinery Company

6125 Norton Center Drive

Norton Shores, MI 49441-6081 USA

ChallengeMachinery.com

MODEL EH-3C

PAPER DRILLING

MACHINE

Sold and Serviced by

F. 352-KO

August 2003

Page 2

INTRODUCTION

WELCOME to the family of Challenge® users. Challenge has been developing and manufacturing Graphics Arts

Equipment for over 100 years and is today one of the world’s leading producers and distributors of Paper Cutters,

Paper Drills and Bindery Equipment.

SAFETY ALERT! This symbol means CAUTION OR WARNING: Personal safety instructions! Pay

special attention to the instructions in bold type. Personal injury may result if the precautions are not

read and followed. See SAFETY PRECAUTIONS, page v.

• This machine is designed for ONE PERSON OPERATION ONLY!

• Always DISCONNECT THE POWER before working on this machine.

• DO NOT OPERATE WITH ANY GUARDS REMOVED! Replace all guards before operating.

• CRUSH HAZARD - Keep hands, hair, cleaning rags, & loose clothing away from drills.

READ THIS MANUAL BEFORE OPERATING! Follow precautions and instructions given and you should have

years of trouble-free operation. If after reading the manual questions still remain, contact your Authorized Challenge Dealer.

FOR PARTS AND SERVICE contact the Authorized Challenge Dealer from whom you purchased your machine.

Use the illustrations and parts lists at the back of this manual to identify the correct parts needed. Always give

the SERIAL NUMBER and MODEL of your machine to insure that the correct parts are sent as soon as possible.

Take a few minutes right now to RECORD YOUR MACHINE SERIAL NUMBER in the space provided on the front

cover of this manual. Also be sure to fill out the warranty card accompanying this manual and return it DIRECT TO

CHALLENGE.

If you bought a used machine, it is important to have the following information on record at Challenge. Copy this

page, fill in the information and send it care of: The Challenge Service Department, 6125 Norton Center Drive,

Norton Shores, MI 49441-6081.

CHALLENGE MODEL SERIAL NUMBER

ATTN COMPANY

ADDRESS

CITY STATE ZIP

PHONE DATE INSTALLED

DEALER’S NAME AND CITY

WARRANTY INFORMATION

PLEASE REVIEW THE WARRANTY SHEET!

It is very important that you read and understand the conditions outlined in the Warranty Information Sheet. It is

in an envelope attached to the outside of the shipping container.

The Warranty Information Sheet must be filled out completely, returned, and be ON-FILE at THE CHALLENGE

MACHINERY COMPANY in order for the warranty to be issued for this machine.

Challenge® is a registered trademark of The Challenge Machinery Company. 6125 Norton Center Drive, Norton Shores, MI 49441-6081.

Copyright © 2003 by The Challenge Machinery Company. All rights reserved. Printed in the U.S.A.

ii

F.352-KO/EH-3C DRILL/AUG 03

Page 3

TABLE OF CONTENTS

INTRODUCTION........................................................................................... ii

SAFETY PRECAUTIONS ..............................................................................v

CAUTION: POWER LOCK-OUT PROCEDURE .............................................v

WARNING LABEL DEFINITIONS..................................................................vi

SPECIFICATIONS ....................................................................................... vii

PACKING LIST .......................................................................................... viii

1.0 INSTALLATION.................................................................................... 1-1

1.1 UNCRATING THE PAPER DRILL ................................................... 1-2

1.2 INSTALLING THE TABLE AND BACKGAUGE ................................ 1-2

1.3 INSTALLING THE DRILL BLOCKS AND DRILLS ............................ 1-3

1.4 HYDRAULIC LEVEL CHECK......................................................... 1-3

1.5 HOOKING UP THE POWER LINE ................................................. 1-3

1.6 INSTALLING THE CHIP CONTAINER ............................................. 1-3

2.0 OPERATION ....................................................................................... 2-1

2.1 STARTING THE MACHINE ............................................................ 2-1

2.2 OPERATING THE DRILL ............................................................... 2-1

2.3 ADJUSTING THE VERTICAL STROKE .......................................... 2-1

2.4 SETTING THE DISTANCE BETWEEN DRILL HEADS .................... 2-1

2.5 SETTING THE BACKGAUGE POSITION ....................................... 2-1

2.6 USING THE SIDE GUIDE .............................................................. 2-2

2.7 ADJUSTING THE STROKE SPEED ............................................... 2-2

2.8 REMOVING THE CUTTING BLOCKS ............................................ 2-2

2.9 REMOVING DRILLS FROM THE SPINDLE.................................... 2-2

2.10 DRILLING TIPS ........................................................................... 2-3

3.0 ACCESSORIES .................................................................................. 3-1

3.1 GENUINE CHALLENGE HOLLOW DRILLS.................................... 3-1

3.2 CHALLENGE DRILL-EASE LUBRICANT STICK ............................. 3-1

3.3 CHALLENGE DRILLING BLOCKS ................................................. 3-1

3.4 HANDI-SHARP DRILL SHARPENER ............................................. 3-2

3.5 HOLLOW DRILL SHARPENER / CHIP REMOVER ........................ 3-2

3.5.1 Using the Chip Remover....................................................... 3-2

3.5.2 Using the Drill Sharpener ..................................................... 3-2

3.6 RIGHT-SIDE SIDEGUIDE KIT ........................................................ 3-3

3.7 AUTO-TRIP BACKGAUGE ............................................................ 3-3

3.7.1 Setting the side guide stops................................................. 3-3

3.8 FIXED GAGES ............................................................................. 3-4

3.9 TWO-HAND CONTROL KIT ........................................................... 3-5

3.10 DRILL SHIELD KIT ...................................................................... 3-6

F.352-KO/EH-3C DRILL/AUG 03

iii

Page 4

NOTES

iv

F.352-KO/EH-3C DRILL/AUG 03

Page 5

SAFETY PRECAUTIONS

This safety symbol means CAUTION/WARNING - PERSONAL SAFETY INSTRUCTION. Read

the instructions because it has to do with safety. Failure to comply with the following instructions may result in personal injury.

• This machine is designed and safeguarded for ONE PERSON operation. NEVER operate the machine

with more than one person.

• Safety of this machine is the responsibility of the user and operator. Use good judgement and com-

mon sense when working with and around this machine.

• READ and understand all instructions thoroughly before using the machine. If questions still remain,

call your Authorized Challenge Dealer - Failure to understand operating instructions may result in

personal injury.

• Only trained and authorized persons should operate the machine.

• DO NOT ALTER SAFETY GUARDS OR DEVICES, they are for your protection and should not be altered

or removed. Severe lacerations could result.

• DISCONNECT POWER before cleaning, lubricating, servicing, or making adjustments not requiring

power. See Power Lockout Procedure below.

• HIGH SPEED DRILL - Keep rags, loose clothing and long hair away form rotating drill. Personal injury

could result from items being caught on drill.

• ALWAYS WEAR SAFETY GLASSES when operating the drill machine.

• Have your electrician make sure the machine is properly grounded.

• Have your electrician check for sufficient power to operate the machine properly.

• OBSERVE ALL CAUTION PLATES AND LABELS on this machine.

• KEEP FOREIGN OBJECTS off table and away from drill.

• BE EXTREMELY CAREFUL when handling and changing the drills. Severe lacerations or dismember-

ment could result from careless handling procedure.

• KEEP THE FLOOR around the machine free of trim, debris, oil and grease.

• When replacing hydraulic parts, loosen the connections slowly to release pressure. Never loosen

connections with the machine running.

• If the machine sounds or operates abnormally, turn it off and consult the Trouble Shooting section of

this manual. If the problem cannot be corrected, have it checked by a qualified service person or

your Authorized Challenge Dealer.

• CRUSH HAZARD, keep feet off the pedal when handling paper under the clamp. DO NOT REST FOOT

ON PEDAL at any time!

• DO NOT REACH UNDER THE DRILL AND CLAMP AREA!

• DO NOT OPERATE WITH ANY GUARDS REMOVED! Replace all guards after adjusting, lubricating or

servicing the machine.

• SEVERE LACERATIONS - Contact with high speed drill could cause severe injury. Always turn ma-

chine off and wait for drill to stop before removing drill bits. Keep hands away from drill(s) when

operating.

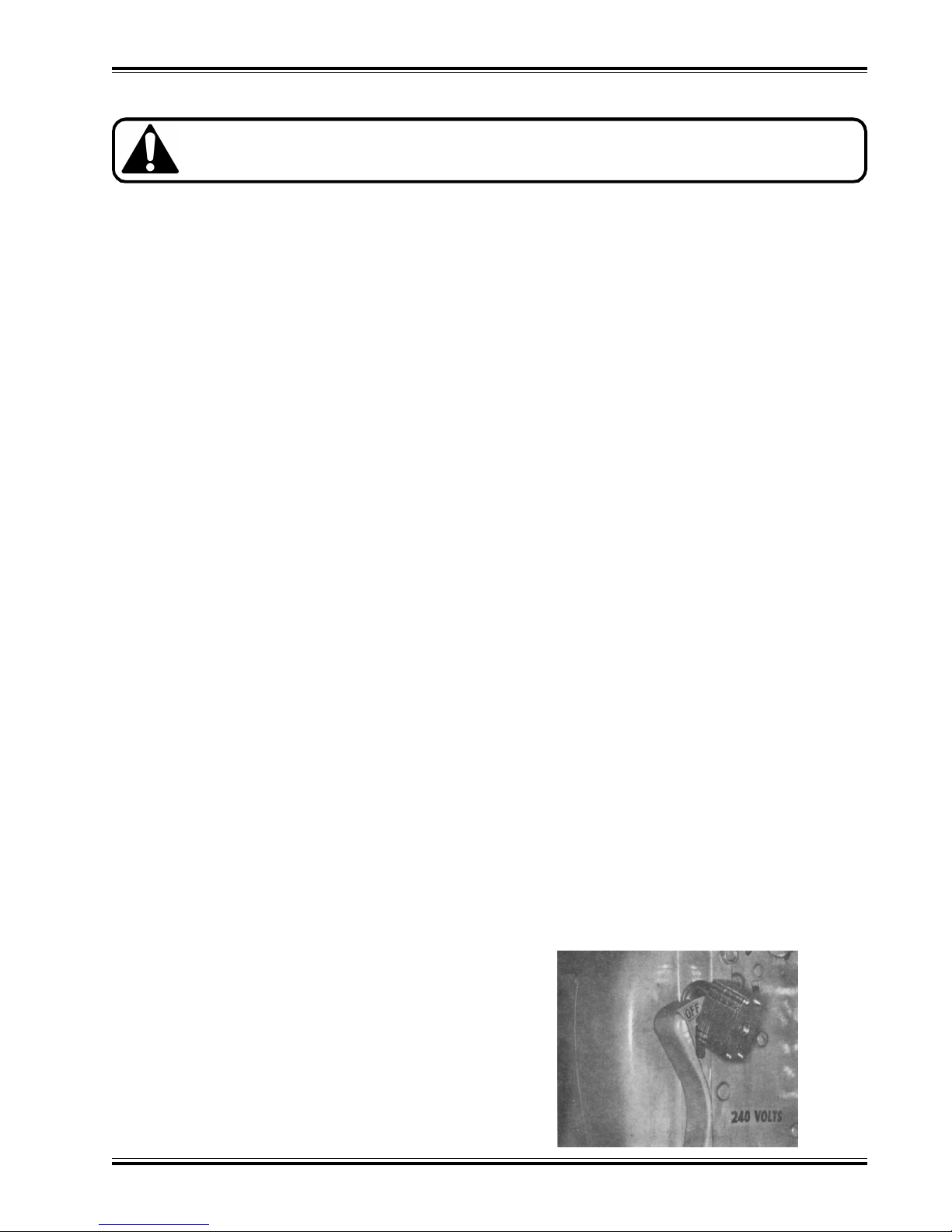

CAUTION: POWER LOCK-OUT PROCEDURE

For maximum safety when making adjustments or

repairs to your machine, be sure to lock out the

main power control switch to which the machine

is connected. The switch should be thrown to the

OFF position and a padlock placed in the loop.

The key should be held by the person servicing

the machine.

F.352-KO/EH-3C DRILL/AUG 03

(fig. i)

v

Page 6

WARNING LABEL DEFINITIONS

CUT/CRUSH HAZARD

SINGLE OPERATOR

SHOCK HAZARD

Keep hands from under drills.

Do not operate with more than one person.

Disconnect power before removing cover. Replace cover

before operation.

vi

SHOCK HAZARD

HAZARDOUS AREA

Disconnect power before removing cover. Replace cover

before operation.

Disconnect power before cleaning, servicing, or making

adjustments not requiring power. Do not alter safety

guards or devices, they are for your protection. Replace all guards, do not operate with any guards removed.

F.352-KO/EH-3C DRILL/AUG 03

Page 7

SPECIFICATIONS

Drilling

Number of Drill Heads 3

Drill Bit Sizes Available

Range Between Drills 23/4” to 41/2” (7 cm to 11 cm)

Range Between Outside Drills 51/2” to 9” (14 cm to 23 cm)

Maximum Drilling Capacity (Pile Height) 21/2” (63 mm)

Backgauge Adjustment Range (Std. Backgauge) 0 to 5” (0 to 13 cm)

Auto Trip Backgauge (Optional) 0 to 41/2” (0 to 11cm)

Side guide Adjustment Range 0 to 14” (0 to 37 cm)

Vertical Adjustment of Individual Heads

Dimensions

Table Size 191/2” x 311/2” (50 cm x 80 cm)

Table Height 37” (94 cm)

Overall Height 591/4” (151 cm)

Floor Space Needed 36” x 411/2” (91 cm x 105 cm)

Net Weight (Approximate) 525 lbs (236 kg)

Shipping Weight (Approximate) 570 lbs (257 kg)

Electrical

208/230 Volts, 18 Amps, 1 Phase, 50/60 Hz, AC. Service size 30 Amps.

Challenge reserves the right to make changes to any product or specification without notice and without

incurring responsibility to existing units.

1

/8” to 1/2” (3 mm to 13 mm)

1

/4” (6mm)

F.352-KO/EH-3C DRILL/AUG 03

vii

Page 8

PACKING LIST

Part No. Description Qty.

Basic Machine ....................................................................1

5700 Backgauge Assembly .........................................................1

5734 Table Assembly ..................................................................1

A-5874 Chip Bag ............................................................................1

KK-281-2 Knockout, Cutting Block ......................................................3

KK-473-3 Drill Blocks, 3” (1 doz).........................................................1

CD-4-2-1/2 Hollow Drills, 1/4” Diameter.................................................3

CD-5-2-1/2 Hollow Drills, 5/16” Diameter............................................... 3

K-85 Drift Hole Cover ..................................................................3

A-4950-2 Hand Drill Sharpener / Chip Remover .................................1

4688 Lubrication Stick .................................................................1

4687 Drill Drift .............................................................................1

W-141 1/8” Allen Wrench ............................................................... 1

W-130 3/16” Allen Wrench .............................................................1

W-137 5/32” Allen Wrench .............................................................1

5841 .018” Shim ..........................................................................3

5841-1 .035” Shim ..........................................................................3

Drill Blocks

Drill

Sharpener

Drift Hole

Covers

Hollow Drills

Drill Drift

Lubrication

Stick

Shims

viii

Allen Wrenches

F.352-KO/EH-3C DRILL/AUG 03

Page 9

1.0 INSTALLATION

Refer to figure 1-1 on this page as well as the parts

lists and drawings in the back of this manual for part

identification and orientation, if necessary.

All guards and instruction plates are installed for your

safety and information and must remain on the machine as shipped from the factory.

1.0 INSTALLATION & SETUP

F.352-KO/EH-3C DRILL/AUG 03

(fig. 1-1)

1-1

Page 10

1.0 INSTALLATION & SETUP

1.1 UNCRATING THE PAPER DRILL

This machine is shipped on a wooden skid and is enclosed with a protective corrugated cover. It is held

onto the skid with plastic straps. Remove the straps

and carefully cut the corrugated cover down the side

and unwrap it from around the machine. The table, backgauge, and other accessories are packed in separate

boxes and are secured to the machine. Remove these

and carefully position the machine on the floor. Immediately after uncrating, check off parts received against

the packing list. Also, examine for any physical signs

of damage incurred during shipping. The machine is

inspected before and after it is crated at our plant. The

responsibility for filing a claim against the carrier for

damages incurred during shipment rests with the receiver of goods (FOB our factory).

Clean all parts with a commercial cleaning solvent before installing or using the machine.

1.2 INSTALLING THE TABLE AND

BACKGAUGE

Set to 6-7/8”

(fig. 1-3)

Locate the four (4) table mounting bolts, washers, &

nuts shipped in the table drawer. Set the table assembly in place and attach using the hardware as shown in

figure 1-2, but leave the hardware loose.

(fig. 1-2)

Using Standard Backgauge:

Pull Down

Shaft

(fig. 1-4)

Using Auto-Trip Backgauge:

Attach the backgauge assembly to the table and set

both sides to the 6” position (as shown in fig. 1-5). Next,

position the table so that the front surface of the backgauge is 1-7/8” from the front of each pull down shaft

(see fig. 1-5). Now tighten the front two table-mounting

screws. Then move the backgauge forward and tighten

the rear two screws.

Pull Down

Ruler set

to 1-7/8”

Backgauge

set to 6”

Shaft

Attach the backgauge assembly to the table and set

both sides to the 6-7/8” position (as shown in fig. 1-3).

Next, position the table so that the back surface of the

backgauge comes in contact with the front of each pull

down shaft (fig. 1-4). Now tighten the front two tablemounting screws. Then move the backgauge forward

and tighten the rear two screws.

1-2

(fig. 1-5)

F.352-KO/EH-3C DRILL/AUG 03

Page 11

1.0 INSTALLATION & SETUP

Note: Further adjustments may be necessary once the

machine is ready to drill. See Table Position Adjustment (section 4.3.1).

1.3 INSTALLING THE DRILL BLOCKS

AND DRILLS

Place the drill block knock-outs in position (refer to fig.

1-1 if necessary). Now set the three drill blocks place.

Check to see if the blocks are flush with the table. Place

shims under the blocks if necessary.

Insert the tapered head of the hollow drills into the

spindles. Be sure that the drift hole covers are in place

before operating the machine (fig 1-1). The drift hole

covers prevent paper chips from flying out while drilling.

CAUTION: Always handle drills with

care to avoid severe lacerations. Even

dull drills are sharp enough to cause

lacerations.

1.4 HYDRAULIC LEVEL CHECK

IMPORTANT: Select the proper transformer primary

tap 208 or 230 Volts to match the voltage supplied

to the machine (fig. 1-6).

(fig. 1-6)

It is also important that the proper line voltage be maintained. Failure to do so will result in improper operation

of the machine (see the troubleshooting section of this

manual for specific problems). It may be necessary to

provide a separate branch power line for the machine.

Check the level of the oil in the hydraulic reservoir. This

check is made by first removing the louvered panel at

the left side of the stand (two screws hold it in place)

and locating the breather cap on the top of the reservoir.

The breather cap has a dip stick attached for checking

the oil. When screwed in (and then removed to check)

there should be approximately an 1/8” (3 mm) of oil on

the stick. Some machines are equipped with a clear

reservoir in which case the oil level can be checked by

visually inspecting the oil level. There is a full level line

marked on the reservoir. Recommended oils are found

in the maintenance section of this manual (section

4.5.1).

CAUTION: Always disconnect the

power when cleaning, servicing, or

lubricating your drill, see Lock Out Procedures, page v.

1.5 HOOKING UP THE POWER LINE

The EH-3C is factory wired for 208/230 Volt, 1 phase,

50/60 hz. operation. It is the customer’s responsibility

to wire the machine for the rated voltage using a 30

Amp circuit (minimum). The recommended circuit overload protection device should be 20 Amps. The recommended wire size for this hookup is #10 gauge.

Since the standard machine is intended for a single

phase hookup, simply fasten either wire of the power

cord to either terminal of the starter and the ground wire

to the designated terminal (fig. 1-7).

(fig. 1-7)

1.6 INSTALLING THE CHIP CONTAINER

The chip container is installed by slipping it over the two

hooks provided on the rear of the machine.

F.352-KO/EH-3C DRILL/AUG 03

1-3

Page 12

1.0 INSTALLATION & SETUP

NOTES

1-4

F.352-KO/EH-3C DRILL/AUG 03

Page 13

2.0 OPERATION

2.0 OPERATION

2.1 STARTING THE MACHINE

The power for this machine is supplied by two motors;

one is for the hydraulic power pack, the other is for the

spindle. They are both started and stopped simultaneously by a single set of start-stop buttons located on

the stand under the table (fig. 1-1). Be sure both motors are operating before trying to drill paper.

2.2 OPERATING THE DRILL

CAUTION: Always wear safety glasses

when operating this machine.

Pressing down on the foot switch activates the hydraulic

unit which brings the drill heads (and drills) down to

the table. When the drills reach the bottom of their

stroke, they will automatically return the “up” position.

(Note: The vertical stroke of the drills must be set before drilling to provide the proper drill depth. See section 2.3 for adjustment procedures). The pedal must

be released and depressed again before drilling the

next set of holes, assuring full control and allowing no

repeat stroke. By releasing the pedal, the operator

can stop the drills in their downward stroke at any time

allowing them to return to their normal position, thus

preventing costly errors. NEVER REST YOUR FOOT

ON THE TREADLE WITHOUT INTENDING TO

BRING DOWN THE DRILLS!

2.3 ADJUSTING THE VERTICAL STROKE

bottom sheets as well as a shorter drill life from drilling

into the cutting block. After the center drill is adjusted,

each outside spindle can be adjusted. Turn counterclockwise to lower and clockwise to raise. No locking

is necessary. Once all three drills are set, drill through

a full lift of paper. A final adjustment of the drill depth

adjusting screw may be necessary to obtain the best

results.

2.4 SETTING THE DISTANCE BETWEEN

DRILL HEADS

This machine incorporates three drilling heads operating on three belt-driven spindles. The center head is

stationary while the two outside heads have a lateral

adjustment of 13/4” each.

This provides an adjustment range of 23/4” to 41/2” (7

cm to 11 cm) between the center drill and either of the

outside drills, or a range of 51/2” to 9” (14 cm to 23 cm)

between the two outside drills.

The lateral adjustment is accomplished by loosening

the clamp knob (a black, plastic hand knob) located at

the rear of each outside head, and then turning the 4lobed, black knob located at the outside of each head.

This moves the heads along a shaft. A scale and pointer

located at the front of the heads gives a reading in

inches and millimeters of the center line relationship to

the center head. When a setting is made, make certain that the clamp knob is tightened again.

Any combination of three heads can be used, that is

one, two, or three holes may be drilled if desired. It is

recommended, however that no more than two half inch

hollow drills be used at the same time.

The vertical stroke of the machine determines the exact

depth the drills will reach at the bottom of their stroke.

Whenever installing a new set of drills, the vertical stroke

must be adjusted before drilling.

The two outside heads are provided with independent

height adjustment while the center head works from the

center overall adjusting screw. This is necessary because of the variance in length of the drills. Start by

adjusting the center head to its highest point. This is

accomplished by turning the drill depth adjustment

screw (fig. 1-1) counterclockwise until it stops turning.

Then adjust the side heads all the way up by turning

the knurled ring on the heads clockwise (use the provided drill drift in the holes if necessary). Now, with

the new drills in the place, put two or three sheets of

paper under the heads. The center spindle should then

be adjusted so that the center drill just cuts through

the paper. Too deep will cause a ragged hole in the

F.352-KO/EH-3C DRILL/AUG 03

2.5 SETTING THE BACKGAUGE

POSITION

The backgauge position is adjusted by first loosening

the two thumb screws under the table. This will allow

the backgauge to move freely. Then use the two scales

on the top of the table to set the backgauge to the desired position. The scales read in inches and millimeters and will give the distance from the edge of the

sheet to the center of the holes. Be sure the 1” (2.5

cm) square pieces mounted to the backgauge are

aligned on top of the scales to provide the proper reading (fig. 1-1). Tighten the thumbscrews when finished.

2-1

Page 14

2.0 OPERATION

2.6 USING THE SIDE GUIDE

(fig. 2-1)

To adjust the position of the side guide, loosen the two

black knobs until the side guide is free to slide sideways. Slide the side guide to the desired position and

then tighten the two knobs. For certain hole positions,

it may be necessary to remove the rectangular spacer

from the side guide assembly (fig. 2-1).

2.8 REMOVING THE CUTTING BLOCKS

Each cutting block is removed by inserting your fingers in the hole provided in the frame (under the table)

and pushing up on the cutting stick knock out. There

are three holes; one on each side of the frame and one

in the front.

2.9 REMOVING DRILLS FROM THE

SPINDLE

Remove the drift hole cover from the spindle to expose the drift hole. Then, with the flat side down, insert the drill drift into the hole and lift upward. The

upward movement forces the drill down and releases

it from the spindle.

2.7 ADJUSTING THE STROKE SPEED

(fig. 2-2)

The hydraulic unit is equipped with an adjustable valve

for regulating the speed on the drill stroke (up and down

travel). Soft stocks such as mimeographs, etc., are

apt to wrinkle at high speeds, and the speed should be

set to a point where the best results are obtained.

This adjustment is made by turning the adjustable valve

(located on the right side of the drilling machine stand)

counterclockwise to reduce speed and clockwise to

increase speed (fig. 2-2)

2-2

F.352-KO/EH-3C DRILL/AUG 03

Page 15

2.0 OPERATION

2.10 DRILLING TIPS

Important! To prevent the drill from overheating, always avoid drilling too slowly. The drill stroke speed should

be set at the fastest speed possible that still allows the drills to cut easily through the paper.

Slotted Holes - Instead of punching slotted holes for five and seven hole universal binding work, save time and

cost by drilling a 1/2” (1.3 cm) diameter hole in place of the slot. The slot is only intended to allow the post or ring

to be used in either location, and the large hole permits this.

Plastic Bindings - Drilling holes for plastic bindings, instead of punching them, is practical and saves a great deal

of time, particularly on long run jobs.

Keep Drills Sharp - A dull drill is the major cause of drill breakage and production tie-ups. Usually after three

hours of drilling, depending on the type of paper being processed, the drill should be sharpened. A dull drill results

in poor quality work.

Keep Drills Clean - A dirty and rusty drill will not permit the free upward passage of the drill chips. Pressure built

up by a clogged drill will split or break the drill. To keep it free from dirt or rust, clean the drill of all chips after each

use and apply a light oil to the inside and outside. Drills should be cleaned out immediately after each use. This

is particularly true if a coated or varnished stock has been drilled. On these jobs the coating on the chips frequently

fuse the chips into one solid mass when the drill cools, causing breakage the next time the drill is used.

Lubricate Drills - Lubrication assists in the passage of the chips and helps avoid overheating of the drills. Use

readily available stick lubricants for this purpose. Hold the end of the stick against the side of the rotating drill. Be

sure to touch the cutting edge with the lubricant also. Wipe off excess oil before drilling. CARE MUST ALWAYS

BE TAKEN WHEN HANDLING DRILLS.

Keep Spindle Clean - Clean out the drill spindle frequently. This will prevent any buildup in the spindle of the drill.

Set the Drills Correctly - Do not cut too deeply into the cutting block. The drill should just touch the block and

cleanly cut through the bottom sheet. During drilling, do not set the drill deeper into the block but change the

position of the block frequently. Drilling deeper into the block dulls the drills quickly. Use a piece of chipboard

underneath your stock. This will make handling the stock easier and will ensure that the last sheet is cut cleanly

through.

Check for Drill Wobble - If spindles are badly worn or bent through misadjustment, have them replaced immediately. A wobbly or loosely held drill can break.

Check Your Drill Sharpener - The cutting edge of the sharpening bit should be inspected frequently to make

certain that it is sharp and free of nicks. Never let a drill drop onto the sharpening bit. It will chip the sharpening

edge. Use gentle pressure when sharpening - let the sharpening bit do the work. Carefully check the sharpness

of the drill after sharpening. The cutting edge should be razor sharp.

Check Belt on the Drilling Machine - The belt should be kept tight to assure proper speed of the drill. When the

drill slows down, it acts more like a punch which results in poor quality work and drill breakage.

Just a little time and effort taken with each use of your paper drilling machine should result in trouble free operation

over many years.

F.352-KO/EH-3C DRILL/AUG 03

2-3

Page 16

2.0 OPERATION

NOTES

2-4

F.352-KO/EH-3C DRILL/AUG 03

Page 17

3.0 ACCESSORIES

3.1 GENUINE CHALLENGE HOLLOW DRILLS

In 13 Standard Sizes For Every Drilling Need

3.0 ACCESSORIES

1/8” 3/16” 1/4” 9/32”

5/32” 7/32”

17

/64” 5/16” 3/8” 7/16”

11

/32”

13

/32” 1/2”

All drills carried in stock by local Challenge dealers (17/32” & 9/16” available by special order).

HOLLOW DRILLS

Diameter x Drill Capacity Cat. No.

1

/8” x 5/8” (3.2 x 16 mm).................... CD-2-3

5

/32” x 11/8” (4 x 29 mm).................... CD-52

3

/16” x 15/8“ (4.8 x 41 mm)................. CD-3

7

/32” x 2” (5.6 x 51 mm) .................... CD-72

1

/4” x 2” (6.3 x 51 mm) ..................... CD-4

1

/4” x 21/2” (6.3 x 63.5 mm) ............... CD-4-21/2

17

/64” x 2” (6.7 x 51 mm) ................... CD-174

9

/32” x 2” (7.1 x 51 mm) .................... CD-92

5

/16” x 2” (7.9 x 51 mm) .................... CD-5

5

/16” x 21/2” (7.9 x 63.5 mm) .............. CD-5-21/2

11

/32” x 2” (8.7 x 51 mm) ................... CD-112

3

/8” x 2” (9.5 x 51 mm) ..................... CD-6

3

/8” x 21/2” (9.5 x 63.5 mm) ............... CD-6-21/2

13

/32” x 2” (10.3 x 51 mm) ................. CD-132

7

/16” x 2” (11.1 x 51 mm) .................. CD-7

1

/2” x 2” (12.7 x 51 mm) ................... CD-8

1

/2” x 21/2” (12.7 x 63.5 mm) ............. CD-8-21/2

TEFLON COATED HOLLOW DRILLS

Diameter x Drill Capacity Cat. No.

1

/8” x 5/8” (3.2 x 16 mm).................... TCD-2-3

5

/32” x 11/8” (4 x 29 mm).................... TCD-52

3

/16” x 15/8“ (4.8 x 41 mm)................. TCD-3

7

/32” x 2” (5.6 x 51 mm) .................... TCD-72

1

/4” x 2” (6.3 x 51 mm) ..................... TCD-4

1

/4” x 21/2” (6.3 x 63.5 mm) ............... TCD-4-21/2

17

/64” x 2” (6.7 x 51 mm) ................... TCD-174

9

/32” x 2” (7.1 x 51 mm) .................... TCD-92

5

/16” x 2” (7.9 x 51 mm) .................... TCD-5

5

/16” x 21/2” (7.9 x 63.5 mm) .............. TCD-5-21/2

11

/32” x 2” (8.7 x 51 mm) ................... TCD-112

3

/8” x 2” (9.5 x 51 mm) ..................... TCD-6

3

/8” x 21/2” (9.5 x 63.5 mm) ............... TCD-6-21/2

13

/32” x 2” (10.3 x 51 mm) ................. TCD-132

7

/16” x 2” (11.1 x 51 mm) .................. TCD-7

1

/2” x 2” (12.7 x 51 mm) ................... TCD-8

1

/2” x 21/2” (12.7 x 63.5 mm) ............. TCD-8-21/2

Special order drills

17

/32” x 2” (13.5 x 51 mm) ................. CD-172

9

/16” x 2” (14.3 x 51 mm) .................. CD-9

3.2 CHALLENGE DRILL-EASE

LUBRICANT STICK

Cat. No. 4688

This lubricating stick provides a dry stainless lubricant

which has many uses throughout the printing plant. It

is specially recommended for use on hollow drills for

easier drilling, particularly when drilling clay coated stock.

It eliminates binding and excessive heating of the drill.

Will not discolor the stock.

CARE MUST ALWAYS BE TAKEN WHEN USING

STICK AND HANDLING DRILLS.

F.352-KO/EH-3C DRILL/AUG 03

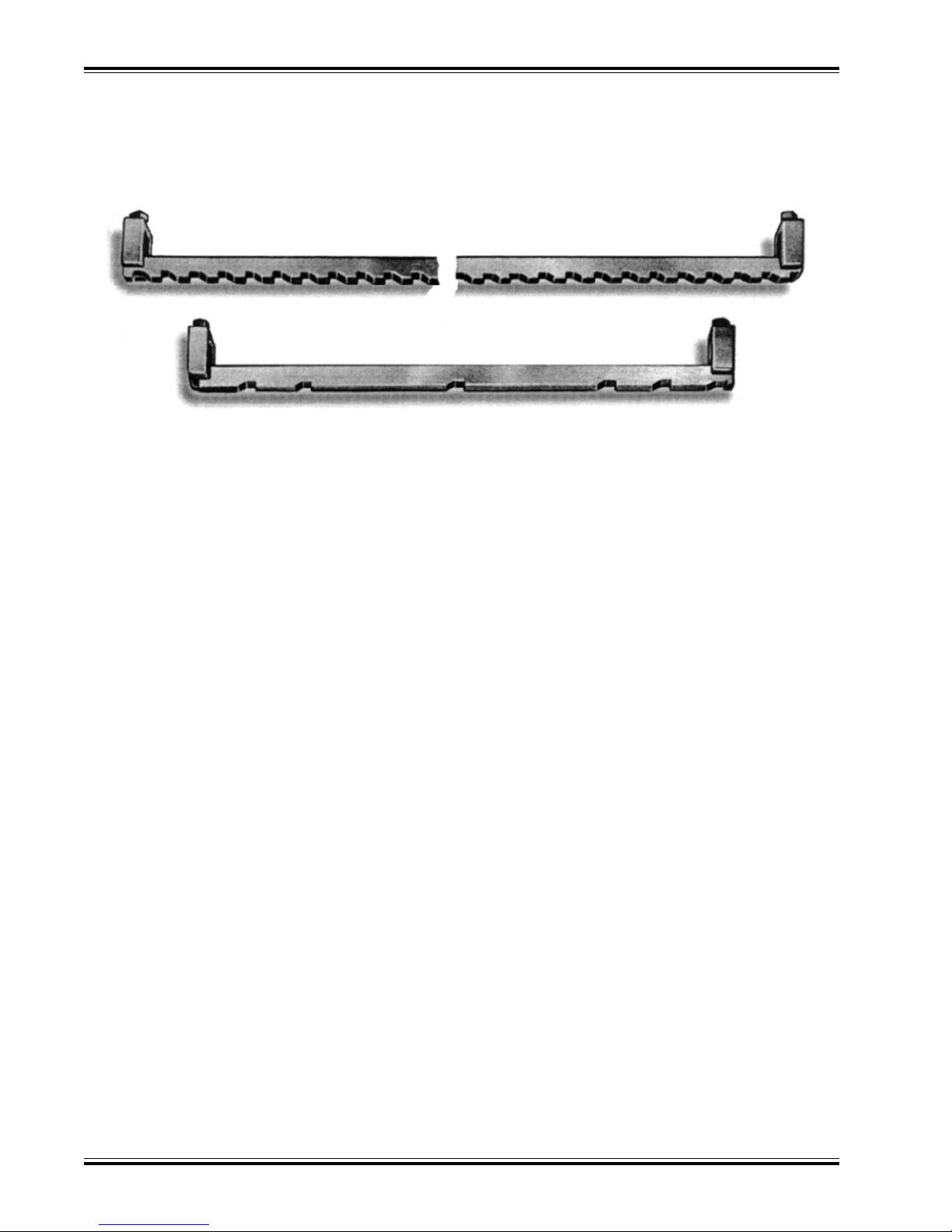

3.3 CHALLENGE DRILLING BLOCKS

Cat. No. KK-473-3

These Challenge 3” End-Wood Drilling Blocks are for

round hole drilling operations. Sold in packages of 12.

3-1

Page 18

3.0 ACCESSORIES

3.4 HANDI-SHARP DRILL SHARPENER

Cat. No. 57100

The Handi-Sharp mounts on the edge of table or bench.

A dull hollow drill bit is placed in the holder, and the

cutting bit is pushed against the end of the hollow drill

until its spring bottoms out. The spring prevents excessive force from being applied while sharpening. Turning

the handle while applying a hone produces a fine edge.

Item Cat. No.

Replacement Cutting Bit 6469

Adapter for other style drill bits 57114

3.5 HOLLOW DRILL SHARPENER / CHIP REMOVER

For fast, easy drill sharpening and chip removal

CAUTION: Drills are sharp even after use. Be careful to keep edge

away from your body. To prevent personal injury and/or damage to

the drill, ALWAYS keep drills in protected area.

3.5.1 Using the Chip Remover

(cut-away view)

NOTE: Chip remover is only for use with hollow drill diameters 3/

16” and larger

1. CAREFULLY place a hollow drill in the holder section as shown, and insert the holder (with drill) into

the chip remover end as shown.

3.5.2 Using the Drill Sharpener

(cut-away view)

2. Firmly tap the entire assembly on a solid surface

to remove the chips from the hollow drill.

1. CAREFULLY place a hollow drill in the holder section as shown, and insert the holder (with drill) into

the sharpener end as shown. Be very careful to

bring the drill and cutting tool together with out

bumping. The cutting tool is made of GLASS

HARD material and may be chipped.

3-2

2. USE CLOCKWISE ROTATION while maintaining

an even pressure, until the hollow drill is sharpened (usually two or three turns). The cutting tool

seldom requires replacing, but when it does become necessary, the bit can be ordered through

your Challenge Dealer (Cat. No. 4952).

F.352-KO/EH-3C DRILL/AUG 03

Page 19

3.6 RIGHT-SIDE SIDEGUIDE KIT

Cat. No. K-5731

This kit includes all of the parts and hardware necessary to add a right-hand sideguide to your existing

backguage. When used in conjunction with the lefthand sideguide, multiple hole patterns can be drilled by

shifting the stock from one sideguide to the other between drilling cycles.

3.7 AUTO-TRIP BACKGAUGE

Cat. No. A-4615-9

3.0 ACCESSORIES

This optional backgauge assembly provides additional

versatility to the EH-3C. The automatic trip on the side

guide permits step and repeat type of operation with a

minimum distance between holes of 3/8” (9.5 mm) with

the standard stops or 1/4” (6.3 mm) minimum by the

use of a fixed gage, available as optional equipment.

As each set of holes is drilled, the side guide is automatically tripped, and as soon as the drills clear the

stock on their up stroke, the guide is free to move to its

next stop. This is accomplished by pushing the stock

to the left and moving the guide at the same time. When

drilling one, two or three holes only, that fall within the

9” (23 cm) limitations of the machine, the automatic

trip bracket (located at the left of the machine) can be

turned so that it does not engage the trip lever.

F.352-KO/EH-3C DRILL/AUG 03

3.7.1 Setting the side guide stops

First set the rear gage to the desired back margin. Be

sure both sides are set to the same dimension and

tighten the two thumbscrews. Next, remove the guide

shaft and set the guide stops to the desired distance

between holes (a scale in the guide shaft is provided for

this purpose). The guide shaft is then replace in the

rear gage and final adjusting or centering of holes is

accomplished with the knurled screw at the extreme

left end of the guide shaft.

The automatic trip gage comes equipped with seven

stops. Additional stops can be purchased at a very

nominal price. Challenge fixed index gages are recommended where the same job is to be handled over and

over again. They are easily and quickly attached and

removed. NOTE: When drilling narrow strips, the side

guide roller assembly should be mounted on the inside

of the side guide assembly.

3-3

Page 20

3.0 ACCESSORIES

3.8 FIXED GAGES

For Fast, Accurate Hole Spacing

(For use with optional auto-trip backgauge only)

These fixed gages with pre-cut hole spacings fit on the

side guide in place of the moveable stops. To use,

position the gage so that the right end lines up with the

dimension on the scale for the centerline of the first

hole to be drilled. Use of the stops on fixed gages is

the same as using the adjustable stops.

In addition to 2-5 hole patterns, fixed gages are available from stock in the following standard types:

22-stop gage, 1/2” centers for multi-ring binders

25-stop gage, 3/8” centers

25-stop gage, 1/4” centers

34-stop gage, 1/2” centers

46-stop gage, 3/8” centers

50-stop gage, 1/4” centers

Custom patterns can also be supplied, call for details.

3-4

F.352-KO/EH-3C DRILL/AUG 03

Page 21

3.9 TWO-HAND CONTROL KIT

Cat. No. A-4851-50

3.0 ACCESSORIES

This 2-hand control safety kit can be installed on the

EH-3C in place of the standard foot pedal control. All

of the necessary hardware and instructions are included

in the kit. The 2-hand control offers anti-tiedown and

F.352-KO/EH-3C DRILL/AUG 03

anti-repeat features, which means both buttons must

be released between each cycle, and both buttons must

be pressed within .5 seconds of each other.

3-5

Page 22

3.0 ACCESSORIES

3.10 DRILL SHIELD KIT

Cat. No. 48004

This drill shield safety kit includes a clear Lexan shield

that protects the operator from contacting the spinning

drills. The kit can be installed on all EH-3A, EH-3B,

and EH-3C machines. All of the necessary hardware

and instructions are included in the kit (see Page 5-

24).

3-6

F.352-KO/EH-3C DRILL/AUG 03

Page 23

NOTES

3.0 ACCESSORIES

F.352-KO/EH-3C DRILL/AUG 03

3-7

Page 24

F.352-KO/EH-3C DRILL/AUG 03© 2003 by The Challenge Machinery Company. All rights reserved. Printed in the U.S.A.

Loading...

Loading...