Page 1

the

Great Outdoors

Assembly and

Owner’s Manual

®

A053041

X-Series

Portable

Gas Grill

L.P. Gas

Cylinder

Not Included

ASSEMBLER / INSTALLER:

Leave these instructions with the consumer.

CONSUMER / USER:

Read all of these instructions and keep them in a safe place for future reference.

FOR YOUR SAFETY

If you smell gas:

1

Shut off gas to the appliance.

2

Extinguish any open flame.

3

Open lid.

4

If odor continues, immediately call

your gas supplier or fire department.

FOR YOUR SAFETY

1

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

2

An unconnected liquid propane

cylinder should not be stored in the

vicinity of this or any other appliance.

FOR YOUR SAFETY: Never leave a grill unattended when in use.

Page 2

Table of Contents

Page Number

Chapter 1 - INSTALLATION

Necessary Information . . . . . . . . . . . . . . . . . . . . . . . . . . .

Choosing a Safe Location . . . . . . . . . . . . . . . . . . . . . . . . .

Portable L.P. Gas Grills . . . . . . . . . . . . . . . . . . . . . . . . . . .

L.P. Gas Dealer Instructions . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 - ASSEMBLY INSTRUCTIONS

Step 1 ( Identifying Parts ) . . . . . . . . . . . . . . . . . . . . . . . . .

Step 2 ( Attach Legs ) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 3 ( Attach Feet ) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 4 ( Tank Retainer ) . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 5 ( Modesty Panel ) . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 6 ( Side Tables ) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 7 ( Grill Head ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 8 ( Ignitor Wire ) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 9 ( Lid Handle ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 10 ( Internal Parts ) . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 11 ( Warming Rack ) . . . . . . . . . . . . . . . . . . . . . . . . .

Step 12 ( Drip Cup ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing an L.P. Gas Cylinder . . . . . . . . . . . . . . . . . . . . .

4

4

4

5-7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22-23

Formerly:

®

Now:

CFM Corporation

2695 Meadowvale Boulevard

Mississauga, Ontario L5N 8A3 Canada

(800) 668-5323

www.cfmcorp.com

Service Note: If you are experiencing difficulties or are dissatisfied with your purchase, please contact CFM at

the telephone number listed above prior to returning your grill to the store.

Page 3

X-Frame Model Series Gas Grill

Installation 1Chapter

Necessary Information to

Safely Use a Gas Grill

The gas fuel used by this product is

highly flammable and must be used in

a responsible and cautious manner.

It is your responsibility to assemble,

operate, and maintain your gas

barbecue grill properly.

·

Operating this or any gas-fired appliance

in an enclosed area can produce a build-up

of carbon-monoxide, which could result in

injury or death.

2. Installation must conform with local

codes

either the National Fuel Gas Code, ANSI

Z223.1, NFPA 54 (USA), or CAN/CGA-B

149.2, Propane Installation Code (Canada)

and CAN/CGA-B 149.1 Natural Gas

Installation Code.

To check local codes, contact your local gas

dealer or gas company listed in the Yellow

Pages for recommended installation

procedures and regulations.

3. This appliance is not intended to be

installed in or on a recreational vehicle

and/or boat.

or, in the absence of local codes, with

If these instructions are ignored, there

is a possibility of a hazardous fire or

explosion which could result in proper-

ty damage, physical injury or death.

Choosing a Safe Location

for a Gas Barbecue Grill

1. The gas barbecue grill may only be used

for cooking out-of-doors.

· Do not operate this barbecue in garages,

breeze ways, sheds or any enclosed area.

4. Keep the barbecue grill at least 24

inches (61 cm) away from any combustible

construction.

·

Do not use a grill under a ceiling or cover

where the heat or flame could cause

damage.

·

Choose a level surface where the grill is

not facing directly into the wind.

·

Avoid moving the grill during use.

5. The grill area must be clear and free from

combustible materials, gasoline, and any

other flammable liquids or vapors.

·

Do not use lighter fluid or charcoal

briquettes in a gas grill. The flow of

combustion and ventilation air is not to be

obstructed. The ventilation openings of the

cylinder enclosure must be kept free and

clear from other debris. Do not store grill

covers or other items in the cylinder area.

4

Page 4

The L.P. Fuel Supply System

9. Make sure that the drip pan is in place

under the grill bottom.

Hot drippings from cooking food could

·

damage the fuel supply system.

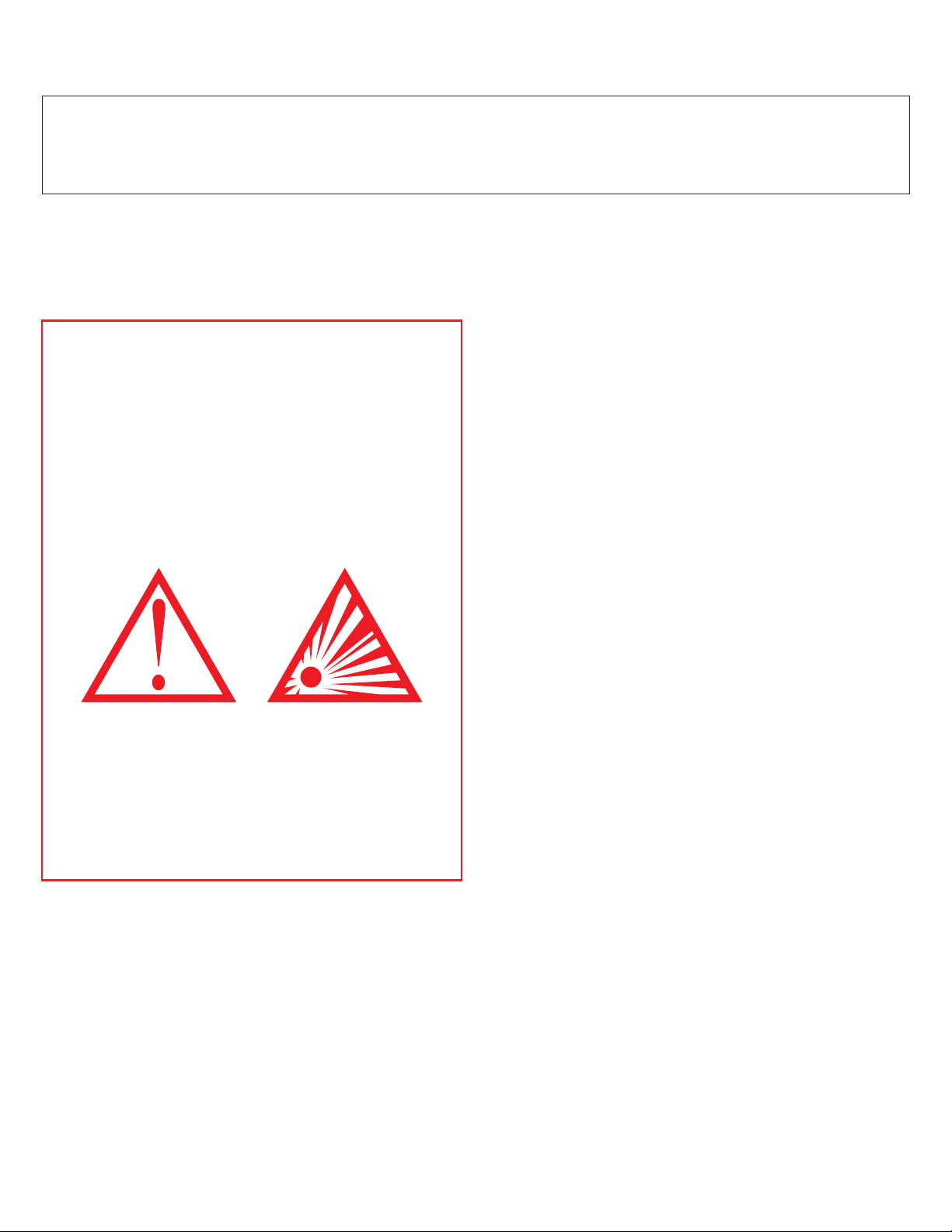

6. Do Not store a spare L.P. gas cylinder

under or near this appliance.

Do not store an L.P. cylinder in a building,

garage or any other enclosed area. Instead,

store the cylinder outdoors in a well

ventilated area, away from people and out of

the reach of children.

7. NOT FOR USE BY CHILDREN.

Place your barbecue grill in a location

·

away from children and pets.

Do not leave grill unattended when in use.

·

IMPORTANT:

unattended when in use.

NEVER leave a grill

Portable L.P. Gas

Barbecue Grills

WARNING:

appliance designed for L.P. gas. Use only

liquid propane (L.P.) gas in an appliance

designed for L.P. gas.

L.P. Gas

Liquid Propane (abbreviated L.P.) gas is

stored under high pressure inside a cylinder

and will vaporize when released. It is

important that there are no leaky connections

on the grill fuel supply system. Refer to the

Leak Testing section of this manual.

The L.P. Fuel Supply System

An L.P. gas grill requires a fuel delivery

system made up of a L.P. gas supply

cylinder, a fuel regulator with hose and a

gas-control valve.

Do not use natural gas in an

8. The outside of the barbecue grill will

become hot during use.

To avoid burns, do not touch any hot grill

·

surface. If necessary, use a protective glove

when operating control knobs, tank shut-off

valve, or lid handle.

Do not place combustible material, such

·

as cloth or plastic, on grill surface during

use.

·

Do not lean on side tables or place more

than 15 pounds of weight on a side table.

The L.P. Fuel Supply System

5

Page 5

Dual Burner

Fuel-Control Valve

4. The pressure regulator and hose

assembly provided is factory set at an outlet

pressure of 11 inches water column (.4 lb.

per sq. Inch).

Type 1 Fuel

Regulator

Fuel Supply

Valve

Orifice

Hose

The L.P. Fuel Supply System

(the fuel regulator and hose)

FUEL REGULATOR AND HOSE

The fuel regulator supplied is equipped with

a Type 1 coupling nut. Do not attempt to

connect to any other L.P. cylinder not

equipped with a mating Type 1 cylinder

valve. This grill is not to be used with any

other cylinder connection device.

The fuel regulator and hose assembly with

the Type 1 fitting supplied must be used with

the appliance. Do not use a hose and

regulator assembly other than the one

supplied with the grill or a manufacturer’s

replacement fuel pressure regulator

assembly.

The Type 1 connection system has the

following features:

1. The system will not allow gas to flow until

a positive connection has been made.

2. The system has a thermal element that

will shut off the flow of gas between 240°F

and 300°F.

3. The system has a flow-limiting device

which, when activated, will limit the flow of

gas to 10 cubic feet per hour.

WARNING:

Any attempt to adjust the

regulator is dangerous and could create a

situation causing personal injury or property

damage. Consult your L.P. gas dealer if you

think the regulator is not working properly.

L.P. GAS SUPPLY CYLINDER

L.P. Cylinders can be obtained at the store

where you purchased your grill or from an

authorized L.P. gas dealer.

Cylinder Control

Valve

L.P. Gas

Cylinder

NOTE:

L.P. Gas

Cylinder

NOT

INCLUDED

The L.P. Fuel Supply System

(L.P. gas cylinder)

L.P. GAS CYLINDER SPECIFICATIONS

Any L.P. gas-supply cylinder used with this

grill must be approximately 12 inches

diameter and 18 inches high.

The maximum

fuel capacity must be 20 pounds of propane.

Full-cylinder weight should be approximately

38 pounds (43.7 lbs. Nominal water

capacity).

6

Page 6

The L.P. gas cylinder must have a shut-off

valve

cylinder-valve outlet.

terminating in a Type 1 L.P. gas-

A Type 1 compatible

cylinder with a Type 1 cylinder valve has a

positive seating connection that does not

permit gas flow until a positive seal has been

obtained.

The cylinder must be arranged for vapor

withdrawal. It must also include a collar to

protect the cylinder valve. A safety-relief

device having direct communication with the

vapor space of cylinder must be provided.

This will expel high-pressure gas if the

cylinder is overfilled or overheated.

Have the gas dealer weigh the cylinder

after filling to ensure that the cylinder is not

overfilled.

DANGER:

a.) Do not store a spare L.P. gas cylinder

under or near this appliance.

b.) Never fill the gas cylinder beyond 80

percent full.

c.) If the information in (a.) and (b.) Is not

followed exactly, a fire causing serious

injury or death may occur.

All L.P. gas cylinders used with this

appliance shall be constructed and marked

in accordance with the specifications for L.P.

gas cylinders of the U.S. Department of

Transportation (DOT) or the National

Standard of Canada, CAN/CSA-B339,

Cylinders, Spheres and Tubes for

Transportation of Dangerous Goods; and

Commission, as applicable; and shall be

provided with a listed overfilling-prevention

device. Read labels on the L.P. gas-supply

cylinder.

DANGER:

Do not insert any foreign objects

into the valve outlet. You may damage the

back check, A damaged back check can

cause a leak, which could result in explosion,

fire, severe personal injury or death.

Allow only a qualified L.P. gas dealer to

fill or repair an L.P. gas-supply cylinder.

Inform the gas dealer if it is a new or used

cylinder to be filled. Caution the gas dealer

not to overfill the fuel cylinder.

TRANSPORTING A FULL CYLINDER

WARNING:

Handle a full cylinder with care.

Gas is under high pressure.

You should transport only one cylinder at a

time. Transport the cylinder in an upright and

secure manner with the control valve turned

off and the POL dust cap in place.

Do not transport a cylinder in the passenger

compartment of a vehicle.

Do not leave cylinder in direct sunlight or in

a high-heat area such as a closed car trunk.

High-heat areas could cause the relief valve

to vent gas.

Use a cylinder cap on the cylinder-valve

outlet during transport and when the cylinder

is not connected to the grill. Keep cylinder

valve closed when not in use.

After filling, have the gas dealer check for

leaks and that the relief valve remains free to

function.

7

Page 7

Take These Instructions to the L.P. Gas Dealer

When using a cylinder exchange, be sure the

exchanged cylinder is a Type 1 cylinder; a 510

POL cylinder will not fit a Type 1 regulator.

FILLING AND PURGING

TYPE 1 L.P. GAS CYLINDERS

DANGER:

cylinders must be performed by personnel who

have been thoroughly trained in accepted L.P.

gas industry procedures. Failure to follow this

instruction may result in explosion, fire, severe

personal injury or death.

IMPORTANT:

filling. This tank is easily filled with a standard

CGA 510 POL filling connection.

Purging and filling of L.P. gas

Purge new cylinders before

The L.P. gas cylinder has a Type 1 cylinder

valve with a back-check module in its outlet

that will not permit gas to flow until an

evacuation device is installed. To purge the

L.P. gas cylinder, the back-check module must

be opened with an evacuation device.

PURGING AND EVACUATION DEVICES

FOR L.P. GAS CYLINDER WITH TYPE 1

CYLINDER VALVES

A. Hose-end valve with a bleed port: Purging

can be accomplished using a hose-end valve

containing a bleed port, which also allows for

evacuation without the use of an adapter.

B. Hose-end valve without a bleed port:

When a hose-end valve does not have a bleed

port, a separate device must be used for

evacuation.

CGA-510 POL

Example A

Filling a Type 1 Cylinder Valve

Example A: shows a CGA-510 POL fitting.

Example B: shows using a Type 1 POL fitting.

Type 1

(cut away to see fitting)

C. Purging using a Type 1 connection: L.P.

gas cylinder evacuation can be accomplished

during each purging by using a Type 1

connection. The Type 1 valve outlet has 15/16” external ACME right-hand thread that will

accept this connection.

CAUTION:

cylinder, do not insert a POL plug into the

valve outlet. Insertion of this plug will prevent

the back-check from closing. Use ONLY the

provided cap and strap attached to the outlet.

Close the cylinder valve knob before returning

the cylinder to the customer.

For proper purging procedures in the USA,

refer to: Safety Bulletin NPGA # 133, “Purging

L.P. Gas Cylinders,” and Safety Bulletin NPGA

#130, “Recommended Procedures for Filling

Cylinders.”

After purging or filling an L.P. gas

Example B

DANGER:

beyond 80% full. If this information is not

followed exactly, a fire causing serious injury

or death may occur.

8

Do not fill an L.P. gas cylinder

Page 8

X-Frame Model Series Gas Grill

Assembly Instructions 2Chapter

Getting Started

1. Please follow the steps in the order that

they are presented.

2. Assemble the grill where you plan to use

it.

3. You may want to place an old towel or

cloth at the assembly site to prevent nuts

and bolts from becoming lost.

4. Have a friend help. An assistant can

make the assembly easier by holding the

parts in place while you fasten the nuts and

bolts.

5. To be ready to barbecue immediately,

have the L.P. gas cylinder filled by an

authorized L.P. dealer or cylinder exchange

center.

Unpacking the Grill Parts

1. Remove and set aside all inner boxes

and parts from the master carton.

2. Remove and set aside all wrapping

paper and additional packaging from the

parts.

3. Do not destroy carton or packing until

your grill is completely assembled and

operating to your satisfaction.

Tools needed to assemble grill:

(tools included)

·

10mm closed-end wrench*

·

Phillips-head screwdriver

·

17mm / 7mm open-end wrench*

A socket set or an adjustable wrench may be used

*

in place of the open-end wrenches if desired.

9

Page 9

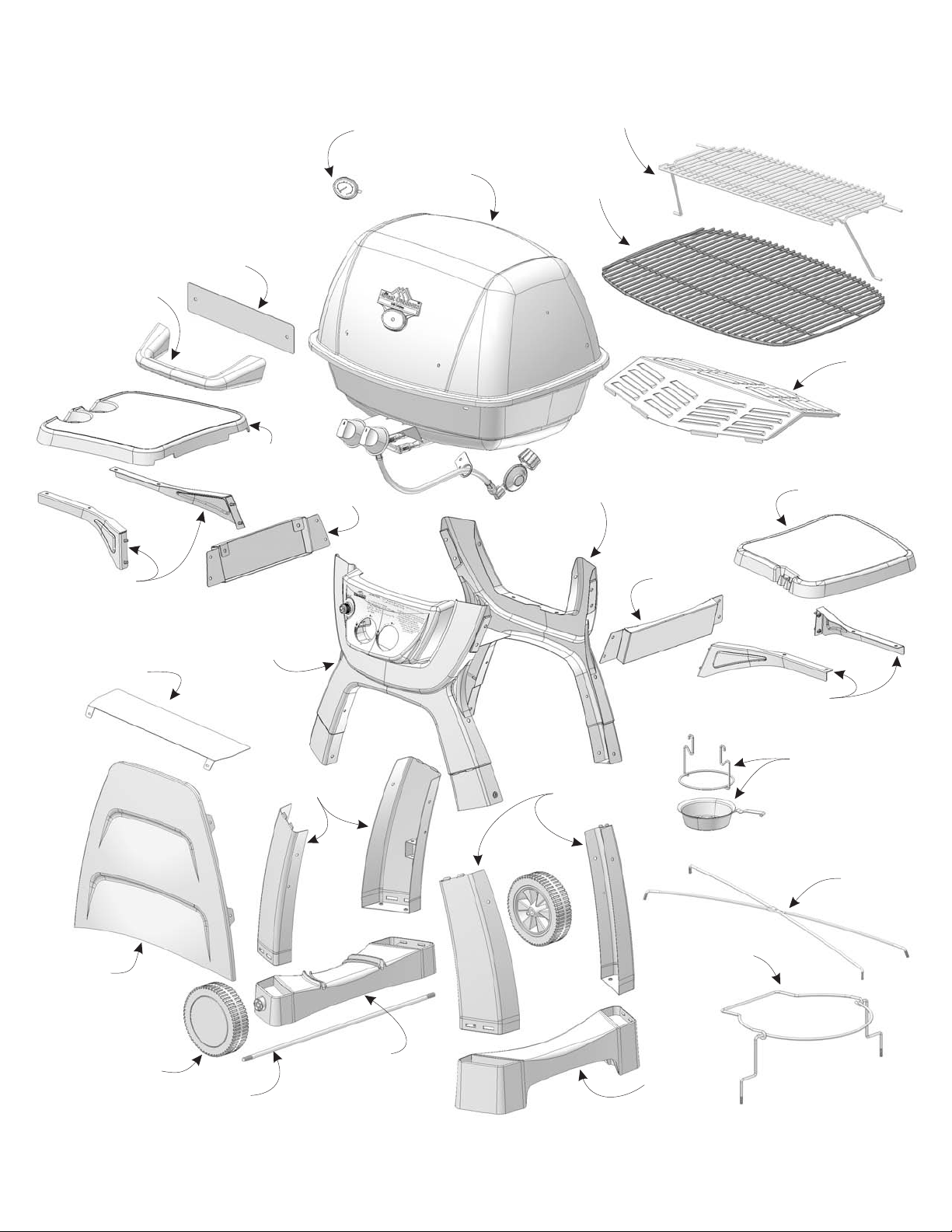

Assembly Step 1 - Identifying the Grill Parts

Locate these parts:

Note: Refer to the parts

listing on page 33 of the

manual for replacement part

information.

Handle

Heat Shield

Lid Handle

Left Side

Table

Table

Bracket

Heat

Indicator

Grill Head

Assembly

Warming Rack

Cooking Grid

Rear

X-Frame

Heat

Plate

Right Side

Table

Table Arms

Tank

Heat Shield

Modesty

Panel

Front X-Frame

with Control Panel

Legs

Table

Bracket

Table Arms

Drip Cup

and Holder

Legs

Wire

X-Brace

Wire Tank

Retainer

Wheel

Axle

Not Pictured:

Master Hardware Pack

Left Foot

(Tank Holder)

Right Foot

10

Page 10

Assembly Step 2 - Attach Legs to X-Frames

Tools Needed:

LOCATE THESE PARTS:

Phillips head screwdriver

USE HARDWARE ”A”

M6x15mm

A

Bolt (8)

Attach the leg to the X-frame by

1.

M6 Flat

B

Washer (8)

inserting the top tabs into the

corresponding slots in the X-frame

as shown.

2.

Line up the bolt holes on the side of

each leg and insert a bolt into each

of the bolt holes.

X-Frame

with

Control

Panel

2 Left

Legs

X-Frame

2 Right

Legs

3.

Tighten the bolts securely.

4.

Repeat steps 1 through 3 above for

each leg and frame. Be sure to

match the correct leg component to

its corresponding side, left/right.

When these steps are complete, you

will have 2 sets of frames with legs

attached.

B

A

11

Page 11

Tools Needed:

Assembly Step 3 - Attach the Feet

LOCATE THESE PARTS:

Phillips head screwdriver

17mm Wrench

USE HARDWARE ”B”

A

Wheel

Washer(2)

Assemble the wheels and axle to the

1.

B

M10 Axle

Nut (2)

C

M6x15mm

Bolt (8)

tank-side foot as shown above right.

Insert the axle through the foot, one

wheel on each end, tighten one nut

and wheel washer on each end, and

snap the hub caps onto the wheels

D

M6 Flat

Washer (8)

B

Axle

Nut

Hub

Cap

A

Wheel

Washer

Left Foot

(tank side)

Wheel

Axle

Right Foot

2.

Attach each foot to the bottom of

the frame assemblies as shown.

The legs will snap into the feet.

Be sure the is on

the of the assembly as

left side

wheeled foot

shown.

3.

For each mounting location,

insert 2 bolts with washers as

shown.

4.

Once all of the bolts are

securely tightened,

position the assembly so

that the wheels are on

your left side as you

face it. (This is the front)

C

D

LEFT

FOOT

12

Page 12

Assembly Step 4 - Install the Tank Retainer

USE HARDWARE ”C”

M4 Wing

A

Nut (1)

Insert the legs of the wire tank retainer

1.

M4x10mm

B

Bolt (1)

M6 Wing

C

Nut (6)

into the mounting brackets inside the grill

legs. The wire tank retainer must be

mounted on the wheel side of the grill.

2.

Align the center hole of the x-brace wires,

insert the M4 bolt through both wires, and

thread on the M4 wing nut as

shown above right.

Tools Needed:

Phillips head screwdriver

LOCATE THESE PARTS:

Wire Tank

Retainer

B

A

Wire

X-Brace

3.

Insert the ends of the wire x-brace

into the mounting

holes located

near the

middle of

the grill legs

and thread

a M6 wing

nut onto

each end.

4.

Thread M6

wing nuts onto

the ends of the

wire tank retainer.

C

C

13

Page 13

Assembly Step 5 - Attach the Modesty Panel

Tools Needed:

LOCATE THESE PARTS:

Phillips head screwdriver

7mm Wrench

USE HARDWARE ”D”

B

M4 KEPS

A

Nut (6)

1.

Position the modesty panel between the front legs of the

M4x15mm

Bolt (6)

assembly. Align the mounting tabs with the bolt holes in

the legs.

From the back side of the assembly, insert the

2.

M4 bolts through each of the mounting holes

and thread on the M4 KEPS nuts.

insert the bolt indicated - it will be installed

yet

DO NOT

during a later assembly step.

IMPORTANT! The Tank Heat Shield

must be properly installed to provide an

additional precautionary safeguard.

Tank

Heat

Shield

Modesty

Panel

A

B

3.

Position the Tank Heat Shield

between the front and rear

x-frame assemblies as shown

below.

B

A

4.5.For each mounting hole, insert M4 bolts and

thread on M4 KEPS nuts.

Securely tighten all the bolts. Remember to set

aside the remaining bolt and nut for a later step.

14

Page 14

Assembly Step 6 - Attach the Side Tables

Tools Needed:

Phillips head

screwdriver

USE HARDWARE ”E”

10mm Wrench

LOCATE THESE PARTS:

Left Side Table

Table Mounting

Brackets (2)

A

M6x25mm

Bolt (8)

1.

To assemble each table, use one left and one right

B

M6 Hex

Nut (8)

C

Lock

Washer (8)

D

Washer

(8)

table arm.

2.

Line up the bolt hole of the table arms

to the INSIDE set of holes on the side

table as shown.

3.

For each bolt location, insert a M6 bolt.

Once all bolts are mounted, securely tighten.

4.

Align the assembled side table, along with one

side table bracket to the side of the grill

assembly as shown. Insert the pre-mounted

bolts through the mounting bracket and onto

the side of the

grill assembly.

Side Table Arms (2 Left, 2 Right)

Right Side Table

A

B

C

D

5.

For each bolt, thread on a flat washer,

lock washer and M6 hex nut.

Do not yet tighten the nuts.

6.

After 4 nuts are in place, securely

tighten all of the bolts.

7.

Repeat steps for the other side table.

15

Page 15

Assembly Step 7 - Installing the Grill Head

Tools Needed:

USE HARDWARE ”F”

Phillips head screwdriver

LOCATE THESE PARTS:

Grill Head

Assembly

M6x15mm

A

Bolt (4)

1.

Holding the grill head upright, slightly rotate

M6 Flat

B

Washer (4)

Bolt

C

Gasket (4)

the knob side down and set it onto the frame

assembly. The knobs will insert through the

control panel first, then rotate the grill head

down until it rests properly onto the frame.

2.

Line up the 4 bolt holes near the

inside corners of the grill tub.

(The lid will need to be opened

to access the bolt locations.)

3.

Loosely insert all of the bolts with

washers and gaskets.

4.

After all bolts are threaded, make sure the

control knobs centered and securely tighten

the bolts.

C

B

A

16

Page 16

Assembly Step 8 - Ignitor Installation

1. Locate the loose end of the

ignitor wire. Connect it to the

ignitor electrode underneath the

grill tub, between the two burner

tubes.

Installing the Battery

1.

Unscrew the cap from the ignitor button.

2.

Insert an AA battery (from the hardware pack)

The positive end of the battery faces out.

2.

Using the remaining bolt and nut from

Step 5 (page 14), bolt the hose bracket

to the frame.

Be sure the bolt mounts through the

modesty panel tabs and the frame leg.

Securely tighten the bolt and nut using

a phillips head screwdriver and 7mm

wrench.

Place the button spring and cap back onto

3.

the ignitor and thread it back on.

Test the ignitor: Make sure gas is off or

disconnected. Press the ignitor button and

check for a spark in the grill tub and the side

burner.

17

Page 17

Assembly Step 9 - Installing the Lid Handle

USE HARDWARE ”G”

M6 Wing

A B C

Nut (2)

M6 Flat

Washer (2)

No tools are required for this step.

LOCATE THESE PARTS:

Handle

Heat Shield

Bolt

Gasket (2)

Lid Handle

1. Align the lid handle bolts with the

mounting holes in the lid and set

the handle on the grill lid.

From the inside of the

2.

lid, thread on a gasket

onto each bolt.

3.

C

Place the Heat Shield

onto the bolts.

4.

B

Thread on a washer

and wing nut for each

A

handle bolt.

5.

Securely tighten the

wing nuts.

18

Page 18

Assembly Step 10 - Installing the Grids

LOCATE THESE PARTS:

Heat PlateCooking Grid

No tools are required

for this step.

2

2

1

1.2.Set the Heat Plate into the tub as

shown. It will rest on the lowest ledge

inside the tub, just above the burner.

Set the cooking grid into the tub. It will

rest on the topmost ledge of the tub.

19

Page 19

Assembly Step 11 - Install the Warming Rack

LOCATE THESE PARTS:

Warming Rack

Assembly

3.4.Work the other end of the rack into the

other side of the lid.

Insert the other foot of the warming

rack into the other side of the grill tub.

It will require slight bending to place

the foot into the mounting hole.

No tools are required for this step.

1.2.Position the warming rack as shown and

insert one end of the rack into the lid as

shown.

Working on the same side of the grill,

insert one foot of the warming rack into

the mounting hole near the top of the grill

tub.

1

3

2

4

20

Page 20

Assembly Step 12 - Install the Drip Cup

LOCATE THESE PARTS:

Drip Cup

Holder

Drip Cup

Grease

Drain

Hole

No tools are required for this step.

1.2.Underneath the grill tub, insert the drip

cup holder into the mounting holes on

either side of the grease drain hole.

Set the drip cup into the drip cup holder.

LOCATE THESE PARTS:

Indicator

Gasket

Heat Indicator

Heat

Indicator

Nut

Heat

1.2.Insert the stem of the heat indicator into

the front of the lid, through the name

plate as shown.

From the inside of the lid, thread on the

heat indicator gasket and nut. Securely

tighten.

10mm wrench required for this step.

21

Page 21

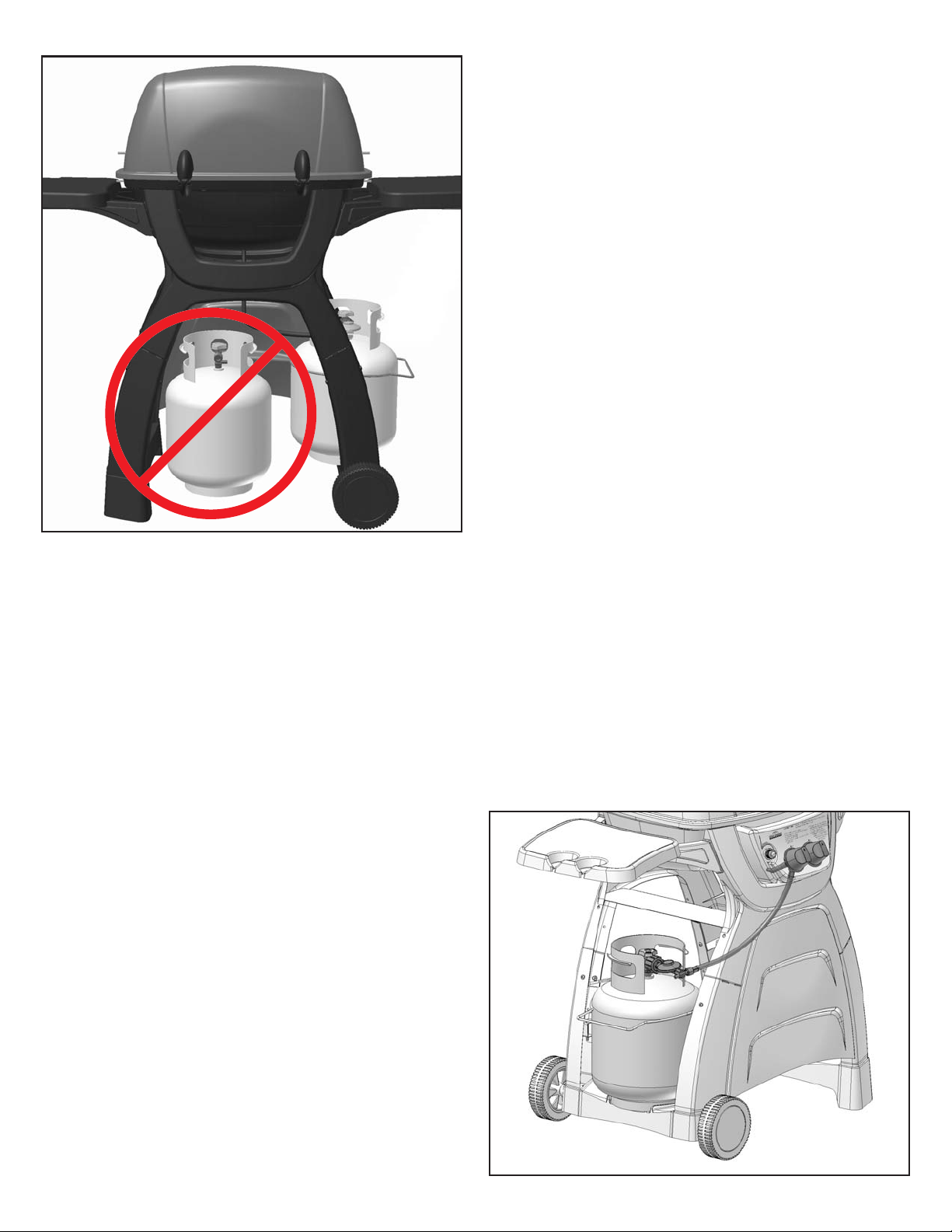

Assembly Step 13 - Attaching the L.P. Gas Cylinder

LOCATE THESE PARTS:

L.P. Gas Cylinder

()NOT INCLUDED

1.2.Lift the tank retainer wire up.

Set the L.P. Gas Cylinder onto the left

foot of the grill, resting it in the grooves.

In order to use your new grill immediately,

have your L.P. Gas Cylinder filled prior to

assembly.

4. Attach the regulator to the L.P. Gas

Cylinder valve.

Refer to the following page for

important L.P. Gas Cylinder

connection information.

3. Lower the tank retainer wire down

around the L.P. Gas Cylinder. Snap it

snugly around the tank.

Tighten

22

Page 22

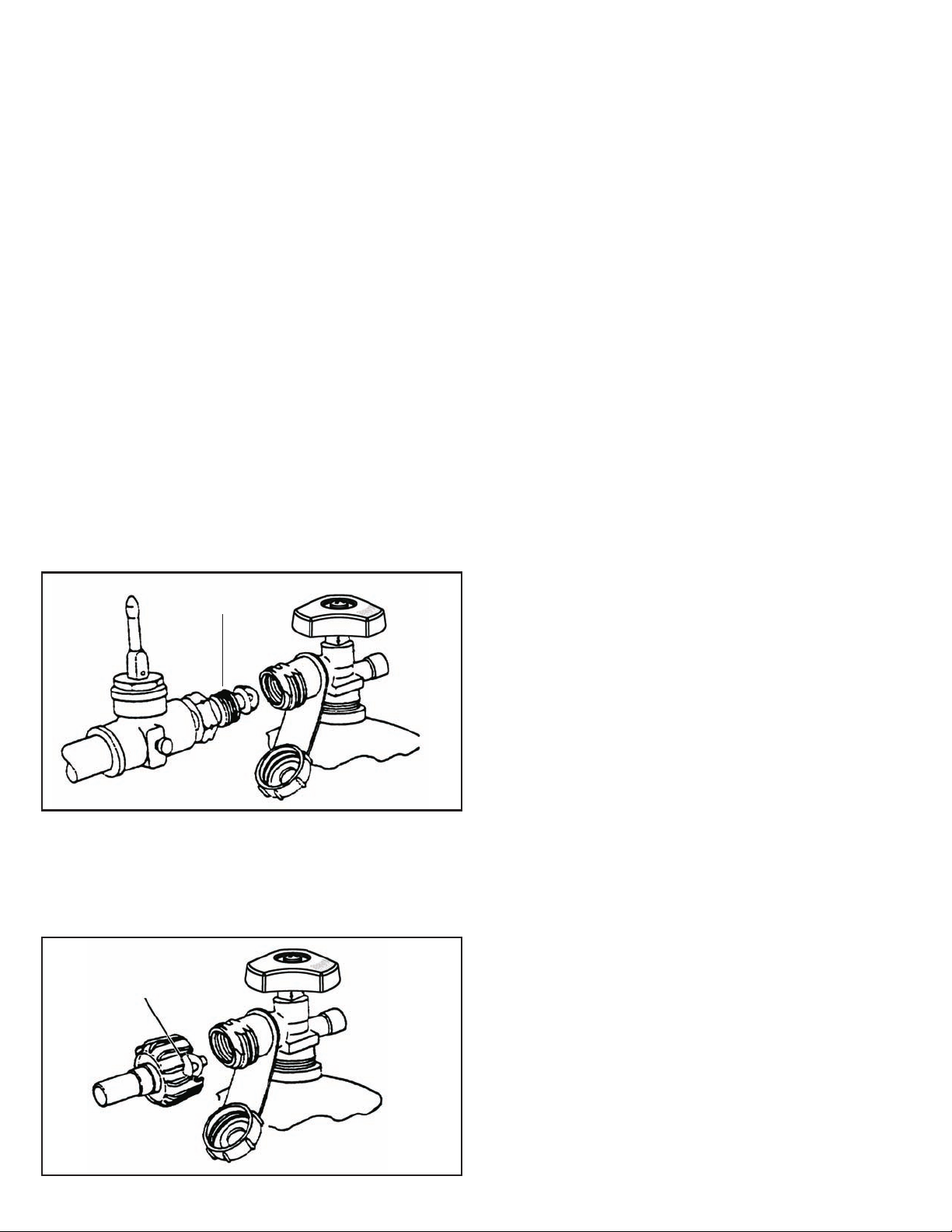

Connecting the L.P. Gas Cylinder

Connecting the Regulator to Cylinder

1. The top knob on the supply cylinder must

be closed. See that the top cylinder knob is

turned clockwise to a full stop.

2. Check that all the grill burner knobs are

turned off.

3. Remove the protective caps from the

cylinder valve and coupling nut, if present.

4. Hold the regulator in one hand and insert

the nipple into the valve outlet. Be sure the

nipple is centered in the valve outlet. The

coupling nut connects to the large outside

threads on the valve outlet. Use care not to

cross thread the connection.

5. Hand tighten the coupling nut clockwise

until it comes to a full stop. Tighten by hand

only. Do not use tools.

6. CAUTION: In the connection process,

the grill side of the connection will seal on

the back check in the valve, resulting in a

slight resistance. The connection requires

about one-half to three-quarters additional

turn to complete the connection.

NOTE: If you cannot complete the final

connection, disconnect the regulator and

repeat steps 4 through 6. If you are still

unable to complete the connection, do not

use this valve and regulator.

7. Make sure the hose has no kinks or

sharp bends and clears any areas that will

become hot during use. Never put strain on

the hose where it joins a fitting. The rubber

fuel supply hose must not touch the bottom

grill casting during use.

8. Before lighting grill, check all connections

for leaks using a mild soapy-water solution.

9. Maker sure the Drip Cup is in place

underneath the grill tub. During use the cup

will catch hot grease drippings that could

damage the fuel supply system.

23

Page 23

X-Frame Model Series Gas Grill

Use and Care Directions 3Chapter

Leak Testing the

Fuel Supply System

Lighting Instructions

Replacement Parts

25

Page 24

Leak Testing

Leak Testing the

Fuel Supply System

(arrows denote primary

areas to check)

DANGER

To prevent fire or explosion hazard:

· Do not smoke while performing a leak

test.

· Do not permit any sources of ignition

in the area when testing for leaks.

· Perform leak tests outdoors only.

· Never perform a leak test near a fire or

lame.

f

How to Check the Fuel Supply System for

Gas Leaks

1. Mix a solution of equal parts mild

detergent or liquid soap and water.

2. Turn off the burner control knobs.

3. Turn the top knob of the fuel-supply

cylinder counterclockwise one rotation to

open.

4. Apply the soap solution to all connections

of fuel-supply assembly.

Perform a leak test each time the gas

supply cylinder is connected to the regulator.

Leak test any time a part of the gas system

is replaced. Perform a leak test at least once

each year whether the L.P. gas supply

cylinder has been disconnected or not.

Have a dealer check the cylinder for

deterioration after 10 years, according to

DOT regulations. Immediately replace

cylinder if any is found.

IMPORTANT! Inspect the gas supply hose

regularly. If there are cuts, excessive

abrasion or wear, replace the hose prior to

operating the appliance.

Use only the hose replacement specified in

the parts list for your grill.

If no soap bubbles appear, the grill is fine

for use.

If bubbles form at the connections, there is

a leak. In case of a leak, try tightening the

joint. If necessary, replace the faulty part with

a replacement part recommended by the

manufacturer.

5. Turn off the knob on fuel-supply cylinder.

6. Turn on the burner control knobs for a

moment to release pressure in hose, then

turn the control knobs back off.

7. Wash off soapy solution with cold water

and towel dry.

WARNING: Do not attempt to repair the

cylinder valve. If it becomes damaged,

the cylinder must be replaced.

If you are unable to stop a leak, shut off the

gas supply at the cylinder valve. Remove the

cylinder from the grill. Call a gas appliance

serviceman or L.P. gas dealer. Do not use

appliance until the leak is fixed.

Leak Testing the

Fuel Supply System

(arrows denote primary

areas to check)

26

Page 25

Lighting Instructions

5

6

IGNITER LIGHTING SYSTEM

The Igniter System consists of an igniter unit,

a gas-collector box, one ceramic electrode,

and lead wires. Gas is collected in the metal

collector box located at the burner. When the

igniter knob is turned, an electric spark is

created at the ceramic electrode. The gas is

then ignited by the spark.

To test: Make sure the L.P. gas cylinder is

shut off or disconnected. Watch the electrode

tip inside the gas collector while activating the

igniter. To avoid a possible shock, do not touch

the burner or metal parts on igniter system

while performing igniter test. A visible spark

should jump from the electrode. The spark gap

is set when the electrode is installed.

If there isn't a spark, check the lead wires

and connections. The igniter wires should be

kept away from the grill bottom. Also check

that the ceramic electrode in the collector box

is not broken.

Sometimes dirt and rust at and around the

electrode can prevent an igniter spark. Clean

them with a degreaser or warm soapy water,

and dry. Remove rust from electrode tip and

metal surfaces by lightly sanding with an

emery cloth or fine-grain sandpaper.

The igniter battery may be removed and

replaced by un-screwing the igniter button.

STEP 4. Go behind the grill and turn on the

fuel supply valve on the L.P. gas cylinder.

Open the valve turns.

only 1-1/2

CAUTION: Do not stand with head or arms

over the grill.

STEP 5. To light using the igniter:

Push in and turn the left burner-control knob

counter-clockwise to the high (light) setting.

STEP 6. Immediately press the igniter button.

You will hear rapid clicks. Repeat if necessary.

The burner should light within 3-5 seconds.

STEP 7. If the burner fails to light properly,

turn the burner control knob off. Also turn off

the L.P. cylinder valve. Wait five minutes

before attempting to light the burner again.

This will allow time for released gas to

disperse.

HINT: If the burner does not light after trying

again, turn off burner-control knob, the L.P.

cylinder valve and try match lighting the grill

once the gas has cleared.

LIGHTING INSTRUCTIONS

(Read all the steps before beginning.)

STEP 1. Check the burner venturi tubes for

blockage from an insect nest (see,

“CLEANING THE BURNER VENTURI

TUBES”).

STEP 2. Ensure that both of the burnercontrol knobs are in the OFF position.

STEP 3.

OPEN GRILL LID

WARNING: Attempting to light the grill with

the lid down could cause an explosion.

5

6

Operating the Control Knobs

Use the LEFT burner gas control knob, PUSH

IN and rotate counter-clockwise to the HIGH

position.

PRESS THE IGNITER BUTTON UNTIL IT

CLICKS rapidly to light the burner.

27

Page 26

Lighting Instructions

MATCH LIGHTING

IMPORTANT: The match lighting hole is

found under the front right corner of the grill

bottom. When match lighting the grill, use the

gas control knob on your RIGHT-HAND side

(closest to the match lighting hole).

Repeat steps 1 to 4 of “Igniter Lighting

Instructions.”

STEP 5. To match light: push down and turn

the RIGHT burner control knob

counterclockwise to the high setting.

STEP 6. IMMEDIATELY strike a match and

position the burning match through match

lighting hole in the grill bottom. Extend the

flame near a burner port in the bottom edge of

the burner. The burner should light. (A match

holder is supplied in the hardware pack to hold

and extend the match into the burning

chamber.)

To light the other side of the burner, press in

and turn the opposite control knob. The flame

will track around the burner. Allow grill to

preheat with the grill lid closed for five to ten

minutes before cooking.

CAUTION: Do not touch any hot grill parts.

The outside of the grill bottom becomes very

hot during use. It may be necessary to use

protective gloves.

HOW TO SHUT OFF THE GRILL

STEP 1. Turn the burner-control knob(s) off.

The burner flame will go out.

STEP 2. Turn off the top L.P. cylinder valve

by turning the knob in a clockwise direction

until it stops.

IMPORTANT: Always have the gas shut off at

the L.P. cylinder valve when the grill is not in

use. The L.P. cylinder has a leak detection

feature which will restrict the amount of gas

flow to the burner if the

tank shut-off valve

has not been

turned off

prior to the

next use.

Locating the Match Lighting Hole

The match lighting access hole is located

underneath the bottom of the grill tub.

Match Light

Access Hole

28

Page 27

Model A053041 Replacement Parts

Replacement parts are available direct from our

warehouse. Some components are not available

preassembled and may be ordered separately. For

convenience, the following parts list is provided along

with a representation of the items listed. Charges for

replacement parts and shipping may apply.

For warranty replacements, proof of ownership and

Parts and Assemblies (See page 10)

description

Master Hardware Pack

Grill Head Assembly

Warming Rack

Cooking Grid

Heat Plate

Lid Handle

Drip Cup

Drip Cup Holder

Wire X-Brace

Wire Tank Retainer

Left Side Table Assembly

Right Side Table Assembly

Front X-Frame Assembly

Rear X-Frame

Left Leg

Right Leg

Left Foot (Tank Holder)

Right Foot

Wheel

Axle

Modesty Panel

Tank Heat Shield

part no.

AZ001354

See Right

AZ001319

AZ001355

AZ001356

AZ001320

AZ001314

AZ001315

AZ001357

AZ001358

See Right

See Right

See Right

AZ001302

AZ001305

AZ001306

AZ001359

AZ001360

AZ001310

AZ001361

AZ001311

AZ001362

Sub-Assemblies

description

Grill Head Assembly

Grill Lid

Heat Indicator / Nameplate

Left Hinge Assembly

Right Hinge Assembly

Grill Tub

Valve Mounting Bracket

HVR Assembly

Burner Control Knob

Venturi Assembly

Stainless Steel H-Burner

Ignitor Electrode Assembly

Left Side Table Assembly

Table Mounting Bracket (L)

Table Mounting Bracket (R)

Left Side Table

Side Bracket (Tub Mount)

date of purchase is required. Please call to receive a

return authorization number before returning any grill

components. To order parts call toll free

in the USA:

in Canada:

1-800-944-8982

1-800-668-5323

part no.

AZ001342

AZ001343

AZ001333

AZ001335

AZ001336

AZ001344

AZ001326

AZ001345

AZ001325

AZ001346

AZ001347

AZ001365

AZ001348

AZ001349

AZ001350

AZ001351

AZ001364

Right Side Table Assembly

Table Mounting Bracket (L)

Table Mounting Bracket (R)

Right Side Table

Side Bracket (Tub Mount)

Front X-Frame Assembly

Front X-Frame

Control Panel

Ignitor Module w/ Wires

Ignitor Battery

33

AZ001352

AZ001349

AZ001350

AZ001353

AZ001364

AZ001301

AZ001302

AZ001330

AZ001328

AZ000803

Loading...

Loading...