better AIRFLOW

by DESIGN

TM

Custom Fan SolutionsTM

• Airfoil adjustable pitch cast aluminum impeller

• Superior performance and sound characteristics

• Advanced computer selection program

• Unit can be built for supply or exhaust configurations

• Heavy gauge steel with baked polyester coating

• GRP [polypropylene] blades available

• Ideal for OEM use or as replacement fans

• Capacities to 34,000 cfm from stock components

PANEL & FLANGE FANS

AFK

DIRECT DRIVE

FLANGE FANS

AAFFKK FFLLAANNGGEE FFAANN

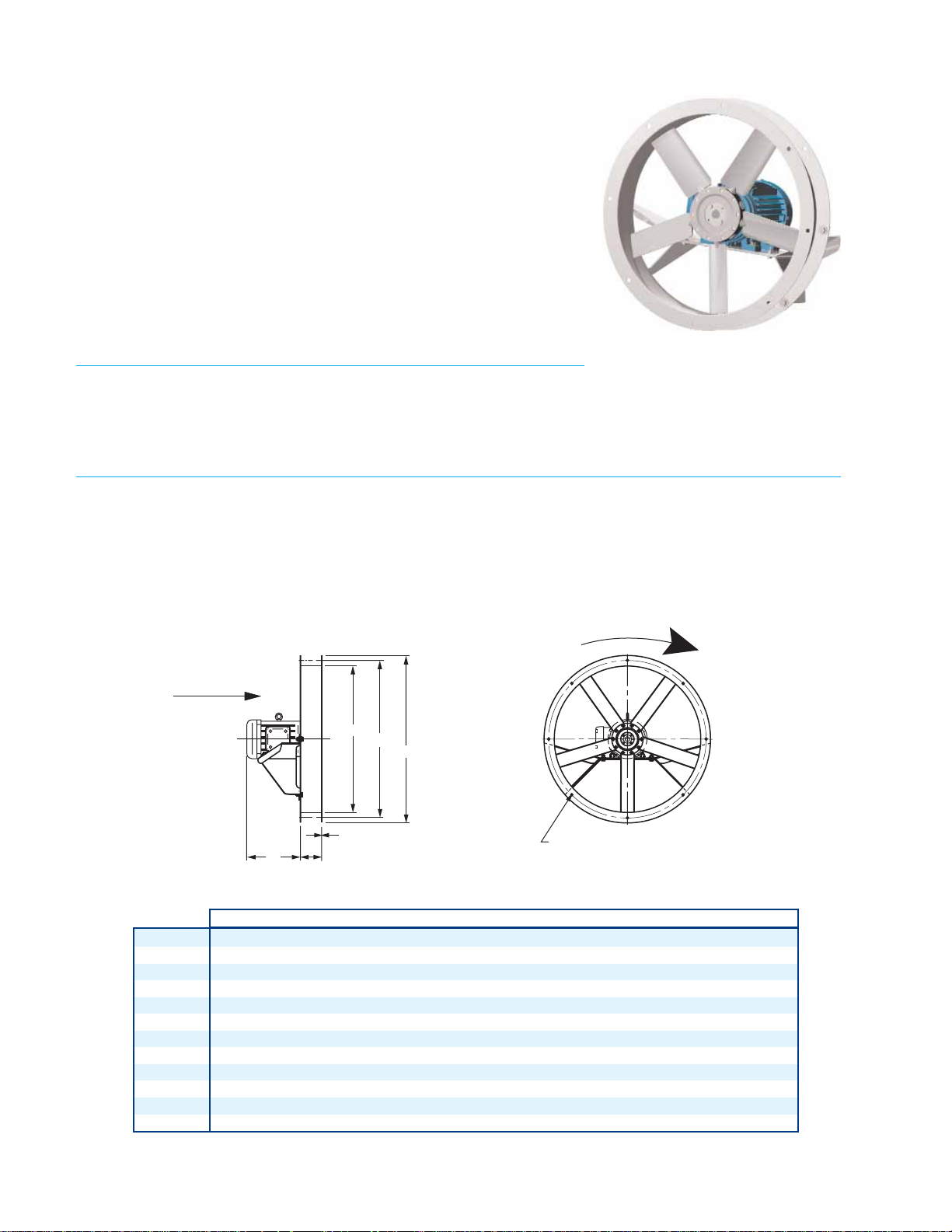

*DO NOT USE FOR CONSTRUCTION

CONSULT FACTORY FOR CERTIFIED PRINTS

MODEL

A B C H J T U MAX MAX MTR FRAME

AFK-12 12.2 13.8 15.0 0.44 3.0 0.06 11.5 143/5T

AFK-14 14.2 16.3 17.5 0.44 3.0 0.06 11.5 143/5T

AFK-16 16.2 18.0 19.5 0.44 4.0 0.08 11.5 143/5T

AFK-18 18.2 20.8 22.0 0.44 4.0 0.08 11.5 143/5T

AFK-21 21.2 23.3 24.5 0.44 4.0 0.08 11.5 143/5T

AFK-24 24.2 26.3 27.5 0.44 4.0 0.08 11.5 143/5T

AFK-27 27.2 29.3 31.0 0.44 4.0 0.08 13.3 182/4T

AFK-30 30.2 32.6 34.5 0.44 4.0 0.11 16.5 213/5T

AFK-32 32.2 34.4 36.5 0.44 4.0 0.11 16.5 213/5T

AFK-36 36.2 38.4 40.5 0.44 5.0 0.11 16.5 213/5T

AFK-42 42.2 44.6 46.5 0.44 5.0 0.11 21.5 254/6T

DIMENSIONS IN INCHES*

SSTTAANNDDAARRDD FFEEAATTUURREESS && BBEENNEEFFIITTSS

• Airfoil adjustable pitch cast aluminum impeller

• Unit can be built for supply or exhaust configurations

• Superior performance and sound characteristics

• Heavy gauge steel with baked polyester coating

• GRP (polypropylene) blades available

• Ideal for OEM applications or new construction

• Fully reversible design option available

• Advanced computerized selection program

• Sizes range from 12” to 42”

• Capacities to 34,000 cfm

AAPPPPLLIICCAATTIIOONNSS

• General ventilation • Marine / Shipboard applications

• Renewable energy • Industrial drying

• OEM condensing units • Circulation / Recirculation units

AACCCCEESSSSOORRIIEESS // OOPPTTIIOONNSS

• Mounting panel • AMCA spark resistant construction

• Motor side guard • Reverse flow construction

• Propeller side guard • Special materials

• Explosion proof motors • Special coatings

• Special duty motors • Housing yoke with mounting bracket

2

STANDARD

ROTATION

STANDARD

AIRFLOW

DIRECTION

U

MAX

A

B

C

T

J

H DIAMETER 8 HOLES EQUALLY SPACED ON

CENTER LINES ABOUT B BOLT CIRCLE DIA.

AAFFKK FFLLAANNGGEE FFAANN

PPRROODDUUCCTT SSPPEECCIIFFIICCAATTIIOONN GGUUIIDDEE

11..00 GGEENNEERRAALL

A. Fans shall be model AFK Flange Fans, as manufactured by Continental Fan Manufacturing Inc., of Buffalo ,

NY, and of the size, capacity and flow direction as indicated on the drawings and fan schedule.

B. Fans shall be rated and tested in accordance with ANSI/AMCA Standard 210-99.

C. All motors and electrical components shall conform to NEMA standards.

22..00 FFAANN HHOOUUSSIINNGG

A. Fan housing shall be constructed of rolled and continuously welded heavy gauge steel.

B. Inlet and outlet flanges shall be integrally formed to ensure concentricity and alignment of the flanges.

C. Adjustable motor base shall be constructed from heavy gauge steel and bolted to the flange.

D. Fan housing and motor base shall be coated with baked polyester powder coat finish.

33..00 FFAANN IIMMPPEELLLLEERR

A. Axial impeller shall be constructed of spark resistant die cast aluminum airfoil shaped blades secured

to a die cast aluminum hub assembly.

B. Axial impeller blades shall be of adjustable pitch construction with multiple hub-to-blade arrangements

to maximize air performance.Blade pitch angles shall be factory set.

C. Axial impeller hub shall be designed to incorporate a split taper bushing, and be keyed directly to drive shaft.

44..00 FFAANN MMOOTTOORR AANNDD DDRRIIVVEE

A. Motor shall be TEFC industrial duty and conform to NEMA standards.

B. Motor shall be of voltage, horsepower, RPM and enclosure as indicated on the fan schedule.

55..00 OOPPTTIIOONNAALL FFAANN AACCCCEESSSSOORRIIEESS

A. Where indicated, fan shall be provided with the following optional accessories:

• Mounting panel

• AMCA spark resistant construction

• Motor side guard

• Reverse flow construction

• Propeller side guard

• Special materials

• Special coatings

• Housing yoke with mounting bracket

• Motors

- Explosion proof

- Special duty

66..00 FFAANN TTEESSTTIINNGG

A. Axial impeller shall be balanced and mounted in fan assembly.

B. Fan assembly shall be run and tested prior to shipment.

C. A test report shall be maintained on file for each individual fan.

3

AFK-0906

AFK DIRECT DRIVE FLANGE FANS

Loading...

Loading...