Page 1

The Challenge Machinery Company provides owner's manuals on its

products s olely as a court esy to i ts cust omers. Se e the inf ormati on belo w

before using this manual.

These manuals are for reference only. These manuals include products which are noncurrent,

unsupported or no longer pr oduced by The Chal l enge M achi nery Com pany , and are pr ov ided sol el y as

an accommodat i on to our c ustom ers. By prov i ding these m anuals, T he Ch al lenge M achi nery Com pany

makes no representation or warranty as to the products, their current condition, or their suitability or

fitness for use in any particular application, which are the sole and i ndependent responsibility of the

product owner and user.

Older produ cts may not co mply with curren t safety pro cedures, guidel ines or regu lat ions, and i t

is the product owner's and user's responsibility to evaluate the suitability and fitness of the

products in their current use and application. The Challenge Machinery Company makes no

representation, warranty or recommendation regarding any modifications which may be

required on non -current o r u nsuppo rted prod ucts. T he Ch allenge Mach inery Co mpan y assumes

no liability for any modification or alteration to any Challenge product, and any such

modification or alteration to any Challenge product is not authorized by The Challenge

Machinery Comp any. The av ailabilit y of t hese manuals is sol el y for t he purpose of provi ding ref erence

information for the products.

This manual may not be complete in all aspects of product maintenance and repair. All products

should be used only by qualified and properly trained personnel, following proper safety

procedures. Al l product s should be regular l y i nspected and m aintai ned, and their condition, appli cation

and use should be periodically evaluated by qualified personnel. Only qualified and properly trained

technicians should perform maintenance, repair and replacement procedures. Attempting these

procedures without pr oper training may cause machine dam age or operat or injury!

Products may be unsup por ted by The Chall enge M ac hinery Company due to age or the unavailability of

parts from their ori ginal m anufactur er. No parts or produc t support will be available to repair or maintain

unsupported prod uc ts. Older products may not be UL listed (if the product does not have a UL l abel it i s

not a listed product), and may not comply with applicable installation or other regulations or

requirement s if rel ocated to a new f acilit y. Many munici palities requi re a product t o be UL l isted bef ore

an electrician will connect power to them. Often the cost of updating an older pro duct to com ply with

current saf ety r egulations is greater than the v alue of t he product .

The Challeng e Machin ery Comp any

6125 Norton Center Drive

Norton Shores, MI 49441-6081 USA

ChallengeMachinery.com

F.254-I-O

February 2014

CHAMPION 305 X, XG, XT

Operator’s Manual

Serial Numbers 07X1360 & Up

Sold and Serviced by

Page 2

1.0 Introduction

1.0 Introductio n

This manual is designed t o help you get the most from your Challenge equipment. Keep this manual

in a safe, convenient place for quick reference by operators and serv ice personnel.

SAFETY ALERT! This symbol means CAUTION: Personal safet y

instructions! Pay special attention to the instructions in bol d ty pe. Personal injury may result if the

precautions are not r ead and followed.

READ THIS MANUAL BEFORE OPERATING! Follow the precautions and instructions given. If

after reading the manual questions still rem ain, contact your Authorized Challenge Dealer.

FOR PARTS AND SERVICE, contact t he Author ized Challenge Dealer from whom you purc hased

the machine. Use the illustrations and parts lists at the back of this manual to identify the correct

parts needed. Always give the SERIAL NUMBER and MODEL of your machine to insure t he correct

parts are sent as soon as possible.

RECORD YOUR MACHINE SERIAL NUMBER in the space provided on the front cover of this

manual. Fill out the warranty c ar d ac c om panyi ng your machine and return it DIRECTLY TO

CHALLENGE.

If you bought a used machine, it is important to have the following information on record at Chall enge.

Copy this page, fill in the information and send it care of The Challenge Serv ice Department, 6125

Norton Center Driv e • Norton Shor es • MI 49441.

CHALLENGE MODEL SERIAL NUMBER

ATTN COMPANY

ADDRESS

CITY STATE/PROVINCE ZIP

PHONE DATE INSTALLED

DEALER NAME & CITY

* WARRANTY INFORMATION *

It is very important that y ou r ead and under st and the conditions outli ned in the Warr anty Information

Sheet att ached to the outside of the shipping cont ainer of your machine.

The Warr anty Inf or m ation Sheet must be filled out completely and returned to THE CHALLENGE

MACHINERY COMPANY in order for the warranty to be issued for this machine.

The Challenge Machinery Company • 6125 Norton Center Dr ive • Norton Shores MI 49417

Copyright© 1997-2014 by The Challenge Machinery Company. All rights reserved. Printed in the U.S.A

2

Challen ge® is a registered trad em ark of

Page 3

1.0 Introduction

TABLE OF CONTENTS

1.0 Introduc tion................................................................................................................................. 2

2.0 Safety.........................................................................................................................................6

2.1 Precautions.............................................................................................................................6

2.2 Power Lockout Proc edur e .......................................................................................................6

2.3 Warning Label Definitions........................................................................................................7

3.0 Packing List.................................................................................................................................9

4.0 Specifications............................................................................................................................10

5.0 Footprint....................................................................................................................................11

6.0 Installation & Setup...................................................................................................................12

6.1 Inspecting Shipment..............................................................................................................12

6.2 Uncrating.............................................................................................................................. 12

6.3 Lifting Instructions.................................................................................................................12

6.4 Moving Instructions............................................................................................................... 13

6.5 Cleaning ............................................................................................................................... 13

6.6 Assembly.............................................................................................................................. 13

6.7 Hydraulic Power Unit Removal.............................................................................................. 14

6.8 Hydraulic Check....................................................................................................................15

6.9 Power Hook-Up.....................................................................................................................15

6.9.1 Three Phase Hook-Up ................................................................................................... 16

6.9.2 Single Phase Hook-Up................................................................................................... 17

7.0 Champion 305 Diagram ............................................................................................................. 18

8.0 Operation X Model .................................................................................................................... 19

8.1 Power – Main Switch.............................................................................................................19

8.2 Table Light ............................................................................................................................ 20

8.3 Presetting the Backgauge ..................................................................................................... 20

8.4 Backlash Indicator.................................................................................................................20

8.5 Backgauge Lock ................................................................................................................... 20

8.6 IN/MM Toggle Soft Key......................................................................................................... 20

8.7 Making a Cut.........................................................................................................................20

8.8 Turning Off the Hydraulic Motor.............................................................................................21

8.9 Jogging Aid........................................................................................................................... 21

8.10 Pre-Clamping...................................................................................................................... 21

8.11 Air Table ON/OFF............................................................................................................... 21

8.12 Adjusting the Clamp Pressure............................................................................................. 22

8.13 Re-calibr ating the Backgauge.............................................................................................. 22

8.14 Knife Down Mode................................................................................................................ 22

8.15 Electric Eyes.......................................................................................................................23

8.16 False Clamp Plate...............................................................................................................23

9.0 Operation – XG Model............................................................................................................... 24

9.1 Using the Machine................................................................................................................ 24

9.1.1 Power - Main Power Switch............................................................................................24

9.1.2 Table Light..................................................................................................................... 24

9.1.3 Start Up......................................................................................................................... 24

9.1.4 Making a Cut..................................................................................................................25

9.1.5 Jogging Aid.................................................................................................................... 25

9.1.6 Adjusting the Clamp Pressure........................................................................................ 26

9.1.7 Pre-Clamping.................................................................................................................26

9.1.8 Knife Change Alarm and Lubrication Alarm .................................................................... 26

9.2 Electric Eyes.........................................................................................................................26

9.3 False Clamp Plate.................................................................................................................26

9.4 Champion XG – Display Panel .............................................................................................. 27

9.5 Definition of Keys.................................................................................................................. 27

3

Page 4

1.0 Introduction

9.5.1 Backgauge Glide Control................................................................................................27

9.5.2 IN/MM Key......................................................................................................................27

9.5.3 Air Ta b le ON / OFF Key....................................................................................................27

9.5.4 Send Key........................................................................................................................27

9.5.5 Push-Out Key.................................................................................................................28

9.5.6 Clear Key........................................................................................................................28

9.5.7 Enter Key........................................................................................................................28

9.5.8 Priority Add (X/Y) Key.....................................................................................................28

9.5.9 Soft Keys........................................................................................................................28

9.5.10 Arrow Keys...................................................................................................................28

9.5.11 Contrast Control (Only on Serial numbers 10x1535 and below).....................................29

9.5.12 Contrast Control (For Serial numbers 10x1536 and up).................................................29

9.6 Manual Backgauge Cont r ol....................................................................................................29

9.6.1 Backgauge Glide Control................................................................................................29

9.6.2 Backgauge Cont rol Knob................................................................................................29

9.6.3 Backlash Indicator..........................................................................................................29

9.7 Send Mode............................................................................................................................30

9.7.1 Entering Math.................................................................................................................30

9.7.2 Entering Fractions...........................................................................................................30

9.8 Repeat Mode.........................................................................................................................31

9.9 Maintenance Mode ................................................................................................................31

9.9.1 Language .......................................................................................................................31

9.9.2 Parameters.....................................................................................................................32

9.9.3 Diagnostic.......................................................................................................................33

9.10 Job Mode.............................................................................................................................34

9.10.1 Lock/Unlocking a Job....................................................................................................34

9.10.2 Copying a Job...............................................................................................................34

9.10.3 Erasing a Job................................................................................................................34

9.10.4 Creating a New Job......................................................................................................35

9.10.5 Editing an Existing Job..................................................................................................39

9.10.6 Running a Programmed Job .........................................................................................40

9.10.7 Exiting a Job.................................................................................................................40

9.11 An Example Job – XG Model ...............................................................................................40

10.0 Operating Tips.........................................................................................................................42

11.0 Knife Installation/Changing.......................................................................................................43

11.1 Knife Removal.....................................................................................................................44

11.2 Knife Installation..................................................................................................................45

11.3 Using the Shielded Knife Lifter.............................................................................................46

11.4 False Clamp Plate................................................................................................................47

11.5 Knife Care Basics................................................................................................................48

11.5.1 Cut Quality....................................................................................................................48

11.6 Bevel Angle.........................................................................................................................49

11.7 Helpful Suggest ions.............................................................................................................49

11.8 Knife Care............................................................................................................................50

12.0 Lubrication...............................................................................................................................51

12.1 Hydraulic System.................................................................................................................53

12.2 Recommended Oils .............................................................................................................54

12.3 Changing the Oil..................................................................................................................54

13.0 Operator Adj ustm ents/Cleaning................................................................................................56

13.1 Line Lights...........................................................................................................................56

13.2 Manual Pr essure Reducer – (305X Only).............................................................................57

13.3 Operator Cleaning................................................................................................................58

13.3.1 Hydraulics.....................................................................................................................58

13.3.2 Table Conditioning........................................................................................................58

13.3.3 Console........................................................................................................................59

4

Page 5

1.0 Introduction

13.3.4 Machine Base.............................................................................................................. 59

14.0 Program Log........................................................................................................................... 60

15.0 Channel Log ............................................................................................................................ 61

16.0 Safety System Tests............................................................................................................... 62

5

Page 6

2.0 Safety

2.0 Safety

2.1 Precautions

• This machine i s designed f or one- per son operation. Never operate the machine with more than

one person.

• Safe use of this machi ne is the r esponsibility of the operator . Use good judgment and common

sense when working with and around this machine.

• Read and understand all instructions thoroughl y before using the machine. If questions remain,

contact the deal er from whic h y ou purchased this machine. Failure to under stand the operating

instructions may result in personal injury.

• Only trained and aut hor iz ed people should operate this machine.

• Do not alter saf ety guar ds or devic es. They are for your protection. Severe personal injury may

result.

• Disconnect power bef or e cl eaning or performing mai ntenance. See S ection 2.2 Power Lockout

Procedure.

• Observe all cauti on labels and plates on this machine.

• Be sure the cutter i s properly grounded.

• Be sure there is sufficient power to operate the cutter properly.

• Keep foreign objec ts off the table and away from cutter blade.

• BE EXTREMELY CAREFUL when handling and changing the cutter knif e. Severe lacerations or

dismemberm ent could result from careless handling pr oc edur es.

• Keep the floor around the cutter free of trim, debris, oil and grease.

• When replacing hy dr aulic parts, loosen the connections slowly to release pressure. Never loosen

connections with the machine running.

• If the cutter sounds unusual or operates abnormally, turn it off and consult the troubleshooting

section of thi s manual. If the problem cannot be corrected, have it chec k ed by a qualified service

person.

• CRUSH HAZARD, keep hands and fingers from under the clamp while clam ping. Use Jogging

Aid to load paper, and use the back gauge to push paper out before unloading. DO NOT REACH

UNDER THE KNIFE AND CLAMP AREA!

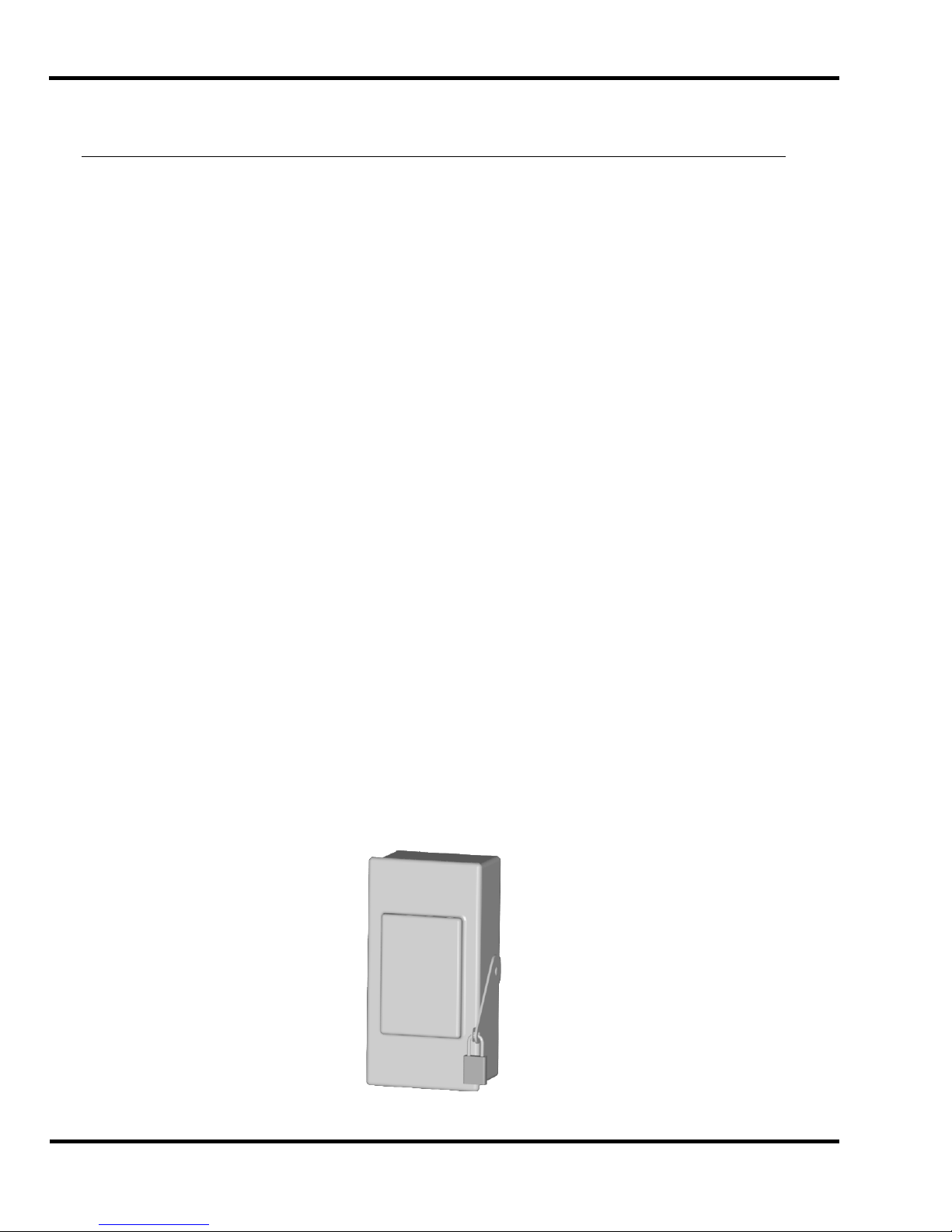

2.2 Power Lockout Procedure

For maximum safety when m aki ng adjustments or repairs to your machine, be sure to lock out the

main power control switch to which the machine is connected. The switch should be moved to the

OFF position and a padlock placed in the loop. The person servicing the machine should hold the

key.

6

Figure 1

Page 7

2.0 Safety

2.3 Warning Label Definitions

The following warni ng labels are found at various loc ations on your machine. Read and understand

the meaning of each symbol. If a label is lost from the machine, it should be replaced. The item

number and locati on of each label can be found in Section 17.0, Schem atics and Parts List.

HAZARDOUS AREA

Disconnect power bef or e cl eaning, servicing, or m aki ng adjustm ents not requiring

power. Do not alter saf ety guar ds or devices; they are for your prot ection. Replace

all guards. Do not operate with any guards removed.

SHOCK HAZARD

Disconnect power bef or e r em ov ing cover. Replace cover before operation.

SHOCK HAZARD

Disconnect power bef or e r em ov ing cover. Replace cover before operation.

SINGLE OPERATOR

Do not operate with m or e than one person.

7

Page 8

2.0 Safety

!OJO!

This Este simbolo de alerta de seguridad significa ¡ OJO ! INSTRUCCIONES DE SEGURIDADPERSONAL. Lea las i nstrucciones po rque se refieren a su

seguridad personal. Fall de obedecer las instrucciones que siguen podria resultar en lesiones

corporales.

• Esta maquina, junto con sus mecanismos de seguridad, esta disenada para ser manejada por

• UNA SOLA PERSONA a la vez. Jamas debe ser manejada por mas de una persona al mi smo

• tiempo.

• La seguridad es la responsabilidad del operario que usa esta maquina.

• LEA DETENIDAMENTE el manual de instrucciones y las PRECAUCIONES DE SEGURIDAD

antes de poner a funcionar la c or tadora. Pidale a su supervisor una copia.

• El manejo de la guill otina debe estar exclusivamente a cargo de per sonal entrenado y autoriz ado

para ello.

• NO MODIFIQUE LOS MECANISMOS DE SEGURI DAD, estan ahi para su proteccion no deben

ni modificar se ni quitarse.

• DESCONECTE LA CORRIENTE ELECTRICA antes de proceder a hacerle servicio de limpieza,

engrasar, o de hacer adjustes que no requieren corrient e. Trabe el interruptor en la posicion

OFF (apagado); vea “Procedimiento para cortar la corriente elect ri c a” al pi e de esta pagi na.

• Eche llave a la guillotina y quite la llave cuando la maquina no esta en operacion; vea “Corriente

electrica”.

• Asegurese de que la guillotina este debidament e a tierra. V ea “Conexion de la fuerza electrica”.

• Verifique el v oltaje y asegurese de que este sea suficient e par a el debido funcionamiento de la

guillotina.

• Preste atenci on a todas las pl ac as con advertencias instaladas en esta guillotina.

• No permita que objetos estranos esten en la mesa o cerca de la cuchilla cort ador a.

• TENGA SUMO CUIDADO al tocar y cambiar la cuchilla. Heridas severas y hasta

desmembrami ento pueden resultar del manejo sin cui dado o negligente.

• El suelo alrededor de la guillotina debe mantenerse despejado y libre de recortes, desperdi c ios,

aceite y grasa.

• Al haber la necesidad de r eem plazar partes hidraulic as, afloje todas las conexiones poco a poco

para dejar escapar l a pr esi on. Jamas debe aflojarse conexiones mientras la maquina este

• andando.

• Si la guillotina empezara a sonar o trabajar difer entemente a lo acostumbrado, desconectela y

consulte la seccion “Troubleshooting” ( Reparador) de este manual. Si no es posible corregir el

problema, llam e a su servi ci o autorizado para que le examinen la maquina.

• PELIGRO DE MACHUQUE - Mantenga manos y dedos f uer a de la agar r ader a mi entras sujeta el

papel. Use el calibr ador trasero y su rueda de mano para empujar el papel cortado. NO PONGA

SUS MANOS BAJOLA CUCHILLA O AREA DE LA AGARRADERA.

• NO OPERE SIN LAS GUARDAS PROTECTORAS!

¡ OJO ! PRECAUCION - Como proceder para desco nect ar

la corriente electrica.

Para maxima seguridad durante ajustes y reparaciones de su maquina, verifique bien que el interruptor principal

de control de corriente al cual la maquina esta conectada, este desconectado. El interruptor deba ser puesto en

la posicion “OFF” (desconectado) y se debe poner un candado en la anilla. La llave del candado debe ser

guardada por la persona que estara efectuando los trabajos de servicio o de reparacion en la guillotina.

Desconecte la corriente electrica antes de proceder a hacer cualquier ajuste o reparacion o de efectuar el

engrase en cualquier maquina.

8

Page 9

3.0 Packing List

3.0 Packing List

Part No. Description Qty.

Basic Machine 1

Extension Side Tables:

47166 18 x 24 Steel Side Table 2

47164-1 Side Table Back Plate 2

H-6913-606 Side Table Bolts 8

H-6424-6 Side Table Hex Nuts 8

H-6939-616 Leveling Screws 4

H-6913-6008 Side Table Mounting Bolts (shipped installed) 4

H-7321-6 Side Table Mounting Washers (shipped i nstalled) 4

47006-2 False Clamp Plate (shipped installed) 1

47507 Knife 2

H-6918-608 Knife Bolts 6

8815 Knife Washers, Special 6

4171 Cutting Sticks (one installed) 4

47575 Knife Lifter Assembly 1

A-12608-4 Jogging Aid 1

Tool Kit:

5064 Cutting Stick Puller 1

W-164 Hex “T” Wrench 1

W-158 5/16 Open End Wrench 1

W-141 1/8” 1

W-137 5/32” 1

Fuses:

E-2308 3.2 A (X, XG Series) 1

E-2330-7 5 A S.B. (X, XG Series) 1

E-889-35 1 A S.B. (X, XG Series) 1

E-889-5 4 A S.B. (X, XG Series) 1

E-889-9 8 A S.B. (X, XG Series) 1

E-2330-8 6.3 A S.B. (XG Series) 1

E-2330-3 2 A S.B. (XG Series) 1

9

Page 10

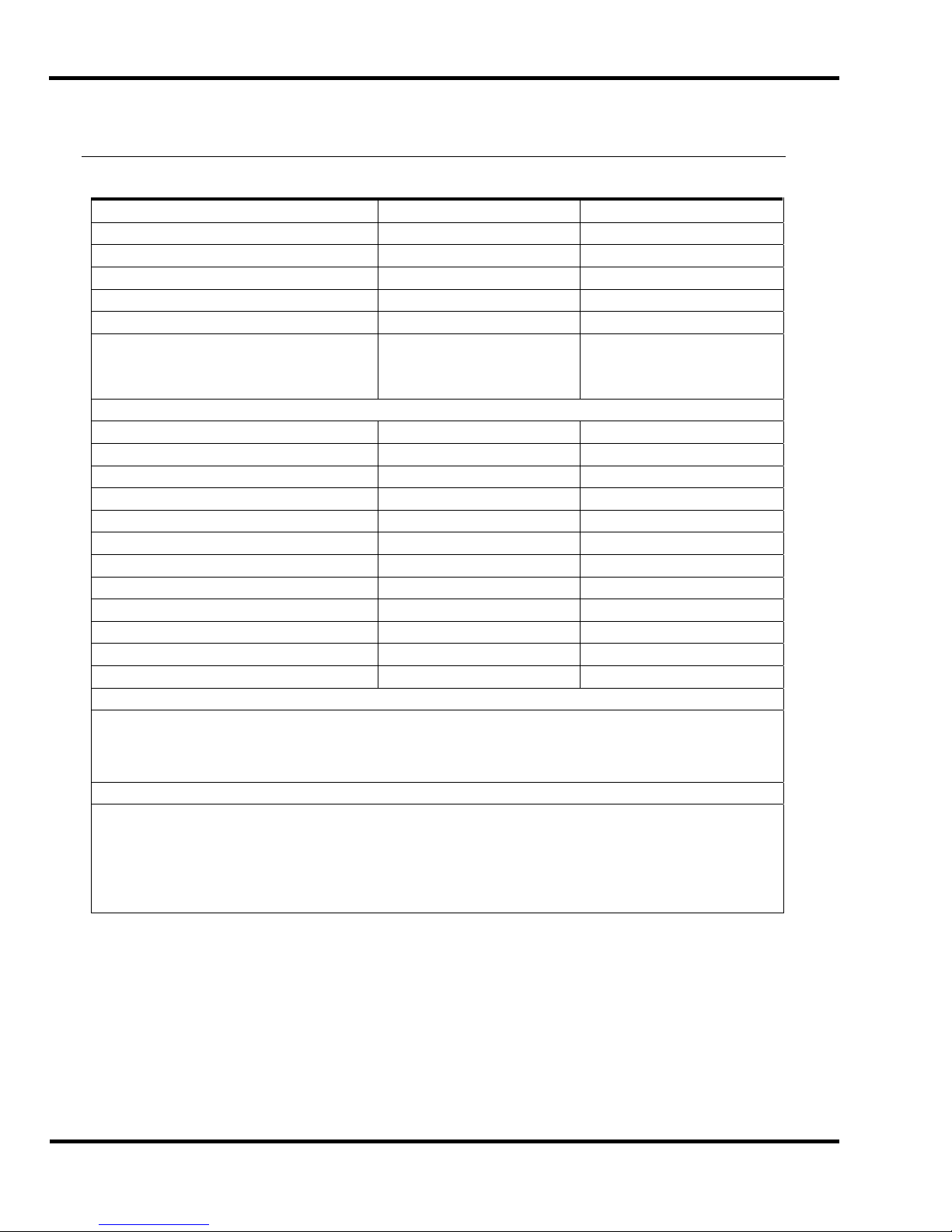

4.0 Specification s

4.0 Specificati ons

Description Inch Units Metric Units

Cutting Width 30 ½” 77.5 cm

Clamp Opening 4” 10.2 cm

Clamping Force 400-5000 lbs. 1.8 – 22 kN

Minimum Cut – Standard ¾” 1.9 cm

- Special ½” 1.3 cm

- w/ False Clamp Plate 2” 5.1 cm

Table Space

Front: (std.)

Back:

Dimensions

Table Height 36 ½“ 92.7 cm

Overall Height 58 ½” 148.6 cm

Overall Length 69 ½” 176.5 cm

Overall Width 48 ½” 123 cm

w/ Side Tables 78 ½” 200 cm

w/o Side Tables 48 ½” 123 cm

Approx. Net Weight 2550 lbs 1157 kg

Approx. Shipping Weight 2750 lbs 1247 kg

Will pass through door:

Assembled 49” 125 cm

Table/treadle out 42” 112 cm

Table/treadle/pwr unit out 24-1/2” 63 cm

Electrical

Standard: 5 HP, 3 Phase, 60 Hz AC; 208/230V, @ 25A or 460V @ 11.5A

Optional: 5 HP, Single Phase, 60 Hz AC; 208V, @ 44A or 230V @ 44A

3 Phase, 50 Hz AC; 220V or 380V

Single Phase, 50 Hz AC; 220V

Spacer

XD & XG series spacer has 9801 cuts on 99 channels.

XT series spacer has 47000 cut positions within the machine. (Unlimited with USB

Port.)

Minimum space between cut positions is 0.005” or 1mm. Repeat positioning accuracy is

0.003” or 0.05mm.

Electri c Eyes –

Response time = 68 ms

Object detection capability = 12 mm

Challenge reserves the right to make changes to any product or specif ication without notic e and

without inc ur ri ng r esponsibility to existing units.

25”

30 ½”

63.5 cm

77.5 cm

10

Page 11

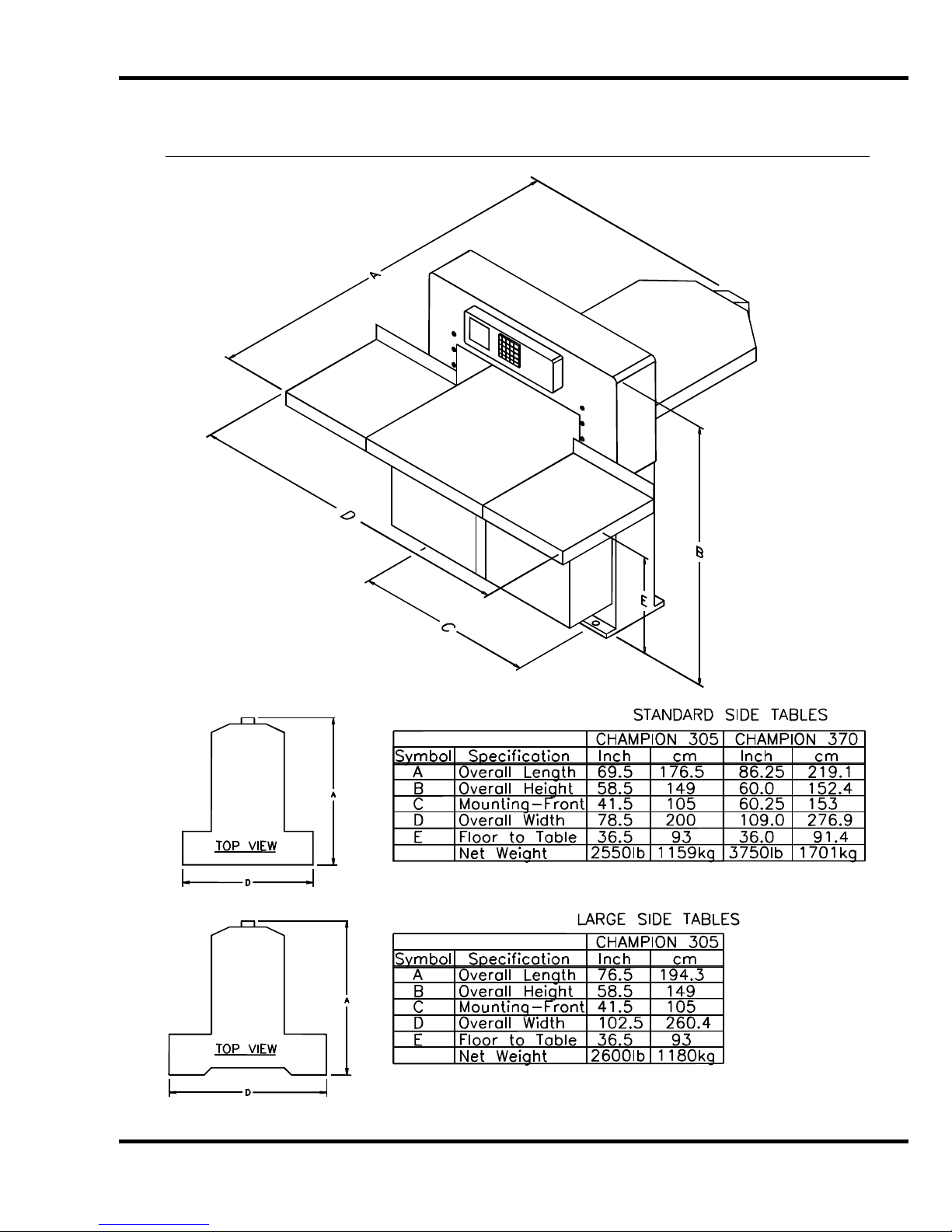

5.0 Footprint

5.0 Footprint

11

Page 12

6.0 Installati on & Setup

6.0 Installation & Setup

6.1 Inspecting Shipm ent

This machine has been carefully packed to prevent damage during shipment. However, claim s f or

damage or loss are the responsibility of the recipient. Inspect all shipment s as soon as they are

received. If there is any noticeable damage, note it on the fr eight bill. Visual and/or hidden damage

must be report ed to the claims department of the carrier within 15 days. Contact your dealer if you

need any assistance. Check the contents of the box against the packing list on page 9. Make sure

there are no missing items.

6.2 Uncrating

This machine i s lagged to a wood skid and covered with a triple-walled cor r ugated container. Loosen

the flaps of the carton where they ar e attached to the skid. When loose, the carton c an be lift ed

straight up. Remove t he side tables and accessory box, which are also attached to the skid. Place

the cutter/skid about where the machine will be positioned and remove the lag screws from the ski d.

6.3 Lifting Instructio ns

Unpacking, handling, and positioni ng shoul d be done by prof essional riggers. If handling or

unpacking is a problem, your dealer or a local trucking facility should be able to supply or recomm end

a qualified rigger. This 2550-lb/1157-kg m achi ne should be moved with experienced people and t he

proper equipment. Do not risk personal injury or damage by att em pting to move machinery with

inadequate equipm ent or manpower.

Champion cutt ers may include an opt i onal bloc k for lifting t he machi ne. Remove the prot ective cov er

from the rear of the arch. Install t he block with the h ole up. Use a hook and chain or lifti ng straps

rated at 3000-l b/1360- kg or higher. Carefull y lift the machi ne off its skid, and remov e the skid. Place

the machine on the fl oor .

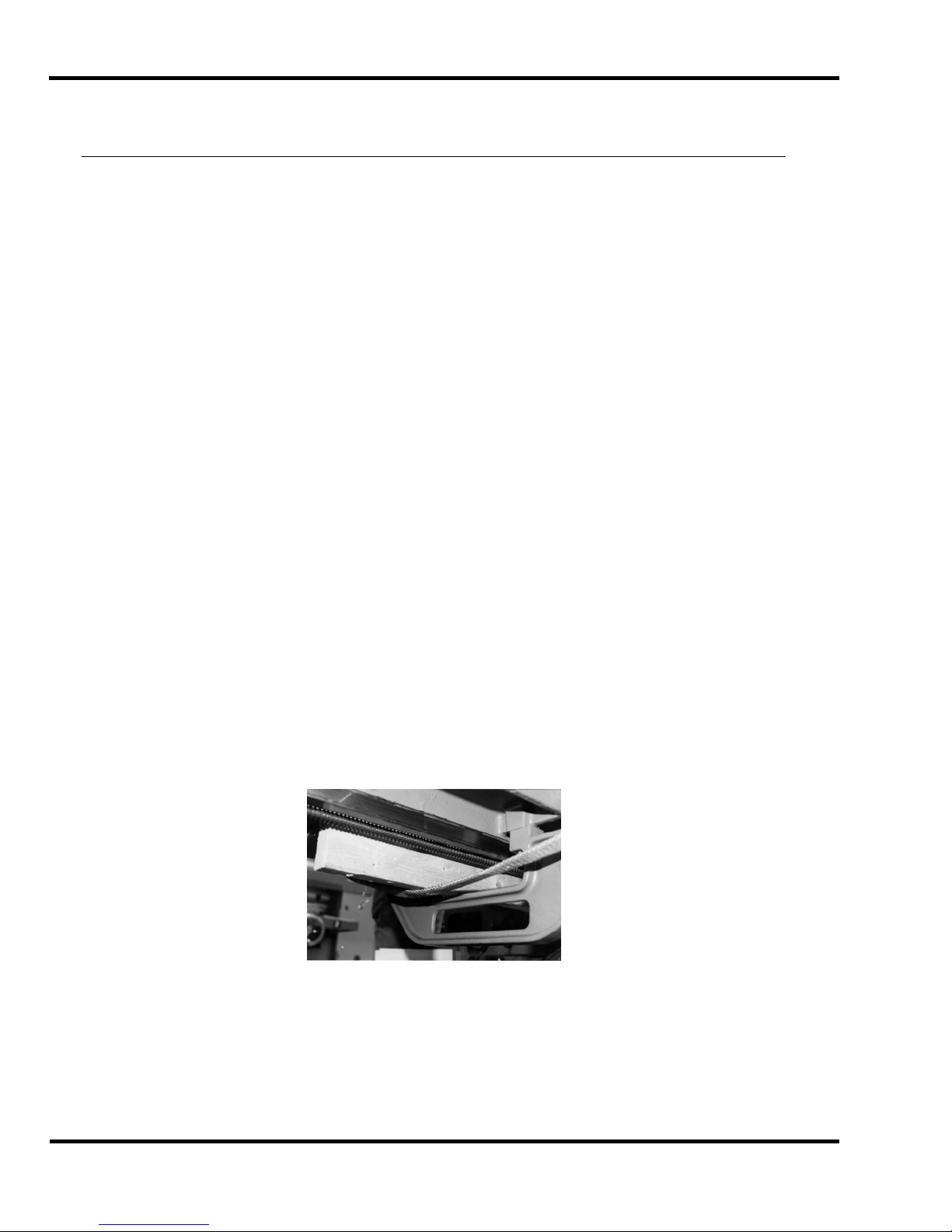

Lifting str aps may also be u sed to lif t the m achine by placi ng the straps arou nd the f ront and rear of

the table. When straps are used i n this way, wood blocks must be pl aced beside the lead screw to

prevent dam age, (Figure 2). A bent lead screw will cause the backgauge to bind.

Figure 2

The backgauge shoul d be po siti oned all the way to th e fr ont of the t able and straps placed a s clo se

the machine body as possible. Gently lift the cutter, r em ov e the skid and caref ully place the cutter on

the floor.

Once the machine is off its skid, it can be moved with a forklift or pallet jack.

12

Page 13

6. 0 In st all ation & Setup

6.4 Moving Instructi ons

Use a forklift or pallet jack to move the machine from the front. Do not attempt to lif t f r om the si des or

rear.

6.5 Cleaning

Wipe down the table and bare m etal surfaces with a non-flammable solvent such as CRC or blanket

wash. The table surf ac e is cast iron, and it will rust if left unprotected. Coat t he table with a nonabrasive wax. A Cutt er Care Kit, p/n 16077, with cleaner and wax, is av ailable through your

Authorized Challenge Dealer. The protective film on the console may be removed. Never clean

console with petroleum based solvents. Damage will result . Also see, Operator Cleani ng, pg. 58.

6.6 Assembly

Unless otherwise speci fied, the only items t hat have been disassem bled for shipping are the knif e,

Reach-Around shiel ds on the electric eyes and extension tables. Knife installati on wil l be c ov er ed

later. Extension table attachment follows.

NOTE: Extension tables are heavy. Use two people to attach them to the machi ne.

1. Assemble the back stops to the extension t ables. The extension table bolt s and hex nut s are

packed in the tool kit box. Tables are installed with the clearanc e hole for the knife gibs

towards the center of the cutter.

2. One person should hold the extension t able in position while the other aligns the holes and

starts threading the mounting bolts with washers. The mounting bolts are shipped installed in

the side of table- remove them to install tables.

3. Use a 9/16” socket and extension to snug tight en the mounting bolts, then tap the ext ensi on

table up or down with your hand or a rubber mallet until it is flush with the main table. Run a

straight edge or sheet of paper over the seam to check the fit. Make sure your stock will not

catch on the seam.

4. Insert the leveling setscrews into t he threaded holes next to the mounting bolts. You may

have to loosen the mounting bolts slightly to allow enough pl ay to level the table. After the

extension tables are leveled and the surface joint s even, tighten the mounti ng bolts securely.

5. The extension tables are powder-coated and need only be wiped down with a dry cloth. DO

NOT apply solvents or abrasive cleaners to extension table surfaces. They may cause

discolorat ion or scratches.

NOTE: The Reach-Around S hields for the electric eyes are in thei r shipping positions – follow the

instructions below to secure them in the operational position.

1. On t he bottom of the electric eye housing – loosen the screw closet to the machine. Do not

remove the screw

2. On t he bottom of the electric eye housing – loosen and rem ove the other two screws – rotate

the shield back out of t he c ut area. Line up the holes and re-install the screws – tighten all

screws (See the i nstr uc tion sheet included in the shipping material for more details).

ATTENTION

POTENTIAL CRUSH/LA CE RATIO N HAZZARD – THE SHIELDS AR E THERE FOR YOUR SAFETY.

: FAILURE TO INSTALL THE REACH-AROUND SHIELDS COULD CAUSE A

13

Page 14

6.0 Installati on & Setup

6.7 Hydraulic Power Unit Removal

If install ati on requi res that t he machi ne pass throu gh a door way that i s les s than 49” but great er t han

or equal to 42” wide, the machine should have been ordered from Challenge “k noc k ed down” with the

table rem oved. If the m achine must fi t through a doorway that is less t han 42” and greater than or

equal to 24-1/2” , the hydr aulic power unit m ust be remov ed on-site. T o remov e the hydrauli c power

unit, follow the instructions below.

1. Disconnect the electrical c onduits to the hydraulic motor, air blower, and hy dr aulic cooling

fan, junction box.

2. Locate the hose that connects the manifold to the oil filter. Disconnect it from the filter.

Disconnect the hy dr aulic pump hose from the manifold. Att ac h the hose that was connected

to the manifold to t he oil filter. Attach the hose that was connected to the filter to the

manifold. This will mi nimi z e oil leak age. After the unit is install ed, rec onnec t the hoses to

their original location.

3. Rem ov e the filler cap and use a transfer pump to remove the hydr aulic fluid into buckets.

4. Rem ov e the ( 4) bolts that attach the hydraulic assembly t o the cutter base. They are located

at the bottom shelf t he base.

5. USE EXTRE M E CAUTION WHILE REMOVING THE POWER UNIT. It is very heavy and

should be removed usi ng a fork truck. CAUTION, the machine will be top heavy and m ay tip

easily with the power unit removed. Move the reservoir thr ough the doorway on its side.

6. DO NOT ATTEMPT TO LIFT THE CUTTER BY PLACING STRAPS OR THE FORKS OF A

TRUCK UNDER THE CLAMP. This can damage the machine.

7. Reinstall the power unit, conduits, hoses, after the machine i s in position. Refill the hydraulic

reservoir.

14

Page 15

6. 0 In st all ation & Setup

6.8 Hydraulic Check

The hydrauli c r eservoir is fill ed with 13-1/ 2 gal lons of ISO VG 46 hydr auli c oil at the f actory . The fl uid

level should be check ed during i nstallati on, and at least onc e per week during norm al operati on. The

reservoir is located behind the cutt er, beneath the tabl e (Figure 3). The hydr aulic tank has a sight

gauge in the rear for c hec ki ng the oil level. The reservoir should be kept full at all times.

Sight

Gauge

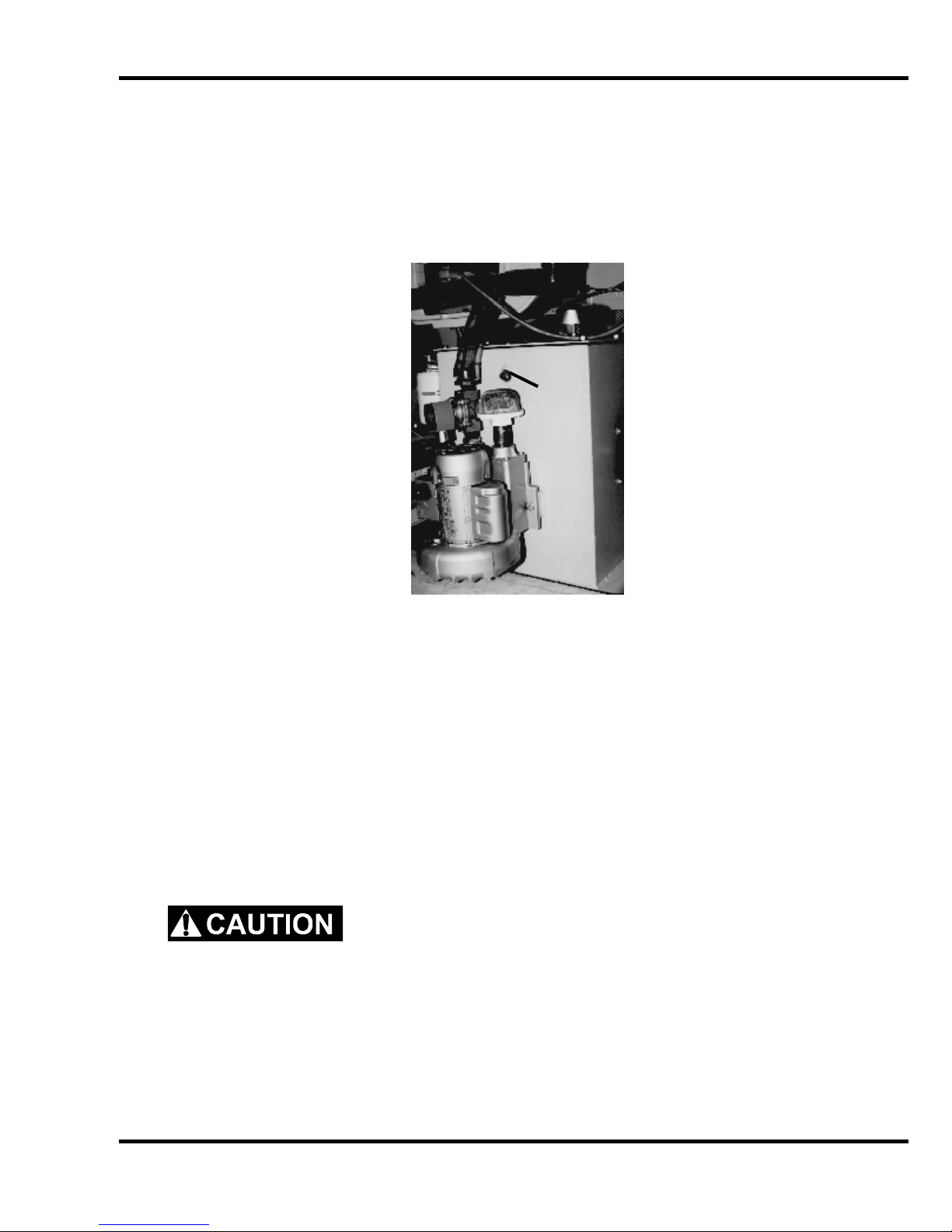

Figure 3

NOTE: DO NOT OVERFILL. Overfilling m ay cause leak age when the machine is hot.

6.9 Power Hook -U p

For satisfact ory oper ation, be sure that your cutt er is wired for the correct phase and v ol tage and has

adequate power. The c orrect elect rical specifi cations for your machine are shown on the seri al plate.

Check the machine serial plate before connecting the power. For future reference, transfer this

information to the front cover of this manual.

Watch Setup Voltage- Inadequate power to the cutter can be a major source of problems. Too

many machines on the same circuit will reduce the power to each machi ne. Inadequat e volt age will

cause ov erheating, loss of power, and in ex treme cases, f ailure to operat e. Test li ne voltage when

the shop is at actual working levels. Challenge recommends a dedicated line with a lockable

disconnect to pr ov ide adequate power for this machine.

CAUTION: SHOCK HAZARD! Always disconnect power at main

power panel befo re working on the cutter. Lock it out to prevent accidental power up. (S ee

Power Loc kout Procedure pa ge 6).

Important: You must have an adequ ate size c ir cuit and heavy enough wiri ng f or t his mac hine. T he

circuit size should be a minimum of 20% greater than the amperage rating on the machine

nameplate. If a wire is run over 75 feet ( 23 meters), the next siz e wire should be used. Check local

electric al c odes.

15

Page 16

6.0 Installati on & Setup

Electrical Specifications for Champion Cutters

Volts Amps Circuit Size Wire Size Metric Wire

3 Phase: 460 V 11.5 20 A #12 AWG 4mm sq.

230 25 35 #8 10mm sq.

208 25 35 #8 10mm sq.

1 Phase: 230 37 44 #6 16mm sq.

208 38.7 44 #6 16mm sq.

6.9.1 Three Phase Hook-Up

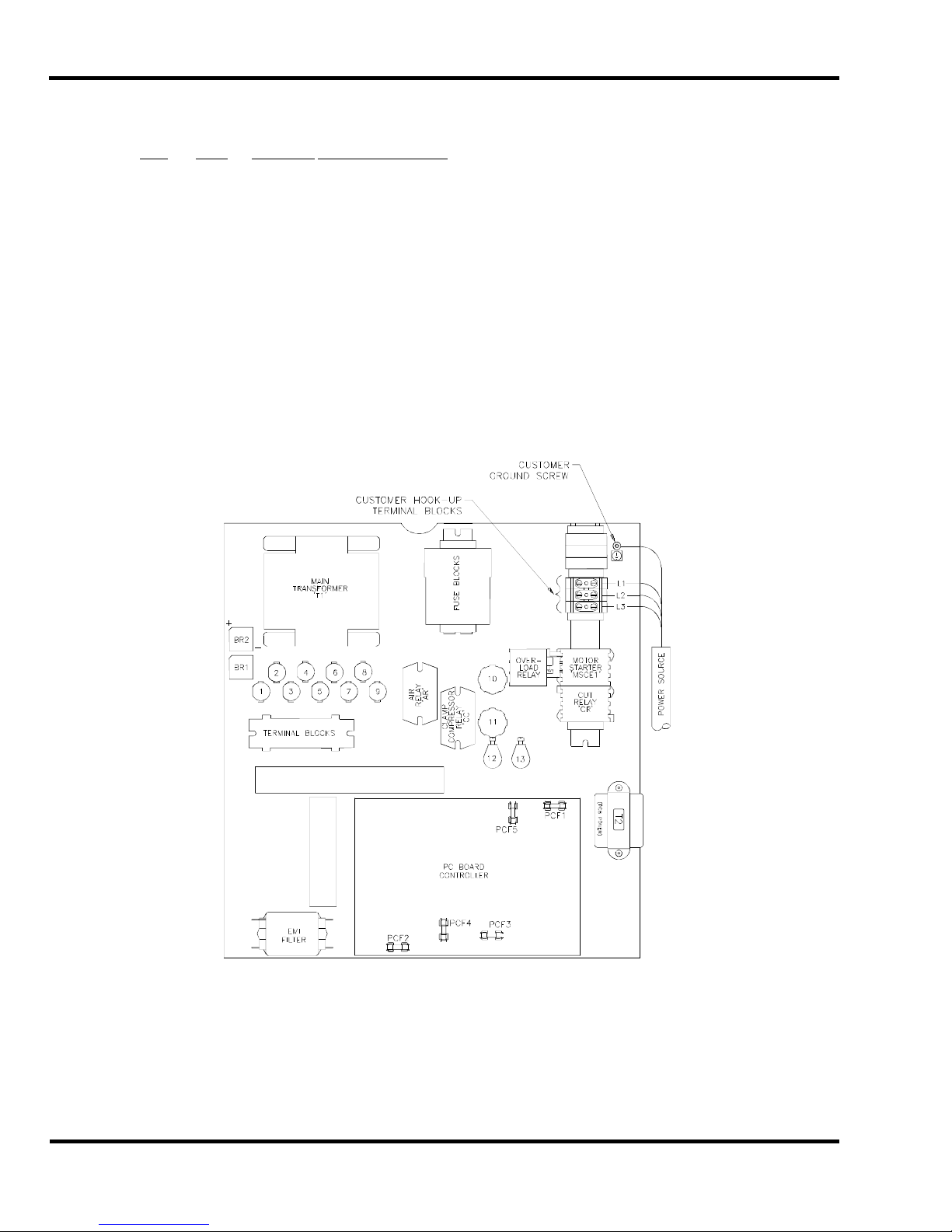

The power source is connect ed to the cutter through the bott om of t he power panel (right hand side).

1. DISCO NNE CT AND LOCK OUT THE POWER at the main panel to prevent accident al power

up. (See Power Lockout, page 6).

2. Thread the power cord through a conduit connec tor into the power panel.

3. Fasten the ground lead to the ground terminal lug (Figure 4).

4. Fasten the three power leads to the thr ee termi nals of the main power terminal block - L1, L2,

& L3.

5. Close the electrical panel doors and l atch them. Unlock the main panel and turn on the

power. Turn on the main power disconnect switch located on the front face of the table.

16

Figure 4

Page 17

6. 0 In st all ation & Setup

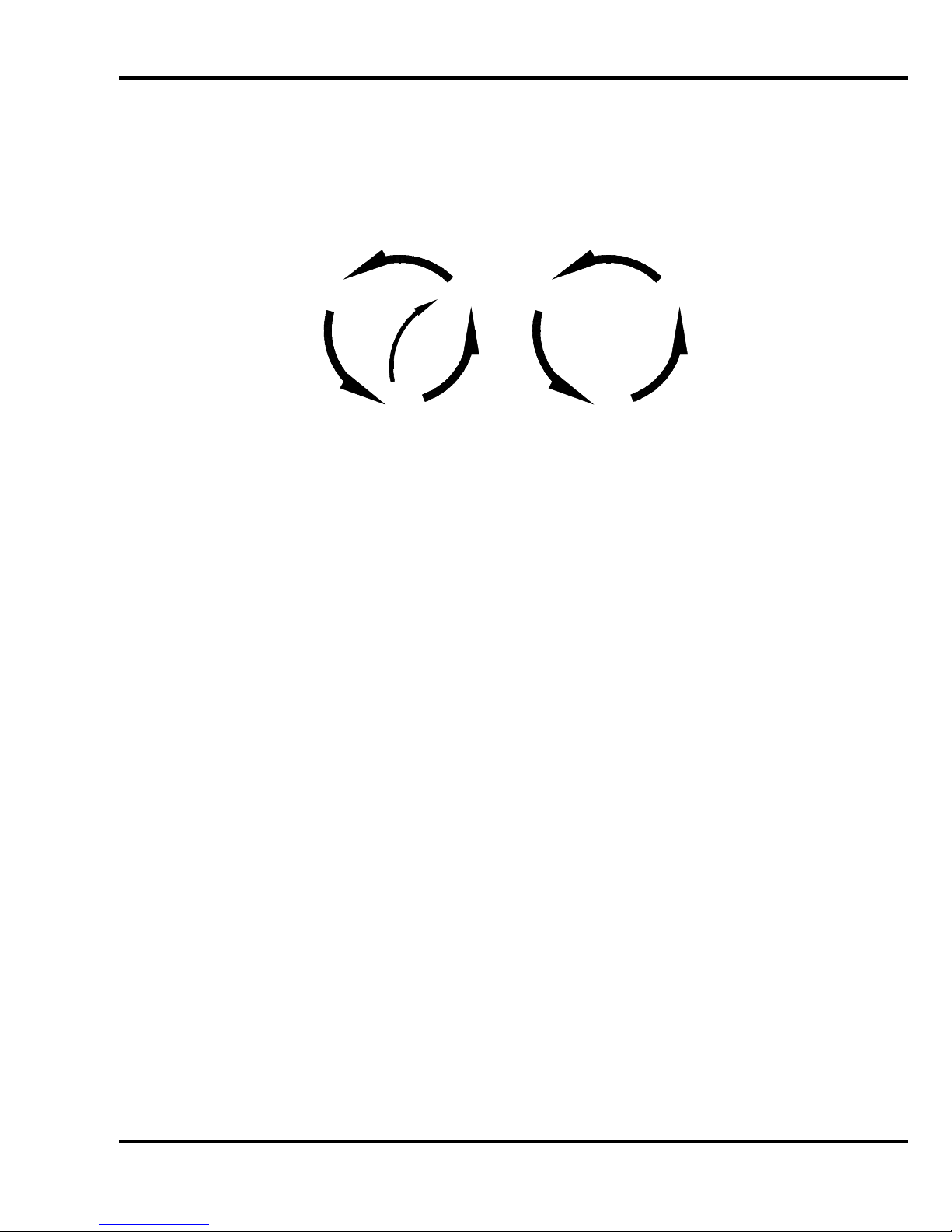

6. Press both cut buttons simultaneously to activate the motor and check to make sure it is

turning the same dir ec tion as the arrow on the motor casing.

If it is not turning the proper direction, disconnect the power and exchange any two leads of the power

cord as in Figure 5.

1

2

31 2

3

Figure 5

6.9.2 Single Phase Hook-Up

The power source is connect ed to the cutter through the bott om of t he power panel (right hand side).

1. DISCO NNE CT THE POWER AND LOCK IT OUT at the main power panel to prevent

accidental power up. ( S ee P ower Lockout, page 6).

2. Thread the power cord through a conduit connec tor into the power panel.

3. Fasten the ground lead to the ground terminal lug, (Figure 4 on page 16).

4. Fasten the two power leads to the L1 and L2 terminal s of the m ain termi nal block.

5. Close the electrical panel doors and l atch them. Unlock the main panel and turn on the

power. Turn on the main power disconnect switch and simult aneousl y pr ess both cut buttons

to start the hydraulic motor.

17

Page 18

7.0 Champion 305 Diagram

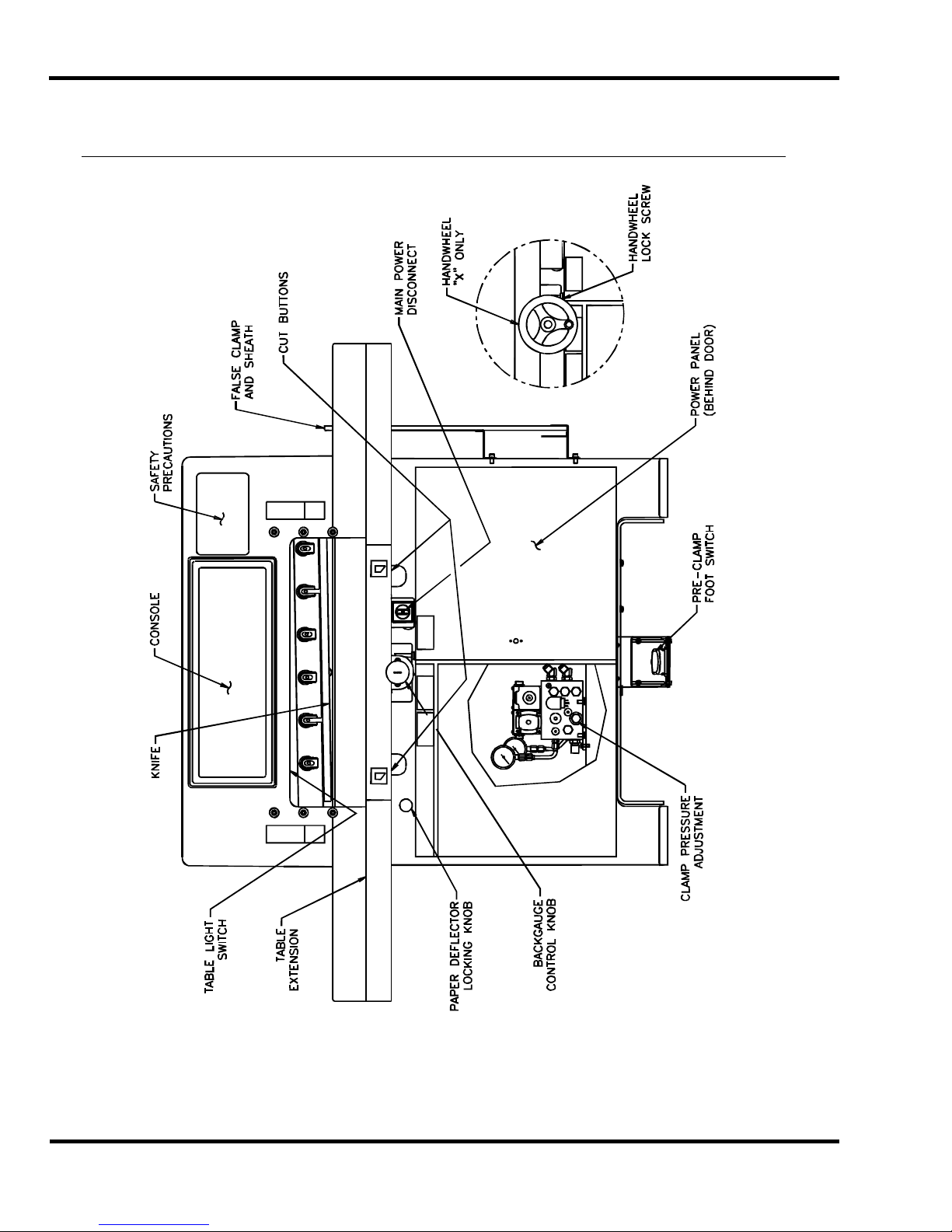

7.0 Champion 30 5 Diag r am

18

Figure 6

Page 19

8.0 Operation X Model

8.0 Operation X Model

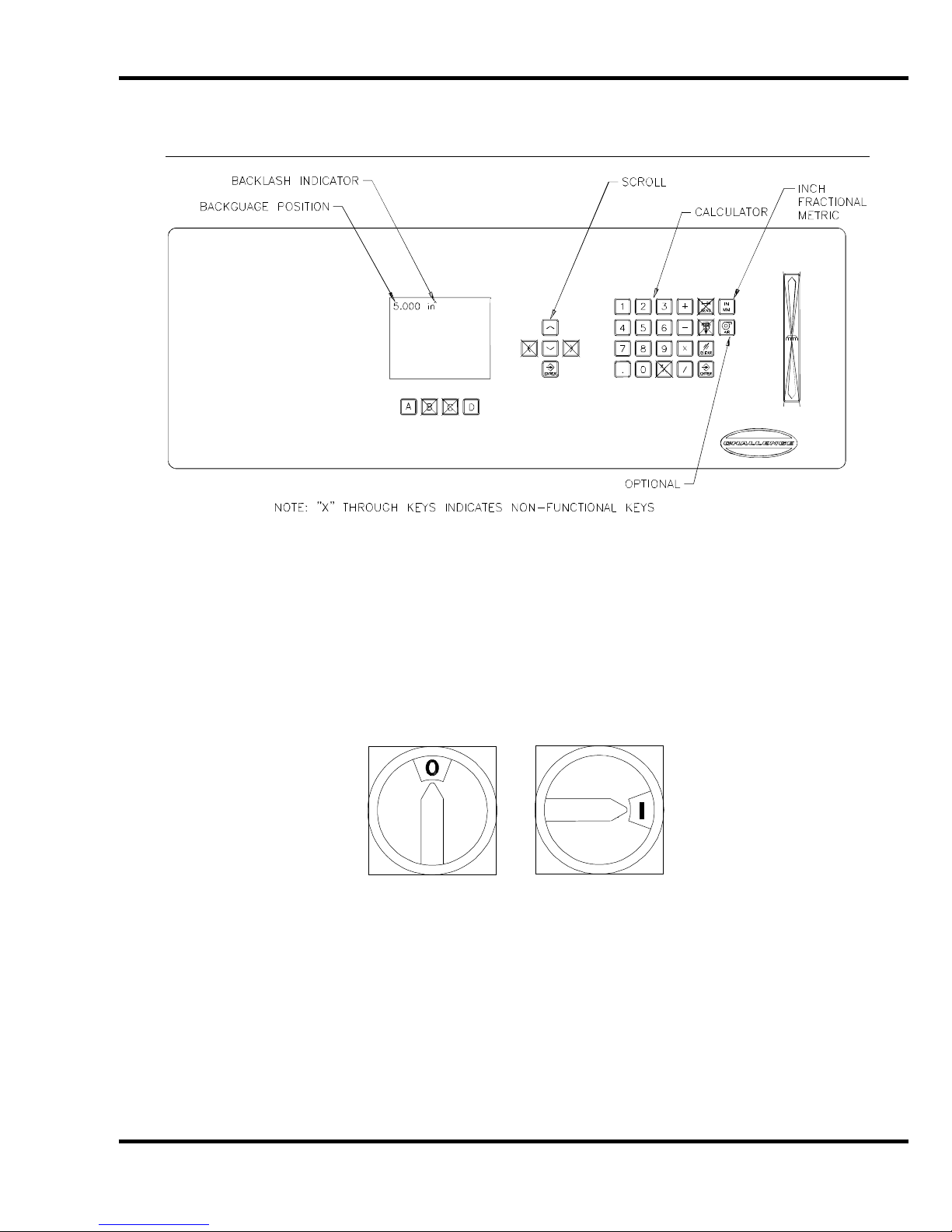

Figure 7

IMPORTANT: DO NOT ATTEMPT TO OPERATE THE CUTTER UNTIL YOU HAVE THOROUGHLY

READ AND UNDERSTAND ALL OF THE FOLLOWING INSTRUCTIO NS. CALL YOUR

AUTHORIZED CHALLENGE DEALER IF YOU STILL HAVE ANY QUESTIONS.

8.1 Power – Main Switch

Power is applied t o the mac hine when the main power switch is turned to t he “ON” position (Figure 8).

The display and line lights are turned on at this time.

OFF ON

Figure 8

The display and line lights will shut off after 2 minutes without any activity. To restore power to the

display and line li ghts, press either cut button.

19

Page 20

8.0 Operation X Model

8.2 Table Light

The table light is turned on and off using a switch located under the ar c h (Figure 6, page 18). The

table light will also turn on and off with the main power, provided t he table light switch is in the “on”

position.

8.3 Presetting the Backgauge

The backgauge must be preset every time the power is turned on. Using the hand wheel, turn the

backgauge until it passes forward through the 5” position. The display readout will then show the

correct back gauge posi tion.

8.4 Backlash Indica to r

A small carat will be displ ay ed nex t to the backgauge position if the back gauge was last moved

backward. To insure accurat e c uts, always approach the desired backgauge position from behi nd

(moving the backgauge forward).

8.5 Backgauge Lock

Tightening the backgauge lock prevents the bac k gauge from mov ing while positioning paper against

it. The Champion X model has a thumb screw l oc k beneath t he hand wheel, (Figure 9).

Thumb Screw

Lock

Figure 9

8.6 IN/MM Toggle Soft Key

This switch will toggle the display readout bet ween inc hes, fractions, and millimet er s. It can be f ound

on the console as shown in Fi gur e 7, on page 19.

8.7 Making a Cut

Place the paper agai nst the backgauge and left side guide. Press and release both c ut buttons once

to start the hydraulic motor. Then press and hold both cut buttons to start the cut cycle. While

holding the cut butt ons, the knife and clamp will complete t he c ut cycle. If the buttons are released at

any time during the c ycle, the knife and clamp will immediately return to the up position.

Note: Both cut butt ons must be released before a new cut can be made. The cut buttons must be

pressed withi n 1/2 second of each other both to start the hydraulic m otor and to make a cut.

20

Page 21

8.0 Operation X Model

DO NOT ATTEMPT TO REMOVE TRIM UNTIL THE KNIFE AND CLAMP

HAVE STOPPED IN THE UP POSITION! Due to static buildup, fine trim may have a tendency to

stick to the clam p or knif e surf ac es. Finger tips might be drawn into the knif e by the cl am p if this is

attempted. Wait until the knif e and cl am p hav e BOTH STOPPED MOVING before removing stock

trim.

8.8 Turning Off the Hydraulic Motor

The hydraulic m otor will turn off after 2 minutes without any activ i ty. The hydraulic motor can also be

shut off manuall y by pressing and hol ding the left cut button.

8.9 Jogging Aid

All Champion cutter s i ncl ude a jogging aid as standard equipment. The jogging aid allows the

operator to load and align stock without placing hands or arm s under t he cl am p and k nife area.

Load and align the paper against the side guide, (Figure 10), then square it to the backgauge for

cutting.

Figure 10

Additional j ogging aids can be purchased by contacting your authorized Challenge deal er .

Always remove the joggi ng aid from the table before making a cut.

8.10 Pre-Cl am ping

All Champion cutter s are equipped with a low pressure clam ping feature which allows the operator to

clamp paper bef or e beginning the cut cycle. To use this feature, press the footswitch until t he cl am p

comes down on the paper. While holding the foot switch down, press the cut but tons. Release it

once the cut has been completed. Although this is low pressure clamping, avoid placing hands under

the clamp at al l ti mes.

8.11 Air Table ON/OFF

If your machine i s equi pped with an air table, it can be turned on and off by pr essing t he soft key

shown in figure 7, page 19.

21

Page 22

8.0 Operation X Model

8.12 Adjusting the C lam p Pressure

DO NOT set the clamp pressure below 300 p si. Pressures below this

will not allow the auto-cycle to operate properly, and the kni f e will come down before the

clamp. Severe lacerations and stock spoilage could result.

A pressure reducer valve and gauge located inside the lef t door housi ng on the front of the cutter

below the table. By adj usting the pressure reducer valve, clamping pressure can be set (see

Hydraulic Adjustments section) to a maximum of 1400 psi for heav y stoc k or large reams to a

minimum of 300 psi f or pressure sensi tive jobs like carbon or NCR sets. For pressure sensit ive stock

using the fal se clamp plate is also recommended.

8.13 Re-calibrating the Backgauge

If the backgauge posit ion readout does not match the actual measurement between the knife and the

backgauge, the cutter must be re-calibrated. This i naccurac y c an oc c ur due t o r ough handling during

shipment.

The accuracy can be check ed by comparing cut sheets of paper. This process is described below.

NOTE: The bac k gauge gibs should be adjusted and t he bac kgauge squared before attempting to re-

zero, see Adjustments.

1. Place a 1/4 to 1/2 inch (5 to 13mm) pile of 8-1/2 X 11 (A4) paper against the center of the

backgauge.

2. Trim cut lengthwise and rotate 180

up to the 10" (254mm) position and make a cut. Move the backgauge up to 5" (127mm) and

make another cut.

3. Take several sheets from the cent er of each lift and compare them to each other. The

encoder system on your cutter will space accurately between your 10” (254mm) and 5"

(127mm) cuts, whether the overall accuracy is corr ec t or not. The stack of paper bet ween

the 10” (254mm) and 5" (127mm ) cuts will be a true 5", but the paper left against the

backgauge will not- if the backgauge position r eadout is off.

4. If the bac k gauge posi tion readout is off, you will have to adjust the accuracy. This parameter

provides a means for adjusting the accuracy of the backgauge. To change the accuracy,

send the backgauge to 2 inches (50.8mm) and cut paper. Measure the paper, and type in

what you actually measure. The computer will calculate the am ount of error and will

compensate. The amount of error could also be added to or subtract ed from the value

already displayed. Press “A” for Maint. Scroll to Param eters and Ent er . Scroll to Accuracy

Adjust and enter the measured value.

6. Run the back gauge back, then bring it forward thr ough the 5" (127mm) pre-setter again and

make another test.

0

. Using the backgauge position r eadout, bring the paper

8.14 Knife Do wn Mo de

The knife down mode is used to send the knife and clamp to the down position without returning up.

This provi des a way for the servi c e technician to change the knife. To send the knife down or up,

enter maintenance m ode, “A”. Select either Knife Down or Knife Up, and then press the cut buttons.

When sending the knif e down, t he c ut but tons must be held until the motor stops.

22

Page 23

8.0 Operation X Model

8.15 Electric Eyes

The electric ey es prevent reaching into the cutti ng ar ea while a c ut is being m ade. If the beams are

broken while a cut i s bei ng made, the knife and clamp will return to the up posi tion.

8.16 False Clamp Plate

The false clamp plate should be stored in its sheath when not in use. The sheath contains a sensor

that signal s the c om puter that the false clamp plate has been rem ov ed. The computer automatically

allows the minim um cut when the sensor detects the false clamp plate.

23

Page 24

9.0 Operation – XG Model

)

)

9.0 Operation – XG Model

IMPORTANT: DO NOT ATTEMPT TO OPERATE THE CUTTER UNTIL YOU HAVE THOROUGHLY

READ AND UNDERSTAND ALL OF THE FOLLOWING INSTRUCTIO NS. CALL YOUR

AUTHORIZED CHALLENGE DEALER IF YOU STILL HAVE ANY QUESTIONS.

9.1 Using the Machi ne

9.1.1 Power - Main Power Switch

OFF ON

Figure 11

Power is brought to the m ac hine when the main power switch is turned to t he “ON” position (Figure

11). The display and line lights are turned on at this time.

The screen saver will activate and the line lights will shut off after 5 minutes without any activit y. This

shut-off time c an be changed i n the Par am eters screen of the Maintenance Mode (see the “ Operating

Controls/Maintenance Mode/Paramet er s/Time Out” section). To restore power to the displ ay and line

lights, press any button on the keyboard.

9.1.2 Table Light

The table light is turned on and off by a switch located under the arch (Figure 6, on page 18). The

table light will also turn on and off with the main power, provided t he table light switch is in the “on”

position.

9.1.3 Start Up

Once power has been turned on, the display will show the following:

Clamp

Pressure

| | | 14 | | |

------------------------------ C) Up

D

Down

55.000 in

>_

Backgauge must move to be

preset. Please clear the table.

Revision 1.0

Press clear to start

E) Maint

Job H) Repeat

F

24

Page 25

9.0 Operation – XG Model

When the CLEAR key is pressed, the bac k gauge will move to coordinate t he true posi tion into the

computer (if the knife and clamp are not in the “up” position, the displ ay will pr om pt the operator to

raise them by pressing t he c ut but tons prior to presetting the bac k gauge) . When finished, the

machine will be i n “Send Mode” and the display will appear similar to the displ ay shown belo w.

The backgauge may now be sent to a desired posi tion by simply typing the dimension and pressing

SEND (see the “Send Mode” secti on, page 30, for more details).

Clamp

Pressure

| | | 14 | | |

------------------------------ C) Up

D) Down

5.070 in

>_

E) Maint

F) Job H) Repeat

9.1.4 Making a Cut

Place the paper agai nst the backgauge and side guide. Press and release both c ut buttons once to

start the hydraulic motor. Then press and hold both cut buttons to star t the cut cycle. While holding

the cut buttons, t he k nife and clamp will complete the cut cycl e. If the but tons are released at any

time during the cy cl e, t he k nife and clamp will immediately return to the up position.

NOTE: Both cut buttons must be r eleased before a new cut can be made. Also, the cut buttons must

be pressed withi n 0.5 seconds of each other in order to make a cut.

DO NOT ATTEMPT TO REMOVE TRIM UNTIL THE KNIFE AND CLAMP

HAVE STOPPED IN THE UP POSITION! Due to static buildup, fine trim may have a tendency to

stick to the clam p or knif e surf ac es. Finger tips might be drawn into the knif e by the cl am p if this is

attempted. Wait until the knif e and cl am p hav e BOTH STOPPED MOVING before removing stock

trim.

The hydraulic m otor c an be shut off at any tim e by pr essing soft-key “B” (Mtr Off). The hydraulic

motor will also shut off when the screen saver is activated. This shut-off time can be changed in the

Parameters screen of the Maintenance Mode (see the “Operat ing Controls/Maintenance

Mode/Paramet er s/Time Out” section, page 32).

9.1.5 Jogging Aid

All Champion cutter s i ncl ude a jogging aid as standard equipment. The jogging aid allows the

operator to load and align stock without placing hands or arm s under t he cl am p and k nife area.

Load and align the paper against the side guide, (Figure 12 on page 26), then square it to the

backgauge for cut ting.

25

Page 26

9.0 Operation – XG Model

Figure 12

Always remove the joggi ng aid from the table before making a cut.

Additional j ogging aids can be purchased by contacting your authorized Challenge deal er .

9.1.6 Adjusting the Clamp Pressure

The clamp pressure can be adjusted by pr es sing soft-key “C” (Up) to inc r ease the pr essure, and softkey “D” (Down) to decrease the pr essure. The pressure scale ranges fr om 0 to 15, 15 being t he

maximum.

9.1.7 Pre-Clam ping

All Champion cutter s are equipped with a low pressure clam ping feature which allows the operator to

clamp paper bef or e beginning the cut cycle. To use this feature, press the footswitch until t he cl am p

comes down on the paper. While holding the foot switch down, press the cut but tons. Release it

once the cut has been completed. Although this is low pressure clamping, avoid placing hands under

the clamp.

9.1.8 Knife Change Alarm and Lubrication Alarm

The Champion 305 XG has two built in alarms that will be displayed after a cer tain number of cuts.

The knife alarm displ ay s a message to r emi nd the operator to change the knife. The lube alarm

displays a message to remind the operator to have the mac hine lubr icated. The lube alarm will also

display the nam e and phone num ber of t he Challenge dealer from which the mac hine was purchased.

To reset either alarm, or to change the knife alarm value, see the “Operating Controls/Maintenance

Mode/Paramet er s/ K nife Count” section on page 32 . The lube alarm value is fact or y set at 2,500

cuts and cannot be changed.

9.2 Electric Eyes

The electric ey es prevent reaching into the cutti ng ar ea while a c ut is being m ade. If the beams are

broken while a cut i s bei ng made, the knife and clamp will return to the up posi tion.

9.3 False Clamp Plate

The false clamp plate should be stored in its sheath when not in use. The sheath contains a sensor

that signal s the c om puter that the false clamp plate has been rem ov ed. The computer automatically

allows the minim um cut when the sensor detects the false clamp plate.

26

Page 27

9.0 Operation – XG Model

9.4 Champion XG – Displa y Pan el

9.5 Definition of Ke ys

9.5.1 Backgauge Glide Control

The backgauge glide c ontrol is used to manually position the backgauge. The speed of the

backgauge will depend upon where the ac tuator is pressed. Press farther from center for a faster

speed, and closer t o c enter for a slower speed. To move the backgauge forward, press down ward.

To move the backgauge backward, pr es s up ward.

9.5.2 IN/MM Key

This key toggles the display to show the position and programmed send values in inches (e.g. 5.250),

inch fractions to the nearest 1/64” (e.g. 5_

9.5.3 Air Table ON/OFF Key

This key turns the ai r table on and off.

9.5.4 Send Key

1

/4), or millimeters (e.g. 133. 3) .

The SEND key is used to send the backgauge to any valid position. If an att em pt is made to send the

backgauge to an illegal position, an error message will be displ ay ed at the bottom of the screen

stating “Number outside limit”. In the Job mode, the SEND key will also adv anc e the back gauge to

the next sequenti al c ut position before performing the cut.

27

Page 28

9.0 Operation – XG Model

9.5.5 Push-Out Key

The push-out key will m ov e the back gauge forward 5 inches (or to the most forward position) and

then return it to its previous position. This allows paper to be removed from the cutter without putting

hands under the knife and clamp.

the backgauge glide control to move the paper to an area where it can be r eac hed.

Never place hands in the clam p and knife ar ea. Use the push-out key or

9.5.6 Clear Key

The CLEAR key is used to clear err or messages and t he c ur r ent entry line.

9.5.7 Enter Key

The ENTER key selects items in the maintenance mode and processes data that has been entered in

the other modes.

9.5.8 Priority Add (X/Y) Key

The priority/add key is used for entering fractions when they are combined with whole num ber s. The

symbol display ed when this key is pressed is the underli ne symbol “ _”. An exam ple of a number

entered using the priority/add key is 1_1/2.

9.5.9 Soft Keys

There are a total of eight Soft Keys labeled “A” through “H”. The func tions of these keys change

depending on the operating mode. The function of each key c an be found on the bottom of the

display screens.

9.5.10 Arrow Keys

The four arrow keys can be used in almost all screens. The arrow keys are prim aril y used for moving

the cursor around on the screen, or to toggle between highlighted selections. In some screens, the

left arrow key act s as a backspace key.

28

Page 29

9.0 Operation – XG Model

9.5.11 Contrast Control (Only on Serial numbers 10x1535 and below)

The contrast of each display screen can be adjusted by using the c ontrast control buttons located

directly abov e eac h displ ay screen.

9.5.12 Contrast Control (For Serial numbers 10x1536 and up)

The contrast of each display is controlled by the comput er if additional adjustments are needed use

the following procedures;

A. To adjust the left hand screen ( Graphic screen) hold the hidden button (located to the

right of the “CLEAR” butt on and below the “AIR” button) and use the ri ght and left scroll

buttons to adjust the contrast.

B. To adjust the ri ght hand screen (Text screen) hold the hidden but ton (located to the right

of the “CLEAR” button and below the “AIR” button) and use the up and down scroll

buttons to adjust the contrast.

9.6 Manual Backgauge Control

9.6.1 Backgauge Glide Control

The backgauge can be moved m anually by use of the backgauge glide control . Pr ess towards the

operator for forward travel and away from the operator for reverse travel. The further away fr om

center that the actuator is pushed, the faster the back gauge will trave l. The backgauge moves faster,

the more the knob is tur ned.

9.6.2 Backgauge Control Knob

The backgauge may also be contr olled using the Backgauge Control Knob l oc ated at the front of the

table. Turning the knob cl oc k wise brings the backgauge forward. Tur ning the knob counterclockwise sends the backgauge bac kward. The more the knob is turned, the faster the backgauge

moves.

9.6.3 Backlash Indicator

To insure accurate cuts, the backgauge must be brought to the cut position from the rear of the table.

In the display, to t he ri ght of the bac k gauge posi tion, there is a small arrow to indicate reverse travel.

This arrow should be off when m aki ng a c ut. Moving back past your cut positi on, then forward to it,

compensates f or any pl ay i n the back gauge nut and lead screw.

29

Page 30

9.0 Operation – XG Model

9.7 Send Mode

Clamp

Pressure

| | | 14 | | |

------------------------------ C) Up

D) Down

The send mode is the first screen displayed after the backgauge is preset. From this screen the

backgauge can be positioned with the backgauge pi npoint control or by entering a value and pr essing

the SEND key. A mathematical expression can also be entered as a send value. Simply type t he

expression and press SEND. Y ou c an also enter an equation which begins with the current

backgauge posit ion. For example, if you want to send the backgauge 2” forward from its current

position, just pr ess [-] [2] and SEND.

The send mode screen can al so be used f or doi ng m ath cal c ulations that are larger than the

backgauge’s rev er se l im it. In this case, you must press ENTER to have the result displayed on the

screen.

9.7.1 Entering Math

5.070 in^

>_

E) Maint

F) Job H) Repeat

Reverse

Indicator

Arrow

In the simple send mode, the Champion XG is capable of calculating an entire math string such as,

10-5+5x6+2_3/ 4. However, the result is limited to 29999.000 and t he r esul t cannot be a negative

value. In the job mode, and duri ng a send, the result of the calculation must be less than the

backgauge limit of 30. 500 inches.

9.7.2 Entering Fractions

Fractions are enter ed with the priority add key X/Y. T he symbol displayed when this key is pressed is

the underli ne sym bol “ _”. This instructs the computer to add the fr actional portion of the entry bef or e

performi ng the rem aining math. This key is useful when entering a formula as follows: 3x2_3/4 =

8_1/4. If a simple plus had been used instead, the result would be as f ollows: 3x 2+3/4 = 6_3/4.

30

Page 31

9.0 Operation – XG Model

9.8 Repeat Mode

This mode allows the operator to make a series of cuts during which the back gauge m oves a

specified distanc e between each cut. To enter repeat mode, press sof t-key “H” (Repeat). The

display will then look like the one below:

Clamp

Pressure

| | | 14 | | |

------------------------------ C) Up

D) Down

Type in the desired initial backgauge position and pr ess ENTER. The backgauge will then move to

that position. Then type in the step value and press ENTER. Positi on the paper and m ak e a c ut.

The backgauge will then move forward by the step amount, and a new cut can be made. When

finished, press sof t-key “H” (Exit) to exit bac k to send mode.

5.070 in

ORIGIN >_

STEP

Initial Position

H) Exit

9.9 Maintenan ce Mode

The maintenance mode is an area where many machine functions can be set or m odified. The four

principl e functions are: Language, Parameter s, Di agnostic, and Knife Adjust. To select a par ticular

function, use the up and down arrow keys to toggle to the desired function and press ENTER. See

the following descriptions for an explanation of each function.

Clamp

Pressure

| | | 14 | | |

------------------------------ C) Up

D) Down

5.070 in

MAINT MENU

LANGUAGE

PARAMETERS

DIAGNOSTICS

KNIFE ADJUST

Select and press enter

G) Send

F) Job H) Exit

9.9.1 Language

In the language screen, use the up and down arrow keys to toggle to the desired language, and press

ENTER. All messages will be displayed in the selected language.

31

Page 32

9.0 Operation – XG Model

9.9.2 Parameters

In the paramet er screen, use the up and down arrow keys to toggle to the desired par am eter, and

press ENTER. See the descriptions that follow for an explanat ion of each parameter.

9.9.2.1 Fal se Cl am p (For serial numbers 03x1012 and below)

The false clamp plate is an optional attachment, whic h reduces the cr easi ng of paper caused by the

clamp. The disadv antage of using the false clamp plate is that it limi ts the smallest cut dimension.

The computer must know when the false clamp plate is installed on the machin e to preven t

the backgaug e from crashi ng into it. In the false clamp screen, use the up and down arrow keys to

toggle between ON or OFF to indicate the presence of the false clam p plate, and press ENTER.

9.9.2.2 Fal se Cl am p (For serial numbers 03x1013 and up)

The false clamp plate should be stored in its sheath when not in use. The sheath contains a sensor

that signal s the c om puter that the false clamp plate has been rem ov ed. The computer automatically

allows the minim um cut when the sensor detects the false clamp plate

9.9.2.3 Time-out

This parameter sets the am ount of idle time for which the screen saver ac tivates and the line lights

and hydraulic motor turn off. The choices are 2, 5, 10, 20, and 30 minutes. I n the time-out screen,

use the up and down arrow keys to toggle to the desired time-out, and press ENTER.

9.9.2.4 Push-out

Normally, whenever the backgauge is sent to a larger dim ensi on, a five-inch (127mm) push-out is

perform ed to aid t he operator in ac c essing the paper. In some situations, it m ay be necessary to turn

this featur e off . It is recommended that this feature be left on whenev er possible. In the push-out

screen, use the up and down arrow keys to t oggle to the on or off status as desired, and press

ENTER.

9.9.2.5 Accuracy Adjust

This parameter pr ov ides a means for adjusting the accuracy of the back gauge. To change the

accuracy, send the bac k gauge to 2 inches (50.8mm) and cut some paper . Measure the paper, and

type in what you actually measure. The computer will calculate the amount of error and will

compensate. A value may al so be added to or subtr acted from the current value.

9.9.2.6 Knife Count

The knife count parameter allows the operator to reset the knife alarm and the lube alarm. The knife

alarm displays a message to r em ind the operator to change the knife. The lube alarm displays a

message to remind the operator to have the machine lubricated. The lube alarm will also display t he

name and phone number of the Challenge dealer from which the machine was purchased.

There are three functions within the knife count par am eter: Clear Count, Knife Alarm, and Clear

Lube. Select the desired function and press ENTER. See the following descri ptions for an

explanati on of eac h function.

Select Clear count to reset the knife c ounter when a knife change has been performed.

Select Knife Alarm to enter or change the knife stroke alarm value. When this value is reac hed, the

display will aler t you to change the knife and reset the knife count er. Knife alarm values for the

32

Page 33

9.0 Operation – XG Model

Champion XG are factor y set at 2, 500 c uts. Howev er , you may want to change this value based on

your specific machine applications. See the Knif e section for help in choosing a knife alarm value f or

your machine.

Select Clear lube to reset the lube alarm after performing the lubrication requirements as shown in

the Lubrication section of this manual. NOTE: The alarm will activ ate after 2,500 cuts. This value is

set at the factory and cannot be c hanged.

9.9.2.7 Machine count

The number displ ay ed is the total number of cuts made by the machine.

9.9.3 Diagnostic

The diagnosti c ar ea can be very hel pful in locating a problem in the ev ent of a machine m alfunction.

Use the up and down arrow keys to toggle to the desired selection, and press ENTER. See the

following descri ptions for an explanation of eac h.

9.9.3.1 Error Code

The Error Code functi on simply recalls the last five err or messages that were di spl ay ed. This can be

very useful in cases when the malfunction cannot be reproduced i n the presence of the service

technician.

9.9.3.2 Sensor Data

Clamp

Pressure

| | | 14 | | |

------------------------------ C) Up

D) Down

5.070 in

DIAGNOSTIC

Error Code

Sensor Data

Clear Memory

Adjust Clamp

Select and press enter

A) Maint G) Send

F) Job H) Exit

The Sensor Data function provides a list of computer inputs and output s (proximity switches, etc.)

along with their status (0 for open, 1 for closed). This functi on allows a service technician to chec k

the status of a switch without removing any covers. Cuts and backgauge movements are allowed in

this screen so that the technician may observe the status of the inputs and outputs during machine

operation.

9.9.3.3 Clear Memory

The Clear Memory function resets the memory to a known state. All cut po sitio ns will be erased

during this operation.

33

Page 34

9.0 Operation – XG Model

9.9.3.4 Knife Adjust

The knife adjust function provides a way for the service technician to change the knife. In the Knife

Adjust screen, use the up and down arro w keys to toggle to the up or down status as desired, and

press ENTER. Press and hold the cut but tons to send the knife to the desired position.

9.10 Job Mode

The Champion XG can be programm ed for up to 99 different jobs. A job is a sequence of

programmed c ut positions. The backgauge moves to each position after a cut cycle is made. Each

job can hold up to 99 send val ues. Job mode is entered by pressing soft-key “F”. W hen the job m ode

is entered, all previously programmed jobs will be displayed along with their name and lock stat us.

Locked jobs display the word “Lock” after their name. A plus “+” sign at the bott om of t he scr een

indicates there ar e m or e jobs programmed than what are displayed. Pressing the left arrow key and

the down arrow key sim ultaneously will page down to the next set of jobs. P age 59 contains an

example of how to program a job.

9.10.1 Lock/Unlocking a Job

Clamp

Pressure

| | | 14 | | |

------------------------------ C) Up

D) Down

>

JOB 1

1>

2>TESTJOB

5>

6>BOBS JOB Lock

7> 8.5 X 11 Lock

9>

10>

+

E) Lock G) Erase

F) Copy H) Exit

In the Job Mode screen, the soft-key “E” will display “Lock” or “ Unlock” depending on the current

status of the job. If a job is locked, the word “Lock” will be displayed t o the ri ght of the job name.

Locking a job prevents it from being edited. To change the lock stat us of a job, sim ply move the

cursor to the desired job using the up and down arrow keys, and press the soft-key “E” (Lock/Unlock) .

9.10.2 Copying a Job

First, select a job to copy by moving the cursor up or down to the desired job number and pr ess the

soft-key “F ” (Copy) . “S elec t Copy to #” will be displayed at the bottom of the screen. Enter a job

number for the new job or move the cur sor to an existing job and press ENTER. If the new job is

locked, the copy will not be allowed. NOTE: if the new job is not locked, but contains data, the old

data WILL BE LOST.

9.10.3 Erasing a Job

Select a job to erase by mov ing the cur sor to the desired job. Press the soft- k ey “G” (Erase). “Clear

channel #” will be displayed, followed by YES or NO. Use the up and down arrow keys to toggle to

YES or NO. YES will erase the job, NO will leave the job unchanged. NOTE: locked jobs cannot be

erased.

34

Page 35

9.0 Operation – XG Model

9.10.4 Creating a New Job

To create a new job, type i n a number t hat is not alr eady assigned t o a job and press ENTER

(entering a job num ber gr eater than 99 will create job #99). The cursor will move to the line

corresponding to t he num ber y ou typed in, prompting you for a job name. If no job name is desir ed,

simply press ENTER again to begin entering send values (see bel ow). To name the job, press the

right arr ow key to move the cur sor to the first character position. Enter a character of the alphabet by

using the up and down arrow keys to toggle to the desired character. The numeri c keys can be used

to enter numbers di r ectly into the job name. When the desired character i s in pl ace, use the right

arrow key to move to the next char ac ter position. The job name can be up to 10 characters l ong. A

letter can be rem ov ed from the job nam e by mov ing the cursor to the undesired character and

pressing the CLEAR k ey. When fi nished, press ENTER to save the name and to begin enteri ng send

values. The screen should now look similar to the one below:

Clamp

Pressure

| | | 14 | | |

------------------------------A) Division

D) Cut & Rec.

9.10.4.1 Entering Send Value

5.070 in JOB1

#1

1>_

E) Insert G) Erase

F) Job H) Exit

Send values can now be entered by using any of the following methods: 1) Type i n the desir ed v alue

and press ENTER, 2) Press ENTER at a blank line - this will enter the current position of the

backgauge as a send val ue, 3) Use the “ Cut and Recor d” feature (described later) or 4) Use the

“Sheet Divi si on” feat ur e.

9.10.4.2 Creating a Stock Loading Position

After typing a send v alue, pressing the right arrow key instead of E NTER will m ov e the cur sor t o the

right and prom pt t he operator to enter a rotation indicator mar k or Load Zone ( LZ). Selecting LZ will

make it impossible to cut at that position. Pressing both cut butt ons on a posit ion marked at a

Loading Zone will pr om pt t he bac k guage to move to the next position in the job. Using a loadi ng

position eliminates the need to reach into the knife/clamp area of the cutter when loading a job.

9.10.4.3 Entering Rotation Mark

After typing in a send value, pr essing the right arrow key instead of ENTER will move the cursor to

the right and prompt t he oper ator to enter a rotation indicat or mark . The di splay will look similar to the

one shown below:

35

Page 36

9.0 Operation – XG Model

Use Soft Keys “C” and “D” to choose a tur n indic ator. Pressing ENTER will place an indicator mark to

the right of the send v alue, as shown below:

When the desired indicator mark is in place, press the ri ght arrow key. The cursor will move to the

right and prom pt t he operator to enter a clamp pressure (see the following section).

NOTE: All new entry lines will have the same turn indicator mark as the one abov e it, until it is

changed.

9.10.4.4 Entering the Clamp Pressure

Turn Indicator

Off

ccw >

cw <

180 Turn >>

Load Zone LZ

Select & Press Enter

C) Up

D) Down

Clamp

Pressure

| | | 14 | | |

------------------------------ C) Up

D) Down

5.070 in JOB1

#1

1> 5.070 _

H) Exit

5.070 in JOB1

#1

1> 5.070 >>

H) Exit

A separate clamp pr essure can be enter ed for each cut in a job. To enter the desired cl amp

pressure, fi r st enter the desired send value (descri bed abov e) , then press the right arrow key and

enter the rot ation mark if necessary (described above), then press the right arrow key agai n to mov e

the cursor to where the clamp pressure can be entered. Use Soft Keys “C” and “ D” t o inc r ease or

decrease the clamp pr essure, or use the numeric keypad to enter a num ber fr om 0 to 15 (see

Adjusting the Clamp Pressure section, page 26 for inf ormation about the clamp pressure setti ng) .

This will com plete the entry for the current line and move the cursor t o the send v alue of the next line.

NOTE: All new entry lines will have the same clamp pressure as the one above it, until it is changed.

9.10.4.5 Cut and Record