Page 1

The Challenge Machinery Company provides owner's manuals on its

products solely as a courtesy to its customers. See the information below

before using this manual.

These manuals are for reference only. These manuals include products which are noncurrent,

unsupported or no longer produced by The Challenge Machinery Company, and are provided solely as

an accommodation to our customers. By providing these manuals, The Challenge Machinery Company

makes no representation or warranty as to the products, their current condition, or their suitability or

fitness for use in any particular application, which are the sole and independent responsibility of the

product owner and user.

Older products may not comply with current safety procedures, guidelines or regulations, and it

is the product owner's and user's responsibility to evaluate the suitability and fitness of the

products in their current use and application. The Challenge Machinery Company makes no

representation, warranty or recommendation regarding any modifications which may be

required on non-current or unsupported products. The Challenge Machinery Company assumes

no liability for any modification or alteration to any Challenge product, and any such

modification or alteration to any Challenge product is not authorized by The Challenge

Machinery Company. The availability of these manuals is solely for the purpose of providing reference

information for the products.

This manual may not be complete in all aspects of product maintenance and repair. All products

should be used only by qualified and properly trained personnel, following proper safety

procedures. All products should be regularly inspected and maintained, and their condition, application

and use should be periodically evaluated by qualified personnel. Only qualified and properly trained

technicians should perform maintenance, repair and replacement procedures. Attempting these

procedures without proper training may cause machine damage or operator inj ury!

Products may be unsupported by The Challenge Machinery Company due to age or the unavailability of

parts from their original manufacturer. No parts or product support will be available to repair or maintain

unsupported products. Older products may not be UL listed (if the product does not have a UL label it is

not a listed product), and may not comply with applicable installation or other regulations or

requirements if relocated to a new facility. Many municipalities require a product to be UL listed before

an electrician will connect power to them. Often the cost of updating an older product to comply with

current safety regulations is greater than the value of the product.

The Challenge Machinery Company

6125 Norton Center Drive

Norton Shores, MI 49441-6081 USA

ChallengeMachinery.com

F.254-J

May 2014

CHAMPION 305 TC

Instruction and Parts Manual

Serial Numbers 1301701 & Up

Sold and Serviced by

Page 2

1.0 Introduction

1.0 Introduction

This manual is designed to help you get the most from your Challenge equipment. Keep this manual

in a safe, convenient place for quick reference by operators and service personnel.

SAFETY ALERT! This symbol means CAUTION: Personal safe ty

instructions! Pay special attention to the instructions in bold type. Personal injury may result if the

precautions are not read and followed.

READ THIS MANUAL BEFORE OPERATING! Follow the precautions and instructions given. If

after reading the manual questions still remain, contact your Authorized Challenge Dealer.

FOR PARTS AND SERVICE, contact the Authorized Challenge Dealer from whom you purchased

the machine. Use the illustrations and parts lists at the back of this manual to identify the correct

parts needed. Always give the SERIAL NUMBER and MODEL of your machine to insure the correct

parts are sent as soon as possible.

RECORD YOUR MACHINE SERIAL NUMBER in the space provided on the front cover of this

manual. Fill out the warranty card accompanying your machine and return it DIRECTLY TO

CHALLENGE.

If you bought a used machine, it is important to have the following information on record at Challenge.

Copy this page, fill in the information and send it care of The Challenge Service Department, 6125

Norton Center Drive • Norton Shores • MI 49441.

CHALLENGE MODEL SERIAL NUMBER

ATTN COMPANY

ADDRESS

CITY STATE/PROVINCE ZIP

PHONE DATE INSTALLED

DEALER NAME & CITY

* WARRANTY INFORMATION *

It is very important that you read and understand the conditions outlined in the Warranty Information

Sheet attached to the outside of the shipping container of your machine.

The Warranty Information Sheet must be filled out completely and returned to THE CHALLENGE

MACHINERY COMPANY in order for the warranty to be issued for this machine.

The Challenge Machinery Company • 6125 Norton Center Drive • Norton Shores MI 49417

Copyright© 1997-2014 by The Challenge Machinery Company. All rights reserved. Printed in the U.S.A

Challenge® is a registered trademark of

2

Page 3

1.0 Introduction

TABLE OF CONTENTS

1.0 Introduction ...................................................................................................................................... 2

2.0 Safety............................................................................................................................................... 5

2.1 Precautions.................................................................................................................................. 5

2.2 Power Lockout Procedure ........................................................................................................... 5

2.3 Warning Label Definitions............................................................................................................ 6

3.0 Packing List...................................................................................................................................... 8

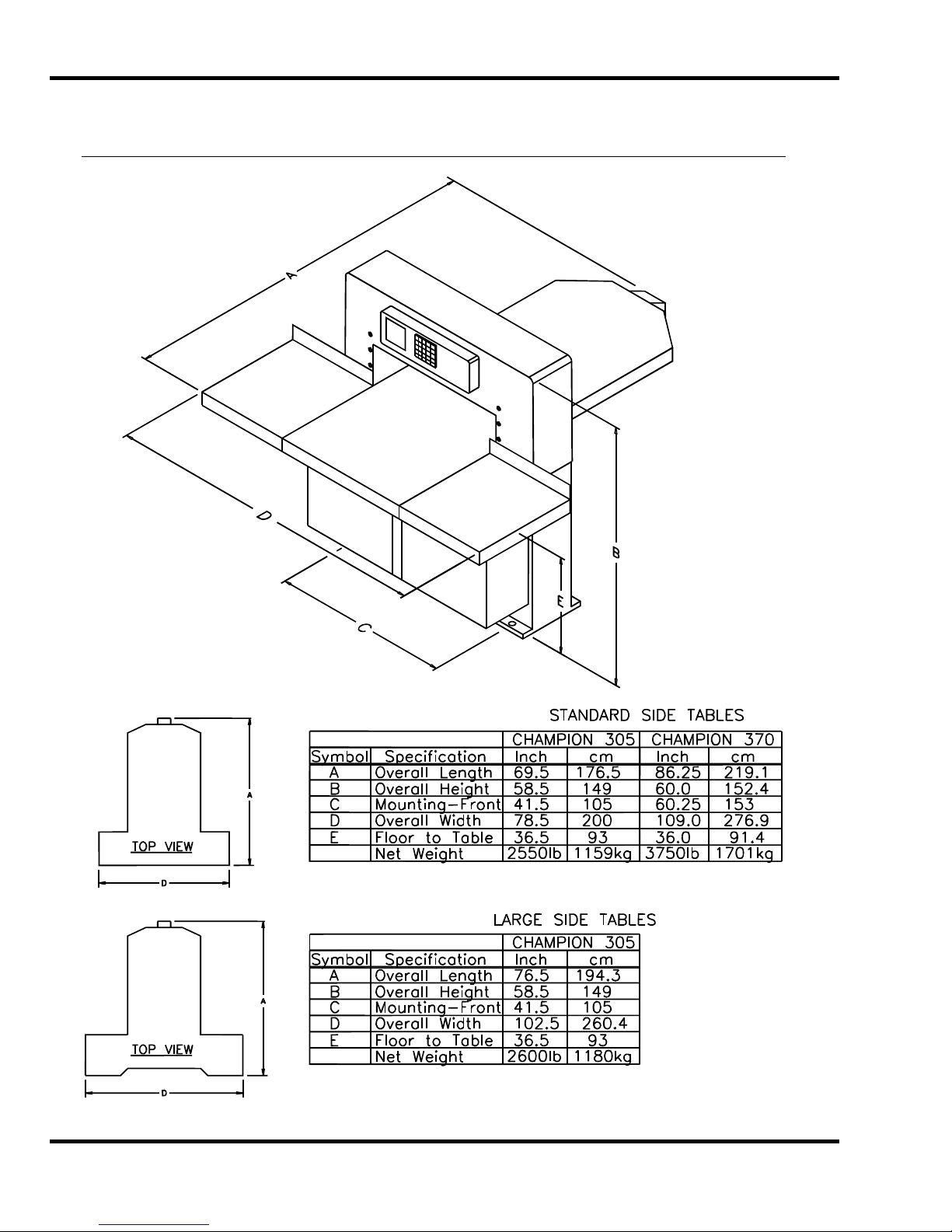

4.0 Specifications................................................................................................................................... 9

5.0 Footprint......................................................................................................................................... 10

6.0 Installation & Setup........................................................................................................................ 11

6.1 Inspecting Shipment.................................................................................................................. 11

6.2 Uncrating ................................................................................................................................... 11

6.3 Lifting/Moving Instructions......................................................................................................... 11

6.4 Cleaning..................................................................................................................................... 12

6.5 Assembly ................................................................................................................................... 12

6.6 Hydraulic Power Unit Removal.................................................................................................. 13

6.7 Hydraulic Check......................................................................................................................... 13

6.8 Power Hook-Up ......................................................................................................................... 14

7.0 Operation ....................................................................................................................................... 16

7.1 False Clamp Plate ..................................................................................................................... 16

8.0 Knife Installation/Changing............................................................................................................ 18

8.1 Knife Removal ........................................................................................................................... 19

8.2 Knife Installation ........................................................................................................................ 20

8.3 Knife Care Tips.......................................................................................................................... 22

8.3.1 Knife Blade Life.................................................................................................................. 22

8.3.2 Cutting Stick ....................................................................................................................... 23

8.3.3 Bevel Angle ........................................................................................................................ 23

8.3.4 Helpful Suggestions ........................................................................................................... 23

8.3.5 Knife Care .......................................................................................................................... 23

Maintenance Section ......................................................................................................................... 25

9.0 Cleaning......................................................................................................................................... 26

9.1 Table.......................................................................................................................................... 26

9.2 Console...................................................................................................................................... 27

9.3 Machine Frame.......................................................................................................................... 27

10.0 Lubrication.................................................................................................................................... 28

11.0 Hydraulic System......................................................................................................................... 31

11.1 Recommended Hydraulic Oil................................................................................................... 31

11.2 Changing the Oil...................................................................................................................... 31

11.3 Hydraulic Valve Adjustments................................................................................................... 32

12.0 Adjustments ................................................................................................................................. 37

12.1 Electric Eye Alignment............................................................................................................. 37

12.2 Backgauge Gib Adjustment..................................................................................................... 38

12.3 Squaring the Backgauge ......................................................................................................... 39

12.4 Backgauge Position Accuracy Adjustment.............................................................................. 40

12.5 Knife Latch Adjustment............................................................................................................ 41

12.6 Line Light Adjustment (Incandescent Type)............................................................................ 42

12.7 Line Light Adjustment (LED Type)...........................................................................................43

12.8 Proximity Switches................................................................................................................... 44

12.9 Clamp Return Speed Adjustment............................................................................................ 46

12.10 Pre-Clamp Pressure Adjustment........................................................................................... 46

12.11 Pre-Clamp Speed Adjustment............................................................................................... 47

3

Page 4

1.0 Introduction

12.12 Clamp Cylinder Adjustment (Clamp Height)..........................................................................48

12.13 Clamp Parallel Rod................................................................................................................48

12.14 Lead Screw Adjustment Nuts.................................................................................................49

12.15 Knife Bar Gibs........................................................................................................................50

13.0 Repair and Replacement..............................................................................................................51

13.1 Fuses........................................................................................................................................51

13.2 Knife Cylinder Replacement.....................................................................................................51

14.0 Troubleshooting............................................................................................................................54

15.0 Schematics & Parts Lists..............................................................................................................58

15.1 Main Assembly – Frame/Tank .................................................................................................58

15.2 Main Assembly – Hydraulics....................................................................................................60

15.3 Main Assembly – Clamp ..........................................................................................................62

15.4 Main Assembly – Final Wiring..................................................................................................64

15.5 Main Assembly – Electrical Components, Lower Front ...........................................................66

15.6 Main Assembly – Electrical Components, Upper.....................................................................68

15.7 Main Assembly – Air Table ......................................................................................................70

15.8 Main Assembly – Table Mounting............................................................................................72

15.9 Main Assembly – TC Backgauge.............................................................................................74

15.10 Main Assembly – Knife...........................................................................................................76

15.11 Main Assembly – Covers and Labels.....................................................................................78

15.12 Main Assembly – Table Extensions.......................................................................................80

15.13 Power Panel Assembly..........................................................................................................82

15.14 Basic Machine Schematic......................................................................................................86

15.15 Interconnection Diagram........................................................................................................87

15.16 Hydraulic Manifold Kit ............................................................................................................88

15.16.1 Knife Down Sequence Valve Assembly..........................................................................89

15.16.2 Hydraulic Manifold Assembly..........................................................................................90

15.17 Hydraulic Schematic ..............................................................................................................92

15.18 TC Control Console Assembly...............................................................................................93

15.19 Electric Eye Assembly............................................................................................................94

15.20 Cut Button Assembly – Standard...........................................................................................96

15.21 Cut Button Assembly – ErgoTouch........................................................................................97

15.22 Knife Latch Assembly.............................................................................................................99

15.23 Line Light Assembly.............................................................................................................100

15.24 Compressor Assembly.........................................................................................................101

15.25 Air Table Blower Assembly..................................................................................................102

15.26 Encoder Cable Assembly.....................................................................................................103

15.27 Power Panel Connection Procedure Label..........................................................................104

15.28 Warning Label......................................................................................................................105

15.29 Paper Deflector Kit (Option).................................................................................................106

15.29.1 Deflector & Shaft Assembly (Part of Paper Deflector Kit).............................................107

16.0 Safety System Tests...................................................................................................................109

4

Page 5

2.0 Safety

2.0 Safety

2.1 Precautions

• This machine is designed for one-person operation. Never operate the machi ne with more than

one person.

• Safe use of this machine is the responsibility of the operator. Use good judgment and common

sense when working with and around this machine.

• Read and understand all instructions thoroughly before using the machine. If questio ns remain,

contact the dealer from which you purchased this machine. Failure to understand the operating

instructions may result in personal injury.

• Only trained and authorized people should operate this machine.

• Do not alter safety guards or devices. They are for your protection. Severe personal injury may

result.

• Disconnect power before cleaning or performing maintenance. See Section 2.2 Power Locko ut

Procedure.

• Observe all caution labels and plates on this machine.

• Be sure the cutter is properly grounded.

• Be sure there is sufficient power to operate the cutter properly.

• Keep foreign objects off the table and away from cutter blade.

• BE EXTREMELY CAREFUL when handling and changing the cutter knife. Severe lacerations or

dismemberment could result from careless handling procedures.

• Keep the floor around the cutter free of trim, debris, oil and grease.

• When replacing hydraulic parts, loosen the connections slowly to release pressure. Never loosen

connections with the machine running.

• If the cutter sounds unusual or operates abnormally, turn it off and consult the troubleshooting

section of this manual. If the problem cannot be corrected, have it checked by a qualified service

person.

• CRUSH HAZARD, keep hands and fingers from under the clamp while clamping. Use Jogging

Aid to load paper, and use the backgauge to push paper out before unloading. DO NOT REACH

UNDER THE KNIFE AND CLAMP AREA!

2.2 Power Lockout Procedure

For maximum safety when making adjustments or repairs to your machine, be sure to lock out the

main power control switch to which the machine is connected. The switch should be moved to the

OFF position and a padlock placed in the loop. The person servicing the machine should h old the

key.

Figure 1

5

Page 6

2.0 Safety

2.3 Warning Label Definitions

The following warning labels are found at various locations on your machi ne. Read and understand

the meaning of each symbol. If a label is lost from the machine, it should be replaced. The item

number and location of each label can be found in Section 15.0 Schematics and Parts List.

HAZARDOUS AREA

Disconnect power before cleaning, servicing, or making adjustments not requiring

power. Do not alter safety guards or devices; they are for your protection. Replace

all guards. Do not operate with any guards removed.

SHOCK HAZARD

Disconnect power before removing cover. Replace cover before operation.

SHOCK HAZARD

Disconnect power before removing cover. Replace cover before operation.

SINGLE OPERATOR

Do not operate with more than one person.

6

Page 7

2.0 Safety

!OJO!

This Este simbolo de alerta de seguridad significa ¡ OJO ! INSTRUCCIONES DE SEGURIDADPERSONAL. Lea las instrucciones porque se refieren a su

seguridad personal. Fall de obedecer las instrucciones que siguen podria resultar en lesiones

corporales.

• Esta maquina, junto con sus mecanismos de seguridad, esta disenada para ser manejada por

• UNA SOLA PERSONA a la vez. Jamas debe ser manejada por mas de una persona al mismo

• tiempo.

• La seguridad es la responsabilidad del operario que usa esta maqu ina.

• LEA DETENIDAMENTE el manual de instrucciones y las PRECAUCIONES DE SEGURIDAD

antes de poner a funcionar la cortadora. Pidale a su supervisor una copia.

• El manejo de la guillotina debe estar exclusivamente a cargo de personal entrenado y autorizado

para ello.

• NO MODIFIQUE LOS MECANISMOS DE SEGURIDAD, estan ahi para su proteccion no deben

ni modificarse ni quitarse.

• DESCONECTE LA CORRIENTE ELECTRICA antes de proceder a hacerle servicio de limpieza,

engrasar, o de hacer adjustes que no requieren corriente. Trabe el interruptor en la posicion

OFF (apagado); vea “Procedimiento para cortar la corriente electrica” al pie de esta pagina.

• Eche llave a la guillotina y quite la llave cuando la maquina no esta en operacion; vea “Corriente

electrica”.

• Asegurese de que la guillotina este debidamente a tierra. Vea “Conexion de la fuerza electrica”.

• Verifique el voltaje y asegurese de que este sea suficiente para el debido funcionamiento de la

guillotina.

• Preste atencion a todas las placas con advertencias instaladas en esta guillotina.

• No permita que objetos estranos esten en la mesa o cerca de la cuchilla cortadora.

• TENGA SUMO CUIDADO al tocar y cambiar la cuchilla. Heridas severas y hasta

desmembramiento pueden resultar del manejo sin cuidado o negligente.

• El suelo alrededor de la guillotina debe mantenerse despejado y libre de recortes, desperdicios,

aceite y grasa.

• Al haber la necesidad de reemplazar partes hidraulicas, afloje todas las conexiones poco a poco

para dejar escapar la presion. Jamas debe aflojarse conexiones mientras la maquina este

• andando.

• Si la guillotina empezara a sonar o trabajar diferentemente a lo acostumbrado, desconectela y

consulte la seccion “Troubleshooting” (Reparador) de este man ual. Si no es posible corregir el

problema, llame a su servicio autorizado para que le examinen la maquina.

• PELIGRO DE MACHUQUE - Mantenga manos y dedos fuera de la agarradera mientras sujeta el

papel. Use el calibrador trasero y su rueda de mano para empujar el papel cortado. NO PONGA

SUS MANOS BAJOLA CUCHILLA O AREA DE LA AGARR ADERA.

• NO OPERE SIN LAS GUARDAS PROTECTORAS!

¡ OJO ! PRECAUCION - Como proceder para desconectar

la corriente electrica.

Para maxima seguridad durante ajustes y reparaciones de su maqu ina, verifique bien qu e el interruptor princi pal

de control de corriente al cual la maquina esta con ectada, este d esconectado. El interru ptor deba ser puesto e n

la posicion “OFF” (desconectado) y se debe poner un candado en la anilla. La llave del candado debe ser

guardada por la persona que estara efectuando los trabajos de servicio o de reparacion en la guillotina.

Desconecte la corriente electrica antes de proceder a hacer cualquier ajust e o reparacion o de efectuar el

engrase en cualquier maquina.

7

Page 8

3.0 Packing List

3.0 Packing List

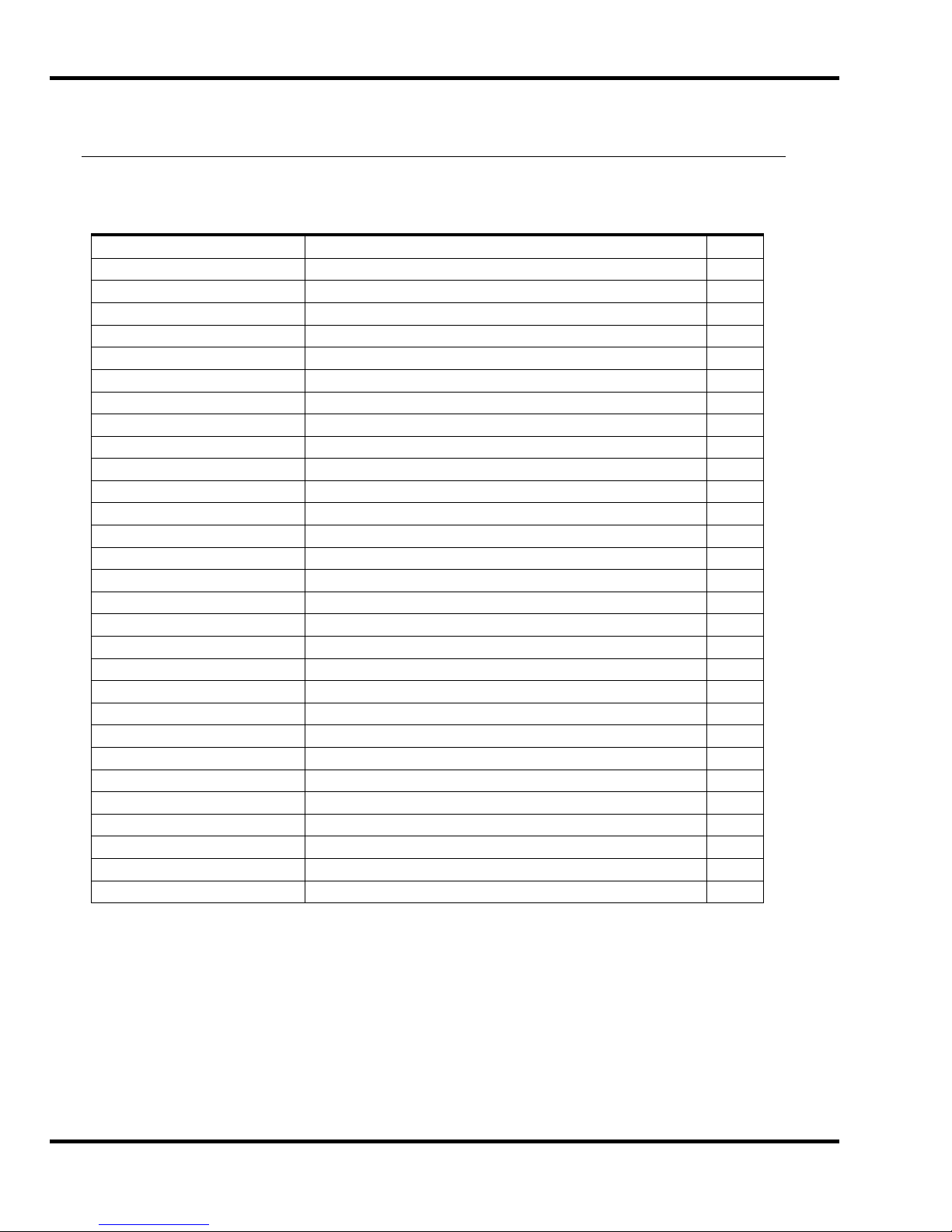

Part No. Description Qty.

Basic Machine 1

Extension Side Tables:

47166 18 x 24 Steel Side Table 2

47164-1 Side Table Back Plate 2

H-6913-606 Side Table Bolts 8

H-6424-6 Side Table Hex Nuts 8

H-6939-616 Leveling Screws 4

H-6913-6008 Side Table Mounting Bolts (shipped installed) 4

H-7321-6 Side Table Mounting Washers (shipped installed) 4

47006-2 False Clamp Plate (shipped installed) 1

47508 Knife – HSS 2

H-6918-608 Knife Bolts 6

8815 Knife Washers, Special 6

4171 Cutting Sticks (one installed) 4

47575 Knife Lifter Assembly 1

A-12608-4 Jogging Aid 1

Tool Kit:

5064 Cutting Stick Puller 1

W-164 Hex “T” Wrench 1

W-158 5/16 Open End Wrench 1

W-141 1/8” 1

W-137 5/32” 1

Fuses:

E-889-35 1 Amp S.B. 1

E-2330-5 3.15 Amp S.B. 1

E-2308 3.2 Amp S.B. 1

E-889-5 4 Amp S.B. 1

E-2330-7 5 Amp S.B. 1

E-2330-8 6.3 Amp S.B. 1

E-889-9 8 Amp S.B. 1

8

Page 9

4.0 Specifications

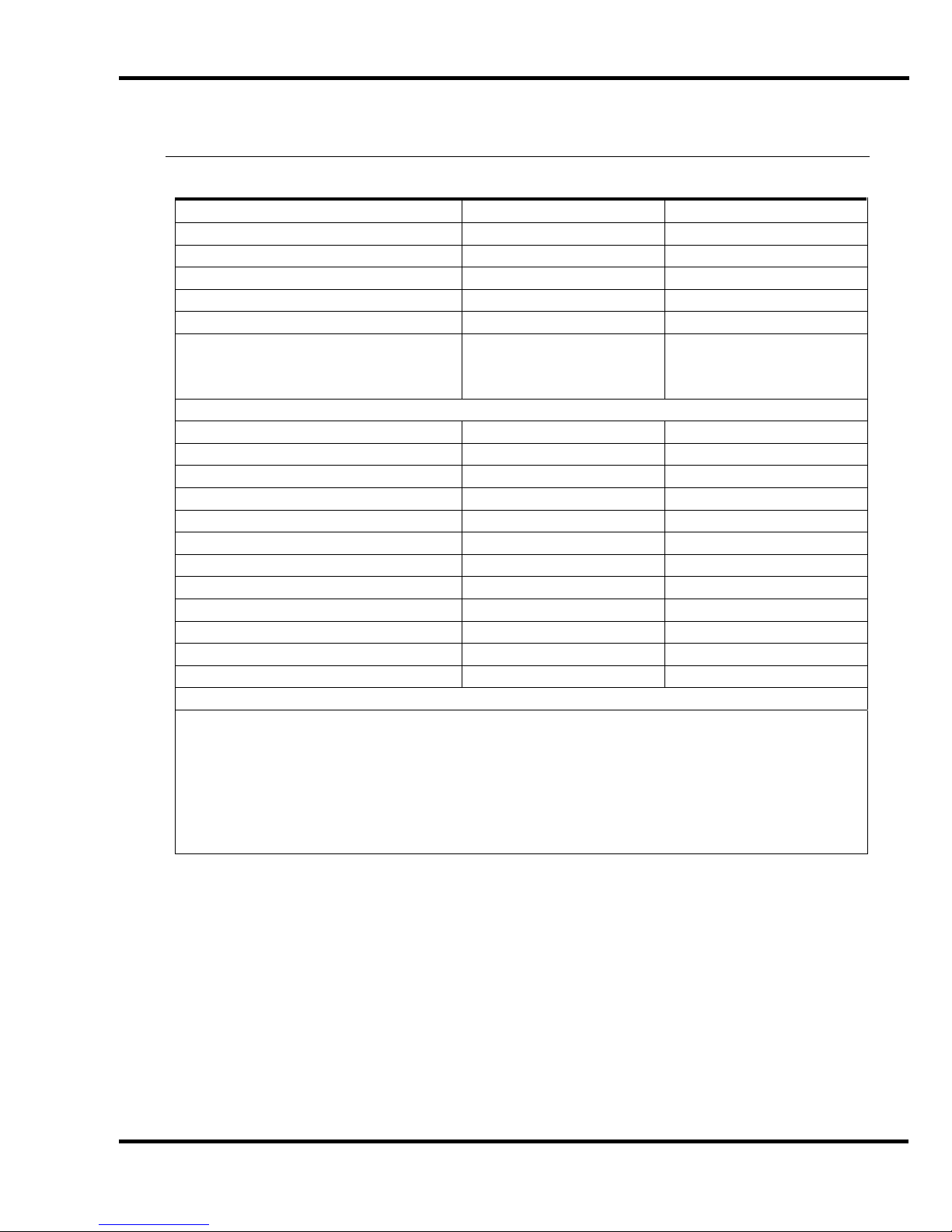

4.0 Specifications

Description Inch Units Metric Units

Cutting Width 30 ½” 77.5 cm

Clamp Opening 4” 10.2 cm

Clamping Force 400-5000 lbs. 1.8 – 22 kN

Minimum Cut – Standard ¾” 1.9 cm

- Special ½” 1.3 cm

- w/ False Clamp Plate 2” 5.1 cm

Table Space

Front: (std.)

Back:

Dimensions

Table Height 36 ½“ 92.7 cm

Overall Height 58 ½” 148.6 cm

Overall Length 69 ½” 176.5 cm

Overall Width 48 ½” 123 cm

w/ Side Tables 78 ½” 200 cm

w/o Side Tables 48 ½” 123 cm

Approx. Net Weight 2550 lbs 1157 kg

Approx. Shipping Weight 2750 lbs 1247 kg

Will pass through door:

Assembled 49” 125 cm

Table/treadle out 42” 112 cm

Table/treadle/pwr unit out 24-1/2” 63 cm

Electrical

Standard: 5 HP, 3 Phase, 60 Hz AC; 208/230V, 25 Amps (Service size: 40 Amps)

Optional Phase Converter Kit: K-3482 (1 Phase, 208/230V, Service size: 50 Amps)

Optional: 5 HP, 3 Phase, 60 Hz AC; 460V, 11.5 Amps (Service size: 20 Amps)

Optional: 5 HP, 3 Phase, 50 Hz AC; 380/415V, 10 Amps (Service size: 20 Amps)

Electric Eyes –

Response time = 68 ms

Object detection capability = 12 mm

Challenge reserves the right to make changes to any product or specification without notice and

without incurring responsibility to existing units.

25”

30 ½”

63.5 cm

77.5 cm

9

Page 10

5.0 Footprint

5.0 Footprint

10

Page 11

6.0 Installation & Setup

6.0 Installation & Setup

6.1 Inspecting Shipment

This machine has been carefully packed to prevent damage during shipment. However, claims for

damage or loss are the responsibility of the recipient. Inspect all shipments as soon as they are

received. If there is any noticeable damage, note it on the freight bill. Visual and/or hidden damage

must be reported to the claims department of the carrier within 15 days. Contact your dealer if you

need any assistance. Check the contents of the box against the packing list on page 8. Make sure

there are no missing items.

6.2 Uncrating

This machine is lagged to a wood skid and covered with a triple-walled corrugated container. Loosen

the flaps of the carton where they are attached to the skid. When loose, the carton can be lifted

straight up. Remove the side tables and accessory box, which are also attached to the skid. Place

the cutter/skid about where the machine will be positioned and remove the lag screws from the skid.

6.3 Lifting/Moving Instructions

Unpacking, handling, and positioning should be done by professional riggers. If handling or

unpacking is a problem, your dealer or a local trucking facility should be able to supply or recommend

a qualified rigger. This 2550-lb/1157-kg machine should be moved with experienced peo ple and the

proper equipment. Do not risk personal injury or damage by attempting to move machinery with

inadequate equipment or manpower.

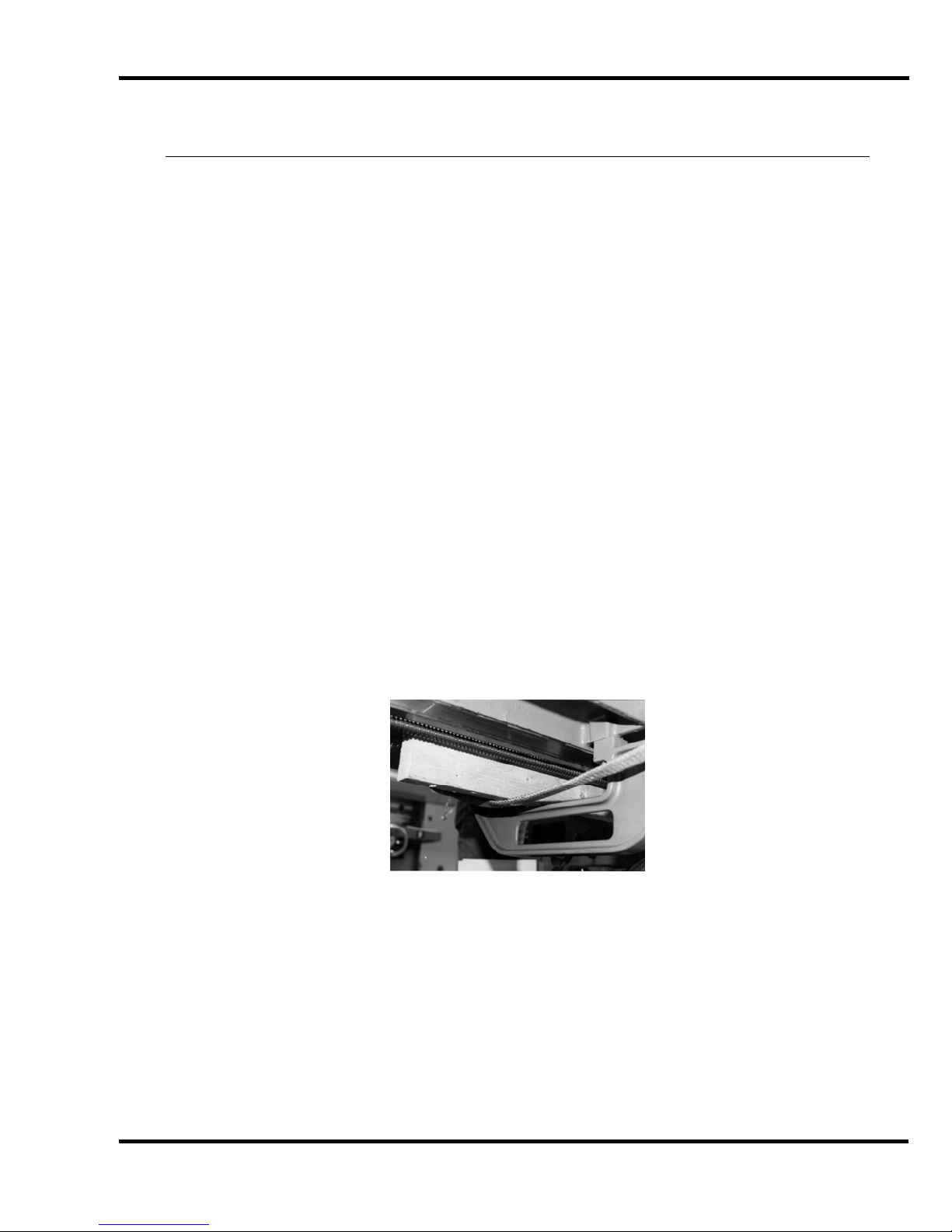

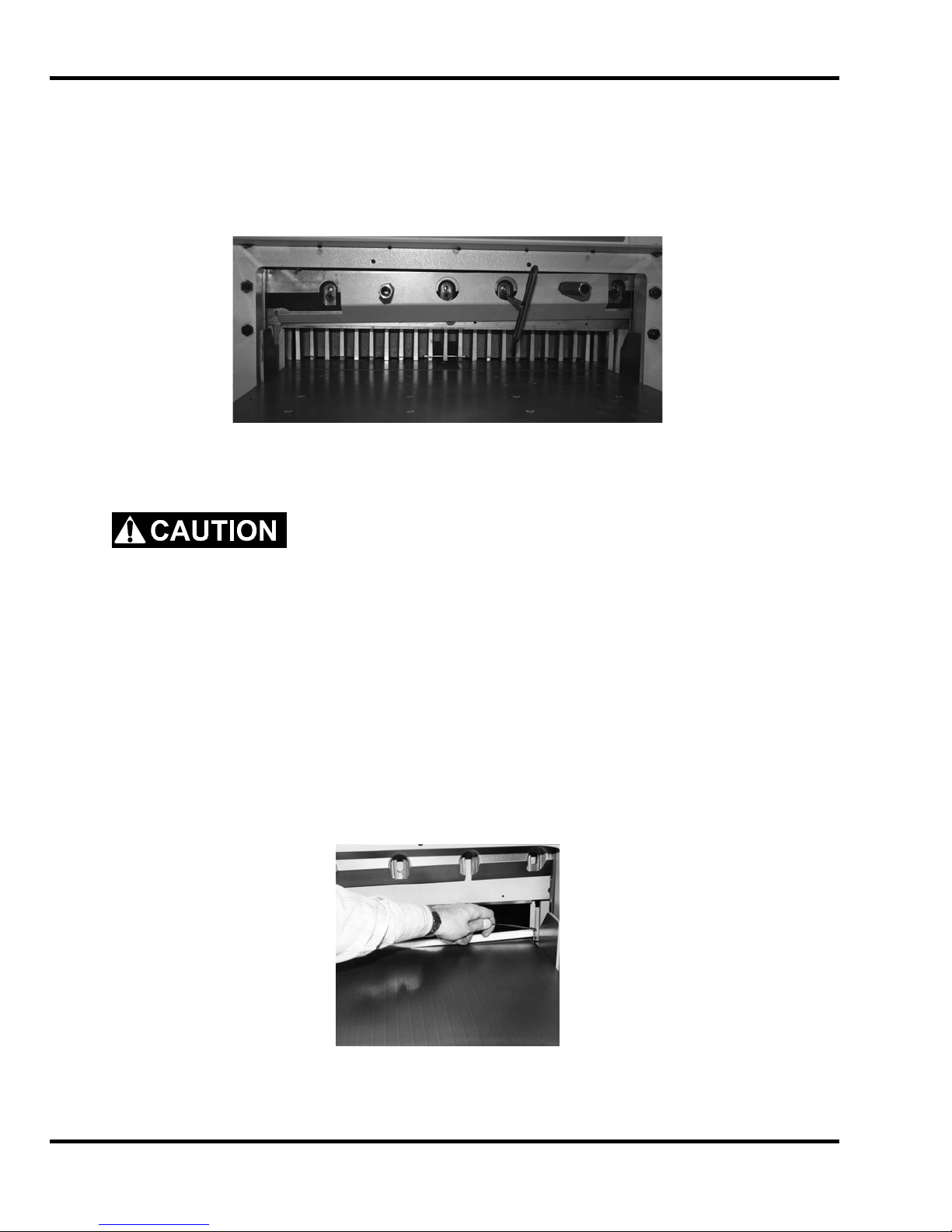

Lifting straps may also be used to lift the machine by placing the straps around the front and rear of

the table. When straps are used in this way, wood blocks must be placed beside the lead screw to

prevent damage, (Figure 2). A bent lead screw will cause the backgauge to bind.

Figure 2

The backgauge should be positioned all the way to the front of the table and straps placed as close

the machine body as possible. Gently lift the cutter, remove the skid and carefully place the cutter on

the floor.

Once the machine is off its skid, it can be moved with a forklift or pallet jack from the front. DO NOT

attempt to lift the machine from the sides or rear.

11

Page 12

6.0 Installation & Setup

6.4 Cleaning

Wipe down the table and bare metal surfaces with a non-flammable solvent such as CRC or blanket

wash. The table surface is cast iron, and it will rust if left unprotected. Coat the table with a nonabrasive wax. A Cutter Care Kit, p/n 16077, with cleaner and wax, is available through your

Authorized Challenge Dealer. The protective film on the console may be removed. Never clean

console with petroleum based solvents – damage will result.

6.5 Assembly

Unless otherwise specified, the only items that have been disassembled for shipping are the knife,

extension tables, and reach-around shields on the electric eyes. Knife installation instructions are

found in Section 8.0 Knife Installation/Changing. Extension table and reach-around shield attachment

instructions are as follows:

NOTE: Extension tables are heavy. Use two people to attach them to the machine.

1. Assemble the back plates to the extension tables. The extension table bolts and hex nuts are

packed in the tool kit box. Install the back plates such that the half-circle notch at the top of

the plates go toward the center of the cutter. These notches provide clearance for adjusting

the lower knife gib bolt.

2. One person should hold the extension table in position while the other aligns the holes and

starts threading the mounting bolts with washers. The mounting bolts are shipped installed in

the side of table- remove them to install tables.

3. Use a 9/16” socket and extension to snug tighten the mounting bolts, then tap the extension

table up or down with your hand or a rubber mallet until it is flush with the main table. Run a

straight edge or sheet of paper over the seam to check the fit. Make sure your stock will not

catch on the seam.

4. Insert the leveling setscrews into the threaded holes next to the mounting bolts. You may

have to loosen the mounting bolts slightly to allow enough play to level the table. After the

extension tables are leveled and the surface joints even, tighten the mounting bolts securely.

5. The extension tables are powder-coated and need only be wiped down with a dry cloth. DO

NOT apply solvents or abrasive cleaners to extension table surfaces. They may cause

discoloration or scratches.

NOTE: The reach-around shields for the electric eyes are in their shipping positions – follow the

instructions below to secure them in their operational position.

1. On the bottom of the electric eye housing, loosen (but do not remove) the screw furthest

back (closet to the machine frame) on each side.

2. On the bottom of the electric eye housing, loosen and remove the front two screws. Now

rotate each shield back and to the side – away from of the cut area. Line up the front holes

and re-install the front two screws. Tighten all screws (See the instruction sheet included in

the shipping material for more details).

ATTENTION

POTENTIAL CRUSH/LACERATION HAZZARD – THE SHIELDS ARE THERE FOR YOUR SAFETY.

: FAILURE TO INSTALL THE REACH-AROUND SHIELDS COULD CAUSE A

12

Page 13

6.0 Installation & Setup

6.6 Hydraulic Power Unit Removal

If installation requires that the machine pass through a doorway that is less than 49” but greater than

or equal to 42” wide, the machine should have been ordered from Challenge “knocked down” with the

table removed. If the machine must fit through a doorway that is less than 42” and greater than or

equal to 24-1/2”, the hydraulic power unit must be removed on-site. To remove the hydraulic power

unit, follow the instructions below.

1. Disconnect the electrical conduits to the hydraulic motor, air blower, and hydraulic cooling

fan, junction box.

2. Remove the filler cap and use a transfer pump to remove the hydraulic fluid into buckets.

3. Locate the hose that connects the manifold to the oil filter. Disconnect it from the filter.

Disconnect the hydraulic pump hose from the manifold. Attach the hose that was connected

to the manifold to the oil filter. Attach the hose that was connected to the filter to the

manifold. This will minimize oil leakage. After the unit is installed, reconnect the hoses to

their original location.

4. Remove the (4) bolts that attach the hydraulic assembly to the cutter base. They are located

at the bottom shelf the base.

5. USE EXTREME CAUTION WHILE REMOVING THE POWER UNIT. It is very heavy and

should be removed using a fork truck. CAUTION, the machine will be top heavy and may tip

easily with the power unit removed. Move the reservoir through the doorway on its side.

6. DO NOT ATTEMPT TO LIFT THE CUTTER BY PLACING STRAPS OR THE FORKS OF A

TRUCK UNDER THE CLAMP. This can damage the machine.

7. Reinstall the power unit, conduits, hoses, after the machine is in position. Refill the hydraulic

reservoir.

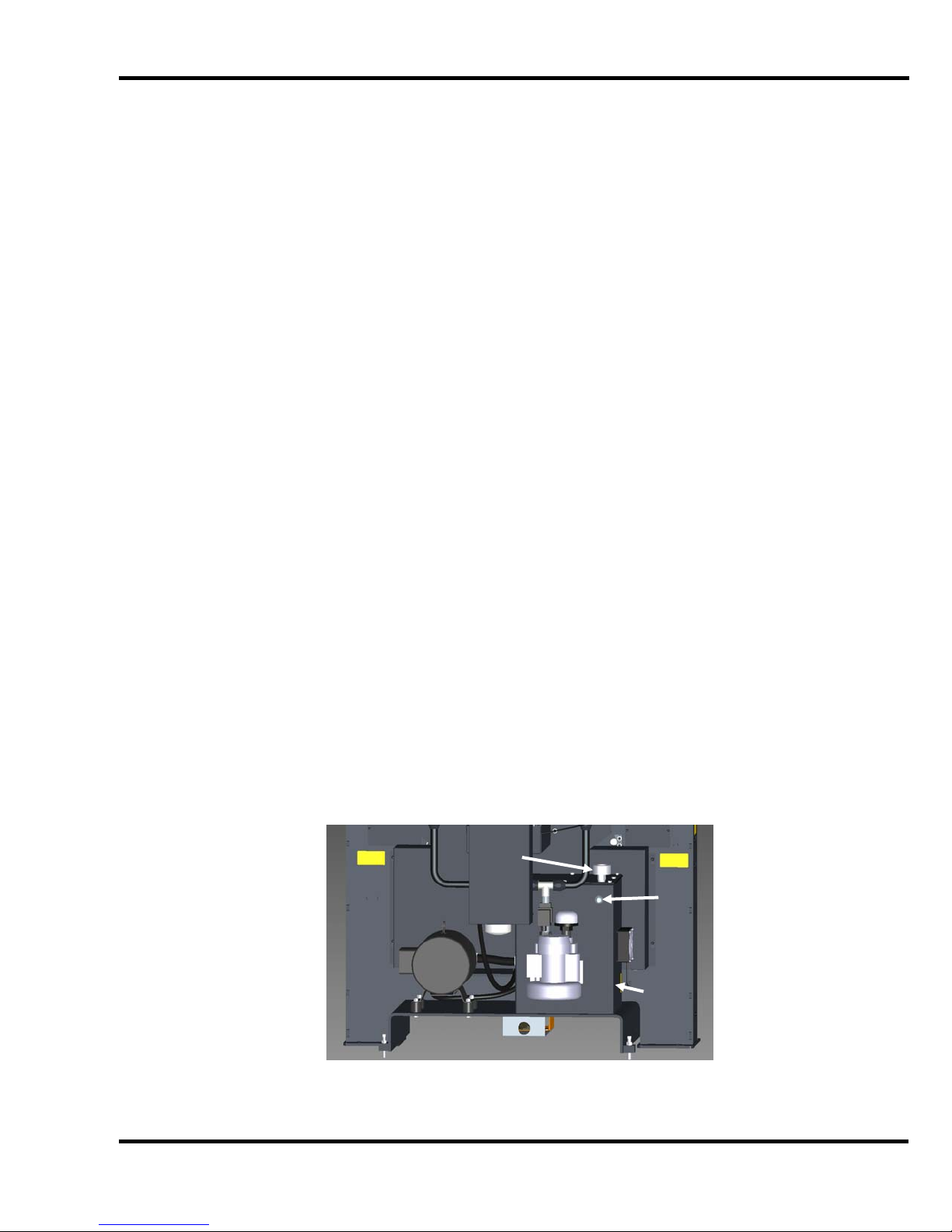

6.7 Hydraulic Check

The hydraulic reservoir is filled with 13-1/2 gallons of ISO VG 46 hydraulic oil at the factory. The fluid

level should be checked during installation, and at least once per week during normal operation. The

reservoir is located behind the cutter, beneath the table (Figure 3). The hydraulic tank has a sight

gauge in the rear for checking the oil level. The reservoir should be kept full at all times.

Filler

Cap

Sight

Gauge

Hydraulic

Tank

Figure 3

NOTE: DO NOT OVERFILL. Overfilling may cause leakage when the machine is hot.

13

Page 14

6.0 Installation & Setup

6.8 Power Hook-Up

For satisfactory operation, be sure that your cutter is wired for the correct phase and voltage and has

adequate power. The correct electrical specifications for your machine are shown on the serial plate.

Check the machine serial plate before connecting the power. For future reference, transfer this

information to the front cover of this manual.

Watch Setup Voltage- Inadequate power to the cutter can be a major source of problems. Too

many machines on the same circuit will reduce the power to each machine. Inadequate voltage will

cause overheating, loss of power, and in extreme cases, failure to operate. Test line voltage when

the shop is at actual working levels. Challenge recommends a dedicated line with a lockable

disconnect to provide adequate power for this machine.

CAUTION: SHOCK HAZARD! Always disconnect power at main

power panel before working on the cutter. Lock it out to prevent accidental power up. (See

Power Lockout Procedure page 5).

Important: You must have an adequate size circuit and heavy enough wiring for this machine. The

circuit size should be a minimum of 20% greater than the amperage rating on the machine

nameplate. If a wire is run over 75 feet (23 meters), the next size wire should be used. Check local

electrical codes.

Electrical Specifications for Champion Cutters

Volts Amps Phase Hz Circuit Size Wire Size Metric Wire

208/230V 25A 3 PH 60 Hz 40A #8 AWG 4mm sq.

460V 11.5A 3 PH 60 Hz 20A #12 AWG 10mm sq.

380/415V 10A 3 PH 50 Hz 20A #12 AWG 10mm sq.

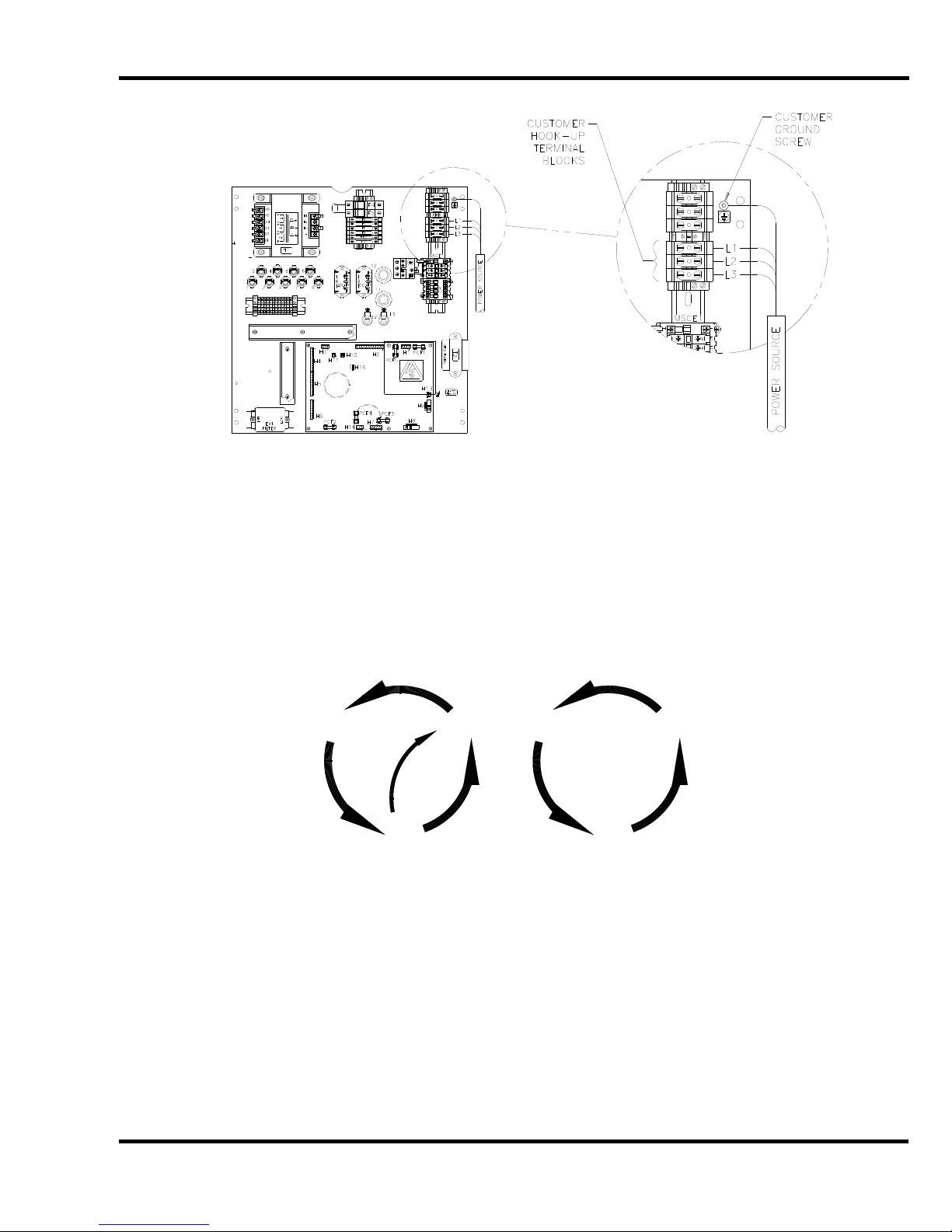

The power source is connected to the cutter through the bottom of the power panel (right hand side).

Hook-up procedure:

1. DISCONNECT AND LOCK OUT THE POWER at the main panel to prevent accidental powe r

up. (See Power Lockout, page 5).

2. Thread the power cord through a conduit connector into the power panel.

3. Fasten the ground lead to the ground terminal lug (Figure 4).

14

Page 15

6.0 Installation & Setup

Figure 4

4. Fasten the three power leads to the three terminals of the main power terminal block- L1, L2,

& L3.

5. Close the electrical panel doors and latch them. Unlock the main panel and turn on the

power. Turn on the main power disconnect switch located on the front face of the table.

6. Press both cut buttons simultaneously to activate the motor and check to make sure it is

turning the same direction as the arrow on the motor casing. If it is not turning the proper

direction, disconnect the power and exchange any two leads of the power cord as in Figure 5.

1

2

31 2

3

Figure 5

15

Page 16

7.0 Operation

7.0 Operation

IMPORTANT: DO NOT ATTEMPT TO OPERATE YOUR CUTTER UNTIL YOU HAVE

THOROUGHLY READ AND UNDERSTAND ALL OF THE INSTRUCTIONS FOUND IN THE

OPERATOR AND INSTRUCTION MANUALS INCLUDED WITH YOUR CUTTER. CALL YOUR

AUTHORIZED CHALLENGE DEALER IF YOU STILL HAVE ANY QUESTIONS.

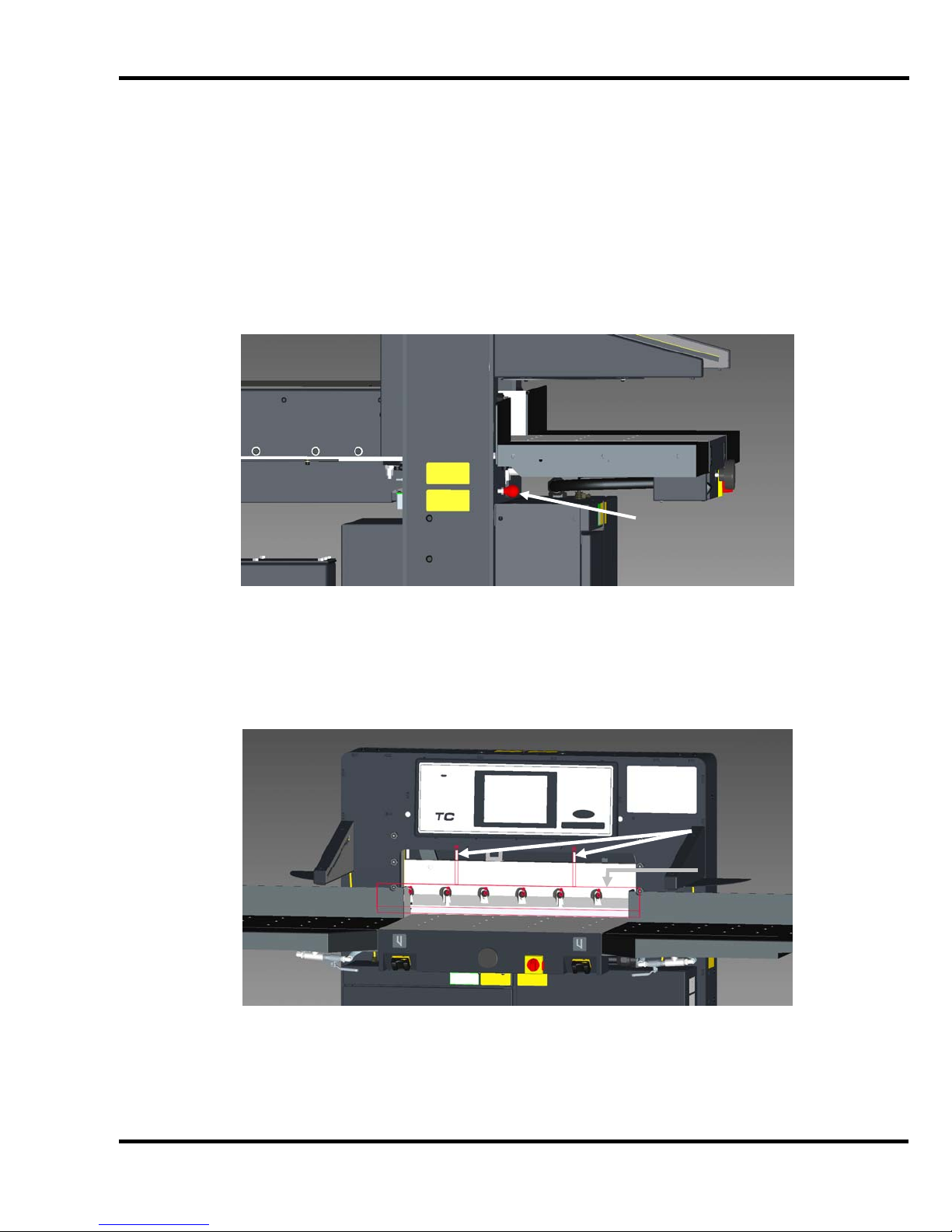

Complete operating instructions for all TC Model paper cutters can be found in the TC Touch Screen

Control Operating Instructions manual that was included with your machine (Fig ure 6). If you do not

have a copy, or to download the latest version, visit: www.challengemachinery.com/support

.

Figure 6

7.1 False Clamp Plate

To prevent marking on pressure sensitive jobs, a false clamp plate has been included (installed) with

your machine. This plate attaches to the bottom of the clamp. It is secured from the front of the

cutter with three set screws.

ALWAYS disconnect the power and LOCK IT OUT before installing or

removing the false clamp plate. NEVER attempt to install or remove the false clamp plate while the

machine is running. Remove all tools and stand clear when recon necting power.

16

Page 17

7.0 Operation

To install:

1. DISCONNECT THE POWER AND LOCK IT OUT! (See Power Lockout, page 5.)

2. Position the false clamp plate under the clamp, (Figure 7). The locator pegs are positioned to

the rear of the cutter and are set into holes in the bottom of the clamp.

1/8” Allen

Wrench

Set

Screws

Locator

pegs

Figure 7

3. With a 1/8" Allen wrench, back off the setscrews in front of the clamp and raise the plate up to

the bottom of the clamp. It may be necessary to bring the clamp down onto a stack of paper

with the foot pedal in order to access the far left setscrew. Raise the false clamp plate evenly

or it will have a tendency to bind. When the plate has been raised into position and is flush

with the bottom of the clamp, tighten the setscrews to hold the plate in position.

4. Make sure that all tools have been taken off the cutter table, reconnect the power, and turn

on the machine.

NOTE: The backgauge will not move to a position less than 2" (51 mm) when the false clamp plate is

installed in the clamp.

When the false clamp plate is not in use, store it on top of the cutter, with the locator pegs inserted

into the 3 holes in the top cover. There is a sensor inside one of these holes that detects when the

false clamp plate is on top of the machine, thereby informing the machine that the false clamp plate is

not installed in the clamp. This allows the backgauge to be positioned less than 2” (51 mm), which it

will not do when the false clamp plate is installed in the clamp.

17

Page 18

8.0 Knife Installation/Changing

8.0 Knife Installation/Changing

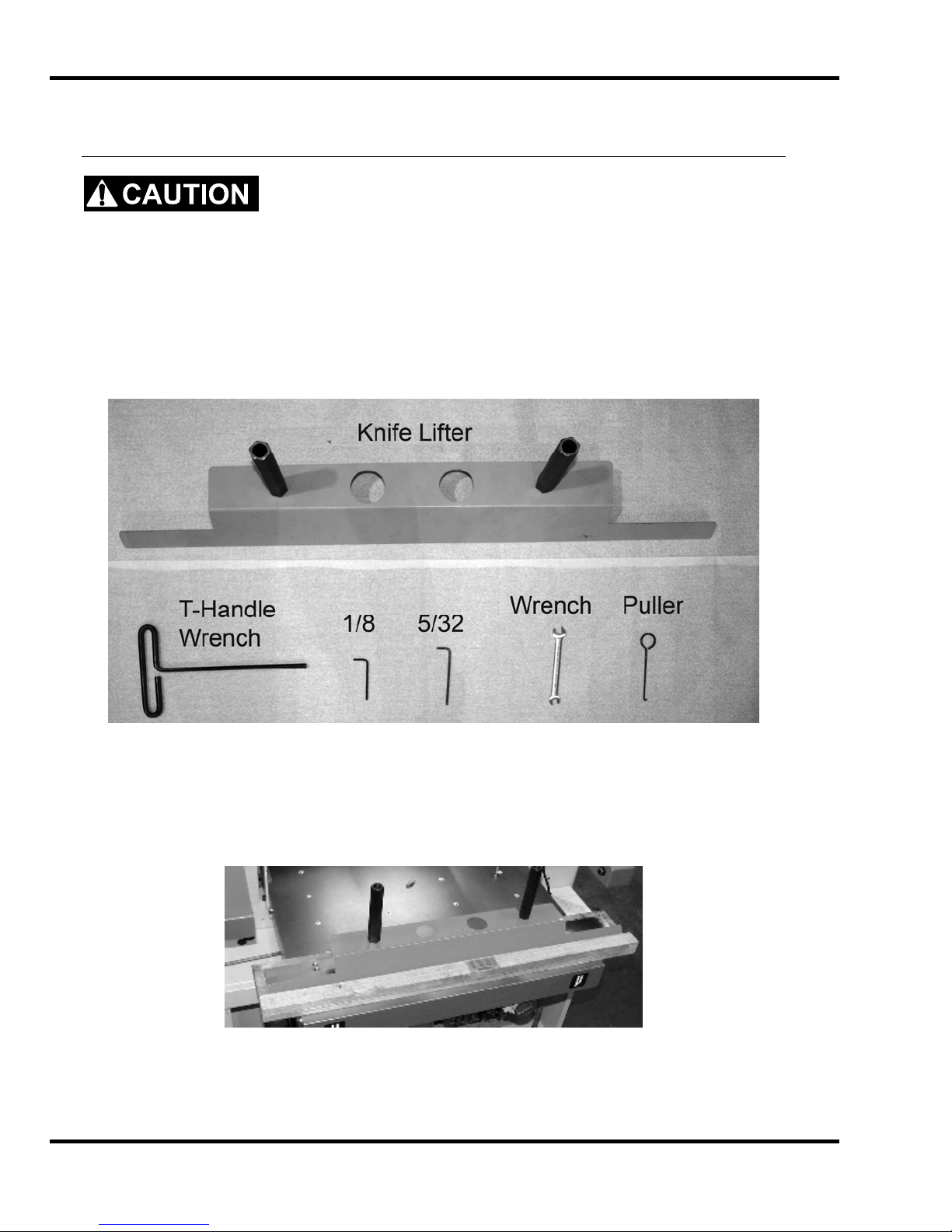

Changing knives can be very dangerous unless safety precautions are

observed and extreme care is taken when handling knives.

• Make sure knife lifters are properly installed, see instructions following.

• Keep handling of unprotected knives to an absolute minimum.

• Clear off cutter table before removing knife.

• Have scabbard on cutter table and insert knife immediately.

• Warn people of any unprotected knife.

• Knife changing is a ONE PERSON OPERATION. Having more than one person trying to

change knives invites accidents.

P/N: 47575

Figure 8 – Knife Changing Equipment

The knife changing equipment shown in Figure 8 is included in the cutter tool kit. The following

instructions show how to remove and install a new or re-sharpened knife. Read these instructions AT

LEAST ONCE before attempting to actually change or install any blades.

Figure 9

18

Page 19

8.0 Knife Installation/Changing

8.1 Knife Removal

1. Clear the cutter table. Place chipboard directly under the knife to prevent nicking if the blade

hits the table. On the TC touch screen menu choose “MAINTENANCE” and then “KNIFE

CHANGE”. Select “Knife Adjust Mode” then press and hold both cut buttons until the knife

and clamp reach the table. Now release the buttons (the knife and clamp should stay down ).

2. DISCONNECT THE POWER AND LOCK IT OUT, (See Power Lockout Procedure on pg. 5).

3. If equipped with the paper deflector option, lock it down by screwing the lock knob all the way

in (Figure 10).

Lock Knob

(Paper Deflector

Option Only)

Figure 10 – Paper Deflector Locking Knob

4. Back off the knife adjusting screws on the top of the knife bar, (Figure 11), as far as they will

go (counter-clockwise). A new knife will cut deeper than a knife that has been ground several

times. If the adjusters are not backed off, damage can result to the new knife and/or the

cutting stick.

Adjusting

Screws

Knife

5. Restore power to the machine and turn it ON. Follow the prompts on the screen to raise the

knife and clamp.

Figure 11 – Knife Adjusting Screws

19

Page 20

8.0 Knife Installation/Changing

6. DISCONNECT THE POWER AND LOCK IT OUT, (See Power Lockout Procedure on pg. 5).

7. Remove the bolts in the two slotted holes of the knife bar and insert the knife lifter by

screwing in the two knife lifter handles. Tighten the handles enough to hold the blade in

place. Remove the remaining four bolts (Figure 12). The leftmost bolt must be removed

while the knife bar is “UP”.

Figure 12

8. Clear the table and put the empty knife scabbard on the table.

DANGER: Used knives are heavy and still very sharp. Be careful to

keep the edge away from your body and keep other people out of the area while handling the

blade. Severe lacerations and dismemberment could result from careless handling procedures.

9. Grasp the knife lifter handles firmly while turning counterclockwise to release the knife from

the knife bar. Slowly lower the knife down and to the right. Bring the left side out first.

10. Place the knife with attached lifter on top of the scabbard. Remove the lifter and slide the

knife into alignment with the scabbard screw holes. DO NOT FORGET TO INSTALL THE

SCABBARD SCREWS!

11. Send the dull knife to the grinder.

8.2 Knife Installation

1. Use the cutting stick puller, (Figure 13), to remove the cutting stick. Turn the cutting stick to a

new surface.

Figure 13

20

Page 21

8.0 Knife Installation/Changing

2. Check to make sure the paper deflector is locked down (Figure 10, page 19). Also check that

the knife adjusting screws have been backed out, (Figure 11, page 19).

3. Place the new knife scabbard on the cutter table.

4. Remove the knife retainer screws.

5. Place your fingers along the top edge of the scabbard and your thumbs in the holes in the

knife.

6. Pull the knife up in its scabbard until the bevel is exposed.

7. Place the lifter on top of the knife and insert the knife lifter handles into the corresponding

knife bolt holes (use the lowest holes) and thread the handles into the knife until they touch

the scabbard. Then back the handles off 1/2 turn.

8. Grasp the knife lifter handles, lift the blade, and insert the blade into the knife bar slot. Slowly

guide the blade into the cutter right end first, then bring the left end in parallel to the knife bar.

Raise the knife into the knife bar slot as high as it will go. Tighten the handles firmly to hold

the knife. An installed lifter is shown in Figure 14 below.

Figure 14

NOTE: If the blade will not go in, either the handles are screwed into the blade too far or the

blade is not centered over the table, and the end of the blade is hitting the end stop in the

knife bar.

9. Insert the rest of the knife bolts and washers, snug tighten them, but don’t tighten completely.

Be sure all bolts have washers. The correct washers are important for proper bolt

clearances!

10. Remove the knife lifter and insert the remaining two bolts and washers and snug tighten.

11. Place paper across the table to cover the cutting stick.

12. Restore power to the machine and turn it ON. Follow the prompts on the screen to preset the

backgauge. Then choose “MAINTENANCE” and then “KNIFE CHANGE”. Select “Knife

Adjust Mode” then press and hold both cut buttons until the knife and clamp reach the table.

Now release the buttons (the knife and clamp should stay down).

13. DISCONNECT THE POWER AND LOCK IT OUT, (See Power Lockout Procedure on pg. 5).

14. Turn the knife adjusters down (Figure 11, page 19) a little at a time, until the blade cuts

through the paper evenly over the entire length of the stick. Be sure the blade is parallel to

21

Page 22

8.0 Knife Installation/Changing

the cutting stick, or one end may cut deeper than the other, causing uneven wear on the

stick.

15. Tighten all the bolts and release the paper deflector.

16. Restore power to the machine and turn it ON. Follow the prompts on the screen to raise the

knife and clamp, and then to preset the backgauge.

17. Make a test cut through a full lift of stock. Make minor adjustments by loosening the bolts

and repeating steps 9 through 11.

NOTE: If the knife ends cut but the middle does not, you could have dips or uneven spots in either

the knife or the cutting stick. These can be eliminated to some extent by laying 1/2" (13mm) strips of

paper beneath the cutting stick to shim it up.

8.3 Knife Care Tips

! KNIFE SAFETY ! Knives are DANGEROUS!!! They are heavy and

very sharp, even after use. Keep the edge away from your body and keep the area clear of

others when handling knives. Never touch the cutting edge! To prevent personal injury and

damage to the knife, always keep knives in their holders with screws tightened. You are

aware of the dangers, but others may not be. Never attempt to hone, polish, or service the

knife in any way. Failure to follow safety procedures may result in severe lacerations or

dismemberment.

8.3.1 Knife Blade Life

Knife blade life, or the time between sharpenings, can be affected by many factors. One important

factor is the type of paper being cut. Abrasive paper, such as recycled paper, soft paper such as

newsprint paper, and bound books can all significantly shorten knife blade life. Also, if the knife depth

is set too deep, the knife will cut too deep into the cutting stick and can dull the knife blade.

A knife can last between 2,000 and 5,000 cuts before it needs to be sharpened. Cutting soft paper

(such as newsprint paper) or paper with high post-consumer recycled content ca n cause the knife to

need sharpening after only 2,000 to 3,000 cuts. Cutting pure paper, such as bond pape r with no

recycled content, or hard paper can allow the knife to be used for as many as 5,000 cuts before it

needs to be sharpened. In all cases, the operator should continually check the quality of the cut to

determine when the knife blade needs to be sharpened. Some characteristics that indicate a blade

needs sharpening are:

• The knife hesitates or stalls while making a cut.

• The sheets are not all cut to the same length (usually the top few sheets are longer than the

rest of the sheets - this is sometimes called “draw”).

• Cut marks appear on the cut face of the paper.

• The profile of the cut (side view) is not perpendicular to the table.

• The cut does not appear straight when viewed from the top.

• The knife makes a “rougher” sound as it passes through paper.

• Nicks are visible on the cutting edge of the knife.

22

Page 23

8.0 Knife Installation/Changing

8.3.2 Cutting Stick

A worn cutting stick can affect the cut quality of the bottom sheets. When this happens, the cut stick

can be rotated. Usually, the stick should be rotated one or two times between knife sharpenings.

There are 8 possible cut stick positions. The stick can be rotated 4 times, and then turned en d to

end, and rotated 4 times again.

8.3.3 Bevel Angle

Challenge recommends that bevel angles for the Champion 305 knives be in the range of 21° to 23°.

In general, a 21° bevel angle will provide better cut quality when cutting soft paper (such as

newsprint), recycled paper, or bound books. However, 21° angle knives can become dull sooner than

23° knives, which results in shorter knife blade life. A knife with a 23° bevel angle, on the other hand,

will not dull as easily, and can provide satisfactory results when cutting most types of paper. Knives

shipped with the Champion 305 from the factory have a bevel angle of 23°.

8.3.4 Helpful Suggestions

If your establishment is large enough to purchase more than one set of knives, have one set

beveled at 21° and the other at 23°. Note: A set consists of 3 knives: one in the machine,

one as a back up, and one at the grinder.

If the machine seems to strain but the cut quality is still good, reduce the pile height. You

may also carefully apply glycerin to the bevel when cutting hard, coated paper. Tie a cloth to

the end of a stick; dip the stick in glycerin, and apply. Never apply by hand! In lieu of

glycerin you may lightly rub white bar soap along the bevel. Lubrication will prolong the life of

your machine and reduce maintenance.

8.3.5 Knife Care

• To prevent corrosion, knives are coated with light oil. It should be REMOVED WITH CARE.

• While removing or installing a knife, be careful not to allow the edge to bump against the

machine. Nicks will result.

• If a knife bolt is damaged, replace it.

• Always keep knife bolts securely tightened.

• Always use the heavy-duty knife bolt washers provided by Challenge. Failure to do so could

result in scratching or marring of the clamp face.

• Store knives in a dry environment to prevent corrosion.

• Never attempt to service a knife in any way.

23

Page 24

8.0 Knife Installation/Changing

NOTES

24

Page 25

8.0 Knife Installation/Changing

Maintenance Section

NOTICE

The instructions on the following

pages are for the use of trained

service personnel only!

Attempting to perform repair and

replacement procedures without

proper training may cause

machine damage or operator

injury!

PARTS CUSTOMERS: Parts with the express understanding that they are to replace parts

found missing or no longer serviceable on equipment designed and/or manufactured at

Challenge. The Challenge Machinery Company assumes no liability for any modification or

alteration to any Challenge products, and any such modification or alteration to any

Challenge product is not authorized by The Challenge Machinery Company. Any

modification or alteration of any Challenge product will void any remaining warranty.

25

Page 26

9.0 Cleaning

9.0 Cleaning

9.1 Table

The table of a paper cutter requires periodic maintenance to remove surface oxidation. Polishing is

also required to provide a smooth surface for paper to move freely. The frequency of this

maintenance will be determined by a number of factors. Among these are the humidity,

environmental dust, handprints, liquid spills, and type of paper stock. We recommend the use of the

Challenge Cutter Care Kit P/N 16077 for of your table care needs.

To prepare a new machine’s table, follow the procedure below:

1. Remove the rust-protective coating from the table with a solvent.

2. Remove all solvent residue from the table with a dry cloth. Continue until the cloth shows no

sign of residue.

3. Apply a light coating of an SAE 10-weight non-detergent motor oil or equivalent to the table

and allow it to penetrate for at least one hour.

4. Remove all excess oil from the table with paper toweling (not cloth) until the paper towel you

are using shows no sign of oil.

5. Apply a paste wax (Challenge P/N 16078) to the table to seal the pores of the metal.

Note: Do not use a wax that contains a cleaning compound on the table. The cleaner contains

microscopic abrasive particles that will cause wear between the table and the bottom of the

backgauge. A silicone spray (Challenge P/N 16079) will show the same type of wear as the

cleaner if the excess silicone is not removed. If the excess is not removed, the silicone spray has

a substance that holds the silicone to the surface it is sprayed on that causes a black, gummy

build-up under the backgauge. If a silicone spray is used, paper toweling must be used to

remove the excess to prevent this wear and build-up.

To clean surface oxidation from a table, follow the procedure below:

1. Spray “Rust-B-Gone” (Challenge P/N 16080) on the table and allow it to dissolve the rust.

Then remove it with paper toweling. Or, pour a small quantity of SAE 10-weight motor oil

onto the table. Using a Scotch-Brite Pad or a 400 grit sand paper, polish the table following

the “grain” of the metal until all oxidation is removed to your satisfaction.

2. Remove all of the oil from the table until the cloth you are using shows no sign of residue.

3. Apply a light coating of an SAE 10-weight non-detergent motor oil or equivalent to the table

and allow it to penetrate for at least one hour.

4. Remove all excess oil from the table with paper toweling (not cloth) until the paper towel you

are using shows no sign of oil.

5. Apply a paste wax (Challenge P/N 16078) to the table to seal the pores of the metal.

Note: Do not use a wax that contains a cleaning compound on the table. The cleaner contains

microscopic abrasive particles that will cause wear between the table and the bottom of the

backgauge. A silicone spray (Challenge P/N 16079) will show the same type of wear as the

26

Page 27

9.0 Cleaning

cleaner if the excess silicone is not removed. If the excess is not removed, the silicone spray has

a substance that holds the silicone to the surface it is sprayed on that causes a black, gummy

build-up under the backgauge. If a silicone spray is used, paper toweling must be used to

remove the excess to prevent this wear and build-up.

9.2 Console

The console should be cleaned with a mild water based detergent applied to a damp cloth or

paper towel. Petroleum based solvents will damage the console.

9.3 Machine Frame

1. The machine frame should be cleaned with a mild, water based detergent applied to a damp

cloth.

2. Always be careful when cleaning around safety warning labels. Use limited am ounts of

cleaners in those areas.

27

Page 28

10.0 Lubrication

10.0 Lubrication

A clean, lubricated machine will cut more accurately, run longer, with less downtime, and fewer

repairs.

Schedule lubrication maintenance both early in the day and early in the week. This allows the

lubricants to work into the machine. Lubrication at the end of the day or week allows the lubricants to

run off without any benefit to the machine.

Clean off dirty, excess grease. Clean accumulated dust off valves, hoses, and connections. Dust

build-up increases operating temperatures and causes premature wear of all hydraulic component s.

Oil and grease WEEKLY as described below.

When necessary, send the knife down by choosing “MAINTENANCE” and then “KNIFE CHANGE” on

the TC touch screen. Select “Knife Adjust Mode” then press and hold both cut buttons until the knife

and clamp reach the table. Now release the buttons (the knife and clamp should stay down).

DISCONNECT THE POWER AND LOCK IT OUT, (See Power Lockout Procedure on pg. 5).

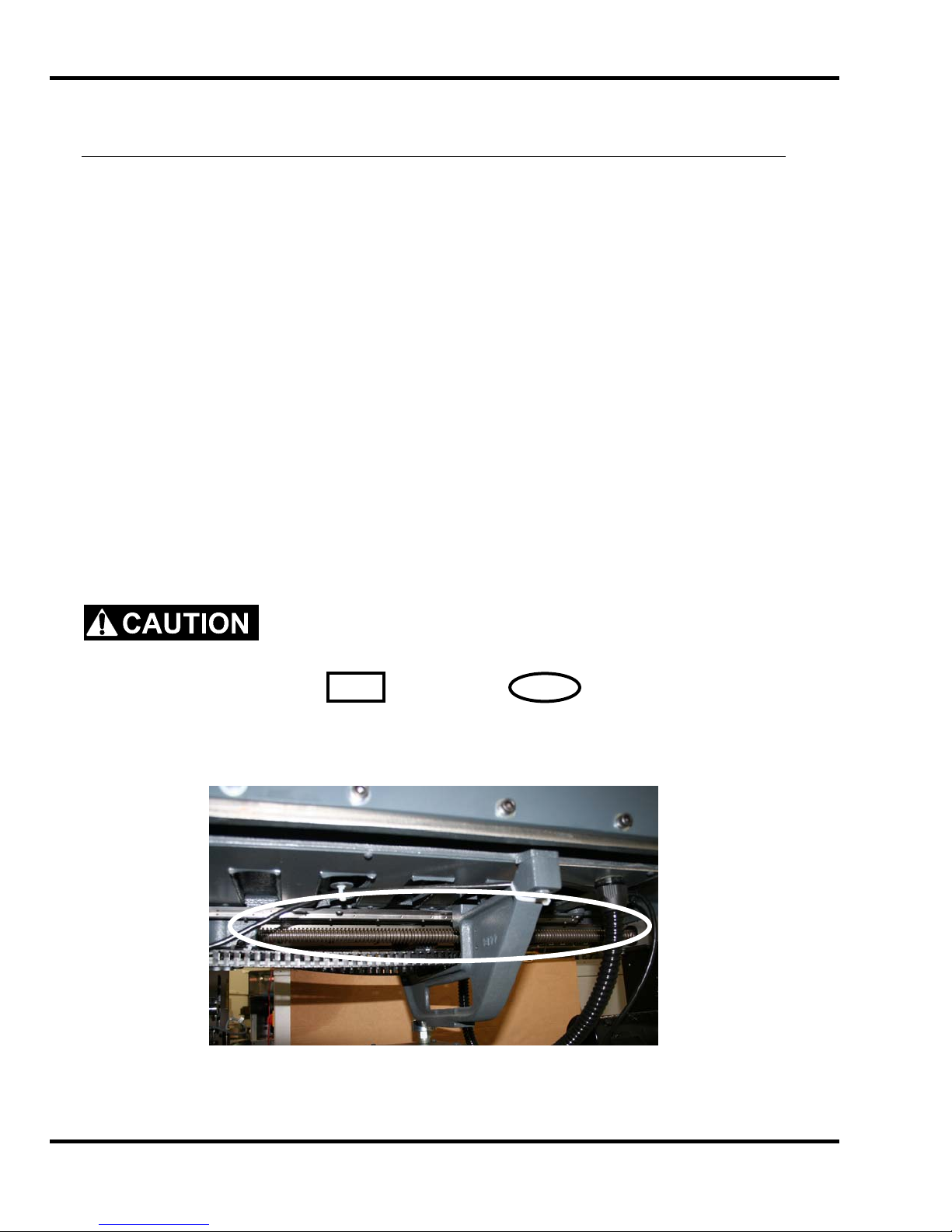

Most moving parts require lubrication. Remove all panel covers and look for all oil locations (marked

with red paint). Make sure oil holes are not plugged and lubricate with a 30 weight oil. See the

photos below for critical locations (not all locations are illustrated here). Notice that some are oil

locations and some are grease points. Wipe off old and excess grease. Use a National Lubricating

Grease Institute No. 1 consistency, extreme pressure grease.

Replace all guards before operating. Never operate cutter with any

guards removed.

GREASE OIL

Backgauge leadscrew (oil):

Figure 15

28

Page 29

10.0 Lubrication

Knife bar pull-down pin (oil):

Figure 16

Left and right clamp guides (grease):

Lower knife and clamp cylinder pins (oil):

Figure 17

Figure 18

29

Page 30

10.0 Lubrication

Wipe down the knife bar to remove dust and debris (Figure 19).

Knife Bar

Figure 19

Check knife bar link, bell crank, and hydraulic cylinder pin keepers to make sure they are in pla ce an d

secure (Figure 20).

Knife Bar

Link Pin

Keepers

(x2)

Bell Crank

Pin Keepers

(x2)

Hyd. Cyl.

Pin Keepers

(x2)

Figure 20

30

Page 31

11.0 Hydraulic System

11.0 Hydraulic System

The Champion Series Cutters have both hydraulic cutting and hydraulic clamping operation. The

cutter is powered by an electric motor coupled directly to a hydraulic pump. The pump has a fixed

flow rate output of 5 GPM at 1,800 psi (max. system relief setting) at 1,800 RPM.

The clamp action is powered by a hydraulic cylinder. When the cut buttons are depressed, this

cylinder pulls on the clamp bell crank and brings the clamp down (or brings the clamp up to full

hydraulic pressure if the manual foot clamp is down). The cutting action is also powered by a

hydraulic cylinder connected directly to the knife bar. The knife sequence valve generates 1,600 PSI

of back pressure throughout the system to maintain full clamp pressure during the cut. One

advantage of the hydraulics is the immediate return of the knife when the cut buttons are released.

The hydraulic fluid should be changed YEARLY or EVERY 1,000 HOURS of operation.

The oil filter (Challenge part H-227-1) should be changed YEARLY or whenever any repairs are

made to the hydraulic system.

NOTE: Failure to change the oil and filter when needed can damage the seals i n the clamp and knife

cylinders.

Check the level of the hydraulic reservoir WEEKLY or whenever the machine sounds like it is

laboring (this could be due to low oil level). The tank has a sight gauge on the back so you can check

the oil level.

The hydraulic tank, fan, manifold, and fittings should be wiped off WEEKLY to maintain maximum

cooling of the tank/hydraulic oil.

11.1 Recommended Hydraulic Oil

Use only ISO (International Standards Organization) Viscosity Grade 46, rust, oxidation, and foam

inhibiting, non-detergent hydraulic oil. Oils other than the recommended type will cause seals,

cups, and O-rings to deteriorate. The proper hydraulic oil can be purchased in 5 gallon containers

from your authorized Challenge Dealer using the Challenge part number: S-1991-3.

NEVER USE Automatic transmission oil or brake fluid as a substitute!

Oils other than the recommended type will cause seals, cups, and O-rings to deteriorate.

Unsafe operations conditions will result.

11.2 Changing the Oil

Only change oil when it is cold. Burns could result from changing hot oil.

Before beginning, you will need (3) empty five gallon buckets, three oil pans or more, a funnel and an

assistant. If oil is hot, wait until it cools.

1. Make sure main power to the machine is off.

2. Remove the reservoir tank cover (Figure 21).

31

Page 32

11.0 Hydraulic System

Reservoir

Tank Cover

Figure 21

3. Using a hand drill and transfer pump commonly found at hardware and home improvement

stores, transfer the used oil to empty containers.

4. Remove the magnet stuck to the bottom of the tank. Clean off any debris that may be

attached to it.

5. With a clean rag, wipe out any visible debris remaining in the tank.

6. Place the magnet at the location from which it was removed.

7. Replace the oil filter. Place a thin film of new hydraulic oil on the seal of the new filter to

insure a proper seal. Firmly hand-tighten the filter onto the filter head.

8. Using the transfer pump, fill the tank with 13.5 gallons of the recommended fluid (See Section

11.1 - Recommended Hydraulic Oil) until the level is just above the sight gauge shown in

Figure 21.

9. Re-install the tank cover with gasket.

10. Before turning on the machine, make sure all hydraulic hose fittings are tight.

11. Turn on main power to the machine. Turn on the hydraulic motor by pressing both cut buttons

once. Inspect the hydraulic system for leaks. If leaks are found, turn off main power to the

machine and tighten any leaking fittings.

11.3 Hydraulic Valve Adjustments

Sight

Gauge

Hydraulic

Tank

Several of the following tests require the machine to be operational for

checking and adjusting. Be very careful that tools and other people are clear of moving parts and that

the cutter is not accidentally operated while adjustments are being made. Disconnect the power and

lock it out, (see Safety Precautions, page 5) whenever working on the machine unless the directions

specifically require the machine to be powered.

NOTE: Pressure settings fluctuate with oil temperature. Set pressures when the oil is hot.

32

Page 33

11.0 Hydraulic System

For initial setup, adjust in the following order:

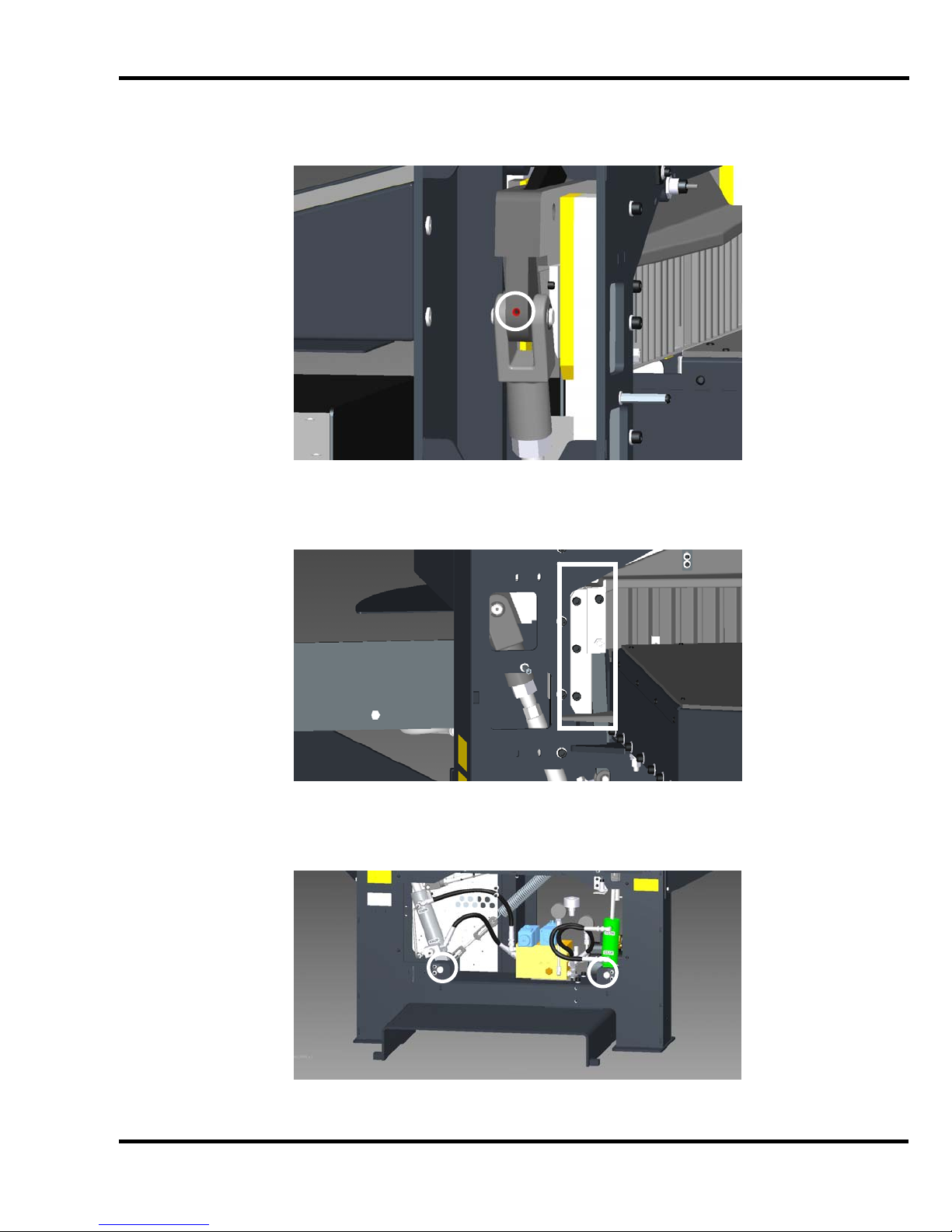

1. Main System Relief Valve (Figure 22) – 1,800 psi

2. Knife Down Sequence Valve (Figure 23) – 1,600 psi

3. Clamp Up Sequence Valve (Figure 22) – 400-600 psi

4. Clamp Pressure (TC Console) – 400min/1,400max psi

Clamp

Pressure

Gauge

Main

System

Gauge

Main System

Relief Valve

Electronic

Clamp Valve

Sequence Valve

Figure 22

Knife Down

Sequence

Valve

Figure 23

1. Main System Relief Valve (Figure 22) – 1,800 psi

This valve maintains the overall hydraulic pressure for the entire system. Factory setting:

1,800 psi.

To Check:

a. Open the left access door on front of the cutter.

Clamp Up

33

Page 34

11.0 Hydraulic System

b. Turn the power on and make a cut to hold the knife down on the cutting stick. Read the

pressure on the main system pressure gauge (front gauge) while the knife is down. If the

gauge does not read 1,800 psi, an adjustment is needed. In order to have more time to

read the gauge, it may be helpful to send the knife down using the “Knife Change” feature

found in the Maintenance pull-down menu.

To Adjust:

a. Loosen the lock nut on the relief valve. Use an Allen wrench to turn the adjusting screw.

Turn clockwise to increase pressure, counter-clockwise, to decrease pressure.

b. Make a cut and hold the buttons in. Or send the knife down using the “Knife Change”

feature found in the Maintenance pull-down menu. Adjust the valve screw until you have

the correct pressure.

c. Tighten the lock nut while holding the hex wrench in place.

2. Knife Down Sequence Valve (Figure 23) – 1,600 psi

This valve controls the clamp and knife sequence. It keeps the knife up until after the clamp

has made contact. It is located near the lower port of the knife cylinder. Factory Setting:

1600 psi.

NOTE: Main System Pressure must be set at 1,800 psi before making this adjustment.

To Check:

a. Open the left access door on front of the cutter.

b. Press the cut buttons while reading the pressure on the main system pressure gauge

(front gauge). The gauge should read approximately 1,600 psi as the knife is moving

down (when bottomed, the gauge will jump to 1,800 psi showing the Main System

Relief Pressure previously set).

To adjust:

a. Remove the lower rear cover.

b. Loosen the lock nut. Note: This lock nut also serves as a seal. Some hydraulic fluid

may leak out while it is loose.

c. Make a cut and hold the buttons in. While reading the main system gauge, adjust the

valve until you have the correct pressure. Clockwise to increase, counter-clockwise to

decrease.

d. Tighten the lock nut while holding the hex wrench in place.

3. Clamp Up Sequence Valve (Figure 22) – 400-600 psi

This valve maintains clamp pressure so the clamp remains down until the knife has stopped

in the up position. Factory setting: 400-600 psi.

To Check:

a. Open the left access door of the cutter.

34

Page 35

11.0 Hydraulic System

b. Press the cut buttons, and while reading the pressure on the main gauge (front

gauge), release them. The gauge should read between 400-600 psi as the clamp is

going up. There should be no clamp movement until the knife is stopped in the up

position.

To Adjust:

a. Remove the protective cap and loosen the lock nut on the clamp up sequence valve.

b. Make a cut, then release the buttons. Read the main gauge as the clamp is

returning. Adjust the valve for a reading of 400-600 psi.

c. Tighten the lock nut while holding the hex wrench in place and replace the protective

cap.

4. Electronic Clamp Pressure Setting (TC Console) – 400min/1,400max psi

The electronic clamping control allows the convenience of changing the clamp pressure at

the control console, as well as the ability to program different clamp pressure settings within

programmed jobs. The clamp pressure is controlled by use of a slide bar on the TC touch

screen located at the lower left corner of the screen. A number between 0 and 15 will be

displayed, indicating the current pressure setting (0 being the lowest, 15 the highest). To

adjust the actual clamp pressures at the minimum (0) and maximum (15) settings, follow the

procedure below:

Adjustment of the Electronic Valve:

a. On the TC touch screen, select the Maintenance pull-down menu then choose Setup.

Then select the Service Info tab, and in the box for Enable Tabs Code, enter 6125.

Now select the Hydraulic Settings tab. The screen should look similar to Figure 24

below:

Figure 24

35

Page 36

11.0 Hydraulic System

b. To set the maximum pressure, first make sure the correct slide bar is “active” by

touching the appropriate slider button. Now press both cut buttons, and after the

clamp has contacted the table and while the knife bar is coming down, read the

pressure on the right hand pressure gauge. It should be set at 1,400 psi. If not,

adjust the maximum clamp pressure slider button higher or lower and re-check the

clamp pressure reading on the gauge. Repeat until the pressure is properly set at

1,400 psi.

c. To set the minimum pressure, first make sure the correct slide bar is “active” by

touching the appropriate slider button. Now press both cut buttons, and after the

clamp has contacted the table and while the knife bar is coming down, read the

pressure on the right hand pressure gauge. It should be set at 400 psi. If not, adjust

the minimum clamp pressure slider button higher or lower and re-check the clamp

pressure reading on the gauge. Repeat until the pressure is properly set at 400 psi.

d. To adjust the directional valve shift delay, first make sure the correct slide bar is

“active” by touching the appropriate slider button. Start with the slider button

somewhere near the middle. Make a cut and watch the motion of the knife bar. If the

knife bar hesitates at the bottom of its stroke, decrease the delay by moving the slider

button to the left. If you hear an unusual “clunk” sound when the knife reaches the

bottom of its stroke, increase the delay by moving the slider button to the right.

e. The knife cushion value is applicable to Titan 265 cutters only. Changing this setting

on Champion 305 cutters has no effect.

f. When finished, press Save and Exit.

36

Page 37

12.0 Adjustments

12.0 Adjustments

Several of the following tests require the machine to be operational

for checking and adjusting. Be very careful that tools and other people are clear of moving

parts and that the cutter is not accidentally operated while adjustments are being made.

Whenever working on the machine, disconnect the power and lock it out (see SAFETY

PRECAUTIONS, page 5) unless the directions specifically require the machine to be powered.

12.1 Electric Eye Alignment

If the electric eyes are not in alignment, or if they become out of alignment during a cut cycle due to

vibration, the machine will see them as blocked and will cease any downward motion.

To check if the electric eyes are aligned properly, turn on the power switch and look at the indicator

light pattern on the receiver (left hand unit). If the eyes are functioning properly and aligned properly,

and if there are no obstructions, the light pattern will look like the one shown in Figure 25 below.

Power

Status

(Green = OK)

(Red = Problem)

Figure 25 – Electric Eye Indicator Lights

To simulate the vibration caused by a normal cut cycle, gently tap on the electric eye housings one at

a time with your hand. Watch the indicator lights to see if any of them change.

If the status light or any of the zone indicator lights are red, this indicates an obstruction. However if

there are no physical obstructions blocking the eye beams, then most likely the electric eyes a r e out

of alignment. To adjust:

1. Remove the inner housing covers from both eye housings.

2. Loosen the outer mounting screws (Figure 26) to adjust the eye beam units until they are

aligned over their length.

Diagnostic

Zone Indicators

(Green = Clear/Aligned)

(Red = Blocked/Misaligned)

37

Page 38

12.0 Adjustments

Outer

Mounting

Screws

Inner Mounting

Figure 26

3. Loosen the inner mounting screws (Figure 26) to rotate the beams until they are aligned over

their width. When the indicator lights indicate proper alignment as shown in Figure 25,

tighten all screws.

4. Replace the inner housing covers and re-check the alignment as indicated above.

Screws

12.2 Backgauge Gib Adjustment

If the backgauge does not stay squared or jumps up and down when jogging paper against it, the

backgauge gib screws are probably loose or worn. Position the backgauge approximately 2” (5055mm) from the rear of the table and turn off power.

Remove the rear table cover. From the back, hold each end of the backgauge and try pulling one

end while pushing the other to rock it side to side. If there is noticeable side-to-side play in the

backgauge, the gibs will need adjusting. Check for play at various positions on the table, (Figure 27).

Note: there will be some front to rear movement between the backgauge nut and screw.

Figure 27

The backgauge has two gibs that ride on an iron rail underneath the table, (Figure 28). These are

adjusted with setscrews, which are held in position with jam nuts.

38

Page 39

12.0 Adjustments

Set Screws

& Jam Nuts

Rail

Figure 28

To adjust:

1. Run the backgauge back to 28” (711mm) and disconnect the power.

2. Always adjust the side gib first. Loosen all jam nuts and adjusting screws then tighten the

front and rear screws.

3. Pull each end of the backgauge and try to rock it side to side as before to check for play.

4. Continue to adjust these two screws until there is no play.

5. Lock the screws in place with the jam nuts.

6. Snug up the middle two screws and lock in place with the jam nuts.

7. Snug up the bottom gib adjusting screws finger tight and lock in place with the jam nuts.

8. Run the backgauge back and forth to make sure it does not bind. Readjust if necessary.

9. Replace the rear table cover.

10. Check the backgauge squareness.

12.3 Squaring the Backgauge

To test the backgauge for squareness, place a small lift of paper against the left side of the

backgauge (but not against the side guide) and make a cut.

Now, leave the backgauge in the same position, flip the lift over and against the right side of the

backgauge (but not against the side guide). Make another cut to see if any of the stock will trim off.

Run two checks, one starting on the left and moving to the right, the other, moving from the right to

the left. Trim in either sequence indicates the backgauge is out of square.

PAPER

Figure 29

39

Page 40

12.0 Adjustments

q

To adjust squareness:

1. As machine wears, make sure the backgauge gibs are set properly first (see previous

section). Then follow steps 2 through 5.

NOTE: Gib adjustment is not necessary on initial machine setup because they have been

adjusted at the factory.

2. Remove the rear table cover.

3. Loosen the backgauge locking screw, then loosen the jam nuts on the backgau ge squaring

screws (Figure 30) .

Locking

Screw

S

uaring Screws

Figure 30

4. Back off the squaring screw slightly on the side that the trim occurred, then turn in the other

squaring screw until tight.

5. With both squaring screws tight, make another test. Continue to adjust and test until no trim

occurs when testing in either sequence.

6. Tighten the jam nuts and lock screw.

7. Replace rear table cover.

NOTE: Once the backgauge is square, restore power to the machine and check the backgauge

accuracy to make sure it is accurate (s ee nex t section).

12.4 Backgauge Position Accuracy Adjustment

If the backgauge position readout does not match the actual measurement between the knife and the

backgauge, the cutter must be re-calibrated.

The accuracy can be checked by comparing cut sheets of paper. This process is described below.

NOTE: The backgauge gibs should be adjusted and the backgauge squared before attempting to

adjust accuracy.

1. Place a 1/4 to 1/2 inch (5 to 13mm) pile of 8-1/2 X 11 (A4) paper against the center of the

backgauge.

2. Trim cut lengthwise and rotate 180

up to the 10" (254mm) position and make a cut. Move the backgauge up to 5" (127mm) and

make another cut.

0

. Using the backgauge position readout, bring the paper

40

Page 41

12.0 Adjustments

3. Take several sheets from the center of each lift and compare them to each other. The

encoder system on your cutter will space accurately between your 10” (254mm) and 5"

(127mm) cuts, whether the overall accuracy is correct or not. The stack of paper between

the 10” (254mm) and 5" (127mm) cuts will be a true 5", but the paper left against the