CFM CR Series, BCMH Series, BFC Series, BR Series, CVR Series Homeowner's Manual

...

How to Enjoy

Your Woodburning Fireplace

Beaucoup de plaisir avec votre foyer à bois

BC, BCMH, BFC, BR, CR, CVR, EWF, ODSHR, ODSR, SC,

SHR, SR, STR, TF, TL, TSH, TST and WMC Series Fireplaces

FOYERS SÉRIES BC, BCMH, BFC, BR, CR, CVR, EWF,

ODSHR, ODSR, SC, SHR, SR, STR, TF, TL, TSH, TST et WMC

Save This Homeowner’s Manual

Conservez ce manuel du propriétaire

20000706 2/07 Rev. 11

Table of Contents

Meeting Your Fireplace .................................................................... 3

How to Operate Your Fireplace ........................................................

Operating Precautions ..................................................................... 9

Maintenance and Care of Fireplace ............................................... 10

Troubleshooting Guide .................................................................. 11

Accessories .................................................................................... 13

Table des Matières

Faites connaissance avec votre foyer ........................................... 16

Mode d’emploi de votre foyer ........................................................ 18

Mesures de précaution .................................................................. 23

Entretien et soins du foyer ............................................................. 24

Guide de dépannage ..................................................................... 25

Accessoires .................................................................................... 27

5

2 20000706

Meet Your New Woodburning Fireplace

Your new fireplace is a highly engineered system

designed to provide maximum pleasure with troublefree operation. It can only perform to its fullest potential

if you operate and care for it properly. This manual is

provided to help you do that.

The first things you should know are the basic parts

of your particular fireplace model and what each part

does. This will give you a better understanding of the

descriptions that follow in this manual. It is important

to note that all of these parts have been engineered

to work together. If you decide to use some unapproved part or make any modification, the fireplace

will not operate as it was engineered to and, therefore, may possibly cause a fire hazard.

CFM Corporation warranty will be voided by, and

CFM Corporation disclaims any responsibility for

the following actions:

• Installation of any damaged fireplace or chimney

component;

• Modification of the fireplace, chimney assembly

or any of the component parts thereof; (except

for chase flashings as detailed in CFM Corporation

Chimney Top installation instructions).

• Installation other than as instructed by

poration

CFM Cor-

or

• Installation and/or use of any component part not

manufactured or approved by

combination or assembly with a

fireplace system, notwithstanding any independent testing laboratory or other third party approval of such component parts or accessory.

Any of the above actions may possibly cause a fire

hazard.

CFM Corporation

CFM Corporation

in

WARNING

Risk of fire! Do not install a firescreen on

this prefabricated fireplace. A firescreen

will prevent proper ventilation and increase

the risk of a chimney fire.

NOTE: Remove the warranty card from the plastic bag in which you found this owner’s manual.

The warranty for your fireplace is located on the

back page of the installation instructions. Keep the

warranty in a safe place for future reference if you

should ever need service covered under this warranty. Fill out the warranty card and mail it to CFM

Corporation. In order to validate your warranty, it is

mandatory that you write the serialization number

(a series of letters and numbers located below the

model number) on the warranty card. The serial

number is stamped into the black plate attached to

the inner dome side of the firebox.

For better understanding of your fireplace, familiarize

yourself with the following parts and terminologies used

in this manual:

The firebox is the main cavity of the fireplace where

the fire is built. Its shape and size are designed to

promote efficient burning of the fire and to reflect the

maximum amount of heat through the fireplace opening

into the room.

The hearth is the floor of the firebox. It is made of a

refractory material and functions as a base for the fire

grate to rest on.

The chimney is the complete vertical structure that

houses the flue. With CFM Corporation fireplaces, the

chimney utilizes a special air-cooled design that keeps

the outside of the chimney from getting too hot.

The flue is the innermost passageway of the chimney

system through which the smoke and gases from the

fire travel to the out-of-doors.

The damper is the door to the flue that prevents loss

of heated room air from escaping up the flue when

the fireplace is not in use. The damper must be in the

open position whenever fire is burning so that smoke

and gases can escape up the flue rather than into the

room. It should not be closed until the fire is completely

out. The BR, BC, BCMH, TF, TL, CR, SR, ODSR, SC,

SHR, ODSHR, TSH, STR, TST, CVR and EWF Series

fireplace damper operates only in the full open or full

closed position. The control is located in the front firebox dome areas. (Figs. 1, 2, 3, 4 & 5)

The EWF damper is open to start or revive the fire and

closed, for normal operation and to control burn rate.

NOTE: Always open the damper before opening the

doors. Close damper to set burn rate.

The WMC Series fireplace damper is adjustable to help

provide a more efficient fireplace operation. Dampering

down the open flue further intensifies the firebox heat

exchanger temperature by reducing the loss of hot flue

gases. The adjustable damper control is located in the

center just below the top outlet grille. (Fig. 1) Refer to

Proper Operating Procedure on Page 4.

20000706

3

The firescreen is a protective curtain of wire mesh that

helps keep sparks and hot embers from leaving the

firebox. The firescreen should always be kept closed

whenever a fire is burning in the firebox.

Your fireplace may also include many of the following

energy efficient components that provide additional

heat output and efficient home operation:

Heat-Circulation adds to the standard radiant heat

output of a traditional fireplace by distributing useful

amounts of convective heat into the home. Heat-circulating fireplaces circulate cool room air around the hot

firebox where it is warmed and returned to the room as

beneficial heat. The BC, BCMH, TL, SC, WMC, BFC

and EWF Series fireplace models feature heat circulation.

The Heat Exchanger is a multiple wall construction

that directs room air around the firebox and back into

the room of a heat-circulating fireplace system. Heat

transfer from the hot fire to the circulating room air occurs through these passageways. The heat exchanger

is the heart of a heat-circulating system which provides

the extra room heat that is lost with conventional fireplaces.

The Air Inlet/Outlet Grilles are part of the heat-circulation system. Cool room air enters through the bottom

grille and/or lower side inlet grilles and travels through

the heat exchanger passageways. The resulting hot air

is then returned to the room through the upper outlet

grille.

NOTE: Air inlet/outlet grilles should never be covered or blocked off. The heat-circulation system

is also used as fireplace cooling system for safe

operation.

Outside Combustion Air: A fire requires a sufficient

amount of air in order to burn properly. Insufficient air

will cause smoking, sooting and harmful gases to filter

out of the fireplace into the room. As the fire burns in

the firebox, replacement air enters the firebox opening

from the room to make up the loss of combustion air.

Often tightly sealed and well insulated homes do not

provide sufficient amounts of air for this natural replacement process. To maintain a constant flow of combustion air, direct outside air may be needed.

CFM Corporation fireplaces are designed with outside

air capabilities which supply outside combustion air

directly to the firebox. The air system requires ducting

from fireplace to an outside air source at time of original

installation. The WMC, BR, BC, BCMH, TF, TL, CR, SC,

SHR, ODSHR, TSH, SR, ODSR, STR, TST and CVR

Series fireplaces offer this feature as standard equipment. The BFC fireplace includes integral outside air

and no additional ducting is necessary.

If your fireplace is equipped with outside air, the control

lever will be located at the front edge of the left side

brick on the BR, TF, SR, ODSR, WMC, STR and TST

Series. On the CR Series fireplaces, it is located at the

lower left or right corner of the air inlet. On the SHR,

ODSHR and TSH Series, the control lever is located in

the center, just above the left side brick. Refer to Page

6 for proper operation procedure.

Primary Air Control: On the EWF Series fireplace, the

primary air control regulates the amount of heat the fire

will produce and how long it will burn. The primary air

control is located in the upper left corner of the unit. It

is the primary source of air for starting, maintaining and

reviving the fire.

The air supply is open to the maximum when the control

lever is rotated clockwise on the EWF36A or pushed

down on the EWF30 and closed when rotated counterclockwise on the EWF36A or pushed up on the EWF30.

To vary the burn rate, adjust the control to the desired

position in between these extremes; opening the

primary air control makes the unit burn hotter. Closing

the control slows the unit down. You can adjust to any

position you desire.

Glass Doors improve fireplace efficiency to help save

home energy. When firing a fireplace, the need for

combustion air draws room air into the firebox where it

mixes with the hot flue gases and then is expelled up

the open flue. The loss of preheated room air is most

significant when burning a low intensive fire which

normally occurs during start-up and shutdown of the

fireplace. CFM Corporation glass doors are specially

designed to reduce the amount of heated room air

loss and, at the same time, allow the proper amount

of combustion air to be filtered into the firebox for safe

operation.

When using glass doors on a heat-circulating fireplace,

the controlled combustion air also intensifies the heat

exchanger temperature and slows the fuel burning rate.

The result is maximum heating while using the least

amount of fuel. Glass doors are standard equipment on

WMC, BFC and EWF Series fireplaces and are offered

as optional accessories for all other CFM Corporation

fireplace models. Refer to proper operation procedures

on Page 6 and 7.

Forced Air Circulation: Heat-circulating fireplaces use

the natural process of hot air rising to distribute heat

from the fireplace to the room. This principle is sufficient for small room application. To distribute a constant

flow of warm air further into a larger room, forced air

fans are recommended. To determine if the fireplace is

equipped with fans, use a flashlight and look through

the lower inlet air grille. CFM Corporation offers optional

fan kits for all heat-circulating models. For easy installation of an optional fan kit, the fireplace should be wired

4 20000706

CLOSED

OPEN

OPEN DAMPER BEFORE CLOSING DOORS

CLOSED

PARTIALLY

OPEN

FULLY

OPEN

during its installation. Fans are standard equipment for

WMC and BFC units.

NOTE: CFM Corporation Forced Air Systems are

designed to distribute heat at a specific cfm rate.

Any attempt to increase air movement through the

heat exchanger will decrease the heat transfer time

which will result in cooler heat circulation temperatures.

Energy efficient options such as glass doors and fans

(Heat-circulating models) can easily be added after

your original fireplace installation. Refer to Page 11 for

description and proper model number.

How to Operate Your Fireplace

Your fireplace can provide countless hours of pleasure

and security. However, use your fireplace carefully

because any time you build a fire inside a house, a

problem may develop.

1. Open Flue Damper

The flue damper is meant to be closed only when the

fire is completely out and the fireplace is not in use.

This prevents the loss of room air up the open flue. Re

member, the damper must always be in the “fully open”

position when a fire is burning.

WMC Damper: The WMC Series fireplace flue damper

is “opened” and “closed” by a knob located just below

the top outlet grille. (Fig. 1) The damper is adjustable

and may be adjusted to a partially open position as

long as the glass doors are closed and smoke buildup

does not occur in the firebox. Most efficient operation is

obtained in the least open position. When refueling, fully

open damper before opening glass doors.

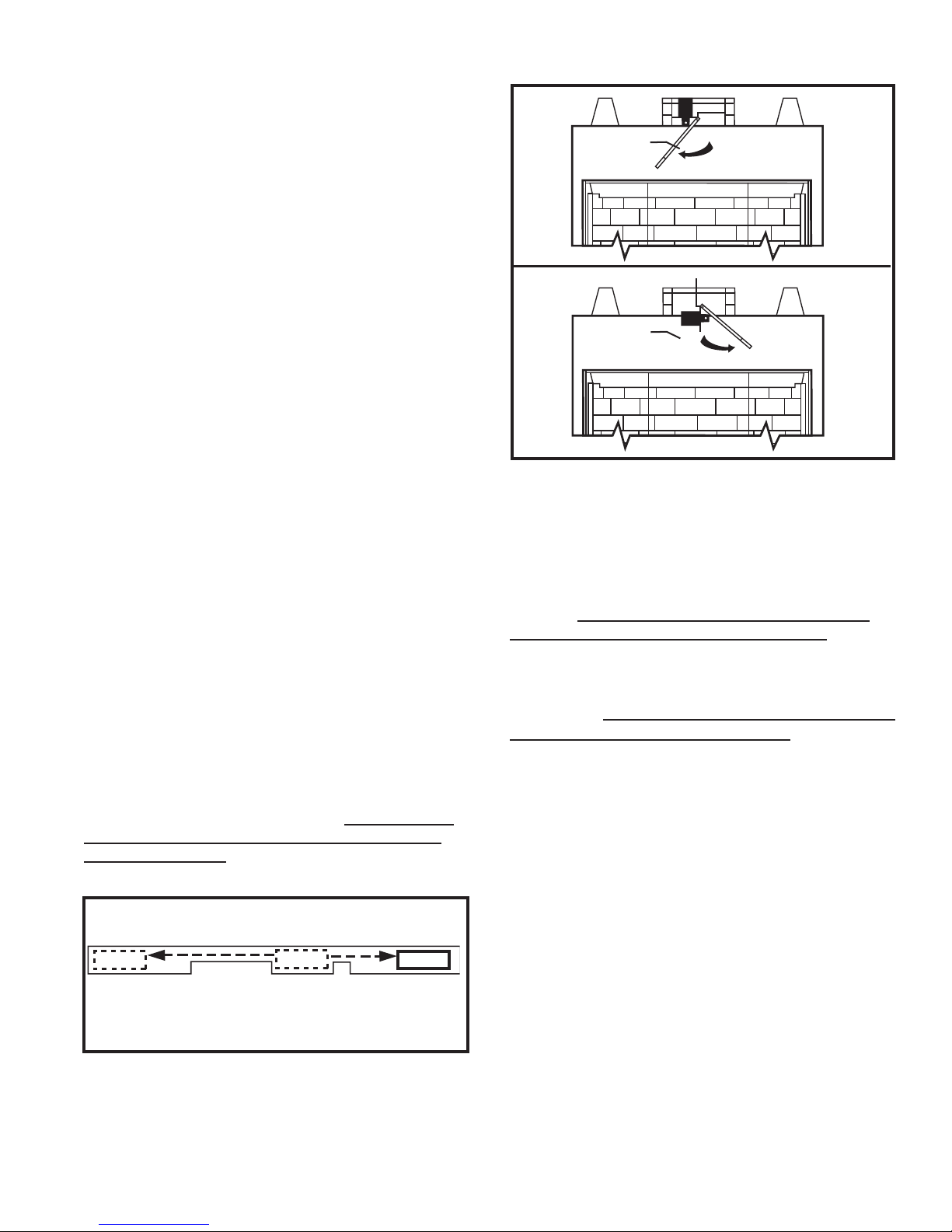

BR, BC, BCMH, TF, TL, CR, SR, ODSR and SC Se

ries Damper: The flue damper is located in the dome

area in the middle of the firebox. The damper is opened

by rotating the lever to the right. The damper is closed

by pushing the lever to the left and is locked closed by

the damper clip located on the dome. The damper is

not adjustable and must only be operated in the

fully open position. (Fig. 2)

-

-

MD706-2

Fig. 2

BR, BC, BCMH, TF, TL, CR, SR, ODSR & SC Series

damper control positions.

STR, TST & CVR Series Damper: The flue damper

is located in the dome area in the middle of the firebox. The damper is opened by pushing the lever in an

upward direction. The damper is closed by pulling the

lever down toward the hearth brick at the bottom of the

fireplace. The damper is not adjustable and must

only be operated in the fully open position. (Fig. 3)

SHR, ODSHR & TSH Series Damper: The flue damp-

er is “opened” and “closed” by an actuator handle and

linkage located in the front of the combustion dome of

the fireplace. The damper is not adjustable and must

be operated in the fully open position. (Figs. 4 & 5)

EWF Series Damper: The flue damper control is locat-

ed in the upper right corner of the fireplace. The damper

is open when the lever is rotated clockwise and pulled

out on the EWF36A and pulled out on the EWF30.

Open the damper to start or revive a fire. The damper is

closed when pushed in. For the EWF36A only, when the

damper is in the open position, with the lever pulled out,

and rotated in the fully clockwise direction, the handle

can ‘telescope’ back without closing the damper or any

damper movement. There are no intermediate settings

for the damper.

Fig. 1 WMC Series damper control positions.

20000706

MD706-1

5

Damper

Control

To Open

To

Close

Side View

Damper

CLOSED

OPEN

MD706-3

Fig. 3 STR, TST & CVR Series damper control positions.

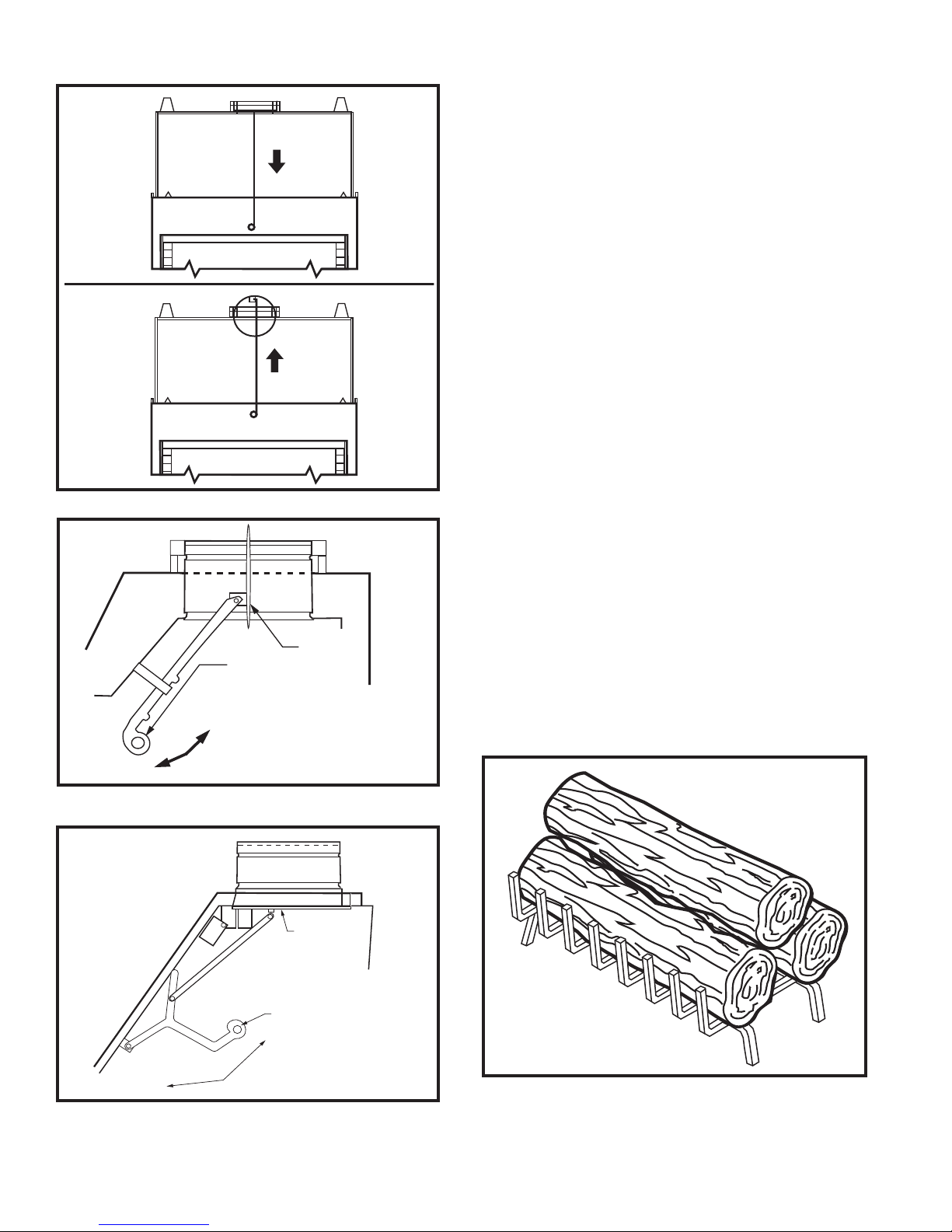

2. Building the Fire

To build a fire, a basket grate should be used to raise

the fuel off the hearth. Combustion air needs to flow up

through the fuel for proper burning. Most CFM Corporation fireplaces come equipped with a basket grate.

A specially designed basket grate is required for your

fireplace. When replacing the basket grate, a specific

model must be used. Refer to Page 11 for the model

number.

The EWF does not use a basket type grate. Build the

fire directly on the grate. Do not elevate the wood.

Place a generous amount of crumpled or twisted newspaper under the grate on the hearth. Allow a few ends

of the paper to extend out beyond the log area for later

lighting. Arrange kindling (small diameter sticks) in a

crisscross pattern on top of the paper.

Place a large diameter log, preferably one that has

been split, across the grate within approximately 1/2” of

the back wall of the fireplace. Place a second split log

1” to 2” in front of the first log. Place a third split log on

top of the other two, forming a crude pyramid. Be sure

the irregularities of the logs form air spaces between

the logs. (Fig. 6) If they do not, place a few sticks of

kindling between the logs to separate them slightly.

Additional logs may be added as needed to maintain

heat output. Logs should be split preferably in quarter

sections or smaller pieces. Split logs have more burning surfaces than whole logs and burn more readily.

The type and condition of wood that you use to build

your fire will have a great effect on the heat output of

your fireplace. For best results use oak, maple, birch,

hickory, apple or similar hardwoods. The wood should

be dry and seasoned 9 months to a year before use.

Fig. 4 SHR36, SHR42A, SHR48, ODSHR42, TSH36, TSH42

Series damper control positions.

Damper

Damper Handle

To Close

To Open

Fig. 5 SHR52 & TSH52 damper control.

6 20000706

MD706-6

MD706-9

MD706-5

Fig. 6 Log placement on grate.

CLOSED

OPEN

Closed

Open

Soft woods, are not as desirable as hardwoods because they burn quickly and can cause resin build up

in the flue. Wet or green wood smolders and often

smokes.

The use of artificial logs of any type has

been found to create smoking and sooting

problems. These types of materials have

also been found to increase the danger

of fire. For these reasons the use of any

type of artificial log is prohibited in any of

our products. The use of any artificial logs

will void any warranty associated with our

products.

Caution: Do not burn scrap lumber, pine branches,

trash, plastic, flame colorants, soot cleaners or

other chemicals or compounds.

3. Starting the Fire

Before starting the fire, make sure the damper is in the

fully open position.

Lay a sheet of newspaper on top of the logs and set it

afire. This warms the chimney, improving the flow of hot

air from the fire when it is started.

When warm-up newspaper is partially burned, ignite

the starter paper under the kindling. Close the fireplace

screens as soon as you have completed this step.

When firing a new fireplace, you may smell a slight odor

and see smoke coming from the fireplace or the heatcirculating outlet grilles. This is the paint curing and oil

burning off the metal. This is normal and will disappear

after the first few fires. If your fireplace is equipped with

glass doors and outside air, open the doors and close

the outside air. The odors and smoke will be drawn into

the firebox and expelled up the flue.

NOTE: Never use gasoline, gasoline type lantern

fuel, kerosene, charcoal lighter fluid or similar

liquids to start or ‘freshen up’ a fire in this fireplace

while it is in use.

4. Open Outside Air Damper

Your fireplace may be equipped with outside combustion air. To determine, refer to “Outside Combustion Air”

on Page 3.

If your fireplace has outside air, the air damper should

be ‘closed’ prior to starting fire. Start the fire and allow

the firebox to preheat 5-10 minutes, then ‘open’ the

air damper. The heat from the hot firebox will draw the

outside air in more effectively.

CR Air Damper. To ‘open’, push control rod to right

and pull out. To ‘close’, push control lever away from

the front face until it stops. Damper is spring-loaded and

will hold closed.

BR, BC, BCMH, TF, TL, SR, ODSR, SC, STR, TST,

CVR, WMC Series Air Damper. To ‘open’, push the

control lever down toward the hearth brick. To ‘close’,

pull the control lever up and over. (Fig. 7)

SHR, ODSHR, TSH Air Damper. To ‘open’, push con

trol lever up and back. To ‘close’, pull lever forward and

down. (Fig. 8)

NOTE: To ‘open’ or ‘close’ damper during firing,

use a long metal probe such as a fireplace poker

to operate lever. Do not use your hand as control

lever is hot.

FP710

Fig. 7 Outside air operation.

FP710a

Fig. 8 SHR & TSH Series outside air operation.

5. Primary Air Control

The EWF has a single air control that regulates the

amount of heat the fire will produce and how long it will

burn.

The Primary Air Control is located in the upper left cor

ner of the unit. It is the primary source of air for starting,

maintaining and reviving the fire.

Generally, more air entering the fireplace makes the fire

burn hotter and faster, while less air prolongs the burn.

The air supply is open to the maximum when the control

lever is rotated clockwise on the EWF36A or pushed

down on the EWF30 and closed when rotated counterclockwise on the EWF36Aor pushed up on the EWF30.

20000706

7

NOTE: The BFC36 fireplace should be operated only

with the doors closed.

BR, BC, BCMH, TF, TL, SHR, ODSHR

TSH, SR, ODSR, SC and WMC SERIES

STR, TST, and CVR SERIES

BFC36

CR SERIES

RIGHT

RIGHT

RIGHT

WRONG

CLOSED

OPEN

CLOSED

OPEN

CLOSED

OPEN

CLOSED

EWF36

CLOSED

OPEN

Optional Spark Screen

RIGHT

WRONG

CLOSED

OPEN

Optional Spark Screen

EWF30

To vary the burn rate, adjust the control to the desired

position in between these extremes; opening the

primary air control makes the unit burn hotter. Closing

the control slows the unit down. You may adjust to any

position you desire.

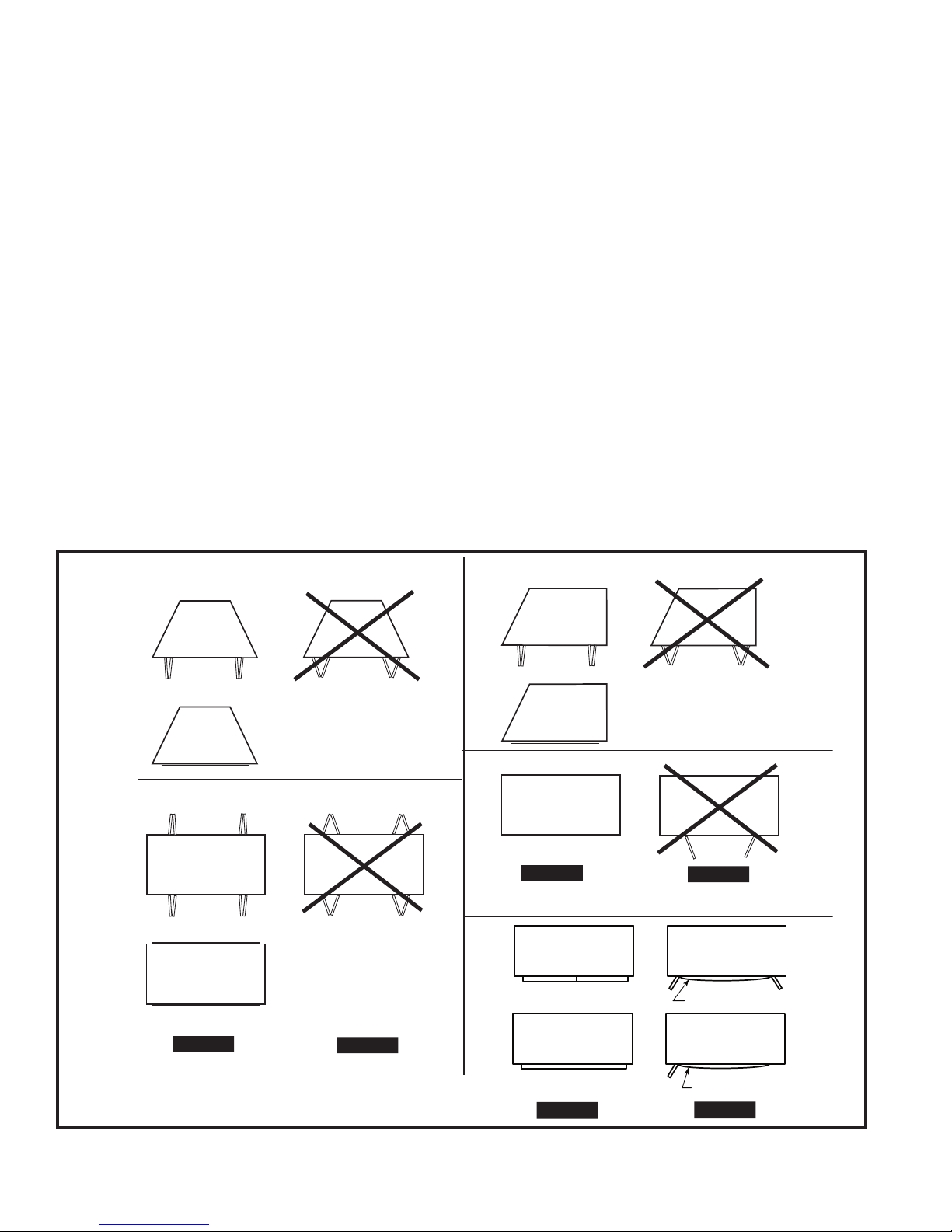

6. Operating Glass Door

WARNING: Use only glass doors approved by CFM

Corporation for use with your particular fireplace.

If your fireplace is equipped with glass doors, start the

fire and leave the doors fully open. AFTER the fire is

well started, then the doors may be closed. We recommend for the most efficient use of glass doors on

all models of CFM Corporation fireplaces, except for

models BFC, EWF and WMC Series, that doors must

be fully open when firing at a ‘moderate’ to ‘hot’ rate.

Firing at a ‘low’ to ‘moderate’ rate or allowing fire to die

out, doors should be closed. The BFC, EWF and WMC

Series fireplaces are designed for maximum heat output with doors fully closed at all times.

NOTE: The BFC fireplace should be operated only with

the doors fully closed.

NOTE: The EWF fireplace should be operated only

with the doors fully closed or fully open only when the

optional spark screen is installed.

WARNING: FIREPLACES EQUIPPED WITH DOORS

SHOULD BE OPERATED WITH DOORS FULLY

OPEN OR DOORS FULLY CLOSED. IF DOORS ARE

LEFT PARTLY OPEN, GAS AND FLAME MAY BE

DRAWN OUT OF THE FIREPLACE OPENING CRE

ATING RISKS OF BOTH FIRE AND SMOKE. Refer to

Figure 9 for correct door positions.

Do not close the glass doors on an excessively hot fire.

This could remove the temper from the glass, causing

it to crack into small pieces. The glass must be allowed

to warm slowly. The tempered glass in the doors will

withstand a gradual temperature rise to 550° F, which

is more than a normal fire will create. An excessively

hot fire can be created by such things as pitch laden

logs, very dry mill end lumber or large amounts of paper

or cardboard cartons. Keep the fire well back from the

doors and never let flames contact the glass.

Breakage may occur if the glass doors are mishandled.

Always use caution when operating the doors and do

not slam or force them into position.

MD706-7

Fig. 9 Top view of glass door operation.

8 20000706

Please note that under moderate firing, some discoloration may occur on brass door frames. Keeping the fire

small and toward the back of the fireplace will prevent

this discoloration.

7. Operating Fan

If your fireplace is heat-circulating with a fan option,

build the fire in the normal manner with the fan(s) ‘

OFF’.

Preheat your firebox and heat exchanger system for 20

- 30 minutes. After a good fire has developed, turn the

fan switch to the ‘ON’ position and heated air will immediately flow from the grille.

8. Tending the Fire

The heat output of a fireplace depends on how well

you build and tend the fire. A well-tended fire assures a

constant heat output. Keep the fire burning at a con

stant level by adding additional logs as necessary. Use

a poker to push the burning logs together into a tight

group at the back of the fireplace each time you add

new logs. Keep the bed of hot ashes located directly

under the logs. This aids in maintaining the fire, but do

not let the ashes get so deep that they interfere with

adequate air flow up through the logs.

Except when adding logs to the fire, the firescreen

should always be kept closed whenever there is a fire

burning in the firebox.

9. At the End of the Day

If your fire has not burned itself out by bedtime, you

may wish to use your tongs to stand any burning logs

on end in the corners of the firebox. In this position,

they usually will quickly burn out and will provide good

base for your next fire. Be sure the firescreen or glass

doors are kept closed and the damper kept open until

the fire is completely out.

10. Disposal of Ashes

Clean the ashes from the firebox before starting each

fire. Ashes should be placed in a metal container with

a tight fitting lid. The closed container of ashes should

be placed on a noncombustible floor or on the ground,

well away from all combustible material, pending final

disposal. If the ashes are disposed of by burial in soil

or otherwise locally dispersed, they should be retained

in the closed container until all cinders have thoroughly

cooled.

Leave only enough ashes to insulate the cold hearth so

the fire will start faster. Excessive ash levels will slow

the burning of your fire and cause your grate to burn out

quickly.

11. Operation of BFC36, Clean-Burning Fireplace

The BFC36 fireplaces have been designed specifically

to reduce smoke and hydrocarbon emissions; however,

the performance of these fireplaces depends on proper

operation. In order to reduce emissions use only well

seasoned firewood. Avoid slow burning smoldering

fires and maintain a hot coal bed on which to place new

wood.

High firebox temeratures help to ensure effective opera

tion of these clean-burning models.

The BFC36 clean-burning fireplaces must be burned

with the cabinet doors fully closed in order to reduce

emissions. Any modifications to the internal components of these fireplaces will likely cause an increase in

emissions. Always use the correct model grate and do

not remove any brick components, baffles or hardware

from the firebox.

12. Operation of EWF36A fireplace.

The EWF36A meets the US Environmental Protection

Agency’s emission limts for wood heaters sold after

July 1, 1990.

The catalytic combustion system in your EWF produces

the best conditions for secondary combustion.

When the stove damper is closed, smoke goes through

the catalytic element, burning at temperatures of

500-600°F (260-315°C), half the temperature normally

needed for unaided secondary combustion.

The catalytic element is a ceramic “honeycomb” coated

with a noble metal, usually platinum. The element is in

the secondary combustion chamber, made of a special high-temperature insulating refractory material.

The chamber provides the correct environment necessary for secondary combustion of the fuel (smoke).

Closing the damper may also reduce draft. Closing

the damper too soon may put out the fire or deactivate

the combustor. Close the damper only when the fire is

well established. When starting a fire, wait until there is

an ember bed of at least 3-4 inches before closing the

damper.

13. Operation of EWF30

The EWF30 meets the US Environmental Protection

Agency’s emission limits for wood heaters sold after

July 1, 1990.

The non-catalytic combustion system produces the

proper conditions for secondary combustion.

When the damper is closed, smoke goes through the

refractory combustion chamber at the back of the until.

Inside this chamber is where the secondary combustion

occurs.

Like the EWF36A, closing the damper too quickly is

detrimental to secondary combustion. When starting a

fire, wait until there is an ember bed of at least 3” - 4”

(76-102 mm) before closing the damper.

-

20000706

9

Loading...

Loading...