Prometer 100

High-precision meter

User Manual

BGX501-943-R01

Page 2 of 72

Prometer 100 User Manual

BGX501-943-R01

Copyright © 2014, SIHPL

BGX501-943-R01 Prometer 100 User Manual Page 3 of 72

Table of Contents

1 Important Safety Information ..................................................................................................... 5

2 Disclaimer .................................................................................................................................... 5

3 Introduction ................................................................................................................................. 5

3.1 Prometer 100 meters ..................................................................................................................................... 5

3.1.1 The Prometer 100 meter in an energy management system ......................................................... 6

4 Physical Features ........................................................................................................................ 7

4.1 Power Supply, Auxiliary and Other Details ................................................................................................... 7

4.2 Front Panel of Prometer 100-R ..................................................................................................................... 9

4.3 Front Panel of Prometer 100-W .................................................................................................................. 10

4.4 Connections to the Prometer 100-R ............................................................................................................ 11

4.5 Connections to the Prometer 100-W ........................................................................................................... 13

4.6 Sealing Arrangement in Prometer 100 - R .................................................................................................. 14

4.6.1 Front Cover Sealing ...................................................................................................................... 14

4.6.2 Rear Sealing Arrangement ........................................................................................................... 14

4.7 Sealing Arrangement in Prometer 100 – W ................................................................................................ 15

4.8 Pulse Inputs and Outputs ............................................................................................................................ 15

5 Prometer 100 and M-Cubed BCS.............................................................................................. 16

5.1 M-Cubed BCS ............................................................................................................................................. 16

6

Using the Display ...................................................................................................................... 16

6.1 Auto Scroll ................................................................................................................................................... 16

6.2 Manual ......................................................................................................................................................... 18

6.3 Display Buttons ............................................................................................................................................ 19

6.4 Menu Example Screens .............................................................................................................................. 20

6.5 Events .......................................................................................................................................................... 34

7 Functions ................................................................................................................................... 35

7.1 Meter clock .................................................................................................................................................. 35

7.1.1 Time Set ........................................................................................................................................ 35

7.1.2 Time Advance and Time Retard (Sliding adjustment) .................................................................. 35

7.1.3 Daylight saving time ...................................................................................................................... 35

7.1.4 External synchronisation ............................................................................................................... 35

7.2 Support for Different Types of Energy ......................................................................................................... 36

7.3 Instant values .............................................................................................................................................. 37

7.3.1 Overview ....................................................................................................................................... 37

7.3.2 Prefix for units in the display ......................................................................................................... 38

7.3.3 Harmonics measurement .............................................................................................................. 38

7.3.4 THD ............................................................................................................................................... 38

7.4 Daily Energy Snapshot ................................................................................................................................ 38

7.5 Digital inputs and outputs ............................................................................................................................ 39

7.5.1 Inputs ............................................................................................................................................ 39

Page 4 of 72

Prometer 100 User Manual

BGX501-943-R01

7.5.2 Outputs ......................................................................................................................................... 40

7.6 Communications and Security ..................................................................................................................... 41

7.6.1 Communication speed .................................................................................................................. 41

7.6.2 Security ......................................................................................................................................... 41

7.7 Loggers ........................................................................................................................................................ 42

7.7.1 Overview ....................................................................................................................................... 42

7.7.2 Logging interval and total channels .............................................................................................. 43

7.7.3 Storage of logged values .............................................................................................................. 44

7.8 Alarms ......................................................................................................................................................... 45

7.8.1 Overview ....................................................................................................................................... 45

7.8.2 Indication ....................................................................................................................................... 46

7.8.3 Display of events .......................................................................................................................... 46

7.9 Maximum demand ....................................................................................................................................... 47

7.10 Historical registers ....................................................................................................................................... 48

7.11 Time of use .................................................................................................................................................. 48

7.11.1 Day t ype ........................................................................................................................................ 49

7.11.2 Season .......................................................................................................................................... 49

7.11.3 Holiday dates ................................................................................................................................ 49

7.11.4 TOU registers................................................................................................................................ 49

7.12 Billing Cycle Support ................................................................................................................................... 49

7.12.1 Billing Cycle .................................................................................................................................. 49

7.12.2 History of Energy, Rate and MD Register .................................................................................... 49

7.12.3 History for the Cause of Billing Register ....................................................................................... 49

7.12.4 Cumulative Maximum Demand Registers .................................................................................... 50

7.13 Meter Reading ............................................................................................................................................. 50

7.14 Scaling Tariff ................................................................................................................................................ 50

7.15 Transformer compensation ......................................................................................................................... 50

7.15.1 Overview ....................................................................................................................................... 50

7.15.2 Instrument transformer compensations ........................................................................................ 51

7.15.3 Power transformer losses ............................................................................................................. 51

7.16 Quality of Supply ......................................................................................................................................... 51

7.16.1 Voltage monitoring ........................................................................................................................ 51

Appendix A: Abbreviations ............................................................................................................ 52

Appendix B: Material Declaration .................................................................................................. 52

Appendix C: Communication Ports ............................................................................................... 53

Appendix D: How to Read Meters through Ethernet Port ............................................................ 55

Appendix E: Calculation Principles ............................................................................................... 61

Appendix F: Connection and General Details ............................................................................... 66

Appendix G: List of DLMS Parameters .......................................................................................... 68

Frequently Asked Questions (FAQs) ............................................................................................. 70

BGX501-943-R01 Prometer 100 User Manual Page 5 of 72

1 Important Safety Information

Installation, wiring, testing and service must be performed in accordance with all local and national electrical

codes.

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Turn off all power supplying this device and the equipment in which it is installed before working on the

device or equipment.

• Always use a properly rated voltage sensing device to confirm that all power is off.

• Do not perform Dielectric (Hi-Pot) or Megger testing on this device.

• Connect protective ground (earth) before turning on any power supplying this device.

Failure to comply with the above safety measures could cause serious injuries.

If the meter is used in a manner not specified by the manufacturer, the protection provided by

connections may be impaired. The manufacturer shall not be held responsible for failure to

comply with the instructions in this manual.

2 Disclaimer

This user manual covers all types of the Prometer 100 energy meter. Depending on the product offering based

on business proposal, some features or functionalities may or may not be available in the supplied version. It is

therefore recommended to refer the features or functionalities according to the business offered.

The details of complete software’s features are out of the scope for this document, please contact concern sales

representative for its details if required. Note that due to variations between computers and improvements in

software, the screen shots shown in this manual may vary slightly from the appearance of the software on your

system.

3 Introduction

This manual discusses the Prometer 100 meter features and provides the information needed to configure and

use the meter. The manual covers all versions of Prometer 100-R (rack-mount) and Prometer 100-W (wallmount) meters.

By the time you are ready to use this guide, your meter should be installed, most basic setup should have been

performed, and communications/basic operation should have been verified. If the unit is not yet installed and

operational, refer to the Installation Guide shipped with the meter.

This section provides an overview of Prometer 100 meters and summarizes many of their key features.

3.1 Pro met er 100 met ers

Prometer 100 meters provide revenue-accurate, true RMS measurements of voltage, current, power and

energy, and are com plemented by extensive I/O capabilities, comprehensive logging, and advanced power

quality measurement and compliance verification functions. The meters come with an extensive selection of preconfigured data screens and measurements, so you can use the meters as they are shipped from the factory or

customize them to fit your unique requirements.

You can integrate the meters with software such as M-Cubed or wit h other energy management, SCADA,

automation and billing systems, using multiple industry-standard communication channels and protocols.

Common meter applications

• Transmission and distribution metering

• Revenue and tariff metering

• Total harmonic distortion monitoring

Page 6 of 72

Prometer 100 User Manual

BGX501-943-R01

• Load management

• System stability monitoring

• Energy pulsing and total i za tion

• CT/VT error compensation

• Transformer loss compensation

3.1.1 The Prometer 100 meter in an energy management system

You can use Prometer 100 meters as standalone devices, but their extensive capabilities are fully realized when

used with software as part of an energy management system (EMS). EMS gives energy suppliers, service

providers, and large industrial and commercial energy consumers the tools to meet all the challenges and

opportunities of the new energy environment. EMS uses real-time information and control to directly address a

broad range of requirements throughout the power delivery chain. This system offers an integrated solution to

managing new billing structures, distributed generation, energy purchasing, energy cost control, operational

efficiency, power quality and reliability.

Applications that include the meter typically require additional equipment. Display and analysis software tools

are almost always used to manage, interpret and distribute the data measured or logged by a meter. There are

usually a variety of tools used, and often these tools are connected using different communications standards

and protocols. In many cases, a meter must also provide control capabilities and device-level data sharing.

The meter can adapt to many situations. Advanced communications allow data to be shared simultaneously

across multiple networks, built-in I/O provides monitoring and control capabilities, and a variety of display and

analysis tools to help you get the most from your power system.

Figure 1: An Overview

Prometer

100

Industry

Standard

Mounting

Graphical

Display

Multiple Pulse

Input and

Output

Wide range

Voltage and

Current supply

Scalability and

Modularity

Multiple

Communication

Channels

BGX501-943-R01 Prometer 100 User Manual Page 7 of 72

4 Ph ysical Features

Prometer 100 is configurable for HV 3-phase 3-wire, HV 3-phase 4-wire or LV 3-phase 4-wire and is suitable for

mounting in a panel or on a wall. Prometer 100 has self-powered and auxiliary-powered variants. The auxiliarypowered variant also comes with dual auxiliary support so that you can put AC or DC voltage for main and

backup supply for powering up the meter. The auxiliary circuit is not intended to be connected to the secondary

of measurement VT. For example, the VT secondary supply of 63.5 V AC (phase to neutral voltage) or 110 V

AC (phase-to-phase voltage) needs to be supplied as a voltage input to the product. Similarly three CTs, namely

R/L1, Y/L2 and B/L3, need (as applicable) to be given as a current input to the product of 1A/ 5A from

secondary side.

Note:

• Only Prometer 100-W variants can be configured as LV 3-phase 4-wire.

4.1 Power Supply, Auxiliary and Other Details

Details for the power supply and measurement options are shown below:

Figure 2: Power Supply Options

Variants Main supply Backup supply

No. of Aux power

supply inputs

supported

Range of Aux supply

Field Replaceable

Battery

(for meter reading

and viewing

display)

Self+Aux

power

supply

Aux. supply

input

(Aux 2)

Measurement

voltage terminals

(VT supply)

One

(Aux 2)

60-240 V AC/DC ± 20%

or

24-48 V DC ± 20%

Optional

Self

power

supply

Measurement

voltage

terminals (VT

supply)

Not available Not available Not applicable Optional

Auxiliary

power

supply

Aux. supply

input

(Aux 2)

Aux 1 (opt iona l)

Two (dual)

(Aux. 1 & Aux. 2)

Both as 60-240 V AC/DC ± 20%

or

one as 24-48 V DC ± 20%

Optional

Table 1: Different Power Supply and other Variants available in Prometer 100

Page 8 of 72

Prometer 100 User Manual

BGX501-943-R01

• In case of auxiliary-powered and self-powered variants, meter will draw power from Aux 2 supply input.

In its absence it will shift to Aux 1 supply (in case of auxiliary-powered variant) and VT supply (in case

of self-powered variant).

• Do not connect voltage transformer (VT) to any of the Aux supply input terminal as a general practice. If

it is necessary to connect VT secondary to Aux input then make sure to connect it to the Aux1 supply

only in presence of Aux 2 so that burden on measurement VT secondary can be minimal.

• Connect your reliable auxiliary supply source like DC bank/AC lighting load/ Aux power transformer etc

to Aux 2 terminal only so that meter burden will be handled by it; or take your best judgment to connect

auxiliary supply source considering the rating and suitable operation of meter and best installation

practices followed.

• The field replaceable battery can be configured to support meter reading in absence of mains power

supply depending on the requirement. It only supplies sufficient power to the meter reading and display

circuitry and will not fully power-up the meter. Contact the concern sales representative or technical

team regarding this useful feature. The battery can be replaced in the field. Take care while inserting

the battery; make sure that the polarity and fitment are correct.

• Ensure that the correct auxiliary voltage rating is used with the meter. The wrong voltage rating could

cause damage to the meter. Therefore it is recommended to verify and crosscheck the rating-plate on

the actual product in use at the site.

Figure 3: Rating Plate of Prometer 100-W (To be verified with realistic information and updated as per latest

changes)

Figure 4: Rating Plate of Prometer 100-R (To be verified with realistic information and can show one of the

rating plates with Aux 1 supply, ‘MADE in UK’ & S. No. here shown in bold and in Wall-mount not bold so

we should use same font style in order to maintain consistency, and updated as per latest changes)

BGX501-943-R01 Prometer 100 User Manual Page 9 of 72

4.2 Front Panel of Prometer 100-R

Figure 5: Front View

The front cover is made of translucent plastic with a transparent window to view the display. The cover has two

top hinges which allow the front cover to swing-up, allowing access to the sealed button and field replaceable

battery. The cover is secured in position by a retaining screw and also has provision to seal it.

Figure 6: Front Cover Opened

Page 10 of 72

Prometer 100 User Manual

BGX501-943-R01

4.3 Front Panel of Prometer 100-W

Figure 7: Front View

The front cover is made of translucent plastic with a transparent window to view the display. The top cover is

used to seal the MD (Maximum Demand) reset button and field replaceable battery. The extended terminal

block cover is secured in position by retaining screws and also has provision to seal it.

Figure 8: Top Cover Removed

BGX501-943-R01 Prometer 100 User Manual Page 11 of 72

4.4 Connections to the Prometer 100-R

The diagram shows the rear connector with its pin diagrams for the meter. There are different options that may

be provided as per the specification agreed with the customer at the time of order.

Connect

R/L1

Y/L2

B/L3

N

CT IN

A01

A02

A03

NC

CT OUT

A1

A2

A3

NC

VT

B1

B2

B3

B0

Dual AUX

Supply

P/+ Terminal N/- Terminal

AUX1

B8

B9

AUX2

B5

B6

Digital Input/Output

8 Outputs and 4 configurable Inputs/Output

O/P 1

C0, C1

I/O 1

D3, D2

O/P 2

C1, C2

I/O 2

D9, D4

O/P 3

C4, C3

I/O 3

D7, D8

O/P 4

C4, C9

I/O 4

D5, D6

O/P 5

C7, C8

O/P 6

C7, C6

O/P 7

D0, D5

O/P 8

D0, D1

Figure 9: Rear Connector with Pin Details

Page 12 of 72

Prometer 100 User Manual

BGX501-943-R01

Note: For 3-phase 3-wire CT/VT operated refer to figure A

For 3-phase 4-wire CT/VT operated refer to figure B

For 3-phase 3-wire and 3-phase 4-wire connections from B5 to D9 are the same.

For self-powered variant Aux.1 (B8 and B9) supply is not available.

Figure 10: Connection Diagram

Note: One side of the CT secondary wiring should be earthed according to local practice.

The recommended size of the CT, VT and Aux power supply cable is 2.5 sq mm with lugs type as ring (M3 type)

for CT and H type for Aux and VT terminals.

In case of Prometer 100-R the internal earthing cable between the meter and the rack should also be

connected, and for this an M4 size screw is used in the meter and in the rack. The same ring type connector as

used in the CT connection can also be used.

The internal earthing cable should be about 5-10 cm in length to allow for ease of fitting and access and not

fouling with sharp edges of rack etc. Finally a proper earthing cable from rack to earth should be put up by

installer. Other accessories or shipway kit is supplied based on the requirement like seals, communication cords

etc.

BGX501-943-R01 Prometer 100 User Manual Page 13 of 72

4.5 Connections to the Prometer 100-W

Connections to the Prometer 100-W are made on the meter terminal under the terminal cover.

Connect

R/L1

Y/L2

B/L3

N

CT IN

1 4 7

NC

CT OUT

3 6 9

NC

VT 2 5 8 11

Dual AUX

Supply

P/+ Terminal N/- Terminal

AUX 1

13

14

AUX 2 15 16

Digital Input/Output

8 Outputs and 4 configurable Inputs/Output

O/P 1

18, 19

I/O 1

32, 33

O/P 2

20, 21

I/O 2

34, 35

O/P 3

22, 23

I/O 3

36, 37

O/P 4

24, 25

I/O 4

38, 39

O/P 5

26, 27

O/P 6

28, 29

O/P 7 30, 31

Figure 11: Rear Connector with Pin Details

Current, Voltage and Auxiliary supply connections

Pulse Input/ Output connections

Figure 12: Connection Diagram

Page 14 of 72

Prometer 100 User Manual

BGX501-943-R01

4.6 Sealing Arrangement in Prometer 100 - R

4.6.1 Front Cover Sealing

Figure 13: Front Cover Sealing Arrangement

The front cover can be sealed in the closed position. This will stop the front cover from being opened and

restrict unauthorised access to the MD Reset pushbutton and internal areas. There are also sealing points on

either side of the meter for securing it to a rack or frame. The sealing bore diameter is 2.0 mm and is suitable for

seals.

4.6.2 Rear Sealing Arrangement

When the meter is fitted into the rack, a cover can be fitted which conceals all the rear connectors. The figure

below show the sealing points for the rear cover. The figure shows the single rack example with an enlarged

detailed view of the sealing points.

Figure 14: Front and Rear Sealing Points – 11” Rack Installation

Front

Cover

Translucent

Transparent

Window

Locking Scr ew

& Sealing points

Right-hand side

Sealing & Locking point

Left-hand s ide

Sealing & Locking point

BGX501-943-R01 Prometer 100 User Manual Page 15 of 72

4.7 Sealing Arrangement in Prometer 100 – W

The meter incorporates sealing bars and screws with through-holes, through which traditional lead/wire seals

can be inserted. When utilized, these lead/wire seals can help prevent unauthorized personnel from gaining

access to meter internals or to button under the cover. The sealing provision in Prometer 100-W is as follows:

• The front cover can be sealed through the two sealing points under the terminal cover.

• The secondary terminal cover can be sealed through a sealing point.

• The extended terminal cover can be sealed through the two sealing points.

• The top cover can be sealed through the two sealing points.

• The 1107 optical communication port can be sealed using rotational seal.

Figure 15: Sealing Points

4.8 Pulse Inputs and Outputs

The product support multiple pulse inputs and outputs. A maximum of eight pulse outputs (for Prometer 100-R)

and seven pulse outputs (for Prometer 100-W); and four configurable pulse input/ output can be provided as per

the specification agreed at the time of order.

Two pulse outputs (3 and 4 in case of Prometer 100-R / 2 and 3 in case of Prometer 100-W, refer to Figure 10

and Figure 12 for details) are linked to two pulse output LEDs indication as available on front side of meter so

that user can have a visualisation sort of feature by physically seeing the LEDs. The pulse output 3 (in case of

Prometer 100-R) / 2 (in case of Prometer 100-W) is linked to pulse output LED 1 and the pulse output 4 (in case

of Prometer 100-R) / 3 (in case of Prometer 100-W) is linked to pulse output LED 2. The Pulse Output LEDs can

be configured through M-Cubed 100 either at factory or in field. One pulse input can be used for time

synchronization applicat ion .

Configurable pulse input/output rating: 24 to 24 0 V AC/DC. Isolation will be available for each individual

input/output.

Pulse output rating: 24 to 40 V DC or 48 to 240 V AC/DC @ 100 mA (Pulse outputs will have volt free contact).

The only one rating will be applicable for entire block (each containing four outputs) and so isolation available

will be for entire block. The outputs are of solid-state type and when the meter is turned off, they are open.

Page 16 of 72

Prometer 100 User Manual

BGX501-943-R01

5 Prometer 100 and M-Cubed BCS

This section describes the various operations that can be performed using the M-Cubed BCS with Prometer 100

meter.

5.1 M-Cubed BCS

Figure 16: Prometer100 and M-Cubed BCS

M-Cubed stands for Modular Meter Management and is the name of Secure’s software suite for programming

meters, reading data and reporting from energy meters. M-Cubed has separate modules that can be configured

to suit particular applications and access rights required by individual users.

M-Cubed can be used for:

• Configuration

• Commissioning

• Meter Reading

• Data Viewing

The M-Cubed helpfile contains a detailed description of all these functions.

6 Using t he Display

There are two types of display mode: Auto Scroll and Manual Mode. The two types of display modes and their

associated settings and parameters are discussed in this section. All single parameters, e.g. voltage, will be

displayed with their OBIS codes. A large selection of parameters (Auto + Manual) can be chosen for display.

6.1 Auto Scroll

Auto Scroll is the default mode. A large number of parameters can be chosen for this mode. The display time

out time can be configured in the field using M-Cubed or by the display keys. Once the display button is

pressed, the Auto Scroll mode will be interrupted and will switch to manual mode. If no button is pressed in

manual mode, the display will time out and revert to auto mode. The display will resume from the last displayed

parameter. The display LCD backlight is always on.

The Auto Display pages will look as shown below (details can be checked as agreed in purchase order):

BGX501-943-R01 Prometer 100 User Manual Page 17 of 72

Page 18 of 72

Prometer 100 User Manual

BGX501-943-R01

Note:

‘T’ stands for Total (Fundamental with harmonics)

‘F’ stands for Fundamental

‘C’ stands for Current

‘MD’ stands for Maximum Demand

6.2 Manual

Display parameters are grouped in to a number of pages. Each page parameters can be individually selected. A

considerable number of parameters can be assigned in manual mode.

Display Groups

The display is arranged into groups for easier navigation.

• Fixed Display Page: Fixed default displays (not configured by tariff)

• User Configurable Pages: User selected parameters. Page name can also be configured. Up to 7 pages

can be configured.

• Favourite: These are selected from the user configurable pages and up to 20 parameters can be

selected in the field.

• Configuration: Configuration page for Metrological LED, Display time out, Delete Favourite page

displays, Reset Battery time, Meter Cons tant, MODBUS and language configuration.

BGX501-943-R01 Prometer 100 User Manual Page 19 of 72

6.3 Display Buttons

The meter has four user buttons. One button can be used for performing MD reset or for navigating through the

sealed button display sequence depending on the requirement and is behind a sealable door. The other three

buttons are used for navigating through the display and configuration menu options.

Figure 17: User Buttons

A page can be selected by pressing the enter button. A navigation screen will appear showing all the available

pages. The Up and Down buttons can then be used to choose a page. Press the Enter button to select your

choice.

Figure 18: Selecting a Page (instead of the word ‘Tamper’, ‘event’ can be used in the display menu)

Once you have selected a target page, you can then use the Up/Down buttons to scroll through that selected

page. Parameters are cyclically displayed in the selected page, i.e. after the last parameter in the list is

displayed, the display will return to the first in the list, and so on.

Press the Enter button to return to the immediate parent page.

Page 20 of 72

Prometer 100 User Manual

BGX501-943-R01

6.4 Menu Example Screens

Fixed Display Page

Select the Fixed Display Page from the top line menu. The following screen will be displayed.

Figure 19: Fixed Display Page

The Fixed Display pages are shown below:

BGX501-943-R01 Prometer 100 User Manual Page 21 of 72

Refer to tariff for Multiplier value

Note:

‘I’ stands for Import

‘E’ stands for Export

‘T’ stands for Total (Fundamental with harmonics)

‘F’ stands for Fundamental

‘R’ stands for Right

‘L’ stands for Left

‘Cfg. IO’ stands for Configurable Input/Outp ut

User Configurable Pages

Up to seven user configurable pages can be defined complete with page title e.g. Instant Parameters, see

Figure 20 below. The page title can have a maximum of 20 alphanumeric characters. The illustrations shown

below are indications of how the pages and their respective displays will be displayed. The final pages and their

corresponding displays are dependent on the specification of your purchase or der.

Page 22 of 72

Prometer 100 User Manual

BGX501-943-R01

Figure 20: User Configurable Pages

Instantaneous Parameter s

Use the Up/Down buttons to scroll to the Instant Parameters page. The

selection will be highlighted.

Press the Enter button to open the page.

Use the Up/Down buttons to scroll within the page and view the various

screens.

BGX501-943-R01 Prometer 100 User Manual Page 23 of 72

Page 24 of 72

Prometer 100 User Manual

BGX501-943-R01

Note:

‘D’ stands for degree

‘M’ stands for minutes

Energy Registers

In this example the user defined page has been configured to view the energy registers and an appropriate

page title has been chosen for easy identification. Always choose a user friendly and self-explanatory name for

your titles. We have used “Energy Register” for our title example.

Use the Up/Down buttons to scroll to the Energy Registers page. The

selection will be highlighted.

Press the Enter button to open the page.

Use the Up/Down buttons to scroll within the page and view the various

screens.

BGX501-943-R01 Prometer 100 User Manual Page 25 of 72

Demand Data

This page has been set up to capture demand values.

Use the Up/Down buttons to scroll to the Demand Data page. The

selection will be highlighted.

Press the Enter button to open the page.

Use the Up/Down buttons to scroll within the page and vie w the various

screens.

Page 26 of 72

Prometer 100 User Manual

BGX501-943-R01

High Resolution Energy Register

This page has been set up to capture hi gh re solution energy registers .

Use the Up/Down buttons to scroll to the High Resolution Energy

Registers page. The selection will be highlighted.

Press the Enter button to open the page.

Use the Up/Down buttons to scroll within the page and view the various

screens.

BGX501-943-R01 Prometer 100 User Manual Page 27 of 72

Previous IP data

This page has been set up to capture p revious IP data .

Use the Up/Down buttons to scroll to the Previous IP Data registers

page. The selection will be highlighted.

Press the Enter button to open the page.

Use the Up/Down buttons to scroll within the page and view the various

screens.

Page 28 of 72

Prometer 100 User Manual

BGX501-943-R01

Event Information

This page details tamper events and status. Events are discussed in section 6.5

Use the Up/Down buttons to scroll to the Tamper Information page. The

selection will be highlighted.

Press the Enter button to open the page.

Use the Up/Down buttons to scroll within the page and view the various

screens.

Miscellaneous

This page details miscellaneous displays.

Use the Up/Down buttons to scroll to the Miscellaneous information

page. The selection will be highlighted.

Press the Enter button to open the page.

Use the Up/Down buttons to scroll within the page and view the various

screens.

BGX501-943-R01 Prometer 100 User Manual Page 29 of 72

Scroll Lock

Locking of individual para meter page in user configurable pag es (manual pages) –

Figure 21: Locking the manual page parameter

The screen can be locked to show a desired parameter. To screen lock a parameter, select the parameter using

the menu buttons (this is applicable under user configurable pages only). Press the Up key for 5 seconds.

During this process the display will temporarily move to the next parameter, then after 5 seconds will display

your selection.

T o unlock the screen (i.e. revert to auto scroll mode) press the Up key for 5 seconds.

Favourite Page

This page is used for your selection of display parameters.

Figure 22: Adding parameter to favourite page

To add a parameter, go to the page containing the parameter that you require. Once the required page is

selected press the down key for 5 seconds, the selected parameter will now be added to your favourite page.

When the favourite page is full, you will need to delete complete list in this page to make space for the new one,

so be sure before selecting parameters as maximum 20 parameters can be selected in favourite display page.

To delete the complete list of Favourite parameters, go to the configuration page and select ‘Del Fav

Parameters’.

press and hold

the Key for

5 seconds

Up

Up

press and hold

the Key

for 5 seconds

Down

Down

Page 30 of 72

Prometer 100 User Manual

BGX501-943-R01

Configuration Page

Figure 23: Front view showing metrological LEDs

The configuration pages are used to set-up and enable features such as the metrological LEDs, display timeout,

meter constant, reset battery time, MODBUS configuration and language on display. They are also used to

manage your favourite selections.

The configuration page is password protected which can be accessed only by users authorized to change the

above configurations.

At the password prompt enter the 6-digit password (default password is ‘000000’) using Up and Down buttons

Use the Down key to enter a digit at the cursor position and use the Up key to move the cursor to the right while

entering a digit. After completing the entry, press the Enter button to confirm. Correct password gives access to

the first screen of configuration page. An incorrect password will display ‘Incorrect Password’ message.

The Prometer 100 meter display can be set to different languages. The following languages are available:

• English

• Swedish

• German

• French

• Spanish

• Russian

• Arabic

The configuration page displays are shown below.

Use the Up/Down buttons to scroll to the Configuration page. The

selection will be highlighted.

Press the Enter button and enter the correct password using Up and

Down buttons to open the page.

Use the Up/Down buttons to scroll within the page and view the various

screens.

BGX501-943-R01 Prometer 100 User Manual Page 31 of 72

Display to be added

Page 32 of 72

Prometer 100 User Manual

BGX501-943-R01

(Russian and Arabic language options are missing in the above display)

The following displays are self-explanatory and occur at the time of events such as configuration, file download

etc. and are included here for your reference only.

BGX501-943-R01 Prometer 100 User Manual Page 33 of 72

User Selectable Display Examples (displays to be updated)

Description

HV (3-phase 4-wire) Display

HV (3-phase 3-wire) Display

Phasor Diagram

Bar graph

Same for HV3 and HV4

MD Value

Same for HV3 and HV4

Battery Status

Greater than equal

to 30%

Same for HV3 and HV4

Battery Status

Less than 30% &

Greater than equal

to 20%

Same for HV3 and HV4

Battery Status

Less than 20%

Same for HV3 and HV4

Page 34 of 72

Prometer 100 User Manual

BGX501-943-R01

Battery Remaining

Hours

Same for HV3 and HV4

6.5 Events

The Prometer 100 has a number of defined events that are stored in the meter’s event log when they occur and

restore. The events are arranged into different logical compartments with defined numbers of events logging. An

event is displayed with a description and a time stamp in M-Cubed. All the events will be displayed in following

categories in meter display as– voltage related, current related and events other than voltage & current related.

The events do not enforce any electrical value changes inside the meter such as running the meter on I

max

etc.

Events are logged if the condition for the detection of an event persists for a specified duration, known as the

persistence time. Events can have a different persistence time for occurrence and restoration as applicable. The

persistence time for an occurrence as well as for restoration is configurable at factory end for respective event

as applicable. However some events like power on/off, magnet will not have any restoration time because of the

nature and type of the event. Similarly some events can have the same condition of tamper detection as per the

nature and type of the event in a given circumstances.

The general events supported are as follows –

1. Phase-wise missing potential

2. Voltage unbalance

3. Invalid Voltage

4. Over Voltage

5. Under Voltage

6. Phase wise current circuit reversal

7. CT Miss

8. Current unbalance

9. Feeder Supply Fail

10. Po wer on/ of f

11. Front cover and ETBC Open detection in power on/off condition (applicable for Prometer 100-W)

There are other customised events like Neutral Disturbance (ND), Magnet immunity, CT open/ Bypass and

%THD for voltage and current are also supported in meter.

BGX501-943-R01 Prometer 100 User Manual Page 35 of 72

7 Functions

This section provides an overview of the functions available in Prometer 100. All functions in the meter can be

both configured and read in M-Cubed. In many cases, M-Cubed can also export data to a file or print out data.

7.1 Meter clock

The Prometer 100 has an integrated real-time clock for time-dependent functions. Information about time

adjustment and daylight saving time status is recorded with tags on the logged values (refer to the section

Loggers on page 42). Time set is also noted as an event in the event log; see the section Display of events (pg.

46).

7.1.1 Time Set

The meter’s date and time can be set to an absolute point in time. Instantaneous adjustment of the meter’s time

can influence logged values. For this reason, instantaneous adjustment of the meter clock is primarily intended

for use at initial configuration of the meter.

7.1.2 Time Advance and Time Retard (Sliding adjustment)

When the Prometer 100 is not being used for on-line application, the meter’s time can be advanced or retarded

using time advance or time retard commands with M-Cubed BCS. The meter time can be retarded or advanced

by t

tc

seconds spanned over Ntc consecutive blocks of 15 minutes (ttc/ N

tc

seconds for each block). The meter

automatically adjusts for any time correction during the load survey reading period. Once a meter gets and

accepts a time advance/retard command, it is not possible to do time adjustment for the next 7 days.

7.1.3 Daylight saving time

Prometer 100 offers the alternative of letting the meter clock follow daylight savings time. At a specified date,

the meter clock is adjusted forward, and at another, adjusted backward. Prometer 100 can store 15 years of

DST configuration.

Example: On 28 March the clock is to be adjusted forward, from 02:00 to 03:00. The adjustment back to

standard time is to occur on 31 October at 3:00 (daylight savings time) when the clock is to be set back to

02:00. The following is set in the meters: Begin March, 28, 02:00. End October, 31, 03:00 and the standard time

is to be adjusted by 60 minutes.

7.1.4 External synchronisation

The meter time can be adjusted by a pulse on one of the meter’s digital inputs. When a pulse is registered, the

clock is adjusted to the closest multiple of a specified synchronisation interval. If the synchronisation interval is,

for example, one minute and the time is 13:00:29, a pulse will adjust the clock to 13:00:00. If the time had

instead been 13:00:31, the clock would have been adjusted to 13:01:00.

Available synchronisation intervals are:

1, 2, 5, 10, 15, 20, 30, 45 and 60 minutes

12 and 24 hours

A digital input must be configured for clock synchronisation (refer to the section Digital inputs and outputs on

page 39).

Note: Meter will not sync the time if the time difference is more than the time adjustment limit configured in the

meter. By default, the time adjustment limit is set as 25 seconds. The time adjustment limit can be configured as

any value between 0 to 30 seconds.

Page 36 of 72

Prometer 100 User Manual

BGX501-943-R01

7.2 Support for Different Types of Energy

Prometer 100 meter is used for feeder based applications where energy may flow in both the directions.

Prometer 100 is an Import Export type meter; its metering unit is capable of logging energy in both directions.

III

III IV

Active power import

(+)

Active power export

(-)

Reactive power

export (-)

Reactive power

import (+)

S

Q

P

Capacitive

Inductive

Quadrants

Phase angle

Current relative to voltage

I

0 to 90°

Lagging

II

90 to 180°

Leading

III

-180 to -90°

Lagging

IV

-90 to 0°

Leading

Prometer 100 supports different tariff structures and number of Energy types (refer to Table 2). Any combination

of energy types can be provided as per the specification agreed at the time of order.

The Energy Channel Registers are shown below:

Sr.

No.

Parameters Instantaneous Billing

TOD MD

/ UMD

TOD Rate

Daily

Energy

Logger 1

Logger 2

1

Active Import Total

(Q1+Q4)

Y

Y Y Y Y Y

Y

2

Active Export Total

(Q2+Q3)

Y

Y Y Y Y Y

Y

3

Active Import

Fundamental

(Q1+Q4)

Y

Y Y Y Y Y

Y

4

Active Export

Fundamental

(Q2+Q3)

Y

Y Y Y Y Y

Y

5

Reactive Import while

Active Import – Q1

Y

Y Y Y Y Y

Y

6

Reactive Import while

Active Export – Q2

Y

Y Y Y Y Y

Y

7

Reactive Export while

Active Export – Q3

Y

Y Y Y Y Y

Y

8

Reactive Export while

Active Import – Q4

Y

Y Y Y Y Y

Y

9

Apparent – While

Active Import (See

Note 2) Y Y Y Y Y Y

Y

10

Apparent – While

Active Export (See

Note 2) Y Y Y Y Y Y

Y

11

Reactive Import

(Q1+Q2)

Y

Y Y Y Y Y

Y

12

Reactive Export

(Q3+Q4)

Y

Y Y Y Y Y

Y

BGX501-943-R01 Prometer 100 User Manual Page 37 of 72

13

Reactive Inductive

(Q1+Q3)

Y

Y Y Y Y Y

Y

14

Reactive Capacitive

(Q2+Q4)

Y

Y Y Y Y Y

Y

15

Net Active (Imp –

Exp) * Y Y

N N

Y Y Y

16

Net Reactive

(Q1+Q2-Q3-Q4) *

Y

Y

N N

Y Y Y

17

Active Import Total

(Q1+Q4) - Phase 1

Y

Y

N N

Y Y Y

18

Active Import Total

(Q1+Q4) - Phase 2

Y

Y

N N

Y Y Y

19

Active Import Total

(Q1+Q4) - Phase 3

Y

Y

N N

Y Y Y

20

Active Export Total

(Q2+Q3) - Phase 1

Y

Y

N N

Y Y Y

21

Active Export Total

(Q2+Q3) - Phase 2

Y

Y

N N

Y Y Y

22

Active Export Total

(Q2+Q3) - Phase 3

Y

Y

N N

Y Y Y

Table 2: Energy Channel Registers

The pre-defined energy channels can be configured for display, billing, TOD, MD, Load Survey and Daily

Energy in line with purchase order requirements at the time of order.

Notes:

1) All the bi-directional energy register s (* marked) will have sign indicat ion (‘-‘sign will be ava ilable for

negative value and no sign for positive value).

2) In ‘Apparent’ and ‘Net Active’ energy calculat ion, ‘Active’ energy can be either ‘fundam ental’ or ‘total’.

This can be configured through the tariff tool. Both energies need to be of same type.

3) Single phase measurements (17-22) are supported by the 4 wire configuration.

For energy types 1-16:

These registers are continuously increased depending on the selected energy.

Example: Main Energy Register kWh (I) will show the total imported active energy logged till date.

Recording of all supported energy types is pos sible but only those energy t ypes are logged into the m emory

which is specified by the ta riff file. An indi vidua l registe r is pr ovided f or al l selec ted ener g y types. T hese regi ster

are called Main Energy Registers . W henever an individual energy type is generated / consum ed, its value is

updated in the corresponding main energy register. These registers cannot be reset.

7.3 Instant values

Besides energy, the Prometer 100 can also measure instant values. Instant values are constantly changing

values such as current, voltage, power and harmonics. The instant values are updated every second. The

formulas and definitions used to calculate the values are presented in Appendix E: Calculation Principles on

page 61.

7.3.1 Overview

This table provides an overview of the instant values that can be read on the meter. Readings can be viewed

with M-Cubed, on the displa y and with other software that has implemented Prometer 100’s communication

protocol. Most instant values can be logged; for more information, see section Loggers on page 42.

Instant value

Available on 3-element meter

Available on 2-element meter

Real Time Clock – Date and Time Yes Yes

Phase Voltage

Yes (L1, L2, L3, Average)

No

Line Voltage (L12, L23, L31, Average)

Yes

Yes

Line Current

Yes (L1, L2, L3, Average)

Yes (L1, L3, Average)

Active Current

Yes (L1, L2, L3, Average)

Yes (L1, L3, Average)

Reactive Current

Yes (L1, L2, L3, Average)

Yes (L1, L3, Average)

Voltage Phase angle (L12, L23, L31) Yes Yes

Page 38 of 72

Prometer 100 User Manual

BGX501-943-R01

Current Phase angle

Yes (L1, L2, L3)

Yes (L1, L3)

Active power total

Yes

Yes

Active power per phase

Yes

No

Active power fundamental Yes Yes

Active power fundamental per phase

Yes

No

Reactive power total

Yes

Yes

Reactive power per phase

Yes

No

Apparent power total

Yes

Yes

Apparent power per phase

Yes

No

Power factor total Yes Yes

Power factor per phase

Yes

No

Frequency

Yes

Yes

Average THD voltage

Yes

Yes

THD voltage per phase

Yes

No

Average THD current

Yes

Yes

THD current per phase

Yes

No

Average THD power Yes Yes

THD power per phase

Yes

No

7.3.2 Prefix for units in the display

The presentation for units and the number of decimals depends on the magnitude of the value.

7.3.3 Harmonics measurement

Harmonics numbers 2 to 31 are measured for all currents and voltages. At a fundamental frequency of 50 Hz,

the second harmonic is 100 Hz, the third harmonic is 150 Hz, etc. Both the harmonics’ amplitude and phase

angle are measured and included in the calculation of power and energy, and their magnitude can be read via

the meter’s communication protocols. In M-Cubed, harmonic magnitude is presented with a diagram.

Voltage harmonics profile

Parameter

Available on 3-element meter

Available on 2-element meter

Real Time Clock – Date and Time

Yes

Yes

Voltage harmonics (2 to 31) – L1

Yes

Yes

Voltage harmonics (2 to 31) – L2 Yes No

Voltage harmonics (2 to 31) – L3 Yes Yes

Current harmonics profile

Parameter

Available on 3-element meter

Available on 2-element meter

Real Time Clock – Date and Time Yes Yes

Current harmonics (2 to 31) – L1 Yes Yes

Current harmonics (2 to 31) – L2

Yes

No

Current harmonics (2 to 31) – L3

Yes

Yes

7.3.4 THD

THD stands for Total Harmonics Distortion and is a measurement of the amount of harmonics present in a

signal. Voltages and currents’ THD can be read via M-Cubed and on the display.

7.4 Daily Energy Snapshot

Energy Snapshot feature saves the value of a particular energy register at a particular time. Prometer 100

stores a snapshot of different energy registers (can be up to 28 energies) on a daily basis at predefined time as

selected from tariff configuration (generally it is set at midnight). Snap shots are generally stored for 45 days

and can be stored for a maximum of 100 days as configured at factory. The updating of Energy Snap shot

records is done in a rollover fashion, i.e. each day a new energy snapshot is stored in the memory and the

earliest record is deleted. So at any time a meter will have energy snapshot records for the last 45 days.

BGX501-943-R01 Prometer 100 User Manual Page 39 of 72

7.5 Digital inputs and outputs

The Prometer 100 has several inputs and outputs that can be configured to perform various tasks. Both inputs

and outputs are protected against overv oltages b y vari s tors . T he y also have an isolated int erf ac e between the

electronics and the surroundings to ensure personal safety. For electrical data on the meter’s inputs and

outputs, see Appendix F: Connection and General Details (page 66).

7.5.1 Inputs

The inputs can be configured as follows:

• Not used

The input is not used.

• Finish historical period (To be verified that only ‘Finish Hist Period’ Input can be set to inverted

as in ConfigView S/W it allows none of the inputs to b e set as inverted)

An incoming pulse will result in the present period ending and registers being copied to historical

registers. The meter registers pulses on positive or negative flanks, depending on if the input is set to

inverted or not. By setting limits for maximum and minimum pulse lengths, the meter can be limited as

to what it detects as a valid pulse. Pulses with lengths beyond the established limits are ignored. For a

pulse to finish historical period, it is also necessary that the Data communication be configured to allow

this. For more information, see the section Historical registers (pg.

48).

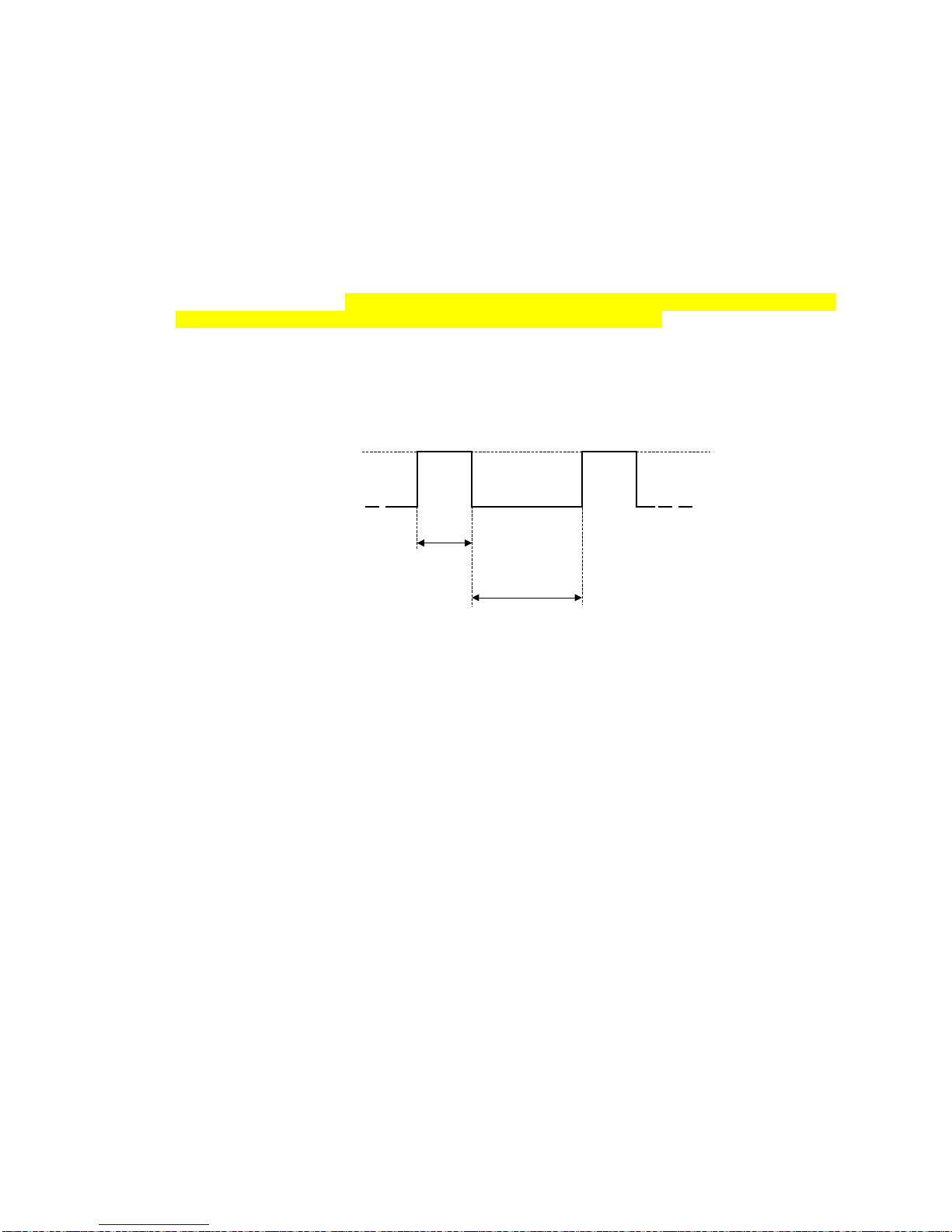

Pulse

length

GND

VCC

Pulse length

(inverted input)

The figure shows pulse lengths when an input is inverted or non-inverted, respectively.

• Pulse input

To register pulses from pulse-producing units such as energy meters, pulse inputs are used. Incoming

pulses are accumulated in registers called external registers. There is an external register connected to

each input on the meter. For external registers, a factor is configured by which the number of incoming

pulses is multiplied. Prefixes and the number of decimals can also be configured for the registers.

Moreover, the registers can be configured with descriptive texts.

• Time synchronisation

When incoming pulses are received, the meter’s clock is synchronised at a specific interval For

available synchronisation intervals and more detailed information on time synchronisation, see the

section Meter clock (pg. 35).

• Rate input

Up to three digital inputs can be configured to control the active rate. Each input will correspond to a bit

and the significance is also defined for the digital input. A high level on the input will signify that the bit is

“1” while a low level will signify “0”. How the digital input levels are mapped to rates is defined in the

Time of use panel (pg.48).

7.5.1.1 Registration of pulses

A pulse must be at least 20 ms (for 50 Hz) and 16 ms (for 60 Hz) long to be guarantee d of being det ected by the

meter. The maximum pulse width that the meter can handle is 300 ms.

Page 40 of 72

Prometer 100 User Manual

BGX501-943-R01

7.5.2 Outputs

The outputs can be configured as follows:

• Not used

The output is not used.

• Energy Pulse output

The output is used to pulse an energy type that the meter is measuring. A multiplier is specified for the

output as pulses/unit and the pulse length is specified for all pulse outputs. The shortest possible pulse

length is 20 ms.

Pulse

Gap

Maximum pulse frequency at outputs is limited so that the gap is at least as long as the pulse length.

• Long Pulse output

The output is used to generate long pulse whose length is between 2 to 15 seconds. By default, the

pulse length is set as 10 seconds. The long pulse output is used for the following functions:

o MD Register Change

On switching the MD registers, the output generates a long pulse.

o Rate Register Change

On switching the Rate registers, the output generates a long pulse.

o Billing Act ion

On performing billing action, the output generates a long pulse.

o DIP Start

At the start of a set demand integration period, the output will go active for the configured pulse

length before returning to the inactive state. See the section Maximum demand (pg. 47).

• Remote control

With this function, the output can be made active or inactive by sending commands to the meter via the

DLMS/PACT protocol. This function can be used to control anything that can be controlled with a digital

relay output. For this, it is also necessary that the Data communication be configured to enable remote

control.

• State Output

o MD Register

With this function, the output remains active or inactive for the time zones during which the

selected MD registers are activated.

o Rate Register

With this function, the output remains active or inactive for the time zones during which the

selected Rate registers are activated.

o Alarm output

When an output is set to function as an alarm output, one of the user-defined alarms can be

chosen to indicate at the output. When an alarm occurs, the output switches to active, and

when the alarm state ceases, the output returns to inactive. In the section Alarms (pg. 45), userdefined alarms are described and how they can be configured.

Note that the outputs are inverted via firmware. If the meter loses its auxiliary power, the relay will open,

regardless of it is inverted or not.

BGX501-943-R01 Prometer 100 User Manual Page 41 of 72

7.5.2.1 Output states

An active output means a closed relay when the output is not inverted. When the output is inverted, the active

relay is open. The Prometer 100 outputs are of the solid-state type and when the meter is turned off, they are

open.

7.5.2.2 Meter vari ants

Inputs/Outputs

Prometer 100-R

Prometer 100-W

4 configurable input/output

●

●

8 outputs and 4 configurable input/output

●

7 outputs and 4 configurable input/output

●

7.6 Communications and Security

Prometer 100 meters have optical port, RS232, RS485 and Ethernet ports for communication.

Note:

The Prometer 100-W supports attachment of field replaceable communication modules for RS232 and RS485.

These modules are optional and can be procured separately.

Communication

channel

Default / Max

supported Baud

rate

Supported protocol Usage

Optical port- IEC1107

300 / 19200 bps DLMS

Local Meter Reading

RS485 (RJ-45 in & out) 9600 / 57600 bps DLMS, Modbus RTU

Meter reading, online

monitoring, third party

interface

RS232 9600 / 57600 bps DLMS

Remote meter reading

through external modem

Ethernet port 10 / 100 Mbps

Modbus TCP (port no.: 502)

DLMS TCP (port no.: 4059)

Meter reading, online

monitoring, third party

interface

Note: For more information on protocol support, see the document ‘Prometer 100 meter reading’.

7.6.1 Communication speed

The meter’s optical port always starts with a baud rate of 300 bps, regardless of what is configured, before

shifting over to the specified communication speed. This means that software (for example, M-Cubed) that

communicates with the meter via the optical port does not need to know the speed that the meter’s optical port

is set to. RS232 and RS485 communication ports differ in this respect. They start at the specified baud rate from

the beginning, which means that connected software must be aware of the speed to be able to communicate.

RS232 communication port can be set at a speed of between 9600 bps and 57600 bps, and RS485

communication port can be set at a speed of between 9600 bps and 57600 bps. The optical port can be set at a

speed of between 300 and 19200 bps.

7.6.2 Security

The meter has five authorisation levels that can limit access to the meter during communication via any of the

meter’s communication ports. Authorisation levels are password-protected.

Authorisation levels

1

Provides access to reading.

2 Provides access to everything in level 1 plus access to set the clock and

finish historical periods (also resets maximum demand values).

Page 42 of 72

Prometer 100 User Manual

BGX501-943-R01

3 Provides access to everything in level 2 plus access to configure the

meter.

4 Provides access to everything in level 3 plus access to transfer new

firmware to the meter.

5 Provides access to everything in level 4 plus access to calibrate the

meter, reset registers and change certain security setting.

7.6.2.1 Limitation of total access attempts

The meter limits the total number of access attempts to six when incorrect passwords are entered. At the

seventh attempt, the meter blocks access whether the password is correct or not. The block is in effect until the

next hour shift. After that, new password attempts may be made.

7.6.2.2 Passwords

A password consists of up to 12 case insensitive alpha-numerical characters. The authorisation check may be

deactivated for a level by deleting the password. When connecting to the meter, access is granted to the highest

level that is lacking password regardless of the password given by the user.

If the setting ‘Require COP password compliance (min length 6)’ is activated, a new password is required to be

at least 6 characters. The setting can only be changed at access level 5.

7.6.2.3 Security settings

The following security settings modify what can be configured at what access level. The settings are of the type

active/not active, and can only be changed at access level 5.

Permit measuring configuration only at level 5 If this setting is active, settings in the

measurement form can only be changed at

access level 5.

Block configuration of transformer compensation If this setting is active, transformer compensation

cannot be changed at all.

Block configuration of display sequence 4 If this setting is active, it is not possible to change

the content of display sequence 4, or change its

name or activation.

7.6.2.4 Access restriction for measurement configuration

Generally the meter allows to be reconfigured at access level 3. This function requires level 5 for measuring

configuration.

7.7 Loggers

The Prometer 100 has two identical, parallel and individually configurable loggers. That which is described in

this section applies both to logger 1 and logger 2.

7.7.1 Overview

A logger in a Prometer 100 can log values for instant quantities, energy registers and external registers. Some

quantities can be logged both by phase and as total values for all three phases, others only as total values. The

table provides an overview of quantities that can be logged. Certain instant values in the table are not available

in 2-element meters and thus cannot be logged; see the section I ns tant va lu es (pg. 37). Logger Parameters can

be read as profile data and SIP wise.

Quantity

Computation Method

Real Time Clock – Date and Time

Instant

Active Import Total (Q1+Q4)

Consumption

Active Export Total (Q2+Q3)

Consumption

Active Import Fundamental (Q1+Q4)

Consumption

Active Export Fundamental (Q2+Q3)

Consumption

Reactive Import while Active Import – Q1

Consumption

Reactive Import while Active Export – Q2

Consumption

BGX501-943-R01 Prometer 100 User Manual Page 43 of 72

Reactive Export while Active Export – Q3

Consumption

Reactive Export while Active Import – Q4

Consumption

Apparent – While Active Import

Consumption

Apparent – While Active Export

Consumption

Reactive Import (Q1+Q2)

Consumption

Reactive Export (Q3+Q4)

Consumption

Reactive Inductive (Q1+Q3) Consumption

Reactive Capacitive (Q2+Q4) Consumption

Net Active (Imp – Exp)* Consumption

Net Reactive (Q1+Q2-Q3-Q4)* Consumption

Active Import Total (Q1+Q4) - Phase 1 Consumption

Active Import Total (Q1+Q4) - Phase 2 Consumption

Active Import Total (Q1+Q4) - Phase 3 Consumption

Active Export Total (Q2+Q3) - Phase 1 Consumption

Active Export Total (Q2+Q3) - Phase 2 Consumption

Active Export Total (Q2+Q3) - Phase 3 Consumption

Phase Voltage - Phase wise, Av erage 3 phase Min / Max / Avg / Instant

Line Voltage - Phase wise, Average 3 phase Min / Max / Avg / Instant

Line Current - Phase wise, Average 3 phase Min / Max / Avg / Instant

Active Power - Phase wise, Average 3 phase Min / Max / Avg / Instant

Reactive Power - Phase wise, Av er age 3 phase Min / Max / Avg / Instant

Apparent Power - Phase wise, Average 3 phase Min / Max / Avg / Instant

Power Factor - Phase wise, Average 3 phase Min / Max / Avg / Instant

THD Voltage (%) - Phase wise, Average 3 phase Min / Max / Avg / Instant

THD Current (%) - Phase wise, Average 3 phase Min / Max / Avg / Instant

THD Power (%) - Phase wise, Average 3 phase Min / Max / Avg / Instant

Frequency Min / Max / Avg / Instant

Voltage Angles Min / Max / Avg / Instant

Voltage Current Angles Min / Max / Avg / Instant

Voltage Harmonics - Phase wise, Average 3 phase (3rd,

5th, 7th, 9th, 11th, 13th and 15th)

Min / Max / Avg / Instant

Current Harmonics - Phase wise, Average 3 phase (3rd,

5th, 7th, 9th, 11th, 13th and 15th)

Min / Max / Avg / Instant

Pulse Input Counter (1 to 4) Instant

Status Flag (Time adjusted, Time disturbed, Alarm,

Parameter Changed, DST, Low / Missing Voltage, Battery

and Power Loss)

Instant

Energy is logged as consumption. Instantaneous values can be logged as average, maximum, minimum and

instant value during the logging interval or as the instantaneous va lue at the end of the logging interval.

Maximums and minimums are detected based on 1 sec. interval snapshots, and average is calculated based on

1 sec. interval snapshots.

Notes:

• Maximum 50 parameters can be selected for each logger.

• Pulse input must be configured through ConfigView.

7.7.2 Logging interval and total channels

A logger can store data in 1 to 50 channels. The logging interval is common for all channels in a logger and it

can be configured from one minute up to one hour. A logger’s capacity is dependent on number of channels and

logging interval. For example, Prometer 100 meters can be configured to store 960 days of load profile data at

30 minutes SIP for 10 parameters. When the logger is full, the oldest values will be written over. The table

shows the capacity in number of days before the oldest value is written over.

Page 44 of 72

Prometer 100 User Manual

BGX501-943-R01

Capacity in days

Number of logging channels

Logging

interval (min)

1

5

10

20

30

40

50

1

320

64

32

16

10 8 6

2

640

128

64

32

21

16

12 3 960

192

96

48

32

24

19 4 1000

256

128

64

42

32

25 5 1000

320

160

80

53

40

32

10

1000

640

320

160

106

80

64

15

1000

960

480

240

160

120

96

20

1000

1000

640

320

213

160

128

30

1000

1000

960

480

320

240

192

60

1000

1000

1000

960

640

480

384

Notes:

• Survey Integration Period (SIP) for Instantaneous parameters can be configured as 1, 2, 3, 4, 5, 10, 15,

20, 30 or 60 minutes.

• Survey Integration Period (SIP) for Energy parameters can be configured as 5, 10, 15, 20, 30 or 60

minutes.

• Maximum 1000 days can be configured

7.7.3 Storage of logged values

Logged values are saved with time stamps and flags that indicate events that have occurred during the logging

interval.

• The time stamp indicates the end-time. If the logging interval is configured to one hour, a value with the

time stamp 15:00 refers to the period 14:00 to 15:00.

• To indicate events or states during an interval, a logged value can be stored with one or more flags.

Event or state

Name of flag

Explanation

Time adjusted

T

During the past interval, the meter clock has been adjusted either instantaneous

or a sliding adjustment is in progress.

Time Disturbed D

The past interval is incomplete. For example, an interval shortened by the meter

being without auxiliary power or if the logging memory has been reset. The first

value after the logging memory having been configured will thus always be

indicated with "Faulty value” (the logging memory is reset in conjunction with

reconfiguration).

Alarm

A

In conjunction with user-d efi ned alarms being configured, it may be specified that

an alarm will also be indicated with logged values. When a user-defined alarm has

triggered during the past interval, this is indicated with the flag “Alarm”.

Parameter

changed

P

The Prometer 100’s configuration, calibration or initiation has changed. Which of

these three the flag refers to can be seen in the event log.

Daylight savings

time

S Daylight sav ing time has been in effect during the past interval.

Voltage

loss/missing

V

During the past interval all measuring voltages have been lost or missing.

Field

Replaceable

Battery (for meter

reading/ RTC

backup)

B

Estimated battery lifetime is up.

Power loss

O

During the past interval, the meter has been without auxiliary power.

BGX501-943-R01 Prometer 100 User Manual Page 45 of 72

For several of the flags, additional information can be viewed in the event log. A more exact time for events

is specified in the log.

Note: When power is calculated from logged energy values, the resulting values will be somewhat more precise

than when power is logged directly. This is because power is logged as an average value of instant values. The

instant values are read twice per second, while energy is accumulated continuously.

7.8 Alarms

The Prometer 100 is equipped with alarms to be able to indicate when measured quantities are over or under a

factory configured limit value. The meter enters the alarm state when the limit value is reached. An alarm is

generated only after the alarm state has continued for a configurable time (persistence time). Alarms are

configurable by the user and are therefore called user-defined alarms. The persistence time can be configured

to a maximum of 60 minutes.

Note: There are alarms and events that cannot be configured, but instead, are always active. Examples of such

alarms are indication that the clock has been changed or that an auxiliary power loss has occurred. For more

information, see the section Display of events (pg. 46).

7.8.1 Overview

For most user-defined alarms, the limit value is specified as a percentage of the nominal value, which is the

configured, nominal primary value (current, voltage or power). For 3-element meters, the limit value corresponds

to phase voltage, and for 2-element meters, phase to phase voltage. The following table provides an overview

of available alarms.

Alarm

Description

Low voltage

Alarm can be configured for low voltage event. Occurred condition is treated as

alarm condition.

High voltage

Alarm can be configured for high voltage event. Occurred condition is treated as

alarm condition.

Voltage unbalance

Alarm can be configured for voltage unbalance event. Occurred condition is

treated as alarm condition.

Current unbalance

Alarm can be configured for current unbalance event. Occurred condition is

treated as alarm condition.

High THD voltage

Alarm can be configured for voltage THD event. Occurred condition is treated as

alarm condition.

High THD current

Alarm can be configured for current THD event. Occurred condition is treat ed as

alarm condition.

High THD power Average value of THD for all power phases exceeds the limit value.

Any phase voltage

missing

Alarm can be configured for PT miss event (any phase). Occurred condition (any

phase) is treated as alarm condition.

Frequency healthy Frequency is (< 49 Hz or >= 51 Hz) or (<59 Hz or >= 61 Hz)

Auxiliary power

supply fail

Any auxiliary supply fails

Low power factor

System power factor is below limit value.

Low active power System active power is below limit value.

High active power System active power is above limit value.

Single harmonic

high voltage

Any phase voltage individual harmonics value (2

nd

to 31st) is above limit value.

Every 5 second meter will scan 2

nd

to 31st harmonic values for one phase and in

next 5 sec meter will scan for next phase. Hence resolution of checking for each

phase is 15 second.