Chago Wallbox

Installation instruction

ENG

Operation instruction

RAK 111

20.10.2016

1

Contents

1. Chago Wallbox 3

2. Safety Instructions 3

3. Delivery Contains 4

4. Accessories 4

5. Installation instructions 5

5.1. Before Installation 5

5.2. Wall Bracket Installation 6

6. Supply Connection 9

7. Commissioning 10

7.1. Connecting to Chago Wallbox 10

7.2. Congurating to Chago Wallbox 11

7.3. Commissioning Standalone Charging Point 12

7.4. Commissioning Online Charging Point 13

8. User Instructions 15

8.1. User Interfaces 15

8.2. Charging 15

9. Technical Information 16

10. Warranty 17

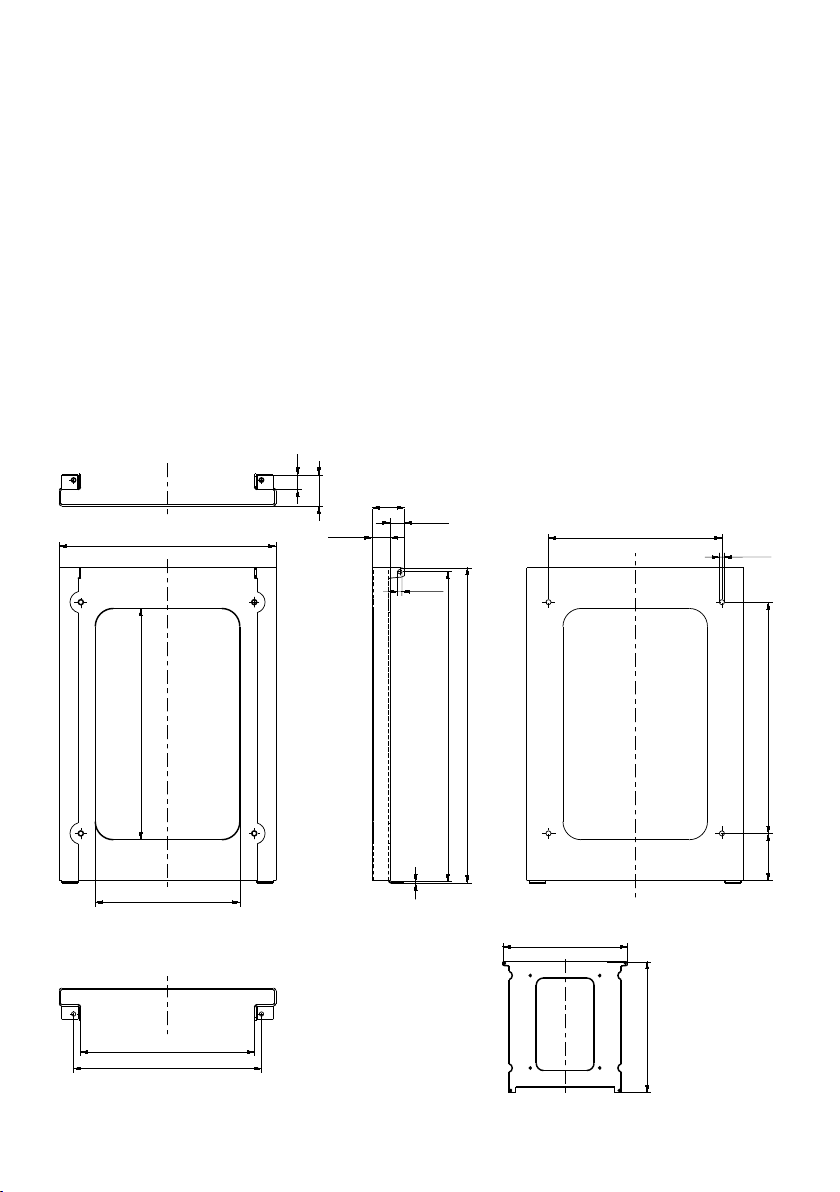

11. Dimension Drawing 17

12. Installation / Commissioning Checklist 18

13. Maintenance / Preventive Maintenance Instructions 19

14. Troubleshooting 20

15. EVB100 Internal Circuit Example 21

16. EVB200 Internal Circuit Example 22

2

1. Chago Wallbox

EVB100: Single charging unit

EVB200: Dual charging unit

Plastic front

cover

Ambient light

(optional)

Painted steel

frame

RFID reader

Front cover

lock

1-2 x Mode 3/ Type 2 socket outlet

3-color LED

indicates the

charging point’s

status

2. Safety Instructions

• Chago Wallbox must be installed by a qualied person.

• Read this instruction manual before installation and usage of the charging point.

• The instruction manual must be stored in a safe location and be available for future installation and

service.

• Follow the guidelines in the instruction manual when installing and using the charging point.

• The installation must be done according to the local safety regulations, restrictions, dimensioning,

rules and standards.

• The information provided in this manual in no way exempts the user of responsibility to follow all

applicable rules and safety standards.

3

3. Delivery Contains

• Chago Wallbox (EVB100 / EVB200)

• Installation and Operation instruction

• Optionally Wall bracket (EVTL40.00)

4. Accessories

Wall bracket

EVTL40.00

Included on Wallbox congurations EVBx00-A/-B/-C/-D.

For other congurations please order separately.

20

43

300

45

25

2x Ø6

20

240

4x Ø7

320

241

260

200

436

429

2

431

452,6

320

65

4

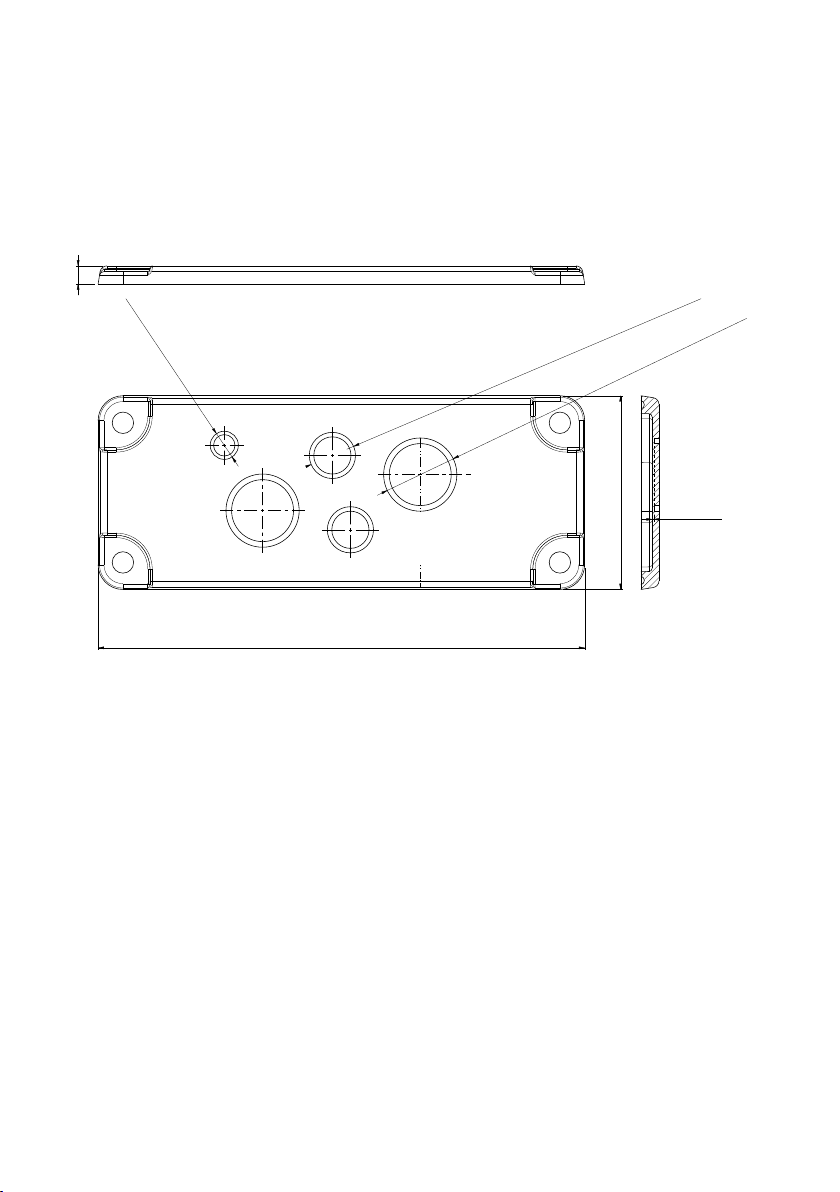

Flange

KOT21715

Included in the delivery.

Note! Cable glands are not included in the delivery.

Please order suitable cable glands separately according to the used supply cable sizes, for example Ensto

KTM... cable gland series (polyamide or brass).

8

Ø12.5 (Knock-out)

Ø20.5 2pcs (Knock-outs)

Ø32.5 2pcs (Knock-outs)

86

216

+0.1

0.7

-0.1

ALL KNOCK-OUTS

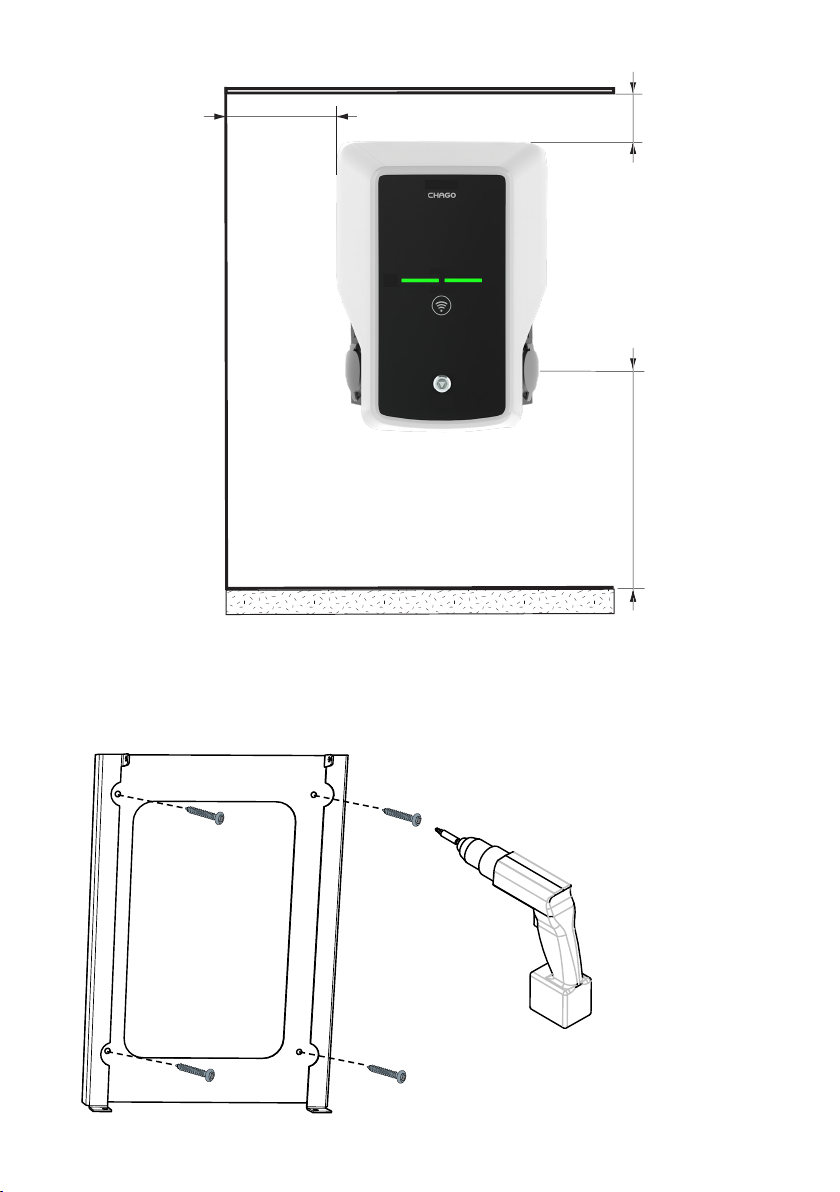

5. Installation instructions

5.1. Before Installation

Remove the Wallbox from it’s package. Do not scratch the surface of the Wallbox after removal from the

package.

When selecting installation site, take into accoun the following:

• The minimum space needed for operating and maintenance.

• Make sure that the wall material is suitable and robust. The mounting surface should be at and

vertical.

• In order to ensure the optimal charging performance, the charging unit should not be exposed to

direct sunlight.

5

min. 400 mm

min. 200 mm

Recommendation

1200 mm

Follow always national regulations

and site requirements

5.2. Wall Bracket Installation

6

Step 1

• Drill screw holes for the wall

bracket.

• Place the wall bracket on the

wall using suitable screws.

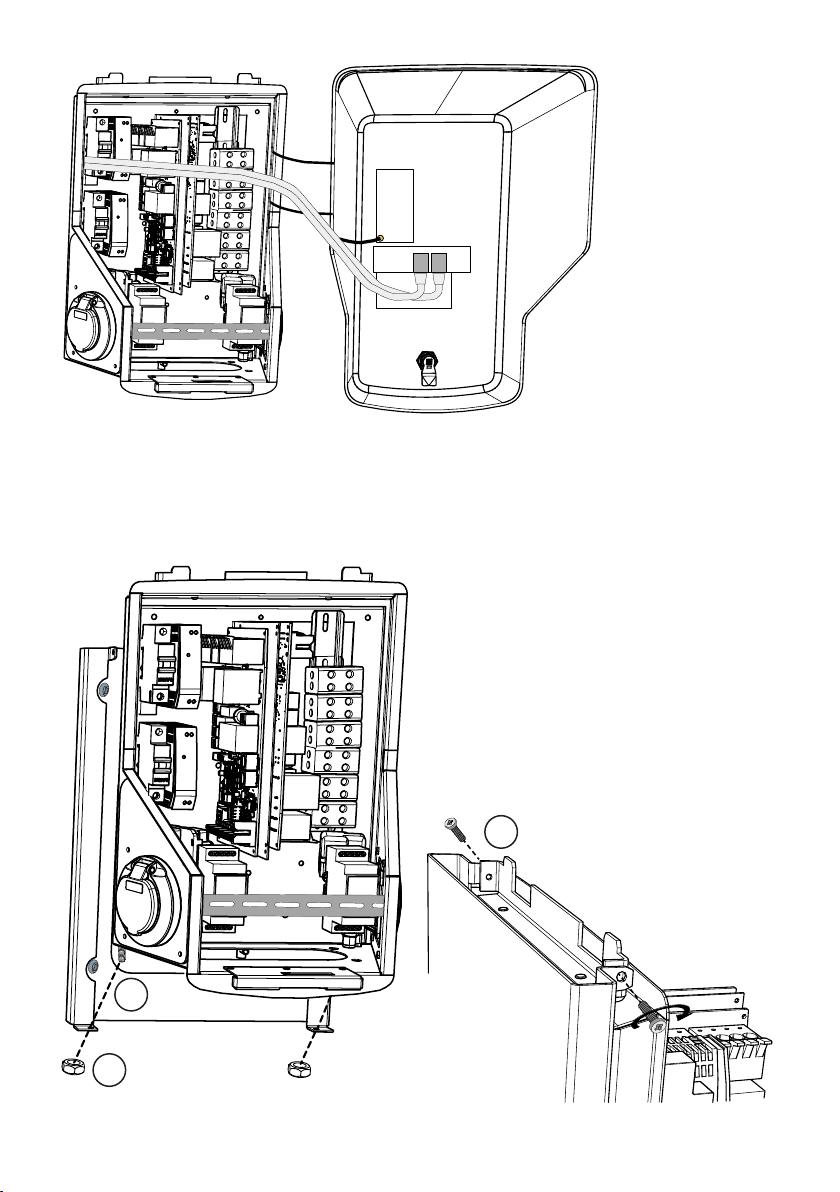

Step 2

• Open the front cover lock

and remove the front cover.

Note! RFID, LED module and 3G

antenna cables are attached to

the front cover. Be careful not to

break any components when you

remove the front cover.

Step 3

• Place the Wallbox on the wall bracket (1).

• Attach the top of the Wallbox on the wall

bracket using the screws included in the

package (2).

• Secure with nuts included in the package (3).

2

1

3

7

Step 4

• Remove the front DIN rail if needed to make more space for the installation work.

• Remove the ange at the bottom of the Wallbox frame.

• Open the knock out needed for the cable gland.

• Put the cable gland in place.

• Put the ange in place.

• Pull the supply cable through the cable gland approx. 600 mm.

• Remove the cable sheath approx. 200 mm measured from the cable gland exit.

• Secure the front DIN rail in place.

• Pull the supply cable leads through the plastic guide included the delivery.

• Run the supply wiring above the DIN rail in such a manner that the outlet locking system is not damaging the supply wires.

• Cut the supply cable leads in dierent lengths. Leave the ground lead long enough so that if a fault

occurs it is the last one that comes loose.

• Strip the leads 25 mm and connect to the supply connectors.

• Ensure that the RFID, LED module and 3G antenna cables are routed correctly.

• Close the front cover.

DC power supply

Controller board / boards

Front DIN rail

8

Supply connectors

Cable route

Plastic guide

Supply cables

6. Supply Connection

The voltage and current ratings including cables and line protector dimensioning must comply with national regulations. System dimensioning must be done by a qualied electrical designer.

Connect separate supply cables for each charging outlet.

Stranded cables are recommended in Wallbox installations.

A Residual current protection device (RCD) and a circuit breaker (MCB) for each charging outlet must be

installed in the switchboard.

Example: Supply connection for Chago Wallbox with 2 outlets

2

F02

L1

L2

L3

2

F01

L1

L2

L3

PE

1

MCB

B6

L1

L2

L3

SUPPLY 2

N

1

MCB

B6

N

PE

L1

L2

L3

SUPPLY 1

N

N

PE

9

7. Commissioning

Before commissioning the Chago Wallbox must be installed according to the installation instructions.

By default all Chago Wallboxes are operating in free charging mode (standalone operation). In this free

charging mode external communication (Ethernet, 2G/3G) is not active. If the Chago Wallbox is going to

be connected to some back-oce (online mode), rst make sure that the basic function ality is working

before establishing communication.

7.1. Connecting to Chago Wallbox

If you want to change the default settings, you must connect to Chago Wallbox via web conguration tool

to be able to proceed with the commissioning settings. Use Firefox or Windows Explorer web-browser for

conguring.

EVB100

micro USB service port

micro USB --- USB cable

PCEVB

EVB200

micro USB service port

10

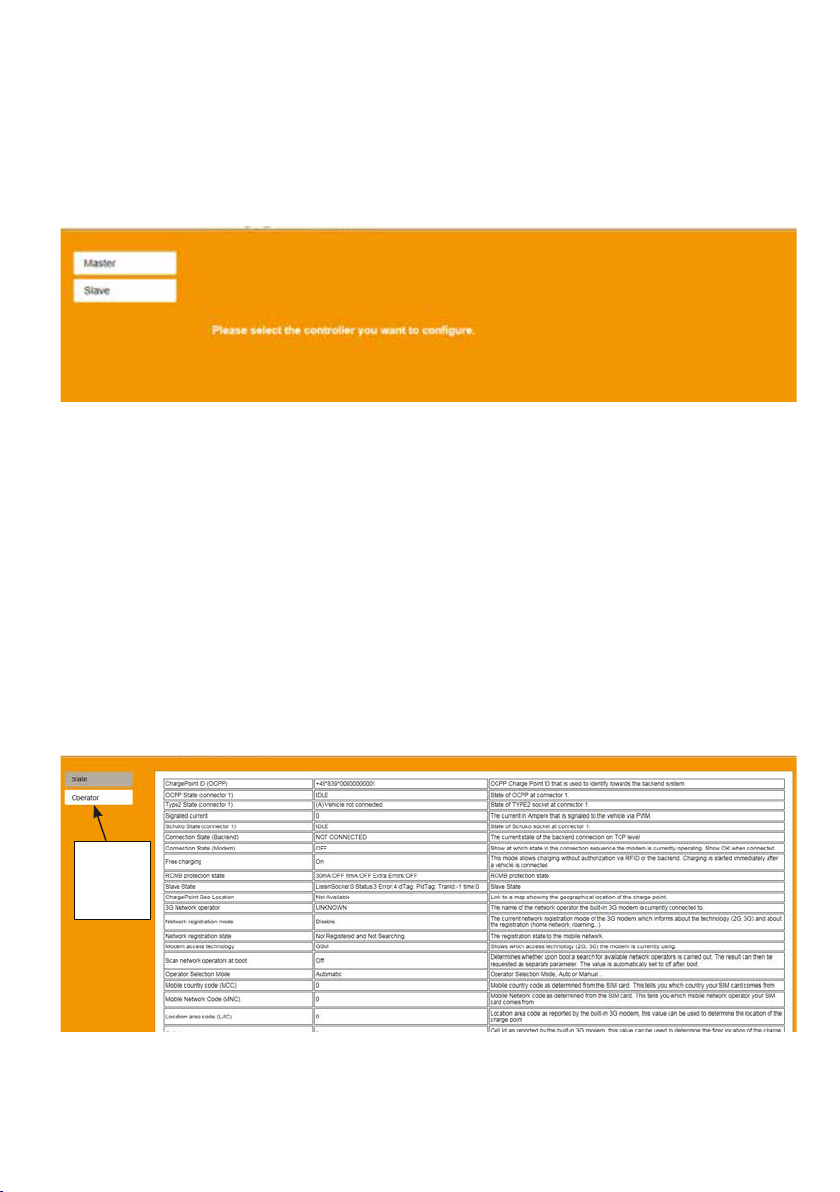

7.2. Congurating to Chago Wallbox

1. If you want to see device status, and settings, login as viewer.

Go to: http://192.168.123.123/

Login page opens, select “Master” or “Slave” controller to review settings.

2. If you want to make changes, login as operator.

Connect to SLAVE controller.

Go to: http://192.168.123.123/operator

Connect to MASTER controller.

Go to: http://192.168.123.123:81/operator

When operator selection is visible you can make changes to connection setting (OCPP, Ethernet, 3G

modem etc.)

When browser asks for username and password, enter the following:

User name = operator

Password = yellow_zone

Operator

selection

visible

11

7.3. Commissioning Standalone Charging Point

1.a) Free Charging

By default “Free Charging” is on. Charging starts immediately after a vehicle is connected. Authorization

using a RFID tag or via backend is not in use.

1. Open the front cover.

2. Switch F01 / F02 ON.

3. Ensure that the DC power supply turns on (green LED).

4. Wait until front cover LED turns from red to green.

Note! The startup takes approx. 1 - 2 minutes.

5. The unit is ready for use in “Free charging” mode.

Note! By default the maximum charging current is 32 A. The maximum charging current can be changed.

Login to the charging point and enter the new maximum current with parameter “Operator Current Limit

(A)”. Apply changes to Master and Slave controllers separately. See chapter 7.1 and 7.2 for details.

Note! Supply phase conguration. By default the charging point is congured with 3-phase supply. In case

of 1-phase supply, change the phase conguration. Login to the charging point and enter the existing

phase parameter “Phases connected to the Charge Point”. Apply changes to Master and Slave controllers

separately. See chapter 7.1 and 7.2 for details.

1.b) Authorized charging

Charging starts when showing RFID tag to the RFID reader.

1. Open the front cover.

2. Switch F01 / F02 ON.

3. Ensure that the DC power supply turns on (green LED).

4. Wait until the front cover LED turns from red to green.

Note! The startup takes approx. 1 - 2 minutes.

5. Connect your service laptop to Wallbox by using a micro-USB service port on the controller board.

6. Log in http://192.168.123.123:81/operator.

7. Select “Free charging” mode o.

12

8. Add RFID ID’s on the internal memory of the charging point:

Note: List of colon-separated IDs for the cache. A maximum of 80 entries are shown. To clear the

cache, the list must be empty. The listed IDs are added, while the other cache entries are not deleted.

See the examples below.

9. When ready, click “Save & Restart” to active the new settings.

10. Wait until the front cover LED turns to green.

11. Close the front cover.

7.4. Commissioning Online Charging Point

2.a) Congurating Ethernet operation

1. Open the front cover.

2. Switch F01 / F02 ON.

3. Ensure that the DC power supply turns on (green LED).

4. Wait until front cover LED turns from red to green.

Note! The startup takes approx. 1 - 2 minutes.

5. Connect your service laptop to Wallbox by using micro-USB service port.

6. Log in http://192.168.123.123:81/operator

7. In order to set the unit to online mode the following settings must be activated:

Back-end connection settings:

◊ Charging point ID (OCPP), by default serial number of the controller (master / slave)

◊ Connection type, select “Ethernet”

◊ OCPP mode (depends on the communication protocol the connected back-end supports)

◊ SOAP / JSON OCPP URL (back-end connection address), select SOAP or JSON based on used

OCPP mode

Ethernet connection settings:

◊ DHCP in use

8. When ready, click “Save & Restart” to active the new settings.

9. Wait until the front cover LED turns to green.

10. Ensure that the set charging point ID is visible at the used back-end system.

11. Close the front cover.

13

2.b) Congurating 3G Operation

One “micro-SIM” card is needed per Wallbox unit.

“Micro-SIM” card

If you need to remove the “micro-SIM” card,

pull the white tape which is attached on

the rear side of the card.

1. Open the front cover.

2. Switch F01 / F02 ON.

3. Ensure that the DC power supply turns on (green LED).

4. Wait until front cover LED turns from red to green.

Note! The startup takes approx. 1 - 2 minutes.

5. Connect your service laptop to Wallbox by using micro-USB service port.

6. Log in http://192.168.123.123:81/operator

7. In order to set the unit to online mode the following settings must be activated:

Back-end connection settings:

◊ Charging point ID (OCPP), by default serial number of the controller (master / slave)

◊ Connection type, select “3G”

◊ OCPP mode (depends on the communication protocol the connected back-end supports)

◊ SOAP / JSON OCPP URL (back-end connection address), select SOAP or JSON based on used

OCPP mode

3G modem settings:

◊ APN name (operator dependent)

◊ APN username / password (if in use)

◊ SIM card PIN number (if NoPin version)

8. When ready, click “Save & Restart” to active the new settings.

9. Wait until the front cover LED turns to green.

10. Ensure that the set charging point ID is visible at the used back-end system.

11. Close the front cover.

14

8. User Instructions

8.1. User Interfaces

LED signal lights will show the status of the charging point as described below:

Charging point status

Charging point free and ready to use

RFID read, user login ongoing

User login fail, access denied

User loggin passed, charging allowed

While connecting the cable

Vehicle connected, charging not started

Vehicle connected, starts charging

Charging ongoing

Error state

LED light LED operation

Green Stable

Green Flashing

Red Stable

Green Waving

Green Flashing twice

Green Waving

Blue Waving

Blue Stable

Red Stable

8.2. Charging

Free charging

• Plug in your electric vehicle to start charging.

• Unplug your electric vehicle to stop charging.

Charging with RFID

You must have an RFID tag which has a permission to access the charging point.

Start Charging with RFID

• When the charging point is free and the indicator light shows green, you can start a charging event.

• Show the RFID tag to the RFID reading area.

• When the RFID tag is read, the charging point will ash green and verify the user permission to

charge. If the user login is failed, the indicator light turns to red. If the user login is passed, the indicator light turns to waving green.

• Now you are logged in to the charging station.

• Plug in the electric vehicle for charging. The indicator light turns to stable blue.

Stop Charging with RFID

• Show the RFID tag to the RFID reading area.

• When you stop the charging event, the indicator light turns to waving green and you are able to

unplug the charging cable.

• After you have unplugged, you are logged out from the charging point and the charging point is

free for the next user.

15

9. Technical Information

Electrical Connections

Nominal supply voltage 1-ph/3-ph, 230/400VAC, 50Hz

Charging current (nominal) 3x32A, congurable between 6A…32A

Charging power (nominal) Max. 22kW per charging outlet

Supply connections and

terminals

Design and Mechanics

Materials Frame: Painted steel frame

Color Frame: Painted steel frame (RAL7021 “Anthracite”)

Weight approx. 10 kg, depends on product conguration

IP class IP54

IK class IK10

Operating temperature -30 C…+50 C

Standards IEC 61851-1

Approvals / markings CE

L1, L2, L3, N, PE

Cu 2.5–50 mm, Al 6–50 mm

Recommended 10 mm at nominal power

Tightening torque Nm: 4 Nm (2.5 - 4 mm²), 12 Nm (6 - 50 mm²)

Cover: Plastic

Cover: White plastic and black tape

IEC 62196-2 (socket outlets/plugs)

IEC 61439-1:2011

User Interface

Socket outlet Mode 3 / Type 2 or Mode 3

Charging status indication 3-color LED (Green/Ready, Blue/Charging, Red/Error)

Use access RFID (ISO/IEC 14443A, ISO/IEC 15693)

Free access

Mobile apps via 3rd party operators

Current measurement Integrated/on-board measurement

Safety Features

RCMB On-board: RCMB (6mA DC residual current detection)

RCD To be located to distribution board (at least type A, 30mA)

MCB To be located to distribution board (class C, nominal current 32A)

Control voltage 12VDC

Temperature control High operating temperature, such as direct sunlight, can cause

reduced charging current or temporary interruption in the charging

procedure

16

Control and Communication

Operation mode Standalone/Online

Wireless 2G/3G

Wired Ethernet

Protocol OCPP1.5 or OCPP1.6

10. Warranty

Warranty conditions, see www.chago.com.

11. Dimension Drawing

348

481

191

17

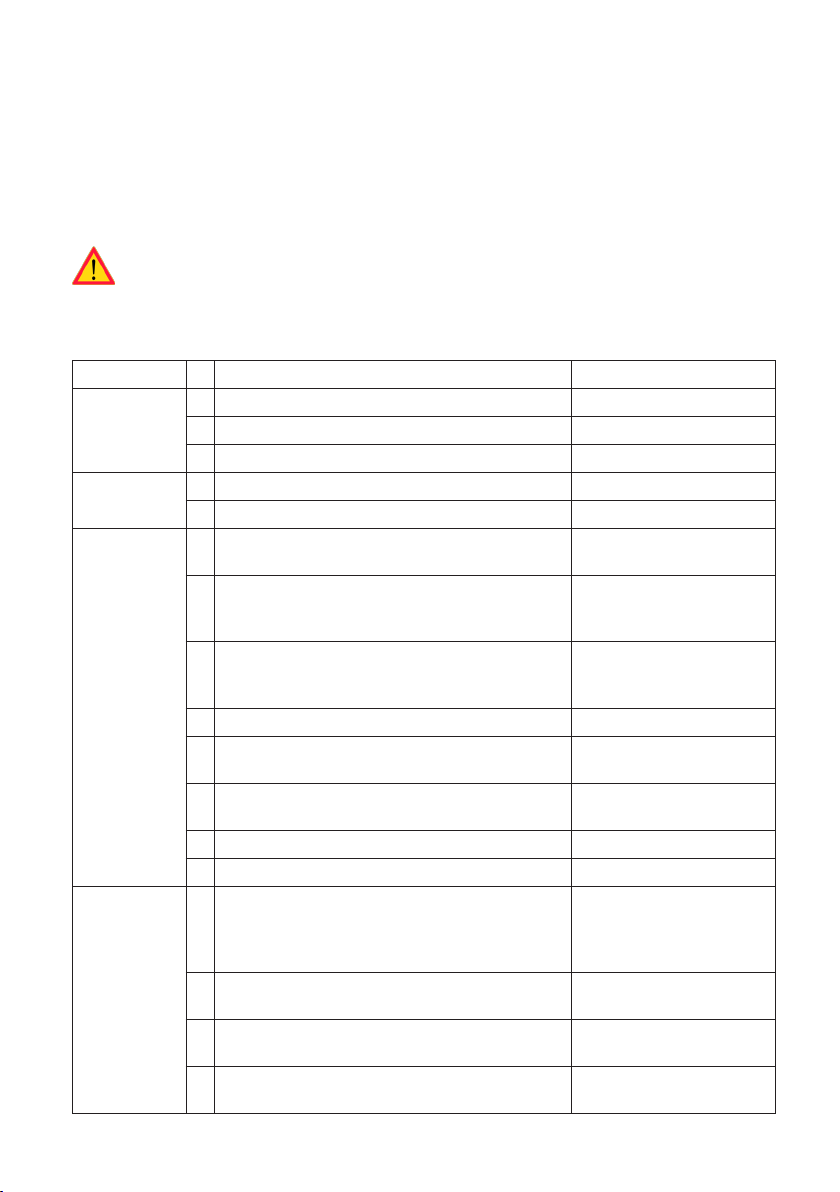

12. Installation / Commissioning Checklist

Introduction

This checklist is a guidance for ensuring both mechanical and electrical installation as well as commissioning of the Chago Wallbox.

Before Installation

Read the product specic installation instructions before performing any actions.

Note! Only trained electrician may perform the installation in accordance with the applicable local and national electrical rules and standards.

Checking the Installation

Go through the visual, mechanical and electrical installation when the charging point is un-powered.

CATEGORY X ITEM NOTES

Overall look Ordered material has been received.

Protective plastic wrapping have been removed.

No scratches or damages may be seen.

Mechanical

installation

Electrical

installation

Operational

check

Charging point is xed properly on the wall.

The front cover opens and closes smoothly.

Charging point’s power supply capacity meets

electrical planning (cable size, MCB…).

Gently push the charging point with a hand to

create vibration to ensure no bad contact / connection exist (wire or PCB).

Gently push the controller to create vibration to

ensure no bad contact / connection exist (wire or

PCB).

Check tightness of the PE-cable screw.

Power supply cables (L1, L2, L3, N and PE) are

properly connected.

Insulation of power supply cables is intact (L1, L2,

L3, N and PE)

Voltage between PE and N is less than 10 V

PE quality is less than 3

All the LED states / color (green, blue, red) and RFID

reader is functioning.

Available electricity at the sockets. All the contacts

(L1, L2, L3) must be tested.

Verify that when charging point LED is green, there

is no power at the socket contact (L1, L2, L3, N).

With Mode 3 tester, test the functioning of Mode 3

(from green to blue).

Review local electrical

design plan.

Create fail and charge (with

RFID tag). Red at bootup,

green at idle and blue while

charging.

Use Mode 3 tester.

18

Ready for use Correct SW in use

Correct operating mode

• Standalone

• Online

13. Maintenance / Preventive Maintenance Instructions

1 x per year

WARNING! Danger of electrical shock or injury.

Disconnect power before working inside the device or removing any components.

X MAINTENANCE ACTION

Retighten all screws (electric components).

Check the Mode 3 socket and if needed change it (burn or parts damage) (socket cost not under

warranty).

Check the charging cable and if needed change it.

Check the sealings.

Gently push the charging point with a hand to create vibration to ensure no bad contact / connection exist (wire or PCB).

Gently push the controller to create vibration to ensure no bad contact / connection exist (wire or

PCB).

Create fail and charge (with RFID card) to check all the LED states / color (green, blue, red) and RFID

reader is functioning.

Test available electricity at the sockets; use Mode 3 tester if needed. All the contacts (L1, L2, L3 must

be tested).

With Mode 3 tester, test the functioning of Mode 3 (from green to blue).

Check tightness of the PE-cable screw.

Test voltage between PE and N (must be less than 10 V).

Test PE quality (must be less than 3 ).

SW update if needed (if in service contract).

Restart the station from F0, ensure it will restart properly.

19

14. Troubleshooting

Charging station is o, no lights on

Issue Corrective action

Mains voltage does not exist in supply connector L1.

Circuit breaker F0 is o. Turn F0 on.

12V power unit has no LED on. Ensure 230V power supply to 12V power unit; if ok re-

The controller has no PWR LED on. Ensure power supply to the controller; if ok replace the

Charging cable is locked in Mode 3 socket outlet

Issue Corrective action

Unexpected fault has occurred while power is

on.

Power is o. Open the front cover. Switch Mode 3 lock into open

Ensure proper power supply.

place the power unit.

controller.

Option 1:

If equipped with Mode 3 lock release functionality,

turn o the power from F0 and pull charging cable

out from the socket.

Option 2:

Turn o the power. Switch Mode 3 lock manually into

open position.

position. Note! If the station has a Mode 3 Lock

Release functionality, then during power cut the

Mode 3 lock opens automatically.

Conguration via web browser

Issue Corrective action

PC does not recognize micro USB plug and connection to the controller cannot be established

via web browser.

Check from Windows 7 / 10 operating system settings

via “Device Manager” that RNDIS network adapter is

available. If not, update the related Windows driver.

20

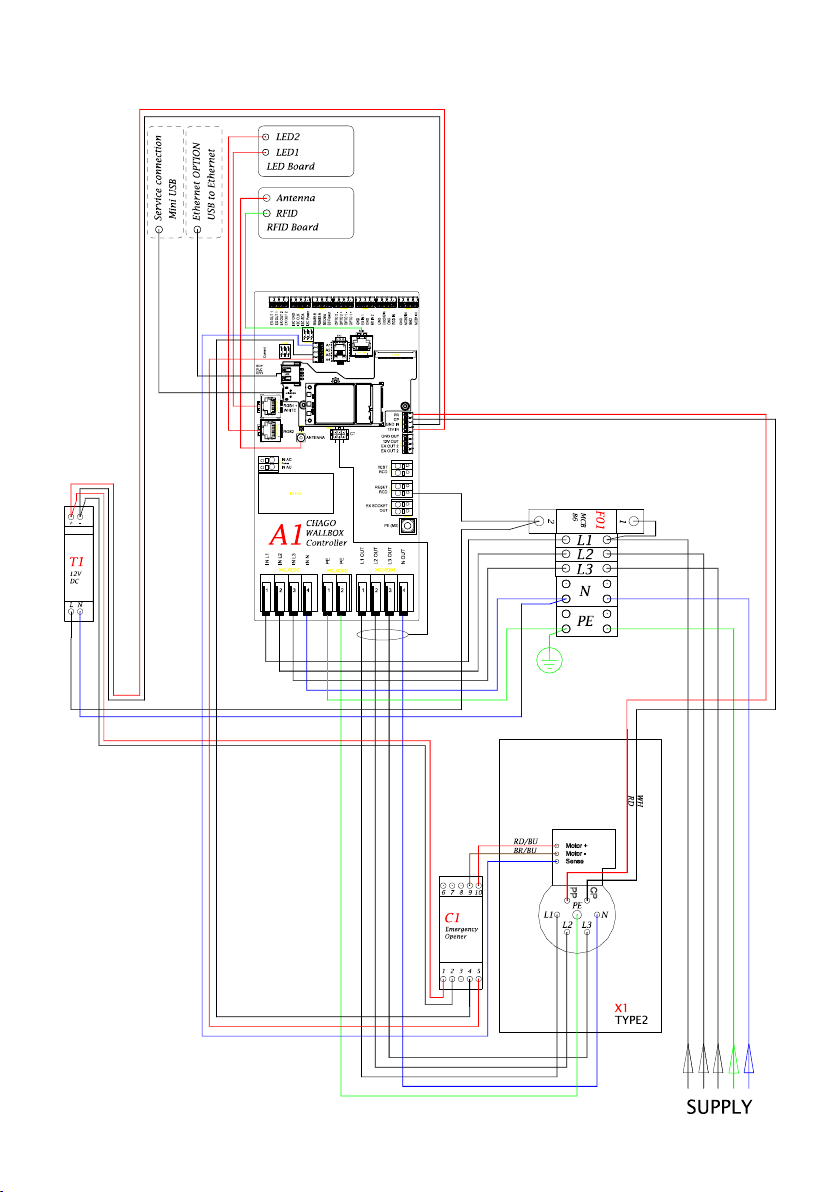

15. EVB100 Internal Circuit Example

21

16. EVB200 Internal Circuit Example

22

23

Ensto Chago Oy

Kipinätie 1, P.O. Box 77

FIN-06101 Porvoo, Finland

Tel. +358 20 47 621

Customer service: chago.support@ensto.com

chago.support@ensto.com

www.ensto.com

Loading...

Loading...