Page 1

INSTALLER/CONSUMER

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

CER TIF IED

SAFETY INFORMATION

PLEASE READ THIS MANUAL

BEFORE INSTALLING AND

USING APPLIANCE

WARNING!

IF THE INFORMATION IN THIS

MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF

LIFE.

FOR YOUR SAFETY

Installation and service must

be performed by a qualified

installer, service agency or

the gas supplier.

Gas Fireplace

Insert

Models: A125

A132

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch;

do not use any phone in your

building.

• Immediately call your gas

supplier from your neighbor’s

phone. Follow the gas suppliers

instructions.

• If you cannot reach your gas

supplier call the fire department.

DO NOT STORE OR USE

GASOLINE OR OTHER

FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE.

Homeowner’s Installation

and Operating Manual

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

10002964 2/08 Rev. 2

Page 2

Gas Fireplace Insert

Table of Contents

PLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS BEFORE USING THIS APPLIANCE.

Thank you and congratulations on your purchase of a CFM Corporation fireplace insert.

IMPORTANT - Read all instructions and warnings carefully before starting installation. Failure to follow these

instructions may result in a possible fire hazard and will void the manufacturers' warranty.

Installation & Operating Instruction

Important Curing/Burning Instructions ................................................................................................

Insert Applications ..............................................................................................................................

Fireplace & Trim Dimensions .............................................................................................................

Locating Your Fireplace Insert ............................................................................................................

Mantels ...............................................................................................................................................

Framing & Finishing ............................................................................................................................

Combustion Air ...................................................................................................................................

Zero Clearance Applications ...............................................................................................................

Gas Specifications ..............................................................................................................................

Gas Inlet & Manifold Pressures ..........................................................................................................

High Elevations ...................................................................................................................................

Preparation .........................................................................................................................................

Gas Line Installation ...........................................................................................................................

Gas Supply Pressures ........................................................................................................................

Installation of Remote Switch for RN/RP Gas Valves .........................................................................

Adjustment of Leveling Bar .................................................................................................................

Venting Instructions ............................................................................................................................

Common Flue Installations .................................................................................................................

Liner Installation .................................................................................................................................

Draft Relief Opening ...........................................................................................................................

Test Chimney Draw .............................................................................................................................

Vent Safety System ............................................................................................................................

Fan Kit Installation ............................................................................................................................

Fan Removal Instructions .................................................................................................................

Operating Instructions

General Glass Information ............................................................................................................... 11

Louvre Removal ...............................................................................................................................11

Glass Cleaning .................................................................................................................................11

Glass Frame Removal ......................................................................................................................11

Installation of Logs and Ember Material ...........................................................................................11

Large Lava Rock Placement ............................................................................................................

Flame Adjustment ............................................................................................................................

Flame Characteristics .......................................................................................................................

First Firing .........................................................................................................................................

Lighting & Operating Instructions ....................................................................................................

Troubleshooting Gas Control (820 Millivolt Gas Valve) ....................................................................

Troubleshooting Gas Control (Honeywell) .......................................................................................

Maintenance

Cleaning the Standing Pilot Control System .....................................................................................

Brass Cleaning .................................................................................................................................

Replacement Parts ..............................................................................................................................................18

Optional Accessories

Ceramic Refractory ...........................................................................................................................

Zero Clearance Kit ............................................................................................................................

Remote Controls ...............................................................................................................................

Trim Options .....................................................................................................................................

Warranty

...............................................................................................................................................................31

3

3

4

5

5

5

6

6

6

6

6

6

6

7

7

7

8

9

9

9

9

9

10

10

12

12

13

13

14

15

16

17

17

20

20

20

20

2

10002964

Page 3

Installation & Operating Instructions

�

This gas appliance should be installed by a qualified installer,

preferably NFI or WETT (Canada) certified, in accordance with

local building codes and with current CSA-B149.1 Installation

codes for Gas Burning Appliances and Equipment.

Installations follow local codes and/or the current National Fuel

Gas Code ANSI Z223.1/NFPA 54.

In the Commonwealth of Massachusetts, all gas fittings and

installation of this heater shall only be done by a licensed gas

fitter or licensed plumber.

FOR SAFE INSTALLATION AND OPERATION OF YOUR

GAS FIREPLACE PLEASE NOTE THE FOLLOWING:

1. This appliance gives off high temperatures and should be

located out of high traffic areas and away from furniture and

draperies.

2. Children and adults should be alerted to the hazards of the

high surface temperatures of this appliance and should stay

away to avoid burns or ignition of clothing.

3. CAUTION: Due to high glass surface temperature chil-

dren should be carefully supervised when in the same

room as fireplace.

4. Under no circumstances should this appliance be modified.

Parts removed for servicing should be replaced prior to

operating this appliance again.

5. Installation and any repairs to this appliance should be

carried out by a qualified installer, preferably NFI or WETT

(Canada) certified. A professional service person should

be contacted to inspect this appliance annually. Make it a

practice to have all of your gas appliances checked annually.

More frequent cleaning may be required due to excess lint

and dust from carpeting, bedding material, etc.

6. Control compartments, burners and air passages in this ap

pliance should be kept clean and free of dust and lint. Make

sure that the gas valve and pilot light are turned off before

you attempt to clean this unit.

7. The venting system (chimney) of this appliance should be

checked at least once a year and if needed your venting

system should be cleaned.

8. Keep the area around your appliance clear of combustible

materials, gasoline and other flammable vapor and liquids.

This appliance should not be used as a drying rack for clothing, nor should Christmas stockings or decorations be hung

in the area of it.

9. Under no circumstances should any solid fuels (wood, coal,

paper or cardboard etc.) be used in this appliance.

10. The flow of combustion and ventilation air must not be obstructed in any way.

For U.S.

-

Gas Fireplace Insert

11. These appliances are certified for installation in a solid

fuel burning fireplace unless using the model HEZC Zero

Clearance Kit. When the zero clearance kit is used, and the

appliance is installed directly on carpeting, vinyl tile or any

combustible material other than wood, the appliance must

be installed on a metal or wood panel extending the full

width and depth of the appliance.

12. This appliance requires adequate ventilation and combus

tion air to operate properly.

WARNING: Check with your electronics manufacturer

before installing a television or other electronic device above this fireplace.

A125 / A132

Certified To

ANSI Z 21.88-2005 / CSA 2.33-2005

Vented Gas Fireplace Heaters

IMPORTANT:

PLEASE READ THE FOLLOWING CAREFULLY

It is normal for fireplaces fabricated of steel to give off some

expansion and/or contraction noises during the start up or

cool down cycle. Similar noises are found with your furnace

heat exchanger or car engine.

It is not unusual for your gas fireplace to give off some odor

the first time it is burned. This is due to the curing of the paint

and any undetected oil from the manufacturing process.

Please ensure that your room is well ventilated - open

all windows.

It is recommended that you burn your fireplace for at least six

(6) the first time you use it. If optional fan kit has been installed,

place fan in the "OFF" position during this time.

Proposition 65 Warning: Fuels used in gas, woodburning or oil fired appliances, and the products of

combustion of such fuels, contain chemicals known to

the State of California to cause cancer, birth defects

and other reproductive harm.

California Health & Safety Code Sec. 25249.6

Insert Applications

Before installing the gas fireplace insert consideration

must be given to the functioning needs of the fireplace.

The size of the fireplace cavity, the design of the chimney

for effective venting should be determined. The availability of the gas supply as well as electricity for the insert fan

must be confirmed.

-

10002964

3

Page 4

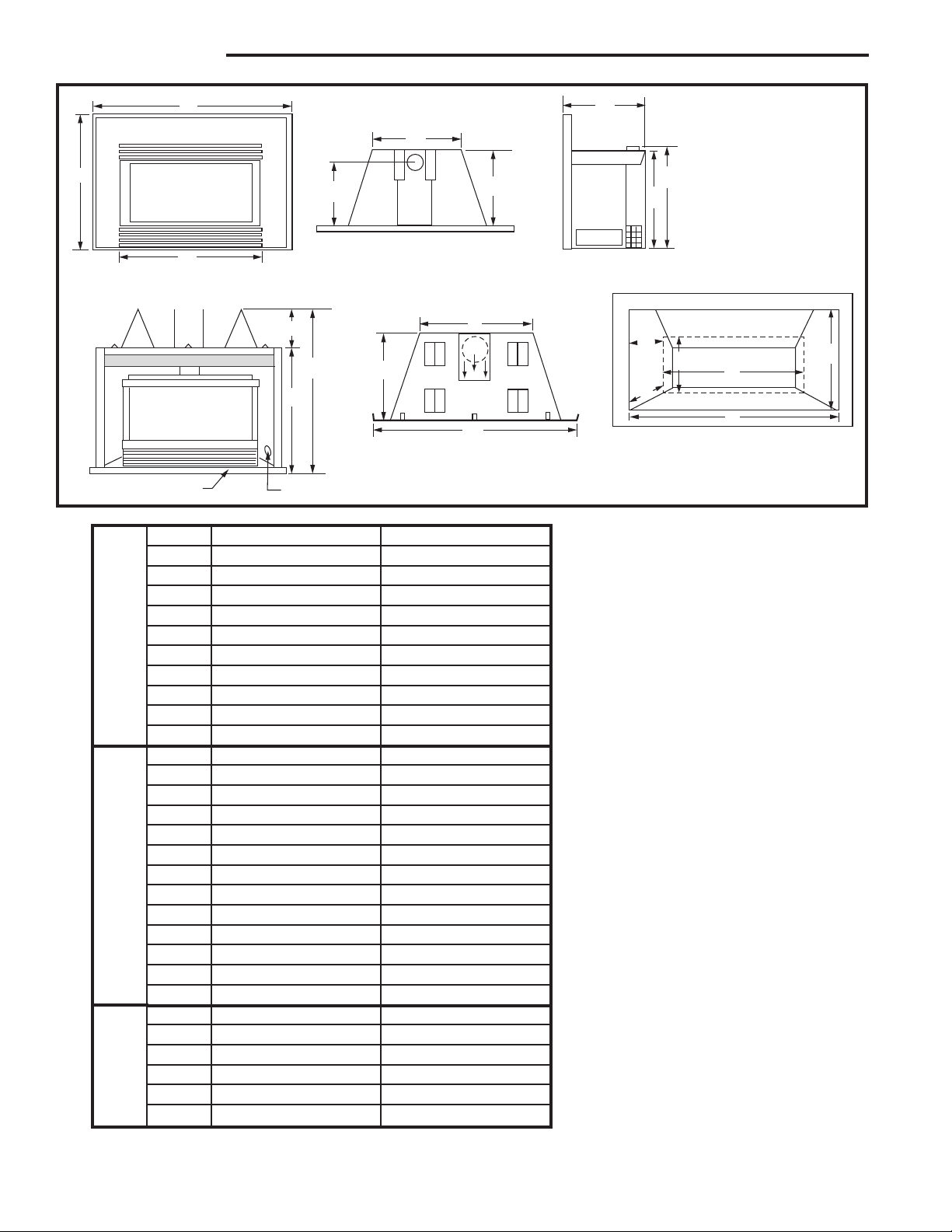

Gas Fireplace Insert

A

B

C

D

J

E

F

G

H

U

V

S

T

R

Q

4“

P

O

N

M

L

K

Maintain 1” Clear-

ance to ‘B’ Vent

Zero Clearance Kit

Air Inlet Channel

A125 A132

A1 26

B1 38

A2 29¹⁄₄” (743 mm) 29” (737 mm)

T

B2 43

R

A3 - - 33” (838 mm)

I

B3 - - 44” (1118 mm)

M

A4 - - 28” (712 mm)

B4 - - 40

A5 - - 30

B5 - - 46” (1171 mm)

C 25

D 17

E 13

F

F 15” (381 mm) 17

I

G 19¹⁄₄” (489 mm) 20¹⁄₂” (521 mm)

R

E

H 17

P

J 9

L

K 26

A

L 25” (635 mm) 26⁵⁄₈” (676 mm)

C

M 1

E

N 30” (762 mm) 37

O 17

P 24¹⁄₂” (616 mm) 27¹⁄₄” (692 mm)

M O

I P

N E

I N

M I

U N

M G

Q 17

R 25” (635 mm) 28” (711 mm)

S 13

T 17

U 14” (356 mm) 16¹⁄₂” (419 mm)

V 17

4

Gas Inlet Knock-out

³⁄₄” (680 mm) 26⁵⁄₈” (676 mm)

¹⁄₂” (978 mm) 38³⁄₈” (957 mm)

¹⁄₂” (1105 mm) 41¹⁵⁄₁₆” (1065 mm)

⁷⁄₈” (1041 mm)

¹⁄₂” (775 mm)

¹⁄₄” (641 mm) 28³⁄₄” (730 mm)

³⁄₈” (441 mm) 17¹⁄₄” (438 mm)

³⁄₄” (349 mm) 15⁵⁄₈” (397 mm)

¹⁄₈” (435 mm)

¹⁄₂” (445 mm) 20” (508 mm)

⁷⁄₈” (251 mm) 12¹⁄₄” (311 mm)

¹⁄₄” (667 mm) 35” (889 mm)

¹⁄₄” (32 mm) 8¹⁄₂” (216 mm)

¹⁄₂” (952 mm)

³⁄₄” (451 mm) 19¹⁄₈” (486 mm)

³⁄₄” (451 mm) 21” (533 mm)

³⁄₄” (349 mm) 16” (407 mm)

¹⁄₂” (445 mm) 17³⁄₄” (451 mm)

³⁄₄” (451 mm) 20¹⁄₄” (514 mm)

R - Fireplace Opening Width

Q - Fireplace Opening Height

S - Depth of Insert

T - Firebox Width at Insert Depth (S)

U - Firebox Depth at Insert Back Height (V)

V - Insert Back Height

1 = SS or SSD Trim

2 = SL or SLD Trim

3 = SXL Trim

4 = BSL Trim

5 = BXL Trim

10002964

Page 5

Gas Fireplace Insert

C

D

B

E

A

F

X

X

X

24" Min.

(610mm)

K

37" (946mm)

P

O

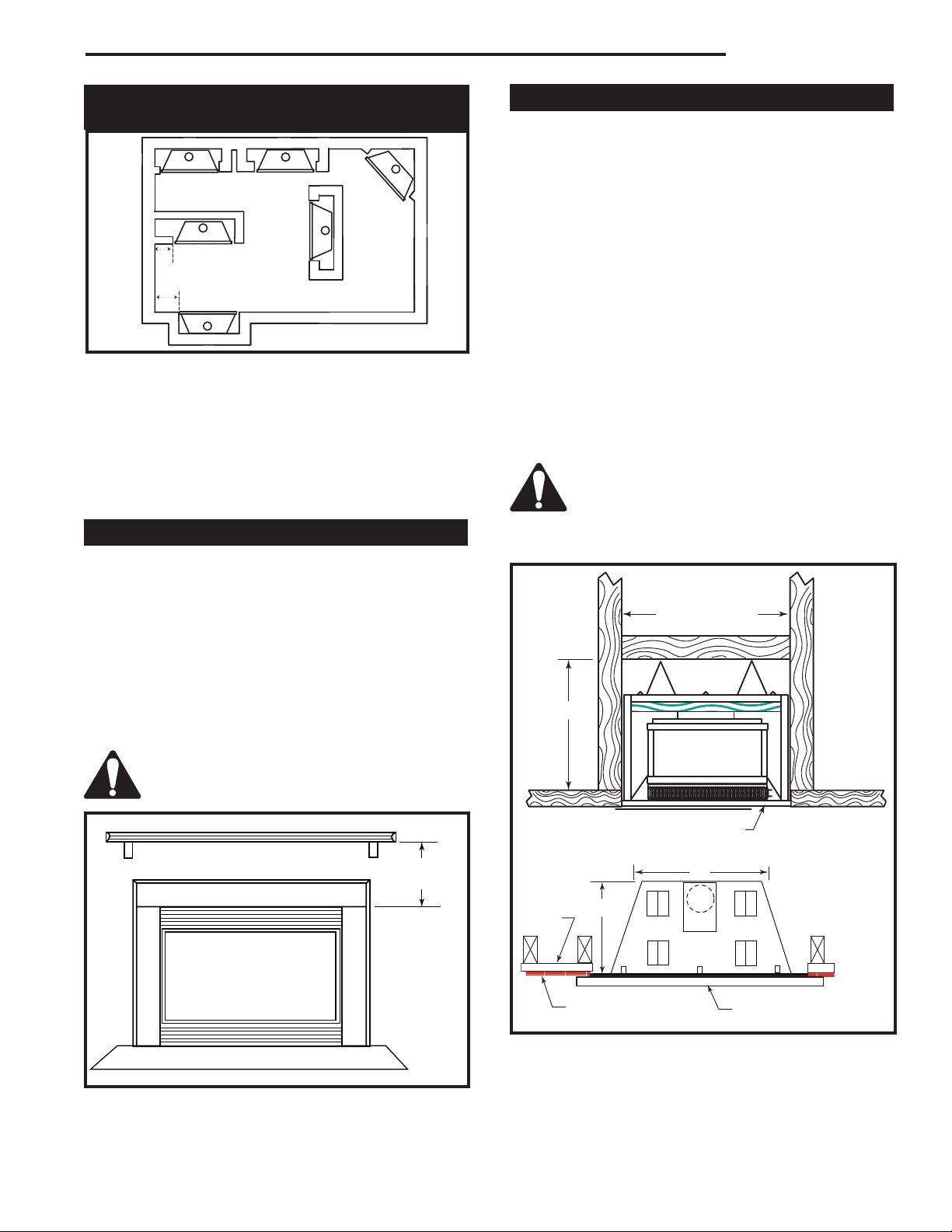

Locating Your Gas Fireplace Insert

with Zero Clearance Kit

FP1249a

Fig. 1 Locating unit with zero clearance kit.

A) Flat on wall B) Cross corner

C) Island D) *Room divider

E) *Flat on wall corner F) Chase installation

NOTE: (Fig. 1)

* When you install your fireplace in (D) Room divider or (E)

Flat on wall corner positions, a minimum of 6” (X) (153mm)

clearance must be maintained from the perpendicular wall

and the outer edge of the trim.

Mantels

When the unit is installed into a woodburning fireplace,

the minimum distance the mantel can be placed above

the fireplace is governed by local building codes applicable to woodburning fireplaces. Consult local authorities having jurisdiction for these clearances.

For applications requiring the use of a Zero Clearance

Kit, the minimum height a mantel can be installed above

the fireplace is 24" (610 mm) from the top of the upper

louvres. The maximum mantel depth is 8" (203 mm).

(Fig. 2)

The underside of the mantel will become

warm. Use only finishes which are heat

resistant and do not discolor.

Framing & Finishing

For Zero Clearance Kit applications, it is important to

determine the finished facing material before beginning

to frame. This will allow for the thickness of the finishing

material between the frame and the fireplace trim.

Similarly, consideration must be given to the 1" inch

depth of the air inlet channel sitting on the fireplace

base. Finishing material for the hearth should be flush

with the top of the air inlet channel.

If the fireplace is installed at floor level a noncombustible hearth must extend a minimum 12" (305 mm) in

front of the fireplace.

If the fireplace is recessed into the wall and at least 12"

(305 mm) above floor level, no hearth is required.

A 3” diameter (for A125) or 4” diameter (for A132)

Class ‘B’ vent must be used when installing the fire

place insert along with the Zero Clearance Kit. The vent

system must be a minimum height of 12’ (3.7 m)

The use of wallpaper adjacent to this fireplace is not recommended as high temperatures given off by this fireplace may

adversely effect the binders in the adhesive used to apply the wallpaper.

-

FP1325

Drywall

Finish Wall

Fig. 3 Insert framing dimensions.

Air Inlet Channel

Decorative Trim Kit

NOTE: For K, O

and P dimensions,

refer to chart on

Page 4

FP1351

Fig. 2 Minimum mantel height above fireplace.

10002964

5

Page 6

Gas Fireplace Insert

Combustion Air

It is very important that an adequate air supply is

available when the unit is being operated. Since most

homes of today are tightly sealed and insulated, additional make-up air is usually necessary.

This fireplace has been designed to operate by drawing

air in from the front and outer perimeters of the fire

place. The air provides combustion air ensuring a clean

burning flame, dilution air for proper venting, as well

as the air which the fan circulates over the firebox/heat

exchanger system.

NOTE: Insulating around the fireplace will result in

overheating and possible malfunctioning of the circulating fan.

-

Zero Clearance Applications

An alternate air supply is recommended

with this component.

For installation other than in existing woodburning fireplaces such as new construction or renovation projects,

a Zero Clearance Kit must be used. The kit enables

these inserts to be installed in combustible environments. Whenever using a Zero Clearance Kit, consideration must be given to the dimensions of the Zero

Clearance Kit and the requirements of the Air Kit when

planning out the installation.

Gas Specifications

Max. Min.

Fuel Gas Input Input

Model Type Control BTU/hr BTU/hr

A125RN Natural Millivolt 20,000 14,000

Hi/Lo

A125RP Propane Millivolt 20,000 15,000

Hi/Lo

A132RN Natural Millivolt 30,000 21,000

Hi/Lo

A132RP Propane Millivolt 30,000 22,500

Hi/Lo

Gas Inlet & Manifold Pressures

Natural LP

Minimum Inlet Pressure 5.5"

Maximum Inlet Pressure 14.0"

Manifold Pressure 3.5"

Do not use this appliance if any part of it

has been under water. Immediately call a

qualified service technician to inspect the

unit and replace any part of the control

which has been under water.

W.C. 11.0" W.C.

W.C. 14.0" W.C.

W.C. 10.0" W.C.

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the

current ANSI Z223.1/NFPA 54 and/or local codes

having jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).

These gas inserts are approved for installation

in solid fuel burning masonry or zero clearance

fireplaces.

Preparation

Before beginning, remove glass door and logs from

unit. Also check to make sure there is no hidden damage to the unit. Take a minute and plan out the gas,

venting and electrical route. It is best to start with the

gas line first followed by the chimney liner. (Refer to

Page 8)

Gas Line Installation

When purging the gas line, the front glass

must be removed.

If gas piping from the source to the heater location

has not been accomplished, install the required pipe.

Consult local plumbing code to assure proper pipe size.

The gas pipeline can be brought in through the rear or

the base of the heater.

NOTE: The gas line connection can be made of either

properly tinned 3/8" copper tubing, 3/8" rigid pipe or

an approved flex connector then reduced to 3/8" to

the heater. Some municipalities have additional local

codes, it is always best to consult your local authority

and the CSA- B149.1 installation code.

U.S. Installations consult the current National Fuel

Gas Code, ANSI Z223.1/NFPA 54.

The gas control inlet is 3/8” N.P.T. therefore the 1/2”

rigid gas line must be reduced to 3/8” N.P.T. A typical

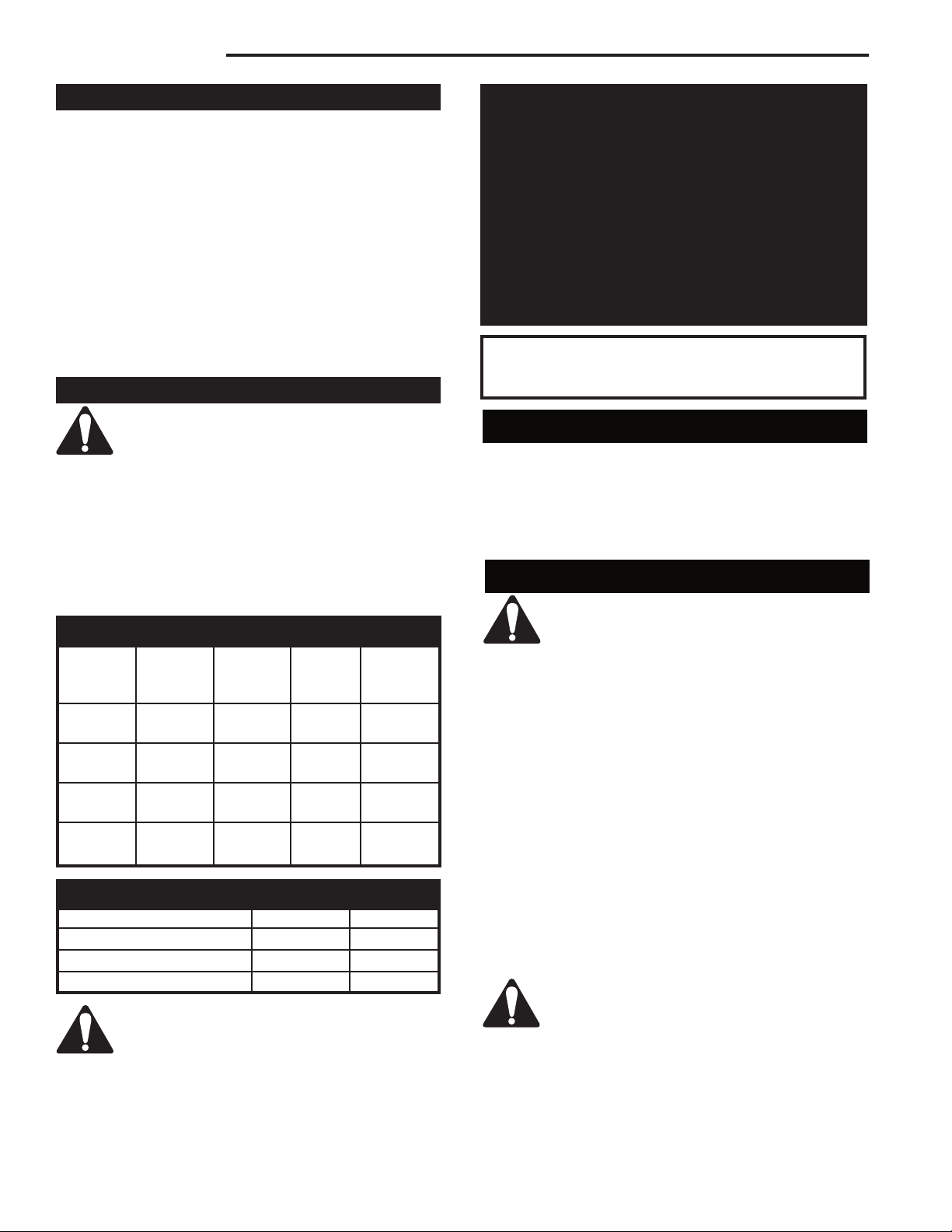

installation layout for rigid pipe is shown in Figure 4.

Always check for gas leaks with a mild

soap and water solution. Do not use an

open flame for leak testing.

The gas control is equipped with a captured screw

type pressure test point, therefore it is not necessary to

provide a 1/8" test point up stream of the control.

6

10002964

Page 7

Gas Fireplace Insert

TPTH

TH

TP

P

I

L

O

T

THTP

TP

TH

When using copper or flex connector, use only

approved fittings. Always provide a union when

using black iron pipe so the gas line can be easily

disconnected for burner or fan servicing. See gas

specifications for pressure details and ratings.

NOTE: If flex connector is used, it must be kept inside

of the heater.

1/2” Gas Supply

1/2” x 3/8” Reducer

3/8” Nipple

3/8” Nipple

3/8” x 3/8” Shut

Off Valve

CFM106

3/8” Nipple

3/8” Union

Fig. 4 Typical gas line installation.

Gas Supply Pressures

This heater must be isolated from the gas supply piping

system by closing its individual manual shut-off valve

during any pressure equal to or less than 1/2 psig

(3.45kPa).

The heater and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.45kPa).

Trim Top

Trim Left Side

Wiring

from

Millivolt

Gas

Valve

FP1657

Trim

Screw

On/Off

Switch

Assembly

Fig. 6 Left side switch installation.

SIT Valve

Thermopile

FP382a

Fig. 7a On/Off switch or millivolt thermostat.

Bracket Switch

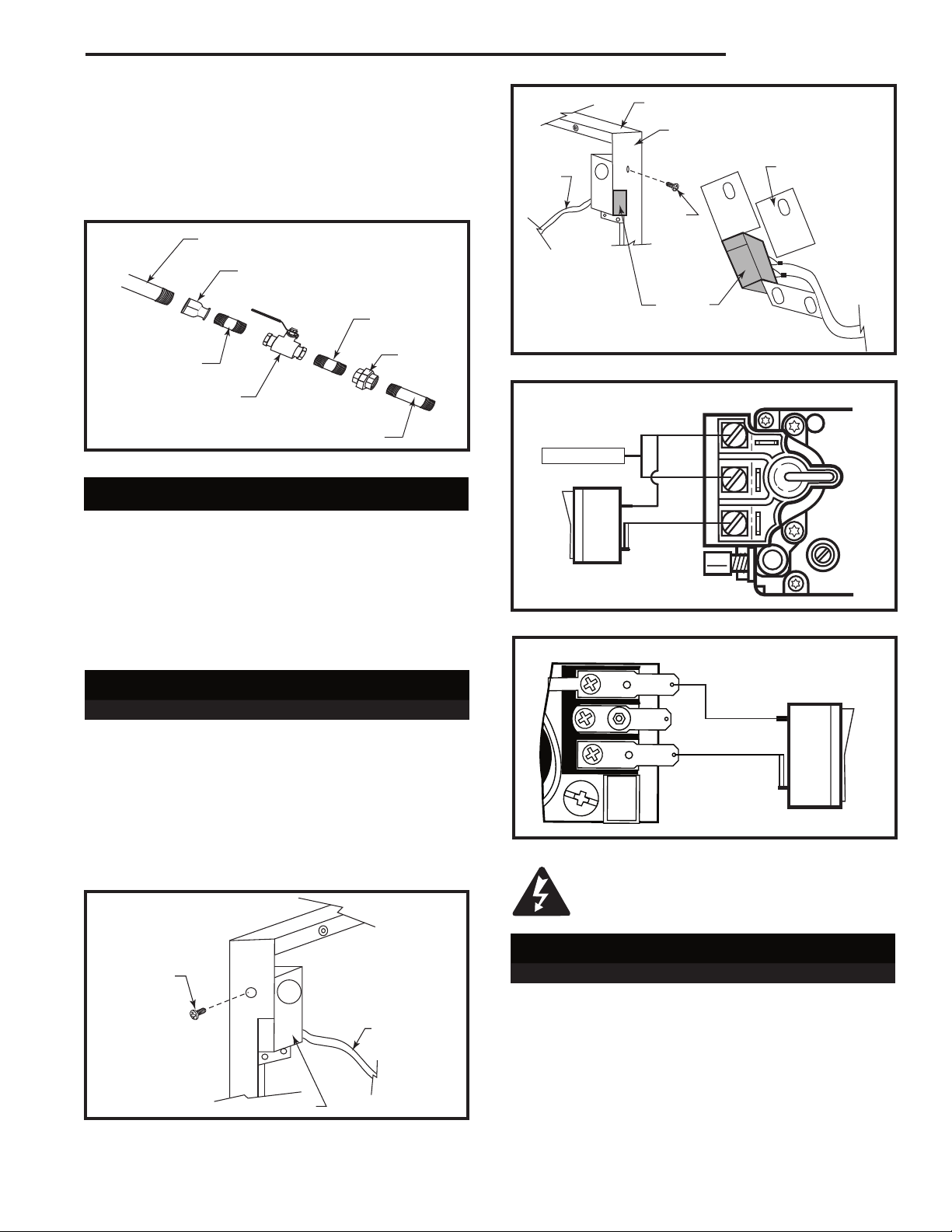

Installation of Remote Switch

for RN/RP Gas Valves

1. Thread wire through gas inlet opening on the right

side of fireplace. Do not cut wire or insulation on

metal edges.

2. Slide switch assembly from the back, between subframe and trim, then fasten the screw. (Fig. 5)

3. For left side installation reverse switch position in

bracket and repeat Step 2. (Fig. 6)

4. Connect wiring to gas valve (Fig. 7a,b) and switch.

Trim Screw

Wiring from

FP1657

Fig. 5 Install switch between subframe and trim.

On/Off Switch Assembly

10002964

Millivolt Gas

Valve

FP1218a

Fig. 7b ON/OFF switch wiring.

CAUTION: Do not wire millivolt remote wall

switch for gas fireplace to a 120 V power

supply.

Adjustment of Leveling Bar

(If Required)

1. Determine height of adjustment.

2. Loosen the four (4) screws. (Fig. 8)

3. Set bar at proper height and tighten the screws.

4. Add the two (2) extra screws to prevent any movement.

NOTE: Leveling bar only applies to A132.

7

Page 8

Gas Fireplace Insert

2' Min.

2'

(610mm)

Min.

3'

Min.

0 To 10'

3'

(914mm)

Min.

0 To 10'

Reference

Point

(3m)

Leveling Bar

FP1658

Fig. 8 Adjust leveling bar on A132 only.

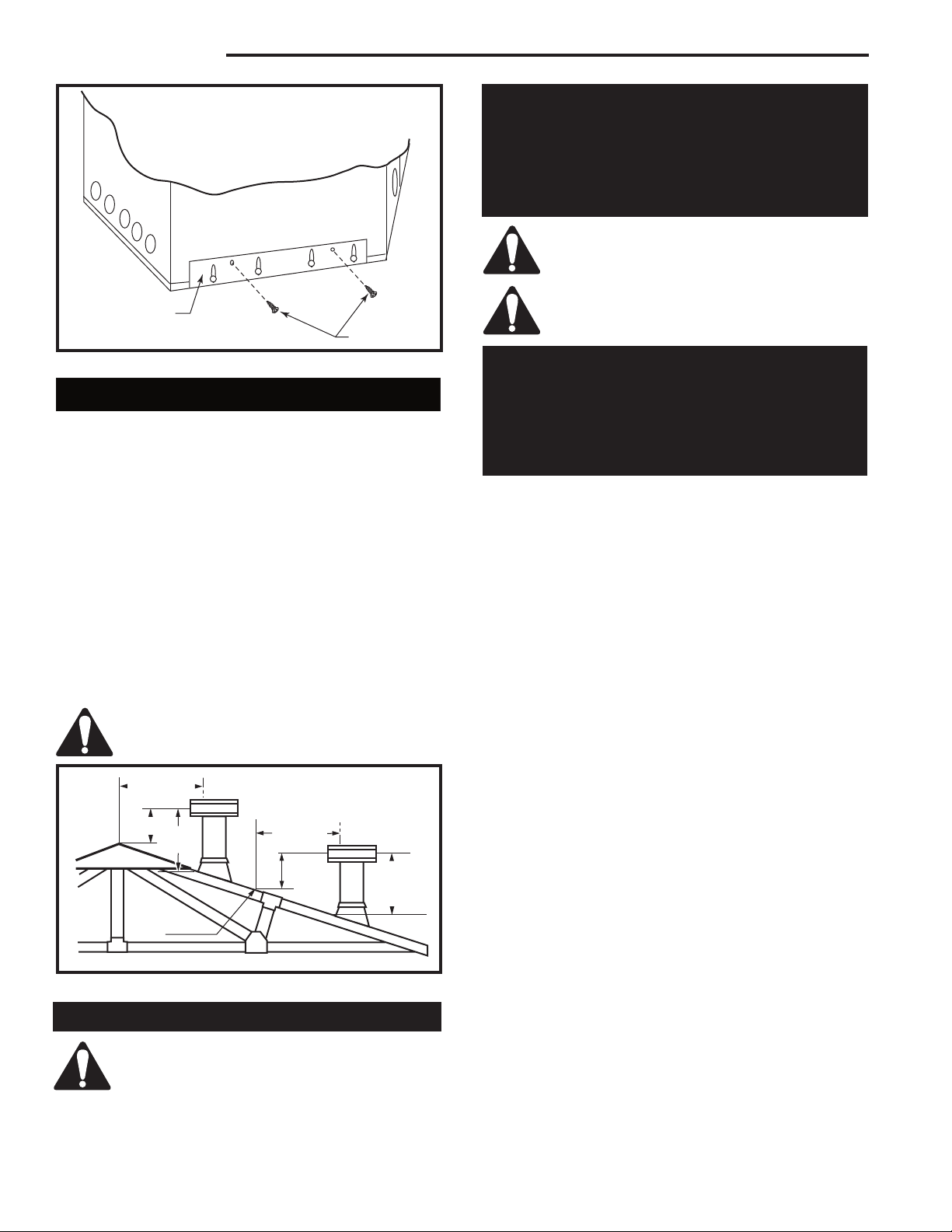

Venting Instructions

Canadian Installations:

The venting system must be installed in accordance

with the current CSA-B149.1 installation code, and the

authority having jurisdiction.

U.S.A. Installations:

The venting system must be installed in accordance

with the current National Fuel Gas Code, ANSI Z223.1/

NFPA 54.

Minimum clearances to combustible materials is 1" (25

mm) for B Vent (use of single wall vent is not al-

lowed).

As with any natural draft appliances, the vent cap must

always extend a minimum of 2' (610 mm) above any

structure within a 10' (3 m) horizontal plane. (Fig. 9)

A minimum 12’ (3.7 m) vent height is re

quired to effectively vent this fireplace.

AC246a

Fig. 9 Example of the 2', 3', 10' rule.

Venting and Installation

8

Installer must attach red warning label to

fireplace.

Set Screws

-

WARNING

This fireplace has been converted for use with

gas only and cannot be used for burning wood

or solid fuels unless all original parts have been

replaced and the fireplace has been re-approved

by the authority having jurisdiction.

Cutting any sheet metal parts of the fire-

place, in which the gas fireplace insert is

to be installed, is prohibited.

Ensure there are no obstructions to side

air passages of decorative trim once in-

stalled on insert.

WARNING

Some factory built fireplaces have air passages

on face of fireplace for zero clearance capabilities. All trim kits are designed so as to allow airflow to these passages. Under no circumstances

should these passages be blocked.

1. Gas inserts are designed for recessed

installations into solid fuel masonry or factory built

noncombustible fireplaces that have been installed

in accordance with the National, Provincial, State

and local building codes.

2. Measure for minimum fireplace opening requirement

on Page 4 of this installation manual. (If firebrick

[refractory] is removed from a factory built

fireplace in order to gain minimum gas fireplace

insert opening requirements, a minimum of 1/4"

(6 mm) air space is required between the gas

insert fireplace's outer casing and the inner wall

of the factory built fireplace).

3. To assure top performance, safety and efficiency,

all inserts must be installed with an approved 4"

diameter flue liner, with exception of A125, which

should be installed with an approved 3" liner,as per

CSA-B.149 or National Fuel Code ANSI Z223/NFPA

54.

4. Flue damper must be fully blocked in the open

position or removed for installation.

5. The chimney must be clean and in good working

order and constructed of noncombustible materials.

6. Make sure that all chimney cleanouts fit properly so

air cannot leak into the chimney.

7. Glass door, screen kits and log grate may be

removed for installation of insert into factory built

fireplace.

8. Install the insert without the trim frame and make all

gas, venting and electrical connections.

9. Install decorative trim frame. Please refer to Frame

Assembly and Mounting instructions In this manual.

10002964

Page 9

Gas Fireplace Insert

Common Flue Installations

In some areas it is possible to vent more than one gas

fireplace into the same flue. You must ensure the flue

being shared has the proper capacity to handle both

fireplaces. Check installation codes for venting capacity

information.

As always it is best to check with the authority having

jurisdiction prior to commencement of the installation.

Liner Installation

Insert liner from top of chimney through the damper

opening and attach to 3" flue collar (for A125); 4" flue

collar (for A132). For best results use three (3) sheet

metal screws and a hose clamp.

For natural draft inserts, packing fibreglass insulation

around the liner in the damper area will isolate the fireplace cavity from the chimney and prevent drafts and

noises during operation.

In case the fireplace opening is only minimum height

(17¹⁄₂" for A125) (20" for A132) and access from the

front is not possible, remove the flue collar plate - unscrew and slide out from the back of the unit. Now

attach the liner to the flue collar, lift up and simply slide

flue collar plate back onto the unit top. It is important

the plate is completely inserted and the front screw is

fastened again in order to line up the flue outlet and the

liner properly. (Fig. 10)

If fireplace lintel is wider than 8" (203 mm),

the height of the fireplace opening must

be 25" (635 mm) to allow for a 90° offset

elbow to be installed.

Damper

Flue

Collar Plate

Clamp

Chimney Liner

Damper

Chimney

Liner

Screw

Clamp

Test Chimney Draw

A "Chimney Draw" test must be made before the

installation is complete.

1. Close all doors and windows in the home and start

exhaust fans in the kitchen and bathroom.

2. Light unit and operate for 5 minutes.

3. Hold an ignited match or cigarette in front of the unit.

Refer to Figure 11 for the location of the draft hood

opening.

4. Check to make sure smoke from the match or

cigarette is drawn into the fireplace. If it is not, turn

the unit off and check for causes creating the lack of

adequate draft.

Test for Draft at This Location

FP1371

Fig. 11 Hold an ignited match in front of fireplace.

Vent Safety System

These inserts are equipped with a vent safety shut

down switch. This switch is factory installed, wired and

tested. Check and make sure the switch and wires are

in the proper position. The safety switch is heat activated and wired in series with the pilot system. (Fig. 12)

Bracket

FP1354a

Fig. 10 Remove flue collar plate and attach to flue collar.

Draft Relief Opening

This insert is equipped with a draft-relief opening which

receives its dilution air supply through the opening

behind the louvres. These openings must not be

obstructed or altered in any way. (Fig. 11)

10002964

Vent Safety

Switch

FP1372

Fig. 12 Vent safety switch.

Operation of this fireplace when not

connected to a properly installed and

maintained venting system or tampering

with the vent safety shutoff system can

result in carbon monoxide (CO) poisoning

and possibly death.

9

Page 10

Gas Fireplace Insert

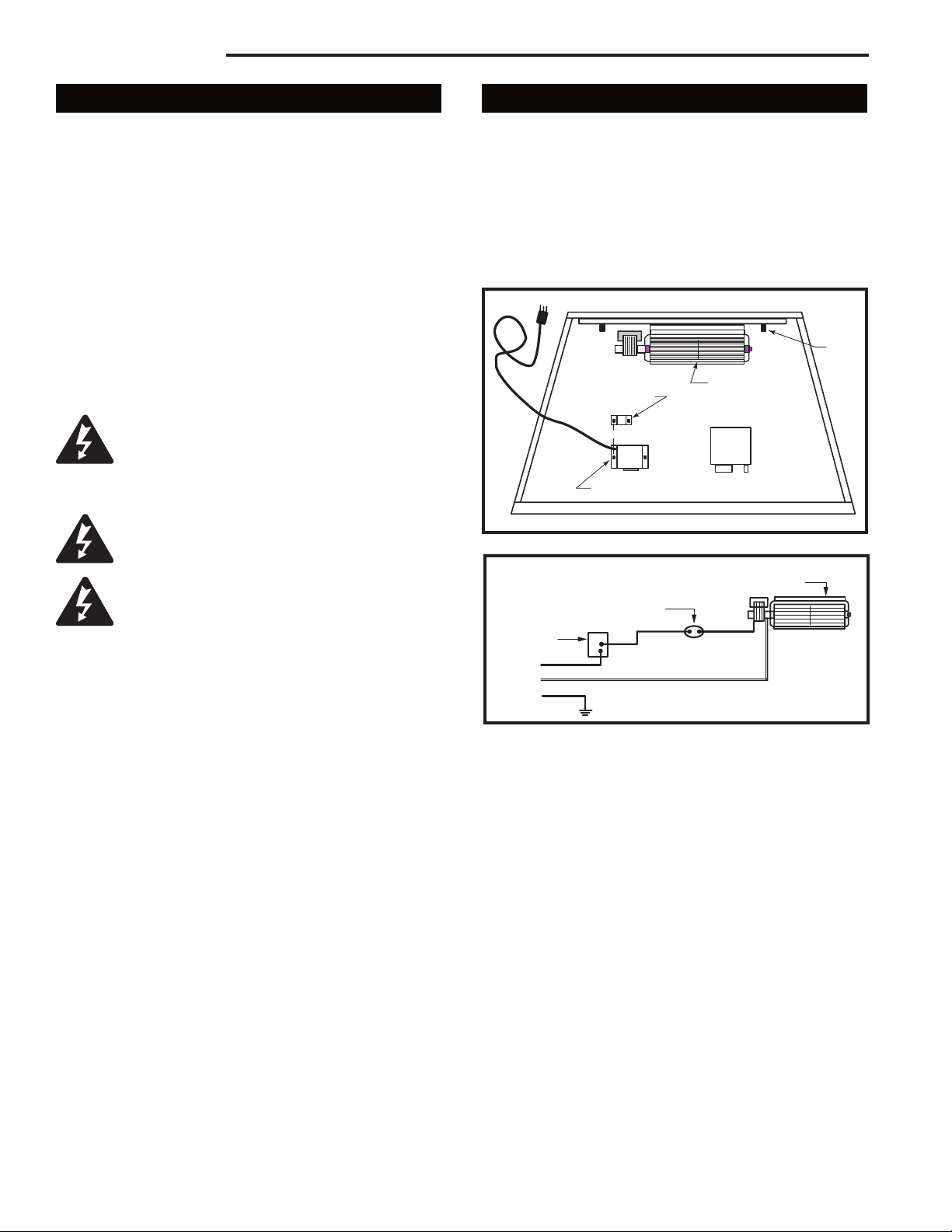

Fan Kit Installation

115 Volt, 60 Hz. 56W

The fan kit includes the following: fan, temperature

sensor, speed control and a 6 ft. cord. The following

explains how to start and set the fan for automatic

operation.

1. Plug in the electrical cord.

2. Start gas fire - see lighting procedures.

3. Turn on fan speed control.

4. Wait until the unit has warmed up sufficiently to

activate the temperature sensor.

5. Once fan starts, adjust speed control to desired fan

speed. The fan will now automatically come on every

time the fireplace is in operation. Should the fan not

be needed simply turn off the speed control.

The appliance, when installed must be

electrically connected and grounded in

accordance with local codes or, in the absence of local codes, with the current CSA

C22.1 Canadian Electrical Code.

For U.S.A. installations, follow local codes

and the national electrical code, ANSI/

NFPA No. 70.

Should this fan require servicing, the

power supply must be disconnected. For

rewiring of any replacement components

refer to Figures 13 & 14.

Fan Removal Instructions

1. Turn off gas and electricity.

2. Remove the front glass.

3. Remove the logs.

4. Remove burner assembly and rear log support plate.

5. Remove the fan mounting nuts (2). (Fig. 13)

6. Slip off the electrical connector at the motor.

7. Lift out the fan.

8. To reinstall, reverse procedure.

Stud

Thermal Sensor is

attached to burner

base

Stud

Fan Speed Control/Junction Box

Fig. 13 Fan location.

Temperature Sensor

Speed

Control

Black

White

Ground

Fig. 14 Wiring diagram RN/RP.

Fan is installed

at the back of

the air intake

box

Valve

FP1252

Fan

FP394

10

10002964

Page 11

Operating Instructions

1.

2.

�

Gas Fireplace Insert

General Glass Information

Only ceramic glass approved by CFM Corporation may be used for replacement on

this unit.

1. The use of substitute glass will void all product

warranties.

2. Care must be taken to avoid breakage of the glass.

3. Under no circumstances should this appliance be

operated without glass properly installed, or with any

cracked or broken glass. Replacement of any glass

assembly as supplied by the manufacturer should be

done by a licensed qualified service person.

Louvre Removal

Glass Frame Removal

1. Remove the top louvre. (Refer to “Louvre Removal”

section)

2. Open access door.

3. Remove two (2) machine screws from the bottom of

glass frame. (Fig. 16)

4. Lift up and unhook glass frame at the top.

Before remounting glass frame, brass

trim must be installed. Refer to “Frame

Mounting” section.

Glass Frame

Screws

Machine Screws

Fig. 16 Remove glass frame.

Open Access Door

FP1373

Installation of Logs and Ember Material

To remove top flat louvre pull louvre up and

then lift out.

Glass

FP444

Fig. 15 Louvre removal.

Panel

Glass Cleaning

It will be necessary to clean the glass periodically.

During start-up, condensation, which is normal, forms

on the inside of the glass and causes lint, dust and

other airborne particles to cling to the glass surface.

Also initial paint curing may deposit a slight film on

the glass. It is therefore recommended the glass

be cleaned two or three times with a non-ammonia

household cleaner and warm water (we recommend

gas fireplace glass cleaner). After that the glass should

be cleaned two or three times during each heating

season depending on the circumstances present.

Clean glass after first two weeks of

10002964

operation.

Louvre

Refer to Figures 17 & 18

1. Remove front glass. (Refer to "Glass Removal" sec

tion)

2. Remove logs from packaging.

3. Place left rear log (N15 or N17) by using the log’s

bottom holes to locate it into the two pin studs located on the left side of the rear log support.

4. Place right rear log (N16 or N18) by using the log’s

bottom holes to locate it into the two pin studs located on the right side of the rear log support.

5. Place front right log (N14 or N20) onto locator

notches. Ensure the log is securely in place.

6. A125: Place front left log (N13) onto locator. Ensure

the log is securely in place.

A132: Place front left log (N19) against the back of

the left burner heat shield and the front edges of the

log should be flat against the front deflector.

7. Place ember material on to the front area of the

burner.

Top logs must be placed properly into

notches.

11

-

Page 12

Gas Fireplace Insert

L

O

H

I

Turn

counterclockwise

to increase

flame height

Turn clockwise

to decrease

flame height

Turn

counterclockwise

to decrease

flame height

Turn clockwise

to increase

flame height

Figure 17

A125

Front Left Log

N13

Left Rear Log

N15

Front Right Log

N14

Right Rear Log

N16

LG479

Ember Material

Figure 18

A132

Front Left Log

N19

Left Rear Log

N17

Front Right Log

N20

Large Lava Rock Placement

The large lava rock provided with this fireplace may be

placed on the firebox base on either side of the burner

assembly.

Under no circumstances should these lava

rocks be placed on top of the burner assembly.

Ember Material

Fig. 19 Flame adjustment knob for SIT Valve.

Right Rear Log

N18

LG481

SIT Valve

Flame Adjustment (RN/RP Models)

For fireplaces equipped with HI/LO valves, flame

adjustment is accomplished by rotating the HI/LO

adjustment knob located near the center of the gas

control. (Figs. 19 or 20)

12

Honeywell Valve

Fig. 20 Flame adjustment knob for Honeywell Valve.

10002964

Page 13

Gas Fireplace Insert

3/8" - 1/2"

Flame Characteristics

It is important to periodically perform a visual check of

the pilot and the burner flames. Compare them to the

Figure 21 and Figure 22 or 23. If any of the flames appear abnormal call a service person.

PSE Pilot

SIT Pilot

F584-703

Fig. 21 Correct pilot flame appearance.

Figure 23

A125

First Firing

Upon completing the gas line connection, a small

amount of air will be in the lines. When first lighting unit

with pilot light, it will take a few minutes to purge themselves of this air. Once the purging is complete, the

pilot and burner will light and operate as indicated in the

instruction manual. Subsequent lightings of the heater

will not require such purging.

When lit for the first time, the appliance will emit a slight

odor for awhile. This is due to paint and lubricants used

in the manufacturing process. After each lighting, vapor

may condense and fog the glass; this moisture disappears within a few minutes of burning.

LG480

Figure 23

A132

LG482

10002964

13

Page 14

Gas Fireplace Insert

PILOT

ON

OFF

ON

P

I

L

O

T

O

F

F

O

F

F

5

4

3

2

1

O

F

F

P

i

l

o

t

3/8" - 1/2"

Lighting and Operating Instructions

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING:If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

A. This heater has a pilot which must be lit manu

ally. When lighting the pilot follow these instructions exactly.

B. BEFORE LIGHTING smell all around the heater

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will

settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any fireplace

• Do not touch any electric switch

• Do not use any phone in your building

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

Lighting Instructions

-

instructions.

• If you cannot reach your gas supplier, call

the Fire Department

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand, do not try to repair it, call a

qualified service technician. Applying force or any

attempted repair may result in a fire or explosion.

D. Do not use this fireplace if any part has been under

water. Immediately call a qualified service techni

cian to inspect the heater and to replace any part of

the control system and any gas control which has

been under water.

-

1. STOP! Read the safety information above.

2. Turn off all electrical power to the fireplace.

3. For MN/MP/TN/TP appliances ONLY, go on to

Step 4. For RN/RP appliances turn the On/Off

switch to “OFF” position or set thermostat to

lowest level.

4. Open control access panel.

5. Push in gas control knob slightly and turn

clockwise to "OFF".

Euro SIT SIT NOVA

Honeywell

6. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow "B" in the safety information above. If you do not smell gas, go to the

next step.

7. Remove glass door before lighting pilot. (See

Glass Frame Removal section).

8. Visibly locate pilot by the main burner.

9. Turn knob on gas control counterclockwise

to "PILOT".

10. Push the control knob all the way in and hold.

Immediately light the pilot by repeatedly depressing the piezo spark ignitor until a flame appears.

Continue to hold the control knob in for about one

(1) minute after the pilot is lit. Release knob and it

will pop back up. Pilot should remain lit. If it goes

out, repeat steps 5 through 8.

• If knob does not pop up when released, stop

and immediately call your service technician or

gas supplier.

• If after several tries, the pilot will not stay lit,

turn the gas control knob to " " and call your service technician or gas supplier.

11. Replace glass door.

12. Turn gas control knob to “ON” position.

13. For RN/RP appliances turn the On/Off switch to

“ON” position or set thermostat to desired setting.

14. Turn on all electrical power to the fireplace.

1. Turn the On/Off switch to "OFF" position or set

the thermostat to lowest setting.

2. Turn off all electric power to the fireplace if

service is to be performed.

14

To Turn Off Gas To Heater

3. Open control access panel.

4. Push in gas control knob slightly and turn clockwise to "OFF". Do not force.

5. Close control access panel.

10002964

Page 15

Gas Fireplace Insert

Troubleshooting the Gas Control System

SIT NOVA 820 Millivolt Valve

NOTE: Before trouble shooting the gas control system, be sure external gas shut off is in the “On” position.

WARNING: Before doing any gas control service work, remove glass front.

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

1. Spark ignitor will not light A. Defective or misaligned Using a match, light pilot. If pilot lights, turn off

electrode at pilot. pilot and push the red button again. If pilot will not

light - check gap at electrode and pilot-should be

1/8" to have a strong spark.

B. Defective ignitor (Push Button) Push Piezo Ignitor Button. Check for spark at

electrode and pilot. If no spark to pilot, and elec

trode wire is properly connected, replace ignitor.

2. Pilot will not stay lit after A. Defective pilot generator Check pilot flame. Must impinge on thermo

carefully following lighting (thermocouple), remote wall couple/thermopile. Note: this pilot burner assem

instructions. switch. bly utilizes both-a thermocouple and a thermopile.

The thermocouple operates the main valve

operation (On and Off). Clean and or adjust pilot for

maximum flame impingement on thermopile and

thermocouple.

B. Defective automatic valve Turn valve knob to “Pilot”. Maintain flow to pilot;

milivolt meter should read greater than 10 mV. If

the reading is okay and the pilot does not stay on,

replace the gas valve. Note: An interrupter block

(not supplied) must be used to conduct this test.

3. Pilot burning, no gas to A. Wall switch or wires defective Check wall switch and wires for proper connec

main burner tions. Jumper wire accross terminals at wall

switch, if burner comes on, replace defective wall

switch. If okay, jumper wires across wall switch

wires at valve, if burner comes on, wires are faulty

or connections are bad.

B. Thermopile may not be 1. Be sure wire connections from thermopile at

generating sufficient gas valve terminals are tight and thermopile is

millivoltage. fully inserted into pilot bracket.

2. One of the wall switch wires may be grounded.

Remove wall switch wires from valve terminals if

pilot now stays lit, trace wall switch wiring for

ground. May be grounded to fireplace or gas

supply.

3. Check thermopile with millivolt meter. Take

reading at thermopile terminals of gas valve.

Should read 250-300 millivolts (minimum 150)

while holding valve knob depressed in pilot

position and wall switch “Off”. Replace faulty

thermopile if reading is below specified minimum.

C. Plugged burner orifice. Check burner orifices for debris and remove.

D. Defective automatic valve Turn valve knob to “On”, place wall switch to “On”

operator. millivolt meter should read greater than 100 mV. If

the reading is okay and the burner does not come

on, replace the gas valve.

4. Frequent pilot outage A. Pilot flame may be too low Clean and/or adjust pilot flame for maximum flame

problem. or blowing (high) causing the impingement on thermopile and thermocouple.

pilot safety to drop out.

B. Possible blockage of the vent Check the vent terminal for blockage (recycling the

terminal. flue gases)

10002964

15

Page 16

Gas Fireplace Insert

Gas Supply On

Supply Line Hooked Up

Shutoff Valve Open

NO

NO

NO

NO

Lockout Has Engaged. Wait

60 Seconds And Try Again.

For Spark At Electrode While

Depressing Piezo — 1/8" Gap To

Pilot Hood Needed.

All Wiring Connections

Replace Piezo Ignitor

For Air In The Lines

Thermopile Needs A Minimum

325mv. Adjust Pilot Flame Height.

All Wiring Connections.

Replace Thermopile

Thermocouple Needs A Minimum

of 14mv.

Defective Valve. Turn To Pilot,

Meter Should Read Greater Than

100 Mv. If Not, Replace.

Pilot Lights With

Piezo Ignitor

YES

YES

YES

YES

Pilot Stays Lit

Pilot Lights Main

Burner

System OK.

START

CHECK

Valve Is Turned On

On/off Switch Is Not Turned On.

Watch For Grounded Wires!

Thermopile Needs A Minimum

325mv.

Plugged Burner Orifice.

Troubleshooting the Gas Control System

Honeywell Millivolt Valve

16

10002964

Page 17

Burner and Burner Compartment

Gas Fireplace Insert

Maintenance

It is important to keep the burner and the burner

compartment clean. At least once per year the logs and

lava rock/ember material should be removed and the

burner compartment vacuumed and wiped out. Remove

and replace the logs as per the instructions in this

manual.

Always handle the logs with care as they are fragile

and may also be hot if the fireplace has been in

use.

Fan Assembly

The fan unit requires periodic cleaning. At least once

per month in the operating season, open the lower

louvre panels and wipe or vacuum the area around the

fan to remove any build up of dust or lint.

Cleaning the Standing Pilot

Control System

The burner and control system consists of:

• main burner • pilot burner

• gas orifice • thermopile

• combination millivolt gas valve

Most of these components may require only an occasional checkup and cleaning and some may require adjustment. If repair is necessary, it should be performed

by a qualified technician.

In order to properly clean the burner and pilot assembly,

turn off the gas to the unit, remove the window frame

panel and logs exposing the burner and pilot assembly.

Clean all foreign materials from the top of the burner.

Check to make sure that burner parts are clean. Visually inspect pilot. Brush or blow away any dust or lint accumulation. If pilot orifice is plugged, disassembly may

be required to remove any foreign material from the

orifice or tubing.

To obtain proper operation, it is imperative the pilot and

burner's flame characteristics are steady, not lifting or

floating.

Typically, the top 1/8" of the thermopile should be engulfed in the pilot flame. (Page 13, Fig. 25)

Brass Cleaning

Clean the brass trim with a soft clean cloth, slightly

dampened with lemon oil and buff with a soft dry cloth.

Do not use brass polish or household cleaners as these

products will damage the trim. Lemon oil can be obtained at supermarkets or hardware stores.

10002964

17

Page 18

Gas Fireplace Insert

1 A125

1a

1b

1c

1d

3

2

4

5

9a/b

8a/b

19

14

16

18

10a/b

18

17

11a/b

13

14

15

20

23a/b

21

22a/b

24

25

26

27

28

30

29

31

32

33

35

34

1a

1b

1c

1d

1 A132

CFM Corporation reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products at any time,

without notice.

A125, A132 Gas Insert

Ref. Description A125 A132

1. Log Set Complete 10002906 10002916

1a. Log Front Left N13 N19

1b. Log Front Right N14 N20

1c. Log Rear Left N15 N17

1d. Log Rear Right N16 N18

2. Ember Material (package) 51915 51915

3. Lava Rock (package) 10001454 10001454

4. Burner Housing w/Tiles (Nat. or Propane) 10002675 10002897

5. Ceramic Tile (single) 57803 57803

6a. Orifice Front Burner - Nat. See Rating Plate for Orifice Size

6b. Orifice Front Burner - Prop. See Rating Plate for Orifice Size

7a. Orifice Main Burner - Nat. See Rating Plate for Orifice Size

7b. Orifice Main Burner - Prop. See Rating Plate for Orifice Size

8a. Orifice Pilot SIT Top Convertible - Nat. 10002268 10002268

8b. Orifice Pilot SIT Top Convertible - Prop. 10002269 10002269

18

10002964

Page 19

Gas Fireplace Insert

A125, A132 Gas Insert

Ref. Description A125 A132

9a. Orifice Pilot PSE - Nat. 10001822 10001822

9b. Orifice Pilot PSE - Prop. 10001823 10001823

10a. Pilot Assembly SIT Top Convertible - Nat. 10002389 10002389

10b. Pilot Assembly SIT Top Convertible - Prop. 10002390 10002390

11a. Pilot Assembly PSE - Nat. 10001739 10001739

11b. Pilot Assembly PSE - Prop. 10001740 10001740

12. Pilot SIT Top Convertible 10002266 10002266

13. Pilot w/Ignitor and Cable PSE 10001824 10001824

14. Pilot Tubing w/Fittings 10001296 10001296

15. Manifold Tubing w/Fittings 57318 57318

16. Thermocouple w/Interrupter SIT 54912 54912

17. Thermocouple w/Interrupter PSE 10001828 10001828

18. Thermopile 51827 51827

19. Eletrode Ignitor w/Cable SIT 10001297 10001297

20. Ignitor Piezo SIT 52464 52464

21. Ignitor Piezo Honeywell 20000062 20000062

22a. Valve SIT 820 - Nat. 52677 52677

22b. Valve SIT 820 - Prop. 52678 52678

23a. Valve Honeywell - Nat. 10001782 10001782

23b. Valve Honeywell - Prop. 10001759 10001759

24. Fan w/Bracket 54103 54103

25. Electrical Cord (6 ft.) 51865 51865

26. FanTemperature Sensor 51704 51704

27. Speed Control 51738 51738

28. Speed Control Knob 51882 51882

29. Glass w/Gasket 10002869 10002871

30. Gasket Glass 57316 57316

31. Frame Window 54455 57914

32. Remote Switch 53606 53606

33. Remote Wire Harness w/Terminals 10002582 10002582

34. Vent Safety Switch 51866 51866

35. Vent Safety Switch Wiring Harness 10003033 10003033

36. Ceramic Refractory Kit (not shown) JT2TB0 KT2TB0

10002964

19

Page 20

Gas Fireplace Insert

Optional Accessories

Ceramic Refractory

Optional for A125 and A132

Model Description

RHE25CR Ceramic Firebox Liner

1. Remove front glass (Refer to Glass Frame Removal

section)

2. Remove logs from unit.

Logs may be hot!

3. Remove refractory from packaging.

Refractory are fragile and must be handled with

care. Where at all possible, two hands should be

used when handling.

4. Take center refractory and tilt so bottom edge slides

into support angle in back of fireplace.

5. Now press center refractory to back side of fireplace

and hold in place.

6. Take left or right refractory and align it so leading

edge faces outward. Place refractory in fireplace

side and slide it back to support center refractory.

7. Install metallic piece in the leading edge (A132 only).

8. Repeat Step 6 and 7 for remaining side refractory.

When side refractory is installed correctly,

the center refractory will be supported by

the side refractory.

9. Fasten top tab supports against refractory to hold

sides in place.

Left Side

Center

Right Side

Follow the instructions supplied with the Zero Clearance

Kit carefully for proper installation.

Remote Controls

Optional remote control units are available to control

different functions of the appliance.

Model Function(s) Controlled

RC1 ON/OFF

RC2 ON/OFF and Temperature

IMTFK Wall mounted thermostat control

A Trim Options for A125

A1 RHE25SSP, RHE25LP

Trim Assembly

RHE25SSP

1. Install trim channels (left and right sides). Use two

screws to assemble each piece.

2. Slide on the trim top channel and fasten it from the

back side.

3. Install the trim top deflector using two screws.

4. Remove ALL plastic protective covering from brass

trim.

Side View

Trim Top Deflector

Leading

Edge

Bottom Edge

Fig. 24 Ceramic refractory.

Leading

Edge

FP1278

Zero Clearance Kit

For installations other than in existing woodburning fireplaces such as new construction or renovation projects,

a Zero Clearance Kit must be used. The HEZC enables

these inserts to be installed in combustible environments. It is recommended that an Air Kit (AKZC) be

installed whenever using a Zero Clearance Kit. Consideration must be given to the dimensions of the Zero

Clearance Kit and the requirements of the Air Kit when

planning out the installation.

20

Trim Frame Top Section

FP1261a

Fig. 25 Trim top deflector.

HE25LP

1. To install the kit you do not have to remove any

piece of brass, you just add the external pieces.

2. Remove the frame trim from the unit if it is already

installed.

3. Install trim channels (left and right sides) by remov

ing the two screws that hold the side brass trim and

put them back to hold both parts.

4. Slide on the trim top channel and fasten it from the

back side.

10002964

-

Page 21

Gas Fireplace Insert

4

2

3

4

1

6

6

5

5. Remove the two screws that hold the top brass trim.

6. Install the two brackets to the studs in the bottom of

the top channel. Use the nuts supplied with top trim

channel.

A flat louvre kit OR a bay window kit need

to be chosen to complete the installation.

RHE25SSP & HE25LP Replacement Parts

FP1289

CFM Corporation reserves the right to make changes in design,

materials, specifications, prices and discontinue colors and products

at any time, without notice.

IMPORTANT: Only trim panel assemblies approved

by CFM Corporation can be used on these products.

ALL repair parts will be available from your local dealer.

When ordering, always give the following information:

Model and serial number, part description with finish

and part number.

Key Description

RHE25SSP HE25LP

1 Trim Frame Black 10001939 2 Trim Top Deflector 55099 3 Trim Top Channel

(1)

55077 4 Trim Side Channel 55096 5 Trim Top Channel - 55097

6 Trim Side Channel - 55080

7 Fasteners Package

(Not Shown) 54618 57633

(1) LP trim to be used with SSP trim.

SSP trim dimensions are for openings smaller than 26

38" W (673mm x 965mm).

LP trim dimensions are for openings smaller than 29" H x 41"

W (736mm x 1040mm).

(1)

¹⁄₂" H x

2. Install top and bottom brass trim by using the shortest black screw. (Fig. 26 & 27)

3. Install bottom decorative plate by simply sliding it

under the unit floor. No fastening is required for this

installation. (Fig. 28) Be sure to remove protective

cover.

4. Install the bottom louvre assembly by fastening the

hinges with four screws to the pre-punched holes in

the cabinet.

5. Re-install the front glass.

6. Install the top louvre by using the hooks to hang it in

place.

Trim Top

Glass Frame

Trim Bottom

Fig. 26 Install top and bottom brass trim.

Louvre

NOTE: Position

brass trim top as

shown (small end

up) to prevent heat

discoloration.

Glass Frame

Fig. 27 Position brass trim to with small end up.

Screws

FP1290

FP1291

A2 HE25FP Trim

For use with A125

HE25FP Flat face louvres with polished window

brass trim

Trim Assembly

1. Remove the front glass (see "Glass Frame Removal"

10002964

section).

Fig. 28 Slide bottom decorative plate under unit floor.

Bottom

Decorative

Plate

FP1292

21

Page 22

Gas Fireplace Insert

1

2

3

4

5

HE25FP Replacement Parts

FP1293

CFM Corporation reserves the right to make changes in design,

materials, specifications, prices and discontinue colors and products

at any time, without notice.

IMPORTANT: Only trim panel assemblies approved

by CFM Corporation can be used on these products.

ALL repair parts will be available from your local dealer.

When ordering, always give the following information:

Model and serial number, part description with finish

and part number.

Key Description HE25FP

1 Trim Window Top/Bottom 55098

2 Trim Bottom Channel 55079

3 Top Louvre Assembly 54603

4 Bottom Louvre Assembly 54604

5 Hinge 52356

6 Fasteners Package (Not Shown) 57916

4. Install the ceramic piece inside the bay window.

5. Install the bay window by hanging it onto the lower

tabs of the hanging brackets. (Fig. 34)

6. Install top louvre by engaging the oblong holes with

the upper tabs of the hanging brackets. (Fig. 35)

7. Install brass trim to the steel frame. (Fig. 36)

Fan Control Box

KT205

Fig. 29 Remove fan control box.

Fan Control

Box

Extension

Bracket

KT207

Fig. 30 Attach the control box to the bracket and install

bracket into the cabinet.

A3 HE25BTKP

For use with A125

HE25BTKP Bay window kit with polished brass trim

Do not remove existing glass with frame.

Extension

Knobs

Trim Assembly

Fig. 31 Install the knob extensions. (RN/RP models Only)

1. Reposition controls.

a. Remove the fan speed control box. (Fig. 29)

b. Attach the fan speed control box to the bracket

Hanging Bracket

(Fig. 30) and install the bracket into the cabinet.

Only for RN/RP VALVE units:

c. Install the control knob extensions onto the ap

-

propriate control valve knobs. (Fig. 31)

On units fitted with a Honeywell brand control

valve the location of the control knobs and

the ignitor button may vary slightly from those

shown in Figure 31. The Honeywell extension

pieces are visually different in design and are

not interchangeable with the RN/RP knobs

2. Install the hanging brackets. (Fig. 32)

shown in Figure 31.

Fig. 32 Hanging bracket alignment.

3. Install bracket on each side of the cabinet. Fig. 33)

22

KT204a

KT209b

10002964

Page 23

Fig. 33 Bracket for HEBTKP.

HI

LO

1

2

8

4

17

15

16

5

10

9

11

12

13

6

7

3

KT210a

Fig. 34 Hang the window grille or the steel frame onto the

lower tabs of the hanging brackets.

KT211a

Fig. 35 Engage the slots in the upper grille top louvre with

the upper tabs of the hanging brackets.

Fig. 36 Attach magnets and brass trim to the steel frame.

10002964

FP1270

KT212a

Gas Fireplace Insert

HE25BTKP Replacement Parts

0801

CFM Corporation reserves the right to make changes in design,

materials, specifications, prices and discontinue colors and products

at any time, without notice.

IMPORTANT: Only trim panel assemblies approved

by CFM Corporation can be used on these products.

ALL repair parts will be available from your local dealer.

When ordering, always give the following information:

Model and serial number, part description with finish

and part number.

Key Description HE25BTKP

1 Trim Window Top & Bottom

(w/magnets) 10000779

2 Top Louvre Assembly 10000780

3 Bottom Louvre Assembly 10000787

4 Control Door 10000786

5 Hinge 52356

6 Glass Side 10000388

7 Glass Front 10000389

8 Ceramic Refractory Bay 10000529

9 Extension Knob On/Off

(only for RN/RP valves) 55163

10 Extension Knob Hi/Lo

(only for RN/RP valves) 55162

11 Bracket Hanging Bay Window 1409129

12 Bracket Extension Rheostat 1409146

13 Bracket Mounting Bay Window 57877

14 Hardware Package (Not Shown) 10000530

15 Extension Knob Hi/Lo

(Honeywell Valve) 20000006

16 Extension Knob On/Off

(Honeywell Valve) 20000007

17 Extension Knob Piezo Ignitor

(Honeywell Valve) 20001427

23

Page 24

Gas Fireplace Insert

B

C

A

A4 Riser Kits

For use with A125

1. Install the unit according to Homeowner’s Manual.

2. Install the trim according to Installation Instructions.

3. Remove the two (2) screws at the bottom of the trim.

4. Install the riser at the bottom of the trim. (Fig. 37)

5. Fasten the trim with the same two (2) screws removed in Step 3.

Riser Trim Dimensions

RHE25R1-Riser 1" 38.3" (973mm) 1" (25.6mm) 2.86" (72.8mm)

RHE25R-2Riser 2" 38.3" (973mm) 2" (50.9mm) 2.89" (73.6mm)

RHE25R5-Riser 5" 38.3" (973mm) 5" (127.9mm) 2.86" (72.8mm)

Riser

Decorative

Trim

Length - A Height - B Depth - C

Trim Kit

10/24 Screws

Frame Top

10/24 Nuts

Left

Frame

Fig. 38 Attache left and right frame to frame top.

Right Frame

FP1259

3. Install the trim top deflector and use two (2) screws

to fasten it. (Fig. 39 & 40)

4. Remove ALL plastic protective covering from brass

trim.

Trim Top

Channel

Trim

Side

Channel

Deflector

Trim Top

Screw

Trim

Side

Channel

FP1276

Fig. 37 RHEBSL, RHEBXL trim kit.

B Trim Options for A132

B1 RHESS, RHESL, RHESSD, RHESLD, &

RHESXL Trims

For use with A132

Frame Assembly

RHESS, RHESL, RHESSD, RHESLD and RHESXL

1. Lay trim top facing and trim side facings, face down

on to an even surface such as a table or floor. Be

sure not to scratch the painted surfaces.

2. Install the nuts and bolts. (Fig. 38)

Trim Assembly

RHESS, RHESL and RHESXL (Fig. 39)

1. Install trim channels (left and right sides). Use two

(2) screws to assemble each piece.

2. Slide on the trim top channel and fasten it from the

back side.

FP1260

Fig. 39 Install trim channels and trim top deflector.

Side View

Trim Top Deflector

Trim Frame Top

FP1261a

Fig. 40 Trim top deflector.

Section

RHESSD and RHESLD (Fig. 41)

1. Install trim channels (left and right sides). Use two

(2) screws to assemble each piece.

2. Peel off plastic protective covering from top edges

of the inner sides where they will be covered by the

inner top trim facing.

3. Place the trim facing inner top in place (do not fasten

it yet). Peel off the plastic protective covering from

the bottom edge.

24

10002964

Page 25

Gas Fireplace Insert

4. Install the trim top deflector and fasten it (will hold

the inner top piece). Use two (2) screws to assemble

them.

5. Install trim channels (left and right sides). Use two

(2) screws to assemble each piece.

6. Slide on the trim top channel and fasten it from the

back side.

7. Remove

ALL plastic protective covering from brass

trim.

Trim Top

Channel

Trim

Side

Channel

Screw

Trim

Framing Inner Sides

Fig. 41 RHESSD and RHESLD trim assembly.

Trim

Side

Channel

FP1262

A flat louvre kit OR a bay window kit need

to be chosen to complete the installation.

Frame Mounting

General Information

The Decorative Front Frame should be installed last

after all other work, such as gas connections, venting, etc., has been completed and thoroughly checked

and tested for operation, leaks and proper installation

requirements.

Fit decorative frame to the fireplace and fasten. (Fig.

42)

Screws

Front View

Fig. 42 Frame mounting.

FP1263

Plastic on the trim must be removed before mounting onto the fireplace.

Glass must be tightly pressed against

the front of the frame in order to prevent

screws from damaging glass edges.

10002964

25

Page 26

Gas Fireplace Insert

5

1

2

3

6

6

4

7

8

9

1

RHESS, RHESL, RHESSD, RHESLD, RHESXL Trim Replacement Parts

IMPORTANT: Only trim panel assemblies approved by CFM Corporation can be used on

these products.

ALL repair parts will be available from your local

dealer.

When ordering, always give the following information: Model and serial number, part description with

finish and part number.

FP1264

CFM Corporation reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products at any time,

without notice.

Key Description RHESS

(2)

RHESL

1 Trim Frame Top, Flat Black 57929 57932 57929 57932 57935

2 Trim Frame Left, Flat Black 57927 57930 57927 57930 57933

3 Trim Frame Right, Flat Black 57928 57931 57928 57931 57934

4 Trim Top Deflector

5 Trim Top Channel

6 Trim Side Channel Left

7 Trim Facing Inner Top

8 Trim Facing Inner Left

9 Trim Facing Inner Right

(1)

(1)

(1)

(1)

- - 17609 17610 -

(1)

- - 17620 17619 -

(1)

- - 17622 17621 -

17634 17634 17634 17634 17634

50586 50587 17611 17612 52787

50589 50590 17623 17624 52788

10 Fasteners Package (Not Shown) 55043 55043 55043 55043 55043

(3)

RHESSD

(3)

RHESLD

(3)

RHESXL

(4)

(1) Specify Finish (Antique or Polished Brass)

(2) SS and SSD trim dimensions are for openings smaller than 26¹⁄₂"H x 38" W (673mm x 965mm)

(3) SL and SLD trim dimensions are for openings smaller than 29"H x 41" W (736mm x 1040mm)

(4) SXL trim dimensions are for openings smaller than 32"H x 43" W (813mm x 1092mm)

26

10002964

Page 27

Gas Fireplace Insert

B

C

A

A4 Riser Kits

For use with A125

1. Install the unit according to Homeowner’s Manual.

2. Install the trim according to Installation Instructions.

3. Remove the two (2) screws at the bottom of the trim.

4. Install the riser at the bottom of the trim. (Fig. 56)

5. Fasten the trim with the same two (2) screws removed in Step 3.

Riser Trim Dimensions

RHE25R1-Riser 1" 42" (1067 mm) 1" (25 mm) 2.55" (64.8 mm)

RHE25R-2Riser 2" 42" (1067 mm) 2" (51 mm) 2.58" (65.6 mm)

RHE25R5-Riser 5" 42" (1067 mm) 5" (128 mm) 2.58" (65.6 mm)

Length - A Height - B Depth - C

NOTE: The riser kit should only be used with the

RHEBSL and RHEBXL trim.

B6 Arch Door Kit

HEADKA - Antique Brass Arch Door

HEADKP - Polished Brass Arch Door

Trim Kit

Riser

Decorative

Trim

FP1276

Fig. 56 RHEBSL, RHEBXL trim kit.

10002964

27

Page 28

Gas Fireplace Insert

28

10002964

Page 29

Gas Fireplace Insert

10002964

29

Page 30

Gas Fireplace Insert

30

10002964

Page 31

LIMITED LIFETIME WARRANTY

Gas Fireplace Insert

PRODUCT COVERED BY THIS WARRANTY

All Vermont Castings gas stoves, gas inserts, and gas fireplaces, and all Majestic brand gas fireplaces equipped with

an Insta-Flame Ceramic Burner, or standard steel tube burner.

BASIC WARRANTY

CFM Corporation (hereinafter referred to collectively as the Company)

warrants that your new Vermont Castings

Stove is free from manufacturing and material defects for a period of

one year from the date of purchase, subject to the following conditions

and limitations.

EXTENDED LIFETIME WARRANTY

The heat exchanger, where applicable, and combustion chamber

of every Vermont Castings or Majestic gas product is warranted for

life against through wall perforation. All appliances equipped with an

Insta-Flame Ceramic Burner have limited lifetime coverage on the

ceramic burner plaque. Warrantees are made to the original owner

subject to proof of purchase and the conditions and limitations listed

on this Warranty Document

COMPONENT WARRANTY

CAST IRON: All external and internal cast iron parts are warranted for a

period of three years.

Note: On porcelain enamel finished external parts and accessories The

Company offers no Warranty on chipping of enamel surfaces. Inspect

all product prior to accepting it for any damage to the enamel.

The salt air environment of coastal areas or a high humidity environment

can be corrosive to the porcelain enamel finish. These conditions can

cause rusting of the cast iron beneath the porcelain enamel finish,

which will cause the finish to flake off.

Dye lot variations with replacement parts and/or accessories can occur

and are not covered by warranty.

GLASS DOORS: Glass doors are covered for a period of one year.

Glass doors are not warranted for breakage due to misuse or accident.

Glass doors are not covered for discoloration or burned in stains due to

environmental issues, or improper cleaning and maintenance.

BRASS PLATED PARTS AND ACCESSORIES: Brass parts should be

cleaned with Lemon oil only.

mix and masonry cleaners may corrode the brass finish. The Company

will not be responsible for, nor will it warrant any brass parts which are

damaged by external chemicals or down draft conditions.

GAS VALVES: Gas valves are covered for a period of one year

ELECTRONIC AND MECHANICAL COMPONENTS: Electronic and

mechanical components of the burner assembly are covered for one year.

All steel tube burners are warranted for one year.

ACCESSORIES: Unless otherwise noted all components and CFM

Corporation company supplied accessories are covered for a period of

one year.

CONDITIONS AND LIMITATIONS

• This Vermont Castings or Majestic product must be installed or serviced

by a qualified installer, preferably NFI or WETT (Canada) certified, as

prescribed by the local jurisdiction. It must be installed and operated at

all times in accordance with the Installation and Operating instructions

furnished with the product. Any alteration, willful abuse, accident, or

misuse of the product shall nullify this warranty.

• This warranty is non-transferable, and is made to the original owner,

provided that the purchase was made through an authorized supplier

of the Company.

• The customer must pay for any Authorized Dealer in-home travel fees

or service charges for in-home repair work. It is the dealers option

whether the repair work will be done in the customer’s home or in the

dealer’s shop.

• If upon inspection, the damage is found to be the fault of the manufacturer,

repairs will be authorized at no charge to the customer parts and/or

labor.

Brass cleaners cannot be used. Mortar

or Majestic Gas Fireplace/

• Any part and/or component replaced under the provisions of this

warranty is covered for six months or the remainder of the original

warranty, whichever is longest.

• This warranty is limited to the repair of or replacement of part(s) found

to be defective in material or workmanship, provided that such part(s)

have been subjected to normal conditions of use and service, after

said defect is confirmed by the Company’s inspection.

• The company may, at its discretion, fully discharge all obligations

with respect to this warranty by refunding the wholesale price of the

defective part(s)

• Any installation, labor, construction, transportation, or other related

costs/expenses arising from defective part(s), repair, replacement,

or otherwise of same, will not be covered by this warranty, nor shall

the Company assume responsibility for same. Further, the Company

will not be responsible for any incidental, indirect, or consequential

damages except as provided by law.

• SOME STATES DO NOT ALLOW FOR THE EXCLUSION OR

LIMITATIONS OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

OR LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOUR

CIRCUMSTANCES. THIS WARRANTY GIVES YOU SPECIFIC

RIGHTS AND YOU MAY HAVE OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

• All other warranties-expressed or implied- with respect to the product,

its components and accessories, or any obligations/liabilities on the

part of the Company are hereby expressly excluded.

• The Company neither assumes, nor authorizes any third party to

assume on its behalf, any other liabilities with respect to the sale of

this Vermont Castings or Majestic product

• The warranties as outlined within this document do not apply to

chimney components or other non CFM Corporation accessories used

in conjunction with the installation of this product..

• Damage to the unit while in transit is not covered by this warranty but

is subject to claim against the common carrier. Contact the dealer

from whom you purchased your fireplace/stove (do not operate the

appliance as this might negate the ability to process the claim with

the carrier).

• The Company will not be responsible for:

a) Down drafts or spillage caused by environmental conditions such