Page 1

SSEEFF,, PPEEFF && GGEEFF EE

XXHHAAUUSSTTFFAANNSS

DD

IIRREECCTT

DD

RRIIVVEE

RREEAADD AANNDD SSAAVVEE TTHHEESSEE IINNSSTTRRUUCCTTIIOONNSS FFOORR FFUUTTUURREE RREEFFEERREENNCCEE

RREEAADD AANNDD SSAAVVEE TTHHEESSEE IINNSSTTRRUUCCTTIIOONNSS FFOORR FFUUTTUURREE RREEFFEERREENNCCEE

AASSSSEEMMBBLLYY IINNSSTTRRUUCCTTIIOONNSS

MMOODDEELLSS SSEEFF--1100 TTHHRROOUUGGHH SSEEFF--2244

CCoonntteennttss::

Pre-assembled guard mount fan, shutter, shutter

mounting hardware kit, package of mounting screws.

To mount shutter to fan assembly:

1. Shutter mounting hardware kit includes: 4 rubber vibration

isolators, 4 nylon inserts, 4 screws (#12 x 1”) and 4 rubberized

washers.

2. Insert screws into washers - rubber side down.

3. Place nylon inserts into square holes of corner gussets at

rear of shutter.

4. Place shutter face down (gusset side up). Center vibration

isolators over nylon inserts.

5. Place fan assembly on shutter so that wire hooks on fan

guard are centered over vibration isolators and nylon

inserts. Junction box must be positioned at bottom with

shutter blades opening upwards.

6. Secure fan assembly to shutter using screws and washers.

7. Ensure that fasteners are snug. Do not over tighten to

avoid stripping nylon inserts.

MMOODDEELL SSEEFF--3300

CCoonntteennttss::

Pre-assembled guard mount fan, shutter, shutter

mounting hardware kit, package of mounting screws.

To mount shutter to fan assembly:

1. Shutter mounting hardware kit includes: 4 rubber vibration

isolators, 8 rubber inserts, 8 screws (#8-32 x 11/2”) and 8

rubberized washers.

2. Insert screws into washers - rubber side down.

3. Place rubber inserts into round holes of corner gussets at

rear of shutter. It may be necessary to twist and push or tap

lightly to seat rubber inserts properly.

4. Place shutter face down (gusset side up). Center vibration

isolators over rubber inserts.

5. Place fan assembly on shutter so that wire hooks on fan

guard are centered over vibration isolators and nylon

inserts. Junction box must be positioned at bottom with

shutter blades opening upwards.

6. Secure fan assembly to shutter using screws and washers.

7. Ensure that fasteners are snug. Do not over tighten to

avoid pulling out rubber inserts.

MMOODDEELLSS PPEEFF--1

100 TTHHRROOUUGGHH PPEEFF--3300

CCoonntteennttss::

Pre-assembled panel mount fan.

MMOODDEELLSS GGEEFF--1100 TTHHRROOUUGGHH GGEEFF--3300

CCoonntteennttss::

Pre-assembled guard mount fan.

IINNSSTTAALLLLAATTIIOONN && MMAAIINNTTEENNAANNCCEE GGUUIIDDEE

CCAAUUTTIIOONN!! TTHHEESSEE FFAANNSS AARREE DDEESSIIGGNNEEDD FFOORR GGEENNEERRAALL

VVEENNTTIILLAATTIIOONN UUSSEE OONNLLYY.. DDOO NNOOTT UUSSEE TTOO EEXXHHAAUUSSTT CCOORRRROO--

SSIIV

VEE,, HHAAZZAARRDDOOUUSS OORR EEXXPPLLOOSSIIVVEE MMAATTEERRIIAALLSS AANNDD VVAAPPOORRSS..

BBEEFFOORREE IINNSSTTAALLLLAATTIIOONN

WWAARRNNIINNGG!! TTOO RREEDDUUCCEE TTHHEE RRIISSKK OOFF FFIIRREE,, EELLEECCTTRRIICCAALL

SSHHOOCCKK,, OORR IINNJJUURRYY TTOO PPEERRSSOONNSS,, PPLLEEAASSEE OOBBSSEERRVVEE TTHHEE

FFOOLLL

LOOWWIINNGG SSAAFFEETTYY PPRREECCAAUUTTIIOONNSS::

1.

TThhiiss ffaann hhaass rroottaattiinngg ppaarrttss!!

Turn impeller by hand to ensure

that it rotates freely.

2. Ensure that electrical service to fan is locked in the

“

OOFFFF

” position to prevent power from being switched on

accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning

device such as a tag to service panel.

3. Do not re-establish power supply until fan and activation

device are completely installed.

4. Installation work, including electrical wiring, must be

performed by a qualified person in accordance with all

applicable codes and standards, including local fire codes.

5. Check voltage at f an to see that it corresponds to fan motor

nameplate rating.

6. Fan is intended to be hard wired to a properly rated

electrical circuit, and must be properly grounded. Do

not use an extension cord.

7. Fan motor is equipped with thermal overload protection,

which causes fan to shut off automatically if motor overheats.

If this should happen, immediately disconnect and lock power

supply to fan.

DDoo nnoott aatttteemmpptt ttoo wwoorrk

k oonn ffaann wwiitthhoouutt ddiissccoonn--

nneeccttiinngg ppoowweerr ssuuppppllyy;; ffaann mmaayy rreessttaarrtt wwiitthhoouutt wwaarrnniinngg!!

8. Fan should not be turned on and off rapidly.

9. Do not use fan with a solid state speed control device.

10. Do not allow fan to become wet or damp.

11. Do not block air intake or exhaust from fan.

12. Do not allow foreign objects to enter fan and come in

contact with fan blades.

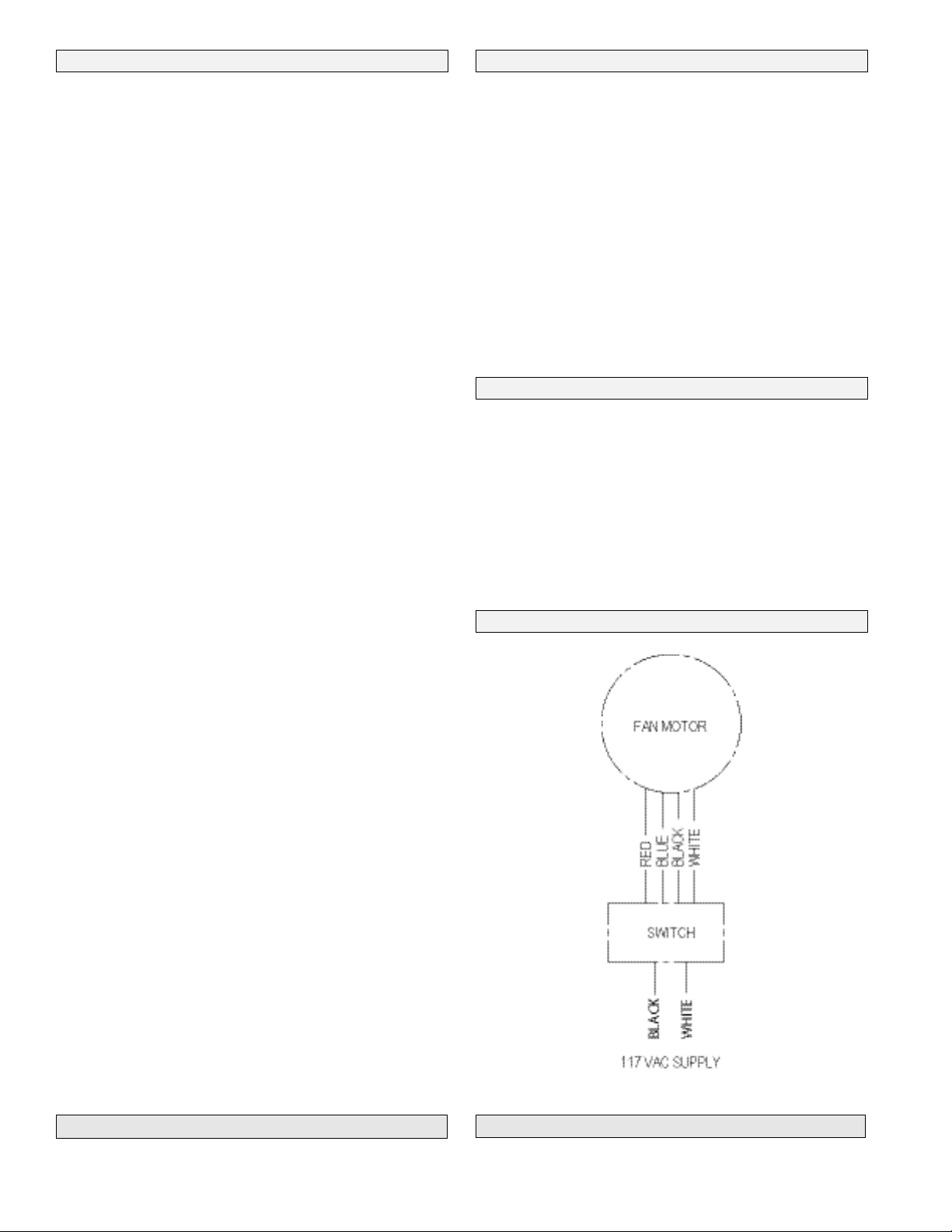

SSPPEEEEDD SSEELLEECCTTOORR SSWWI

ITTCCHH

Fan is equipped with either a 2-speed or 3-speed pull chain s witch,

allowing user to select desired airflow. Pulling a speed selector

switch repeatedly will cause fan speed to cycle as follows:

22--SSppeeeedd SSwwiittcchh::

OFF – FIRST SPEED – OFF – SECOND SPEED – OFF

33--SSppeeeedd SSwwiittcchh::

OFF – HIGH – MEDIUM – LOW – OFF

SSEEFF SSHHUUTTTTEERR MMOOUUNNTT FFAANN PPEEFF PPAANNEELL MMOOUUNNTT FFAANN GGEEFF GGUUAARRDD MMOOUUNNTT FFAANN

Page 2

USA

www.continentalfan.com

Canada

www.aeroflo.com

CCoonnttiinneennttaall FFaann MMaannuuffaaccttuurriinngg IInncc..

203 Eggert Rd.

Buffalo, NY 14215

Tel: 716-842-0670 Toll:800-779-4021 Fax: 716-842-0611

AAeerroofflloo IInncc..

12-205 Matheson Blvd. East

Mississauga, ON L4Z 3E3

Tel:905-890-6192 Toll: 800-779-4021 Fax: 905-890-6193

IINNSSTTAALLLLAATTIIOONN PPRROOCCEEDDUURREE

MMOODDEELLSS SSEEFF--1100 TTHHRROOUUGGHH SSEEFF--3300

When shutter is mounted to fan assembly:

1. Cut square wall opening size ½” larger than fan blade

diameter.

2. From inside of building / room, center fan assembly over

wall opening. Fan must be positioned so that junction box

is located at bottom and shutter is level and square, with

shutter blades opening upwards.

3. Lag fan to wall through mounting holes in shutter gusset,

using appropriate fasteners (by others).

4. Rotate fan impeller by hand, ensuring that it is unobstructed

and rotates freely.

5. Make electrical connections to fan junction box.

When shutter and fan assembly are mounted separately:

1. Cut wall opening size ½” larger than fan blade diameter.

2. From inside of building / room, center fan assembly over

wall opening. Fan must be positioned so that junction box

is located at bottom.

3. Lag fan to wall through wire hooks on guard, using the

appropriate fasteners (by others).

4. Apply caulking compound (by others) to rear of shutter

gusset.

5. From outside of building / room, center shutter over wall

opening, ensuring that shutter is level and square, with

shutter blades opening upwards.

6. Lag shutter to wall through mounting holes in shutter gusset,

using appropriate fasteners (by others).

7. Rotate fan impeller by hand, ensuring that it is unobstructed

and rotates freely.

8. Make electrical connections to fan junction box.

MMOODDEELL PPEEFF--1100 TTHHRROOUUGGHH PPEEFF--3300

1. Cut wall opening size ½” larger than fan venturi opening.

2. From inside of building / room, center fan panel assembly

over wall opening. Fan must be positioned so that

junction box is located at bottom.

3. Lag fan to wall through mounting holes in panel, using

appropriate fasteners (by others).

4. Rotate fan impeller by hand, ensuring that it is unobstructed

and rotates freely.

5. Make electrical connections to fan junction box.

MMOODDEELLSS GGE

EFF--1100 TTHHRROOUUGGHH GGEEFF--3300

1. Cut wall opening size ½” larger than fan blade diameter.

2. From inside of building / room, center fan assembly over

wall opening. Fan must be positioned so that junction box

is located at bottom.

3. Lag fan to wall through wire hooks on fan guard, using the

appropriate fasteners (by others).

4. Rotate fan impeller by hand, ensuring that it is unobstructed

and rotates freely.

5. Make electrical connections to fan junction box.

RREECCOOMMMMEENNDDEEDD MMAAIINNTTEENNAANNCCEE

1. When undertaking maintenance or service work, ensure

that electrical service to fan is locked in the “OFF” position

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device such as a tag

to service panel.

2. Do not re-establish power supply until maintenance or

service work has been completed.

3. Maintenance or service work must be performed by a qualified person in accordance with all applicable codes and

standards, including local fire codes.

4. Motor bearings are factory lubricated and do not require

additional lubrication.

5. Remove airborne contaminants that have settled on motor

using an air hose or vacuum.

6. Clean fan blades, guard or shutter using a mild detergent.

Do not allow cleanser to come in contact with fan motor or

electrical parts.

LLIIMMIITTEEDD WWAARRRRAANNTTYY

This equipment is warranted to be free from defects in material

and workmanship for a period of one (1) year from date of

purchase. Any units or parts which prove to be defective

during warranty period will be repaired or replaced at

Vendor’s option. Vendor is not responsible for any removal,

installation or transportation costs.

Motors are warranted separately by motor manufacturer for

a period of one (1) year, and should be returned to nearest

authorized motor service center for repair.

All warranty claims must be processed through point of purchase.

WWIIRRIINNGG PPRROOCCEEDDUURREE

SEF-PEF-GEF I&M-0710

Loading...

Loading...