cGuard Litom

User guide

1

Contents

1. Copyrights and guarantees .................................................................................................................. 2

2. Introduction ........................................................................................................................................ 3

3. Specifications .................................................................................................................................. 4

4. Set contains ................................................................................................................................... 6

5. Components of cGuard Litom ......................................................................................................... 6

6. Interface connector description .................................................................................................. 7

7. First-time setting ............................................................................................................................. 8

7.1 Channel setting .......................................................................................................................... 9

7.2 Remote configuration .............................................................................................................. 10

8. Connecting the automobile cGuard tracker .................................................................................... 11

8.1. Inserting a SIM-card ............................................................................................................... 11

8.2. Power connection ................................................................................................................... 12

8.3. Connecting the analog sensors to tracker ................................................................................. 14

8.4. Connecting contact sensors (buttons) ...................................................................................... 15

8.5. Ignition detecting .................................................................................................................... 16

8.6. Connecting the frequency/pulse inputs of tracker .................................................................... 17

8.7. Connecting the power output of the tracker ............................................................................. 20

8.8. Connecting devices to RS-485 interface .................................................................................. 21

8.9 Connecting devices to 1-Wire interface .................................................................................... 22

9. Device status indication..................................................................................................................... 24

SAT indicator ................................................................................................................................ 24

DAT indicator ............................................................................................................................... 24

10. Contacts ................................................................................................ .......................................... 25

2

1. Copyrights and guarantees

This guide contains descriptions of the device and its functionality, and methods of its

connection and installing

This guide is designed for specialists acquainted with repair and installation work on automobile

transport and having professional knowledge about electronic and electric equipment of various

vehicles. All the data about functions and specifications and other information in this guide is

mentioned to be actual for the publication date. cGuard LLC company keeps its right to make

changes in this information and specifications without additional notifying.

cGuard LLC company isn’t responsible to any harm or problems, caused by using functions or

consumables other from original cGuard products or approved by cGuard.

cGuard LLC company isn’t responsible for any harm, problems, losses or expenses caused by

inappropriate using of a product, accidents, unwarranted modification, repair or changes in

product, or impossibility to strictly follow the working and service instructions worked by

cGuard.

Important!

Officially released by cGuard LLC and recommended to install on trackers are

firmware versions named like this:

fw-[fnxx-]a.b.c-hash

fw-[fnxx-]a.b.c-[oem-]hash

here:

fw – short for “firmware”;

fnxx – here n – digit corresponding to processor type in tracker;

a.b.c – firmware version;

oem – sign of a company the special firmware designed for;

hash – hash-code.

Data in square brackets is optional.

Ex.: fw-f2xx-3.0.9- 4fc22f89439a

Firmwares like:

fw-[fnxx-]a.b.c[rck]-hash - release candidate

fw-[fnxx-]a.b.c-dev[-description]-hash - test version

fw-[fnxx-]a.b.c-hash+ - developer version, provided to

users only in special cases

can be installed to tracker under user’s responsibility, and cGuard LLC isn’t

responsible for any negative consequences caused by using these firmwares.

Version of a firmware installed on tracker is shown in configurator (“Tracker” tab) (see

«first time setting»).

3

2. Introduction

This guide represents the user instructions for the user terminal of transport monitoring cGuard

Litom (“Tracker” as further in text), designed for monitoring vehicles by executing following

functions:

Real-time locating current vehicle’s;

Sending data to server for tracking the vehicle in monitoring system;

Measuring the voltage of the vehicle mains;

Control over vehicle’s parameters by measuring analog and discrete signals from

state vehicle’s sensors (ex. fuel level or engine’s temperature sensors, dooroperated switches etc.);

Control over vehicle’s or load’s parameters by installing addictive sensors of

other manufacturers;

Ability to detect driver’s actions performed in order to prevent the control process

by remembering the moments of voltage disappearing and recovery and

positioning signals.

Also, the data sent by tracker helps to realize the following functions in monitoring system:

Vehicle’s mileage count;

Detecting of passing the checkpoints of the route by vehicle;

Determination of current speed and computing the average speed in specified time

interval;

Downtime count.

4

3. Specifications

Global positioning system:

Satellite system .............................................................................................. GLONASS/GPS

Antenna type ................................................................................................................ Internal

Cold start, s ......................................................................................................................... 601

Hot start, s.............................................................................................................................. 1

Channels .............................................................................................................................. 72

Navigational receiver sensitivity, dBm ................................................................ .............. -167

Position accuracy, m ................................................................................................ .............. 5

GSM:

Frequency range, MHz ........................................................................................................... 900/1800

Antenna type ................................................................................................................. Internal

Data transfer methods ............................................................................................ GPRS/SMS

Energy consumption:

Power voltage, V............................................................................................................... 8-40

Maximum power voltage, V ................................................................................................. 44

Consumable amperage (average), not more, mA ................................................................ 150

Maximum (peak) consumable amperage, mА. ................................................................... 350

Interfaces:

Analog inputs (0..30 V), pcs.. ................................................................................................. 2

Frequency/pulse (0..30 V), pcs. ................................................................ .............................. 2

Power output with open drain ................................................................................................. 1

RS-485 (TIA/EIA-485-A), pcs ............................................................................................... 1

1-Wire2 .................................................................................................................................. 1

General:

Average lifetime, years .......................................................................................................... 6

1

May vary depending on satellites position and weather conditions.

2

Optional. In basic complectation (cGuard Litom Base) this contact is inactive.

5

PC-connection interface .............................................................................................. USB 2.0

Internal nonvolatile memory, MB/route points ............................................... 4 / 60 thousand3.

Internal accelerometer ............................................................................................................ 1

Temperature:

Operating temperature range, ˚С ................................................................................ - 40..+50

Physical parameters:

Dimensions, mm ................................................................................................... 70 x 50 x 20

Case material ......................................................................................................... ABS plastic

Weight, g ............................................................................................................................. 52

3

Depends on data which is sent together with navigation.

6

4. Set contains

1. cGuard Litom tracker .............................................................................................. 1 pcs.

2. Screws .................................................................................................................... 2 pcs.

3. Micro-Fit connector 6x2 .......................................................................................... 1 pcs.

4. Wires set ................................................................................................................. 1 pcs.

5. Device passport ....................................................................................................... 1 pcs.

5. Components of cGuard Litom

Pic.1.Components of automobile tracker

1. Micro-Fit connector 6x2

2. miniUSB connector

3. GSM status LED - DAT

4. Positioning status LED – SAT

7

6. Interface connector description

Pic.2. Interface connector X1

Table.1.Interface connector pinout for external sensors installation

Contact number

Input purpose

1

Main power plus

2

Main power minus

3

RS-485 (input А)

4

RS-485 (input В)

5

n/a

6

n/a

7

Analog/Discrete input (0-30 V) 1

8

Analog/Discrete input (0-30 V) 2

9

1-Wire

4

10

Frequency/pulse input 2

11

Frequency/pulse input 1

12

Power output with open drain

4

Optional. In basic complectation (cGuard Litom Base) this contact is inactive

8

7. First-time setting

The cGuard trackers can be configured by using official application – cGuard Configurator. This

program allows to set tracker’s parameters for GPS/GLONASS monitoring and also to tune the

data exchange and analysis to work with data from tracker and external devices.

Actual version of this application can be downloaded from manufacturer’s website.

Pic.3.cGuard Configurator

“Tracker” tab contains general information about tracker, its location, IMEI, ID and current

firmware version. Also, there’s the ability to change the unique ID (for identifying the device in

monitoring system), upload the firmware, and to upload the configuration (saved to file before).

More about working with configurator can be seen in the remote configuration guide on the

website.

9

7.1 Channel setting

For tracker status monitoring and working with external devices it is necessary to set up the data

channels. It can be done in “Channels” tab in configurator.

Pic.4.Channel setting in cGuard Configurator

Configurator shows the channel data values in real time, allows turning on/off data sending from

each channel and setting the sending conditions. The list of available channels of cGuard Litom

is shown in the table 2. The correspondence between channels and inputs can be seen in table 3.

It is important to turn on the data sending of a channel with data from external sensor

after connecting the sensor to tracker (channel choosing depends on input connected

with sensor, and on sensor purpose).

To allow the data sending for the channel, go to “Channels” tab in configurator, then select the

needed channel in the channel list, get sure that the name of this channel is shown at the right

side (“Per-channel settings”) and set at least one of the sending conditions.

10

Table 2. сGuard Litom channel list

Channel

Purpose

Values

Notes

CSQ1

GSM signal level

0..100%

NSQ1

Captured satellites quantity

0..24

NSQ2

Satellites data validity

0 or 1

1 – valid, 0 - invalid

AIN1, AIN2

Analog channels

0..30 V

DIN1, DIN2

Discrete channels

0 or 1

See section 8.3

PWR1

Mains voltage

0..40 V

REL1

Relay control

0 or 1

1 – on, 0 - off

FRQ1, FRQ2

Frequency channels

0..2000 Hz

CNT1, CNT2

Pulse counter

0..4294967295

LLS1..LLS12

Digital sensors data (RS-485)

See section 8.8

WIR1..WIR3

1Wire sensor temperature

See section 8.9

IBT1

iButton ID

See section 8.9

Table 3. Correspondence between logical channels and physical inputs of tracker

Inputs

Channels

AIN1

AIN1 – value of voltage on analog input

DIN1 – result of program comparator, comparing the analog input signal and

assigned threshold

AIN2

AIN2 - value of voltage on analog input

DIN2 - result of program comparator, comparing the analog input signal and

assigned threshold

FRQ1 (DIN1)5

FRQ1 – frequency measuring

CNT1 – pulse counter

FRQ2 (DIN2)

5

FRQ2 – frequency measuring

CNT2 – pulse counter

RS-485

LLS1-LLS12

1Wire

WIR1..WIR3

IBT1 - for iButton

DOUT

REL1

7.2 Remote configuration

There are two data channels for remote configuration:

SMS

GPRS

The remote configuration guide and the list of available commands can be downloaded from our

website.

GPRS configuration allows customizing device parameters and uploading device firmware.

SMS-commands can change device parameters and make requests for device status and location.

5

DIN marking was indicated on trackers cGuard Litom, manufactured earlier than September 2017.

11

8. Connecting the automobile cGuard tracker

8.1. Inserting a SIM-card

Tracker sends data to server by using GSM net, so it needs a SIM-card. To insert the SIM-card

follow these instructions:

1. Remove the back cover of tracker’s case by removing two fixing screws.

2. Insert a SIM-card into the holder.

3. Put back the case cover and fix it by two screws.

Important!

Before installing the SIM-card check it’s workability in your cellphone. Get sure

that the GPRS/SMS/USSD services are working, and the SIM-card’s balance is

positive and enough to these services functioning.

To make the process of setting up the SIM-card easier you can use M2M SIM-card.

12

8.2. Power connection

Before connection the power to the tracker get sure that the mains voltage fits the acceptable

range (see the section “Specifications”)

Plug in the connector with the crimped wires to the X1 connector in the tracker, to connect the

GND contact to the wire of the main power, and PWR contact to the plus wire of the main

power. The wires’ cut must be 0.5 mm or more. All connections must provide dependable

contact and be safely isolated.

The preferable version is connection the tracker to the mains after the ground switcher.

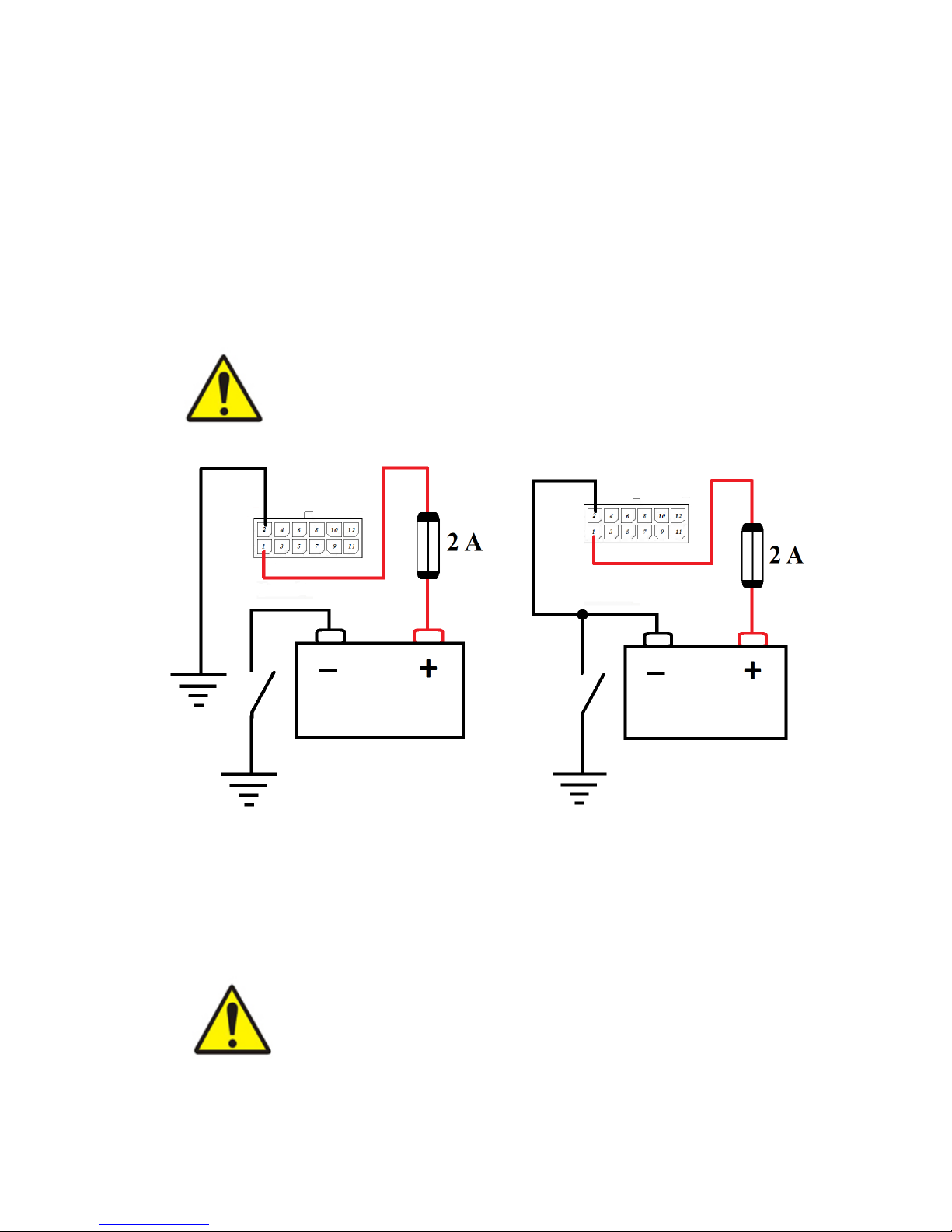

Important!

Keep the power polarity!

It is necessary to set a 2 A fuse to the power circuit!

After the ground switch Before the ground switch

Pic.5.Connecting the main power to the X1 connector before and after the ground switch

schemes

Important!

When doing the electric welding on the automobile, or when the engine is

starting by the external current source the tracker must be disconnected from

automobile board mains! Otherwise the device can break down.

13

To prevent the intervention to device’s work and intentional damage it is recommended to seal

up the connectors, terminal blocks and the case of the tracker after its installation.

After the installation and connection the device is ready to work. If it was connected

appropriately, it starts the work automatically. The LED indication of the right working device

can be seen in the following section of this guide.

14

8.3. Connecting the analog sensors to tracker

Tracker has two analog inputs (AIN1 and AIN2) available in the interface connector X1. These

inputs can be used for measuring the direct current voltage in range 0..30 V.

Analog inputs can be used for measuring the vehicle parameters with value proportional to the

voltage level (ex. fuel level value from internal or external sensor)

Typical scheme of connecting the sensor to analog input can be seen on pic. 6.

To increase the accuracy of measurements it’s recommended to draw the minus wire directly

from the sensor, but it’s acceptable to use the common ground.

Pic.6.Installing analog sensors to AIN input

There are two ways of analyzing data from analog input, by the setting AIN or DIN channel with

corresponding number:

AIN channel shows the voltage on the corresponding input;

DIN channel indicates that the voltage on this input is higher, than the threshold, assigned

in TLD parameter for this channel (see pic. 7). If the voltage is higher, than this

threshold, the channel value is 1, if it’s lower – 0.

15

Pic.7.DIN channel setting in configurator

8.4. Connecting contact sensors (buttons)

To connect a contact sensor (button) to tracker use one of the following ways – closing to a

common ground or to a common plus (vehicle mains) (both cases use analog input, schemes

illustrate it on example of AIN1):

Pic.8. Connecting button to analog input closing to a common ground

16

Pic.9. Connecting button to analog input closing to common mains

To use this kind of sensors set up the DIN channel in configurator (with same number as used

input) (see pic.7).

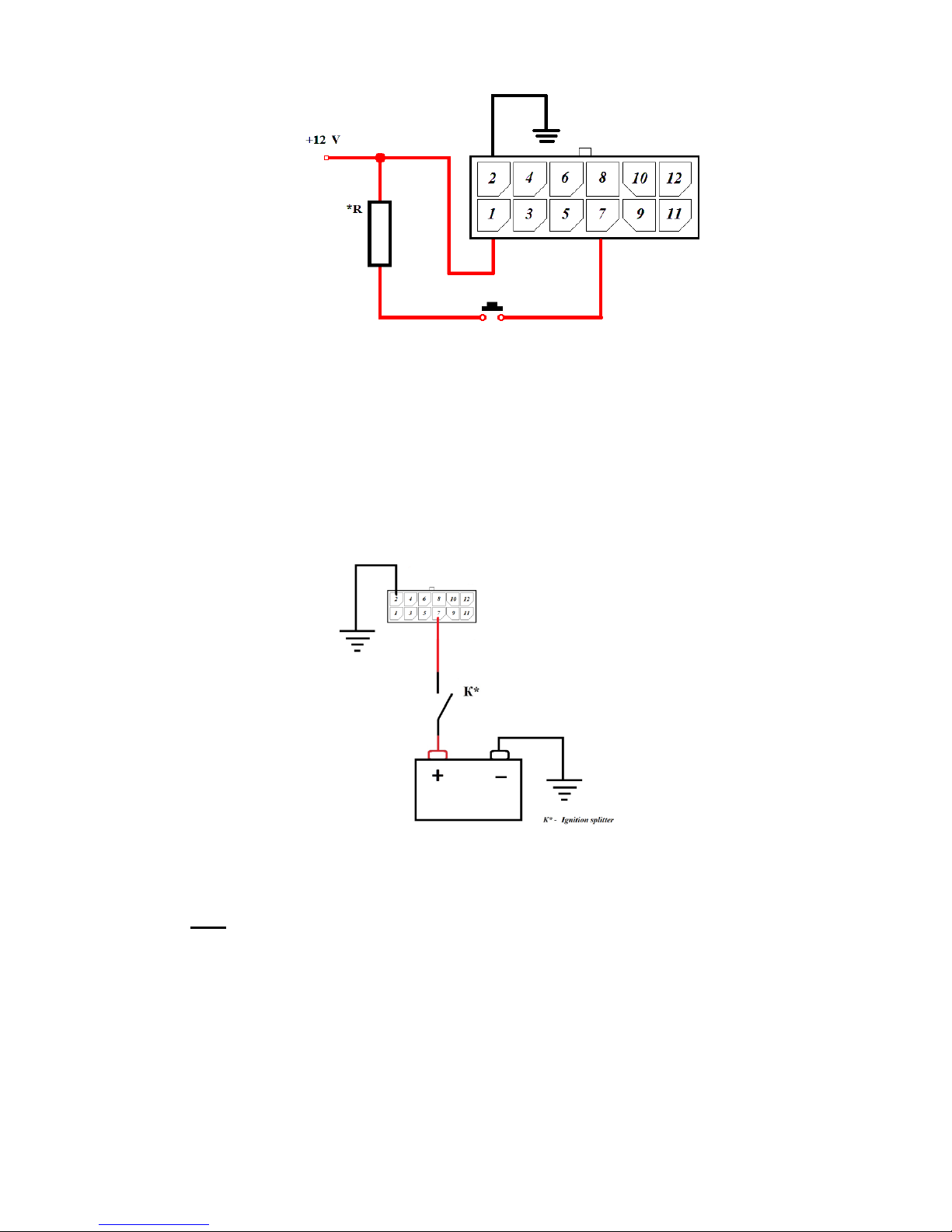

8.5. Ignition detecting

To detect the automobile ignition also use analog input, connected by the following schemes:

If there’s a plus-circuit splitter in the automobile, use the scheme from pic. 10 to detect

the ignition.

Pic.10.Ignition detecting in plus circuit

If there’s a minus-circuit splitter in automobile, use the scheme from pic. 11.

Note: external resistor 15 kΩ to 51 kΩ, capacity from 0.1 W.

17

Pic.11.Ignition detecting in minus circuit

To detect the automobile ignition it is recommended to use the DIN channel with parameter TLD

set to value 8 (see pic. 7). It is acceptable to use the AIN channel instead, but in this case the

threshold must be set in virtual ignition sensor in monitoring system.

8.6. Connecting the frequency/pulse inputs of tracker

Tracker has two frequency/pulse inputs (FRQ1, FRQ2)6. One of the working modes (frequency

or pulse) can be chosen for each of them.

Use one of the following schemes to connect an external device, depending on its type.

To connect the sensor with positive output to the tracker, plug in the connector with the crimped

wires the way to connect the GND contact to the ground, and the FRQ1 or FRQ2 to positive

output of external sensor.

Pic.12.Installing the sensor with frequency output to the tracker

6

These inputs were marked DIN1 and DIN2 on trackers manufactured earlier than September 2017.

18

To connect a device with “open collector” output it is necessary to add a resistor 2..10 KΩ

(depending on acceptable output amperage) by the pic.13 scheme:

Pic.13. Connecting the “open collector” output device

To connect a device with optocoupled output use the following scheme (pic.14). It is

recommended to add a resistor to a optron collector’s circuit (resistor’s parameters are the same

as in previous kind of conection).

Pic.14. Connecting device with optocoupled output

Get sure that the incoming voltage for these inputs fit the appropriate range:

2..30 V.

19

External sensors must be serviceable and provide dependable work. Otherwise,

manufacturer isn’t responsible for right sensor status registration (losing the

contact etc.).

To work with sensor data set up the corresponding channel in configurator (as seen in Channel

setting in configurator):

To count the pulses from sensor set the CNT channel;

To measure the frequence set the FRQ channel.

20

8.7. Connecting the power output of the tracker

Tracker has one power output (DOUT contact). It can be used for controlling the external

executive devices.

Important!

Maximum acceptable load voltage must not be higher than 30 V.

Maximal acceptable amperage - 1 А.

Typical load connection scheme (pic. 15):

Pic.15.Power output load connection (right side – internal scheme of power output)

For external device control use the channel REL1. When its value is set to 1 (in configurator (as

in pic. 16) or by remote command (SMS or TCP, see remote configuration guide on the

website)), the ground circuit of the controlled device (“load” on the pic. 15) connects with

ground circuit of a vehicle, providing the device work. When the value is 0, contact disconnects.

Pic.16. Setting the value to REL1 channel in configurator

21

8.8. Connecting devices to RS-485 interface

Tracker has an ability to read data from digital sensors by RS-485 interface (those that work by

LLS protocol). This interface allows connecting several sensors simultaneously. Typical scheme

of connecting devices to this interface is on pic. 17:

Pic.17.Connecting devices to RS-485 interface

Data from sensors connected by this interface is shown in channels LLS1..LLS12. To set the

correspondence between sensor and channel use the address parameter (ADDR). Also there is a

parameter to set working mode - MODE with these acceptable values:

FUEL – fuel level measuring mode,

TMP – temperature measuring mode,

RFID – reading RFID-marks.

Pic.18.LLS channel parameter

22

8.9 Connecting devices to 1-Wire interface

1-Wire allows to work with DS18B20 temperature sensors and iButton electronic identifiers.

There’s an ability to work with DS18B20 only in parasitic power mode. Connection is shown on

scheme:

Pic.19 Connecting temperature sensor to tracker 1-Wire input

It is possible to connect three sensors at the same time. Also, it’s possible to connect one iButton

device parallel to sensors.

Pic.20.Connecting several sensors to 1-Wire input

Data from sensors is shown in WIR1..WIR3 channels. iButton identifying number – IBT1.

There’s a parameter WIR_AUTOSEARCH, which allows searching for external sensors and

assigning channels to them automatically. Default value of this parameter is 1 (autosearch is

enabled). To disable it, change the value of parameter to 0 in configurator (“Settings” tab,

“Advanced” button).

In case of disabled autosearch, the manual setting of the channel is necessary. To set the channel

to the sensor, assign its ID to the corresponding parameter of the channel (as in pic.21)

23

Pic.21 Settings of WIR channel in configurator

24

9. Device status indication

There are two status LEDs on a tracker: SAT and DAT.

SAT indicator

SAT LED indicates the positioning status (GPS/GLONASS satellites).

When power is connected appropriately, LEDs light and go out twice in order from SAT to

DAT: it signals that work started successfully. Then SAT begins to blink once or twice in 5

seconds – it is a stable device work indication. If it blinks twice, the device is searching for

satellites; if it blinks once – satellites are captured.

DAT indicator

DAT indicator lights while sending data sets by GPRS and indicates the work with mobile net. If

it’s lighting permanently, the connection is not established yet, if it’s blinking – data is sending

successfully.

If both LEDs are blinking, or both LEDs light permanently, there’s a

system error of device. You should connect the service center.

25

10. Contacts

Phone: 8 (800) 700-42-73

E-mail: info@cguard.ru

Website: cguard.ru

Address: 432027, Russian Federation,

Ulyanovsk,

Yunosti str., 5а

Technical support:

E-mail: support@cguard.ru

Skype: cguard_support

Loading...

Loading...